Implementation of ABAQUS User Subroutines for Viscoplasticity of 316 Stainless Steel and Zircaloy-4

Abstract

1. Introduction

2. Viscoplastic Constitutive Equation

2.1. The Framework of the Unified Viscoplastic Constitutive Model

2.2. Isotropic Viscoplastic Constitutive Model for 316 Stainless Steel

2.3. Anisotropic Viscoplastic Constitutive Model for Zircaloy-4

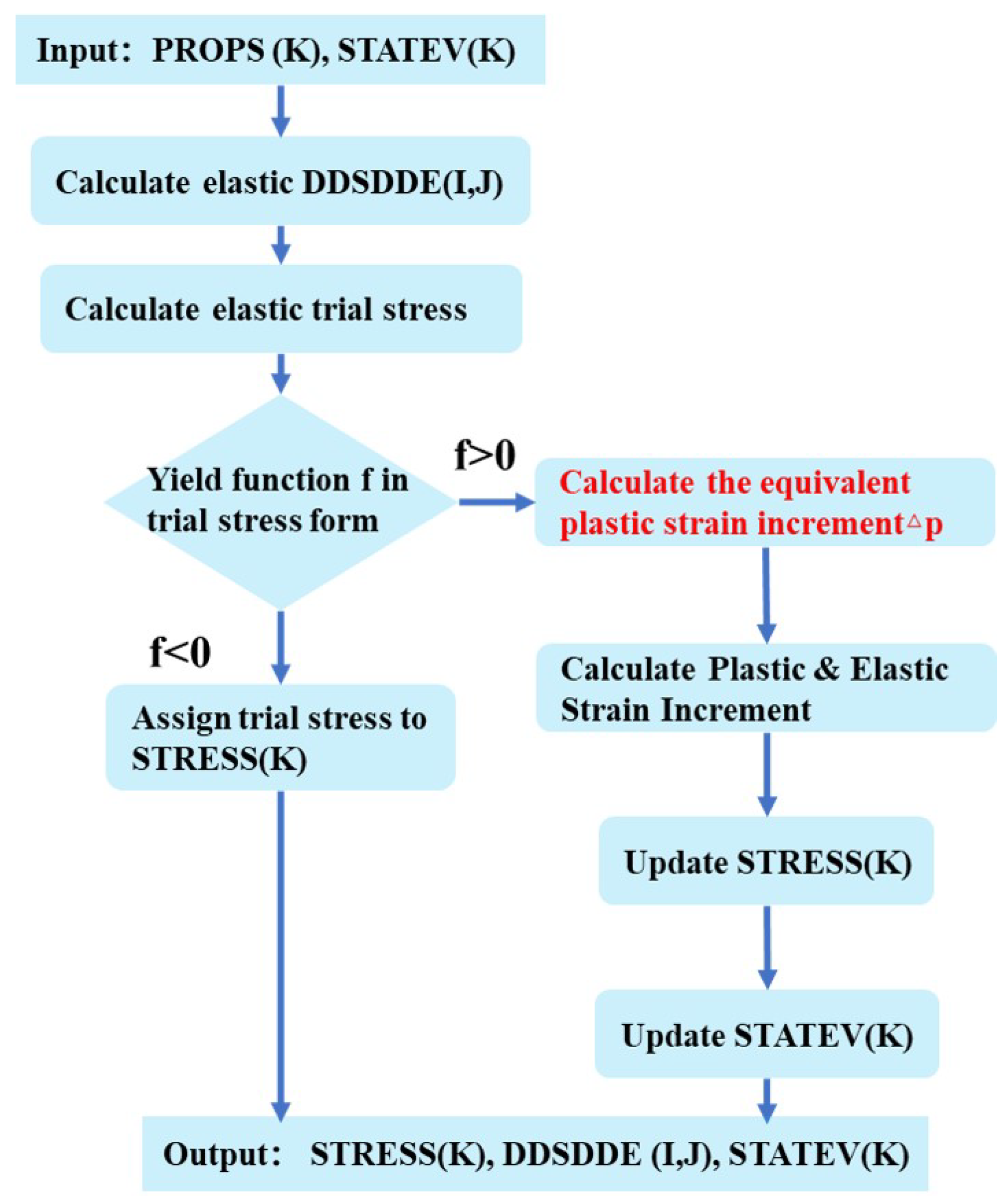

3. Computational Algorithm

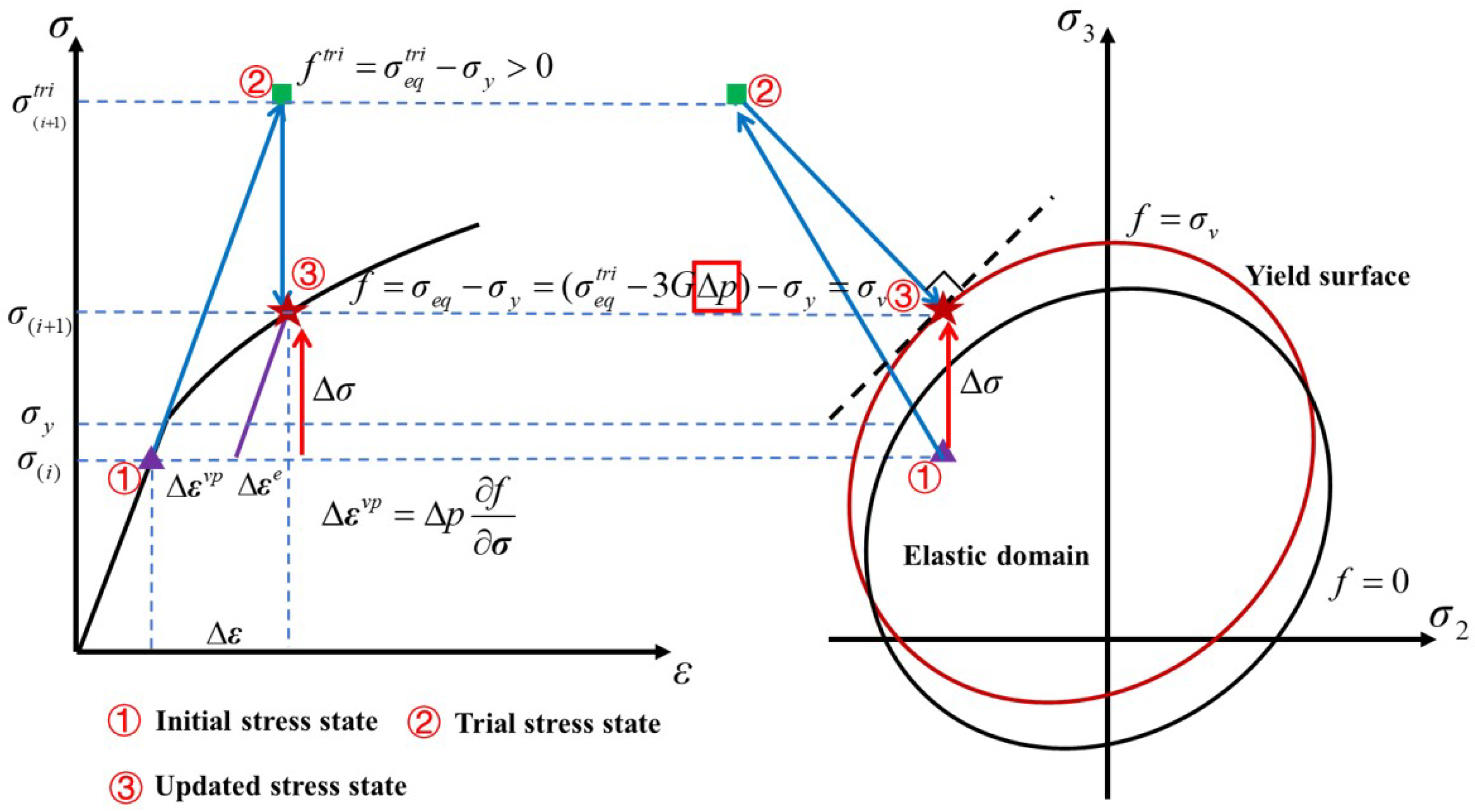

3.1. Return Mapping Algorithm

3.2. Stress Update Algorithm of 316 Stainless Steel Model

3.3. Stress Update Algorithm of Zircaloy-4 Model

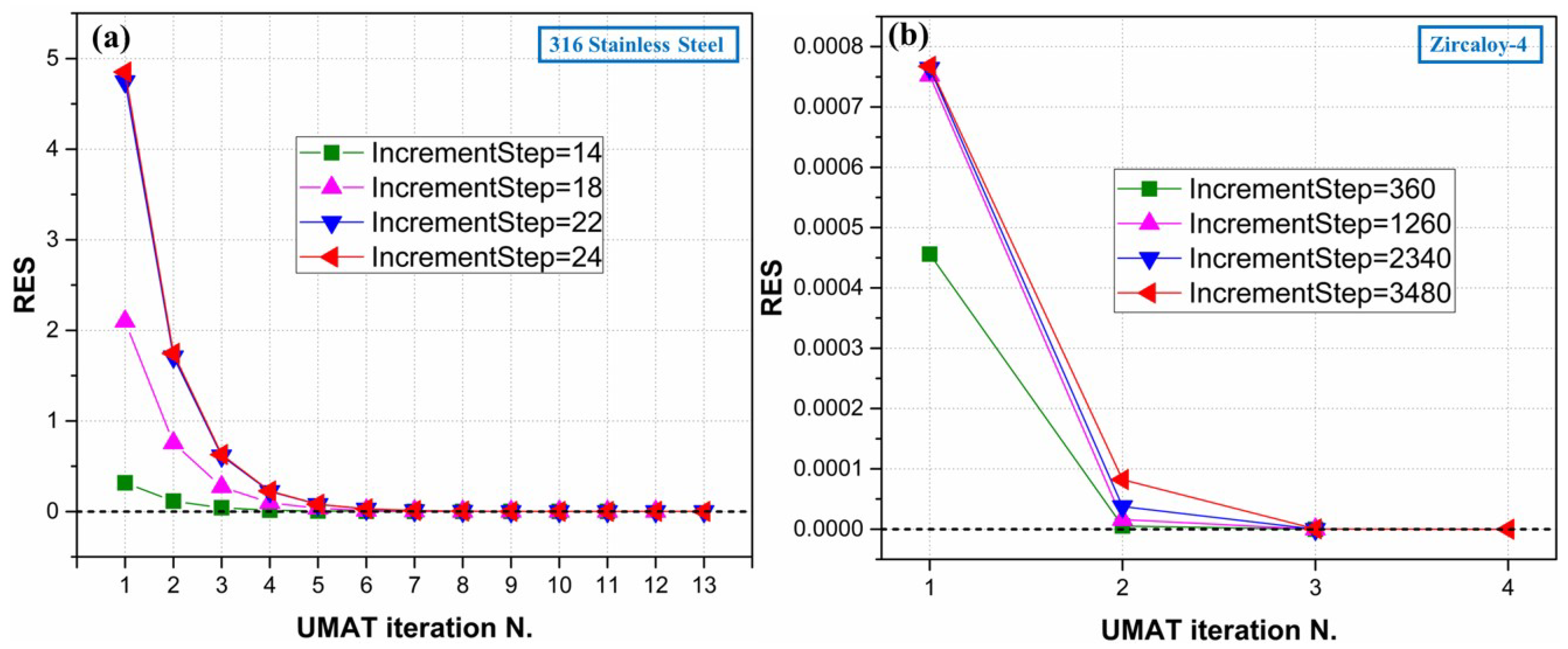

4. Verification and Validation of FE Modeling and UMAT Code

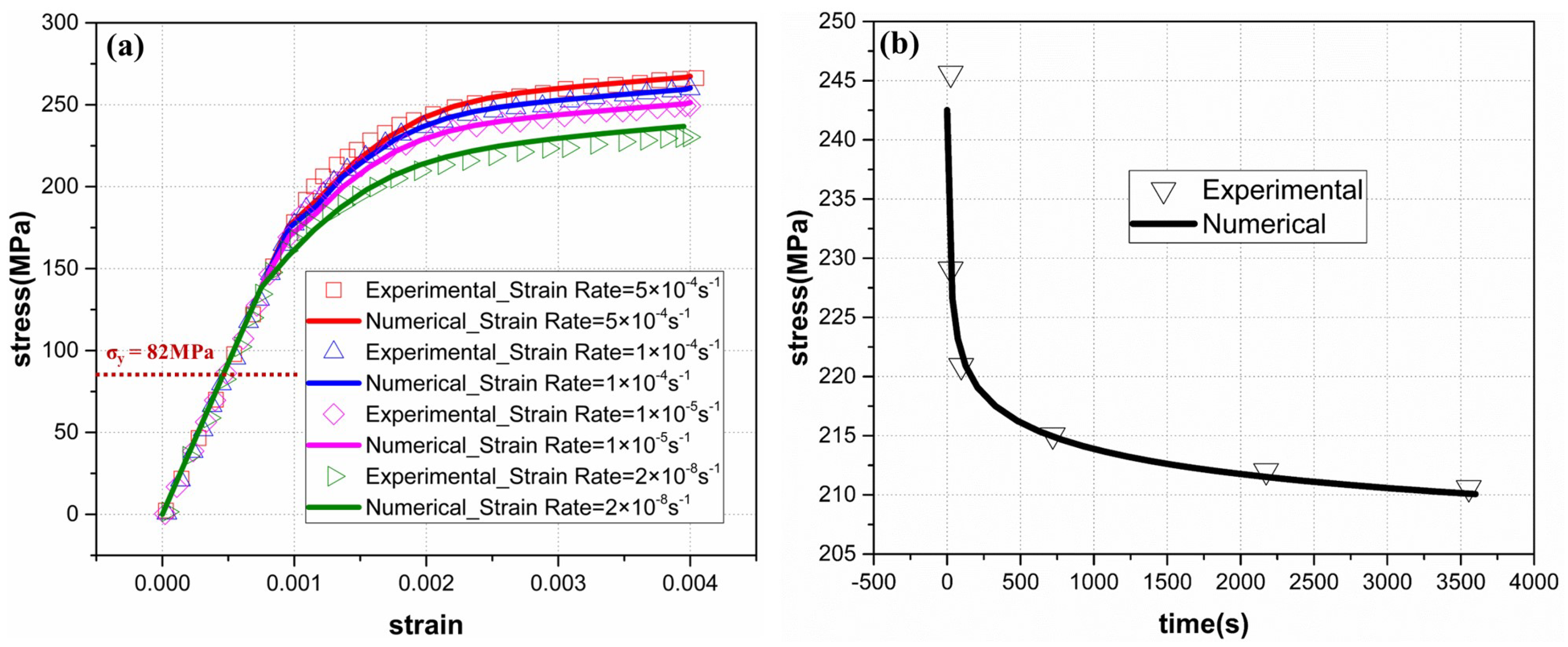

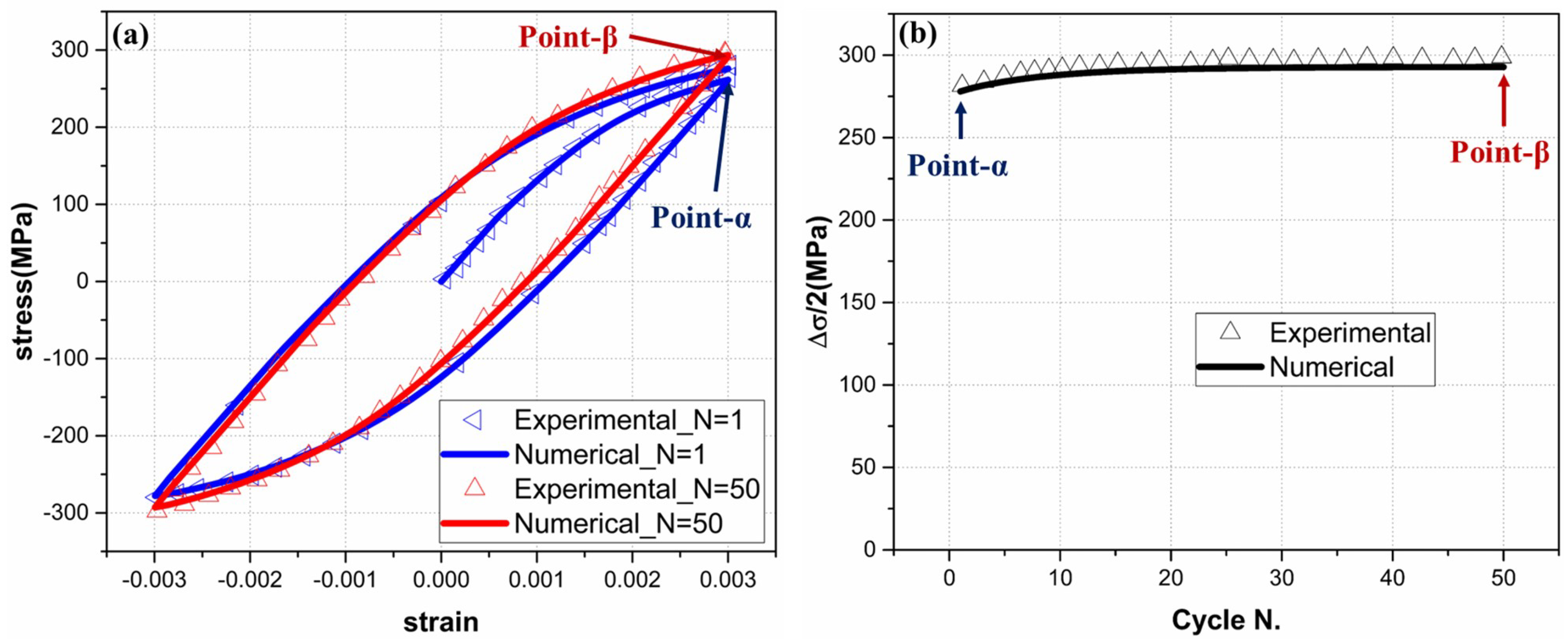

4.1. 316 Stainless Steel

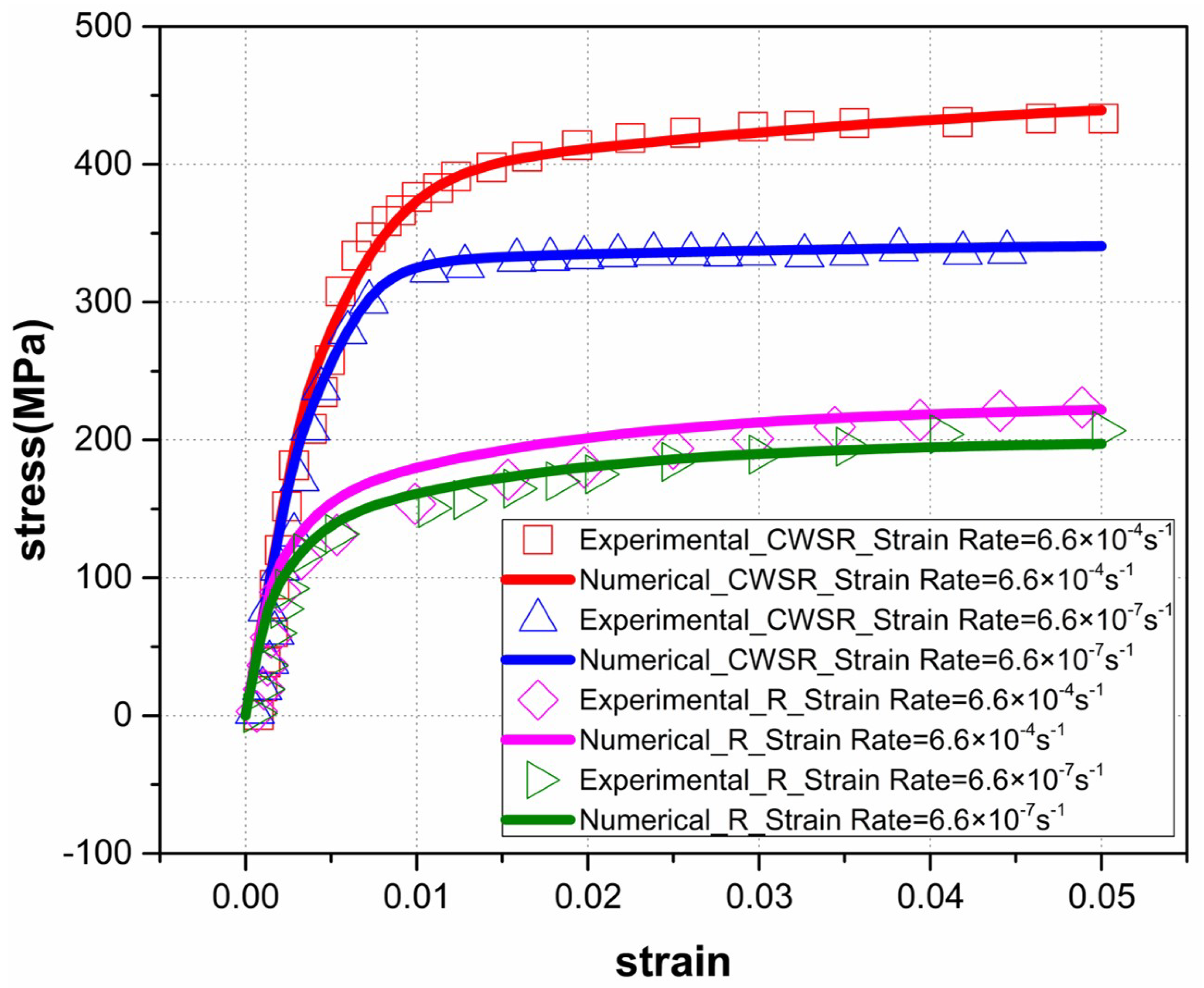

4.2. Zircaloy-4

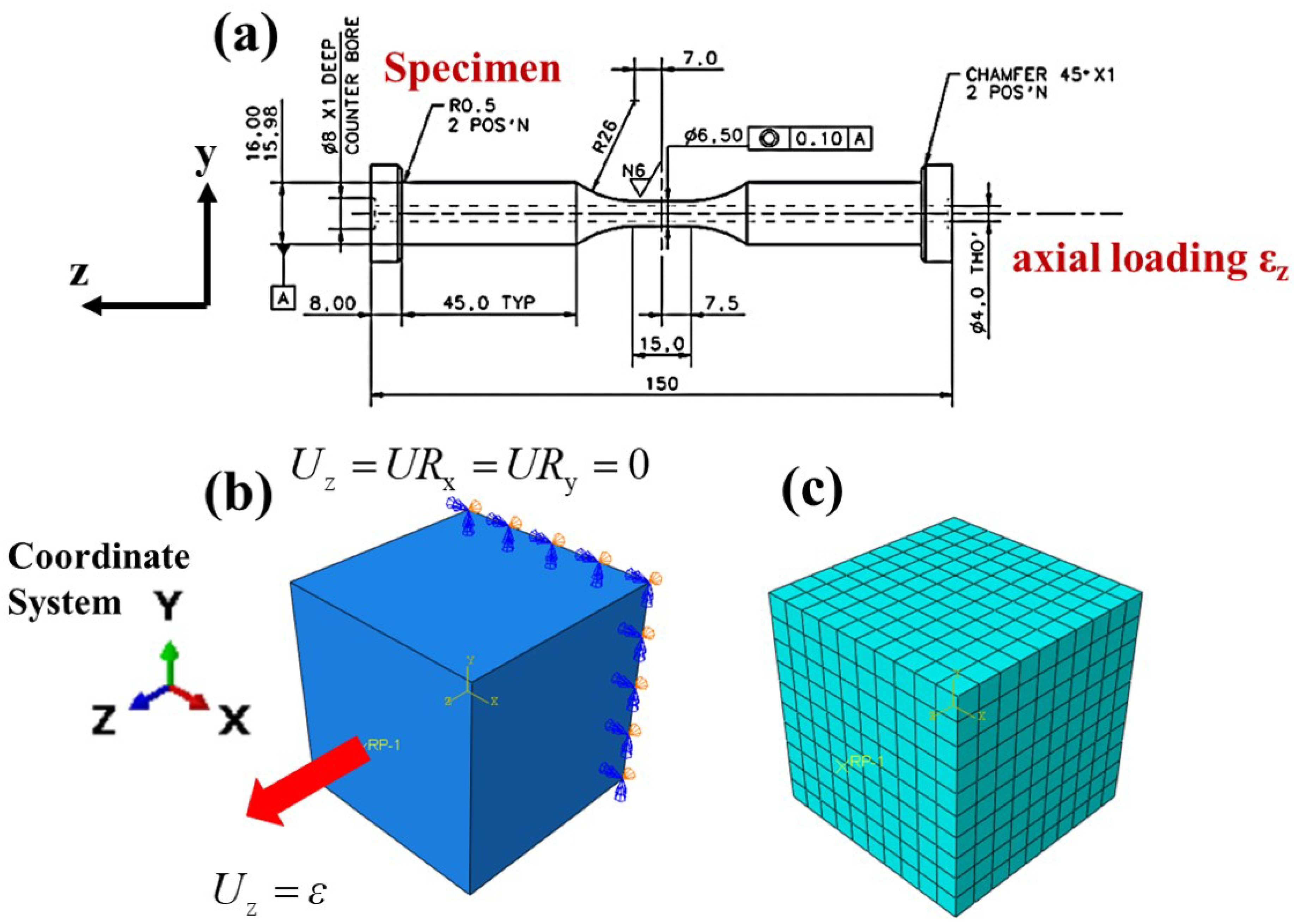

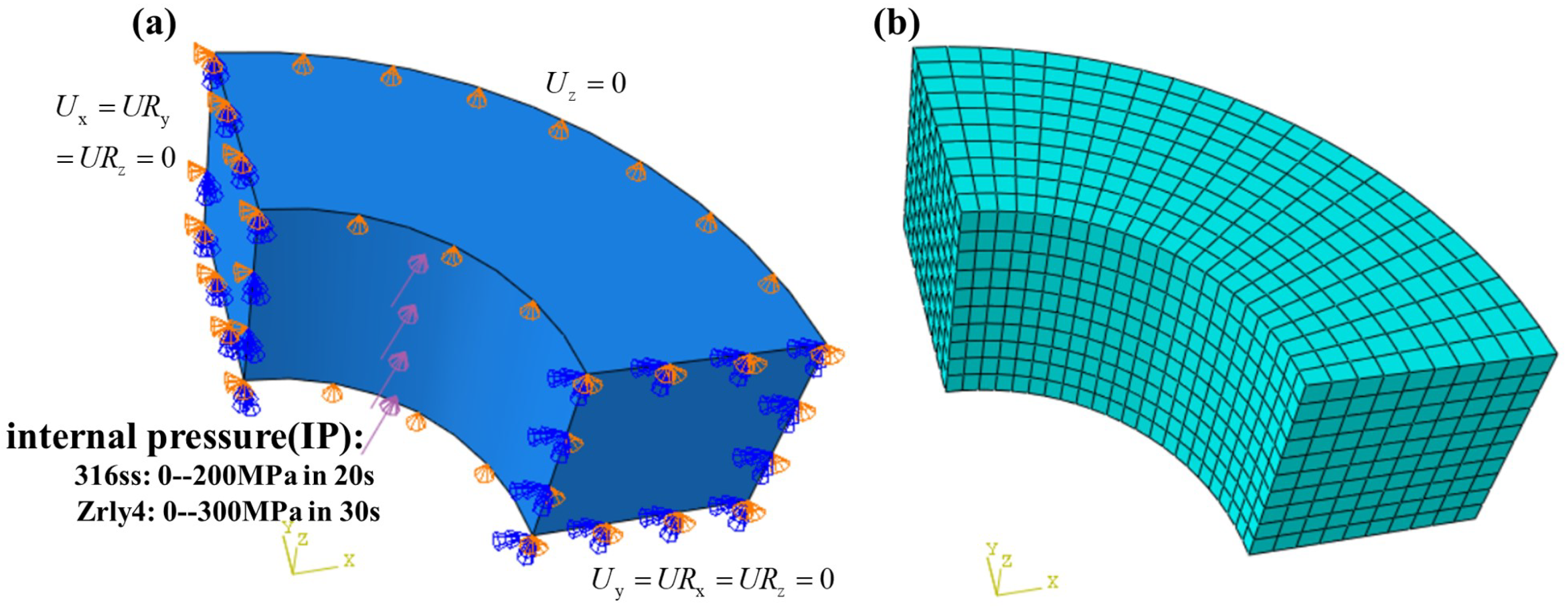

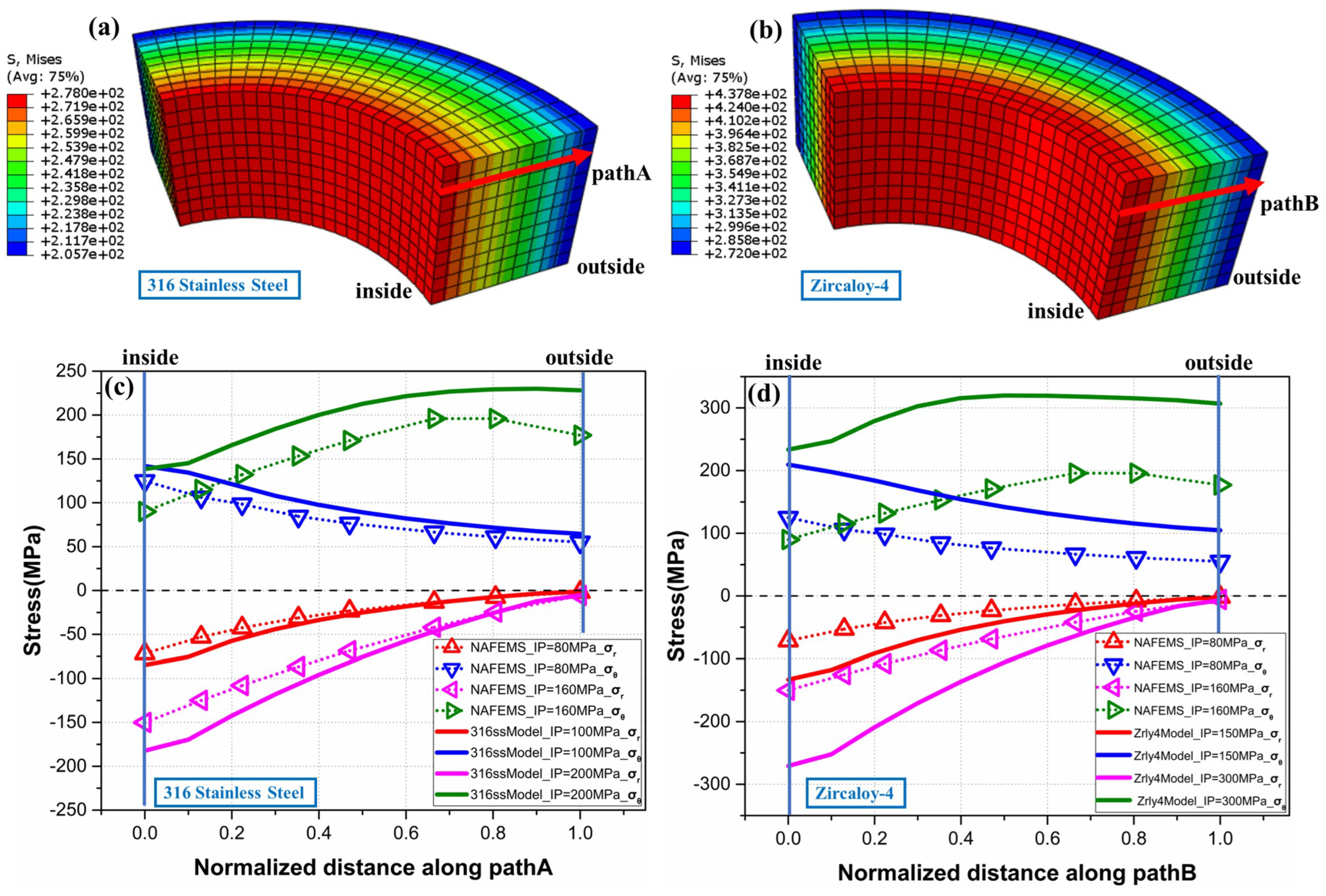

4.3. Multiaxial Stress State Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cox, B. Pellet-clad interaction (PCI) failures of zirconium alloy fuel cladding—A review. J. Nucl. Mater. 1990, 172, 249–292. [Google Scholar]

- Jezequel, T.; Auzoux, Q.; Le Boulch, D.; Bono, M.; Andrieu, E.; Blanc, C.; Chabretou, V.; Mozzani, N.; Rautenberg, M. Stress corrosion crack initiation of Zircaloy-4 cladding tubes in an iodine vapor environment during creep, relaxation, and constant strain rate tests. J. Nucl. Mater. 2018, 499, 641–651. [Google Scholar]

- d’Ambrosi, V.; Destouches, C.; Ricciardi, G.; Bréaud, S.; Lebon, F.; Gatt, J.M.; Julien, J.; Parrat, D. Fuel rod nonlinear vibrations to detect and characterize Pellet-Cladding Interaction. Nucl. Eng. Des. 2021, 379, 111214. [Google Scholar]

- Li, Y.; Ge, C.; Liu, Y.; Li, G.; Dong, X.; Gu, Z.; Zhang, Y. Influencing factors and mechanism of iodine-induced stress corrosion cracking of zirconium alloy cladding: A review. Int. J. Miner. Metall. Mater. 2022, 29, 586–598. [Google Scholar]

- Hallstadius, L.; Johnson, S.; Lahoda, E. Cladding for high performance fuel. Prog. Nucl. Energy 2012, 57, 71–76. [Google Scholar]

- Azevedo, C.d.F. Selection of fuel cladding material for nuclear fission reactors. Eng. Fail. Anal. 2011, 18, 1943–1962. [Google Scholar]

- Li, Q.; Song, P.; Zhang, R.; Li, Z.; Wang, Y.; Du, P.; Lu, J. Oxidation behavior and Cr-Zr diffusion of Cr coatings prepared by atmospheric plasma spraying on zircaloy-4 cladding in steam at 1300 °C. Corros. Sci. 2022, 203, 110378. [Google Scholar]

- Berna, G.; Beyer, G.; Davis, K.; Lanning, D. FRAPCON-3: A Computer Code for the Calculation of Steady-State, Thermal-Mechanical Behavior of Oxide Fuel Rods for High Burnup; Technical Report; US Nuclear Regulatory Commission (NRC): Washington, DC, USA; Division of Systems Technology, Pacific Northwest National Lab. (PNNL): Richland, WA, USA; Idaho National Lab. (INL): Idaho Falls, ID, USA, 1997.

- Hughes, T. FPIN2 Analysis of Metal Fueled Pins; Technical Report; Argonne National Lab. (ANL): Argonne, IL, USA, 1985. [Google Scholar]

- Yagnik, S.; Rashid, Y.; Dunham, R.; Montgomery, R. Fuel Analysis and Licensing Code: FALCON MOD01, Volume 1: Theoretical and Numerical Bases; Technical Report; EPRI: Palo Alto, CA, USA, 2004; p. 1011307. [Google Scholar]

- Allison, C.; Berna, G.; Chambers, R.; Coryell, E.; Davis, K.; Hagrman, K.; McComas, M. SCDAP/RELAP5/MOD3.1 Code Manual Volume IV: MATPRO; Technical Report; NUREG/CR-6150; Idaho National Laboratory: Idaho Falls, ID, USA, 1993. [Google Scholar]

- Williamson, R.L.; Hales, J.; Novascone, S.; Tonks, M.; Gaston, D.; Permann, C.; Andrs, D.; Martineau, R. Multidimensional multiphysics simulation of nuclear fuel behavior. J. Nucl. Mater. 2012, 423, 149–163. [Google Scholar]

- Newman, C.; Hansen, G.; Gaston, D. Three dimensional coupled simulation of thermomechanics, heat, and oxygen diffusion in UO2 nuclear fuel rods. J. Nucl. Mater. 2009, 392, 6–15. [Google Scholar]

- Williamson, R.L.; Hales, J.D.; Novascone, S.R.; Pastore, G.; Gamble, K.A.; Spencer, B.W.; Jiang, W.; Pitts, S.A.; Casagranda, A.; Schwen, D.; et al. BISON: A flexible code for advanced simulation of the performance of multiple nuclear fuel forms. Nucl. Technol. 2021, 207, 954–980. [Google Scholar] [CrossRef]

- Williamson, R. Enhancing the ABAQUS thermomechanics code to simulate multipellet steady and transient LWR fuel rod behavior. J. Nucl. Mater. 2011, 415, 74–83. [Google Scholar] [CrossRef]

- Miao, Y.; Oaks, A.; Mo, K.; Billone, M.; Matthews, C.; Zabriskie, A.X.; Novascone, S.; Yacout, A.M. Metallic fuel cladding degradation model development and evaluation for BISON. Nucl. Eng. Des. 2021, 385, 111531. [Google Scholar] [CrossRef]

- Phan, V.T.; Messner, M.; Sham, T.L. A unified engineering inelastic model for 316H stainless steel. In Proceedings of the ASME 2019 Pressure Vessels and Piping Conference, San Antonio, TX, USA, 14–19 July 2019. [Google Scholar]

- Li, Z.; Wen, Z.; Pei, H.; Yue, X.; Wang, P.; Ai, C.; Yue, Z. Creep life prediction for a nickel-based single crystal turbine blade. Mech. Adv. Mater. Struct. 2022, 29, 6039–6052. [Google Scholar] [CrossRef]

- Chaboche, J.L. A review of some plasticity and viscoplasticity constitutive theories. Int. J. Plast. 2008, 24, 1642–1693. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, T.; Zhang, W.; Wahab, M.A.; Gong, J. An improved unified viscoplastic model for modelling low cycle fatigue and creep fatigue interaction loadings of 9–12% Cr steel. Eur. J. Mech.-A/Solids 2021, 85, 104123. [Google Scholar] [CrossRef]

- Chaboche, J.; Rousselier, G. On the plastic and viscoplastic constitutive equations—Part I: Rules developed with internal variable concept. J. Press. Vessel. Technol. 1983, 105, 153–158. [Google Scholar] [CrossRef]

- Chaboche, J.L.; Rousselier, G. On the plastic and viscoplastic constitutive equations—Part II: Application of internal variable concepts to the 316 stainless steel. J. Press. Vessel. Technol. 1983, 105, 159–164. [Google Scholar] [CrossRef]

- Chaboche, J.L. Constitutive equations for cyclic plasticity and cyclic viscoplasticity. Int. J. Plast. 1989, 5, 247–302. [Google Scholar] [CrossRef]

- Miled, B.; Doghri, I.; Delannay, L. Coupled viscoelastic–viscoplastic modeling of homogeneous and isotropic polymers: Numerical algorithm and analytical solutions. Comput. Methods Appl. Mech. Eng. 2011, 200, 3381–3394. [Google Scholar] [CrossRef]

- Tian, J.; Li, J.; Xie, H.; Yang, Y.; Kan, Q. Finite element implementation of a temperature-dependent cyclic plastic model for SA508-3 steel. Metals 2018, 8, 955. [Google Scholar] [CrossRef]

- Du, R.; Zhang, X.; Wang, H.; Liu, X.; Wei, Y. A revised Chaboche model from multiscale approach to predict the cyclic behavior of type 316 stainless steel at room temperature. Int. J. Fatigue 2023, 167, 107303. [Google Scholar] [CrossRef]

- Santus, C.; Grossi, T.; Romanelli, L.; Pedranz, M.; Benedetti, M. A computationally fast and accurate procedure for the identification of the Chaboche isotropic-kinematic hardening model parameters based on strain-controlled cycles and asymptotic ratcheting rate. Int. J. Plast. 2023, 160, 103503. [Google Scholar] [CrossRef]

- Murty, K.L.; Charit, I. Texture development and anisotropic deformation of zircaloys. Prog. Nucl. Energy 2006, 48, 325–359. [Google Scholar] [CrossRef]

- Murty, K.L.; Adams, B.L. Biaxial creep of textured zircaloy I: Experimental and phenomenological descriptions. Mater. Sci. Eng. 1985, 70, 169–180. [Google Scholar] [CrossRef]

- Grosjean, C.; Poquillon, D.; Salabura, J.C.; Cloué, J.M. Experimental creep behaviour determination of cladding tube materials under multi-axial loadings. Mater. Sci. Eng. A 2009, 510, 332–336. [Google Scholar] [CrossRef][Green Version]

- Rautenberg, M.; Poquillon, D.; Pilvin, P.; Grosjean, C.; Cloué, J.M.; Feaugas, X. Thermal isocreep curves obtained during multi-axial creep tests on recrystallized Zircaloy-4 and M5™ alloy. Nucl. Eng. Des. 2014, 269, 33–37. [Google Scholar] [CrossRef]

- Guo, W.; Li, G.; Yuan, F.; Han, F.; Zhang, Y.; Ali, M.; Ren, J.; Yuan, G. Texture development and mechanical behavior of Zircaloy-4 alloy plates fabricated by cold rolling and annealing. Mater. Sci. Eng. A 2021, 807, 140846. [Google Scholar] [CrossRef]

- Delobelle, P. Synthesis of the elastoviscoplastic behavior and modelization of an austenitic stainless steel over a large temperature range, under uniaxial and biaxial loadings, part II: Phenomenological modelization. Int. J. Plast. 1993, 9, 87–118. [Google Scholar] [CrossRef]

- Delobelle, P.; Robinet, P.; Geyer, P.; Bouffioux, P. A model to describe the anisotropic viscoplastic behaviour of Zircaloy-4 tubes. J. Nucl. Mater. 1996, 238, 135–162. [Google Scholar] [CrossRef]

- Richard, F.; Delobelle, P.; Leclercq, S.; Bouffioux, P.; Rousselier, G. Modeling of the cold work stress relieved Zircaloy-4 cladding tubes mechanical behavior under PWR operating conditions. In Proceedings of the Transactions of the SMiRT 17, Prague, Czech Republic, 17–18 August 2003. [Google Scholar]

- Dunne, F.; Petrinic, N. Introduction to Computational Plasticity; Oxford University Press: New York, NY, USA, 2005. [Google Scholar]

- Armstrong, P.J.; Frederick, C. A Mathematical Representation of the Multiaxial Bauschinger Effect; Technical Report; Berkeley Nuclear Laboratories: Berkeley, CA, USA, 1966.

- Hill, R. A theory of the yielding and plastic flow of anisotropic metals. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1948, 193, 281–297. [Google Scholar]

- Marin, E.; McDowell, D. A semi-implicit integration scheme for rate-dependent and rate-independent plasticity. Comput. Struct. 1997, 63, 579–600. [Google Scholar] [CrossRef]

- Hyde, C.J.; Sun, W.; Leen, S.B. Cyclic thermo-mechanical material modelling and testing of 316 stainless steel. Int. J. Press. Vessel. Pip. 2010, 87, 365–372. [Google Scholar] [CrossRef]

- Dassault, S. Abaqus 6.14 Documentation; Simulia Systems: Providence, RI, USA, 2014. [Google Scholar]

- Guo, W.; Li, G.; Han, F.; Zhang, Y.; Ali, M.; Ren, J.; Wang, Q.; Yuan, F.; Tong, M. Deformation mechanism and cyclic stress response of Zircaloy-4 alloy cladding tube during low cycle fatigue at room temperature. Int. J. Fatigue 2022, 160, 106875. [Google Scholar] [CrossRef]

| T (°C) | E (GPa) | (MPa) | b | Q (MPa) | (MPa) | K (MPa | n | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| RT * | 185 | 0.3 | 82 | 8 | 60 | 58 | 2800 | 270 | 25 | 151 | 24 |

| 550 | 141.26 | 0.3 | 31 | 31 | 27.8 | 86.3 | 6939 | 114.8 | 957.69 | 173 | 10 |

| Recrystallized Zircaloy-4 | Cold Worked Stress Relieved Zircaloy-4 |

|---|---|

| MPa, | MPa, |

| MPa, | MPa, |

| MPa | MPa MPa |

| MPa, | MPa, |

| MPa, MPa | MPa, MPa, MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, X.; Zhou, J. Implementation of ABAQUS User Subroutines for Viscoplasticity of 316 Stainless Steel and Zircaloy-4. Metals 2023, 13, 1554. https://doi.org/10.3390/met13091554

Yue X, Zhou J. Implementation of ABAQUS User Subroutines for Viscoplasticity of 316 Stainless Steel and Zircaloy-4. Metals. 2023; 13(9):1554. https://doi.org/10.3390/met13091554

Chicago/Turabian StyleYue, Xiaowei, and Jinxiong Zhou. 2023. "Implementation of ABAQUS User Subroutines for Viscoplasticity of 316 Stainless Steel and Zircaloy-4" Metals 13, no. 9: 1554. https://doi.org/10.3390/met13091554

APA StyleYue, X., & Zhou, J. (2023). Implementation of ABAQUS User Subroutines for Viscoplasticity of 316 Stainless Steel and Zircaloy-4. Metals, 13(9), 1554. https://doi.org/10.3390/met13091554