Abstract

This article presents a 95% IN718 + 5% (75% Cr2O3 + TiO2) ceramic coating on the SS316L substrate surface with laser additives. The macro shape, phase, microstructure, interface, wear resistance and tensile resistance of metal base composite materials are analyzed. The results show that metal matrix composite (MMC) laminated composite materials have good microscopic hardness and wear resistance compared to single materials. Comparative analyses with single IN718 materials indicate that the laminated composite materials exhibit superior microscopic hardness and wear resistance. Additionally, the study reveals a positive correlation between material hardness and wear resistance, characterized by reduced wear coefficient and average abrasion with increased material hardness. The findings of this research offer a cost-effective and practical method for producing high-resistance coating layer composite materials.

1. Introduction

In recent years, additive manufacturing technology has undergone rapid development, offering a highly promising approach for the rapid production of intricate components, including magnesium alloys, high-temperature alloys, and ultra-high-strength steels [1]. Notably, this technology has extended its application to a diverse range of materials, encompassing metals, ceramics, polymers, and even bios [2,3]. One of the distinguishing features of additive manufacturing is its computer-driven, layer-by-layer construction or assembly of parts, eliminating the need for specific tools dedicated to each part [4,5]. While there have been some concerns about its suitability for mass production, the industrial adoption of additive manufacturing is steadily increasing, thanks to advancements in new technologies. This ever-evolving technology enables the precise and robust fabrication of complex objects at faster production speeds, potentially surpassing traditional manufacturing methods in the foreseeable future [6].

There is a growing demand for metal matrix composites (MMCs) that incorporate secondary phases such as WC, TiB2, and TiC. These composite materials find applications in various industries, including aircraft, space, military, automotive, and electronics. To enhance the tribological and mechanical properties of ceramic composites, researchers have been adding different types of reinforcements [7]. For instance, Wang et al. [8] conducted a study on TiC-reinforced high-strength steel composites using conventional powder metallurgy techniques. They investigated the impact of sintering temperature and heat treatment on the density, hardness, and strength of the composites. The results showed that high-ceramic content (TiB + TiC)-enhanced laminate-based composite coatings exhibited significant improvements in hardness and wear resistance [9]. Furthermore, Gu et al. [10] explored the addition of nanotubes to accelerate the cooling rate and core formation rate of γ phase in the composites. This led to the refinement of the spacing of columnar branch crystals, thereby enhancing the tensile strength of the composites. Cai et al. [11] investigated a composite coating comprising TiC and Al2O3 ceramic particles enhanced with Cr12MoV steel. The study revealed that when the ceramic enhancement content reached 15%, noticeable cracks appeared on the coating, indicating a critical threshold for the ceramic content. Similarly, Li et al. [12,13] examined the effect of adding different amounts of Ti on the microscopic structure of the material. They observed a gradual increase in the size of the paralytic phase as Ti content was increased. The introduction of Ti powder during the additive manufacturing process led to enhanced microhardness and wear resistance due to the formation of synthetic particles such as Ti (C, N). In another study, Xia et al. [14] utilized TiO2, Al, graphite, and ZL101 powder to prepare Al2O3-TiC/ZL101 composite materials. As the TiC content increased, the distribution of the enhancer became more uniform, resulting in significantly improved hardness and wear resistance compared to the pure ZL101 material. Zhao et al. [15] prepared TiC-TiN-B4C compound ceramic coatings and investigated the impact of TiC, TiN, and Ti (C, N) ceramic content on microscopic hardness and friction coefficient in microbial tissue. The study aimed to understand how the different ceramic components affect the mechanical and tribological properties of the coatings. In another study, Zhao et al. [16] explored the incorporation of Ti and C particles in NbC-Ni composite coatings. This addition was found to effectively eliminate large blocks of NbC structures. When the composite coatings had a Ti/C/NbC quality score ratio of 7:2:21, adding 30% NbC resulted in a remarkable 11-fold increase in the wear resistance of the composite layer.

Furthermore, Sam et al. [17] conducted a comparison of the effects of various carbide ceramics (B4C, SiC, TiC) as enhancers on the friction performance and mechanical strength of the A333 composite material. This study aimed to assess the suitability of different carbide ceramics in enhancing the overall performance of the A333 composite material. Włodarczyk-Fligier et al. [18] investigated the impact of heat treatment and Ti(C, N) particles on the mechanical properties and wear resistance of EN AW-AlCu4Mg1(A) aluminum alloys. The study aimed to understand how heat treatment and the addition of Ti (C, N) particles influence the performance of aluminum alloys, particularly concerning their mechanical strength and resistance to wear. Similarly, Solodkyi et al. [19] conducted an analysis of B4C-TiB2 crystalline particles with different Ti contents to enhance Ti in the composite materials. The study revealed that higher amounts of Ti added resulted in larger shifts and greater break resistance, indicating the potential for improving the mechanical properties of the composites through controlled Ti enhancement. In the context of iron-based materials, Yang et al. [20] focused on enhancing wear resistance by forming an in situ Ti (C, N) ceramic reinforcement phase through laser cladding. The results indicated that the in situ synthesis of Ti (C, N) ceramics significantly improved the wear resistance of the Fe313 layer, demonstrating the effectiveness of this approach for enhancing iron-based coatings. Yan et al. [21] successfully prepared an alcocrfenisi-based high magnesium alloy coating enhanced with original Ti (C, N) particles. They conducted a comprehensive study on the wear resistance and hardness of the coating, aiming to understand the effect of Ti (C, N) enhancements on the material’s performance. In the work of Xi et al. [22], a novel interface structure was proposed to improve the manufacturing quality and wear performance of selective laser melting (SLM)-based composite materials by combining hybrid enhancements. The study explored the synergistic effects of different enhancements to enhance the overall properties of the composite materials. Pazhouhanfar et al. [23] investigated the effects of adding titanium nitride (TiN) on the combustion properties, mechanical properties, and microscopic tissue development of tick-based materials. The study aimed to understand how TiN enhances the material and its influence on different characteristics. These studies contribute valuable insights into the use of various ceramic enhancements to improve the properties of metal matrix composites. The findings highlight the importance of optimizing the content and distribution of ceramic particles to achieve enhanced performance in terms of hardness, wear resistance, and overall structural integrity. Despite the significant progress in developing metal matrix composites (MMC) using the methods mentioned above, challenges remain. The fabrication processes for MMCs are often complex, time-consuming, and costly. Moreover, they may result in undesirable coarse structures, leading to reduced ductility. Consequently, the precision machining of MMCs continues to be a challenge that requires further development to achieve acceptable production quality and cost-effectiveness. Ongoing research and innovation are crucial to overcome these obstacles and unlock the full potential of MMCs in various industrial applications.

Interfaces have emerged as crucial factors in the performance of composite materials, and enhancing the strength and plasticity of interfaces has become a significant challenge [24]. Wang et al. [25] successfully prepared an iron matrix composite coating using synchronous powder feed plasma transfer arc (PTA) cladding technology. They incorporated submicron Ti (C, N) particles in situ on the Q235 low-carbon steel matrix, resulting in a dense structure and strong bonding at the interface between the coating and the matrix. Xi et al. [22] explored the use of different starting powders, such as Ti-TiC, Ti-TiN, Ti-TiC-TiN, and Ti-TiN-graphene, to prepare ceramic particles for enhancing the base composite material. Their efforts led to the development of a composite material with a well-structured interface, enhancing its overall performance. In the research conducted by Liu et al. [26], a nano-engineering method was employed to create micro-mass TiBw crystals, effectively reinforcing the GNPs-TiC layer-ti interface. The study demonstrated that TiBw played a role in suppressing the interfaces of GNPs and delaying the destruction of the TiC layer, contributing to improved performance. These studies highlight the importance of optimizing interfaces in composite materials. By employing innovative techniques and incorporating specific enhancements, researchers are striving to improve the strength, plasticity, and overall performance of composite materials in various applications.

In conclusion, numerous researchers have investigated the preparation process and mechanical properties of the additive manufacturing metal matrix composites. However, there is limited research on layered composites incorporating ceramic particles, which have the potential to enhance overall performance with a small ceramic content. Therefore, this paper focuses on the use of 316 stainless steel as the substrate material and 95% IN718 + 5% (75% Cr2O3 + TiO2) as the ceramic composites. The study aims to analyze the mechanical properties of a laser-additive ceramic-enhanced MMC/316L composite material. The impact of the microstructure and interface characteristics on mechanical properties is also explored. The MMC/316L composite material is subjected to tests for tensile strength, flexural strength, and microhardness.

2. Material and Experimental Procedure

2.1. Preparation of Samples

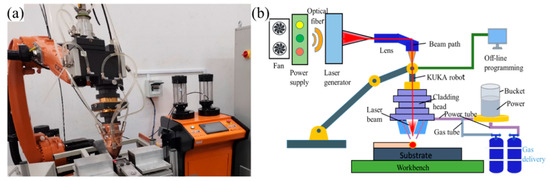

Samples were prepared using optical fiber laser equipment. The substrate used was a 316L stainless steel with dimensions of 60 mm × 60 mm × 15 mm. Prior to the experiment, the surface was cleaned using water-free ethanol and acetone to remove any oil and impurities. The experiment employed a 4000 W optical fiber laser with a spot diameter of 4 mm, laser power set at 1400 W, scanning speed at 480 mm/min, and a clutch rate of 50%. The experimental setup is illustrated in Figure 1. To prevent sample oxidation, the experiment was conducted under a hydrogen-protected atmosphere. The powder used for the sedimentary layer was 95% IN718 + 5% (75% Cr2O3 + TiO2), with a particle diameter ranging from 53 to 150 μm.

Figure 1.

(a) KUKA-DED experimental platform, (b) oriented energy deposit manufacturing process instructions.

2.2. Experimental Procedure

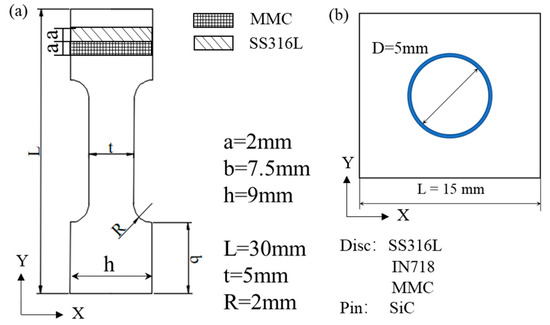

The sample was polished using sandpapers ranging from 180# to 4000#. This process removed the material and obtained metal phase samples. The corrosion liquid used was a mixture of V (HCL) and V (H2O2) in a ratio of 10:3, and the erosion time was set to 10 s. Subsequently, a stretch test was performed on an INSTON 5569 electronic universal material testing machine. The sample size used for the test is depicted in Figure 2a, with a stretch speed of 1 mm/min and an initial distance of 11 mm. The shape of the microscopic structure was observed using the OLS4100 (OLYMPUS, Tokyo, Japan) and KC-H030 (KathMatic, Nanjing, China) laser microscope. Additionally, the Zeiss Merlin Field Launch Scanning Electron Microscope (FE-SEM) was used to observe the high-magnification structure and rupture shape, and the elemental content of the microscopic structure was measured using the equipped EDS (Energy-dispersive X-ray Spectroscopy). After the friction wear, the samples were tested again using the OLS4100 laser microscope and Keynes VK-X250K (Keynes, Osaka, Japan). The wear loss and coefficient of friction were measured using the M-2000 wear test machine. The friction side option utilized SiC, with a size of Φ4 mm, and the radius of the wear mark was 2.5 mm. The size of the wear sample used was 15 mm × 15 mm × 5 mm, as illustrated in Figure 2b. Before conducting the friction wear experiment, the sample surface was polished with sandpaper to remove surface oil pollution and achieve a smooth grinding surface.

Figure 2.

(a) Shape and size of tensile specimen, (b) size of friction and wear test.

3. Results and Discussion

3.1. Microstructures

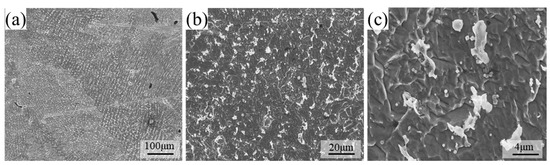

Figure 3 displays a typical dissipation phase shape observed through scanning electron microscopy of the sedimentary layer, which is taken from the cross-section. The sedimentary layer is predominantly composed of columnar crystals, and some regions exhibit a rough laves phase. The process of laser additive manufacturing introduces extension growth characteristics, significantly influencing the structure of the molded part based on the orientation of the base crystals. Consequently, the crystalline orientation of the base material is imparted layer by layer during the forming process. Moreover, the growth direction of dendrites is not entirely parallel to the deposition direction; rather, it possesses a certain angle with the deposition direction. This occurrence primarily arises due to the powder reaching the molten pool during the forming process, causing a tilt in the molten pool. As the molten pool condenses from the bottom to the top, the temperature gradient rapidly shifts from the deposited direction to the perpendicular scanning direction. This phenomenon leads to a deviation in the growth direction of the branch crystals along the scanning direction.

Figure 3.

Morphology of the deposited microstructures.

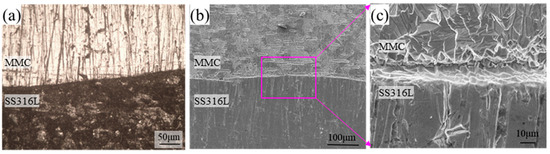

Figure 4 illustrates the microstructure shape of the interface in the MMC laminated composite materials, as observed under an optical microscope and a scanning electron microscope. The interface between the ceramic-reinforced IN718 base composite material and the 316L stainless steel base has undergone significant changes. The two sides of the interface exhibit distinctly different microscopic structures, yet no defects, such as cracks caused by thermal stress, are observed at the interface. The laser additive process involves melting the coating materials and substrate surfaces, leading to their mixing and bonding through metallurgy. The precise control of the position and energy of the laser beam by laser additives is crucial. This high precision control ensures accurate coating application, effectively managing any gaps or irregularities between the substrate and coating and enhancing the integrity of the interface.

Figure 4.

Interface characteristics of MMC. (a) the optical OM observation interface; (b) the SEM observance interface; (c) the amplification result of Figure 4b.

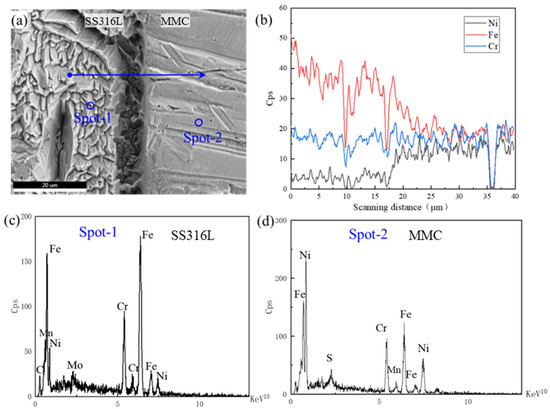

Figure 5 depicts the changes in the element content at the interface of the MMC layered composite materials. The test method progresses from left to right, representing the direction from the substrate. The Fe element and the Ni element serve as representative elements of 316L stainless steel and IN718 high-temperature alloy, respectively. In the EDS line scan shown in Figure 5a, the Ni element content exhibits an approximately linear increase while the Fe element content gradually decreases. Additionally, upon scanning the EDS line (Figure 5b), it was observed that there was almost no range of element transitions at the interface. To further verify this, EDS point analyses were conducted on both sides of the interface. The results confirmed that on the left side (Figure 5c), there is an area of SS316L stainless steel with high Fe content, while on the right side (Figure 5d), there is an area of IN718 reinforced with ceramics, exhibiting high Ni content. These findings highlight the distinct elemental compositions on either side of the interface, indicating a clear demarcation between the SS316L stainless steel and the IN718 high-temperature alloy reinforced with ceramics in the MMC layered composite materials.

Figure 5.

Analysis of the MMC interface elements content. (a) Interface morphology, (b) EDS line scanning results, (c) EDS point result of Spot-1, and (d) EDS point result of Spot-2.

3.2. Microhardness

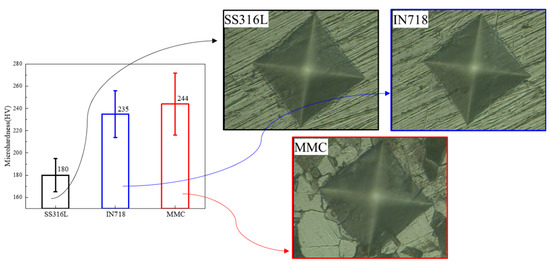

Figure 6 displays the results of the comparison of microhardness in different samples. The hardness of the SS316L substrate measures approximately 180 HV, while the hardness of the IN718 material manufactured through additive processes is around 235 HV. Due to the high toughness of both 316L stainless steel and IN718, no cracks were observed at the square indentation edges during the microhardness test. However, the addition of 5% (75% Cr2O3 + TiO2) ceramics led to a significant decrease in the ductility of the IN718 base composite material. Consequently, the edges of the square compressions showed noticeable fractures and collapse issues. This change in the microhardness and fracture behavior indicates the impact of the ceramic reinforcement on the mechanical properties of the IN718 base composite material. The presence of ceramics alters the material’s response to indentation, resulting in reduced ductility and an increased likelihood of fracture.

Figure 6.

Results of different microbial hardness tests.

3.3. Tensile Performance

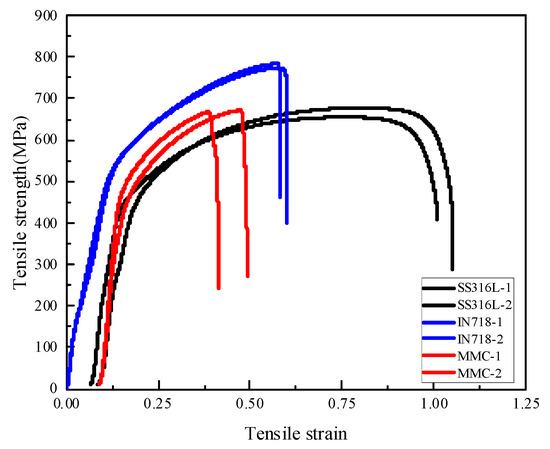

Figure 7 presents the tensile stress–strain curves for SS316L stainless steel, IN718, and MMC laminated composite materials. The yield strength of SS316L stainless steel is 419 MPa, and the tensile ultimate strength is 677 MPa. For IN718, the yield strength is 508 MPa, and the tensile ultimate strength is 783 MPa. The MMC laminated composite has a yield strength of about 440 MPa and a tensile ultimate strength of about 652 MPa. It is evident from the data that the tensile yield strength and tensile ultimate strength of the MMC laminated composite with 5% ceramics fall between those of SS316L stainless steel and IN718. However, the addition of ceramic particles in the MMC leads to a significant reduction in material toughness. This is evident from the noticeable reduction in tensile fracture elongation and the occurrence of cracks at the edges of hardness test indentations. These changes indicate that the mechanical properties of the deposited layer material have been affected by the presence of ceramics, leading to reduced ductility and increased brittleness.

Figure 7.

Tensile stress–strain curves of different samples.

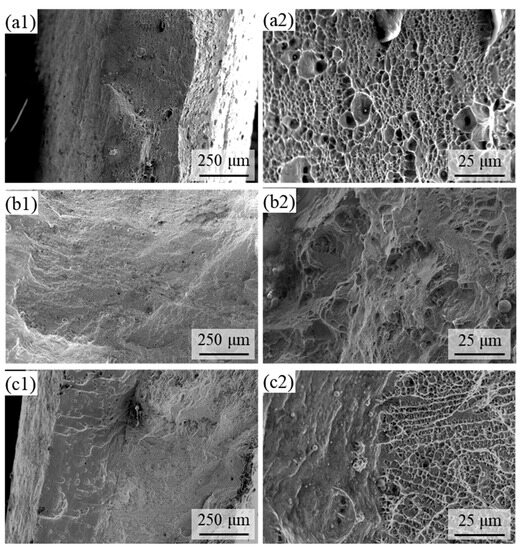

Figure 8 presents the fracture morphology after tensile testing. The surface of SS316L stainless steel is covered with dimples of various sizes, indicating good toughness and typical ductile fracture behavior. On the other hand, the fracture surface of IN718 in this experiment did not exhibit typical dimples, possibly due to the influence of the quality of the deposited powder, resulting in lower tensile elongation compared to SS316L stainless steel. The fracture surface of the MMC laminated composites also shows significant interface characteristics. One side of SS316L displays dense dimples, while the surface of the ceramic-reinforced composite on the other side is similar to the fracture surface of IN718, with a few small particles present. These observations contribute to the understanding of the reduced tensile elongation of the MMC laminated composites. The interface characteristics and the presence of ceramic particles appear to influence the fracture behavior and mechanical properties of the composite material during tensile testing.

Figure 8.

Tensile fracture morphologies of different samples. (a1,a2) SS316L, (b1,b2) IN718, (c1,c2) MMC.

3.4. Friction and Wear Performance

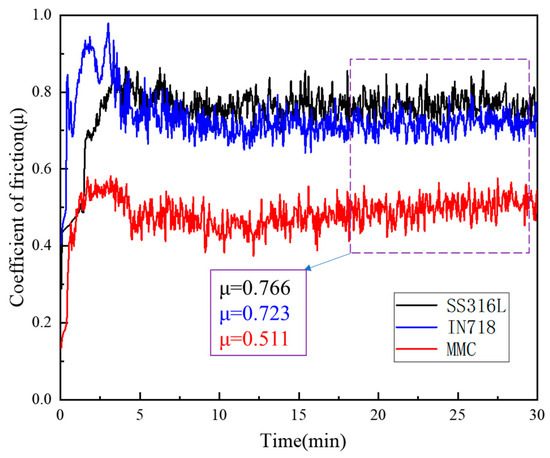

Figure 9 displays the time–friction coefficient for 316 stainless steel, IN718 alloy, and the MMC coating. The experiment was conducted over a period of 30 min. From the experimental results, it is evident that the addition of Cr2O3 and TiO2 as enhancements had a significant effect on the relative friction performance. After stabilizing, the friction coefficient for 316 stainless steel is 0.766, for IN718 alloy it is 0.723, and for MMC it is 0.511. The friction coefficient for MMC is notably lower compared to the other two materials. The reduction in the friction coefficient for MMC is attributed to the addition of Cr2O3 and TiO2 enhanced phase, which induces a significant chemical reaction leading to the formation of ceramics. This reaction is responsible for the decrease in the friction coefficient, making the MMC more effective in reducing friction compared to the other materials.

Figure 9.

Friction coefficient curves.

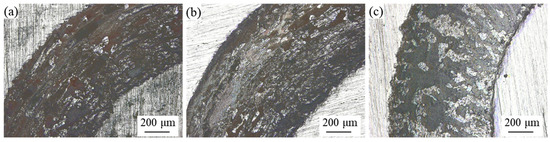

Figure 10 presents the actual morphology of the abraded surfaces of the three samples after friction and wear, as captured by laser confocal photography. The wear marks of SS316L and IN718 samples show similar appearances, with both exhibiting significant adhesion wear and abrasive wear. However, when a small amount of Cr2O3 and TiO2 enhancers are added, the friction and wear mechanism of the IN718 composite undergoes significant changes, primarily manifesting as adhesive wear. On the surface of the wear marks, there are numerous blocky materials, largely attributed to the addition of ceramic particles. This addition creates a substantial difference in hardness at the microscopic level, causing the matrix with lower hardness to be flattened upon contact with the grinding ball (SiC), resulting in adhesive wear. The introduction of Cr2O3 and TiO2 intensifiers alters the friction and wear behavior of the IN718 composite, and the resulting wear marks display distinct characteristics, indicating the influence of the ceramic reinforcement on the wear mechanism.

Figure 10.

Morphology of wear marks of different samples after 30 min of friction and wear test. (a) SS316L, (b) IN718, (c) MMC sediments.

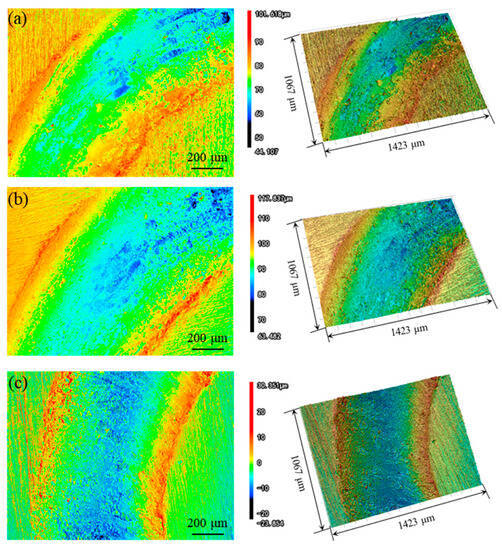

Figure 11 presents the three-dimensional morphology of wear marks from different samples. After horizontal calibration, color height analysis reveals distinct differences among the wear marks of SS316L stainless steel, IN718 superalloy, and MMC. The wear marks of SS316L stainless steel and IN718 superalloy are characterized by significant unevenness, and the wear marks of IN718 are not uniformly distributed. In contrast, the wear marks of the MMC sediments appear relatively uniform. After friction and wear, the edges of the wear marks extend beyond the base level. Upon analysis, the peak-to-peak value of the wear marks for SS316L is 57 μm, for IN718 is 84 μm, and for MMC is 53 μm. These measurements indicate the extent of wear and unevenness experienced by the respective materials during friction and wear testing. The results further highlight the impact of ceramic reinforcement on the wear behavior and wear mark morphology of the MMC composite.

Figure 11.

The three-dimensional shape of different samples 30 min after the friction wear test. (a) SS316L, (b) IN718, (c) MMC sedimentary layer.

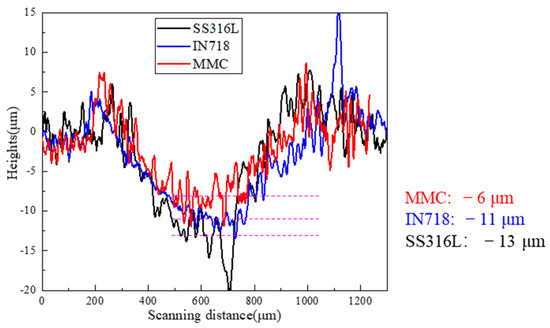

Figure 12 provides a detailed analysis of the shape and size of abrasions in different samples. The key observation index is the mean depth of the abrasion center. The results reveal that the MMC has the smallest abrasion depth, measuring approximately 6 μm. On the other hand, SS316L stainless steel, due to its lower hardness, exhibits the largest average wear depth, reaching about 13 μm. From the analysis conducted so far, it is evident that higher hardness in the materials used in this experiment correlates with better wear resistance, smaller wear coefficient, and reduced average abrasion. This emphasizes the importance of material hardness in determining wear performance and highlights the advantages of MMC sediments with enhanced ceramic reinforcement in terms of wear resistance.

Figure 12.

Different samples in the intersection shape 30 min after the friction wear test.

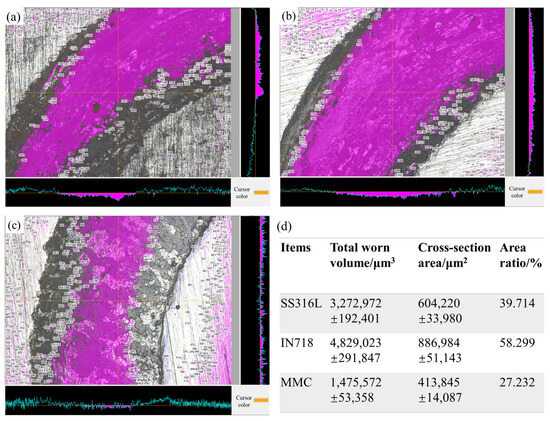

Figure 13 presents the analysis of wear performance based on wear volume. In this analysis, all reference levels are unworn areas on both sides, and multiple tests were conducted to determine the levels. The results indicate that, when analyzing areas of the same size, the total wear loss of SS316L stainless steel is the largest, approximately 3,272,972 μm3, and the wear area is 604,220 μm2, accounting for about 39.7% of the analyzed area. Conversely, MMC exhibits the lowest wear volume (1,475,572 μm3), smallest wear area (413,845 μm2), and the lowest area ratio (27.2%) of all the samples. Interestingly, the wear amount of IN718 superalloy is greater than that of SS316L stainless steel. The wear volume, wear area, and area proportion for IN718 are 4,829,023 μm3, 886,984 μm2, and 58.2%, respectively. This phenomenon is different from the wear depth results. Further analysis of the purple grooves in the wear scars reveals that the measurable areas below the horizontal surface of IN718 are significantly higher than those of SS316L and MMC, leading to a larger calculated volume of wear for IN718. This highlights the importance of considering wear volume as a comprehensive metric for evaluating wear performance, as it provides a more comprehensive understanding of the wear behavior in different materials.

Figure 13.

Different sample volume/area measurements in 30 min after the friction wear test. (a) SS316L, (b) IN718, (c) MMC layer of sedimentation, (d) comparison of wear loss.

3.5. Discussion

Ceramic particles have been utilized as reinforcing phases to enhance the properties of depositing coatings. Specifically, the presence of refined grains and precipitated needle-like phases can lead to improvements in hardness, strength, and chemical stability of the composite coating by inhibiting grain growth or replacing strengthening particles [16]. As a result, the microstructure morphology undergoes significant changes upon the addition of 5% (75% Cr2O3 + TiO2) ceramics. The long-chain Laves phase in the deposited layer transforms into short particles, and their size is significantly reduced (Figure 3). The composite coatings exhibit good metallurgical bonding with the substrate, and no obvious defects are found at the juncture. Tan et al. [27] have found that there is an optimum value for the content of ceramic reinforcement in the coating. At lower values, the enhancement from the ceramic reinforcement is not significant, while at excessive values, the reinforcement may agglomerate within the coating, becoming a potential source of cracks. The addition of ceramics leads to improvements in yield strength and ultimate tensile strength for both SS316L stainless steel and IN718. It also results in a decrease in the friction coefficient and wear depth, indicating enhanced wear resistance. However, for IN718, the wear volume increases after adding ceramics, possibly due to the presence of agglomerated reinforcement affecting wear behavior. Overall, the addition of ceramics has a positive impact on the mechanical properties of the composite coatings. Table 1 summarizes the changes in mechanical properties after adding ceramics to SS316L stainless steel and IN718.

Table 1.

Mechanical properties of SS316L and IN718 matrix composites with different ceramics.

The addition of ceramic particles indeed has a significant impact on the hardness and brittleness of the material. First, the microhardness of the MMC is notably higher, even with only 5% ceramics added. The microhardness increases from 180 HV of SS316L stainless steel and 235 HV of IN718 to 244 HV. Second, while both SS316L stainless steel and IN718 exhibit good plasticity, the MMC shows lower plasticity, leading to the appearance of numerous tiny cracks around the edges of the quadrilateral indentations in the microhardness test (Figure 6). This decrease in plasticity is due to the presence of ceramic reinforcements, which contribute to the higher hardness of the MMC coating compared to the substrate. Similar findings were observed by Cai et al. [11], where the microhardness of MMC coatings was significantly enhanced with increasing ceramic reinforcement content, resulting in increased microhardness of the substrate. Furthermore, the tensile stress–strain curves also confirm that the addition of ceramic particles reduces the plasticity of the MMC (Figure 7). The elongation of the MMC is significantly lower than that of SS316L or IN718. This reduction in plasticity is attributed to the strengthening effect of the added ceramic particles, leading to a more brittle behavior in the MMC compared to the base materials.

Based on the observed improvement in microhardness, the addition of ceramic particles indeed enhances the wear resistance of the deposition layer (Figure 9). Similar findings were reported by Cai et al. [11], who found that the wear volume loss and wear weight loss decreased with the increase in ceramic reinforcement content, indicating that the wear resistance of the coating exhibits a similar trend with microhardness. Singh et al. [48] also reported that an increase in microhardness effectively enhances the wear resistance of composite coatings. The examination of wear morphology in Figure 10 further supports these findings, as the addition of ceramics leads to significant changes in the wear mechanism, resulting in the presence of numerous blocky materials at the bottom of the wear marks. Moreover, compared to SS316L or IN718, MMC displays the smallest wear depth (Figure 11) and the lowest volume of wear marks (Figure 13), providing additional evidence that the addition of ceramic particles contributes to the improvement of wear resistance in the deposited layer. These findings collectively demonstrate that the incorporation of ceramic particles plays a crucial role in enhancing the wear resistance of the composite coating.

4. Conclusions

The addition of ceramic particles has a significant impact on the metal materials in additive manufacturing, particularly in the formation of composite materials. In this study, 5% (75% Cr2O3 + TiO2) ceramic particles were added to the IN718 matrix, resulting in the formation of MMC laminated composite materials. Through in-depth analysis of microstructure and properties, the following discussions were made:

(1) Microstructural Changes: The addition of ceramic particles induces noticeable microstructural changes in the composite material. The original long-chain Laves phase transforms into short particles with a significantly reduced size. This refinement of microstructure contributes to improved hardness, strength, and chemical stability of the material. Moreover, the good metallurgical bonding between the metal matrix and ceramic particles ensures the absence of significant defects at the interface, thereby enhancing the overall performance of the composite material.

(2) Mechanical Properties: The addition of ceramic particles significantly increases the hardness of the composite material, resulting in a higher microhardness compared to SS316L stainless steel and IN718 alloy. However, this enhancement in hardness also leads to a reduction in plasticity, as evidenced by the appearance of noticeable cracks at the edges of the quadrilateral indentations during microhardness testing. The tensile yield strength and tensile ultimate strength of the MMC laminated composite fall between those of SS316L stainless steel and IN718.

(3) Wear Resistance: The addition of ceramic particles considerably enhances the wear resistance of the composite material, leading to a lower friction coefficient compared to SS316L and IN718. Microscopic examination of the wear marks reveals the presence of blocky materials at the bottom, indicating a change in the wear mechanism. Furthermore, MMC exhibits the smallest wear volume and area, indicating superior wear resistance.

In conclusion, the addition of ceramic particles significantly improves the hardness and wear resistance of the composite material. However, it also reduces plasticity. Further research could focus on optimizing the content and size of ceramic reinforcements to strike a balance between hardness and toughness, thus preventing brittle fractures in the composite material. These findings contribute to the design and application of ceramic-enhanced metal matrix composites in diverse engineering applications.

Author Contributions

Conceptualization, L.L. and P.L.; methodology, Q.Y., Z.X. and P.L.; software, Q.Y. and L.L.; validation, Q.Y. and L.L.; formal analysis, Q.Y., L.L. and P.L.; investigation, L.L. and Z.X.; resources, Z.X. and P.L.; data curation, Q.Y. and P.L.; writing—original draft preparation, Q.Y., Z.X. and P.L.; writing—review and editing, Q.Y., Z.X. and P.L.; visualization, L.L. and P.L.; supervision, L.L., Z.X. and P.L.; project administration, P.L.; funding acquisition, P.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (No. 52305363), the National Science and Technology Major Project (2017ZX04001001), the National Science Foundation of Jiangsu Province (No. BK20210758), China Postdoctoral Science Foundation Funded Project (No. 2022M710060), and Jiangsu Key Laboratory of Green Process Equipment (No. GPE202305).

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Xue, A.; Lin, X.; Wang, L.; Lu, X.; Ding, H.; Huang, W. Heat-affected coarsening of β grain in titanium alloy during laser directed energy deposition. Scr. Mater. 2021, 205, 114180. [Google Scholar] [CrossRef]

- Qi, K.; Yang, Y.; Liang, W.; Jin, K.; Xiong, L. Effect of magnetic field on the microstructure and wear properties of TiB2/metal composite layers synthesized in situ by laser cladding on Ti–6Al–4V alloy. Ceram. Int. 2021, 47, 29463–29474. [Google Scholar] [CrossRef]

- Zhang, M.; Li, M.; Wang, S.; Chi, J.; Ren, L.; Fang, M.; Zhou, C. Enhanced wear resistance and new insight into microstructure evolution of in-situ (Ti, Nb)C reinforced 316 L stainless steel matrix prepared via laser cladding. Opt. Lasers Eng. 2020, 128, 106043. [Google Scholar] [CrossRef]

- Li, P.; Zhou, J.; Li, L.; Gong, Y.; Lu, J.; Meng, X. Influence of depositing sequence and materials on interfacial characteristics and mechanical properties of laminated composites. Mater. Sci. Eng. A 2021, 827, 142092. [Google Scholar] [CrossRef]

- Pfeiffer, S.; Florio, K.; Puccio, D.; Grasso, M.; Colosimo, B.M.; Aneziris, C.G.; Wegener, K.; Graule, T. Direct laser additive manufacturing of high performance oxide ceramics: A state-of-the-art review. J. Eur. Ceram. Soc. 2021, 41, 6087–6114. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The role of additive manufacturing in the era of industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Stojanovic, B.; Glisovic, J. Application of Ceramic Matrix Composite in Automotive Industry; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; Volume 2, ISBN 9780128197318. [Google Scholar]

- Wang, Z.; Lin, T.; He, X.; Shao, H.; Tang, B.; Qu, X. Fabrication and properties of the TiC reinforced high-strength steel matrix composite. Int. J. Refract. Met. Hard Mater. 2016, 58, 14–21. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, D.; Cong, W. Feasibility study of adding buffer layers for the laser deposition of high-ceramic content (TiB + TiC)–Ti coatings using B4C/Ti powders. Ceram. Int. 2022, 48, 23387–23396. [Google Scholar] [CrossRef]

- Gu, D.; Zhang, H.; Dai, D.; Xia, M.; Hong, C.; Poprawe, R. Laser additive manufacturing of nano-TiC reinforced Ni-based nanocomposites with tailored microstructure and performance. Compos. Part B Eng. 2019, 163, 585–597. [Google Scholar] [CrossRef]

- Cai, Y.; Luo, Z.; Feng, M.; Liu, Z.; Huang, Z.; Zeng, Y. The effect of TiC/Al2O3 composite ceramic reinforcement on tribological behavior of laser cladding Ni60 alloys coatings. Surf. Coat. Technol. 2016, 291, 222–229. [Google Scholar] [CrossRef]

- Li, P.; Yang, Q.; Li, L.; Gong, Y.; Zhou, J.; Lu, J. Microstructure evolution and mechanical properties of in situ synthesized ceramic reinforced 316L / IN718 matrix composites. J. Manuf. Process. 2023, 93, 214–224. [Google Scholar] [CrossRef]

- Li, P.; Liu, J.; Liu, B.; Li, L.; Zhou, J.; Meng, X.; Lu, J. Microstructure and mechanical properties of in-situ synthesized Ti (N, C) strengthen IN718/1040 steel laminate by directed energy deposition. Mater. Sci. Eng. A 2022, 846, 143247. [Google Scholar] [CrossRef]

- Xia, P.; Wu, Y.; Yin, T.; Xie, K.; Tan, Y. Formation mechanism of TiC–Al2O3 ceramic reinforcements and the influence on the property of ZL101 composites. Ceram. Int. 2022, 48, 2577–2584. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, T.; Guan, C.; Sun, J.; Tan, X. Microstructure and friction coefficient of ceramic (TiC, TiN and B4C) reinforced Ni-based coating by laser cladding. Ceram. Int. 2019, 45, 20824–20836. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, L.; Sun, J.; Wu, W.; Yu, T. Microstructure evolution and wear resistance of in-situ synthesized (Ti, Nb) C ceramic reinforced Ni204 composite coatings. Ceram. Int. 2022, 48, 17518–17528. [Google Scholar] [CrossRef]

- Sam, M.; Radhika, N. Influence of carbide ceramic reinforcements in improving tribological properties of A333 graded hybrid composites. Def. Technol. 2022, 18, 1107–1123. [Google Scholar] [CrossRef]

- Włodarczyk-Fligier, A.; Dobrzański, L.A.; Adamiak, M. Wear resistance of PM composite materials reinforced with the Ti (C, N) ceramic particles. J. Achiev. Mater. Manuf. Eng. 2008, 30, 147–150. [Google Scholar]

- Solodkyi, I.; Bogomol, I.; Bolbut, V.; Loboda, P.; Kuncser, A.; Vasylkiv, O.; Badica, P. Hierarchical composites of B4C–TiB2 eutectic particles reinforced with Ti. Ceram. Int. 2020, 46, 28132–28144. [Google Scholar] [CrossRef]

- Yang, L.; Yu, T.; Li, M.; Zhao, Y.; Sun, J. Microstructure and wear resistance of in-situ synthesized Ti (C, N) ceramic reinforced Fe-based coating by laser cladding. Ceram. Int. 2018, 44, 22538–22548. [Google Scholar] [CrossRef]

- Yan, G.; Zheng, M.; Ye, Z.; Gu, J.; Li, C.; Wu, C.; Wang, B. In-situ Ti (C, N) reinforced AlCoCrFeNiSi-based high entropy alloy coating with functional gradient double-layer structure fabricated by laser cladding. J. Alloys Compd. 2021, 886, 161252. [Google Scholar] [CrossRef]

- Xi, L.; Ding, K.; Gu, D.; Guo, S.; Cao, M.; Zhuang, J.; Lin, K.; Okulov, I.; Sarac, B.; Eckert, J. Interfacial structure and wear properties of selective laser melted Ti/(TiC + TiN) composites with high content of reinforcements. J. Alloys Compd. 2021, 870, 159436. [Google Scholar] [CrossRef]

- Pazhouhanfar, Y.; Namini, A.S.; Delbari, S.A.; Nguyen, T.P.; Van Le, Q.; Shaddel, S.; Pazhouhanfar, M.; Shokouhimehr, M.; Asl, M.S. Microstructural and mechanical characterization of spark plasma sintered TiC ceramics with TiN additive. Ceram. Int. 2020, 46, 18924–18932. [Google Scholar] [CrossRef]

- Yang, H.-Y.; Wang, Z.; Chen, L.-Y.; Shu, S.-L.; Qiu, F.; Zhang, L.-C. Interface formation and bonding control in high-volume-fraction (TiC + TiB2)/Al composites and their roles in enhancing properties. Compos. Part B Eng. 2021, 209, 108605. [Google Scholar] [CrossRef]

- Wang, M.; Cui, H.; Wei, N.; Ding, L.; Zhang, X.; Zhao, Y.; Wang, C.; Song, Q. A new design of in situ Ti (C, N) reinforced composite coatings and their microstructures, interfaces, and wear resistances. ACS Appl. Mater. Interfaces 2018, 10, 4250–4265. [Google Scholar] [CrossRef]

- Liu, L.; Li, Y.; Zhang, H.; Cheng, X.; Fan, Q.; Mu, X.; Guo, S. Good strength-plasticity compatibility in graphene nanoplatelets/Ti composites by strengthening the interface bonding via in-situ formed TiB whisker. Ceram. Int. 2021, 47, 4338–4343. [Google Scholar] [CrossRef]

- Tan, H.; Luo, Z.; Li, Y.; Yan, F.; Duan, R. Microstructure and wear resistance of Al2O3–M7C3/Fe composite coatings produced by laser controlled reactive synthesis. Opt. Laser Technol. 2015, 68, 11–17. [Google Scholar] [CrossRef]

- AlMangour, B.; Kim, Y.K.; Grzesiak, D.; Lee, K.A. Novel TiB2-reinforced 316L stainless steel nanocomposites with excellent room- and high-temperature yield strength developed by additive manufacturing. Compos. Part B Eng. 2019, 156, 51–63. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Yang, J.M. Selective laser melting of TiB2/316L stainless steel composites: The roles of powder preparation and hot isostatic pressing post-treatment. Powder Technol. 2017, 309, 37–48. [Google Scholar] [CrossRef]

- Das, A.; Yadav, V.; AlMangour, B.; Prasad, H.C.; Sathish, N.; Ashiq, M.; Srivastava, A.K. Additive manufacturing of graphene reinforced 316L stainless steel composites with tailored microstructure and mechanical properties. Mater. Chem. Phys. 2023, 303, 127826. [Google Scholar] [CrossRef]

- Li, B.; Wang, T.; Li, P.; Wang, S.; Wang, L. Selective laser melting of 316L stainless steel: Influence of Co-cr-mo-w addition on corrosion resistance. Metals 2021, 11, 597. [Google Scholar] [CrossRef]

- AlMangour, B.; Baek, M.S.; Grzesiak, D.; Lee, K.A. Strengthening of stainless steel by titanium carbide addition and grain refinement during selective laser melting. Mater. Sci. Eng. A 2018, 712, 812–818. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, J.; Bai, P.; Qu, H.; Liang, M.; Liao, H.; Wu, L.; Huo, P.; Liu, H.; Zhang, J. Microstructure and mechanical properties of tic-reinforced 316l stainless steel composites fabricated using selective laser melting. Metals 2019, 9, 267. [Google Scholar] [CrossRef]

- Salman, O.; Funk, A.; Waske, A.; Eckert, J.; Scudino, S. Additive Manufacturing of a 316L Steel Matrix Composite Reinforced with CeO2 Particles: Process Optimization by Adjusting the Laser Scanning Speed. Technologies 2018, 6, 25. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Borkar, T.; Yang, J.M. Densification behavior, microstructural evolution, and mechanical properties of TiC/316L stainless steel nanocomposites fabricated by selective laser melting. Mater. Des. 2018, 138, 119–128. [Google Scholar] [CrossRef]

- Riquelme, A.; Sánchez de Rojas Candela, C.; Rodrigo, P.; Rams, J. Influence of process parameters in additive manufacturing of highly reinforced 316L/SiCp composites. J. Mater. Process. Technol. 2022, 299, 117325. [Google Scholar] [CrossRef]

- Almangour, B.; Grzesiak, D.; Yang, J.M. Rapid fabrication of bulk-form TiB2/316L stainless steel nanocomposites with novel reinforcement architecture and improved performance by selective laser melting. J. Alloys Compd. 2016, 680, 480–493. [Google Scholar] [CrossRef]

- Ning, J.; Lan, Q.; Zhu, L.; Xu, L.; Yang, Z.; Xu, P.; Xue, P.; Xin, B. Microstructure and mechanical properties of SiC-reinforced Inconel 718 composites fabricated by laser cladding. Surf. Coat. Technol. 2023, 463, 129514. [Google Scholar] [CrossRef]

- Meng, G.; Zhu, L.; Zhang, J.; Yang, Z.; Xue, P. Statistical analysis and multi-objective process optimization of laser cladding TiC-Inconel718 composite coating. Optik 2021, 240, 166828. [Google Scholar] [CrossRef]

- Zhang, J.; Meng, G.; Zhu, L.; Yang, Z.; Xue, P.; Xu, P. Formation mechanism and mechanical properties of TiC reinforced Inconel 718 composite coatings by laser cladding on H13 steel. Int. J. Adv. Manuf. Technol. 2022, 121, 3597–3611. [Google Scholar] [CrossRef]

- Hong, C.; Gu, D.; Dai, D.; Gasser, A.; Weisheit, A.; Kelbassa, I.; Zhong, M.; Poprawe, R. Laser metal deposition of TiC/Inconel 718 composites with tailored interfacial microstructures. Opt. Laser Technol. 2013, 54, 98–109. [Google Scholar] [CrossRef]

- He, S.; Park, S.; Shim, D.S.; Yao, C.; Zhang, W.J. Study on microstructure and abrasive behaviors of inconel 718-WC composite coating fabricated by laser directed energy deposition. J. Mater. Res. Technol. 2022, 21, 2926–2946. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, J. Effect of post heat treatment on the microstructure and tensile properties of nano TiC particulate reinforced inconel 718 by selective laser melting. J. Manuf. Sci. Eng. Trans. 2020, 142, 051004. [Google Scholar] [CrossRef]

- Tang, B.; Tan, Y.; Zhang, Z.; Xu, T.; Sun, Z.; Li, X. Effects of process parameters on geometrical characteristics, microstructure and tribological properties of TiB2 reinforced inconel 718 alloy composite coatings by laser cladding. Coatings 2020, 10, 76. [Google Scholar] [CrossRef]

- Sun, X.; Ren, X.; Qiang, W.; Feng, Y.; Zhao, X.; Huang, B. Microstructure and properties of Inconel 718 matrix composite coatings reinforced with submicron TiC particles prepared by laser cladding. Appl. Surf. Sci. 2023, 637, 157920. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, J.; Wang, J.; Meng, X.; Li, P.; Huang, S.; Zhu, H. Effect of hybrid ultrasonic-electromagnetic field on cracks and microstructure of Inconel 718/60% WC composites coating fabricated by laser cladding. Ceram. Int. 2022, 48, 33901–33913. [Google Scholar] [CrossRef]

- Vasudev, H.; Thakur, L.; Singh, H.; Bansal, A. Effect of addition of Al2O3 on the high-temperature solid particle erosion behaviour of HVOF sprayed Inconel-718 coatings. Mater. Today Commun. 2022, 30, 103017. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, D.; Mishra, S.K.; Tiwari, S.K. Laser cladding of Stellite 6 on stainless steel to enhance solid particle erosion and cavitation resistance. Surf. Coat. Technol. 2014, 251, 87–97. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).