The Effects of Layer Thickness on the Mechanical Properties of Additive Friction Stir Deposition-Fabricated Aluminum Alloy 6061 Parts

Abstract

1. Introduction

2. Materials and Methods

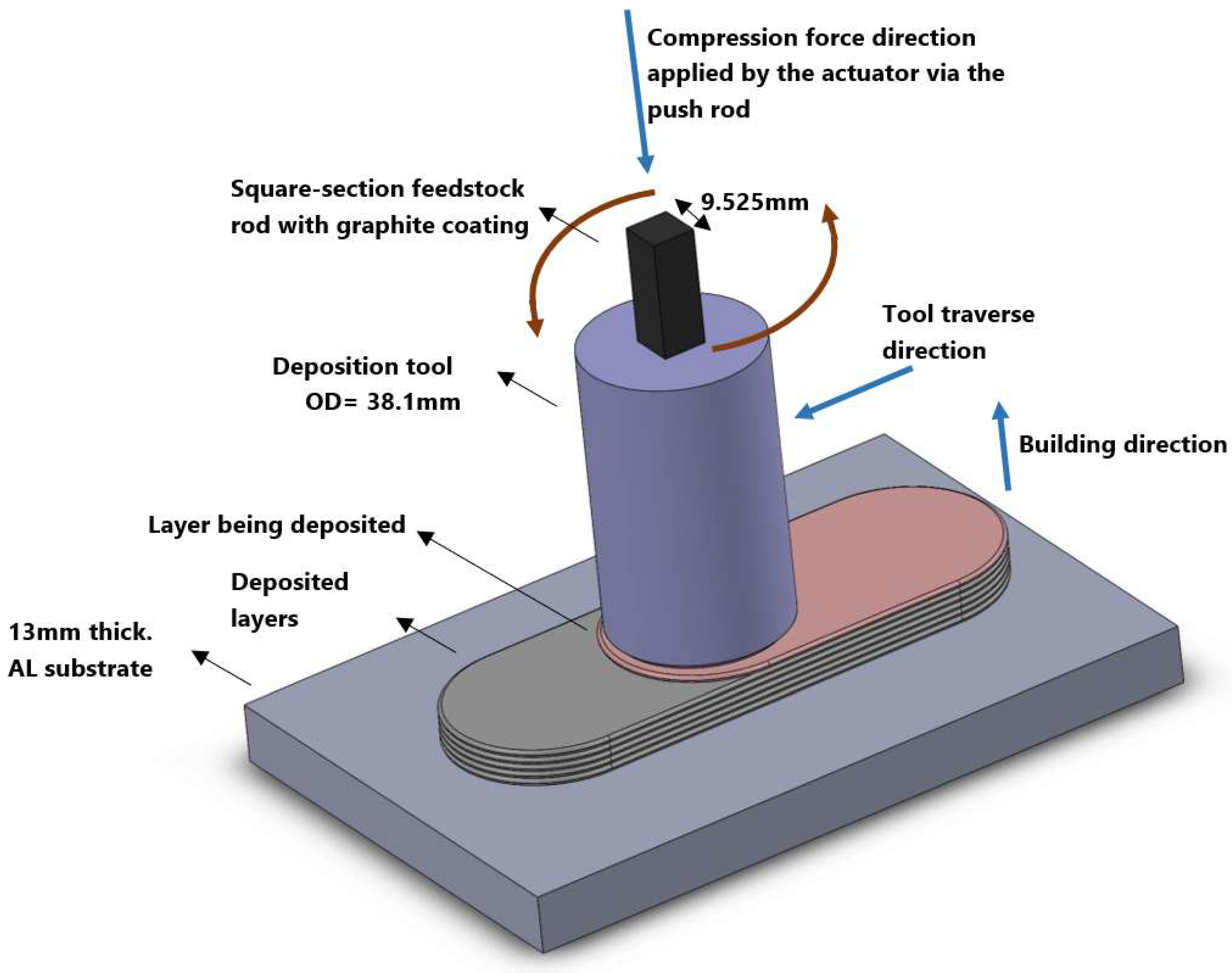

2.1. Additive Friction Stir Deposition Process and Layer Thickness

2.2. AFSD Part Deposition Parameters and Feedstock Material

2.3. Tensile Test Specimen

2.4. Microhardness Test Specimen

2.5. Statistical Analysis of Groups’ Means

3. Results

3.1. Layer-by-Layer Deposition

3.2. Tensile Properties

3.2.1. The Effect of Layer Thickness

3.2.2. The Effect of Test Specimen Direction

3.2.3. The Effect of the Specimens’ Position in relation to the Width of the Block

3.2.4. The Effect of the Specimens’ Position in the Building Direction

3.3. Comparing the Tensile Properties of AFSD Blocks and the Feedstock

3.4. Vickers Microhardness Distribution

4. Discussion

4.1. Applied Torque on the Deposition Tool

4.2. Reaction Force during Deposition

4.3. Correlation between Torque and Force

4.4. Substrate Temperature and Temperature History

4.5. Effect of Temperature History on Microstructure

4.6. Effect of Deposition Layer Thickness on Mechanical Properties

5. Conclusions

- The layer thickness of deposition affects the tensile properties of the as-deposited part in the Z direction. Specifically, the Z specimens derived from the 1 mm block showed considerably smaller fracture strains and ultimate stress values compared to their counterparts from the other two blocks. This can be a result of the effect of the layer thickness (where there are more defects in the gauge section of the test specimens in case of a thinner layer thickness of deposition) as well as the difference among the temperature histories experienced by each block. The disparities in the tensile properties between the specimens cut from the uppermost sections of the parts (which displayed higher ultimate stress levels and smaller fracture strains) and those from the lower regions along the building direction are notably pronounced.

- The tensile properties in the X and Y directions exhibited no noteworthy distinctions across the three blocks (1 mm, 2 mm, and 3 mm). For properties across the part’s width, p-values from the statistical test indicated no compelling evidence to confirm substantial differences. The tensile properties remained consistent across the part’s width.

- Specimens derived from the as-deposited blocks consistently displayed increased fracture strain attributes and distinct reductions in ultimate strength when compared to their feedstock counterparts.

- Microhardness values exhibited a non-linear decline along the measured lines for all blocks, with more pronounced decreases at higher layers, leveling off as measurement points nearer the part’s bottom. The microhardness values obtained for the as-deposited parts are notably lower than those measured for the feedstock material.

- The statistical analysis of data showed that the thickness of the deposition layer has an impact on the microhardness properties of the as-deposited parts within the cross-sectional plane. The average microhardness values for the 1 mm block were marginally lower compared to the 2 mm and 3 mm blocks. Across the width of the part’s cross-section for the 1 mm and 2 mm blocks, the microhardness values along the center line are slightly smaller than those along the left and right lines. However, no such difference was observed in the case of the 3 mm block.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dong, H.; Li, X.; Xu, K.; Zang, Z.; Liu, X.; Zhang, Z.; Xiao, W.; Li, Y. A Review on Solid-State-Based Additive Friction Stir Deposition. Aerospace 2022, 9, 565. [Google Scholar] [CrossRef]

- Williams, M.B.; Robinson, T.W.; Williamson, C.J.; Kinser, R.P.; Ashmore, N.A.; Allison, P.G.; Jordon, J.B. Elucidating the Effect of Additive Friction Stir Deposition on the Resulting Microstructure and Mechanical Properties of Magnesium Alloy WE43. Metals 2021, 11, 1739. [Google Scholar] [CrossRef]

- Shao, J.; Samaei, A.; Xue, T.; Xie, X.; Guo, S.; Cao, J.; MacDonald, E.; Gan, Z. Additive friction stir deposition of metallic materials: Process, structure and properties. Mater. Des. 2023, 234, 112356. [Google Scholar] [CrossRef]

- Garcia, D.; Hartley, W.D.; Rauch, H.A.; Griffiths, R.J.; Wang, R.; Kong, Z.J.; Zhu, Y.; Yu, H.Z. In Situ Investigation into Temperature Evolution and Heat Generation during Additive Friction Stir Deposition: A Comparative Study of Cu and Al-Mg-Si. Addit. Manuf. 2020, 34, 101386. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Saha, P. A critical review on process metrics–microstructural evolution–process performance correlation in additive friction stir deposition (AFS-D). J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 422. [Google Scholar] [CrossRef]

- Yu, H.Z.; Mishra, R.S. Additive friction stir deposition: A deformation processing route to metal additive manufacturing. Mater. Res. Lett. 2020, 9, 71–83. [Google Scholar] [CrossRef]

- Stubblefield, G.G.; Fraser, K.A.; Van Iderstine, D.; Mujahid, S.; Rhee, H.; Jordon, J.B.; Allison, P.G. Elucidating the influence of temperature and strain rate on the mechanics of AFS-D through a combined experimental and computational approach. J. Mater. Process. Technol. 2022, 305, 117593. [Google Scholar] [CrossRef]

- Palanivel, S.M.; Rajiv, S. Building without melting: A short review of friction-based additive manufacturing techniques. Int. J. Addit. Subtractive Mater. Manuf. 2017, 1, 82–103. [Google Scholar] [CrossRef]

- Mishra, R.S.; Haridas, R.S.; Agrawal, P. Friction stir-based additive manufacturing. Sci. Technol. Weld. Join. 2022, 27, 141–165. [Google Scholar] [CrossRef]

- MELD Manufacturing Corporation. Available online: https://www.meldmanufacturing.com/ (accessed on 16 September 2023).

- Khodabakhshi, F.; Gerlich, A.P. Potentials and strategies of solid-state additive friction-stir manufacturing technology: A critical review. J. Manuf. Process. 2018, 36, 77–92. [Google Scholar] [CrossRef]

- Calvert, J.R. Microstructure and Mechanical Properties of We43 Alloy Produced via Additive Friction Stir Technology. Master’s Thesis, Virginia Tech University, Blacksburg, VA, USA, 29 June 2015. [Google Scholar]

- Perry, M.E.J.; Griffiths, R.J.; Garcia, D.; Sietins, J.M.; Zhu, Y.; Yu, H.Z. Morphological and microstructural investigation of the non-planar interface formed in solid-state metal additive manufacturing by additive friction stir deposition. Addit. Manuf. 2020, 35, 101293. [Google Scholar] [CrossRef]

- Yu, H.Z.; Jones, M.E.; Brady, G.W.; Griffiths, R.J.; Garcia, D.; Rauch, H.A.; Cox, C.D.; Hardwick, N. Non-beam-based metal additive manufacturing enabled by additive friction stir deposition. Scr. Mater. 2018, 153, 122–130. [Google Scholar] [CrossRef]

- Kandasamy, K. Solid State Joining Using Additive Frction Stir Processing. U.S. Patent 9,511,445 B2, 6 December 2016. [Google Scholar]

- Innovation Meets Function: Aeroprobe Corporation Commercializes Patented MELD Technology, a Revolutionary Manufacturing Process for Metal. Available online: https://www.meldmanufacturing.com/innovation-meets-function-aeroprobe-corporation-commercializes-patented-meld-technology-a-revolutionary-manufacturing-process-for-metal/ (accessed on 16 September 2023).

- Griffiths, R.J.; Garcia, D.; Song, J.; Vasudevan, V.K.; Steiner, M.A.; Cai, W.; Yu, H.Z. Solid-state additive manufacturing of aluminum and copper using additive friction stir deposition: Process-microstructure linkages. Materialia 2021, 15, 100967. [Google Scholar] [CrossRef]

- Gopan, V.; Leo Dev Wins, K.; Surendran, A. Innovative potential of additive friction stir deposition among current laser based metal additive manufacturing processes: A review. CIRP J. Manuf. Sci. Technol. 2021, 32, 228–248. [Google Scholar] [CrossRef]

- Griffiths, R.J.; Perry, M.E.J.; Sietins, J.M.; Zhu, Y.; Hardwick, N.; Cox, C.D.; Rauch, H.A.; Yu, H.Z. A Perspective on Solid-State Additive Manufacturing of Aluminum Matrix Composites Using MELD. J. Mater. Eng. Perform. 2018, 28, 648–656. [Google Scholar] [CrossRef]

- Kincaid, J.; Charles, E.; Garcia, R.; Dvorak, J.; No, T.; Smith, S.; Schmitz, T. Process planning for hybrid manufacturing using additive friction stir deposition. Manuf. Lett. 2023, 37, 26–31. [Google Scholar] [CrossRef]

- Kincaid, J.; Zameroski, R.; No, T.; Bohling, J.; Compton, B.; Schmitz, T. Hybrid Manufacturing: Combining Additive Friction Stir Deposition, Metrology, and Machining. In Proceedings of the TMS Annual Meeting & Exhibition, San Diego, CA, USA, 19–23 March 2023. [Google Scholar]

- Hartley, W.D.; Garcia, D.; Yoder, J.K.; Poczatek, E.; Forsmark, J.H.; Luckey, S.G.; Dillard, D.A.; Yu, H.Z. Solid-state cladding on thin automotive sheet metals enabled by additive friction stir deposition. J. Mater. Process. Technol. 2021, 291, 117045. [Google Scholar] [CrossRef]

- Avery, D.Z.; Cleek, C.E.; Phillips, B.J.; Rekha, M.Y.; Kinser, R.P.; Rao, H.M.; Brewer, L.N.; Allison, P.G.; Jordon, J.B. Evaluation of Microstructure and Mechanical Properties of Al-Zn-Mg-Cu Alloy Repaired via Additive Friction Stir Deposition. J. Eng. Mater. Technol. 2022, 144, 031003. [Google Scholar] [CrossRef]

- Griffiths, R.J.; Petersen, D.T.; Garcia, D.; Yu, H.Z. Additive Friction Stir-Enabled Solid-State Additive Manufacturing for the Repair of 7075 Aluminum Alloy. Appl. Sci. 2019, 9, 3486. [Google Scholar] [CrossRef]

- Martin, L.P.; Luccitti, A.; Walluk, M. Repair of aluminum 6061 plate by additive friction stir deposition. Int. J. Adv. Manuf. Technol. 2021, 118, 759–773. [Google Scholar] [CrossRef]

- Agrawal, P.; Haridas, R.S.; Yadav, S.; Thapliyal, S.; Gaddam, S.; Verma, R.; Mishra, R.S. Processing-structure-property correlation in additive friction stir deposited Ti-6Al-4V alloy from recycled metal chips. Addit. Manuf. 2021, 47, 102259. [Google Scholar] [CrossRef]

- Jordon, J.B.; Allison, P.G.; Phillips, B.J.; Avery, D.Z.; Kinser, R.P.; Brewer, L.N.; Cox, C.; Doherty, K. Direct recycling of machine chips through a novel solid-state additive manufacturing process. Mater. Des. 2020, 193, 108850. [Google Scholar] [CrossRef]

- Chemin, A.E.A.; Afonso, C.M.; Pascoal, F.A.; Maciel, C.I.d.S.; Ruchert, C.O.F.T.; Bose Filho, W.W. Characterization of phases, tensile properties, and fracture toughness in aircraft-grade aluminum alloys. Mater. Des. Process. Commun. 2019, 1, 1–13. [Google Scholar] [CrossRef]

- Zeng, C.; Ghadimi, H.; Ding, H.; Nemati, S.; Garbie, A.; Raush, J.; Guo, S. Microstructure Evolution of Al6061 Alloy Made by Additive Friction Stir Deposition. Materials 2022, 15, 3676. [Google Scholar] [CrossRef] [PubMed]

- Nemati, S.; Butler, L.G.; Ham, K.; Knapp, G.L.; Zeng, C.; Emanet, S.; Ghadimi, H.; Guo, S.; Zhang, Y.; Bilheux, H. Neutron Imaging of Al6061 Prepared by Solid-State Friction Stir Additive Manufacturing. Metals 2023, 13, 188. [Google Scholar] [CrossRef]

- Ghadimi, H.; Ding, H.; Emanet, S.; Talachian, M.; Cox, C.; Eller, M.; Guo, S. Hardness Distribution of Al2050 Parts Fabricated Using Additive Friction Stir Deposition. Materials 2023, 16, 1278. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Elfishawy, E.; Alzahrani, B.; Touileb, K.; Habba, M.I.A. The Effect of Temper Condition and Feeding Speed on the Additive Manufacturing of AA2011 Parts Using Friction Stir Deposition. Materials 2021, 14, 6396. [Google Scholar] [CrossRef] [PubMed]

- Anderson-Wedge, K.; Stubblefield, G.; Zhu, N.; Long, B.; Daniewicz, S.R.; Allison, P.; Sowards, J.; Rodriguez, O.; Amaro, R. Characterization of the evolution of 2219-T87 aluminum as a function of the friction stir welding process. Int. J. Fatigue 2021, 142, 105954. [Google Scholar] [CrossRef]

- Rivera, O.G.; Allison, P.G.; Brewer, L.N.; Rodriguez, O.L.; Jordon, J.B.; Liu, T.; Whittington, W.R.; Martens, R.L.; McClelland, Z.; Mason, C.J.T.; et al. Influence of texture and grain refinement on the mechanical behavior of AA2219 fabricated by high shear solid state material deposition. Mater. Sci. Eng. A 2018, 724, 547–558. [Google Scholar] [CrossRef]

- Phillips, B.J.; Williamson, C.J.; Kinser, R.P.; Jordon, J.B.; Doherty, K.J.; Allison, P.G. Microstructural and Mechanical Characterization of Additive Friction Stir-Deposition of Aluminum Alloy 5083 Effect of Lubrication on Material Anisotropy. Materials 2021, 14, 6732. [Google Scholar] [CrossRef]

- Li, Y.; Yang, B.; Zhang, M.; Wang, H.; Gong, W.; Lai, R.; Li, Y.; Teng, J. The corrosion behavior and mechanical properties of 5083 Al-Mg alloy manufactured by additive friction stir deposition. Corros. Sci. 2023, 213, 110972. [Google Scholar] [CrossRef]

- Shen, Z.; Zhang, M.; Li, D.; Liu, X.; Chen, S.; Hou, W.; Ding, Y.; Sun, Z.; Su, Y.; Li, W.; et al. Microstructural characterization and mechanical properties of AlMg alloy fabricated by additive friction stir deposition. Int. J. Adv. Manuf. Technol. 2023, 125, 2733–2741. [Google Scholar] [CrossRef]

- Rekha, M.Y.; Avery, D.; Allison, P.G.; Jordon, J.B.; Brewer, L. Nanostructure Evolution in AA7075 Alloy Produced by Solid State Additive Manufacturing—Additive Friction Stir—Deposition. Microsc. Microanal. 2021, 27, 3118–3119. [Google Scholar] [CrossRef]

- Avery, D.Z.; Phillips, B.J.; Mason, C.J.T.; Palermo, M.; Williams, M.B.; Cleek, C.; Rodriguez, O.L.; Allison, P.G.; Jordon, J.B. Influence of Grain Refinement and Microstructure on Fatigue Behavior for Solid-State Additively Manufactured Al-Zn-Mg-Cu Alloy. Metall. Mater. Trans. A 2020, 51, 2778–2795. [Google Scholar] [CrossRef]

- Stubblefield, G.G.; Williams, M.B.; Munther, M.; Tew, J.Z.; Rowe, R.A.; Barkey, M.E.; Jordon, J.B.; Allison, P.G. Ballistic Evaluation of Aluminum Alloy (AA) 7075 Plate Repaired by Additive Friction Stir Deposition Using AA7075 Feedstock. J. Dyn. Behav. Mater. 2022, 9, 79–89. [Google Scholar] [CrossRef]

- Yu, H.Z.; Hahn, G.D. Potential and challenges for large-scale near-net-shaping of 7xxx aerospace grade aluminum via additive friction stir deposition. Mater. Lett. X 2023, 19, 100217. [Google Scholar] [CrossRef]

- Farabi, E.; Babaniaris, S.; Barnett, M.R.; Fabijanic, D.M. Microstructure and mechanical properties of Ti6Al4V alloys fabricated by additive friction stir deposition. Addit. Manuf. Lett. 2022, 2, 100034. [Google Scholar] [CrossRef]

- Sharma, S.; Mani Krishna, K.V.; Radhakrishnan, M.; Pantawane, M.V.; Patil, S.M.; Joshi, S.S.; Banerjee, R.; Dahotre, N.B. A pseudo thermo-mechanical model linking process parameters to microstructural evolution in multilayer additive friction stir deposition of magnesium alloy. Mater. Des. 2022, 224, 111412. [Google Scholar] [CrossRef]

- Joshi, S.S.; Sharma, S.; Radhakrishnan, M.; Pantawane, M.V.; Patil, S.M.; Jin, Y.; Yang, T.; Riley, D.A.; Banerjee, R.; Dahotre, N.B. A multi modal approach to microstructure evolution and mechanical response of additive friction stir deposited AZ31B Mg alloy. Sci. Rep. 2022, 12, 13234. [Google Scholar] [CrossRef]

- Joshi, S.S.; Patil, S.M.; Mazumder, S.; Sharma, S.; Riley, D.A.; Dowden, S.; Banerjee, R.; Dahotre, N.B. Additive friction stir deposition of AZ31B magnesium alloy. J. Magnes. Alloys 2022, 10, 2404–2420. [Google Scholar] [CrossRef]

- Avery, D.Z.; Rivera, O.G.; Mason, C.J.T.; Phillips, B.J.; Jordon, J.B.; Su, J.; Hardwick, N.; Allison, P.G. Fatigue Behavior of Solid-State Additive Manufactured Inconel 625. JOM 2018, 70, 2475–2484. [Google Scholar] [CrossRef]

- Rivera, O.G.; Allison, P.G.; Jordon, J.B.; Rodriguez, O.L.; Brewer, L.N.; McClelland, Z.; Whittington, W.R.; Francis, D.; Su, J.; Martens, R.L.; et al. Microstructures and mechanical behavior of Inconel 625 fabricated by solid-state additive manufacturing. Mater. Sci. Eng. A 2017, 694, 1–9. [Google Scholar] [CrossRef]

- Joey Griffiths, R.; Gotawala, N.; Hahn, G.D.; Garcia, D.; Yu, H.Z. Towards underwater additive manufacturing via additive friction stir deposition. Mater. Des. 2022, 223, 111148. [Google Scholar] [CrossRef]

- Beladi, H.; Farabi, E.; Hodgson, P.D.; Barnett, M.R.; Rohrer, G.S.; Fabijanic, D. Microstructure evolution of 316L stainless steel during solid-state additive friction stir deposition. Philos. Mag. 2022, 102, 618–633. [Google Scholar] [CrossRef]

- Agrawal, P.; Haridas, R.S.; Yadav, S.; Thapliyal, S.; Dhal, A.; Mishra, R.S. Additive friction stir deposition of SS316: Effect of process parameters on microstructure evolution. Mater. Charact. 2023, 195, 112470. [Google Scholar] [CrossRef]

- Priedeman, J.L.; Phillips, B.J.; Lopez, J.J.; Tucker Roper, B.E.; Hornbuckle, B.C.; Darling, K.A.; Jordon, J.B.; Allison, P.G.; Thompson, G.B. Microstructure Development in Additive Friction Stir-Deposited Cu. Metals 2020, 10, 1538. [Google Scholar] [CrossRef]

- Agrawal, P.; Haridas, R.S.; Agrawal, P.; Mishra, R.S. Deformation based additive manufacturing of a metastable high entropy alloy via Additive friction stir deposition. Addit. Manuf. 2022, 60, 103282. [Google Scholar] [CrossRef]

- Merritt, G.R.; Williams, M.B.; Allison, P.G.; Jordon, J.B.; Rushing, T.W.; Cousin, C.A. Closed-Loop Temperature and Force Control of Additive Friction Stir Deposition. J. Manuf. Mater. Process. 2022, 6, 92. [Google Scholar] [CrossRef]

- Stubblefield, G.G.; Fraser, K.A.; Robinson, T.W.; Zhu, N.; Kinser, R.P.; Tew, J.Z.; Cordle, B.T.; Jordon, J.B.; Allison, P.G. A computational and experimental approach to understanding material flow behavior during additive friction stir deposition (AFSD). Comput. Part. Mech. 2023, 10, 1629–1643. [Google Scholar] [CrossRef]

- Stubblefield, G.G.; Fraser, K.; Phillips, B.J.; Jordon, J.B.; Allison, P.G. A meshfree computational framework for the numerical simulation of the solid-state additive manufacturing process, additive friction stir-deposition (AFS-D). Mater. Des. 2021, 202, 109514. [Google Scholar] [CrossRef]

- Stubblefield, G.; Fraser, K.; Phillips, B.; Jordon, J.; Allison, P. Smoothed Particle Hydrodynamic Modeling of Additive Friction Stir Deposition Manufacturing of Aluminum Alloy 6061. In Proceedings of the Welding Institute 12th International Symposium on Friction Stir Welding, Chicoutimi, QC, Canada, 26–28 June 2018. [Google Scholar]

- Kincaid, K.C.; MacPhee, D.W.; Stubblefield, G.G.; Jordon, J.B.; Rushing, T.W.; Allison, P.G. A Finite Volume Framework for the Simulation of Additive Friction Stir Deposition. J. Eng. Mater. Technol. 2023, 145, 031002. [Google Scholar] [CrossRef]

- Phillips, B.J.; Avery, D.Z.; Liu, T.; Rodriguez, O.L.; Mason, C.J.T.; Jordon, J.B.; Brewer, L.N.; Allison, P.G. Microstructure-deformation relationship of additive friction stir-deposition Al–Mg–Si. Materialia 2019, 7, 100387. [Google Scholar] [CrossRef]

- Chen, G.; Wu, K.; Wang, Y.; Sun, Y.; Wang, X.; Zhu, Z.; Hu, F. Quantitative study on the correlation between microstructure and mechanical properties of additive friction stir deposited 6061-T6 Al-Mg-Si alloy. J. Mater. Res. Technol. 2023, 25, 6725–6736. [Google Scholar] [CrossRef]

- Chen, G.; Wu, K.; Wang, Y.; Zhu, Z.; Nie, P.; Hu, F. Effect of rotational speed and feed rate on microstructure and mechanical properties of 6061 aluminum alloy manufactured by additive friction stir deposition. Int. J. Adv. Manuf. Technol. 2023, 127, 1165–1176. [Google Scholar] [CrossRef]

- Zhu, N.; Avery, D.Z.; Chen, Y.; An, K.; Jordon, J.B.; Allison, P.G.; Brewer, L.N. Residual Stress Distributions in AA6061 Material Produced by Additive Friction Stir Deposition. J. Mater. Eng. Perform. 2022, 32, 5535–5544. [Google Scholar] [CrossRef]

- Amooie, M.A.; Khonsari, M.M. On the effect of environmental temperature on fracture fatigue entropy. Int. J. Fatigue 2022, 168, 107411. [Google Scholar] [CrossRef]

- Sehhat, M.H.; Mahdianikhotbesara, A.; Yadegari, F. Impact of temperature and material variation on mechanical properties of parts fabricated with fused deposition modeling (FDM) additive manufacturing. Int. J. Adv. Manuf. Technol. 2022, 120, 4791–4801. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Khonsari, M. Investigation of metal fatigue using a coupled entropy-kinetic model. Int. J. Fatigue 2022, 161, 106907. [Google Scholar] [CrossRef]

- Moghanlou, M.R.; Khonsari, M. On the kinetic formulation of fracture fatigue entropy of metals. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 565–577. [Google Scholar] [CrossRef]

- Rutherford, B.A.; Avery, D.Z.; Phillips, B.J.; Rao, H.M.; Doherty, K.J.; Allison, P.G.; Brewer, L.N.; Jordon, J.B. Effect of Thermomechanical Processing on Fatigue Behavior in Solid-State Additive Manufacturing of Al-Mg-Si Alloy. Metals 2020, 10, 947. [Google Scholar] [CrossRef]

- Zhu, N.; Avery, D.Z.; Rutherford, B.A.; Phillips, B.J.; Allison, P.G.; Jordon, J.B.; Brewer, L.N. The Effect of Anodization on the Mechanical Properties of AA6061 Produced by Additive Friction Stir-Deposition. Metals 2021, 11, 1773. [Google Scholar] [CrossRef]

- Gumaste, A.; Dhal, A.; Agrawal, P.; Haridas, R.S.; Vasudevan, V.K.; Weiss, D.; Mishra, R.S. A Novel Approach for Enhanced Mechanical Properties in Solid-State Additive Manufacturing by Additive Friction Stir Deposition Using Thermally Stable Al-Ce-Mg Alloy. JOM 2023, 75, 4185–4198. [Google Scholar] [CrossRef]

- Battelle Memorial Institute. Metallic Materials Properties Development and Standardization (MMPDS-17); Battelle Memorial Institute: Columbus, OH, USA, 2022. [Google Scholar]

- Ostertagová, E.O. Oskar Methodology and Application of One-way ANOVA. Am. J. Mech. Eng. 2013, 1, 256–261. [Google Scholar]

- González-Estrada, E.; Villaseñor, J.A.; Acosta-Pech, R. Shapiro-Wilk test for multivariate skew-normality. Comput. Stat. 2022, 37, 1985–2001. [Google Scholar] [CrossRef]

- Gastwirth, J.L.; Gel, Y.R.; Miao, W. The Impact of Levene’s Test of Equality of Variances on Statistical Theory and Practice. Stat. Sci. 2009, 24, 343–360. [Google Scholar] [CrossRef]

- Sherwani, R.A.K.; Shakeel, H.; Awan, W.B.; Faheem, M.; Aslam, M. Analysis of COVID-19 data using neutrosophic Kruskal Wallis H test. BMC Med. Res. Methodol. 2021, 21, 215. [Google Scholar] [CrossRef] [PubMed]

- Kruskal, W.H.; Wallis, W.A. Use of Ranks in One-Criterion Variance Analysis. J. Am. Stat. Assoc. 1952, 47, 583–621. [Google Scholar] [CrossRef]

- Nanda, A.; Mohapatra, D.B.B.; Mahapatra, A.P.K.; Mahapatra, A.P.K.; Mahapatra, A.P.K. Multiple comparison test by Tukey’s honestly significant difference (HSD): Do the confident level control type I error. Int. J. Stat. Appl. Math. 2021, 6, 59–65. [Google Scholar] [CrossRef]

- Hilton, A.A.; Richard, A. Statnote 6: Post-hoc ANOVA tests. Microbiologist 2006, 7, 34–36. [Google Scholar]

- Ghadimi, H.; Jirandehi, A.P.; Nemati, S.; Ding, H.; Garbie, A.; Raush, J.; Zeng, C.; Guo, S. Effects of Printing Layer Orientation on the High-Frequency Bending-Fatigue Life and Tensile Strength of Additively Manufactured 17-4 PH Stainless Steel. Materials 2023, 16, 469. [Google Scholar] [CrossRef]

- Rao, P.N.; Viswanadh, B.; Jayaganthan, R. Effect of cryorolling and warm rolling on precipitation evolution in Al 6061 alloy. Mater. Sci. Eng. A 2014, 606, 1–10. [Google Scholar] [CrossRef]

- Feng, A.H.; Chen, D.L.; Ma, Z.Y. Microstructure and Low-Cycle Fatigue of a Friction-Stir-Welded 6061 Aluminum Alloy. Metall. Mater. Trans. A 2010, 41, 2626–2641. [Google Scholar] [CrossRef]

| Property | Value | Unit |

|---|---|---|

| E, modulus of elasticity | 68.3 | GPa |

| G, modulus of rigidity | 26.2 | GPa |

| Poisson′s ratio | 0.33 | - |

| Density | 2713 | Kg/m3 |

| Ultimate tensile stress | 290 | MPa |

| Tensile yield stress | 241 | MPa |

| Part’s Name | Deposition Layer Thickness (mm) | Deposition Tool’s Rotation Speed (rpm) | Tool’s Traverse Speed (mm/min) | Feed Rate (mm/min) |

|---|---|---|---|---|

| Sample #1 (1 mm block) | 1 (0.04 in) | 300 | 279.4 (11.0 in/min) | 152.4 (6.0 in/min) |

| Sample #2 (2 mm block) | 2 (0.08 in) | 300 | 127.0 (5.0 in/min) | 152.4 (6.0 in/min) |

| Sample #3 (3 mm block) | 3 (0.12 in) | 300 | 96.5 (3.8 in/min) | 152.4 (6.0 in/min) |

| Layer Thickness of The Block | Specimen’s Direction in Part | Specimen’s Position in Part’s Width (Block’s Width) | Specimen’s Position in Part’s Height (Building Direction) |

|---|---|---|---|

| 1, 2, or 3 | X | Center (C), Left (L), or Right (R) | Bottom (B), Middle (M), Middle-Top (MT), or Top (T) |

| 1, 2, or 3 | Y | Not Applicable | Bottom (B), Middle (M), Middle-Top (MT), or Top (T) |

| 1, 2, or 3 | Z | Center (C), Left (L), or Right (R) | Not Applicable |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghadimi, H.; Talachian, M.; Ding, H.; Emanet, S.; Guo, S. The Effects of Layer Thickness on the Mechanical Properties of Additive Friction Stir Deposition-Fabricated Aluminum Alloy 6061 Parts. Metals 2024, 14, 101. https://doi.org/10.3390/met14010101

Ghadimi H, Talachian M, Ding H, Emanet S, Guo S. The Effects of Layer Thickness on the Mechanical Properties of Additive Friction Stir Deposition-Fabricated Aluminum Alloy 6061 Parts. Metals. 2024; 14(1):101. https://doi.org/10.3390/met14010101

Chicago/Turabian StyleGhadimi, Hamed, Mojtaba Talachian, Huan Ding, Selami Emanet, and Shengmin Guo. 2024. "The Effects of Layer Thickness on the Mechanical Properties of Additive Friction Stir Deposition-Fabricated Aluminum Alloy 6061 Parts" Metals 14, no. 1: 101. https://doi.org/10.3390/met14010101

APA StyleGhadimi, H., Talachian, M., Ding, H., Emanet, S., & Guo, S. (2024). The Effects of Layer Thickness on the Mechanical Properties of Additive Friction Stir Deposition-Fabricated Aluminum Alloy 6061 Parts. Metals, 14(1), 101. https://doi.org/10.3390/met14010101