Effects of Aging Treatments on the Age Hardening Behavior and Microstructures in an Al-Mg-Si-Cu Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

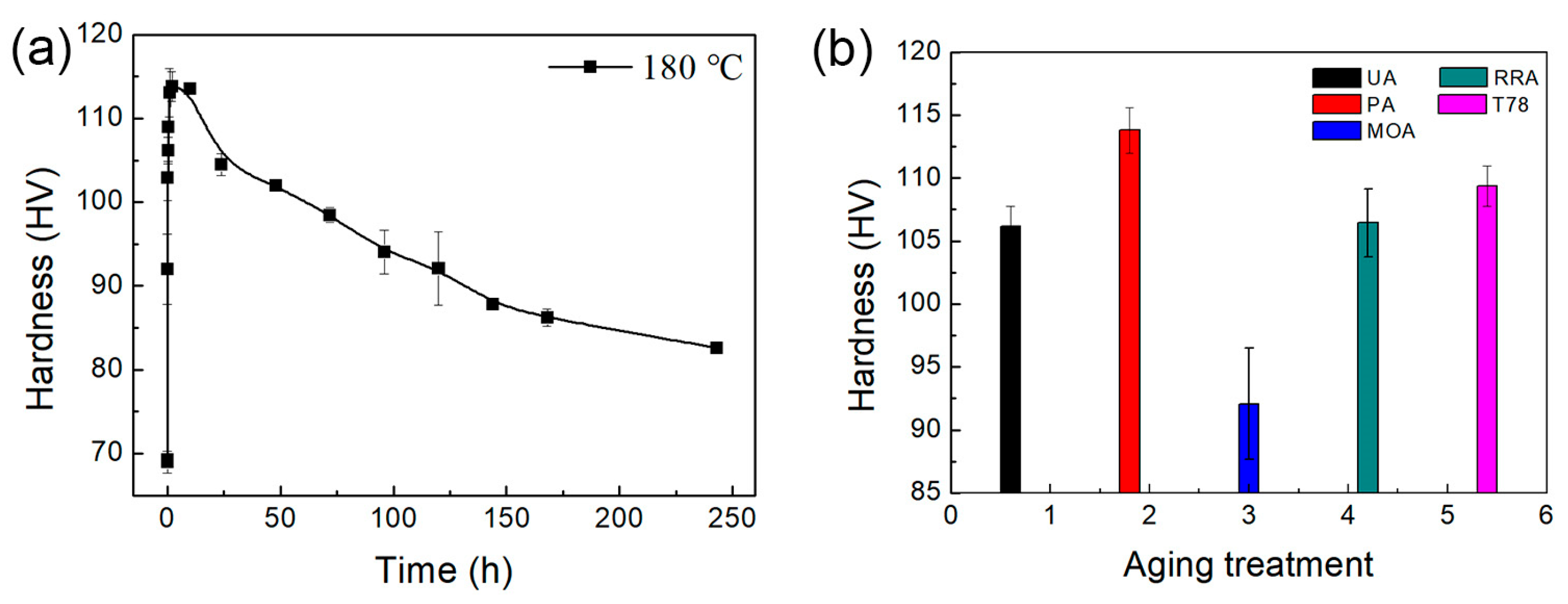

3.1. Age Hardening Response of Various Heat Treatments

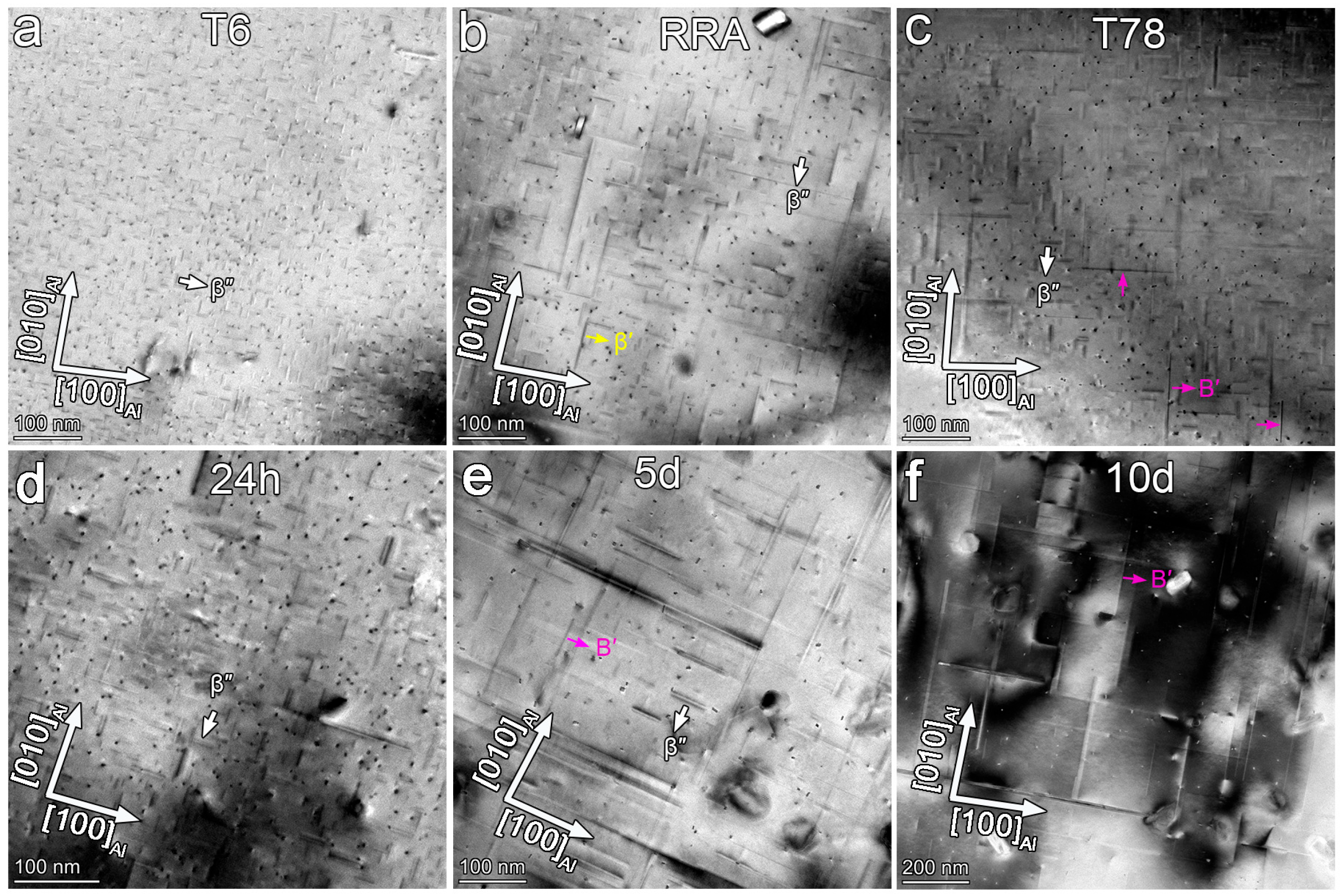

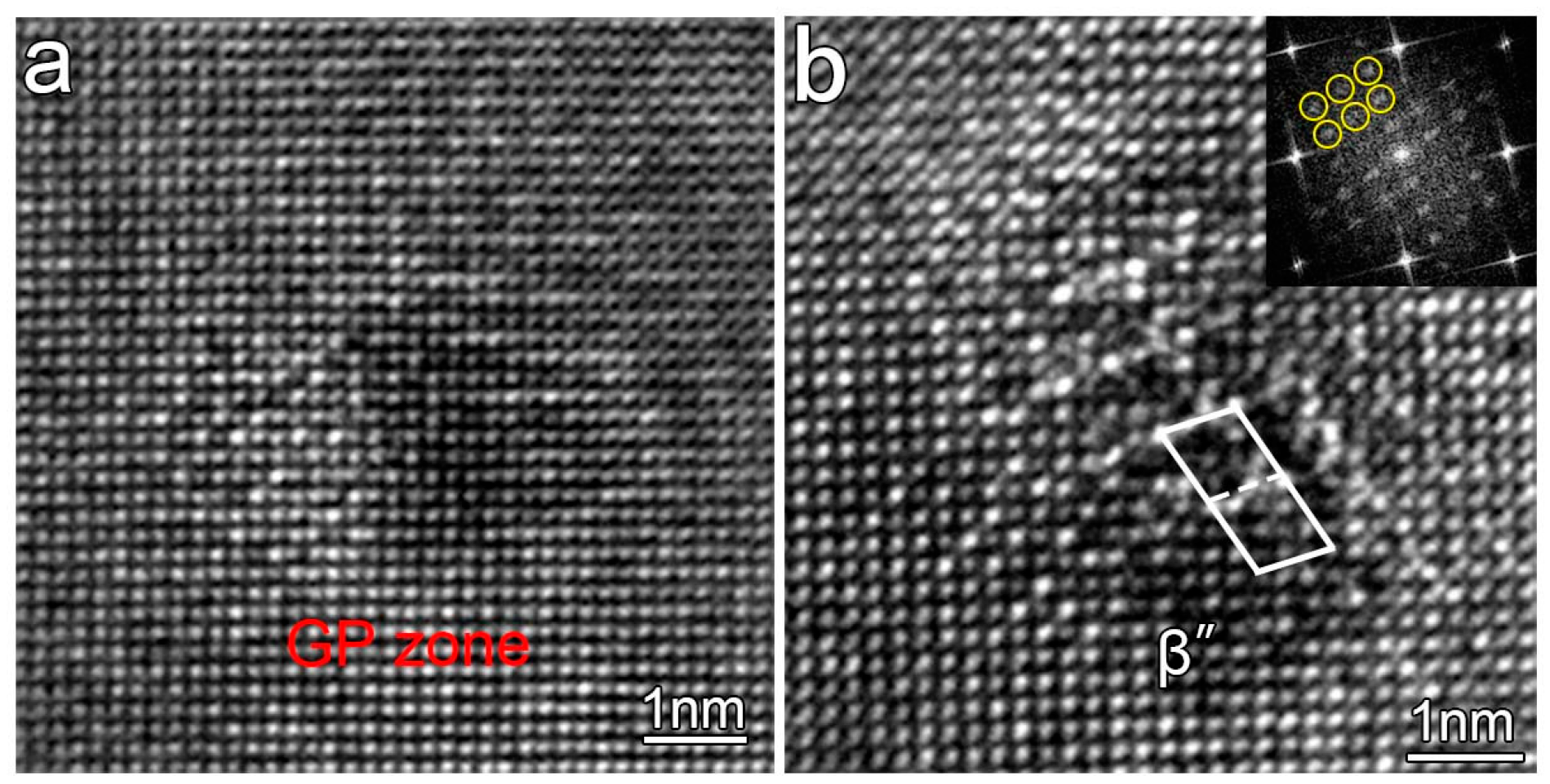

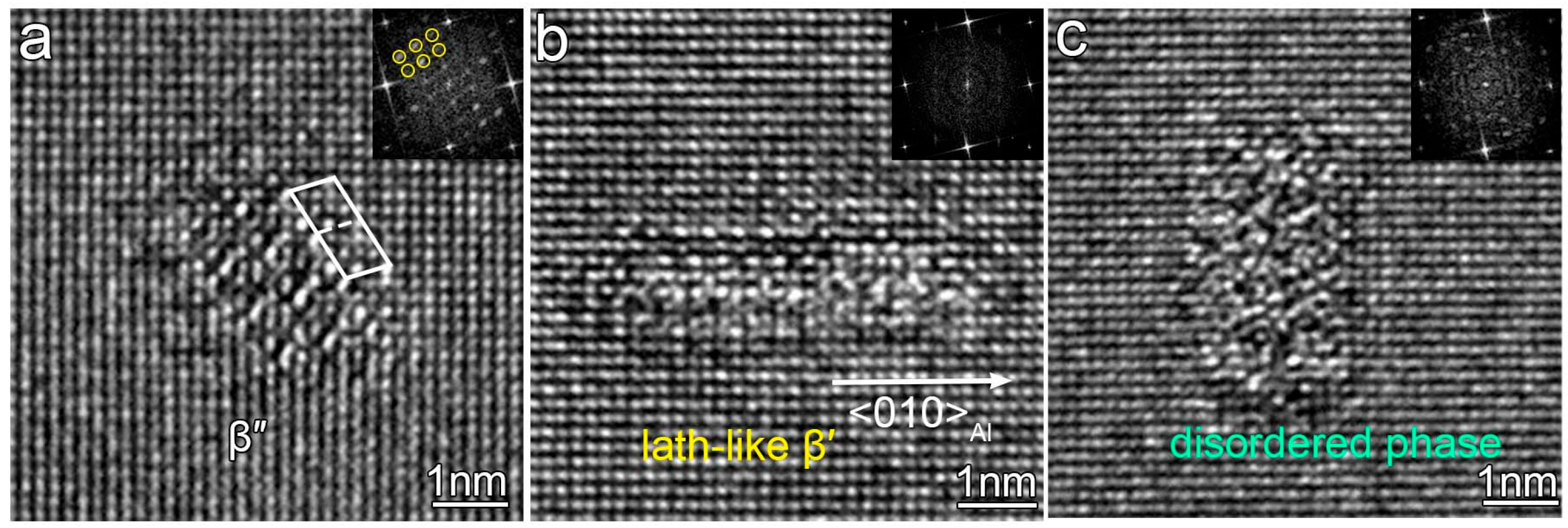

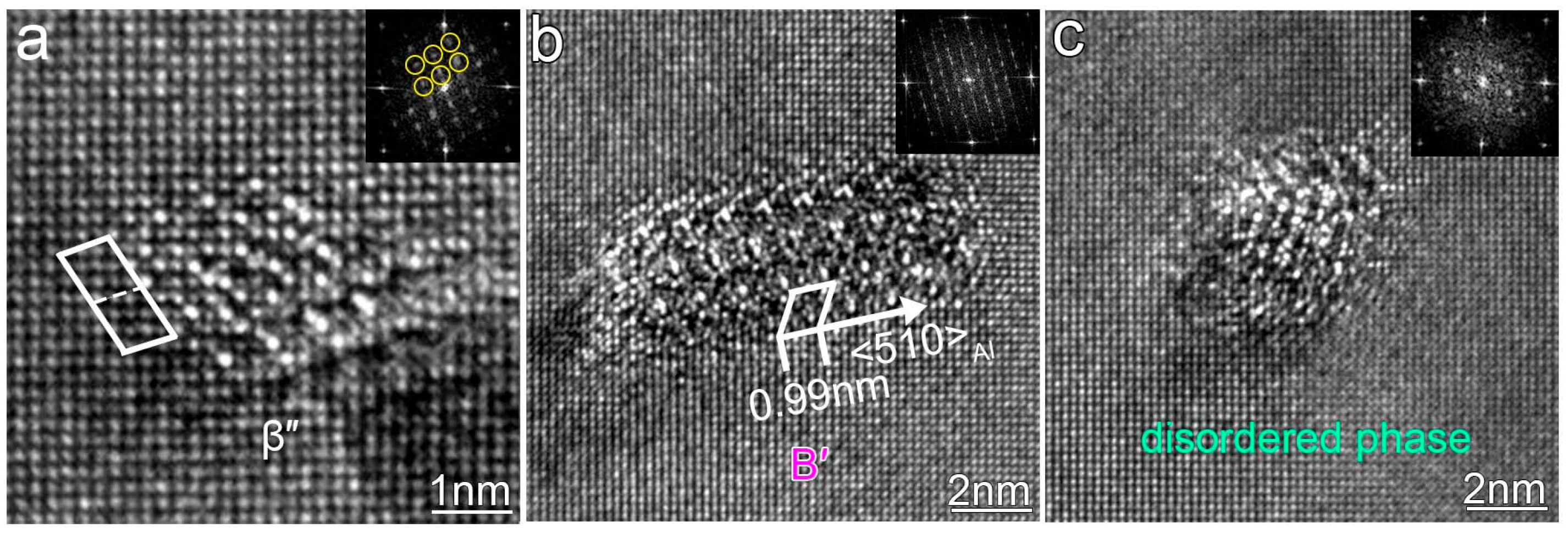

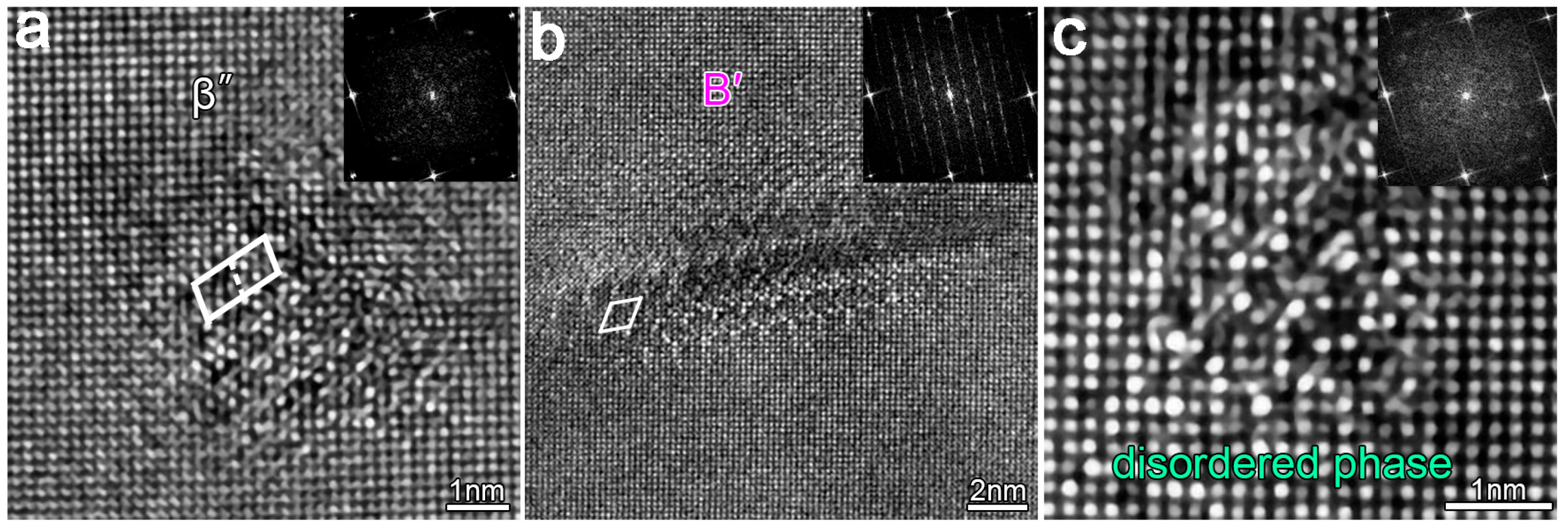

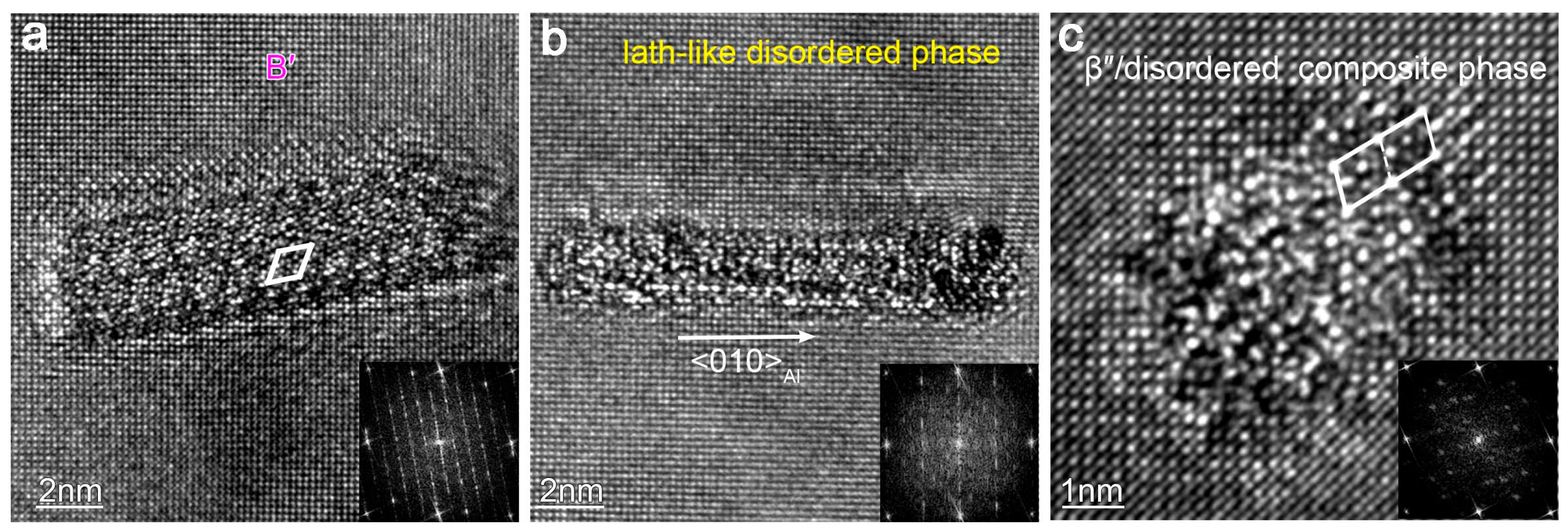

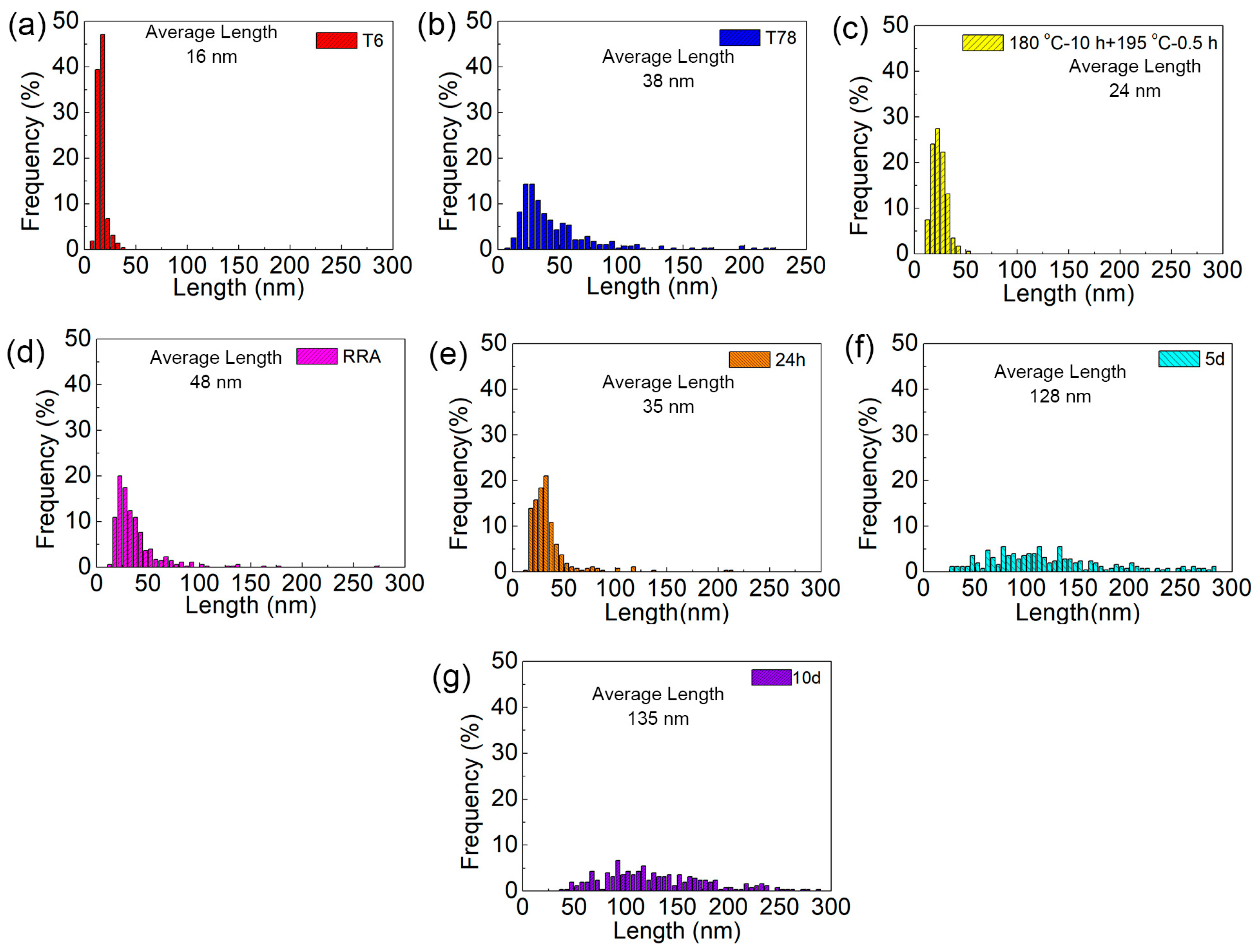

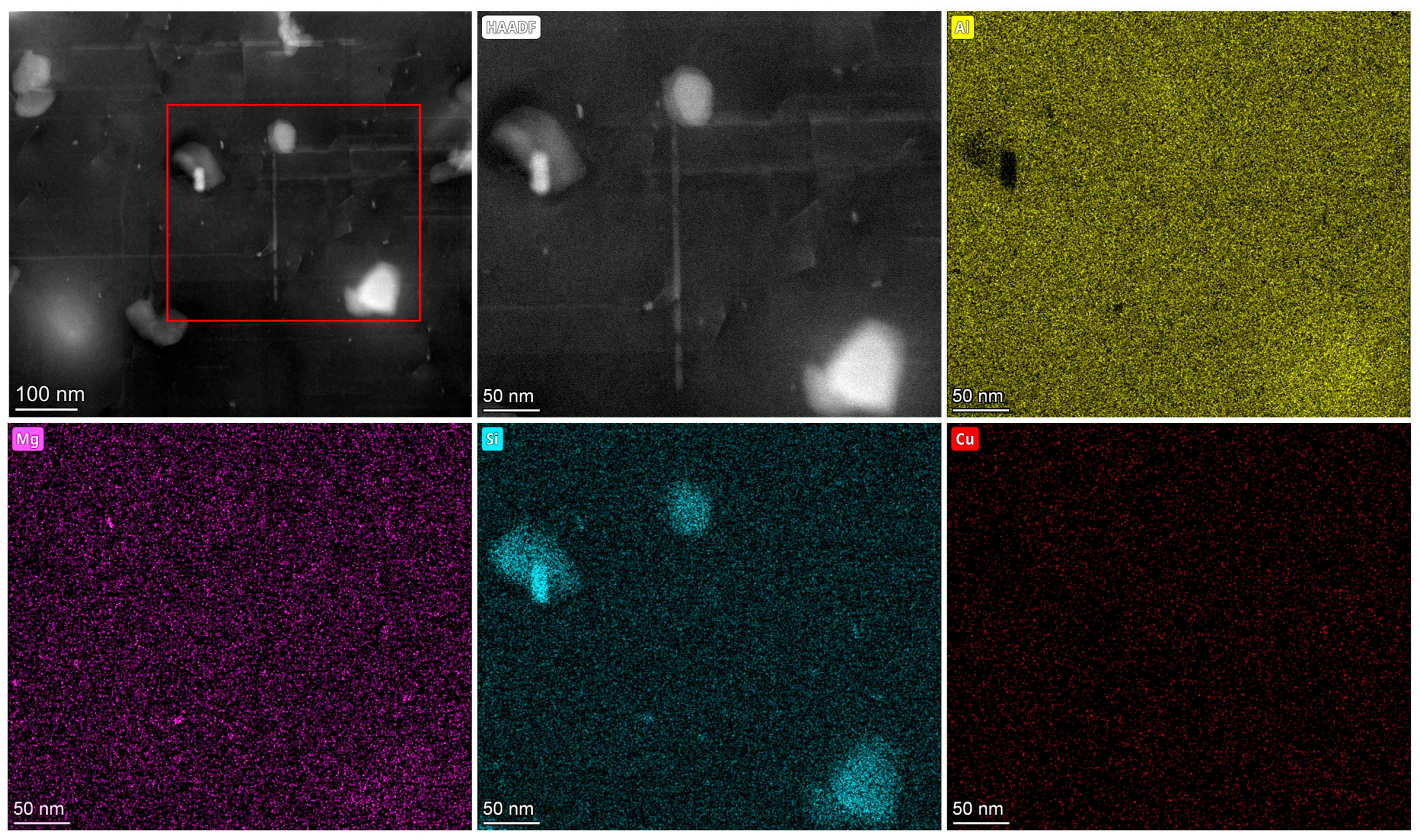

3.2. TEM and HRTEM Overviews of Precipitates Distributed in the Matrix

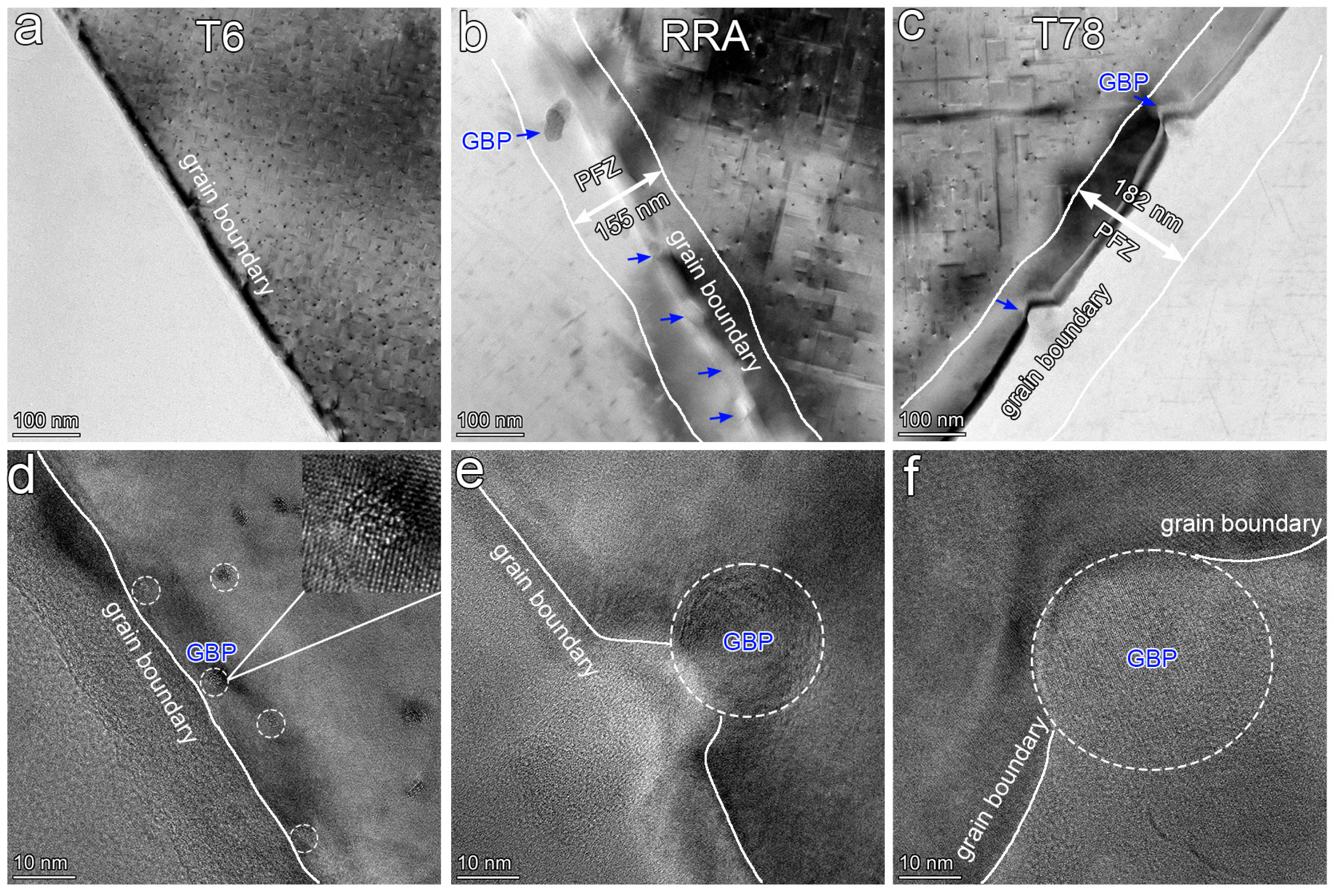

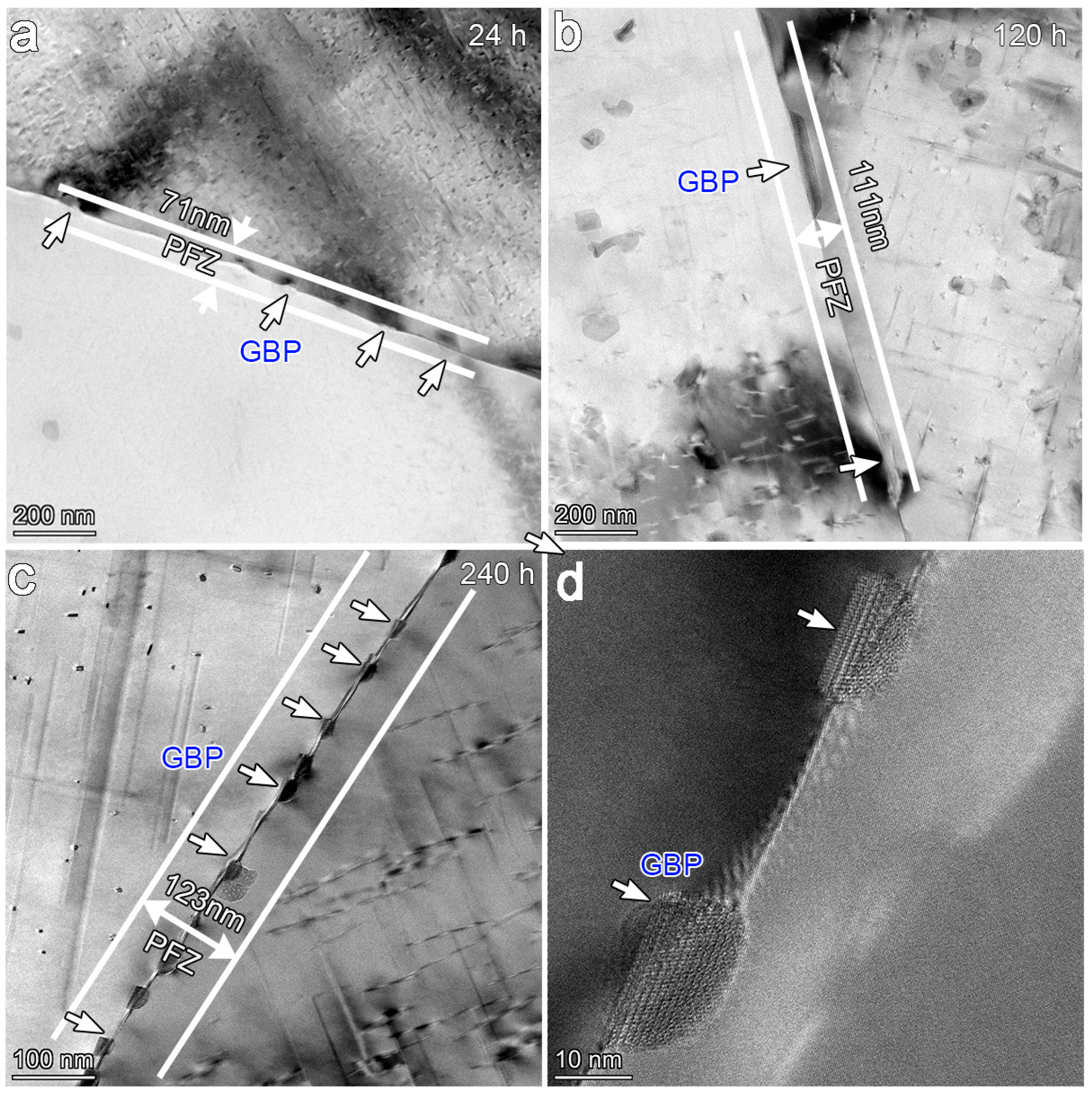

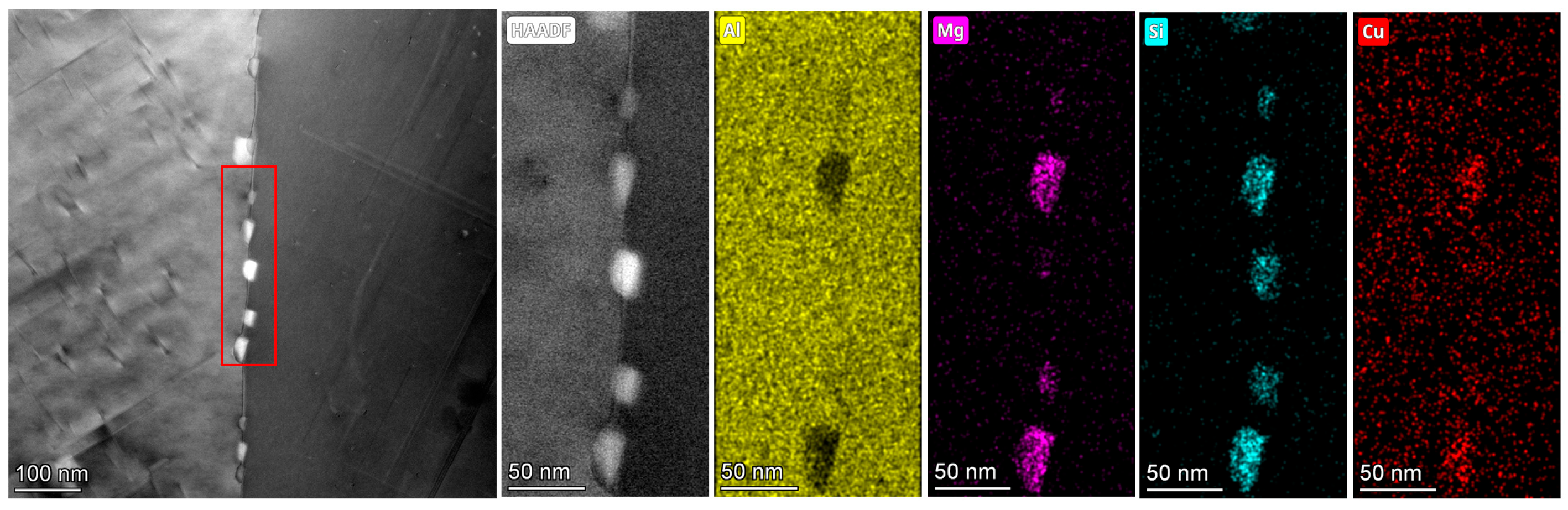

3.3. TEM and HRTEM Overviews of Precipitates at/near the Grain Boundaries

3.4. The Relationship between Microstructures and Hardness

4. Conclusions

- (1)

- The T6 treatment exhibited the highest hardness due to the presence of a high density of fine needle-like β″ strengthening effects.

- (2)

- The over-aging treatments resulted in the precipitation of lath-like β′, β″/disordered, or B′/disordered composite phases. The MOA treatment caused the coarsening of the grain boundary precipitates (GBPs) and the widening of the PFZ, while the HOA treatment led to the re-precipitation of the Cu-containing GBPs and increased the GBP density. The RRA treatment precipitated β″, lath-like β′, and disordered phases, while the T78 treatment precipitated β″, B′, and disordered phases. Both the T78 and RRA treatments led to the coarsening of the GBPs and the widening of the PFZs.

- (3)

- Decreased hardness during post-over-aging treatment was attributed to a combination of coarsening intragranular precipitates and/or wider precipitation-free zones (PFZs) and the change of precipitate types.

- (4)

- The T78 and RRA treatments achieved 95.5% and 94% of the hardness values of the T6 treatment (113 HV), respectively. The hardness of the T78 and RRA treatments was nearly equivalent to that of the SOA treatment.

- (5)

- The hardness of the RRA and T78 treated alloys depended on the presence of finer nano-sized (<10 nm) precipitates formed during the high temperature process. These finer nano-sized precipitates could compensate for the loss of hardness caused by the increase of the widths of the PFZs and the coarser matrix precipitates.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, J.; Liu, X.; Yan, D.; Rong, L. A novel GP-Li precursor and the correlated precipitation behaviors in Al-Cu-Li alloys with different Cu/Li ratio. Acta Mater. 2023, 243, 118442. [Google Scholar] [CrossRef]

- Ma, Y.; Chen, H.; Zhang, M.-X.; Addad, A.; Kong, Y.; Lezaack, M.B.; Gan, W.; Chen, Z.; Ji, G. Break through the strength-ductility trade-off dilemma in aluminum matrix composites via precipitation-assisted interface tailoring. Acta Mater. 2023, 242, 118470. [Google Scholar] [CrossRef]

- Singh, P.; Ramacharyulu, D.A.; Kumar, N.; Saxena, K.K.; Eldin, S.M. Change in the structure and mechanical properties of Al–Mg–Si alloys caused by the addition of other elements: A comprehensive review. J. Mater. Res. Technol. 2023, 27, 1764–1796. [Google Scholar] [CrossRef]

- Yang, M.; Ruan, Z.; Lin, H.; Li, K.; Yang, M.; Wang, Z.; Lan, X.; Xie, Y.; Xiao, Y.; Yan, Q.; et al. Quantified effect of quench rate on the microstructures and mechanical properties of an Al–Mg–Si alloy. J. Mater. Res. Technol. 2023, 24, 6753–6761. [Google Scholar] [CrossRef]

- Abúndez, A.; Pereyra, I.; Campillo, B.; Serna, S.; Alcudia, E.; Molina, A.; Blanco, A.; Mayén, J. Improvement of ultimate tensile strength by artificial ageing and retrogression treatment of aluminium alloy 6061. Mater. Sci. Eng. A 2016, 668, 201–207. [Google Scholar] [CrossRef]

- Chen, X.P.; Mei, L.; Chen, D.; Bao, Z.L.; Liu, Q. The effect of initial aging treatment on the microstructure and mechanical properties of cryorolled 6016 Al alloy. Mater. Sci. Eng. A 2016, 667, 311–316. [Google Scholar] [CrossRef]

- Engler, O.; Marioara, C.D.; Aruga, Y.; Kozuka, M.; Myhr, O.R. Effect of natural ageing or pre-ageing on the evolution of precipitate structure and strength during age hardening of Al–Mg–Si alloy AA 6016. Mater. Sci. Eng. A 2019, 759, 520–529. [Google Scholar] [CrossRef]

- Ninive, P.H.; Strandlie, A.; Gulbrandsen-Dahl, S.; Lefebvre, W.; Marioara, C.D.; Andersen, S.J.; Friis, J.; Holmestad, R.; Løvvik, O.M. Detailed atomistic insight into the β″ phase in Al–Mg–Si alloys. Acta Mater. 2014, 69, 126–134. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andersen, S.J.; Jansen, J.; Zandbergen, H.W. The influence of temperature and storage time at RT on nucleation of the β″ phase in a 6082 Al–Mg–Si alloy. Acta Mater. 2003, 51, 789–796. [Google Scholar] [CrossRef]

- Chen, J.H.; Costan, E.; Huis, M.A.V.; Xu, Q.; Zandbergen, H.W. Atomic Pillar–Based Nanoprecipitates Strengthen AlMgSi Alloys. Science 2006, 312, 416–419. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andersen, S.J.; Stene, T.N.; Hasting, H.; Walmsley, J.; van Helvoort, A.T.J.; Holmestad, R. The effect of Cu on precipitation in Al-Mg-Si alloys. Phil. Mag. 2007, 87, 3385–3413. [Google Scholar] [CrossRef]

- Guo, M.; Sun, M.; Huang, J.; Pang, S. A Comparative Study on the Microstructures and Mechanical Properties of Al-10Si-0.5Mg Alloys Prepared under Different Conditions. Metals 2022, 12, 142. [Google Scholar] [CrossRef]

- Zhou, P.; Wang, D.; Nagaumi, H.; Wang, R.; Zhang, X.; Li, X.; Zhang, H.; Zhang, B. Microstructural Evolution and Mechanical Properties of Al-Si-Mg-Cu Cast Alloys with Different Cu Contents. Metals 2023, 13, 98. [Google Scholar] [CrossRef]

- Vissers, R.; van Huis, M.A.; Jansen, J.; Zandbergen, H.W.; Marioara, C.D.; Andersen, S.J. The crystal structure of the β′ phase in Al–Mg–Si alloys. Acta Mater. 2007, 55, 3815–3823. [Google Scholar] [CrossRef]

- Chen, K.; Liu, C.; Yang, J.; Ma, P.; Zhan, L.; Huang, M.; Li, J. Stabilizing Al–Mg–Si–Cu alloy by precipitation nano-phase control. Mater. Sci. Eng. A 2020, 769, 110883. [Google Scholar] [CrossRef]

- Liu, Y.; Lai, Y.X.; Chen, Z.Q.; Chen, S.L.; Gao, P.; Chen, J.H. Formation of β”-related composite precipitates in relation to enhanced thermal stability of Sc-alloyed Al-Mg-Si alloys. J. Alloys Compd. 2021, 885, 160942. [Google Scholar] [CrossRef]

- Lai, Y.X.; Fan, W.; Yin, M.J.; Wu, C.L.; Chen, J.H. Structures and formation mechanisms of dislocation-induced precipitates in relation to the age-hardening responses of Al-Mg-Si alloys. J. Mater. Sci. Technol. 2020, 41, 127–138. [Google Scholar] [CrossRef]

- Hasting, H.S.; Frøseth, A.G.; Andersen, S.J.; Vissers, R.; Walmsley, J.C.; Marioara, C.D.; Danoix, F.; Lefebvre, W.; Holmestad, R. Composition of β″ precipitates in Al–Mg–Si alloys by atom probe tomography and first principles calculations. J. Appl. Phys. 2009, 106, 12. [Google Scholar] [CrossRef]

- Torsæter, M.; Hasting, H.S.; Lefebvre, W.; Marioara, C.D.; Walmsley, J.C.; Andersen, S.J.; Holmestad, R. The influence of composition and natural aging on clustering during preaging in Al–Mg–Si alloys. J. Appl. Phys. 2010, 108, 7. [Google Scholar] [CrossRef]

- Andersen, S.J.; Marioara, C.D.; Frøseth, A.; Vissers, R.; Zandbergen, H.W. Crystal structure of the orthorhombic U2-Al4Mg4Si4 precipitate in the Al–Mg–Si alloy system and its relation to the β′ and β″ phases. Mater. Sci. Eng. A 2005, 390, 127–138. [Google Scholar] [CrossRef]

- Saito, T.; Marioara, C.D.; Andersen, S.J.; Lefebvre, W.; Holmestad, R. Aberration-corrected HAADF-STEM investigations of precipitate structures in Al–Mg–Si alloys with low Cu additions. Philos. Mag. 2013, 94, 520–531. [Google Scholar] [CrossRef]

- Urban, K.W. Studying atomic structures by aberration-corrected transmission electron microscopy. Science 2008, 321, 506–510. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Lu, J.; Kong, Y.; Li, K.; Yang, T.; Meingast, A.; Yang, M.; Lu, Q.; Du, Y. Atomic scale investigation of the crystal structure and interfaces of the B′ precipitate in Al-Mg-Si alloys. Acta Mater. 2020, 185, 193–203. [Google Scholar] [CrossRef]

- Weng, Y.; Jia, Z.; Ding, L.; Du, K.; Duan, H.; Liu, Q.; Wu, X. Special segregation of Cu on the habit plane of lath-like β′ and QP2 precipitates in Al-Mg-Si-Cu alloys. Scr. Mater. 2018, 151, 33–37. [Google Scholar] [CrossRef]

- Li, K.; Béché, A.; Song, M.; Sha, G.; Lu, X.; Zhang, K.; Du, Y.; Ringer, S.P.; Schryvers, D. Atomistic structure of Cu-containing β″ precipitates in an Al–Mg–Si–Cu alloy. Scr. Mater. 2014, 75, 86–89. [Google Scholar] [CrossRef]

- Saito, T.; Muraishi, S.; Marioara, C.D.; Andersen, S.J.; Røyset, J.; Holmestad, R. The effect of low Cu additions and pre-deformation on the precipitation in a 6060 Al-Mg-Si alloy. Metall. Mater. Trans. A 2013, 44, 4124–4135. [Google Scholar] [CrossRef]

- Torsæter, M.; Ehlers, F.J.H.; Marioara, C.D.; Andersen, S.J.; Holmestad, R. Applying precipitate–host lattice coherency for compositional determination of precipitates in Al–Mg–Si–Cu alloys. Philos. Mag. 2012, 92, 3833–3856. [Google Scholar] [CrossRef]

- Sunde, J.K.; Marioara, C.D.; Holmestad, R. The effect of low Cu additions on precipitate crystal structures in overaged Al-Mg-Si(-Cu) alloys. Mater. Charact. 2020, 160, 110087. [Google Scholar] [CrossRef]

- Schnatterer, C.; Zander, D. Influence of the grain boundary chemistry on the intergranular corrosion mechanisms of a high-strength Al-Mg-Si alloy. Surf. Interface Anal. 2016, 48, 750–754. [Google Scholar] [CrossRef]

- Pan, D.; Wang, Z.; Li, H.; Zheng, Z.Q. Effects of two-step ageing treatment on tensile properties and intergranular corrosion of 6061 aluminum alloy. Chin. J. Nonferrous Met. 2010, 20, 435–441. [Google Scholar]

- Wang, Z.; Zhu, F.; Zheng, K.; Jia, J.; Wei, Y.; Li, H.; Huang, L.; Zheng, Z. Effect of the thickness reduction on intergranular corrosion in an under–aged Al–Mg–Si–Cu alloy during cold–rolling. Corros. Sci. 2018, 142, 201–212. [Google Scholar] [CrossRef]

- Li, H.; Qingzhong, M.; Wang, Z.; Miao, F.; Fang, B.; Song, R.; Zheng, Z. Simultaneously enhancing the tensile properties and intergranular corrosion resistance of Al–Mg–Si–Cu alloys by a thermo-mechanical treatment. Mater. Sci. Eng. A 2014, 617, 165–174. [Google Scholar] [CrossRef]

- Li, H.; Zhao, P.; Wang, Z.; Mao, Q.; Fang, B.; Song, R.; Zheng, Z. The intergranular corrosion susceptibility of a heavily overaged Al-Mg-Si-Cu alloy. Corros. Sci. 2016, 107, 113–122. [Google Scholar] [CrossRef]

- Li, X.; Chen, J.; Liu, C.; Feng, J.; Wang, S. Effects of T6 and T78 tempers on the microstructures and properties of Al-Mg-Si-Cu alloys. Acta Metall. Sin. 2013, 49, 243–250. [Google Scholar] [CrossRef]

- Liu, L.; Lai, Y.; Liu, C.; Chen, J. Optimized combinatorial properties of an AlMgSi(Cu) alloy achieved by a mechanical–thermal combinatorial process. Acta Metall. Sin. 2018, 33, 751–758. [Google Scholar] [CrossRef]

- Guillaumin, V.; Mankowski, G. Influence of Overaging Treatment on Localized Corrosion of Al 6056. Corrosion 2000, 56, 12–23. [Google Scholar] [CrossRef]

- Li, G.; Zhang, X.; Li, P.; You, J. Effects of retrogression heating rate on microstructures and mechanical properties of aluminum alloy 7050. Trans. Nonferrous Met. Soc. China 2010, 20, 935–941. [Google Scholar] [CrossRef]

- Li, J.F.; Birbilis, N.; Li, C.X.; Jia, Z.Q.; Cai, B.; Zheng, Z.Q. Influence of retrogression temperature and time on the mechanical properties and exfoliation corrosion behavior of aluminium alloy AA7150. Mater. Charact. 2009, 60, 1334–1341. [Google Scholar] [CrossRef]

- Oliveira, A.F.; de Barros, M.C.; Cardoso, K.R.; Travessa, D.N. The effect of RRA on the strength and SCC resistance on AA7050 and AA7150 aluminium alloys. Mater. Sci. Eng. A 2004, 379, 321–326. [Google Scholar] [CrossRef]

- Peng, G.; Chen, K.; Chen, S.; Fang, H. Influence of repetitious-RRA treatment on the strength and SCC resistance of Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A 2011, 528, 4014–4018. [Google Scholar] [CrossRef]

- Xiao, Y.P.; Pan, Q.L.; Li, W.B.; Liu, X.Y.; He, Y.B. Influence of retrogression and re-aging treatment on corrosion behaviour of an Al–Zn–Mg–Cu alloy. Mater. Des. 2011, 32, 2149–2156. [Google Scholar] [CrossRef]

- Tao, G.H.; Liu, C.H.; Chen, J.H.; Lai, Y.X.; Ma, P.P.; Liu, L.M. The influence of Mg/Si ratio on the negative natural aging effect in Al–Mg–Si–Cu alloys. Mater. Sci. Eng. A 2015, 642, 241–248. [Google Scholar] [CrossRef]

- Ma, P.; Liu, C.; Chen, Q.; Wang, Q.; Zhan, L.; Li, J. Natural-ageing-enhanced precipitation near grain boundaries in high-strength aluminum alloy. J. Mater. Sci. Technol. 2020, 46, 107–113. [Google Scholar] [CrossRef]

- Zou, Y.; Liu, Q.; Jia, Z.; Xing, Y.; Ding, L.; Wang, X. The intergranular corrosion behavior of 6000-series alloys with different Mg/Si and Cu content. Appl. Surf. Sci. 2017, 405, 489–496. [Google Scholar] [CrossRef]

- Kairy, S.K.; Alam, T.; Rometsch, P.A.; Davies, C.H.J.; Banerjee, R.; Birbilis, N. Understanding the Origins of Intergranular Corrosion in Copper-Containing Al-Mg-Si Alloys. Metall. Mater. Trans. A 2016, 47, 985–989. [Google Scholar] [CrossRef]

- Svenningsen, G.; Larsen, M.H.; Walmsley, J.C.; Nordlien, J.H.; Nisancioglu, K. Effect of artificial aging on intergranular corrosion of extruded AlMgSi alloy with small Cu content. Corros. Sci. 2006, 48, 1528–1543. [Google Scholar] [CrossRef]

| Alloy | Mg | Si | Cu | Al |

|---|---|---|---|---|

| 6016 | 0.4 | 1.0 | 0.2 | balance |

| Full Name of Heat Treatments | Abbreviations |

|---|---|

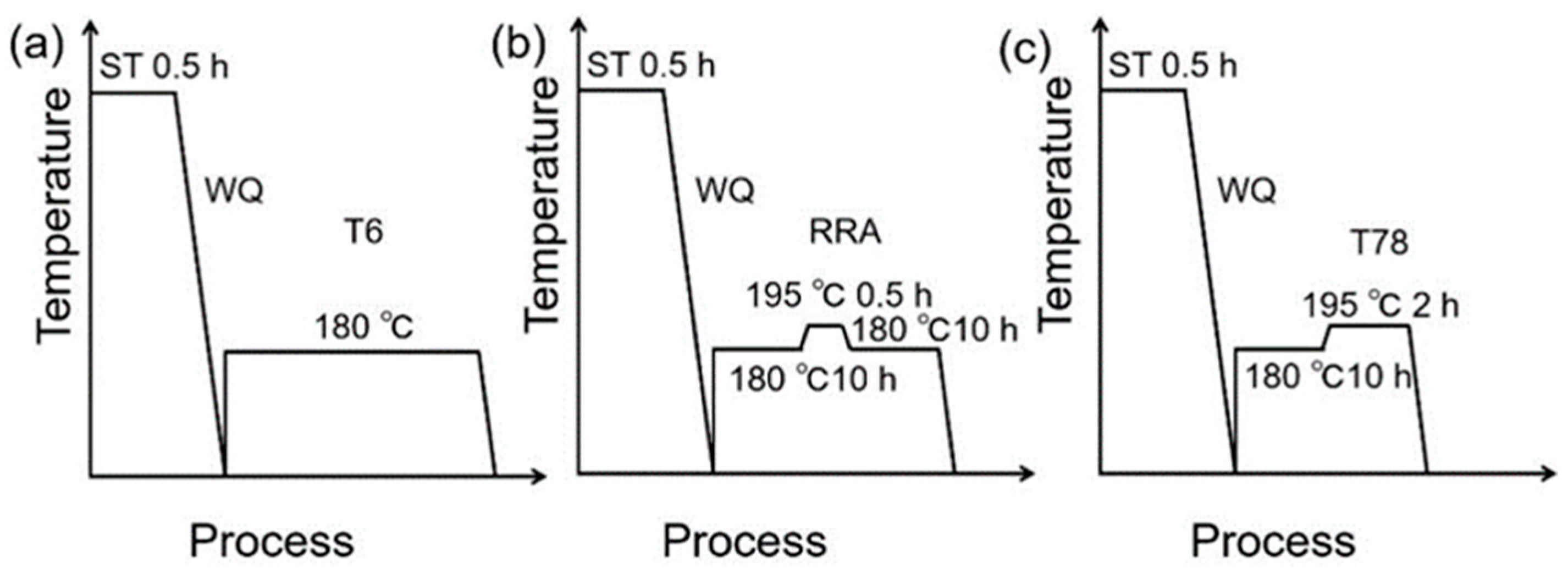

| 180 °C × 10 h (peak aging) | T6 |

| 180 °C × 0.5 h (under aging) | UA |

| 180 °C × 24 h (slight over-aging) | SOA |

| 180 °C × 120 h (moderate over-aging) | MOA |

| 180 °C × 240 h (heavy over-aging) | HOA |

| 180 °C × 10 h + 195 °C × 2 h (two steps aging) | T78 |

| 180 °C × 10 h + 195 °C × 0.5 h + 180 °C × 10 h (retrogression and re-aging) | RRA |

| Temper | <10 nm | 10~30 nm | 30~100 nm | >100 nm |

|---|---|---|---|---|

| T6 | 0.02 | 0.96 | 0.02 | 0.00 |

| 180 °C × 10 h + 195 °C × 0.5 h | 0.02 | 0.80 | 0.18 | 0.00 |

| RRA | 0.11 | 0.47 | 0.35 | 0.07 |

| T78 | 0.12 | 0.61 | 0.25 | 0.02 |

| SOA | 0.00 | 0.48 | 0.49 | 0.03 |

| MOA | 0.00 | 0.01 | 0.39 | 0.60 |

| HOA | 0.00 | 0.00 | 0.32 | 0.68 |

| Aging Condition | Types of Matrix Precipitates | Width of PFZ (nm) | Average Length of Needle-Like Phases (nm) |

|---|---|---|---|

| T6 | GP zones + β″ phase | <10 | 16 |

| 180 °C × 10 h + 195 °C × 0.5 h | GP zones + β″ phase | 24 | |

| RRA | β″ + lath-like β′ + disordered phases | 155 | 48 |

| T78 | β″ + B′ + disordered phases | 182 | 38 |

| SOA | β″ + B′ + disordered phases | 71 | 35 |

| MOA | B′ + lath-like β′ + β″/disordered composite phases | 111 | 128 |

| HOA | B′ + B′/disordered composite + disordered phases | 123 | 135 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Hou, Y.; Ye, T.; Zhang, L.; Huang, X.; Gong, Y.; Liu, C.; Wu, Y.; Duan, S. Effects of Aging Treatments on the Age Hardening Behavior and Microstructures in an Al-Mg-Si-Cu Alloy. Metals 2024, 14, 238. https://doi.org/10.3390/met14020238

Liu L, Hou Y, Ye T, Zhang L, Huang X, Gong Y, Liu C, Wu Y, Duan S. Effects of Aging Treatments on the Age Hardening Behavior and Microstructures in an Al-Mg-Si-Cu Alloy. Metals. 2024; 14(2):238. https://doi.org/10.3390/met14020238

Chicago/Turabian StyleLiu, Limei, Yingpeng Hou, Tuo Ye, Like Zhang, Xuan Huang, Yuqing Gong, Chao Liu, Yuanzhi Wu, and Shiyun Duan. 2024. "Effects of Aging Treatments on the Age Hardening Behavior and Microstructures in an Al-Mg-Si-Cu Alloy" Metals 14, no. 2: 238. https://doi.org/10.3390/met14020238

APA StyleLiu, L., Hou, Y., Ye, T., Zhang, L., Huang, X., Gong, Y., Liu, C., Wu, Y., & Duan, S. (2024). Effects of Aging Treatments on the Age Hardening Behavior and Microstructures in an Al-Mg-Si-Cu Alloy. Metals, 14(2), 238. https://doi.org/10.3390/met14020238