Numerical Simulation of Thermal Field and Performance Study on H13 Die Steel-Based Wire Arc Additive Manufacturing

Abstract

:1. Introduction

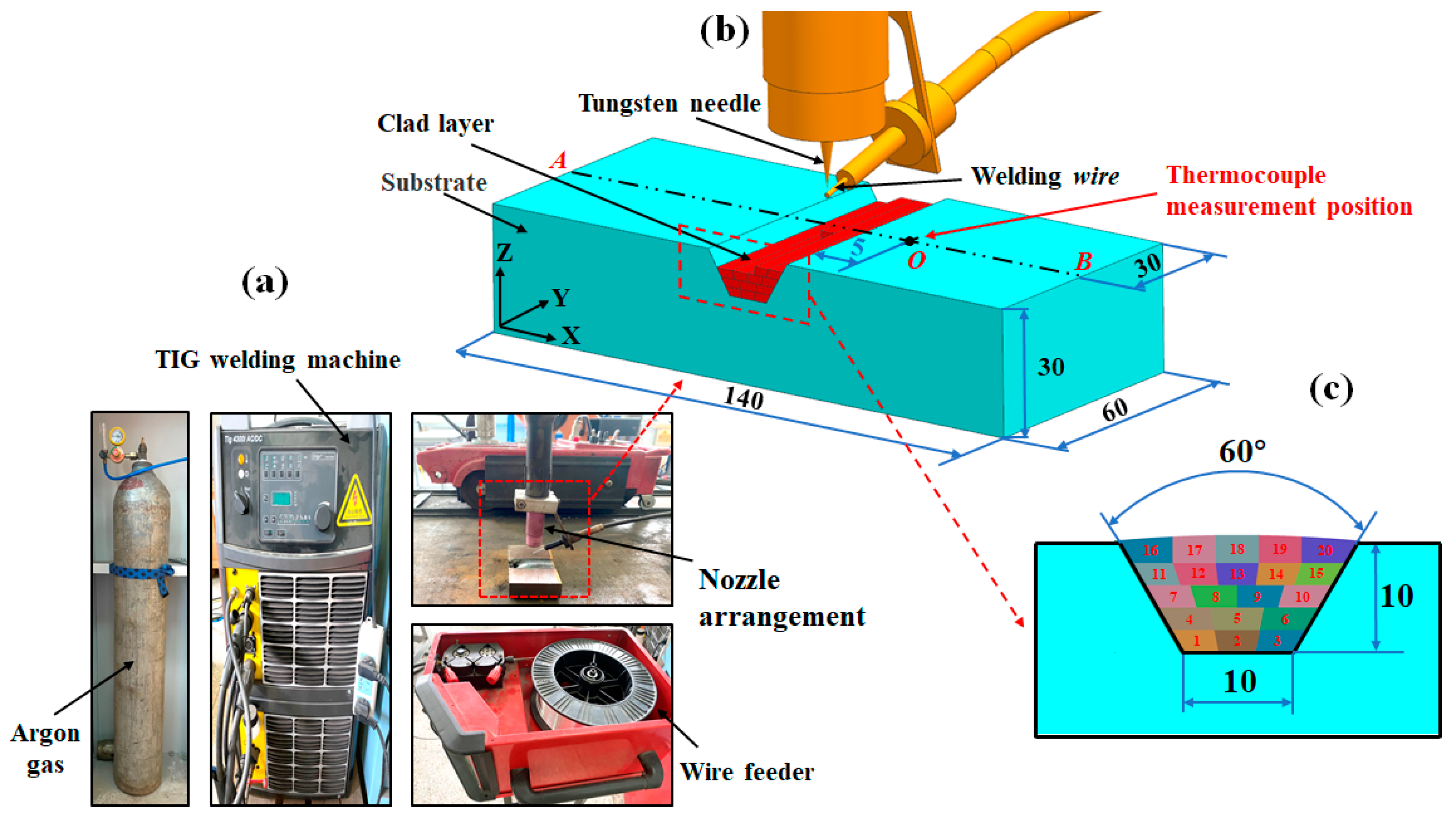

2. Experiments and Methods

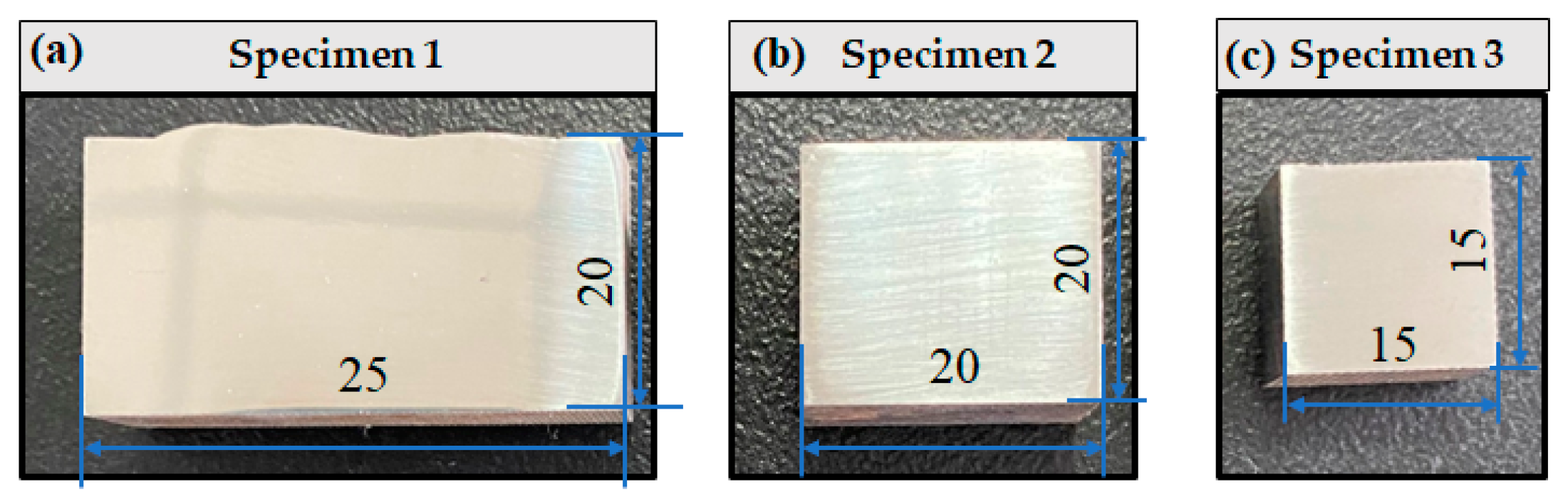

2.1. Materials and Procedures

2.2. Measurement of Thermal History, Residual Stress, Microstructure, and Mechanical Performance

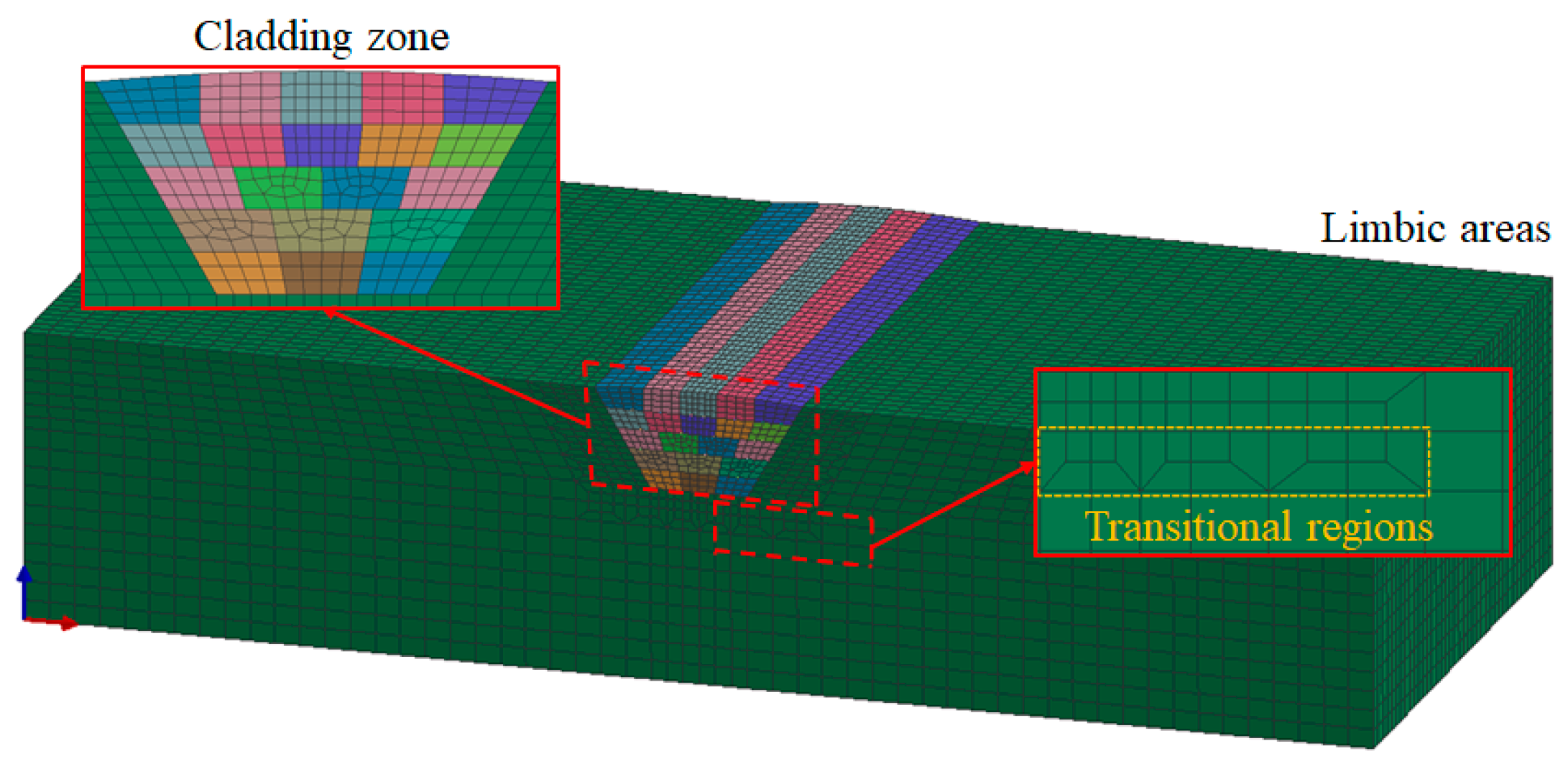

3. Numerical Simulation

3.1. Finite Element Mode

3.2. Thermal Physical Performance Parameters of the Material

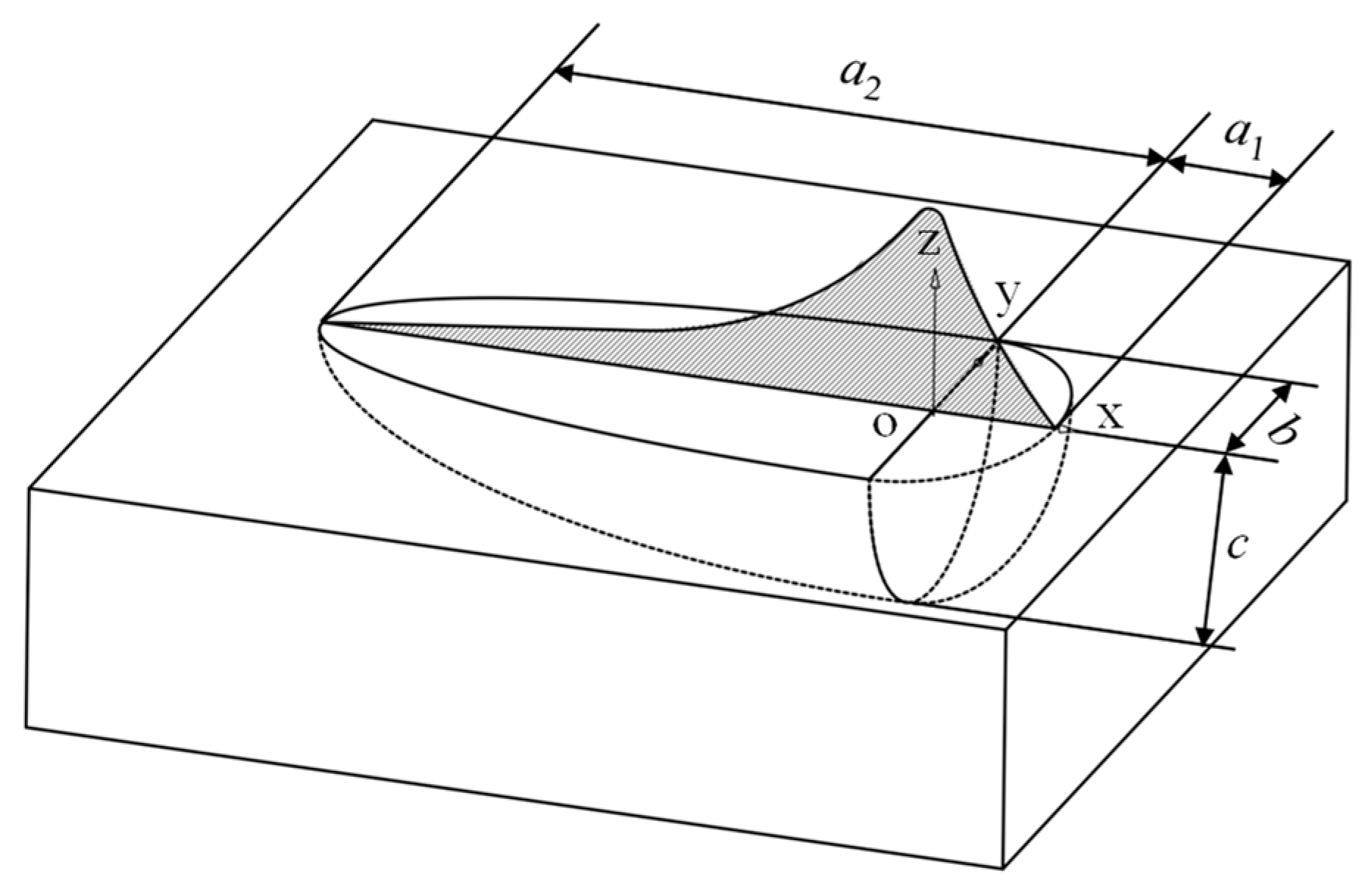

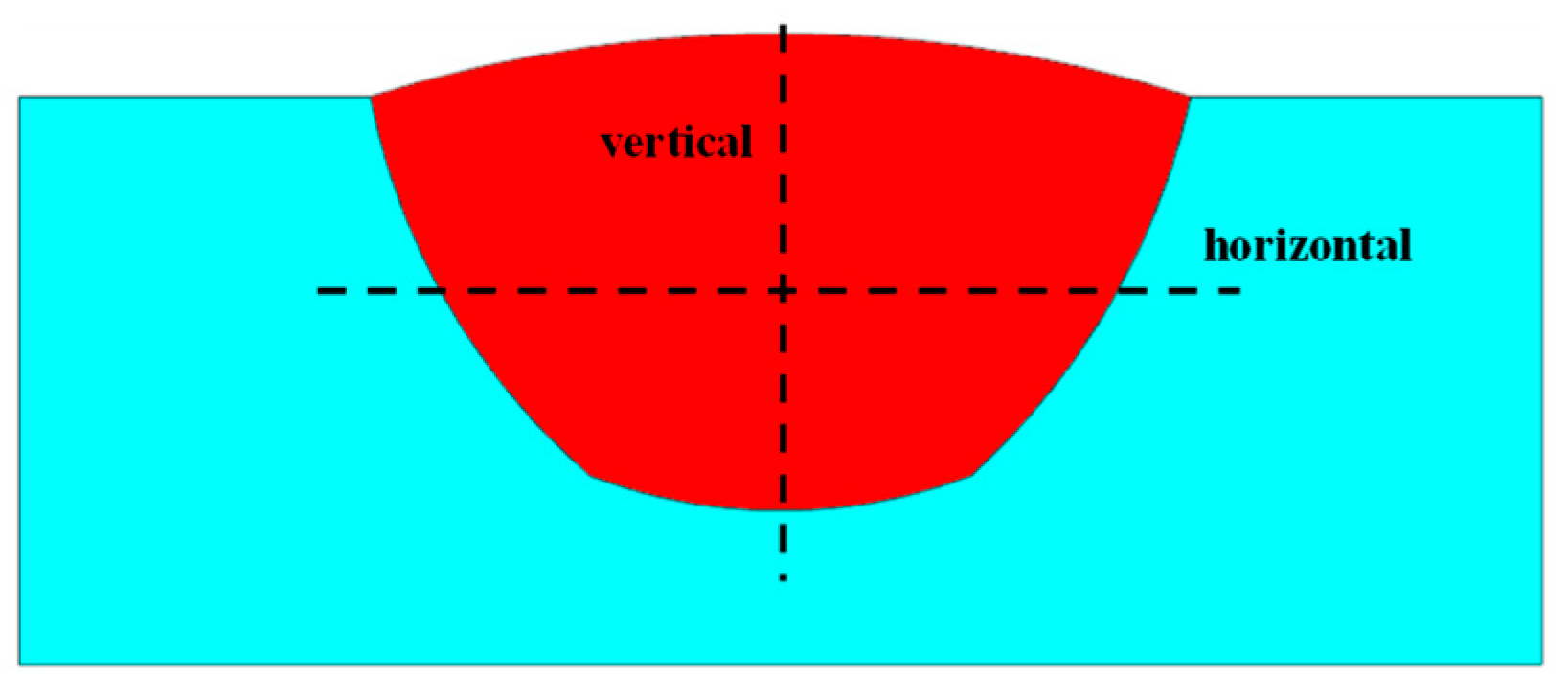

3.3. Thermal Source Model and Boundary Conditions

4. Results and Discussion

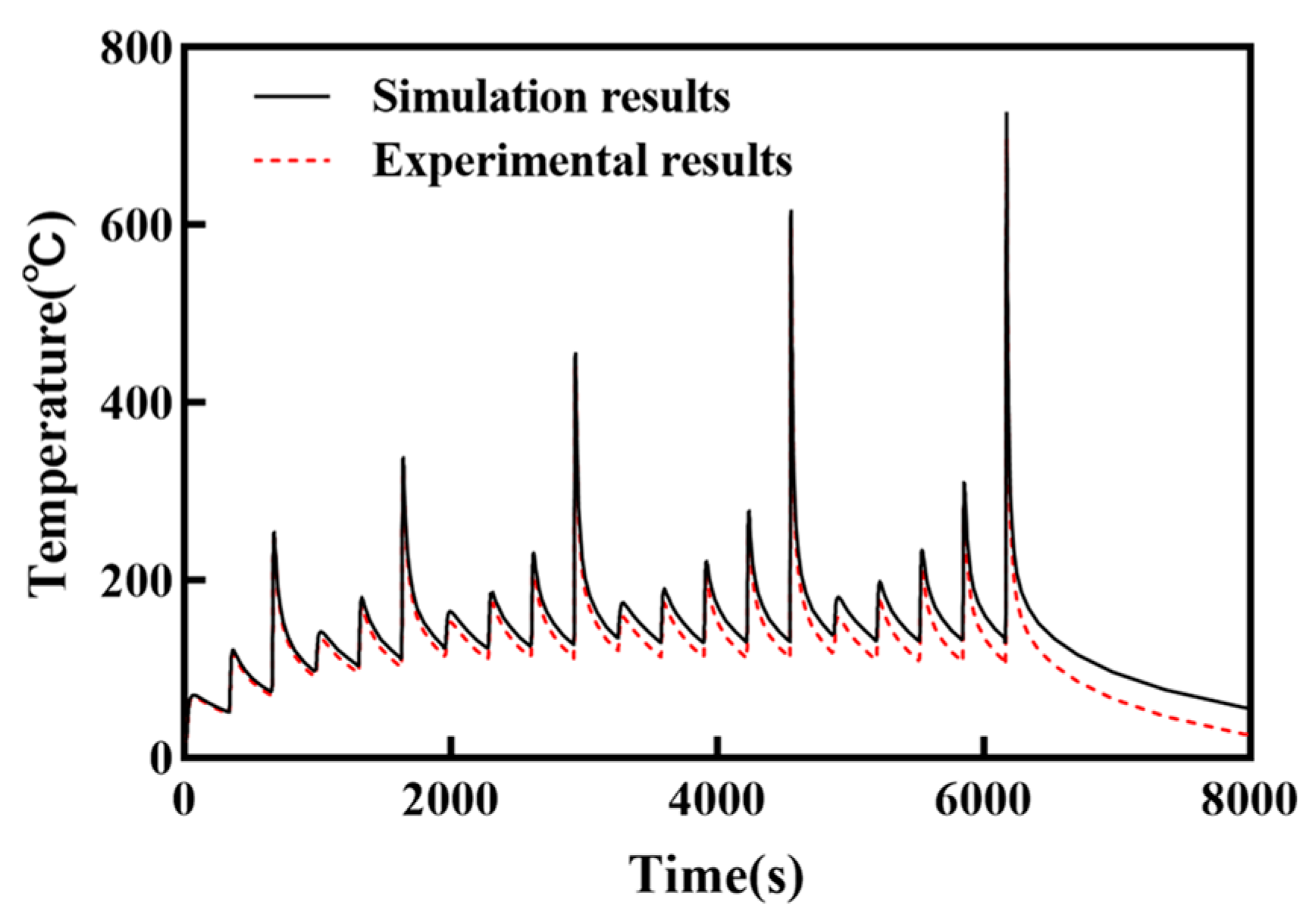

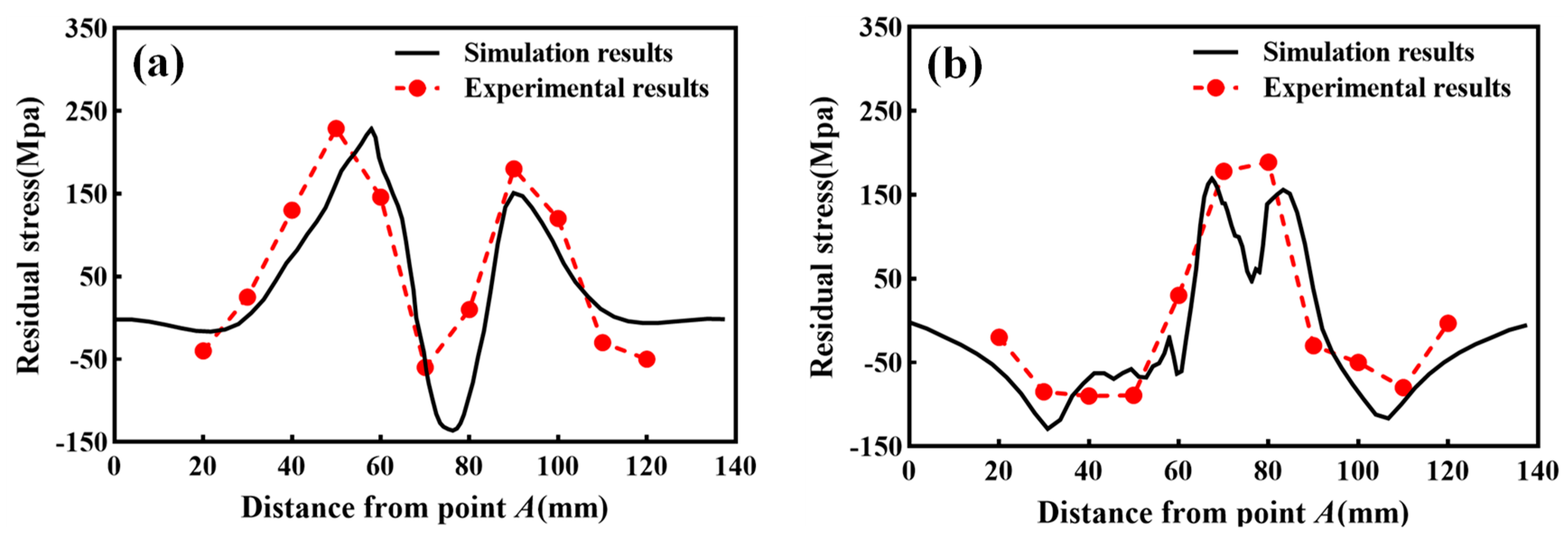

4.1. Comparison between the Simulation and Experimental Results

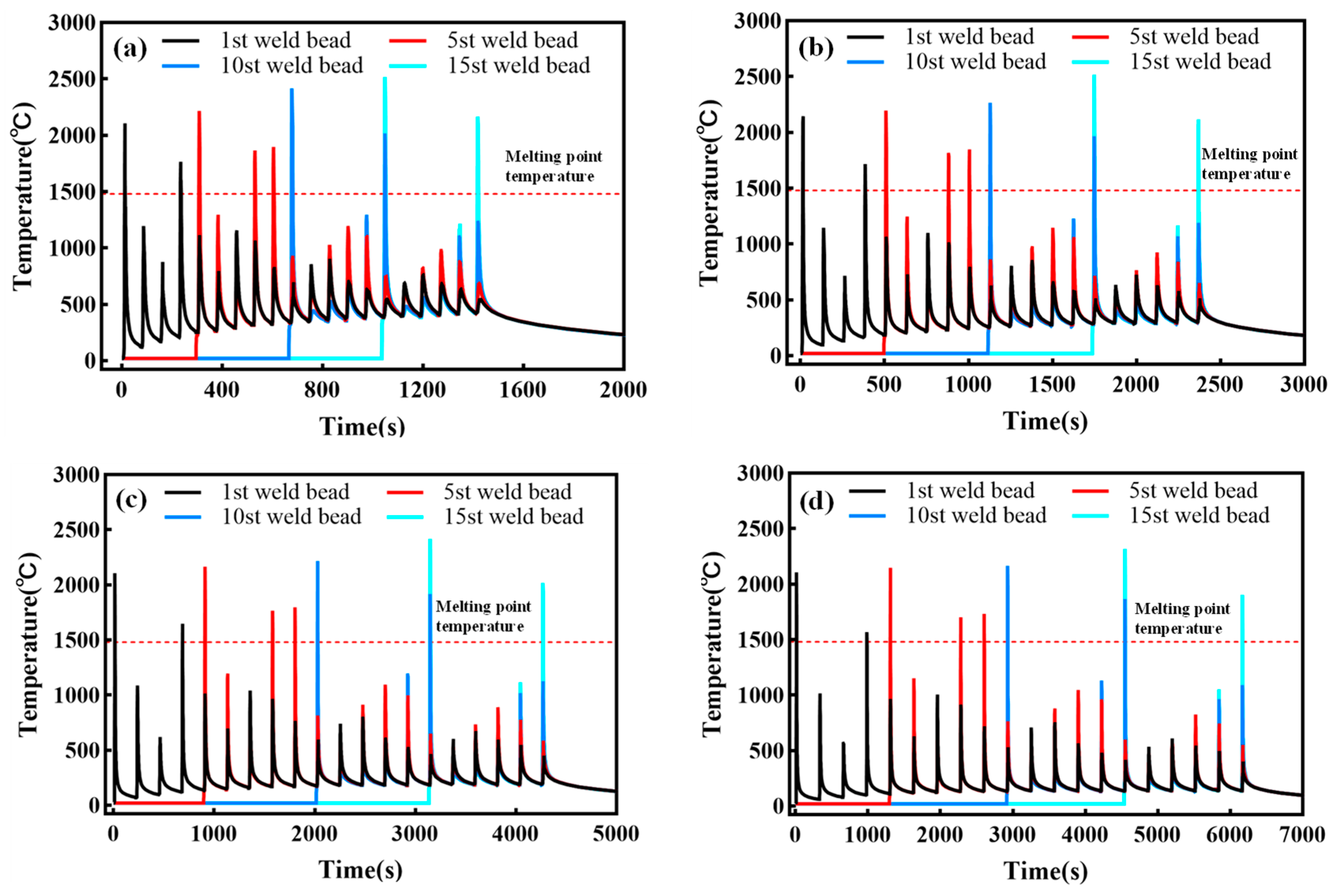

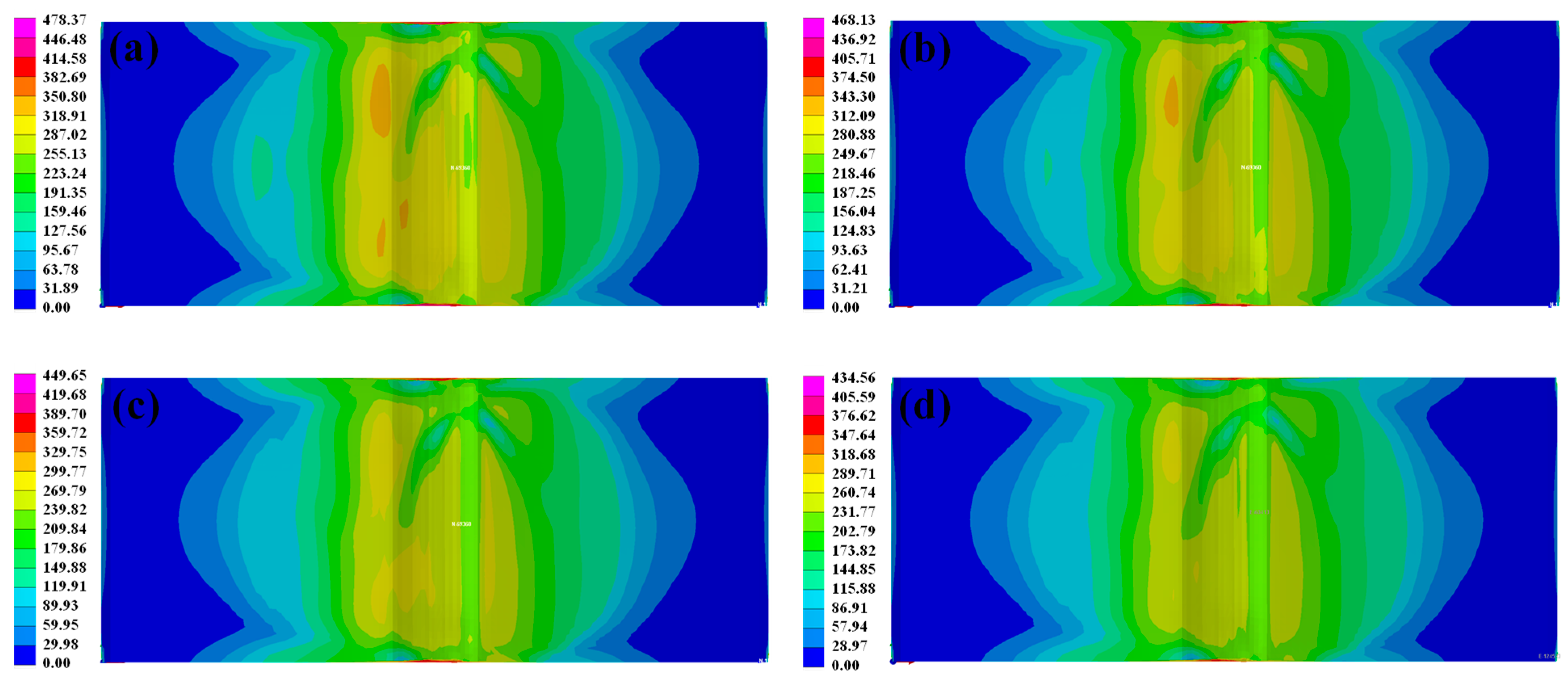

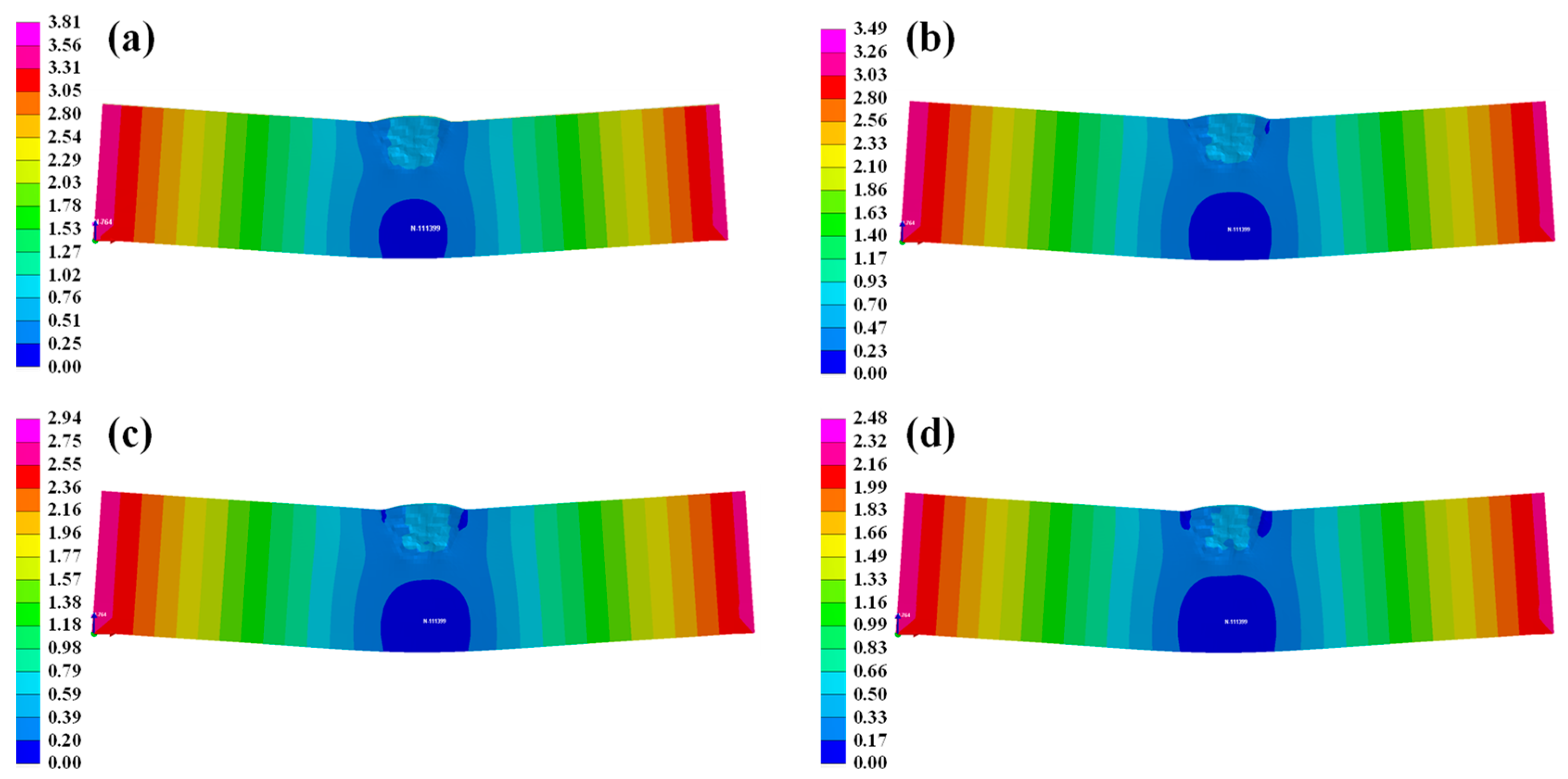

4.2. The Thermal Field and Deformation for Different Inter-Layer Cooling Time

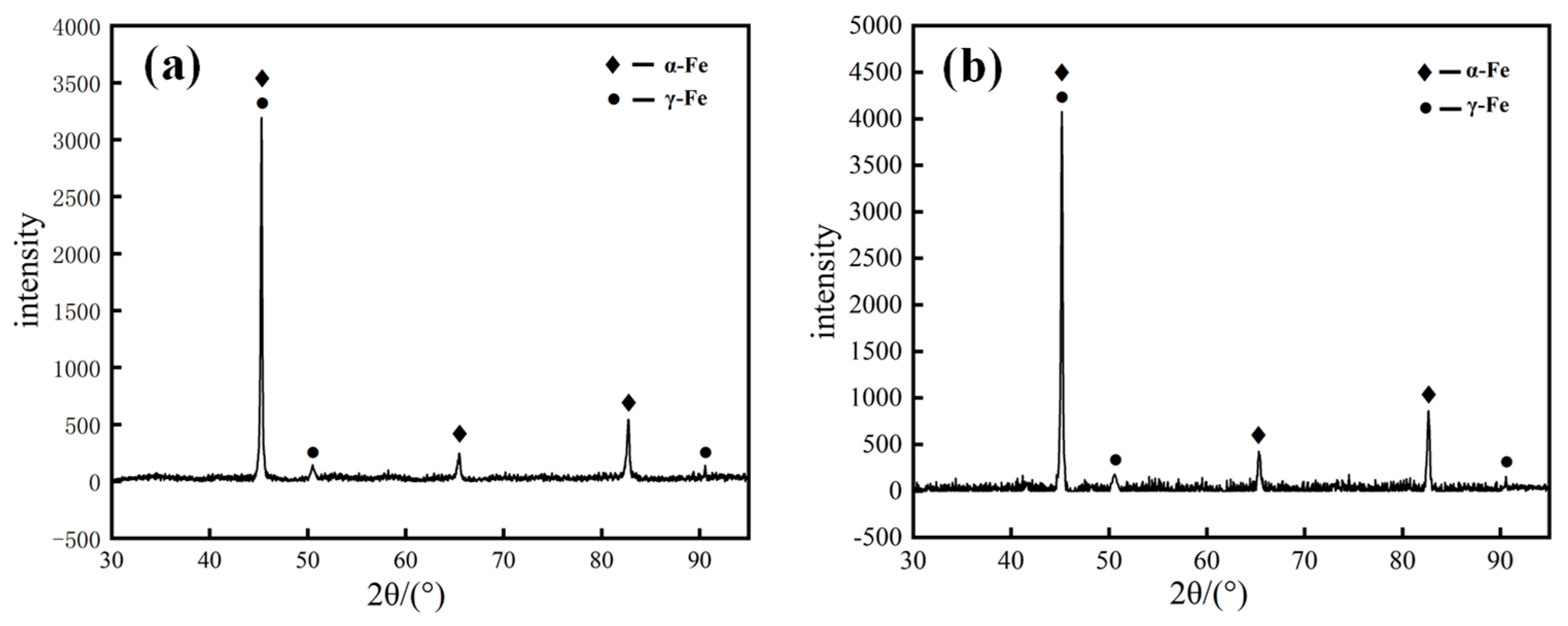

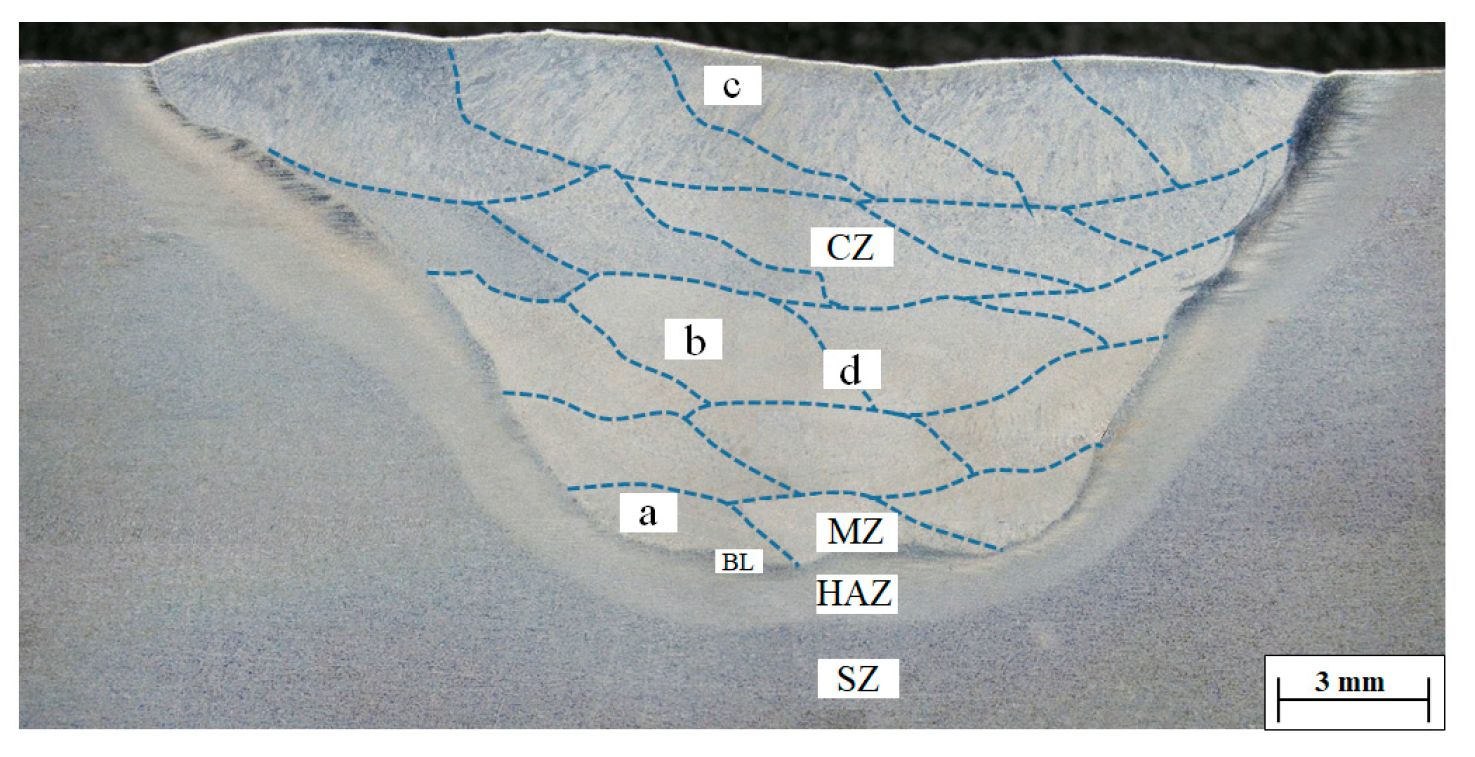

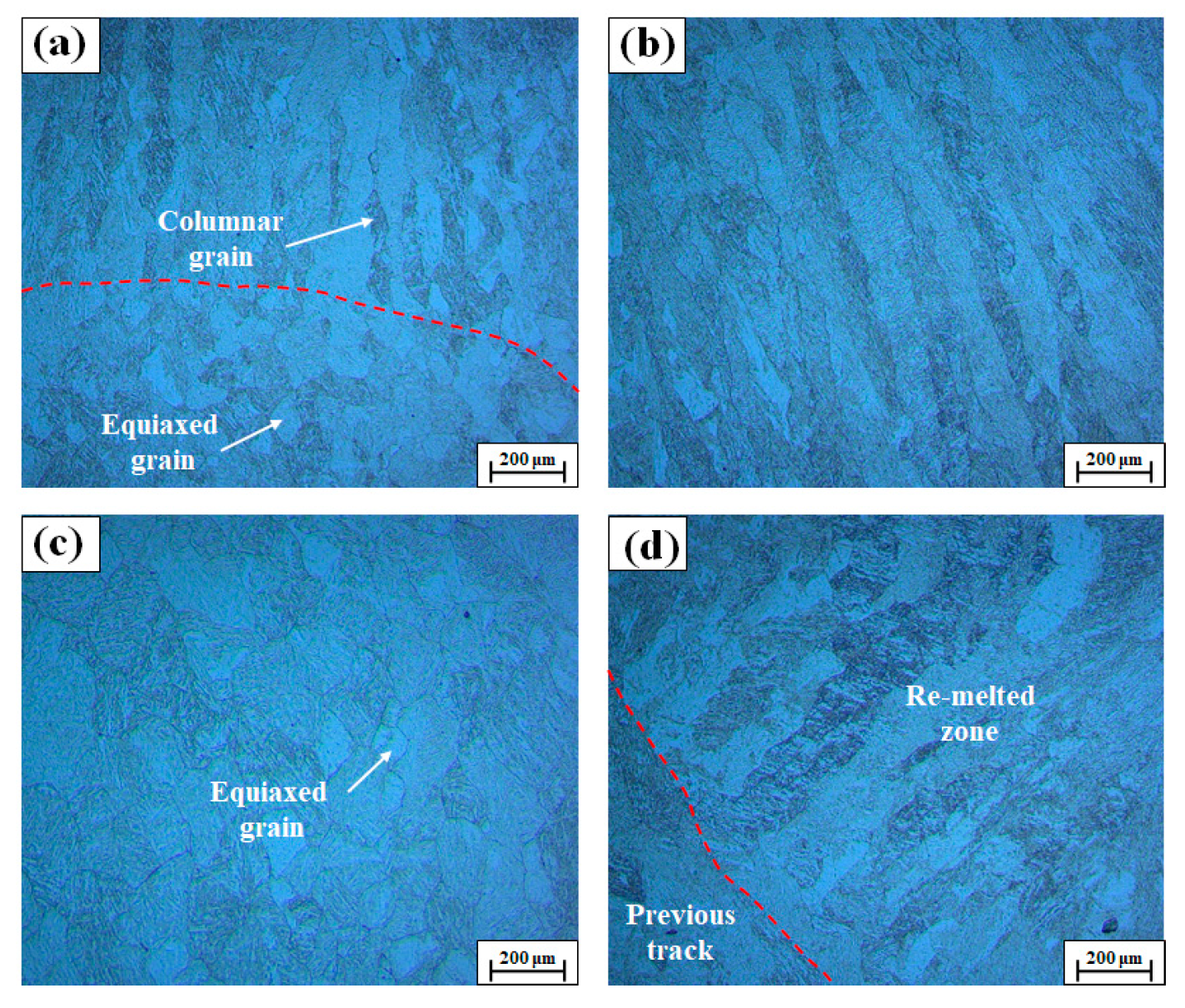

4.3. Phase Composition and Microstructure

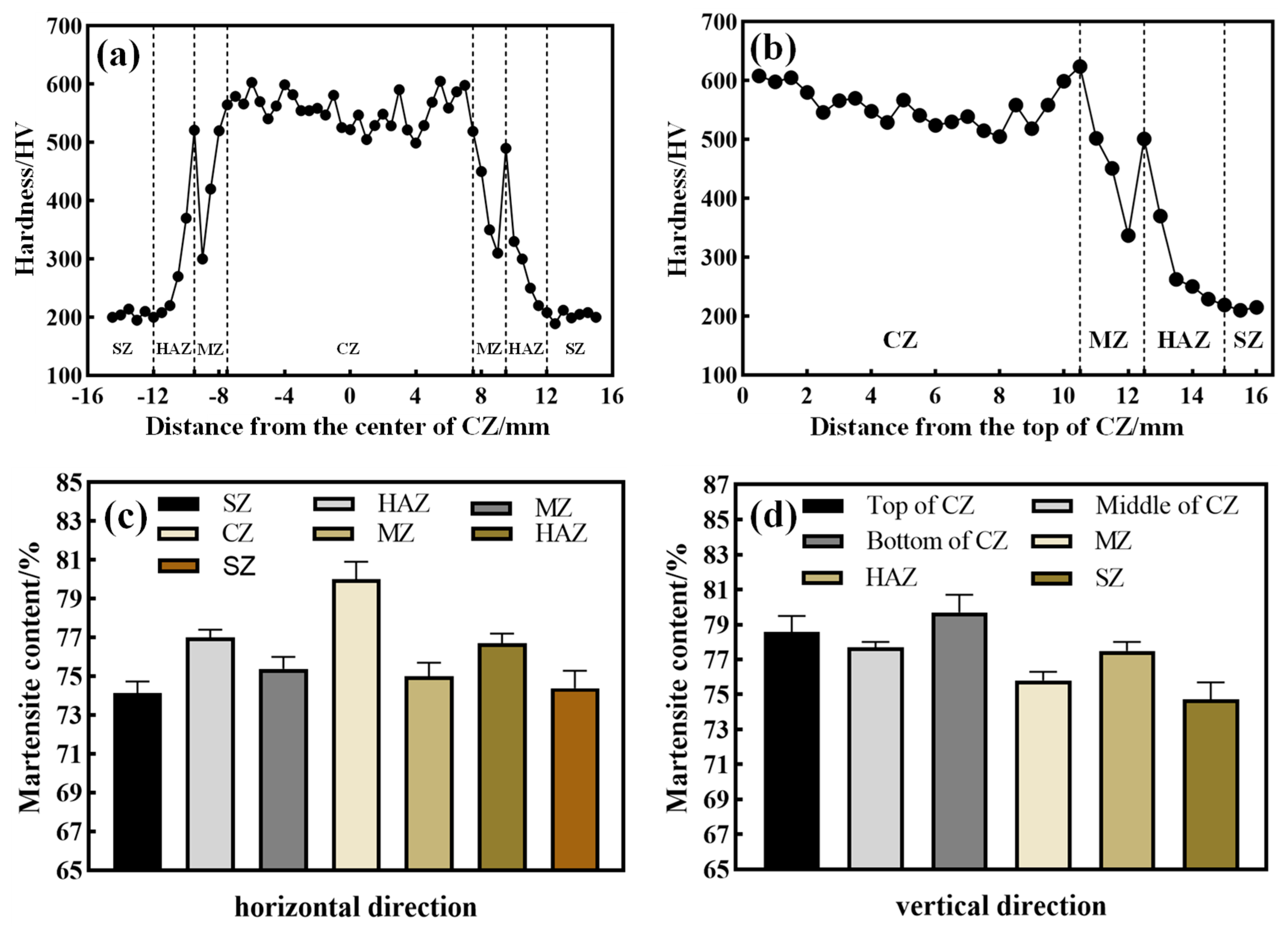

4.4. Microhardness Analysis

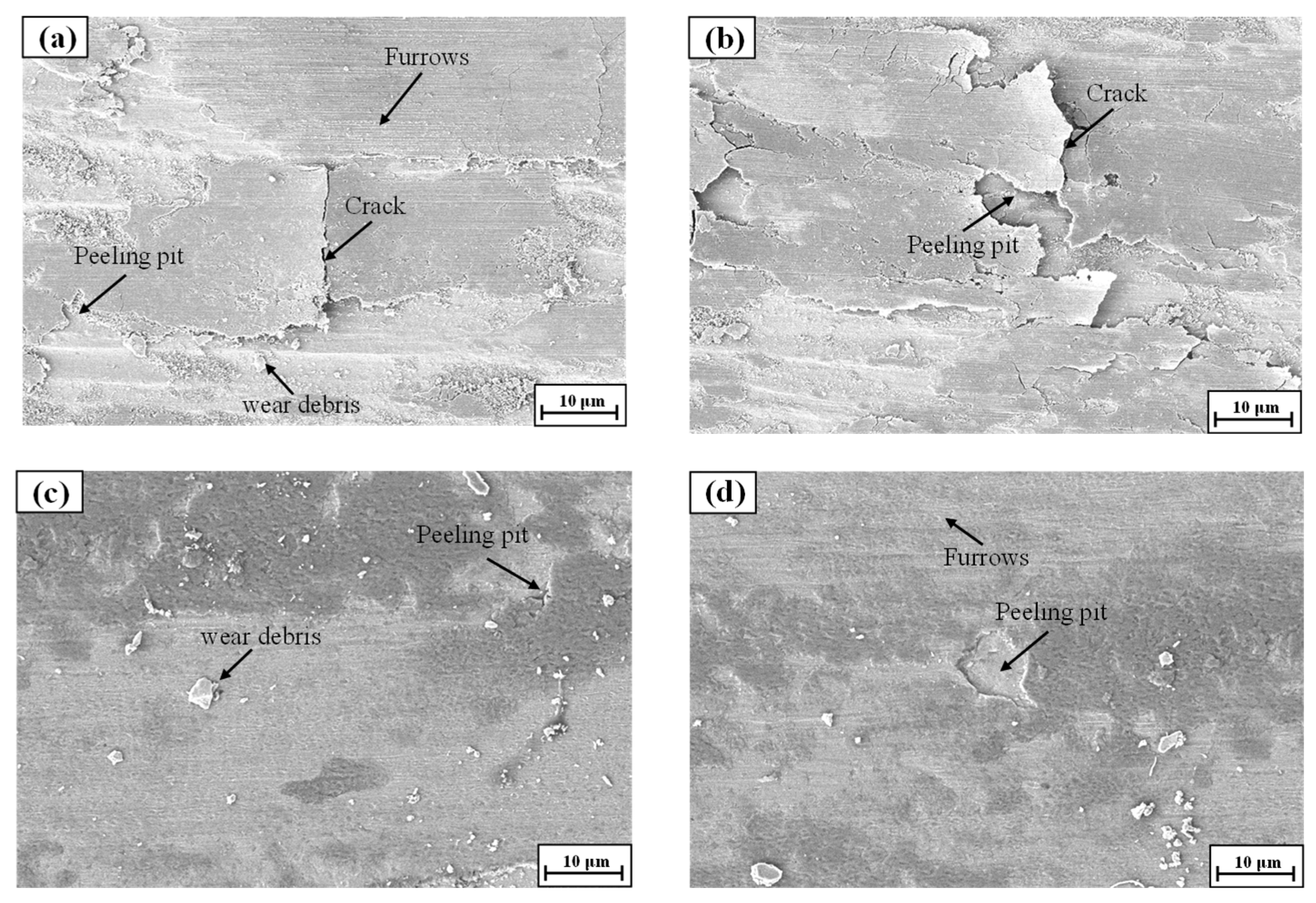

4.5. Friction and Wear Performance Analysis

5. Conclusions

- (1)

- The simulation thermal cycling curves and stress distribution curves obtained using SYSWELD software were in good agreement with the experimental data, confirming the reliability of the simulation model;

- (2)

- The heat dissipation performance of the cladding layer gradually reduced with severe heat accumulation as the number of weld beads increased. The residual stress was highly accumulated in the cladding zone, gradually dispersing towards both sides. The deformation of the repaired component was large at both ends but small in the middle;

- (3)

- The peak temperature of beads and heat accumulation in the cladding layer decreased when the cooling time increased from 50 s to 300 s. Meanwhile, the values of the residual stress and deformation in the repaired component were gradually reduced;

- (4)

- At the cooling time of 300 s, the microstructure was primarily composed of martensite and austenite. The average microhardness and wear resistance of cladding zone were 2.73 and 7.60 times higher than that of the substrate, respectively, indicating positive correlation with each other;

- (5)

- Based on this study, it was recommended to utilize numerical simulation techniques to select appropriate process parameters when applying the WAAM technique into mold restoration, which ensured both the efficiency and quality of remanufacturing.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Almangour, B.; Grzesiak, D.; Yang, J.M. Nanocrystalline TiC-reinforced H13 steel matrix nanocomposites fabricated by selective laser melting. Mater. Des. 2016, 96, 150–161. [Google Scholar] [CrossRef]

- Li, J.Y.; Chen, Y.L.; Huo, J.H. Mechanism of improvement on strength and toughness of H13 die steel by nitrogen. Mater. Sci. Eng. A 2015, 640, 16–23. [Google Scholar] [CrossRef]

- Lu, H.F.; Cai, J.; Luo, K.Y.; Xing, F.; Zhang, Q.L.; Yao, J.H.; Lu, J.Z. Thermal fatigue life and improvement mechanism of Fe-based coatings on H13 extrusion die by laser additive remanufacturing. Surf. Coat. Technol. 2021, 408, 126808. [Google Scholar] [CrossRef]

- Shinde, T.; Chavan, R.; Savadekar, P.; Patil, I.; Walke, O.; Wagh, G. Analysis of nitrided H13 steel in rotating bending fatigue. Mater. Today Proc. 2021, 44, 2507–2510. [Google Scholar] [CrossRef]

- Zhu, L.D.; Wang, S.H.; Pan, H.C.; Yuan, C.T.; Chen, X.S. Research on remanufacturing strategy for 45 steel gear using H13 steel powder based on laser cladding technology. J. Manuf. Process. 2020, 49, 344–354. [Google Scholar] [CrossRef]

- Vachhani, H.; Rathod, M.; Shah, R. Dissolution and erosion behavior of AISI H13 shot sleeve in high pressure die casting process. Eng. Fail. Anal. 2019, 101, 206–214. [Google Scholar] [CrossRef]

- Huang, Y.M.; Hou, S.S.; Yang, L.J.; Tian, G.; Yong, Z.; Liu, S.Y. Effect of arc dynamic behavior on deposition quality of additive manufactured aluminum alloys. J. Mater. Process. Technol. 2021, 295, 117172. [Google Scholar] [CrossRef]

- Yin, Z.Q.; Xiong, J. Stereovision measurement of layer geometry in wire and arc additive manufacturing with various stereo matching algorithms. J. Manuf. Process. 2020, 56, 428–438. [Google Scholar] [CrossRef]

- Almangour, B.; Grzesiak, D.; Yang, J.M. Selective laser melting of TiB2/H13 steel nanocomposites: Influence of hot isostatic pressing post-treatment. J. Mater. Process. Technol. 2017, 244, 344–353. [Google Scholar] [CrossRef]

- Mcandrew, A.R.; Rosales, M.A.; Colegrove, P.A.; Hönnige, J.R.; Ho, A.; Fayolle, R.; Eyitayo, K.; Stan, I.; Sukrongpang, P.; Crochemore, A.; et al. Interpass rolling of Ti-6Al-4V wire+arc additively manufactured features for microstructural refinement. Addit. Manuf. 2018, 21, 340–349. [Google Scholar] [CrossRef]

- Liu, J.; Zheng, J.; Fu, B.; Bu, L.; Li, R.; Liu, S. Thermo-Mechanical Study of TIG Welding of Ti-6Al-4V for Residual Stresses Considering Solid State Phase Transformation. Metals 2023, 13, 1001. [Google Scholar] [CrossRef]

- Ma, Y.; Cuiuri, D.; Shen, C.; Li, H.J.; Pan, Z.G. Effect of interpass temperature on in-situ alloying and additive manufacturing of titanium aluminides using gas tungsten arc welding. Addit. Manuf. 2015, 8, 71–77. [Google Scholar] [CrossRef]

- Wang, T.T.; Zhang, Y.B.; Wu, Z.H.; Shi, C.W. Microstructure and properties of die steel fabricated by WAAM using H13 wire. Vacuum 2018, 149, 185–189. [Google Scholar] [CrossRef]

- Taraphdar, P.K.; Thakare, J.G.; Pandey, C.; Mahapatra, M.M. Novel residual stress measurement technique to evaluate through thickness residual stress fields. Mater. Lett. 2020, 277, 12847. [Google Scholar] [CrossRef]

- Rani, K.; Rajiv Kumar, R.; Mahapatra, M.M.; Mulik, R.S.; Świerczyńska, A.; Fydrych, D.; Pandey, C. Wire Arc Additive Manufactured Mild Steel and Austenitic Stainless Steel Components: Microstructure, Mechanical Properties and Residual Stresses. Materials 2022, 15, 7094. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Lei, Y.Y.; Chen, H.; Zhng, G.G. Fabrication of inclined thin-walled parts in multi-layer single-pass GMAW-based additive manufacturing with flat position deposition. J. Mater. Process. Technol. 2017, 240, 397–403. [Google Scholar] [CrossRef]

- Kozamernik, N.; Braun, D.; Klobar, D. WAAM system with interpass temperature control and forced cooling for near-net-shape printing of small metal components. Int. J. Adv. Manuf. Technol. 2020, 110, 1955–1968. [Google Scholar] [CrossRef]

- Li, F.; Chen, S.J.; Shi, J.B.; Zhao, Y.; Tian, H.Y. Thermoelectric Cooling-Aided Bead Geometry Regulation in Wire and Arc-Based Additive Manufacturing of Thin-Walled Structures. Appl. Sci. 2018, 8, 207. [Google Scholar] [CrossRef]

- Wu, B.T.; Pan, Z.X.; Ding, D.H.; Cuiuri, D.; Li, H.J.; Fei, Z.Y. The effects of forced interpass cooling on the material properties of wire arc additively manufactured Ti6Al4V alloy. J. Mater. Process. Technol. 2018, 258, 95–105. [Google Scholar] [CrossRef]

- Lei, Y.Y.; Xiong, J.; Li, R. Effect of inter layer idle time on thermal behavior for multi-layer single-pass thin-walled parts in GMAW-based additive manufacturing. Int. J. Adv. Manuf. Technol. 2018, 96, 135–1365. [Google Scholar] [CrossRef]

- Feng, G.; Wang, H.; Wang, Y.; Deng, D.; Zhang, J. Numerical Simulation of Residual Stress and Deformation in Wire Arc Additive Manufacturing. Crystals 2022, 12, 803. [Google Scholar] [CrossRef]

- Turgut, B.; Gürol, G.; Onler, R. Effect of interlayer dwell time on output quality in wire arc additive manufacturing of low carbonlow alloy steel components. Int. J. Adv. Manuf. Technol. 2023, 126, 5277–5288. [Google Scholar] [CrossRef]

- Somashekara, M.A.; Naveenkumar, M.; Kumar, A.; Viswanath, C.; Simhambhatla, S. Investigations into effect of weld-deposition pattern on residual stress evolution for metallic additive manufacturing. Int. J. Adv. Manuf. Technol. 2017, 90, 2009–2025. [Google Scholar] [CrossRef]

- Ahmad, A.S.; Wu, Y.X.; Gong, H.; Nie, L. Finite element prediction of residual stress and deformation induced by double-pass tig welding of al 2219 plate. Materials 2019, 12, 2251. [Google Scholar] [CrossRef] [PubMed]

- He, M.; Zhang, Z.F.; Mao, W.M.; Li, B.; Bai, Y.L.; Xu, J. Numerical and Experimental Study on Melt Treatment for Large-Volume 7075 Alloy by a Modified Annular Electromagnetic Stirring. Materials 2019, 12, 820. [Google Scholar] [CrossRef] [PubMed]

- Olshanskaya, T.; Fedoseeva, E. Porosity Formation in Thin Welded Joints of Al–MG–LI Alloys. Materials 2022, 15, 348. [Google Scholar] [CrossRef] [PubMed]

- Afazov, S.M.; Ratchev, S.M.; Segal, J. Prediction and experimental validation of micro-milling cutting forces of AISI H13 steel at hardness between 35 and 60 HRC. Int. J. Adv. Manuf. Technol. 2012, 62, 887–899. [Google Scholar] [CrossRef]

- Goladk, J.; Chakravariti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Cao, J.; Gharghouri, M.A.; Nash, P. Finite-element analysis and experimental validation of thermal residual stress and distortion in electron beam additive manufactured Ti-6Al-4V build plates. J. Mater. Process. Technol. 2016, 237, 409–419. [Google Scholar] [CrossRef]

- Zareh, P.; Urbanic, R.J. Numerical simulations for laser clad beads with a variable side-to-side overlap condition. Int. J. Adv. Manuf. Technol. 2020, 109, 1027–1058. [Google Scholar] [CrossRef]

- Ma, M.M.; Wang, Z.M.; Zeng, X.Y. Effect of energy input on microstructural evolution of direct laser fabricated IN718 alloy. Mater. Charact. 2015, 106, 420–427. [Google Scholar] [CrossRef]

- Hemmati, I.; Ocelík, V.; De Hosson, J.T.M. Dilution effects in laser cladding of Ni–Cr–B–Si–C hardfacing alloys. Mater. Lett. 2012, 84, 69–72. [Google Scholar] [CrossRef]

- Trojan, K.; Ocelík, V.; Čapek, J.; Čech, J.; Canelo-Yubero, D.; Ganev, N.; Kolařík, K.; De Hosson, J.T.M. Microstructure and Mechanical Properties of Laser Additive Manufactured H13 Tool Steel. Metals 2022, 12, 243. [Google Scholar] [CrossRef]

- Xu, P.; Lin, C.X.; Zhou, C.Y.; Yi, X.P. Wear and corrosion resistance of laser cladding AISI 304 stainless steel/Al2O3 composite coatings. Surf. Coat. Technol. 2014, 238, 9–14. [Google Scholar] [CrossRef]

- Shan, X.H.; Cong, M.Q.; Lie, W.N. Effect of Cladding Current on Microstructure and Wear Resistance of High-Entropy Powder-Cored Wire Coating. Metals 2022, 12, 1718. [Google Scholar] [CrossRef]

| H13 | Cr | Mo | Si | V | Mn | C | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Substrate | 5.50 | 1.20 | 1.20 | 0.90 | 0.45 | 0.40 | 0.01 | 0.002 | Bal. |

| Welding wire | 4.90 | 1.35 | 0.94 | 0.95 | 0.35 | 0.37 | 0.007 | 0.006 | Bal. |

| Parameters | Value/Unit |

|---|---|

| Welding current | 202 A |

| Welding speed | 2.5 mm/s |

| Wire feed speed | 125 mm/min |

| Argon gas flow | 15 L/min |

| Cooling time | 300 s |

| Overlap coefficient | 0.55 |

| Temperature | 20 °C | 200 °C | 400 °C | 600 °C | 800 °C | 1000 °C | 1200 °C | 1400 °C | 1600 °C |

|---|---|---|---|---|---|---|---|---|---|

| Density (10−3 g/mm3) | 7.67 | 7.63 | 7.57 | 7.50 | 7.45 | 7.39 | 7.33 | 7.21 | 6.85 |

| Specific Heat (10−1 J/g·°C) | 4.50 | 5.73 | 6.49 | 8.48 | 8.43 | 7.17 | 6.65 | 7.75 | 8.30 |

| Thermal conductivity (10−2 J/mm·s·°C) | 1.8 | 2.1 | 2.1 | 2.4 | 2.6 | 2.8 | 3.1 | 3.2 | 3.4 |

| Young’s Modulus (GPa) | 207 | 196 | 160 | 142 | 125 | 107 | 90 | 48 | 1 |

| Poisson’s ratio (10−3) | 280 | 290 | 300 | 310 | 320 | 350 | 360 | 380 | 500 |

| Thermal expansion (10−7/°C) | 117 | 122 | 130 | 133 | 135 | 137 | 139 | 141 | 143 |

| Yield strength (MPa) | 1130 | 844 | 127 | 115 | 108 | 40 | 5 | 2 | 1 |

| Q/(KW) | η | a1/(mm) | a2/(mm) | b/(mm) | c/(mm) |

|---|---|---|---|---|---|

| 2.43 | 0.80 | 1.66 | 3.34 | 4.75 | 1.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Chen, J.; Li, X. Numerical Simulation of Thermal Field and Performance Study on H13 Die Steel-Based Wire Arc Additive Manufacturing. Metals 2023, 13, 1484. https://doi.org/10.3390/met13081484

Zhu Y, Chen J, Li X. Numerical Simulation of Thermal Field and Performance Study on H13 Die Steel-Based Wire Arc Additive Manufacturing. Metals. 2023; 13(8):1484. https://doi.org/10.3390/met13081484

Chicago/Turabian StyleZhu, Yu, Jufang Chen, and Xiaoping Li. 2023. "Numerical Simulation of Thermal Field and Performance Study on H13 Die Steel-Based Wire Arc Additive Manufacturing" Metals 13, no. 8: 1484. https://doi.org/10.3390/met13081484

APA StyleZhu, Y., Chen, J., & Li, X. (2023). Numerical Simulation of Thermal Field and Performance Study on H13 Die Steel-Based Wire Arc Additive Manufacturing. Metals, 13(8), 1484. https://doi.org/10.3390/met13081484