Optimization of the Laser Drilling Processing Parameters for Carbon Steel Based on Multi-Physics Simulation

Abstract

1. Introduction

2. Numerical Simulation

2.1. Mathematical Model

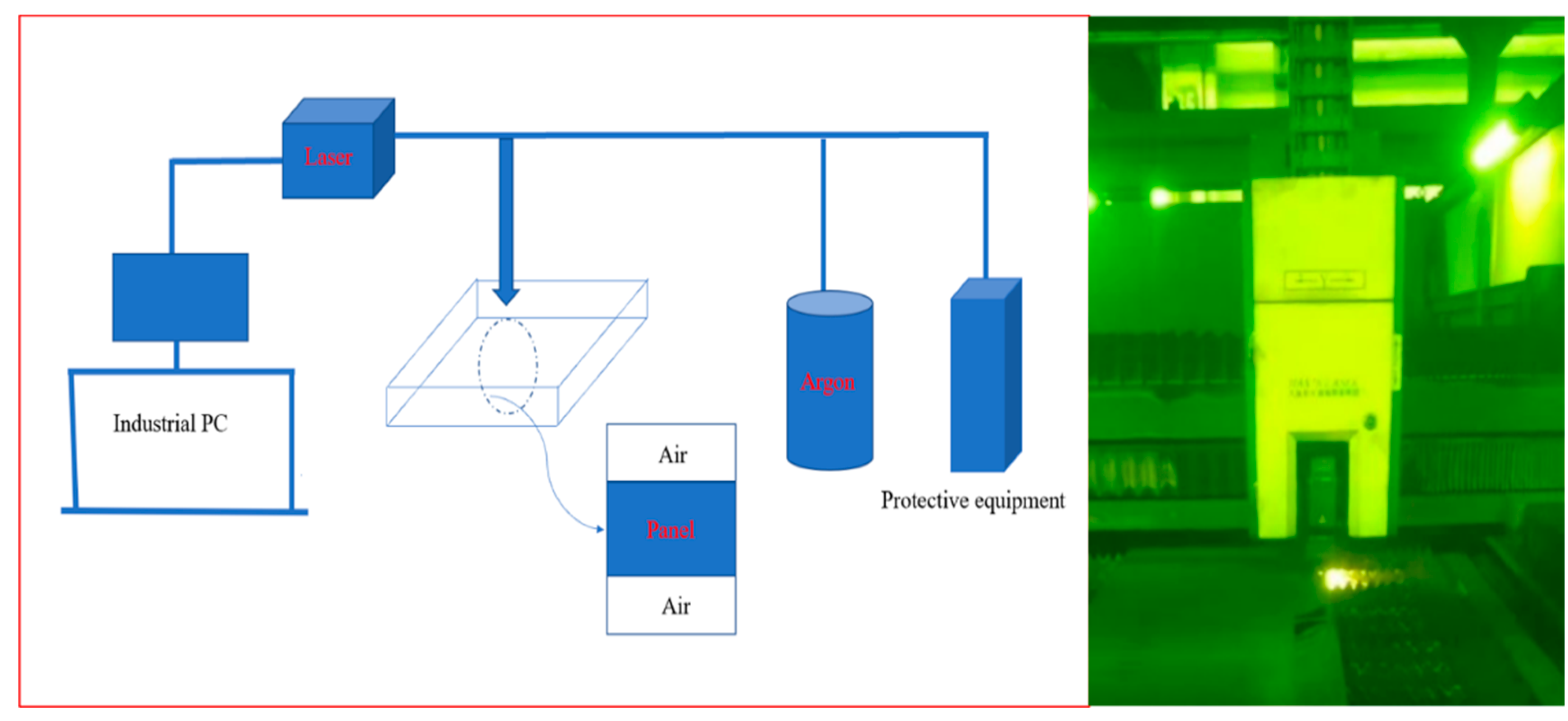

2.2. Experimental Method

3. Results and Discussions

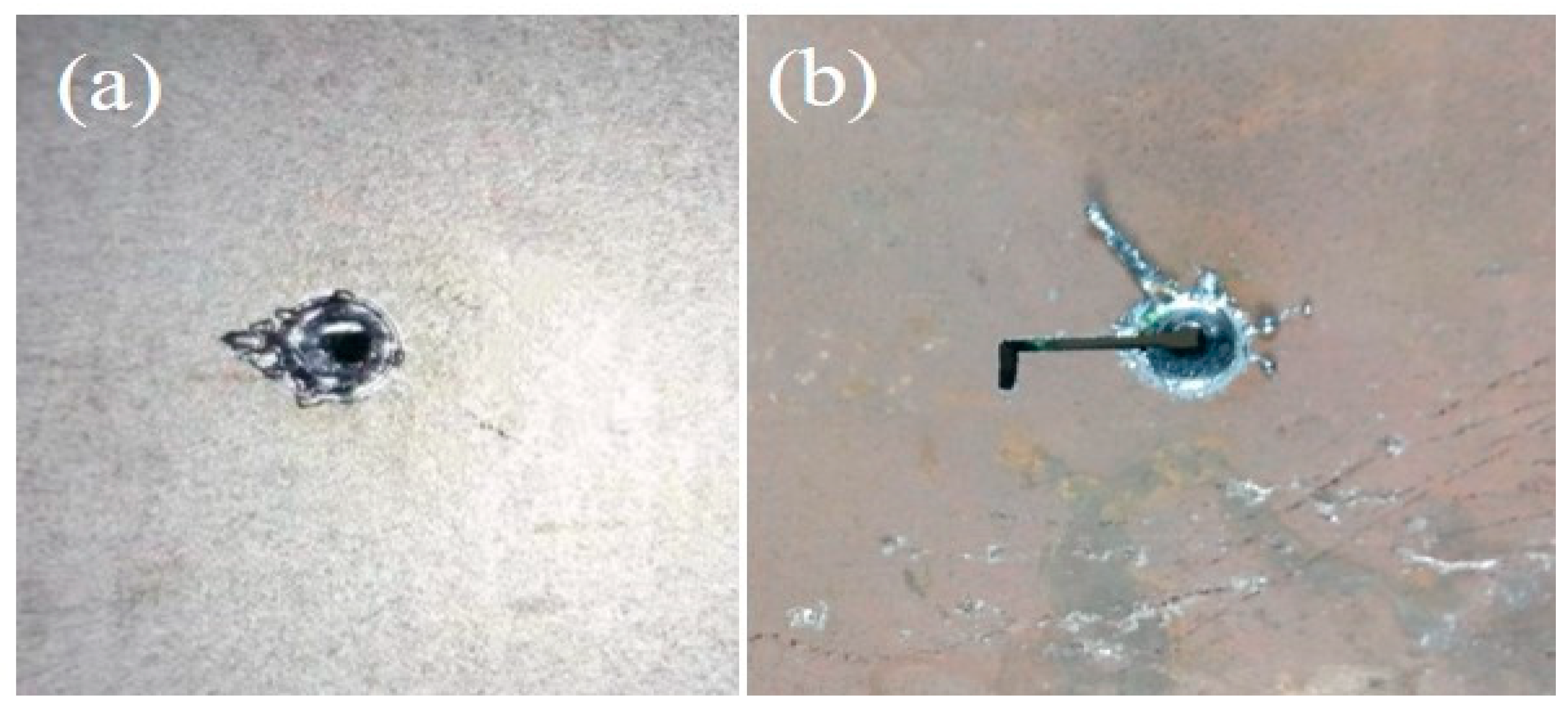

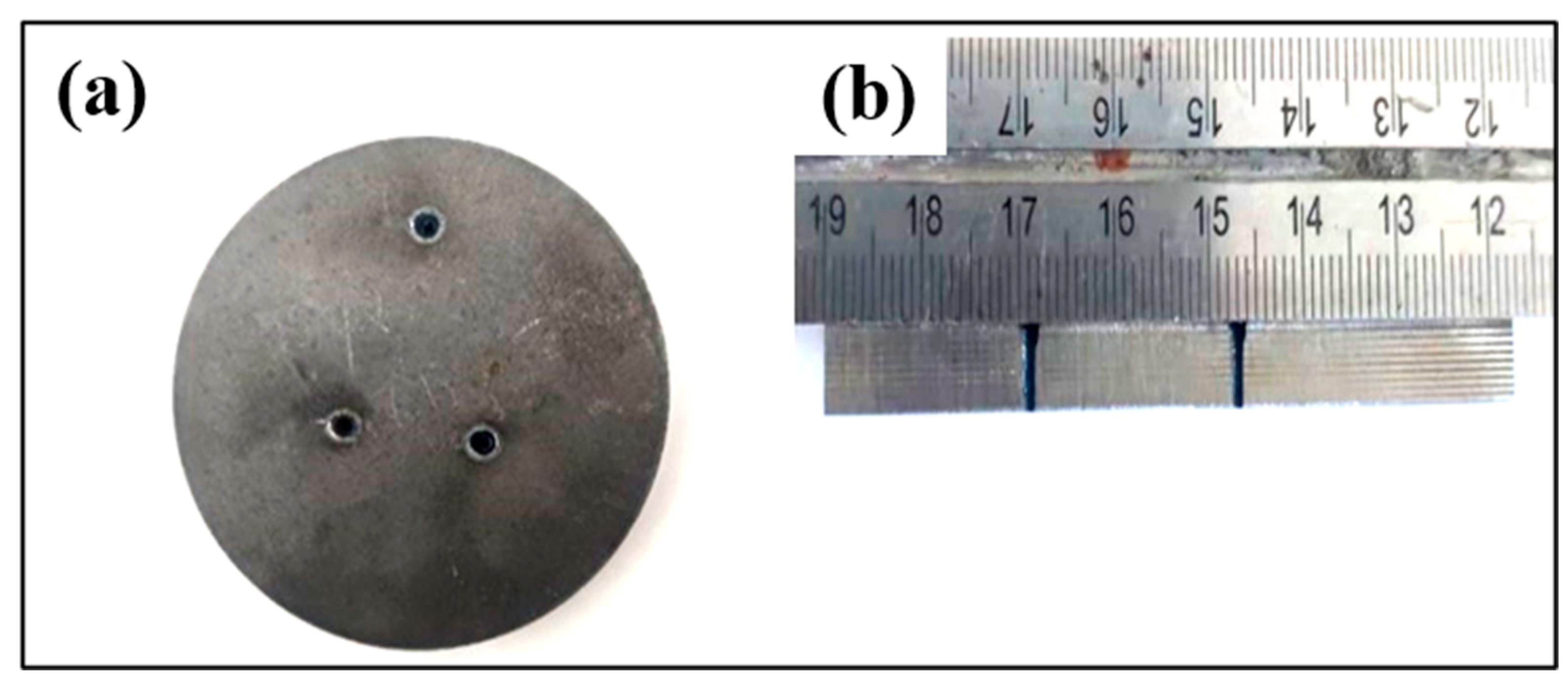

Verification of the Simulation Results

4. Results and Discussion

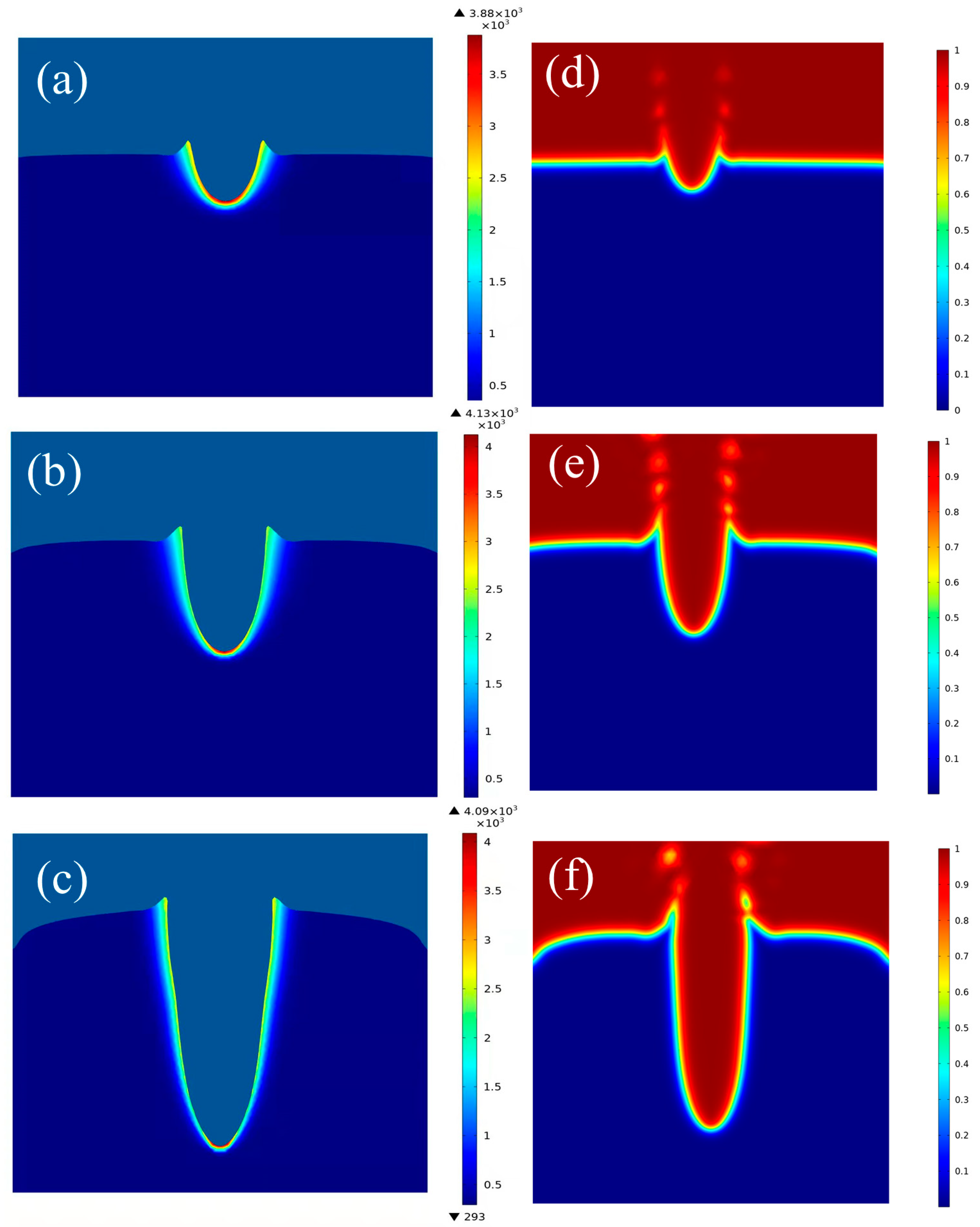

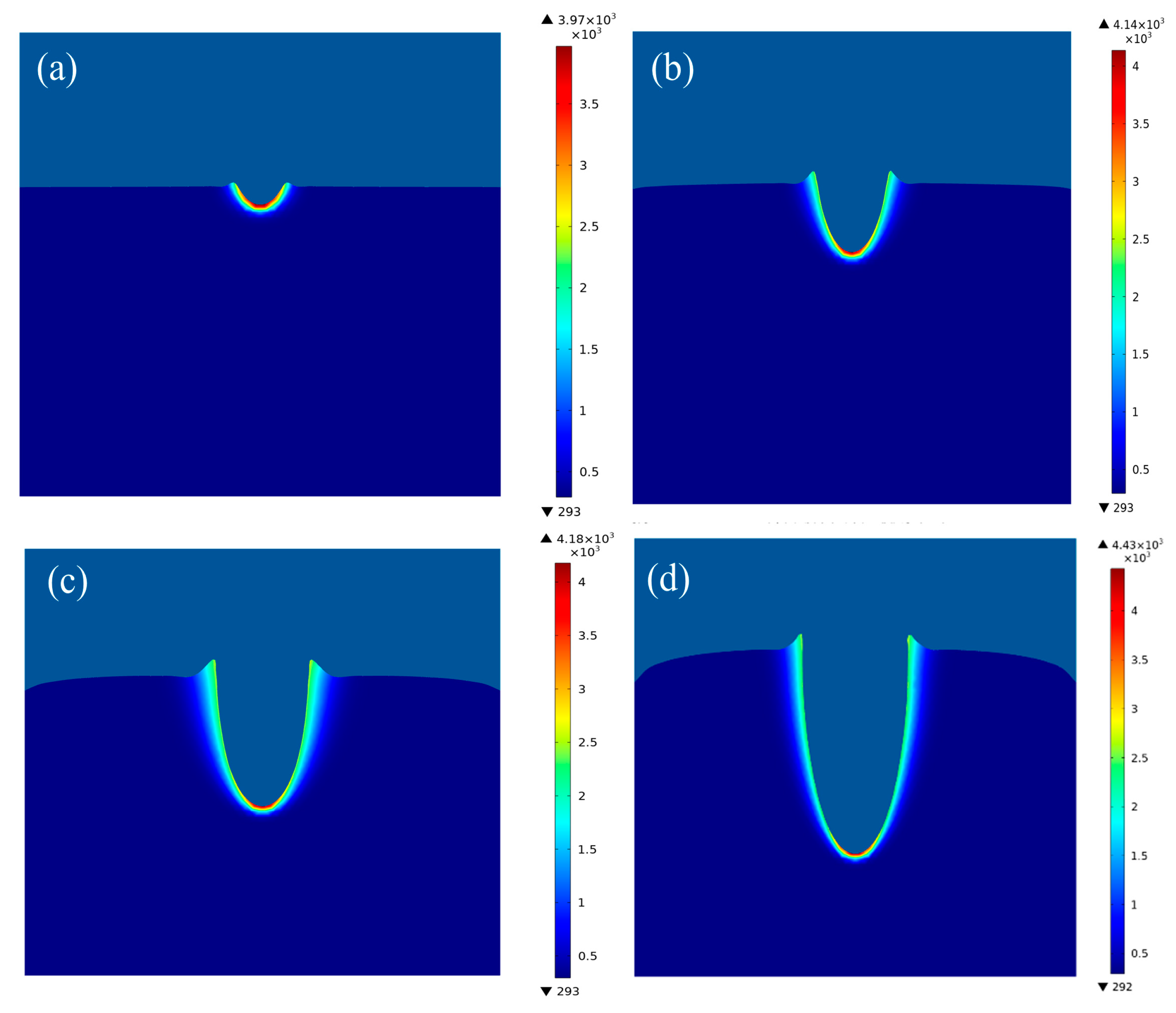

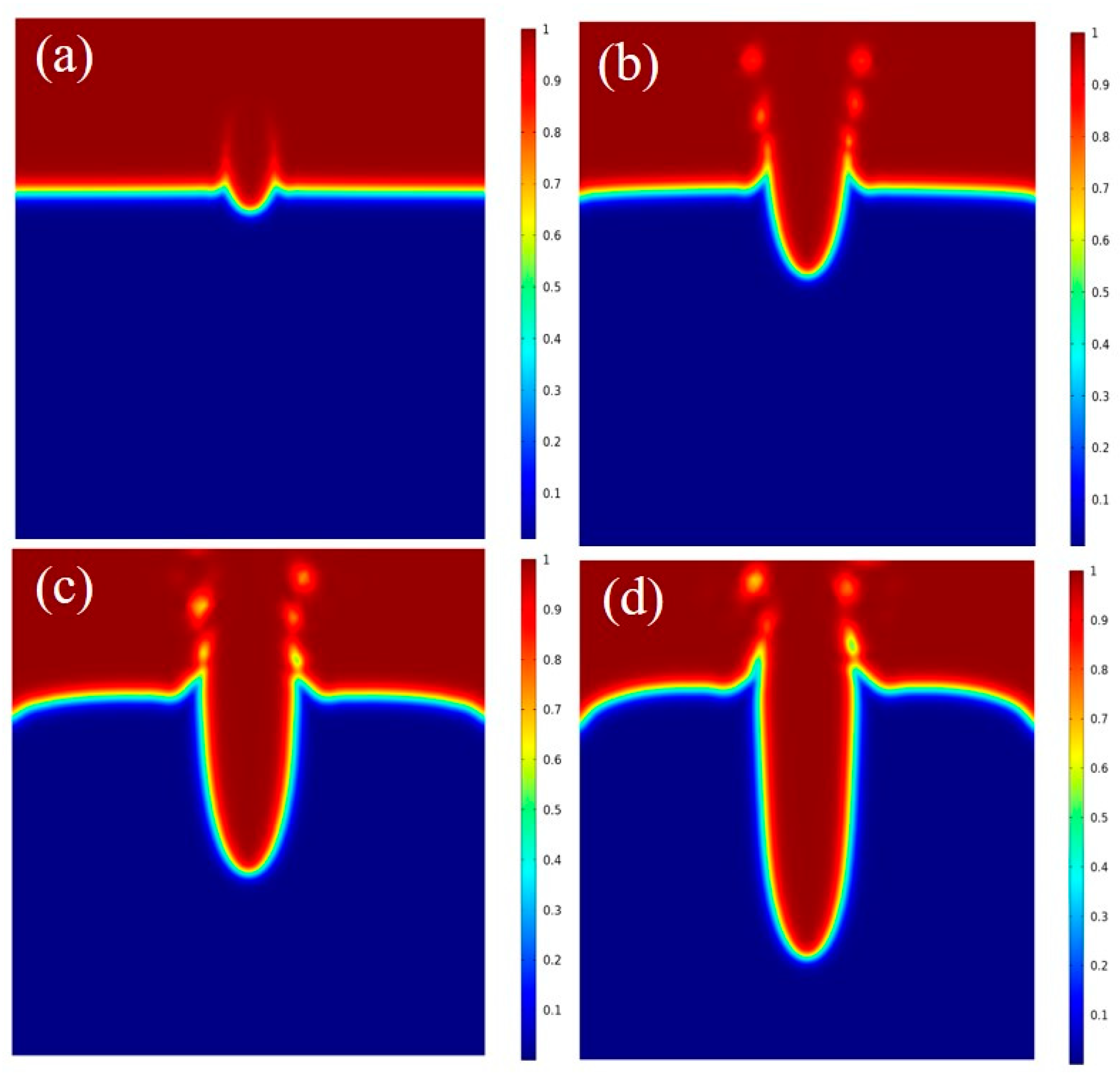

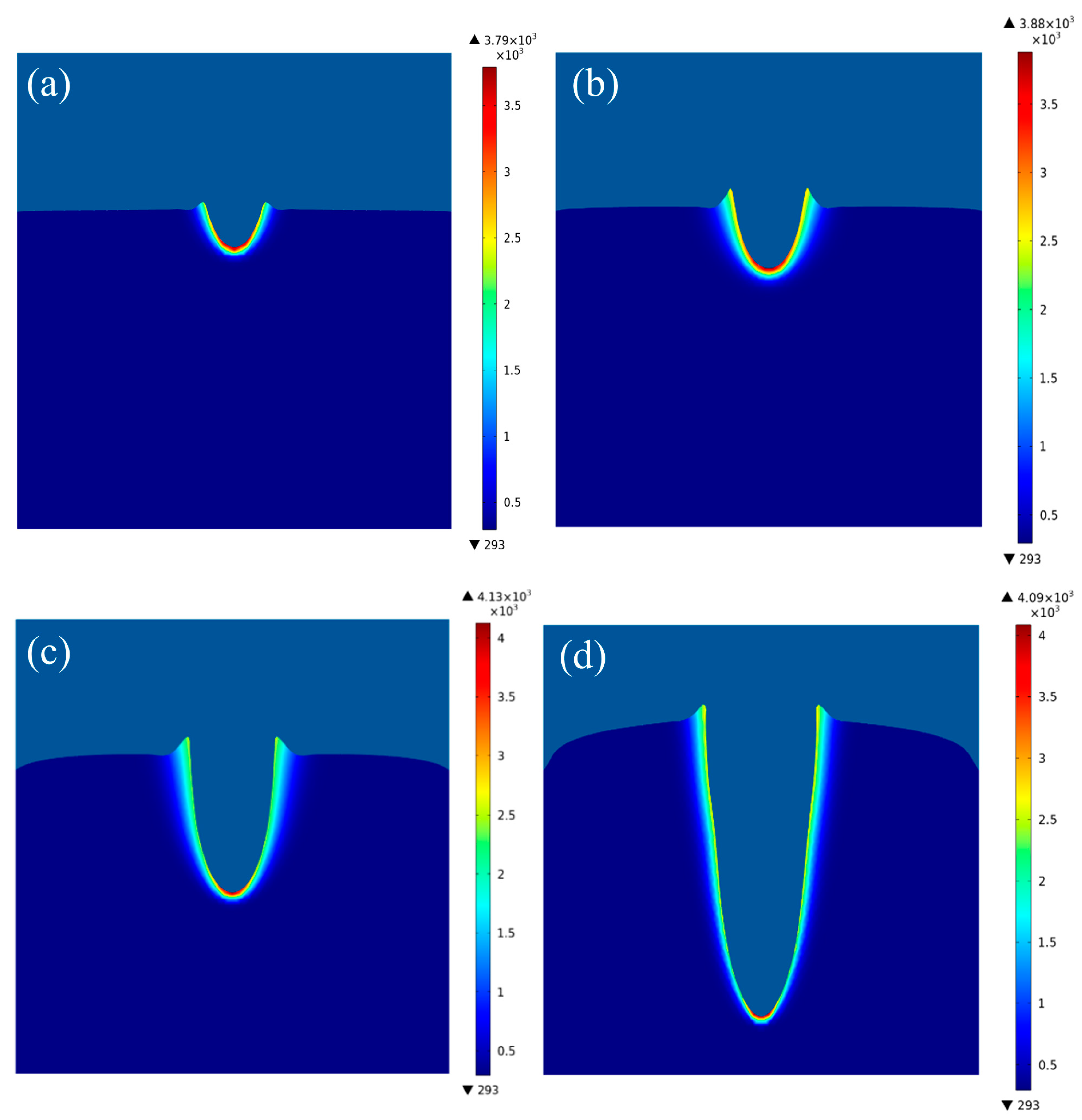

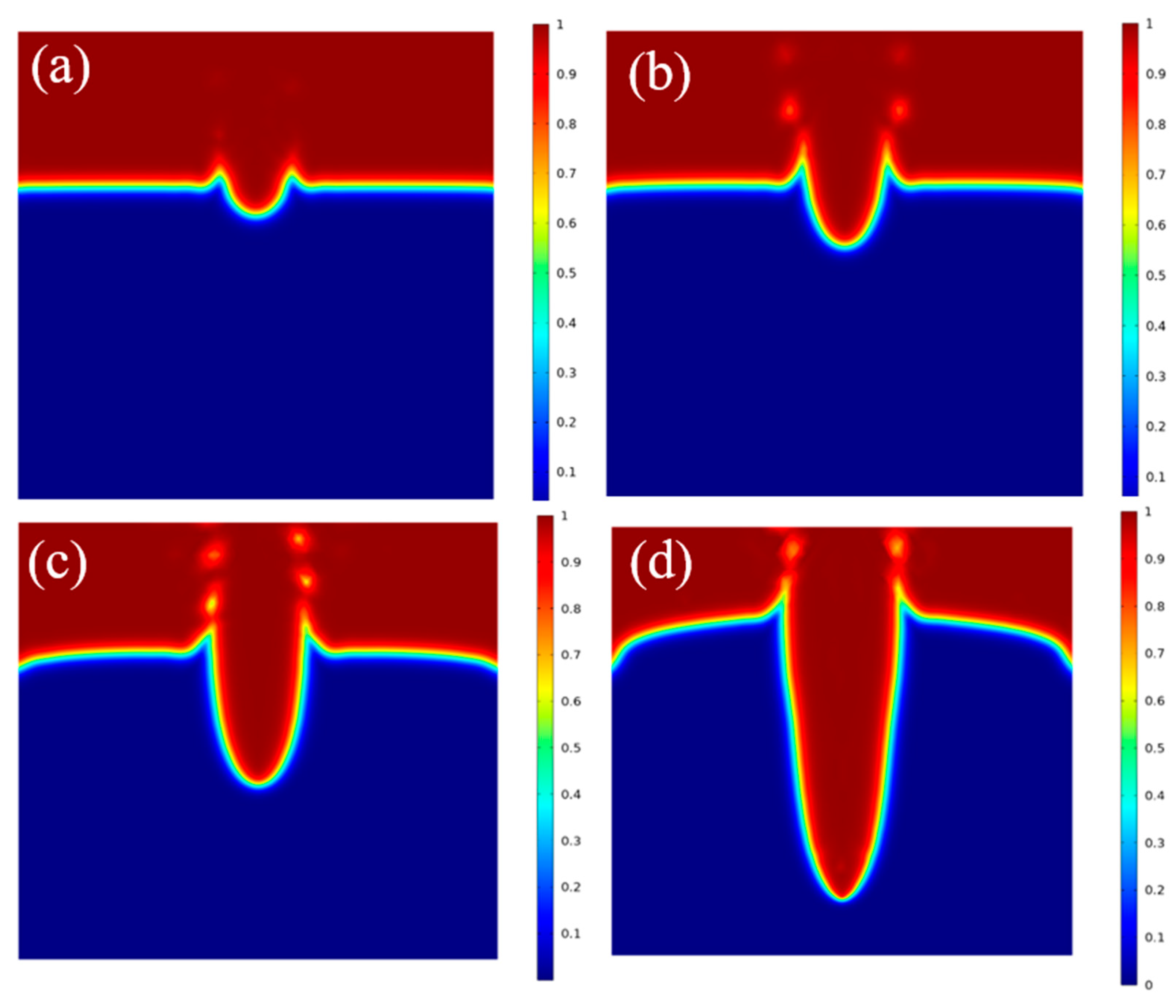

4.1. Effect of the Focus Bias

4.2. Effect of the Laser Power

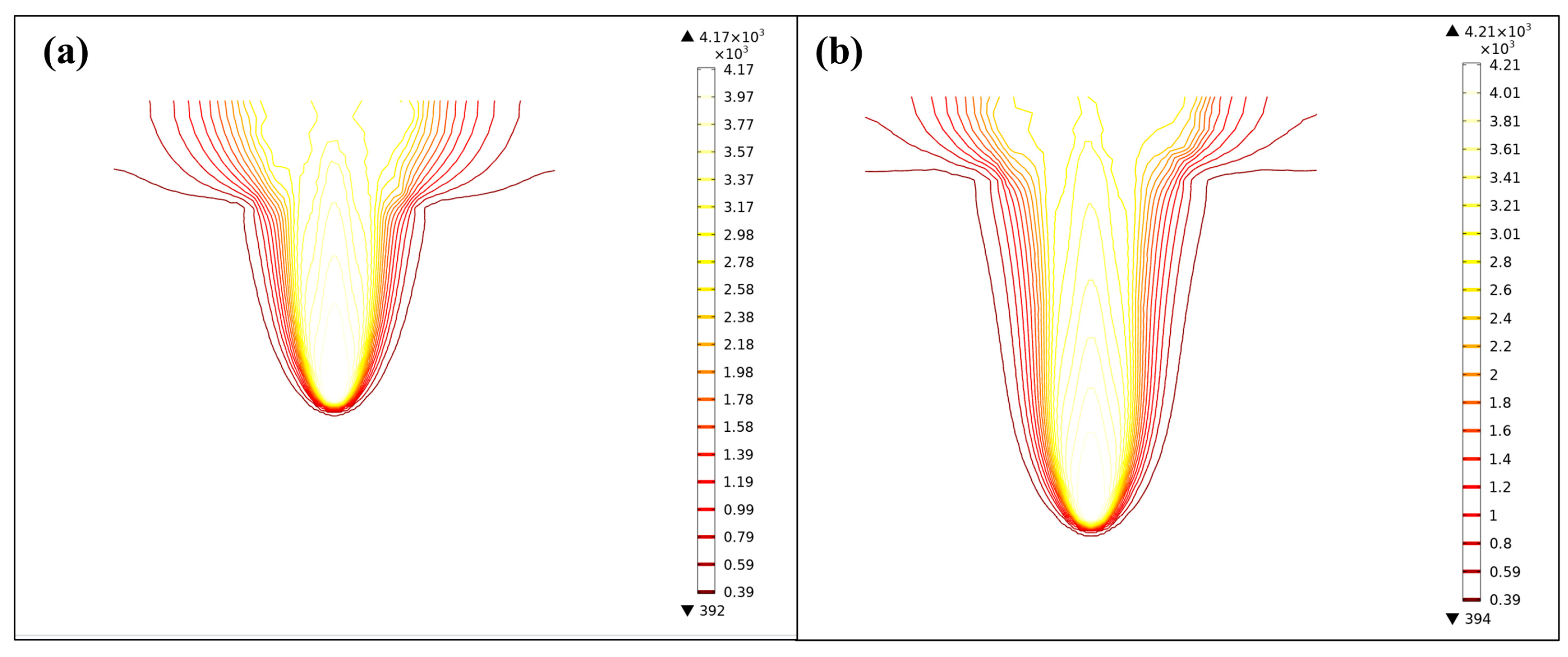

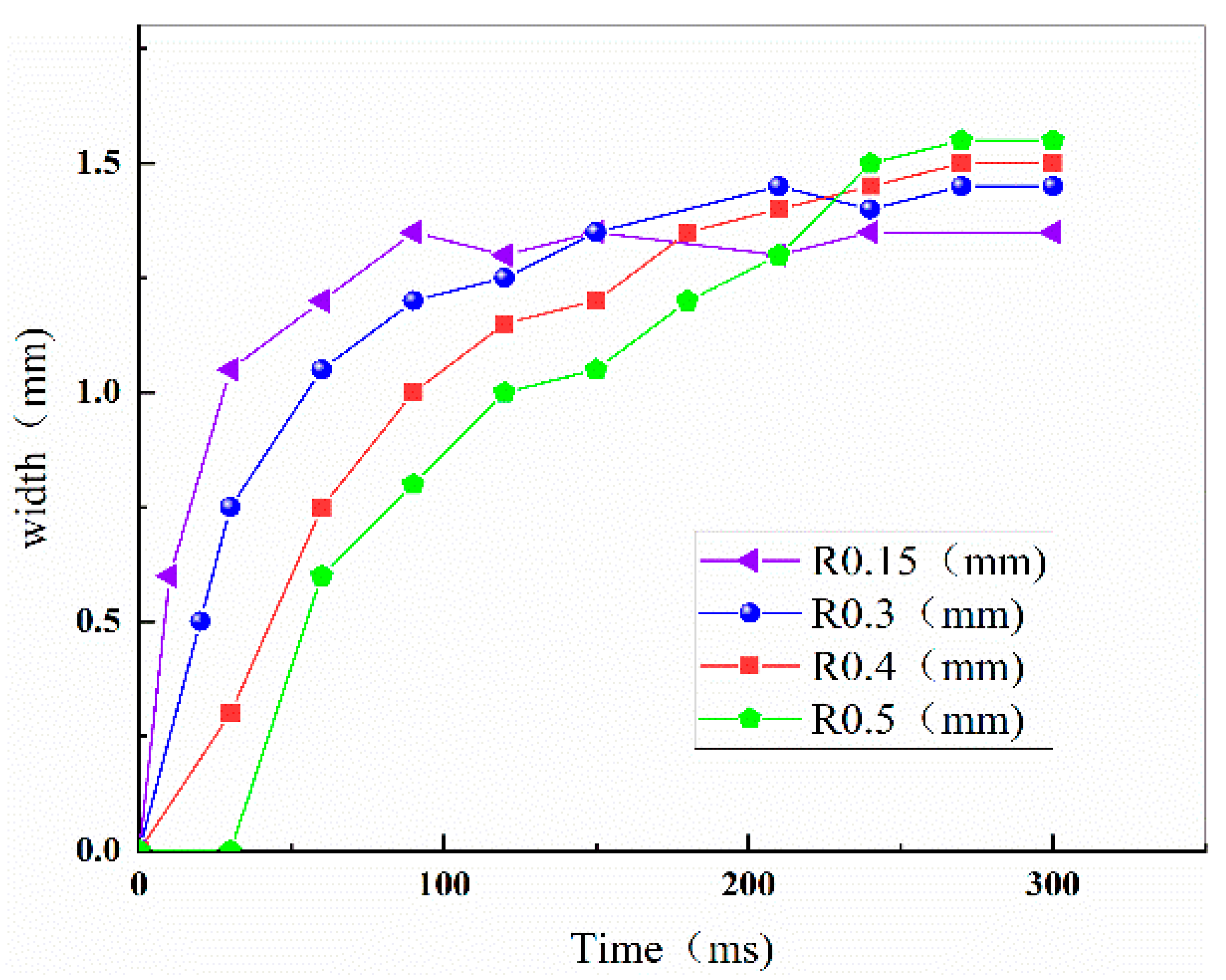

4.3. Effect of the Laser Heat Source Radius

5. Conclusions

- (1)

- Considering the splash evolution of the material during the complex drilling process, the transient evolution of the temperature field, the flow of the molten fluid, the geometrical changes, and the absorption of the laser energy during the laser drilling process were investigated. The simulated borehole dimensions were consistent with the experimental results. The different process parameters had a great influence on the distribution of the temperature field and the behavior of the fluid flow in the molten pool, as well as on the morphology of the perforation. Results show that, when the pulsed laser beam acted on the surface of carbon steel, the heat diffusion coefficient was high, the temperature gradient was small, and the fluid region of the hole wall was prone to produce a large number of melt jets. The molten liquid and the molten pool undergo violent oscillations to produce splashing, which greatly affects the efficiency of the perforation and the quality of the molding.

- (2)

- Heat transfer and flow behavior played an important role in the carbon steel drilling process. The relationship between the melt sputtering process and the process parameters were verified. The laser power and the laser heat source radius determined the energy density transmitted to the materials. With the increase in laser power and the decrease in laser heat source radius, the time required for perforation decreased, the flow of melt accelerated, the perforation efficiency increased, and the hole wall became smoother, but the spattering increased.

- (3)

- The quasi-quantitative relationship between melt injection and the processing parameters of laser power and laser heat source radius was established by combining the results from both the numerical simulation analysis and the experiments. The optimized laser drilling processing parameters of carbon steel material were obtained: a laser heat source radius of 0.3 mm and a laser power of 3000 W, both of which were also verified by the experimental test where the buildup of the melt inside the hole was reduced, the degree of slag splash was lower, and a smooth and slag-free perforated surface was obtained.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Zhu, H.-N.; Pei, Z.-D.; Kong, Y.-F.; Xu, J.-J. Molecular dynamic simulations of surface morphology and pulsed laser deposition growth of lithium niobate thin films on silicon substrate. Chin. Phys. B 2015, 24, 056802. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.-P.; Lu, F.; Carlson, B.E.; Sigler, D.R. Analysis of Al-steel resistance spot welding process by developing a fully coupled multi-physics simulation model. Int. J. Heat Mass Transf. 2015, 89, 1061–1072. [Google Scholar] [CrossRef]

- Zhang, T.-Z.; Jia, Z.-C.; Cui, H.-C.; Zhu, D.-H.; Ni, X.-W.; Lu, J. Analysis of melt ejection during long pulsed laser drilling. Chin. Phys. B 2016, 25, 054206. [Google Scholar] [CrossRef]

- Duan, W.; Wang, K.; Dong, X.; Mei, X.; Wang, W.; Fan, Z. Experimental characterizations of burr deposition in Nd:YAG laser drilling: A parametric study. Int. J. Adv. Manuf. Technol. 2014, 76, 1529–1542. [Google Scholar] [CrossRef]

- Voisey, K.T.; Clyne, T.W. Laser drilling of cooling holes through plasma sprayed thermal barrier coatings. Surf. Coat. Technol. 2004, 176, 296–306. [Google Scholar] [CrossRef]

- Leitz, K.-H.; Koch, H.; Otto, A.; Schmidt, M. Numerical simulation of process dynamics during laser beam drilling with short pulses. Appl. Phys. A 2011, 106, 885–891. [Google Scholar] [CrossRef]

- Otto, A.; Koch, H.; Leitz, K.-H.; Schmidt, M. Numerical Simulations—A Versatile Approach for Better Understanding Dynamics in Laser Material Processing. Phys. Procedia 2011, 12, 11–20. [Google Scholar] [CrossRef]

- Geiger, M.; Leitz, K.H.; Koch, H.; Otto, A. A 3D transient model of keyhole and melt pool dynamics in laser beam welding applied to the joining of zinc coated sheets. Prod. Eng. 2009, 3, 127–136. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Wegener, K. 3D Thermal Simulation of a Laser Drilling Process with Meshfree Methods. J. Manuf. Mater. Process. 2020, 4, 58. [Google Scholar] [CrossRef]

- Pattanayak, S.; Panda, S.; Dhupal, D. Laser micro drilling of 316L stainless steel orthopedic implant: A study. J. Manuf. Process. 2020, 52, 220–234. [Google Scholar] [CrossRef]

- Jia, X.; Chen, Y.; Liu, L.; Wang, C.; Duan, J.A. Advances in Laser Drilling of Structural Ceramics. Nanomaterials 2022, 12, 230. [Google Scholar] [CrossRef] [PubMed]

- Dada, M.; Popoola, P.; Mathe, N.; Adeosun, S.; Aramide, O. 2D numerical model for heat transfer on a laser deposited high entropy alloy baseplate using Comsol Multiphysics. Mater. Today Proc. 2022, 50, 2541–2546. [Google Scholar] [CrossRef]

- Parekh, R.; Buddu, R.K.; Patel, R.I. Multiphysics Simulation of Laser Cladding Process to Study the Effect of Process Parameters on Clad Geometry. Procedia Technol. 2016, 23, 529–536. [Google Scholar] [CrossRef]

- Yaagoubi, H.; Abouchadi, H.; Taha Janan, M. Numerical simulation of heat transfer in the selective laser sintering process of Polyamide12. Energy Rep. 2021, 7, 189–199. [Google Scholar] [CrossRef]

- Zhang, Y.; He, X.; Yu, G.; Li, S.; Tian, C.; Ning, W.; Zhang, Y. Dynamic evolution of keyhole during multi-pulse drilling with a millisecond laser on 304 stainless steel. Opt. Laser Technol. 2022, 152, 108151. [Google Scholar] [CrossRef]

- Zhang, S.; Fan, Y.; Huang, Y.; Yang, X.; Zhang, M.; Luo, J.; Deng, G.; Zhou, Q.; Song, H.; Wang, Y. Improvement of the surface condition of laser-drilled holes via a dual-wavelength double-pulse train. Opt. Laser Technol. 2023, 157, 108681. [Google Scholar] [CrossRef]

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y.-J. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- Cao, Z.; Dong, M.; Liu, K.; Fu, H. Temperature Field in the Heat Transfer Process of PEEK Thermoplastic Composite Fiber Placement. Materials 2020, 13, 4417. [Google Scholar] [CrossRef] [PubMed]

- Li, T.Q.; Wu, C.S.; Feng, Y.H.; Zheng, L.C. Modeling of the thermal fluid flow and keyhole shape in stationary plasma arc welding. Int. J. Heat Fluid Flow 2012, 34, 117–125. [Google Scholar] [CrossRef]

- Tan, W.; Bailey, N.S.; Shin, Y.C. Investigation of keyhole plume and molten pool based on a three-dimensional dynamic model with sharp interface formulation. J. Phys. D Appl. Phys. 2013, 46, 055501. [Google Scholar] [CrossRef]

- Courtois, M.; Carin, M.; Le Masson, P.; Gaied, S.; Balabane, M. A complete model of keyhole and melt pool dynamics to analyze instabilities and collapse during laser welding. J. Laser Appl. 2014, 26, 042001. [Google Scholar] [CrossRef]

- Rai, R.; Elmer, J.W.; Palmer, T.A.; DebRoy, T. Heat transfer and fluid flow during keyhole mode laser welding of tantalum, Ti–6Al–4V, 304L stainless steel and vanadium. J. Phys. D Appl. Phys. 2007, 40, 5753–5766. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, Z.; Ni, X. Modeling and simulation on long pulse laser drilling processing. Int. J. Heat Mass Transf. 2014, 73, 429–437. [Google Scholar] [CrossRef]

- Ya, W.; Pathiraj, B.; Liu, S. 2D modelling of clad geometry and resulting thermal cycles during laser cladding. J. Mater. Process. Technol. 2016, 230, 217–232. [Google Scholar] [CrossRef]

- Hirano, K.; Fabbro, R.; Muller, M. Experimental determination of temperature threshold for melt surface deformation during laser interaction on iron at atmospheric pressure. J. Phys. D Appl. Phys. 2011, 44, 435402. [Google Scholar] [CrossRef]

| Nomenclature | Value |

|---|---|

| Carbon steel solid density (kg/m3) | 7850 |

| Carbon steel liquid density (kg/m3) | 7200 |

| Thermal conductivity (Wm−1 K−1) | 46.5 |

| Liquid thermal conductivity (Wm−1 K−1) | 30 |

| Carbon steel solid specific heat (J/kg−1 K−1) | 470 |

| Carbon steel liquid specific heat (J/kg−1 K−1) | 510 |

| Viscosity (Pa·s) | 0.26 × 10−3 × exp (13.10 × 103/8.314/T) |

| Latent heat of fusion (J/kg−1) | 2.68 × 105 |

| Latent heat of vaporization (J/kg−1) | 3.462 × 106 |

| Carbon steel melting point (K) | 1788 |

| Carbon steel boiling point (K) | 2293 |

| Laser heat source radius (mm) | 0.3 |

| Convective heat transfer coefficient (Wm2 K−1) | 20 |

| Element | Standard Request | Measured Value |

|---|---|---|

| C | 0.2 | 0.16 |

| Si | 0.081 | |

| Mn | 1.40 | 0.311 |

| S | 0.045 | 0.006 |

| P | 0.045 | 0.009 |

| Nomenclature | Value |

|---|---|

| Processing power (W) | 3000 |

| Focus of setover (−10–12 mm) | 0 |

| Type of gas (1 = AIR/2 = O2/3 = N2) | 3 |

| Gas pressure (0.5–25 Bar) | 1.2 |

| Impulse frequency (5–5000 Hz) | 16 |

| Pulse duty factor (1–100%) | 32 |

| Pulse slope regulation (m s) | 32 |

| Slope regulation time (m s) | 100 |

| Process time (m s) | 600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, S.; Li, F.; Liu, Y.; Yi, J.; Eckert, J. Optimization of the Laser Drilling Processing Parameters for Carbon Steel Based on Multi-Physics Simulation. Metals 2024, 14, 682. https://doi.org/10.3390/met14060682

Liang S, Li F, Liu Y, Yi J, Eckert J. Optimization of the Laser Drilling Processing Parameters for Carbon Steel Based on Multi-Physics Simulation. Metals. 2024; 14(6):682. https://doi.org/10.3390/met14060682

Chicago/Turabian StyleLiang, Shanqing, Fengxian Li, Yichun Liu, Jianhong Yi, and Jürgen Eckert. 2024. "Optimization of the Laser Drilling Processing Parameters for Carbon Steel Based on Multi-Physics Simulation" Metals 14, no. 6: 682. https://doi.org/10.3390/met14060682

APA StyleLiang, S., Li, F., Liu, Y., Yi, J., & Eckert, J. (2024). Optimization of the Laser Drilling Processing Parameters for Carbon Steel Based on Multi-Physics Simulation. Metals, 14(6), 682. https://doi.org/10.3390/met14060682