Interfacial Stress Development and Cracking Susceptibility during Laser Powder Bed Fusion of Random TiB2-Particle-Reinforced AlSi10Mg Matrix Composites

Abstract

1. Introduction

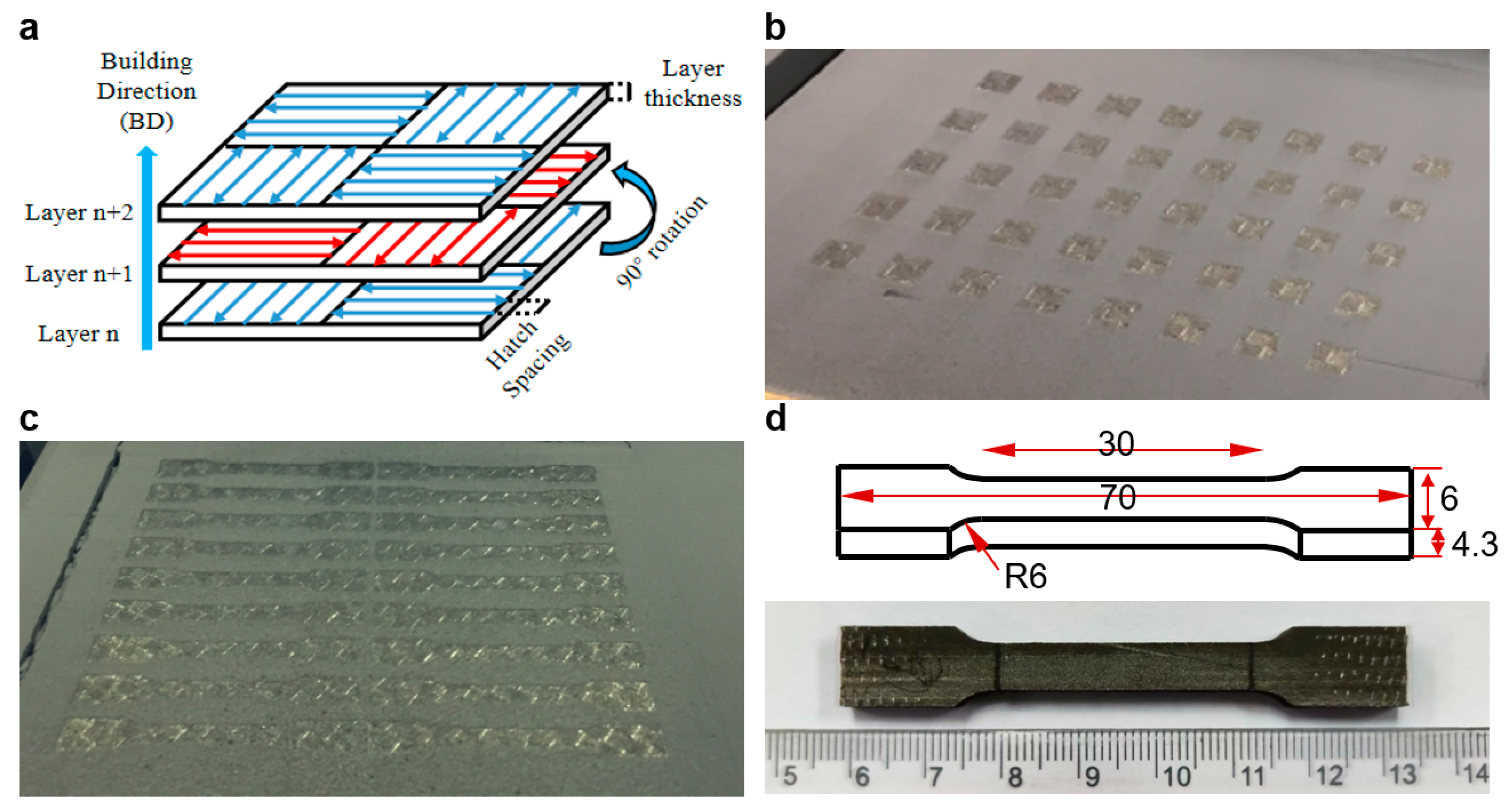

2. Materials and Methods

2.1. Experiment Investigation

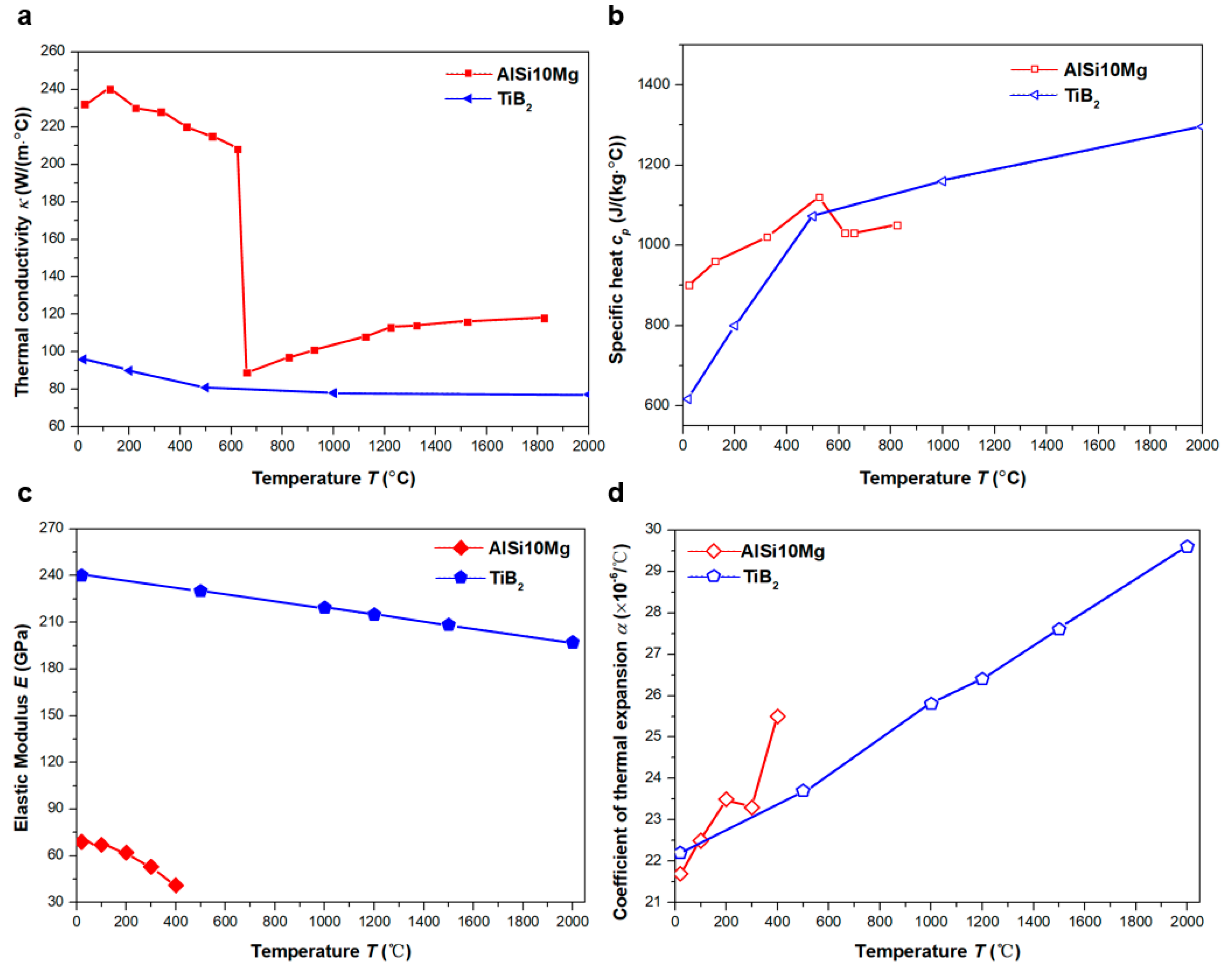

2.2. Modeling Approach

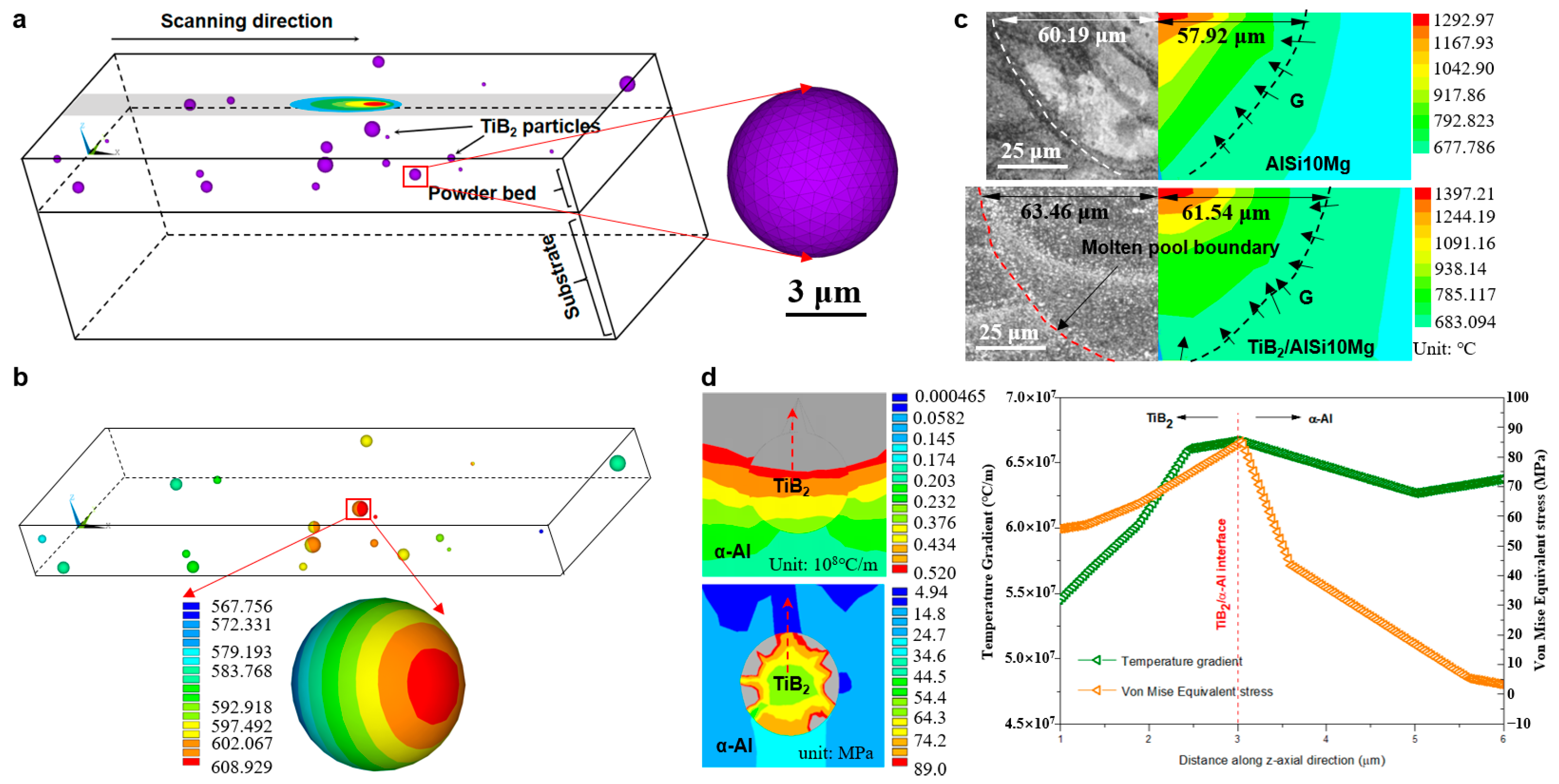

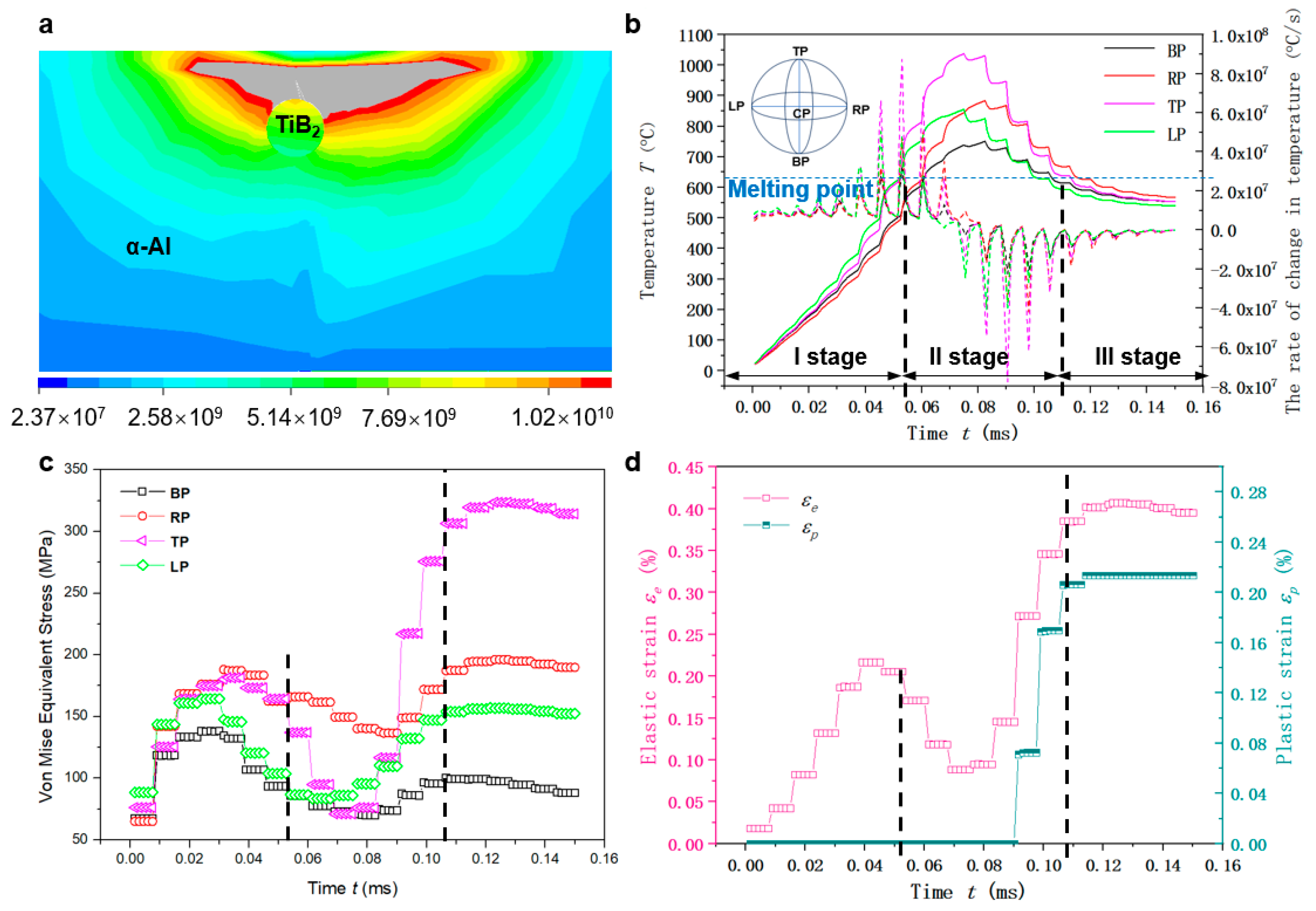

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramnath, B.V.; Parswajinan, C.; Dharmaseelan, R.; Thileepan, K.; Krishna, K.N. A review on aluminium metal matrix composites. Mater. Today Proc. 2021, 46, 4341–4343. [Google Scholar] [CrossRef]

- Gill, R.S.; Samra, P.S.; Kumar, A. Effect of different types of reinforcement on tribological properties of aluminium metal matrix composites (MMCs)—A review of recent studies. Mater. Today Proc. 2022, 56, 3094–3101. [Google Scholar] [CrossRef]

- Imran, M.; Khan, A.A. Characterization of Al-7075 metal matrix composites: A review. J. Mater. Res. Technol. 2019, 8, 3347–3356. [Google Scholar] [CrossRef]

- Liu, M.; Zhan, J.; Zhu, B.; Zhang, X. Topology optimization of flexure hinges with a prescribed compliance matrix based on the adaptive spring model and stress constraint. Precis. Eng. 2021, 72, 397–408. [Google Scholar] [CrossRef]

- Dejene, N.D.; Lemu, H.G. Current Status and Challenges of Powder Bed Fusion-based Metal Additive Manufacturing: Liter-ature Review. Metals 2023, 13, 424. [Google Scholar]

- Liu, X.; Zhuo, L.; Wang, Z.; Zhao, Z.; Zhang, H.; Yuan, B.; An, Z.; Li, C.; Yin, E.; Xu, T. Effects of processing parameters and post-process heat treatment on selective laser melted SiC/AlSi10Mg composites. Mater. Lett. 2022, 308, 131254. [Google Scholar] [CrossRef]

- Shi, Q.; Mertens, R.; Dadbakhsh, S.; Li, G.; Yang, S. In-situ formation of particle reinforced Aluminium matrix composites by laser powder bed fusion of Fe2O3/AlSi12 powder mixture using laser melting/remelting strategy. J. Mater. Process Technol. 2022, 299, 117357. [Google Scholar]

- Biffi, C.A.; Bassani, P.; Fiocchi, J.; Albu, M.; Tuissi, A. Selective laser melting of AlCu-TiB2 alloy using pulsed wave laser emission mode: Processability, microstructure and mechanical properties. Mater. Des. 2021, 204, 109628. [Google Scholar]

- Prabhakar, S.; Radhika, N.; Raghu, R. Analysis of Tribological Behavior of Aluminium/B4C Composite Under Dry Sliding Mo-tion. Procedia Eng. 2014, 97, 994–1003. [Google Scholar]

- Sun, M.; Yang, Z.; Zhang, J.; Zhang, S.; Yang, Q.; Song, S.; Lu, B. Effects of ZrO2 nanoparticles on the microstructure and me-chanical properties of ZrO2/AlSi10Mg composites manufactured by laser powder bed fusion. Ceram. Int. 2023, 49, 19673–19681. [Google Scholar]

- Chen, Y.; Ren, Y.; Li, K.; Dang, B.; Jian, Z. Laser powder bed fusion of oxidized microscale SiC-particle-reinforced AlSi10Mg matrix composites: Microstructure, porosity, and mechanical properties. Mater. Sci. Eng. A 2023, 870, 144860. [Google Scholar]

- Marchese, G.; Aversa, A.; Lorusso, M.; Manfredi, D.; Calignano, F.; Lombardi, M.; Biamino, S.; Pavese, M. Development and Characterisation of Aluminium Matrix Nanocomposites AlSi10Mg/MgAl2O4 by Laser Powder Bed Fusion. Metals 2018, 8, 175. [Google Scholar] [CrossRef]

- Lee, C.; Park, H.; Yoo, J.; Lee, C.; Woo, W.; Park, S. Residual stress and crack initiation in laser clad composite layer with Co-based alloy and WC + NiCr. Appl. Surf. Sci. 2015, 345, 286–294. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater Sci. 2018, 92, 112–224. [Google Scholar]

- Chowdhury, S.; Yadaiah, N.; Prakash, C.; Ramakrishna, S.; Dixit, S.; Gupta, L.R.; Buddhi, D. Laser powder bed fusion: A state-of-the-art review of the technology, materials, properties & defects, and numerical modelling. J. Mater. Res. Technol. 2022, 20, 2109–2172. [Google Scholar] [CrossRef]

- Han, Q.; Low, K.W.; Gu, Y.; Wang, X.; Wang, L.; Song, B.; Huang, C.; Setchi, R. The dynamics of reinforced particle migration in laser powder bed fusion of Ni-based composite. Powder Technol. 2021, 394, 714–723. [Google Scholar] [CrossRef]

- Meng, G.; Zhang, J.; Li, J.; Jiang, Z.; Gong, Y.; Zhao, J. Impact of pore defects on laser additive manufacturing of Inconel 718 alloy based on a novel finite element model: Thermal and stress evaluation. Opt. Laser Technol. 2023, 167, 109782. [Google Scholar] [CrossRef]

- Touloukian, Y.S.; Buyco, E.H. Thermophysical Properties of Matter: Specific Heat-Metallic Elements and Alloy, 1st ed.; IFI/Plenum: New York, NY, USA, 1970. [Google Scholar]

- Munro, R.G. Material properties of titanium diboride. J. Res. Natl. Inst. Stand. Technol. 2000, 105, 709–720. [Google Scholar] [CrossRef] [PubMed]

- Bag, S.; Trivedi, A.; De, A. Development of a finite element based heat transfer model for conduction mode laser spot welding process using an adaptive volumetric heat source. Int. J. Therm. Sci. 2009, 48, 1923–1931. [Google Scholar] [CrossRef]

- Hansel, A.; Spittel, T. Kraft und Arbeitsbedarf bildsamer Formgebungsverfahren, 1st ed.; Deutscher Verlag fur Grund-Stoffindustrie: Leipzig, Germany, 1978. [Google Scholar]

- Le Mercier, K.; Guerin, J.-D.; Dubar, M.; Dubar, L.; Puchi-Cabrera, E. Physically-based constitutive description of a commercial Al-Mg-Si alloy deformed under cold-warm working conditions. J. Alloys Compd. 2019, 790, 1177–1191. [Google Scholar] [CrossRef]

- Gao, C.; Zhang, L. A constitutive model for dynamic plasticity of FCC metals. Mater. Sci. Eng. A 2010, 527, 3138–3143. [Google Scholar] [CrossRef]

- Newman, M.L.; Robinson, B.J.; Sehitoglu, H.; Dantzig, J.A. Deformation, residual stress, and constitutive relations for quenched W319 aluminum. Met. Mater. Trans. A 2003, 34, 1483–1491. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Muñoz-Morris, M.A.; Morris, D.G. Contribution of microstructural parameters to strengthening in an ultrafine-grained Al–7% Si alloy processed by severe deformation. Acta Mater. 2007, 55, 1319–1330. [Google Scholar]

- Zamani, M.; Dini, H.; Svoboda, A.; Lindgren, L.-E.; Seifeddine, S.; Andersson, N.-E.; Jarfors, A.E. A dislocation density based constitutive model for as-cast Al-Si alloys: Effect of temperature and microstructure. Int. J. Mech. Sci. 2017, 121, 164–170. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; Fang, Z.; Wu, M.; Miao, X.; Wang, Q. Interfacial Stress Development and Cracking Susceptibility during Laser Powder Bed Fusion of Random TiB2-Particle-Reinforced AlSi10Mg Matrix Composites. Metals 2023, 13, 1405. https://doi.org/10.3390/met13081405

Ma C, Fang Z, Wu M, Miao X, Wang Q. Interfacial Stress Development and Cracking Susceptibility during Laser Powder Bed Fusion of Random TiB2-Particle-Reinforced AlSi10Mg Matrix Composites. Metals. 2023; 13(8):1405. https://doi.org/10.3390/met13081405

Chicago/Turabian StyleMa, Chenglong, Ziyu Fang, Meiping Wu, Xiaojin Miao, and Quanlong Wang. 2023. "Interfacial Stress Development and Cracking Susceptibility during Laser Powder Bed Fusion of Random TiB2-Particle-Reinforced AlSi10Mg Matrix Composites" Metals 13, no. 8: 1405. https://doi.org/10.3390/met13081405

APA StyleMa, C., Fang, Z., Wu, M., Miao, X., & Wang, Q. (2023). Interfacial Stress Development and Cracking Susceptibility during Laser Powder Bed Fusion of Random TiB2-Particle-Reinforced AlSi10Mg Matrix Composites. Metals, 13(8), 1405. https://doi.org/10.3390/met13081405