2. Materials and Methods

The powder composites with WC and the NiCo 29-18 alloy were obtained. Two different WC powders were used—synthesized nanopowder and commercial micropowder (KZTS, Kirovgrad, Russia). Nanopowder synthesis (W and NiCo 29-18) was carried out via the electric explosion of wire (EEW) method, and the production technology and the study of the powder are given in the article [

22].

The samples with nanopowders were prepared from the following components: W, NiCo 29-18, carbon black treated with vaseline oil, stabilizing additive (0.8 wt%). Different W:C ratios were used, and the content of NiCo 29-18 was 10 wt.% for all samples. The samples with micropowders were prepared from the following mixtures: WC-89.5 wt.%, NiCo 29-18-10 wt.%, sintering additives-0.5 wt.%. The following additives were used in the samples: VC, Cr3C2, NbC, Y2O3, and Nd2O3. A sample without additives was also prepared for a comparison. Mixing of the powders was carried out in a turbula-type mixer (Turbula S2.0, Vibrotechnik JSC, Saint-Petersburg, Russia). Petroleum ether grade 70–100 (5–7 cm3) and dioctyl adipate (7–10 drops) as a plasticizer were added to the powder mixtures, and the resulting suspensions were dispersed via ultrasonication for 30 min in an ultrasonic bath (STEGLER 5DT, Stegler, Moscow, Russia China). Then, the solvent was evaporated and the resulting dry residue was ground. Tablets were obtained from each composition by pressing at 200 MPa in a mold with a diameter of 10 mm using a hydraulic press with a maximum load of 200 tons.

The samples were sintered in a vacuum furnace (Nabertherm GmbH, Lilienthal, Germany). Heating to 450 °C was carried out at a rate of 20 K/min, followed by holding at 450 °C for 1 h. Heating to 1150 °C was carried out at a rate of 10 K/min, followed by holding at 1150 °C for 1 h. Heating to 1440 °C was carried out at a rate of 5 K/min, followed by holding at 1440 °C for 4 h. Next, the samples were cooled with a furnace.

For oxidation resistance experiments, cylindrical samples (⌀ = 10 mm, h = 5 mm) were used. All samples have been prepared by polishing on a 4000 grit SiC paper. Before testing, the samples were ultrasonically cleaned with ethanol and then dried. All samples have been oxidized in a muffle furnace with a hole (⌀ = 20 mm) for air recirculation. The mass of the samples has been measured before and after oxidation using an Adventurer Pro AV264C laboratory balance (Ohaus, Parsippany, NJ, USA) with an accuracy of ±0.1 mg.

The microstructure and fracture surfaces of the fabricated samples were examined using a LEO EVO 50 (Carl Zeiss, Oberkochen, Germany) scanning electron microscope (SEM) using secondary electrons (SE) and backscattered electron (BSD) detectors. The attachment for energy-dispersive X-ray spectroscopy (EDX) was used to investigate the elemental composition of the samples (Oxford instruments, Abingdon, UK). The phase composition was investigated using X-ray diffraction (XRD) on the Shimadzu XRD-7000 (Shimadzu, Kyoto, Japan) set up. The Vickers hardness was measured using a Duramin-500 (Struers, Copenhagen, Denmark) hardness tester at a 500 gf load and a 10 s dwell time.

Demo samples of 5 × 5 × 18 mm

3 were fabricated (

Figure 1) to demonstrate the feasibility of fabricated WC-Co granulated feedstock products using additive manufacturing technology (Material Extrusion Additive Manufacturing, MEAM). Polyol polymer brand MC-2163 (OleoChemical, Hamburg, Germany) was used as a polymer binder. The feedstock was produced by mixing polymer and powder together with a 60:40 polymer/powder ratio using an MTE-20 twin-screw extruder (Meizlon, Nanjing, China), and then it was granulated in cylindrical granules using a dicing cutter (length = 5 mm, ⌀ = 1.75 mm).

The MEAM process was carried out on a commercial Prusa i3 printer with an upgraded print head to work with granulated feedstocks. The samples were obtained at a print speed of 60 mm/min, a printed layer height of 0.15 mm, and a nozzle diameter of 0.8 mm, a 100% fill density, and a rectilinear fill pattern. A nozzle temperature of 155 °C and heating of the printing table of 60 °C were chosen.

Debinding of the MEAM samples was carried out in acetone. Acetone was used as a binder removal agent for the green samples. The samples were kept in an acetone bath at 45 °C for 24 h. The MEAM samples were sintered in a vacuum furnace at 1300 °C for 4 h. During sintering, isothermal exposure was performed at a temperature of 260 °C and 360 °C for 2 h to remove the residual binder. The rate of heating and cooling was 5 K/min. The melt flow index (MFI) according to ASTM D1238 was chosen as a criterion to evaluate flowability and formability. All compositions were tested using an extrusion plastometer at a load of 50 N and a temperature of 160 °C.

3. Results and Discussion

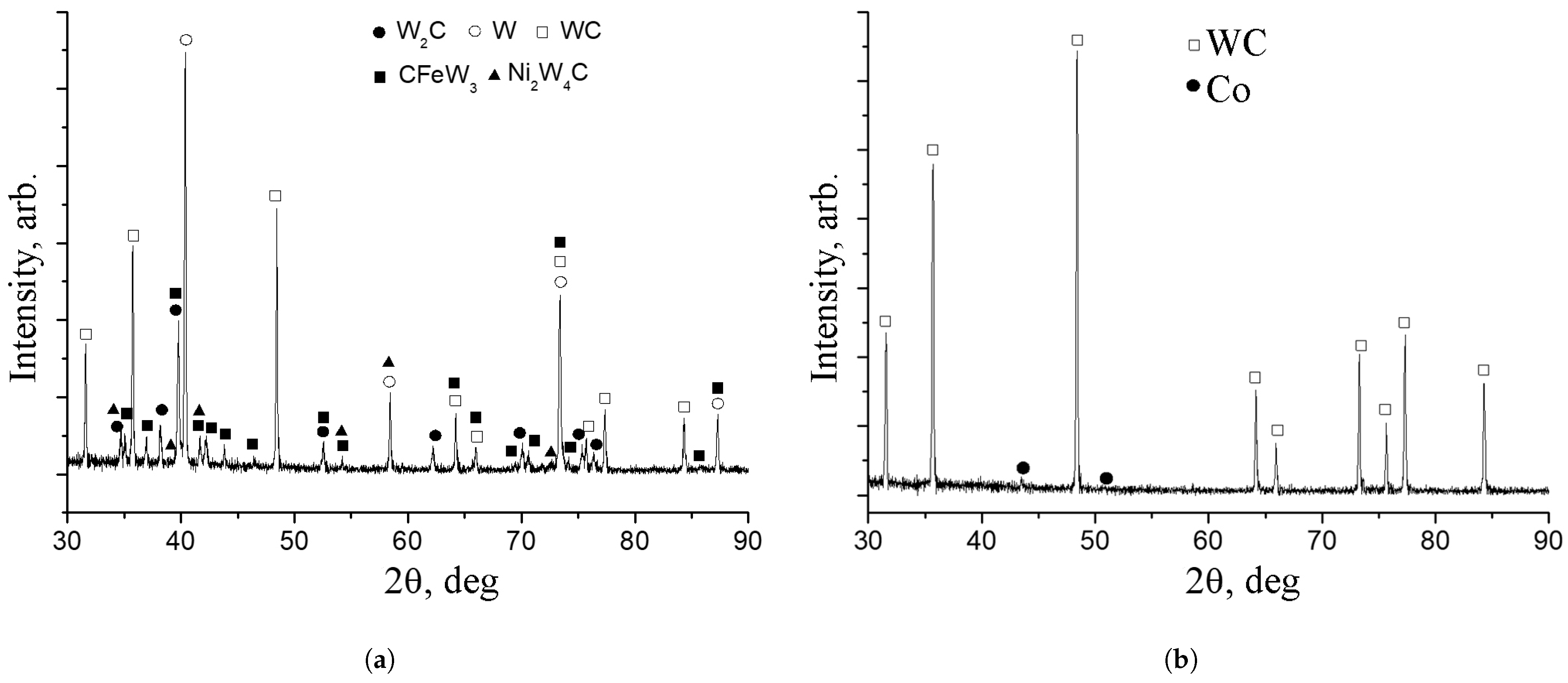

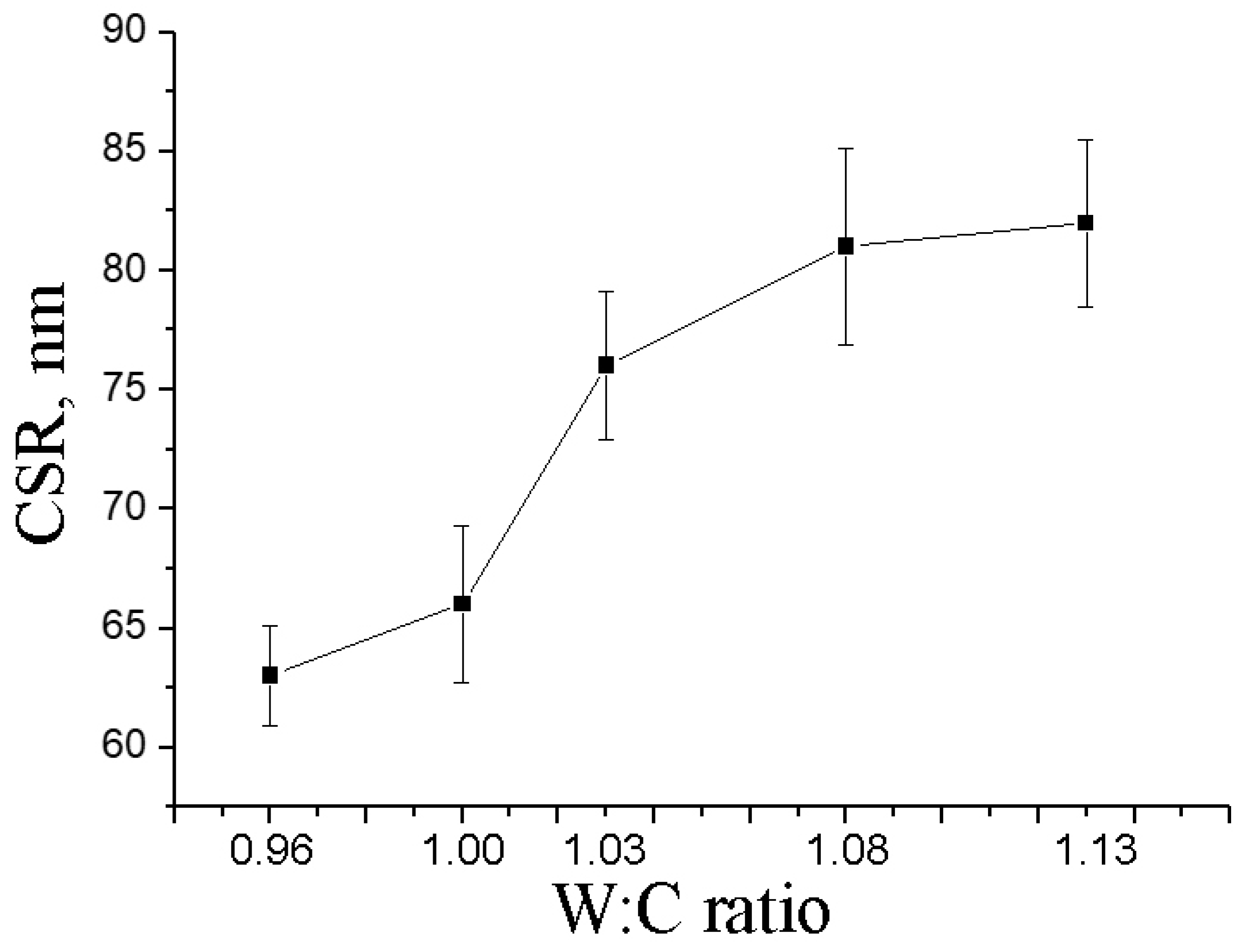

3.2. Microstructure and Phase Composition

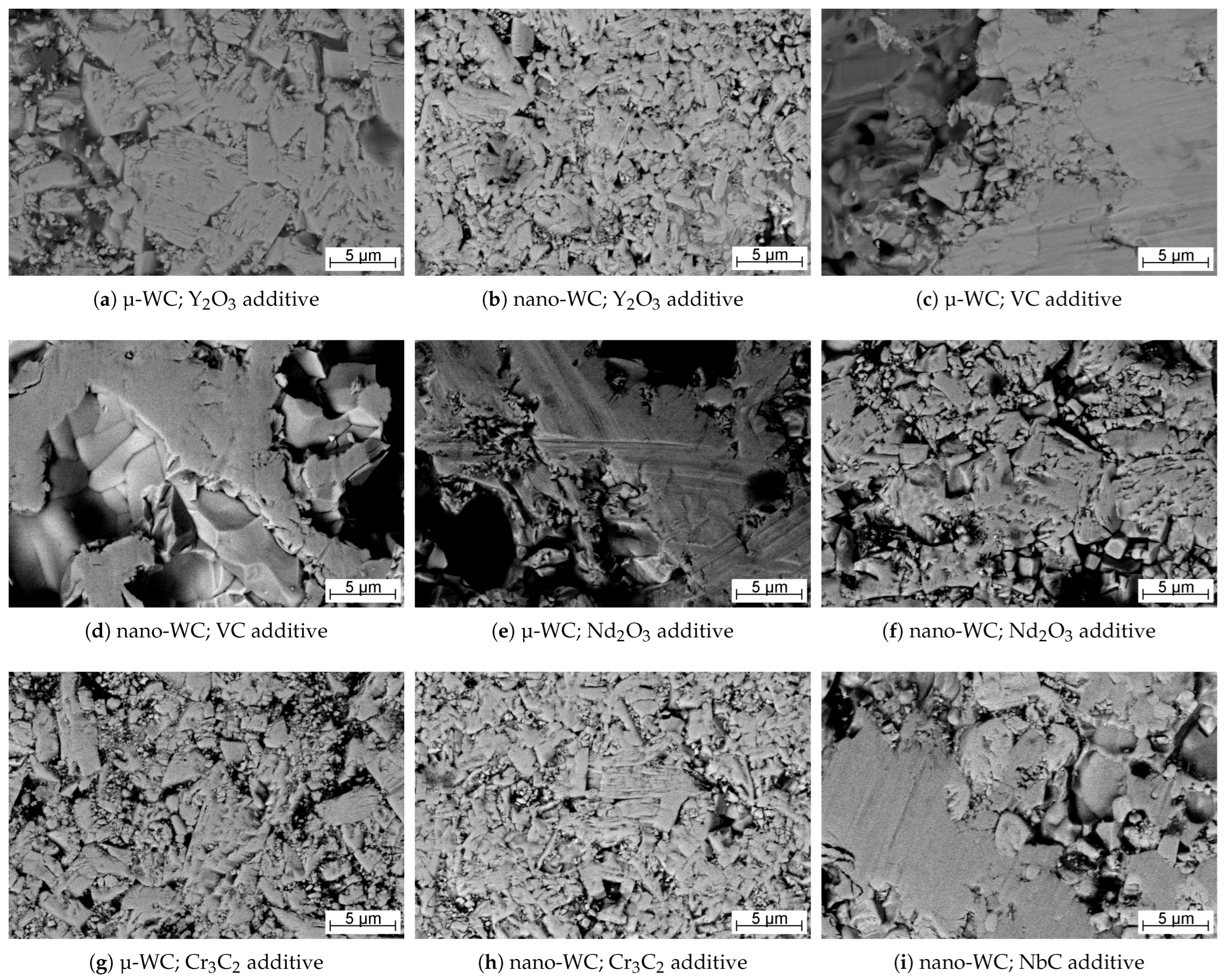

The microstructure of the samples (

Figure 5) differs significantly depending on the additives used, despite the fact that the samples were sintered simultaneously. The introduced additives segregate along the grain boundaries [

23,

24]. As a result, grain growth is limited during the sintering process. In addition, the powder particles coalesce, which leads to an increase in the density of the samples. In all samples, a uniform distribution of the additives over the sample volume is observed. All investigated additives make it possible to limit the grain growth and improve the sintering process in the WC-Co system, but not all additives are effective in this work. The reason is the more complex composition of the binder. For example, the presence of NbC in the samples with iron [

25] leads to an increase in the grain size.

Additives VC (

Figure 5c,d) and NbC (

Figure 5i) do not suppress grain growth during sintering for both micron (

-WC) and nanopowders (n-WC) of WC. The addition of Nd

2O

3 to the

-WC powder also does not suppress grain growth, besides large pores forming in the sample (

Figure 5e). The most effective grain growth suppression was observed with the addition of Y

2O

3 (

Figure 5a,b) and Cr

3C

2 (

Figure 5g,h). When using these additives, large pores do not form in the microstructure of the samples. The addition of Nd

2O

3 to the samples with n-WC (

Figure 5f), in contrast to the samples with micron particles, makes it possible to suppress grain growth; nevertheless, large pores are formed in the sample.

The elemental composition of the samples with the addition of Y2O3 provides valuable evidence of an even distribution pattern throughout the sample, supported by the uniform intensity of the yttrium. Factors such as proper mixing protocols, homogenous and deagglomerated starting materials, and proper sintering conditions contribute to achieving an even distribution of yttrium oxide in the sample. Particularly noticeable is the non-uniformity of the material distribution over the spectrum of iron—its highest concentration is contained in the areas that have a dark color on the original SEM image (pores).

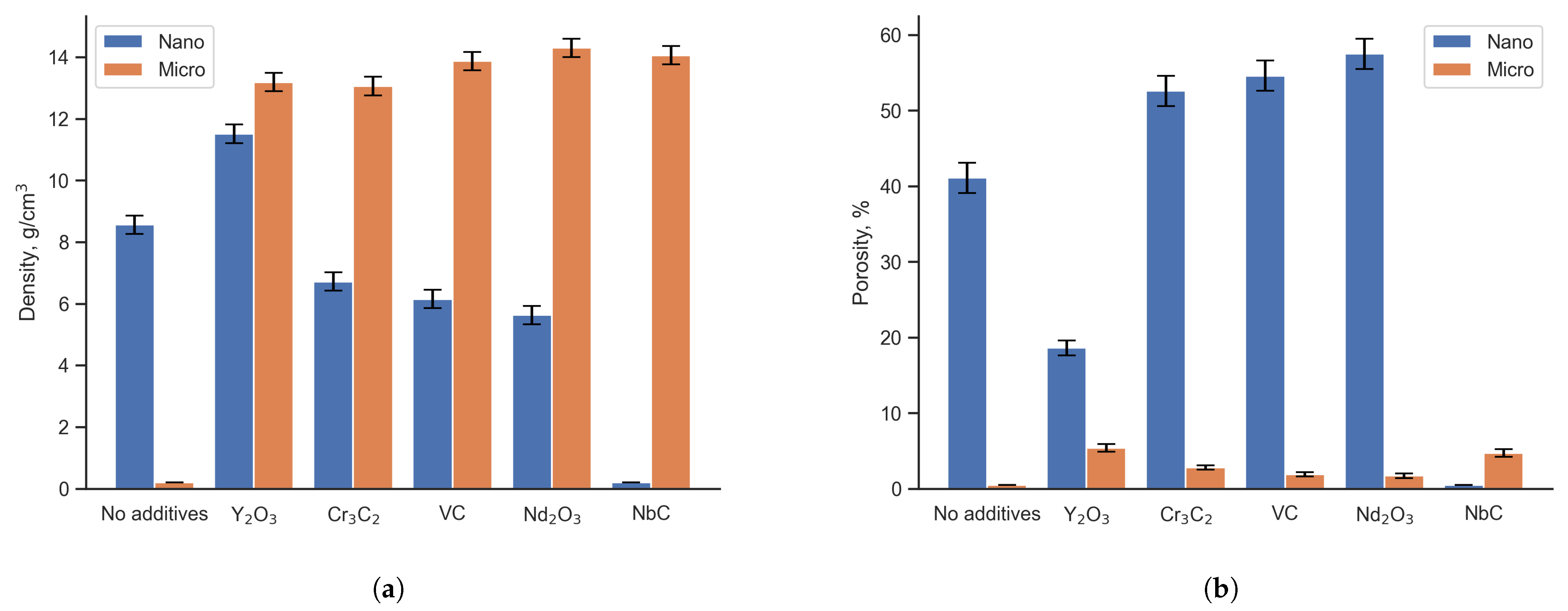

The density and porosity of the samples were examined (

Figure 6). The samples with

-WC powder did not sinter without the addition of additives. The remaining samples with

-WC have a density in the range of 13.0–14.3 g/cm

3 for all samples, regardless of the additives used. For the samples with n-WC powder, when Y

2O

3 is added, the density is higher than that for a sample without additives (11.5 g/cm

3). When other additives are used, the density of the samples is lower than without their use. A similar trend is observed with porosity—

-WC powders have a porosity of no more than 5% for all samples, while the smallest porosity for the samples with n-WC is 18% with the addition of Y

2O

3. Thus, the additives used in the article gives a better effect when using with

-WC powder. When using n-WC powder, the sintering kinetics change and the additives work differently.

The additives are used to suppress grain growth during the sintering process. In WC-Co alloys, inhibitors are preferentially dissolved in cobalt during the sintering process. After the inhibitors are dissolved, their distribution in volume becomes uniform. Inhibitors affect the adsorption/desorption of WC in Co, which prevents the sintering of WC grains. Grain growth is slowed down by reducing effective contacts, leading to the aggregation of WC grains. In addition, additives can inhibit the dissolution–precipitation process during sintering, which also reduces the growth rate of WC grains.

Maintaining a fine-grained structure by suppressing the growth of WC grains is necessary to ensure high mechanical properties in the sintered material, achievable only with small grains. WC-Co alloys with large grains have lower strength, hardness, and wear resistance, while being more ductile. This combination of properties is unacceptable for the use of WC-Co as a tool material. The use of grain growth inhibitors in materials with n-WC is the only way to effectively suppress grain growth.

In addition to suppressing grain growth during sintering, additives ensure the formation of a more dense material structure. When a WC grain grows, a change in the volume of the sample occurs. The grain growth rate without additives can be high, as a result, intense shrinkage will not occur and the final sample will have high porosity. In addition, it is even possible to increase the volume of the sample. The densification mechanism of -WC and n-WC powders is the same, but due to the different surface area and surface energy, the processes occurs differently. For example, nanopowder is actively oxidized, forming an oxide layer on the surface that prevents reactions, sintering, and coalescence.

All additives used in this work show good solubility in Co, and theoretically, all of them can be used to suppress grain growth. However, suppression of grain growth does not provide high hardness or oxidation resistance. The effectiveness of inhibition is different for all additives by different reasons, including different solubility in Co.

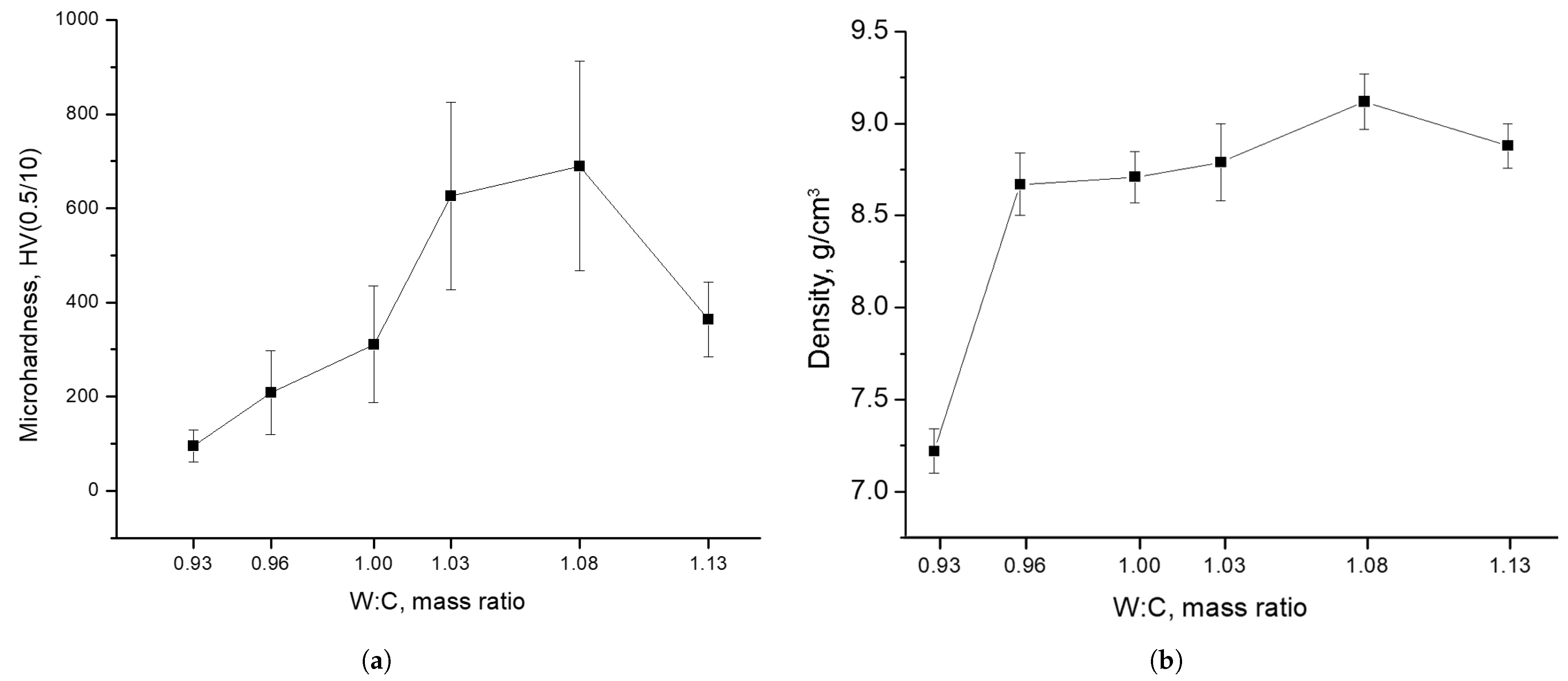

3.3. Microhardness

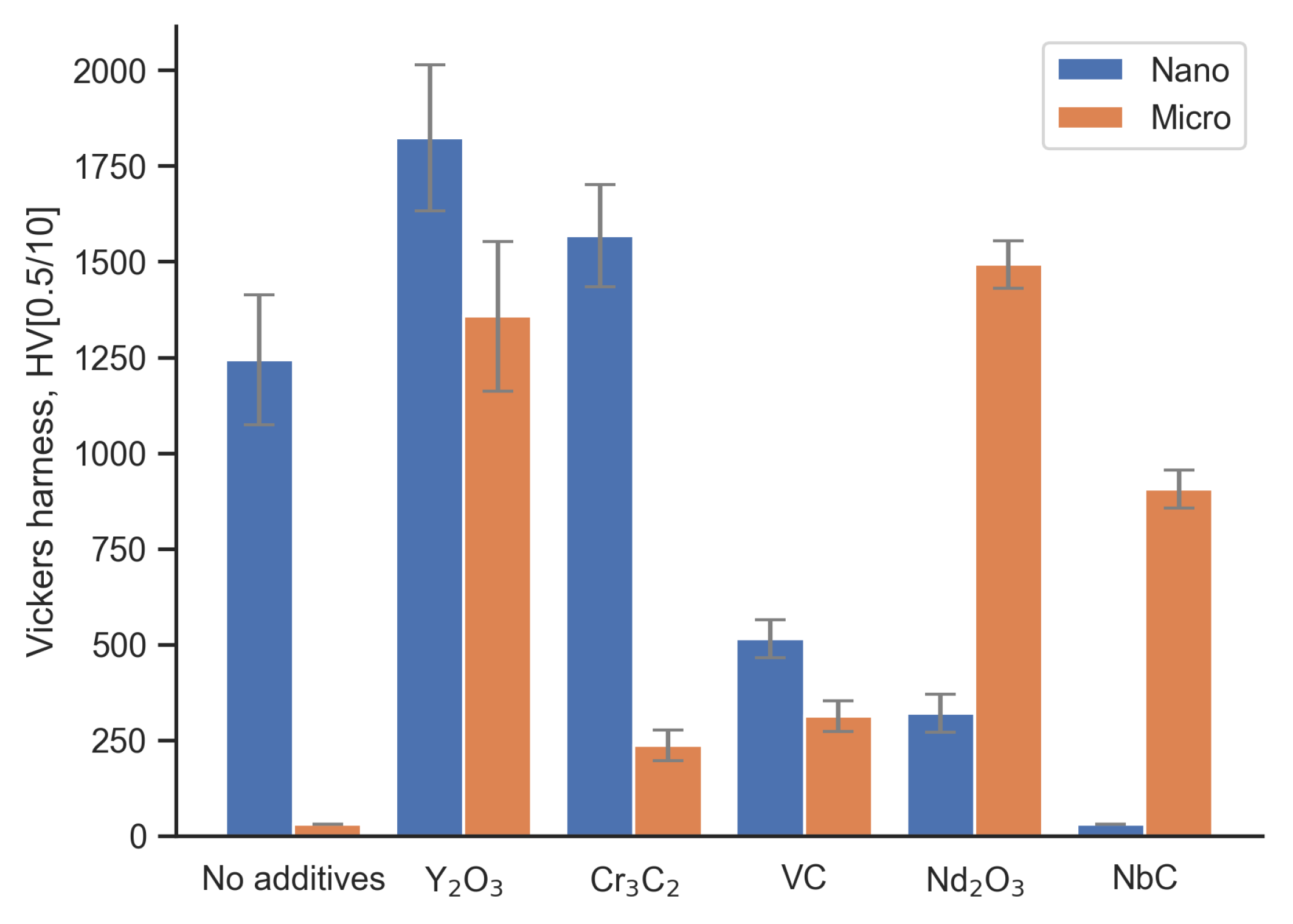

Additives limit grain growth and affect the sinterability of materials. Thus, the additives should affect the mechanical properties. The hardness of all obtained samples was measured (

Figure 7). It was found that the samples with n-WC and Y

2O

3 additives, as well as the samples with

-WC powders and a Nd

2O

3 additive, demonstrate the highest hardness. Thus, the hardness is provided by different mechanisms in

-WC and n-WC powders. References are made in the literature to the Hall–Petch effect [

26,

27,

28], which states that as the grain size decreases, the hardness increases. However, using n-WC does not provide a higher microhardness than in the samples with

-WC. As our experiments show, this mechanism of hardness formation is provided not only by the Hall–Petch effect, and it is not the most prevailing one in the formation of the hardness of the studied materials.

Dispersion strengthening by carbide and oxide particles is not so obvious in carbide materials, since WC is a high-strength material. The introduction of inhibiting particles, which are oxide and carbide additives, allows for the formation of a more dense structure with smaller carbide grains. This makes a greater contribution to the increase in hardness than the introduction of inhibiting additives as strengthening ones.

The most noticeable tendency for the indirect effect of additives on hardness is observed in the samples with n-WC. The hardness of the samples with n-WC follows the trend for density. Thus, the introduction of additives that increase the sinterability of n-WC and form a more dense structure provides higher hardness of the samples. Pores and other macrodefects affect the strength and overall hardness of the samples.

In the samples with -WC powder at densities close to each other, the hardness is very different. Hardness is more correlated with grain size in these samples. The -WC powders do not sinter without additives, so it is not possible to compare the hardness results of the samples with and without additives. Despite the fact that the porosity has the same value in the samples with -WC, the nature of the pore distribution itself differs. In the samples with Nd2O3 and VC additives, large macropores are present, while in the samples with other additives, the pores are mainly interparticle. At the same time, the hardness of the samples with Nd2O3 is the highest of all samples with -WC, and that of the samples with VC is one of the lowest (the hardness of one sample with the addition of Cr3C2 is lower).

The hardness of the samples of the same composition with -WC and n-WC powder also differs significantly. The hardness of the samples with -WC powder and Nd2O3 additives is the highest among all samples with -WC powder, while the hardness of the samples with n-WC and Nd2O3 additives is the lowest. At the same time, the grain size is smaller and the porosity is lower for the sample with n-WC.

Thus, for -WC powders, the additives mainly work at the intergranular level and macrodefects do not have a strong effect on microhardness. For nanopowders, the main purpose of additives is to increase the density of the samples during sintering, which leads to an increase in hardness.

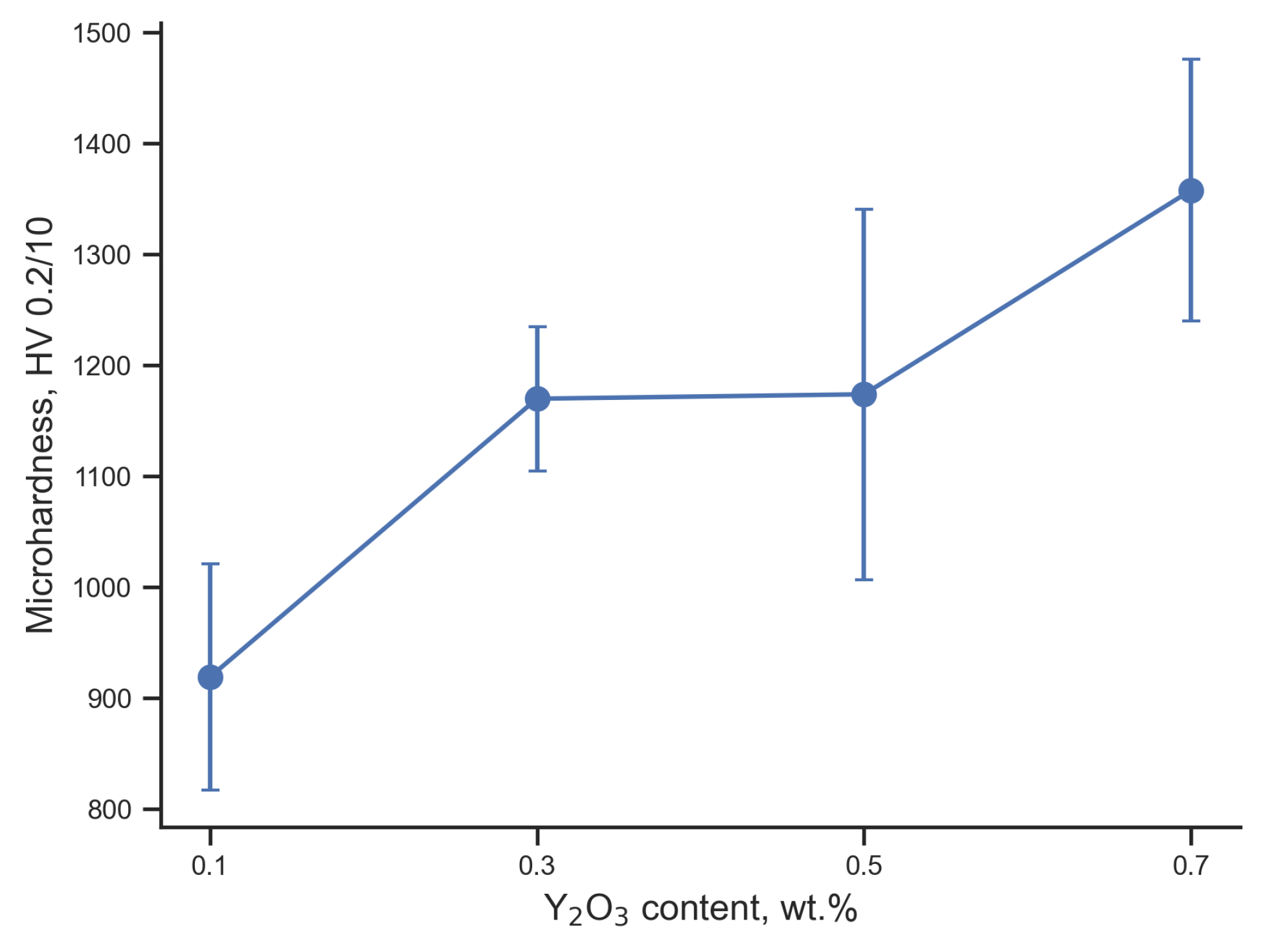

A series of experiments on the influence of the Y

2O

3 amount on the hardness of the obtained samples was carried out. The samples were sintered at 1300 °C for 4 h. The content of the Y

2O

3 additive (

Figure 8) was varied. With the increasing yttrium oxide content, the hardness of the sintered samples monotonically increased. At the same time, the samples with a Y

2O

3 content = 0.7% cracked after sintering, and the samples with 0.9% were completely delaminated after sintering. Thus, the optimum content of yttrium oxide from the point of view of mechanical properties and the quality of the samples is 0.5 %.

The purpose of introducing yttrium oxide is to suppress the growth of WC grains in the sintering process. When yttrium oxide particles are distributed along grain boundaries, grain growth can be suppressed most successfully. Y

2O

3 also limits the formation of extrinsic phases, such as Co

3W

3C, which embrittle and reduce the hardness of the material. At too high a concentration, yttrium oxide begins to prevent sintering of the material, forming complex compounds and solid solutions in the interparticle layer [

17,

29].

It is difficult to compare the contribution of grain size and porosity into the strength properties of the material. A series of the samples with different porosities but the same grain size, as well as a series of the samples with different grain sizes and the same porosity, are required. In the framework of this work, such an experiment was not carried out, and possible factors affecting hardness were taken on the basis of the literature data. Porosity makes a negative contribution to the strength properties, but in addition to the absolute value of porosity, pore size and the distribution of pores over the volume is also important.

3.4. Oxidation

Additives also affect the resistance of the samples to oxidation. Oxidation experiments were carried out on all obtained samples in the air at a temperature of 800 °C. It was found that the samples with n-WC powder oxidized much faster than the samples with -WC. Nanosized powders, including those obtained by the EEW method, have a high surface activity. As shown earlier, the samples with n-WC are characterized by higher porosity and finer grain size. Thus, the samples with fine WC powder are characterized by a high surface area of contact with oxygen, which additionally increases the rate of sample oxidation.

During oxidation, the chemical composition of additives plays a role. Tungsten carbide is more resistant to oxidation than cobalt, so oxidation primarily begins with cobalt layers. If there are inhibiting additives in cobalt, the rate of oxidation of the sample will be determined by the activity of interaction of the inhibiting additives with oxygen. Thus, the ideal additive would be a material that both inhibits grain growth and is resistant to oxidation.

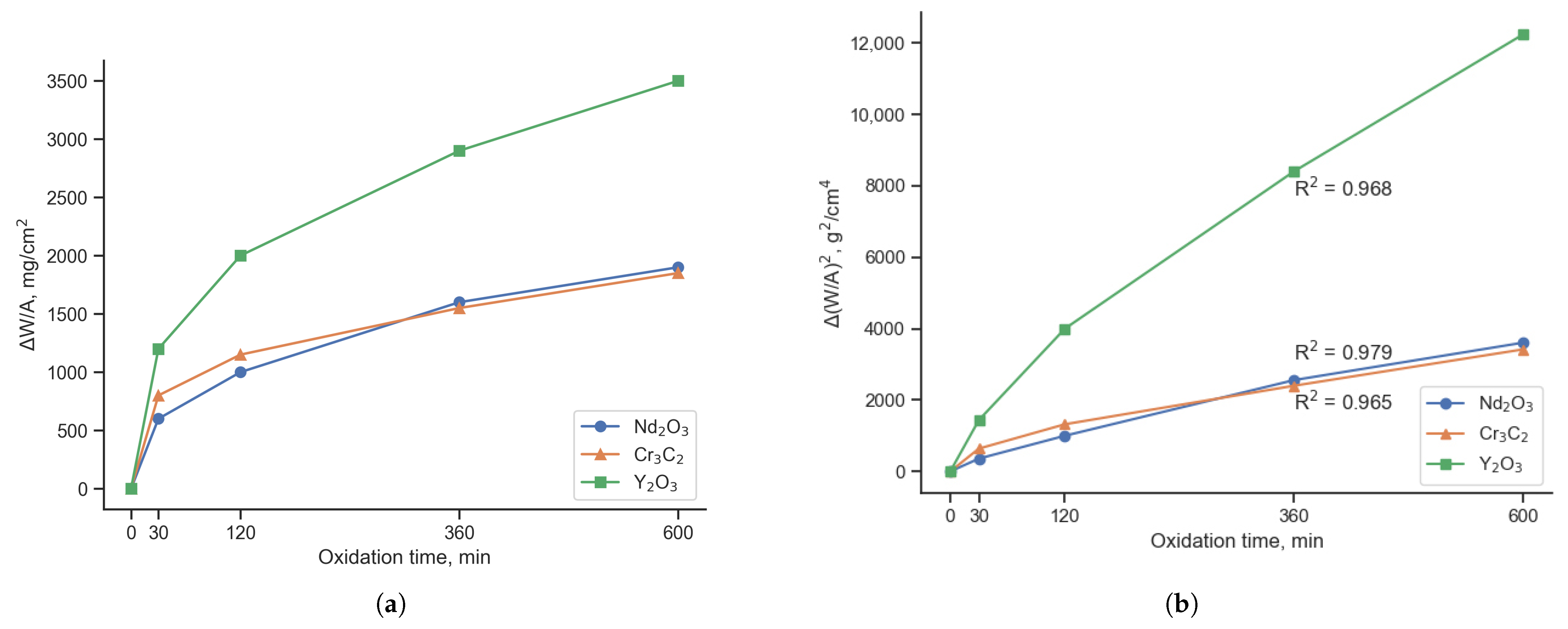

The samples with

-WC powder oxidize slower; however, the samples with VC and NbC additives show extreme oxidation (mass gain over 1 g/cm

2 per hour) and are completely destroyed after 10 h of oxidation. The samples with commercial

-WC powder and additives Nd

2O

3, Cr

3C

2, and Y

2O

3 showed (

Figure 9) the highest resistance to oxidation (the smallest mass gain).

The most intense oxidation of the samples occurs in the first hour. The largest weight gain is demonstrated by the sample with Y

2O

3 additives. In the next hours, the mass gain slows down, but does not reach a plateau. The dependence of the squared mass gain on time is close to linear for all samples (R

2 from 0.965 to 0.979 for all samples). Proximity to linearity shows that the classical parabolic oxidation law [

30,

31] is realized for all samples. Additives affect the kinetics of the oxidation reaction, but do not change the mechanism of oxidation. The K

p value for all samples are 5.98 mg

2cm

−4min

−1 (Nd

2O

3), 5.29 mg

2cm

−4min

−1 (Cr

3C

2), and 19.76 mg

2cm

−4min

−1 (Y

2O

3).

The obtained data on oxidation resistance correlate with the data on the density of the samples—the higher the density, the lower the oxidation rate. It should be noted that carbide ceramics perform worse, both for the formation of strength and resistance to oxidation of the samples. The samples with the addition of Cr

3C

2 are highly resistant to oxidation and limit the weight gain due to the behavior of chromium carbide. Chromium dissolves in the material of the samples, limits oxidizing activity, and forms chromium oxide, which further slows down the oxidation process at high temperatures [

32,

33,

34].

Oxide additives (Nd

2O

3 and Y

2O

3) increase the oxidation resistance of materials, but it is necessary to regulate the content of additives because, when a certain limit is reached, the oxidation resistance, on the contrary, begins to decrease [

35,

36,

37,

38]. When the content of additives is 0.1–0.6 wt.%, the highest resistance to oxidation of the materials studied by the authors is retained; when 0.8 wt.% is exceeded, the resistance to oxidation decreases, meaning that the results may be worse than for the samples without additives.

In the present study, the addition of 0.5 wt.% Nd

2O

3 and Y

2O

3 improves the oxidation resistance. Oxide particles of additives are segregated along the grain boundaries, which makes it possible to slow down diffusion processes during oxidation and, in general, reduce the oxidation rate [

39]. Since oxide particles do not dissolve in the material, their presence at the grain boundaries affects not only the oxidation resistance, but also the grain growth rate and strength properties, as shown above.

Author Contributions

Conceptualization, M.L.; Methodology, M.K., N.V.S., N.R. and E.R.; Formal analysis, N.V.S.; Investigation, M.K., N.R. and E.R.; Resources, M.L.; Data curation, N.V.S.; Writing—original draft, M.K., N.R. and E.R.; Visualization, N.V.S.; Project administration, M.L. All authors have read and agreed to the published version of the manuscript.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to ethical reasons.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gurland, J.; Bardzil, P. Relation of strength, composition, and grain size of sintered WC-Co alloys. JOM 1955, 7, 311–315. [Google Scholar] [CrossRef]

- Guimarães, B.; Fernandes, C.; Figueiredo, D.; Cerqueira, M.; Carvalho, O.; Silva, F.S.; Miranda, G. A novel approach to reduce in-service temperature in WC-Co cutting tools. Ceram. Int. 2020, 46, 3002–3008. [Google Scholar] [CrossRef]

- Kumar, K.; Batra, U. Fabrication of High Aspect Ratio WC-Co Micro Electrodes for μ-EDM Application. Mater. Today Proc. 2019, 18, 2970–2976. [Google Scholar] [CrossRef]

- Chandran, M. Diamond deposition on WC–Co substrates with interlayers for engineering applications. In Nanomaterials for Sensing and Optoelectronic Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 311–330. [Google Scholar]

- Mariani, M.; Goncharov, I.; Mariani, D.; De Gaudenzi, G.P.; Popovich, A.; Lecis, N.; Vedani, M. Mechanical and microstructural characterization of WC-Co consolidated by binder jetting additive manufacturing. Int. J. Refract. Met. Hard Mater. 2021, 100, 105639. [Google Scholar] [CrossRef]

- Mariani, M.; Mariani, D.; De Gaudenzi, G.P.; Lecis, N. Effect of printing parameters on sintered WC-Co components by binder jetting. Eur. J. Mater. 2022, 2, 365–380. [Google Scholar] [CrossRef]

- Li, H.; Zhang, H.; Li, G.; Zhao, D.; Jiang, Z. Effects of holding time on interface microstructure and element diffusion of WC-Co-Ni/stainless steel composites. Int. J. Refract. Met. Hard Mater. 2022, 108, 105951. [Google Scholar] [CrossRef]

- Mishra, T.K.; Kumar, A.; Sinha, S. Investigation of sliding wear behaviour of Ni-WC microwave cladding. Mater. Today Proc. 2020, 26, 1418–1422. [Google Scholar] [CrossRef]

- Gao, Y.; Luo, B.H.; He, K.J.; Jing, H.B.; Bai, Z.H.; Chen, W.; Zhang, W.W. Mechanical properties and microstructure of WC-Fe-Ni-Co cemented carbides prepared by vacuum sintering. Vacuum 2017, 143, 271–282. [Google Scholar] [CrossRef]

- Wang, L.; Gao, Z.; Wu, M.; Weng, F.; Liu, T.; Zhan, X. Influence of specific energy on microstructure and properties of laser cladded FeCoCrNi high entropy alloy. Metals 2020, 10, 1464. [Google Scholar] [CrossRef]

- Škamat, J.; Černašėjus, O.; Zhetessova, G.; Nikonova, T.; Zharkevich, O.; Višniakov, N. Effect of laser processing parameters on microstructure, hardness and tribology of NiCrCoFeCBSi/WC coatings. Materials 2021, 14, 6034. [Google Scholar] [CrossRef]

- Upadhyaya, G.S. Materials science of cemented carbides—An overview. Mater. Des. 2001, 22, 483–489. [Google Scholar] [CrossRef]

- Chang, S.H.; Chang, P.Y. Study on the mechanical properties, microstructure and corrosion behaviors of nano-WC-Co-Ni-Fe hard materials through HIP and hot-press sintering processes. Mater. Sci. Eng. A 2014, 618, 56–62. [Google Scholar] [CrossRef]

- Lin, T.; Li, Q.; Han, Y.; Song, K.; Wang, X.; Shao, H.; Dong, J.; Wang, H.; Deng, X. Effects of Nb and NbC additives on microstructure and properties of WC-Co-Ni cemented carbides. Int. J. Refract. Met. Hard Mater. 2022, 103, 105782. [Google Scholar] [CrossRef]

- Lee, H.R.; Kim, D.J.; Hwang, N.M.; Kim, D.Y. Role of vanadium carbide additive during sintering of WC-Co: Mechanism of grain growth inhibition. J. Am. Ceram. Soc. 2003, 86, 152–154. [Google Scholar] [CrossRef]

- Yamamoto, T.; Ikuhara, Y.; Watanabe, T.; Sakuma, T.; Taniuchi, Y.; Okada, K.; Tanase, T. High resolution microscopy study in Cr3C2-doped WC-Co. J. Mater. Sci. 2001, 36, 3885–3890. [Google Scholar] [CrossRef]

- Liu, Y.; Li, X.; Zhou, J.; Fu, K.; Wei, W.; Du, M.; Zhao, X. Effects of Y2O3 addition on microstructures and mechanical properties of WC-Co functionally graded cemented carbides. Int. J. Refract. Met. Hard Mater. 2015, 50, 53–58. [Google Scholar] [CrossRef]

- Yang, Y.; Luo, L.M.; Zan, X.; Zhu, X.Y.; Zhu, L.; Wu, Y.C. Study on preparation and properties of WC-8Co cemented carbide doped with rare earth oxide. Int. J. Refract. Met. Hard Mater. 2021, 98, 105536. [Google Scholar] [CrossRef]

- Du, M.; Wang, L.; Gao, Z.; Yang, X.; Liu, T.; Zhan, X. Microstructure and element distribution characteristics of Y2O3 modulated WC reinforced coating on Invar alloys by laser cladding. Opt. Laser Technol. 2022, 153, 108205. [Google Scholar] [CrossRef]

- Liu, M.; Wang, Z.; Wu, J.; Li, Q. Effects of Nd2O3 on the mechanical properties and oxidation behavior of Ti/Al2O3 composites by vacuum hot pressing sintering. J. Alloys Compd. 2015, 648, 116–121. [Google Scholar] [CrossRef]

- Konyashin, I.; Schwedt, A. The influence of various Re: Co ratios on microstructures and properties of WC-Co-Re cemented carbides. Mater. Lett. 2019, 249, 57–61. [Google Scholar] [CrossRef]

- Pervikov, A.V.; Krinitcyn, M.; Glazkova, E.A.; Rodkevich, N.G.; Lerner, M.I. Synthesis of tungsten carbide from bimodal tungsten powder produced by electrical explosion of wire. Int. J. Refract. Met. Hard Mater. 2022, 103, 105733. [Google Scholar] [CrossRef]

- Dillon, S.J.; Harmer, M.P. Demystifying the role of sintering additives with “complexion”. J. Eur. Ceram. Soc. 2008, 28, 1485–1493. [Google Scholar] [CrossRef]

- Jorgensen, P.; Anderson, R. Grain-boundary segregation and final-stage sintering of Y2O3. J. Am. Ceram. Soc. 1967, 50, 553–558. [Google Scholar] [CrossRef]

- Perrard, F.; Deschamps, A.; Maugis, P. Modelling the precipitation of NbC on dislocations in α-Fe. Acta Mater. 2007, 55, 1255–1266. [Google Scholar] [CrossRef]

- Roa, J.; Jiménez-Piqué, E.; Tarragó, J.; Sandoval, D.; Mateo, A.; Fair, J.; Llanes, L. Hall-Petch strengthening of the constrained metallic binder in WC–Co cemented carbides: Experimental assessment by means of massive nanoindentation and statistical analysis. Mater. Sci. Eng. A 2016, 676, 487–491. [Google Scholar] [CrossRef]

- Armstrong, R.W. The hardness and strength properties of WC-Co composites. Materials 2011, 4, 1287–1308. [Google Scholar] [CrossRef]

- Milman, Y.V.; Luyckx, S.; Northrop, I. Influence of temperature, grain size and cobalt content on the hardness of WC–Co alloys. Int. J. Refract. Met. Hard Mater. 1999, 17, 39–44. [Google Scholar] [CrossRef]

- Xiao, D.; He, Y.; Song, M.; Lin, N.; Zhang, R. Y2O3-and NbC-doped ultrafine WC–10Co alloys by low pressure sintering. Int. J. Refract. Met. Hard Mater. 2010, 28, 407–411. [Google Scholar] [CrossRef]

- Khanna, A.S. High temperature oxidation. In Handbook of Environmental Degradation of Materials; Elsevier: Amsterdam, The Netherlands, 2005; pp. 105–152. [Google Scholar]

- Zhang, J.S. High Temperature Deformation and Fracture of Materials; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Matthews, S.; Berger, L.M. Inter-diffusion between thermally sprayed Cr3C2-NiCr coatings and an Alloy 625 substrate during long-term exposure at 500 °C, 700 °C and 900 °C. J. Alloys Compd. 2019, 770, 1078–1099. [Google Scholar] [CrossRef]

- Zhai, W.; Gao, Y.; Sun, L.; He, L.; Wang, Y. Improvement of high temperature oxidation behavior of Cr3C2-20 wt% Ni cermets by adding 1 wt% Mo. J. Alloys Compd. 2018, 731, 271–278. [Google Scholar] [CrossRef]

- Reddy, N.C.; Kumar, B.A.; Reddappa, H.; Ramesh, M.; Koppad, P.G.; Kord, S. HVOF sprayed Ni3Ti and Ni3Ti+ (Cr3C2+ 20NiCr) coatings: Microstructure, microhardness and oxidation behaviour. J. Alloys Compd. 2018, 736, 236–245. [Google Scholar] [CrossRef]

- Guo, C.; Yu, Z.; Liu, C.; Li, X.; Zhu, Q.; Ward, R.M. Effects of Y2O3 nanoparticles on the high-temperature oxidation behavior of IN738LC manufactured by laser powder bed fusion. Corros. Sci. 2020, 171, 108715. [Google Scholar] [CrossRef]

- Sun, D.; Liang, C.; Shang, J.; Yin, J.; Song, Y.; Li, W.; Liang, T.; Zhang, X. Effect of Y2O3 contents on oxidation resistance at 1150 C and mechanical properties at room temperature of ODS Ni-20Cr-5Al alloy. Appl. Surf. Sci. 2016, 385, 587–596. [Google Scholar] [CrossRef]

- Zhao, J.; Ouyang, K.; Xie, X.; Zhang, J. Influence of Y2O3/Nd2O3 particles additive on the corrosion resistance of MAO coating on AZ91D magnesium alloy. Int. J. Electrochem. Sci. 2017, 12, 2400–2411. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, J.; Xu, G.; Li, Z.; Wei, S. Effect of Nd2O3 on microstructure, corrosion and wear properties of laser cladding Zr-based amorphous composite coatings on AZ91D magnesium alloy. Appl. Surf. Sci. 2023, 611, 155587. [Google Scholar] [CrossRef]

- Ma, X.; He, Y.; Wang, D.; Zhang, J. Superior high-temperature oxidation resistance of a novel (Al2O3–Y2O3)/Pt laminated coating. Appl. Surf. Sci. 2012, 258, 4733–4740. [Google Scholar] [CrossRef]

- Csanádi, T.; Vojtko, M.; Dusza, J. Deformation and fracture of WC grains and grain boundaries in a WC-Co hardmetal during microcantilever bending tests. Int. J. Refract. Met. Hard Mater. 2020, 87, 105163. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).