Mechanical Response of Zr51.9Cu23.3Ni10.5Al14.3 Metallic Glass Ribbon under Varying Strain Rates

Abstract

1. Introduction

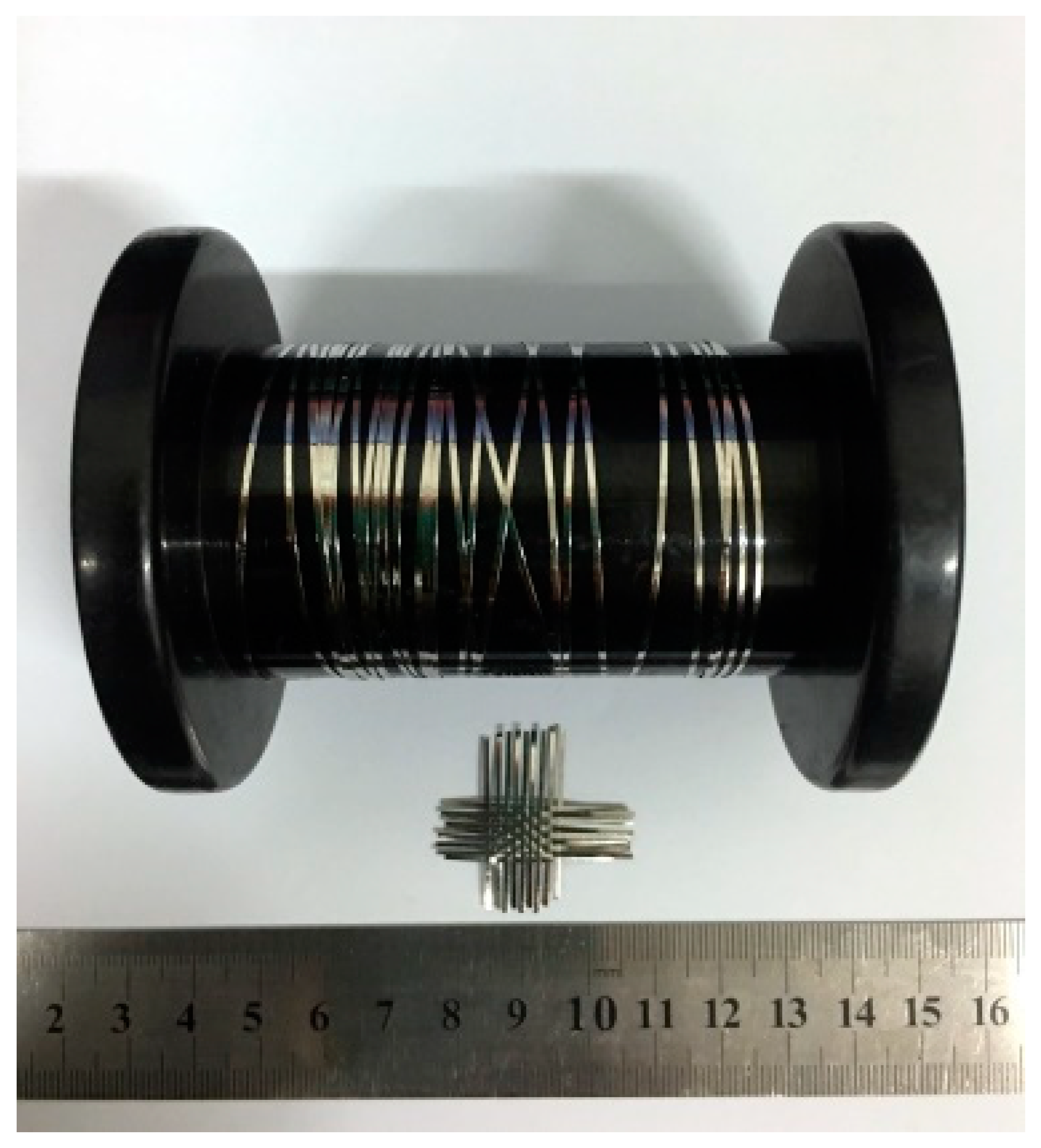

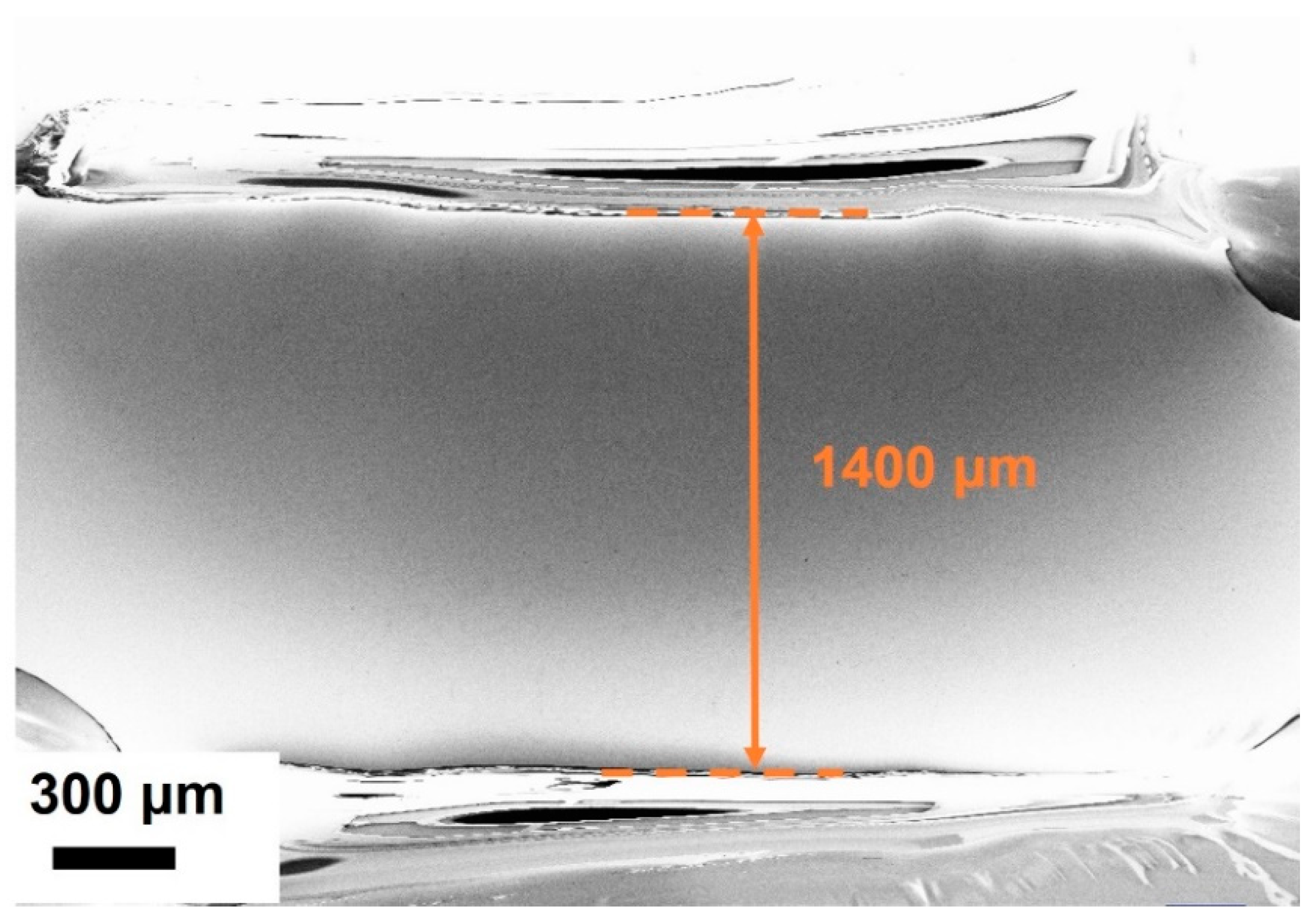

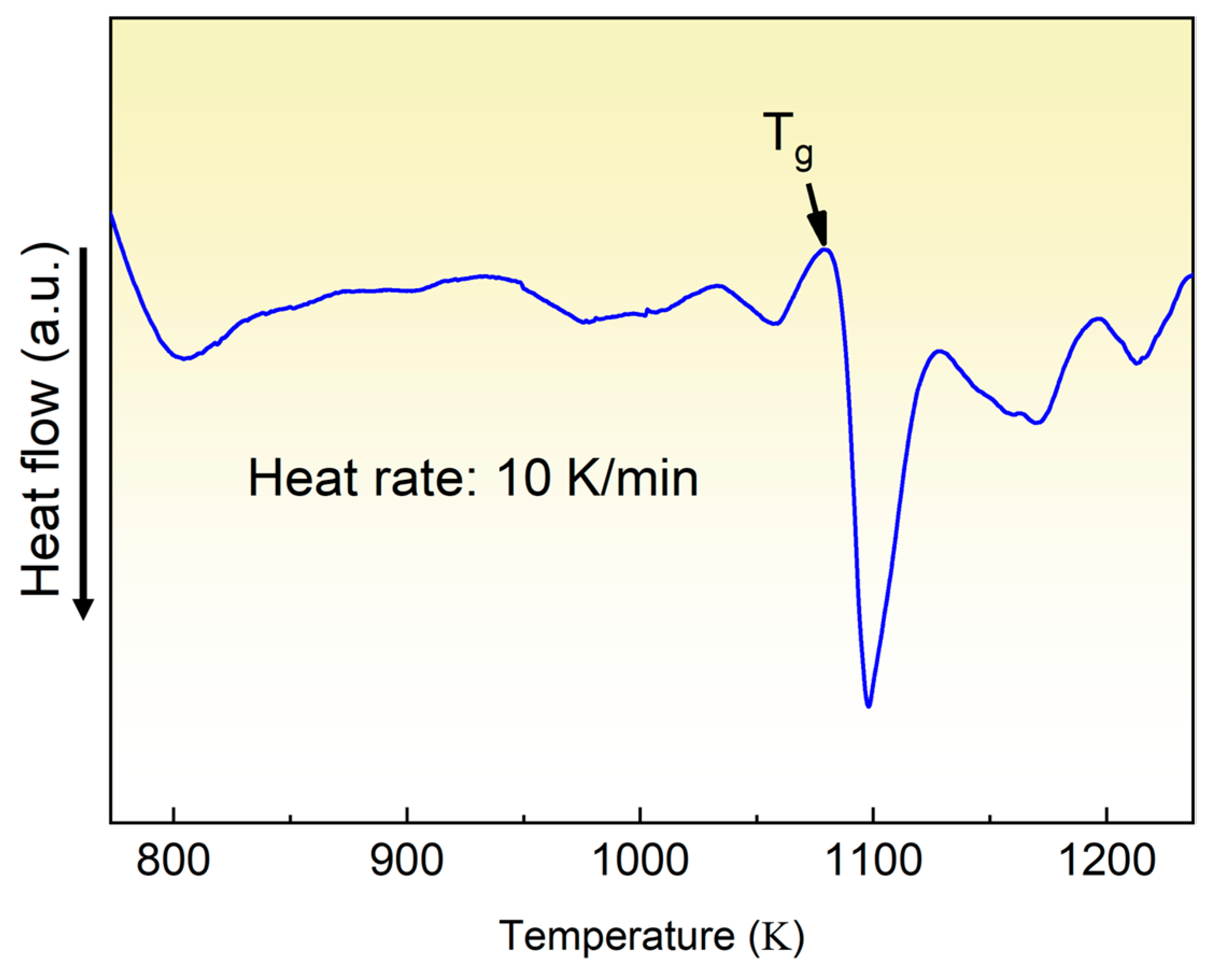

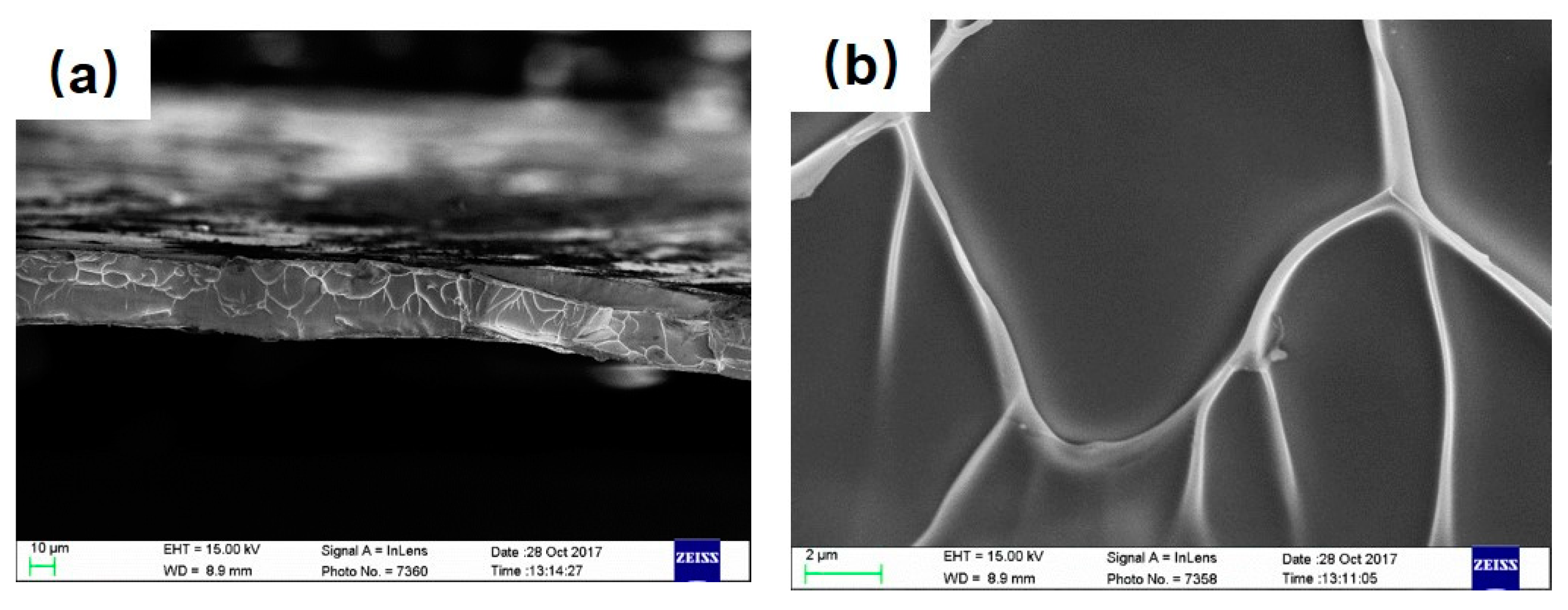

2. Experiment

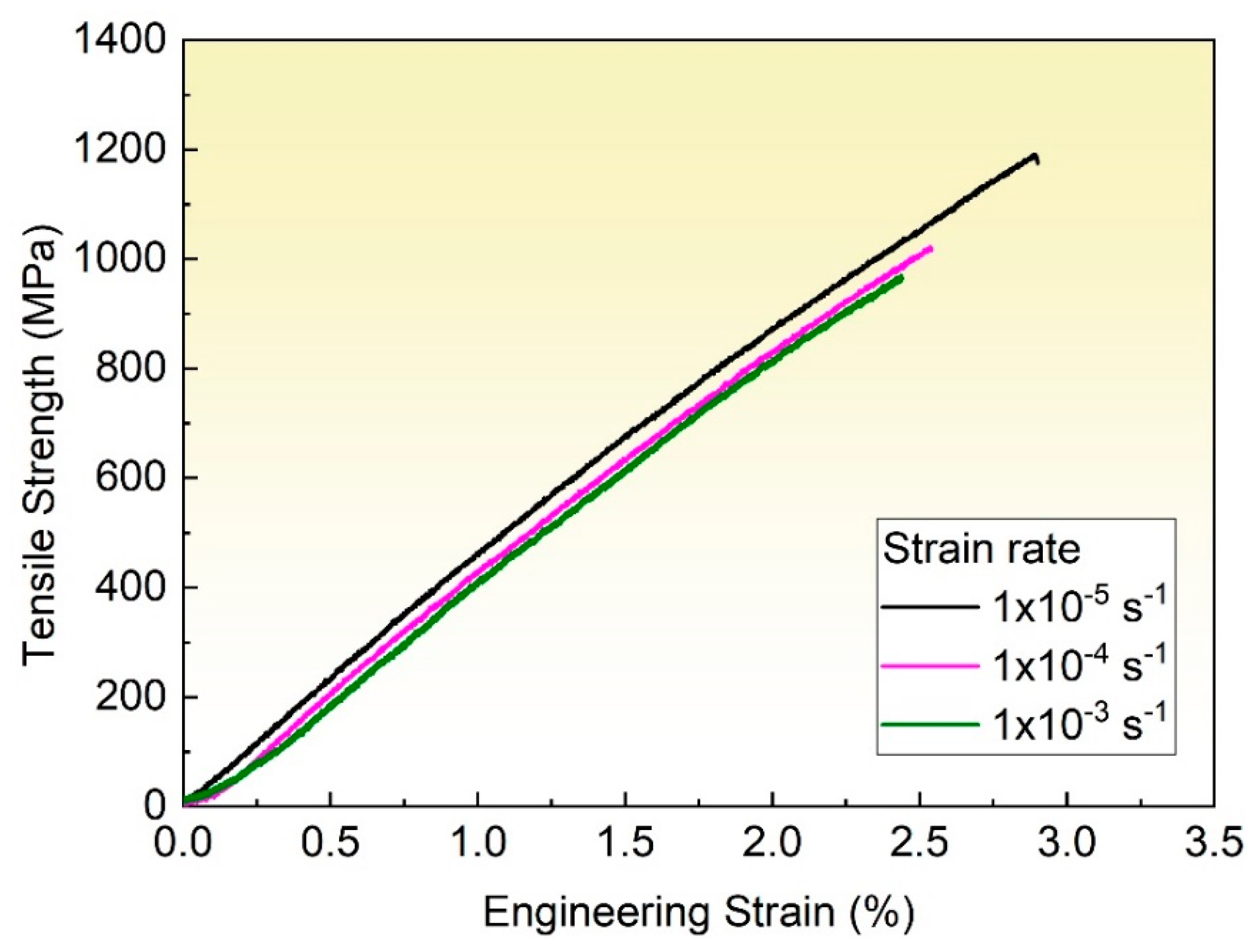

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Schuh, C.A.; Hufnagel, T.C.; Ramamurty, U. Mechanical behavior of amorphous alloys. Acta Mater. 2007, 55, 4067–4109. [Google Scholar] [CrossRef]

- Qiao, J.; Wang, Q.; Pelletier, J.; Kato, H.; Casalini, R.; Crespo, D.; Pineda, E.; Yao, Y.; Yang, Y. Structural heterogeneities and mechanical behavior of amorphous alloys. Prog. Mater. Sci. 2019, 104, 250–329. [Google Scholar] [CrossRef]

- Ming, W.; Guo, X.; Xu, Y.; Zhang, G.; Jiang, Z.; Li, Y.; Li, X. Progress in non-traditional machining of amorphous alloys. Ceram. Int. 2023, 49, 1585–1604. [Google Scholar] [CrossRef]

- Wang, A.; Zhao, C.; He, A.; Men, H.; Chang, C.; Wang, X. Composition design of high bs fe-based amorphous alloys with good amorphous-forming ability. J. Alloys Compd. 2016, 656, 729–734. [Google Scholar] [CrossRef]

- Wang, A.; Zhao, C.; Men, H.; He, A.; Chang, C.; Wang, X.; Li, R.W. Fe-based amorphous alloys for wide ribbon production with high bs and outstanding amorphous forming ability. J. Alloys Compd. 2015, 630, 209–213. [Google Scholar] [CrossRef]

- Parra, C.; Bolivar, F. Effect of cobalt addition on the microstructural evolution, thermal stability and magnetic properties of fe-based amorphous alloys. Vacuum 2019, 169, 108911. [Google Scholar] [CrossRef]

- Abrosimova, G.; Aronin, A. Nanocrystal formation in al-and ti-based amorphous alloys at deformation. J. Alloys Compd. 2018, 747, 26–30. [Google Scholar] [CrossRef]

- Chen, Q.; Yan, Z.; Guo, L.; Zhang, H.; Zhang, L.; Kim, K.B.; Li, X.; Wang, W. Enhancing the acid orange dye degradation efficiency of mg-based glassy alloys with introducing porous structure and zinc oxide. J. Alloys Compd. 2020, 831, 154817. [Google Scholar] [CrossRef]

- Martínez, C.; Briones, F.; Rojas, P.; Aguilar, C.; Guzmán, D.; Ordoñez, S. Microstructural and mechanical characterization of copper, nickel, and cu-based alloys obtained by mechanical alloying and hot pressing. Mater. Lett. 2017, 209, 509–512. [Google Scholar] [CrossRef]

- Xing, W.; Ouyang, D.; Li, N.; Liu, L. Estimation of residual stress in selective laser melting of a zr-based amorphous alloy. Materials 2018, 11, 1480. [Google Scholar] [CrossRef]

- Wang, X.; Zeng, M.; Nollmann, N.; Wilde, G.; Wang, J.; Tang, C. Thermal stability and non-isothermal crystallization kinetics of pd82si18 amorphous ribbon. AIP Adv. 2017, 7, 065206. [Google Scholar] [CrossRef]

- Chen, Q.; Yan, Z.; Zhang, H.; Zhang, L.; Ma, H.; Wang, W.; Wang, W. High mb solution degradation efficiency of fesibzr amorphous ribbon with surface tunnels. Materials 2020, 13, 3694. [Google Scholar] [CrossRef]

- Li, X.; Wu, J.; Pan, Y. Preparation of nanostructured cu/zr metal mixed oxides via self-sustained oxidation of a cuzr binary amorphous alloy. J. Mater. Sci. Technol. 2019, 35, 1601–1606. [Google Scholar] [CrossRef]

- Thorsson, L.; Unosson, M.; Pérez-Prado, M.T.; Jin, X.; Tiberto, P.; Barrera, G.; Adam, B.; Neuber, N.; Ghavimi, A.; Frey, M.; et al. Selective laser melting of a fe-si-cr-bc-based complex-shaped amorphous soft-magnetic electric motor rotor with record dimensions. Mater. Des. 2022, 215, 110483. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, T.; Li, L.; Yang, J.; Zhang, M.; Chengyong, W. Fatigue behavior of zr58cu15. 46ni12. 74al10. 34nb2. 76y0. 5 bulk metallic glass fabricated by industrial-grade zirconium raw material. Metals 2021, 11, 187. [Google Scholar] [CrossRef]

- Lin, J.; Wang, Z.; Cheng, J.; Kang, M.; Fu, X.; Hong, S. Evaluation of cavitation erosion resistance of arc-sprayed fe-based amorphous/nanocrystalline coatings in nacl solution. Results Phys. 2019, 12, 597–602. [Google Scholar] [CrossRef]

- Lamichhane, T.N.; Sethuraman, L.; Dalagan, A.; Wang, H.; Keller, J.; Paranthaman, M. Additive manufacturing of soft magnets for electrical machines—A review. Mater. Today Phys. 2020, 15, 100255. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Y.; Li, F.; Jiang, S.Q.; Li, M.; Liu, L. Mechanical relaxation-to-rejuvenation transition in a zr-based bulk metallic glass. Sci. Rep. 2017, 7, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.M.; Deen, K.M.; Haider, W. Combinatorial development and assessment of a zr-based metallic glass for prospective biomedical applications. J. Non-Cryst. Solids 2019, 523, 119544. [Google Scholar] [CrossRef]

- Su, X.; Hu, H.; Kong, X. The research progress of zr based amorphous composite materials. IOP Conf. Ser. Mater. Sci. Eng. 2017, 275, 012002. [Google Scholar] [CrossRef]

- Liu, L.; Ma, J.; Yu, C.; Huang, X.; He, L.; Zhang, L.; Li, P.; Liu, Z. Determination of forming ability of high pressure die casting for zr-based metallic glass. J. Mater. Process. Technol. 2017, 244, 87–96. [Google Scholar] [CrossRef]

- Marattukalam, J.J.; Pacheco, V.; Karlsson, D.; Riekehr, L.; Lindwall, J.; Forsberg, F.; Jansson, U.; Sahlberg, M.; Hjörvarsson, B. Development of process parameters for selective laser melting of a zr-based bulk metallic glass. Addit. Manuf. 2020, 33, 101124. [Google Scholar] [CrossRef]

- Zhou, W.; Meng, Y.; Duan, F.; Huang, W.; Yao, J.; Pan, J.; Wang, Y.; Li, Y. The effect of oxygen on phase formation in an industrial zr based bulk metallic glass. Intermetallics 2021, 129, 107055. [Google Scholar] [CrossRef]

- Dong, F.; Chu, Y.; He, M.; Zhang, Y.; Li, W.; Liaw, P.; Wang, B.; Luo, L.; Su, Y.; Ritchie, R. Manipulating internal flow units toward favorable plasticity in zr-based bulk-metallic glasses by hydrogenation. J. Mater. Sci. Technol. 2021, 102, 36–45. [Google Scholar] [CrossRef]

- Li, M.; Jiang, M.; Ding, G.; Peng, Z.; Jiang, F.; He, L.; Sun, J. The correlation between weakest configurations and yield strength of zr-based metallic glasses. J. Non-Cryst. Solids 2017, 468, 52–57. [Google Scholar] [CrossRef]

- Li, M.; Jiang, M.; Li, G.; Sun, J.; Jiang, F. Ductile to brittle transition of fracture of a zr-based bulk metallic glass: Strain rate effect. Intermetallics 2016, 77, 34–40. [Google Scholar] [CrossRef]

- Yu, W.; Zeng, H.; Sun, Y.; Sun, Y.; Hua, Z. Effect of heating rates on the crystallization process of fe64co16zr10b10 amorphous alloy. Phys. Lett. A 2017, 381, 1573–1576. [Google Scholar] [CrossRef]

- Bian, X.; Sun, M. Thermal-rate treatment and critical thickness for formation of amorphous al85ni10ce5 alloy. Mater. Lett. 2003, 57, 2460–2465. [Google Scholar] [CrossRef]

- Lin, S.; Chen, S.; Chen, J.; Lin, Y. Formation and magnetic properties of fe–si–b–dy amorphous alloy. Intermetallics 2010, 18, 1826–1828. [Google Scholar] [CrossRef]

- Zhang, J.; Teng, X.; Xu, S.; Xingjing, G.; Leng, J. Temperature dependence of resistivity and crystallization behaviors of amorphous melt-spun ribbon of mg66zn30gd4 alloy. Mater. Lett. 2017, 189, 17–20. [Google Scholar] [CrossRef]

- Sun, Y.; Qu, D.; Huang, Y.; Liss, K.; Wei, X.S.; Xing, D.W.; Shen, J. Zr–cu–ni–al bulk metallic glasses with superhigh glass-forming ability. Acta Mater. 2009, 57, 1290–1299. [Google Scholar] [CrossRef]

- Gu, J.; Duan, F.; Liu, S.; Cha, W.; Lu, J. Phase engineering of nanostructural metallic materials: Classification, structures, and applications. Chem. Rev. 2024; Online ahead of print. [Google Scholar] [CrossRef]

- Hossain, T. Mechanical Testing of Metallic Glass Ribbons. Master’s Programme in Mechanical Engineering (MEC). Master’s Thesis, Aalto University, Helsinki, Finland, 2021. [Google Scholar]

- Yüce, E.; Zarazúa-Villalobos, L.; Ter-Ovanessian, B.; Sharifikolouei, E.; Najmi, Z.; Spieckermann, F.; Eckert, J.; Sarac, B. New-generation biocompatible ti-based metallic glass ribbons for flexible implants. Mater. Des. 2022, 223, 111139. [Google Scholar] [CrossRef]

- Kouzoudis, D.; Samourgkanidis, G.; Tapeinos, C.I. Contactless detection of natural bending frequencies using embedded metallic-glass ribbons inside plastic beams made of 3-d printing. Recent Prog. Mater. 2021, 3, 1–12. [Google Scholar] [CrossRef]

- Tabbakh, T.; Kurdi, A.; Basak, A.K. Effect of strain rate and extrinsic size effect on micro-mechanical properties of zr-based bulk metallic glass. Metals 2021, 11, 1611. [Google Scholar] [CrossRef]

- Burgess, T.; Laws, K.; Ferry, M. Effect of loading rate on the serrated flow of a bulk metallic glass during nanoindentation. Acta Mater. 2008, 56, 4829–4835. [Google Scholar] [CrossRef]

- Fu, X.; Li, Y.; Schuh, C. Temperature, strain rate and reinforcement volume fraction dependence of plastic deformation in metallic glass matrix composites. Acta Mater. 2007, 55, 3059–3071. [Google Scholar] [CrossRef]

- Boltynjuk, E.; Gunderov, D.; Ubyivovk, E.; Monclús, M.; Yang, L.; Molina-Aldareguia, J.; Tyurin, A.; Kilmametov, A.; Churakova, A.; Churyumov, A. Enhanced strain rate sensitivity of zr-based bulk metallic glasses subjected to high pressure torsion. J. Alloys Compd. 2018, 747, 595–602. [Google Scholar] [CrossRef]

- Chen, T.-H.; Tsai, C.-K. The microstructural evolution and mechanical properties of zr-based metallic glass under different strain rate compressions. Materials 2015, 8, 1831–1840. [Google Scholar] [CrossRef]

- Zhang, J.; Park, J.M.; Kim, D.H.; Kim, H.S. Effect of strain rate on compressive behavior of ti45zr16ni9cu10be20 bulk metallic glass. Mater. Sci. Eng. A 2007, 449, 290–294. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, H.; Gu, J.; Guo, N.; Shao, L.; Zhang, Y.; Yao, K.; Chen, N. High strain rate sensitivity of hardness in ti-zr-hf-be-(cu/ni) high entropy bulk metallic glasses. J. Alloys Compd. 2018, 742, 312–317. [Google Scholar] [CrossRef]

- Qin, F.; Xie, G.; Dan, Z.; Zhu, S.; Seki, I. Corrosion behavior and mechanical properties of mg–zn–ca amorphous alloys. Intermetallics 2013, 42, 9–13. [Google Scholar] [CrossRef]

- Wolff, U.; Pryds, N.; Johnson, E.; Wert, J. The effect of partial crystallization on elevated temperature flow stress and room temperature hardness of a bulk amorphous mg60cu30y10 alloy. Acta Mater. 2004, 52, 1989–1995. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Sahu, S.; Sankaranarayanan, S.; Gupta, S.; Gupta, M. Development of novel mg–ni60nb40 amorphous particle reinforced composites with enhanced hardness and compressive response. Mater. Des. 2014, 53, 849–855. [Google Scholar] [CrossRef]

- Pandya, K.S.; Roth, C.C.; Mohr, D. Strain rate and temperature dependent fracture of aluminum alloy 7075: Experiments and neural network modeling. Int. J. Plast. 2020, 135, 102788. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, B. Material embrittlement in high strain-rate loading. Int. J. Extrem. Manuf. 2019, 1, 022003. [Google Scholar] [CrossRef]

- Ran, C.; Chen, P.; Li, L.; Zhang, W.; Liu, Y.; Zhang, X. High-strain-rate plastic deformation and fracture behaviour of ti-5al-5mo-5v-1cr-1fe titanium alloy at room temperature. Mech. Mater. 2018, 116, 3–10. [Google Scholar] [CrossRef]

- Sirigiri, V.K.R.; Gudiga, V.Y.; Gattu, U.S.; Suneesh, G.; Buddaraju, K.M. A review on johnson cook material model. Mater. Today Proc. 2022, 62, 3450–3456. [Google Scholar] [CrossRef]

- Shi, J.; Huang, Z.; Zu, X.; Xiao, Q.; Wang, Y. Research on non-cohesive jet formed by zr-based amorphous alloys. Sci. Rep. 2023, 13, 4149. [Google Scholar] [CrossRef]

- Nieh, T.; Schuh, C.; Wadsworth, J.; Li, Y. Strain rate-dependent deformation in bulk metallic glasses. Intermetallics 2002, 10, 1177–1182. [Google Scholar] [CrossRef]

| Strain Rate | Tensile Strength (MPa) | Elongation | Modulus |

|---|---|---|---|

| 1 × 10−3 s−1 | 980 | 2.4 | 40.0 |

| 1 × 10−4 s−1 | 1030 | 2.5 | 41.2 |

| 1 × 10−5 s−1 | 1200 | 2.8 | 42.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Wu, C.; Su, Y.; Xie, L.; Zhang, Y.; Wang, W. Mechanical Response of Zr51.9Cu23.3Ni10.5Al14.3 Metallic Glass Ribbon under Varying Strain Rates. Metals 2024, 14, 220. https://doi.org/10.3390/met14020220

Li D, Wu C, Su Y, Xie L, Zhang Y, Wang W. Mechanical Response of Zr51.9Cu23.3Ni10.5Al14.3 Metallic Glass Ribbon under Varying Strain Rates. Metals. 2024; 14(2):220. https://doi.org/10.3390/met14020220

Chicago/Turabian StyleLi, Dongyue, Chengshuang Wu, Yitian Su, Lu Xie, Yong Zhang, and Wenrui Wang. 2024. "Mechanical Response of Zr51.9Cu23.3Ni10.5Al14.3 Metallic Glass Ribbon under Varying Strain Rates" Metals 14, no. 2: 220. https://doi.org/10.3390/met14020220

APA StyleLi, D., Wu, C., Su, Y., Xie, L., Zhang, Y., & Wang, W. (2024). Mechanical Response of Zr51.9Cu23.3Ni10.5Al14.3 Metallic Glass Ribbon under Varying Strain Rates. Metals, 14(2), 220. https://doi.org/10.3390/met14020220