Prediction of Tool Wear Rate and Tool Wear during Dry Orthogonal Cutting of Inconel 718

Abstract

1. Introduction

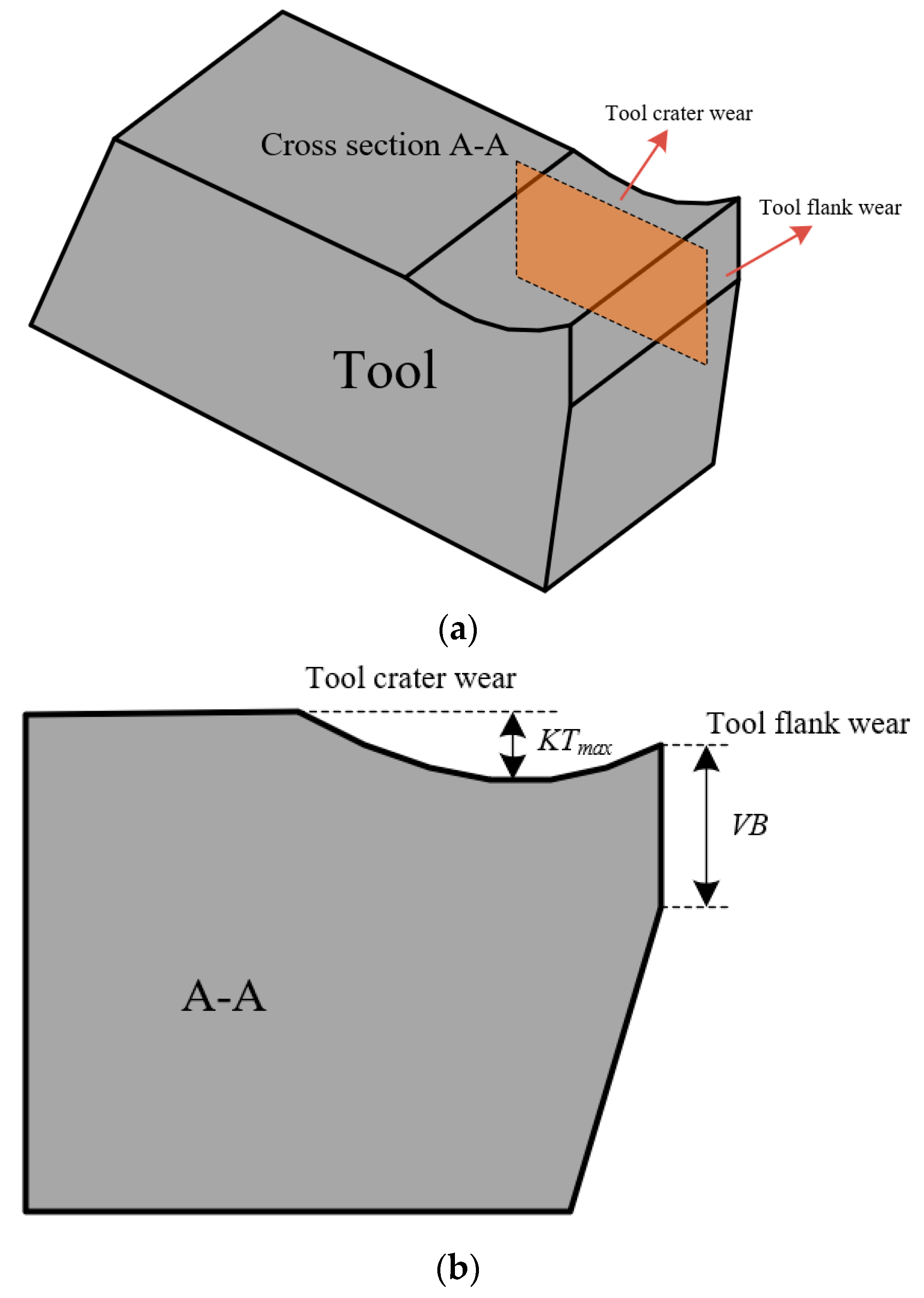

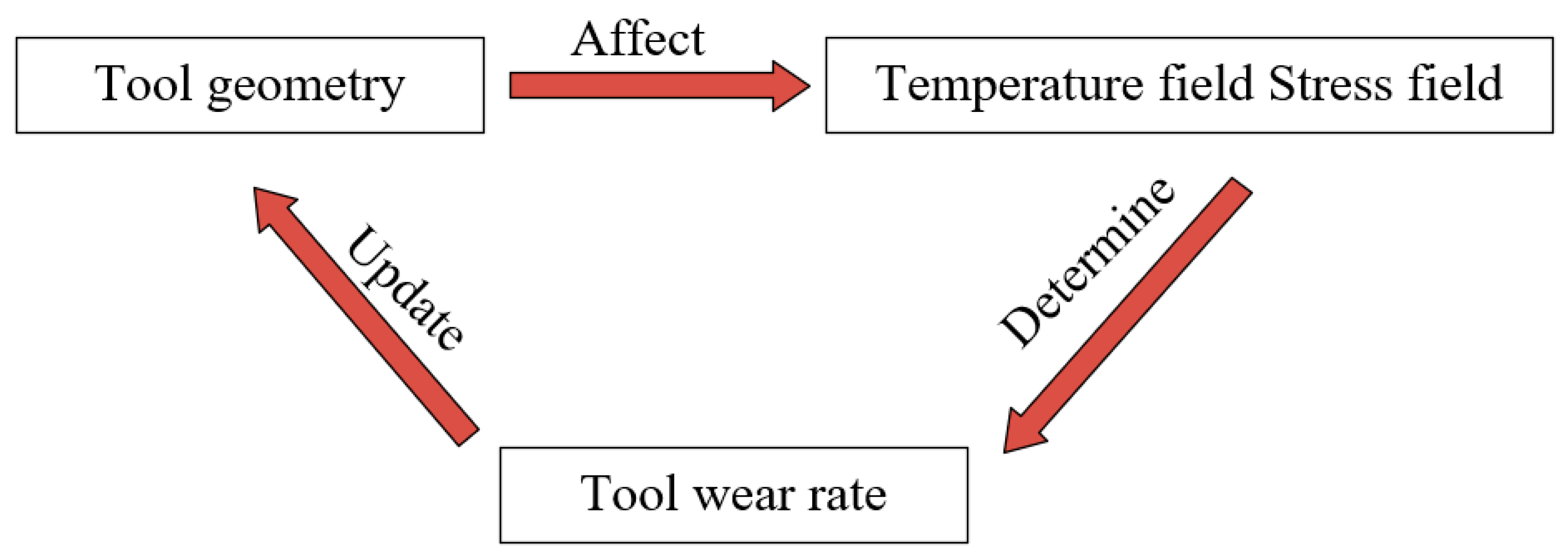

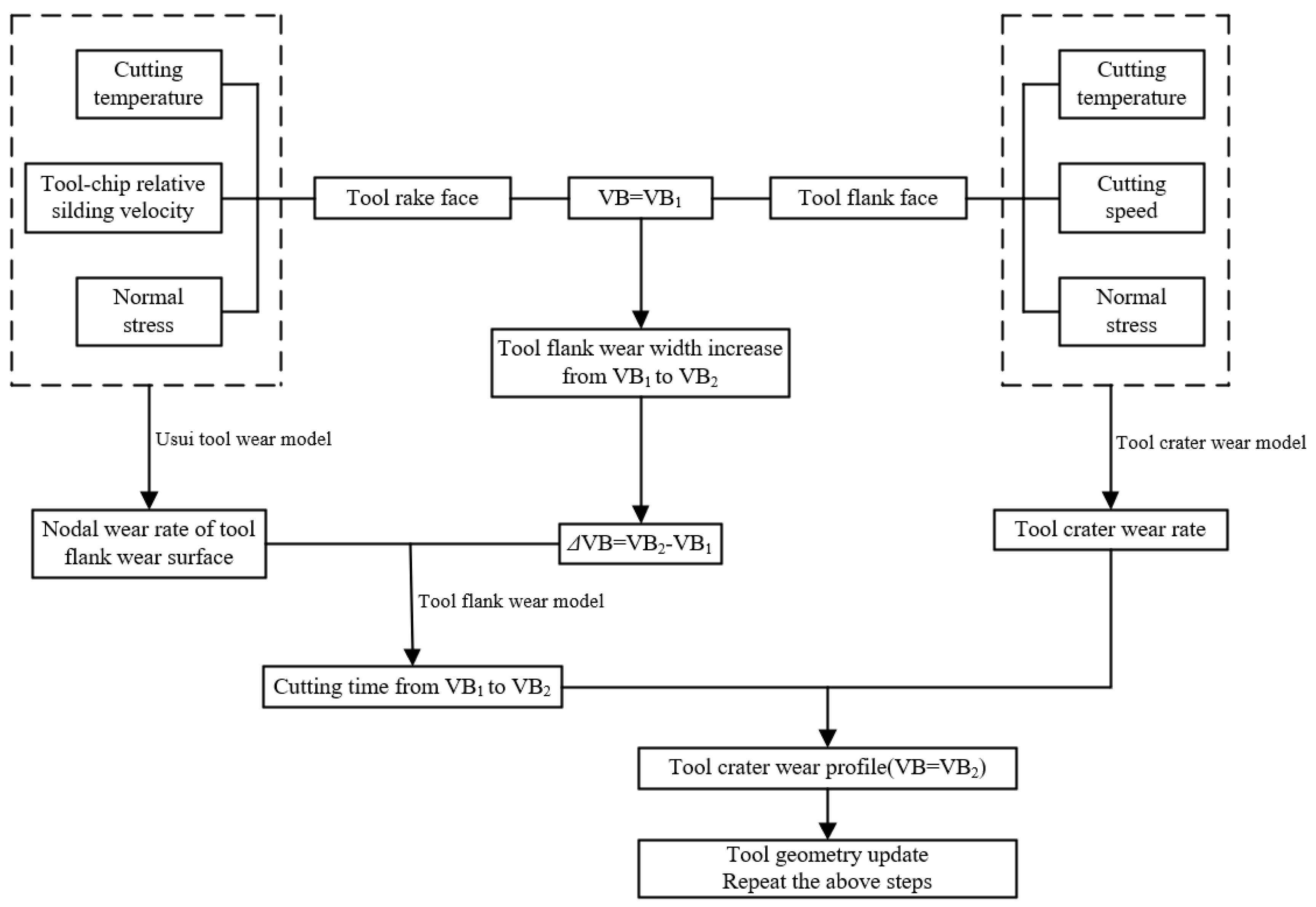

2. Tool Wear Rate and Tool Wear Prediction Method

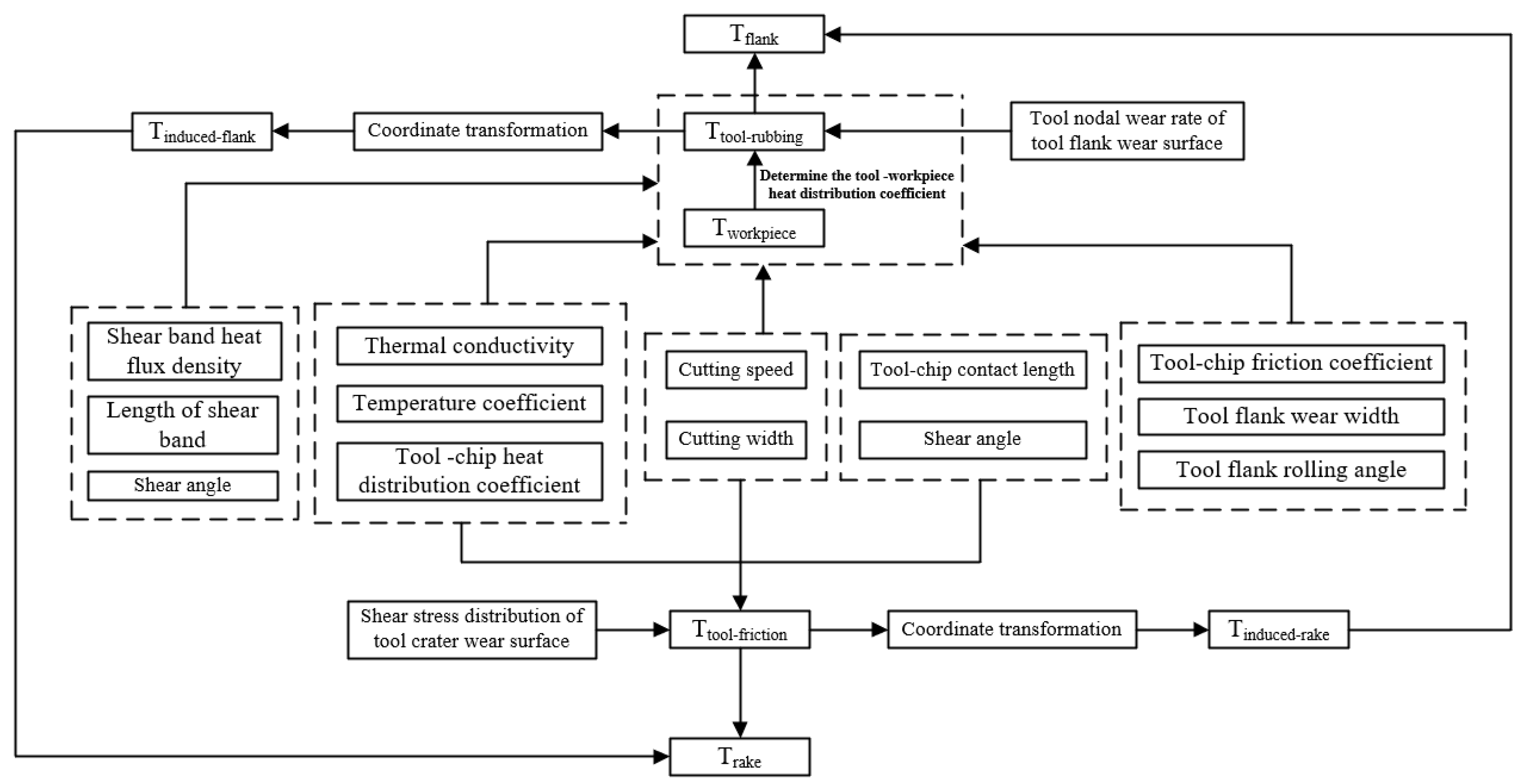

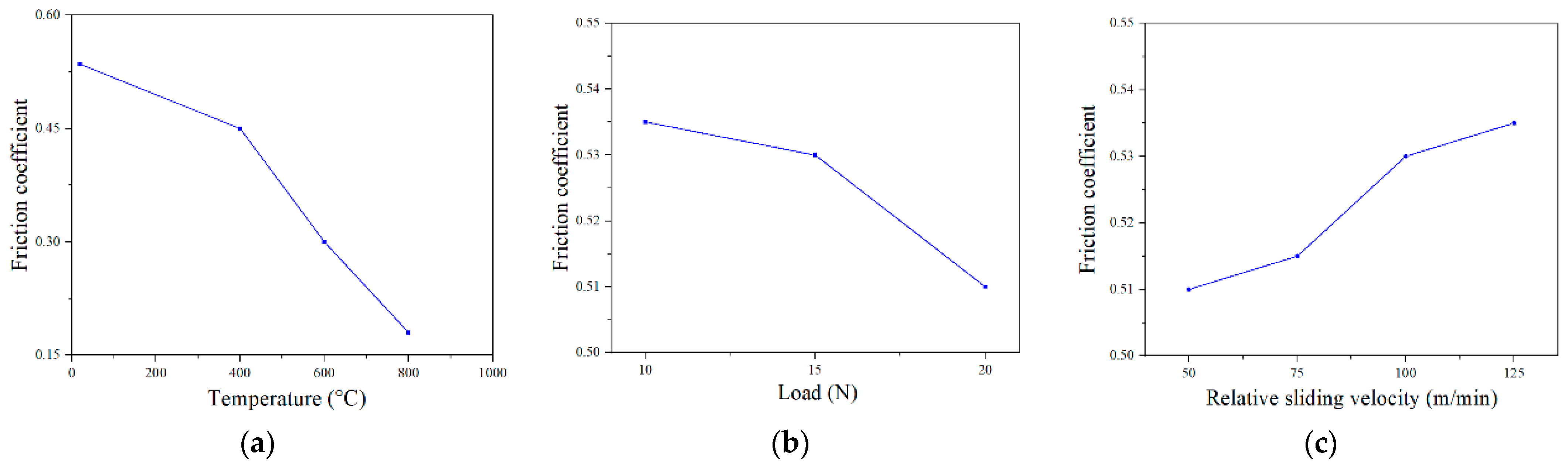

2.1. Tool Wear Rate

- (1)

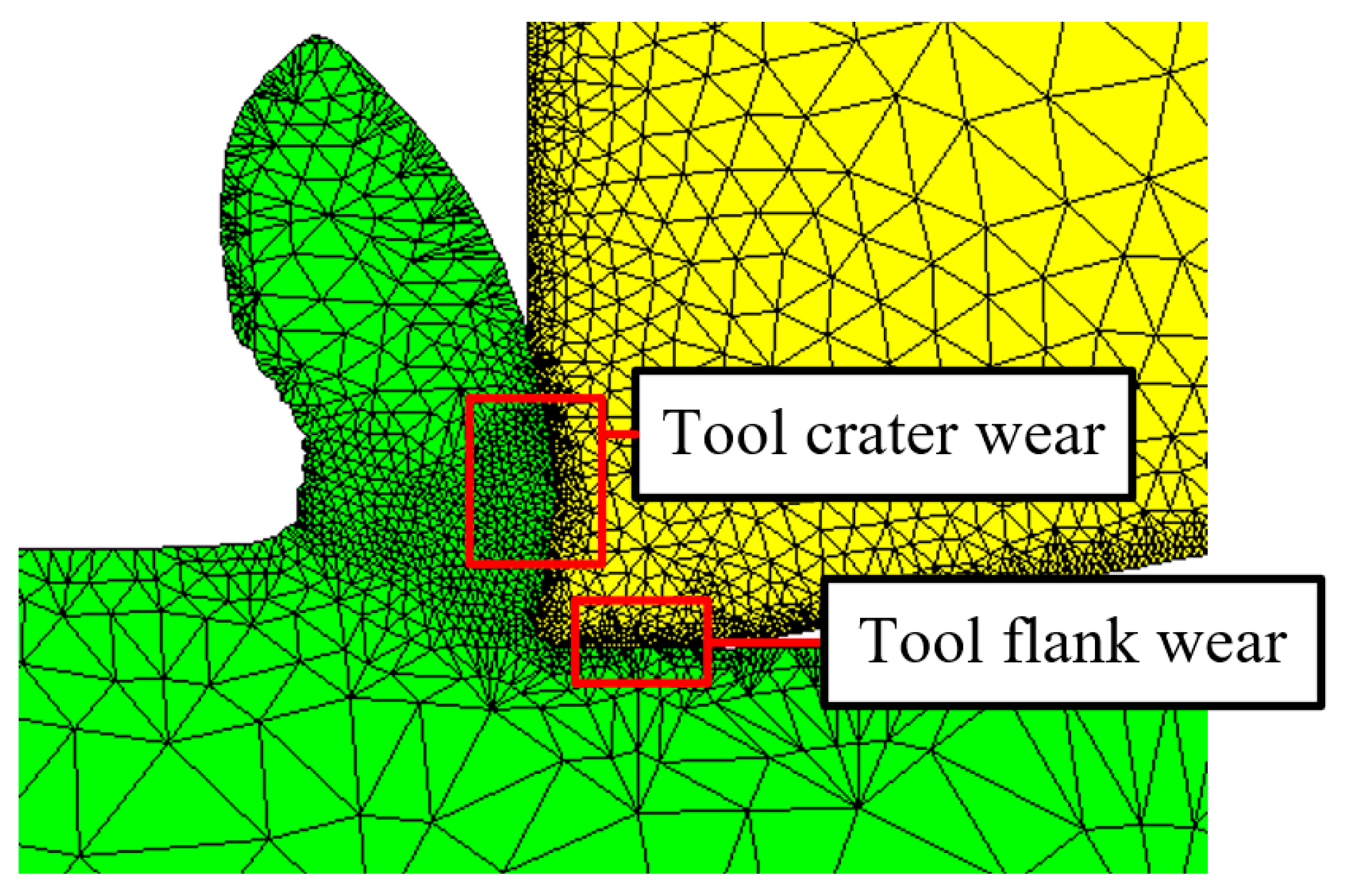

- Tool crater wear rate model

- (2)

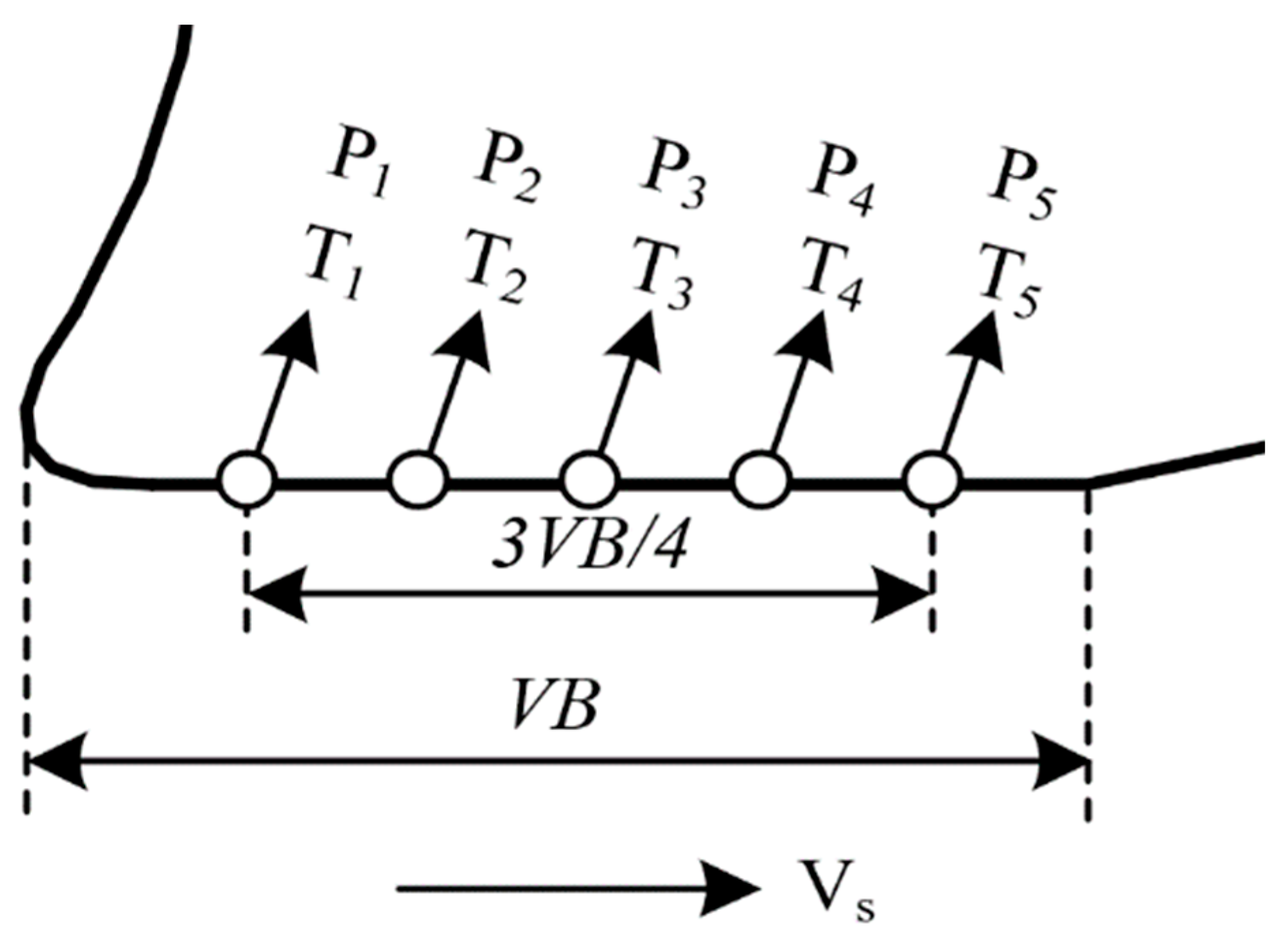

- Tool flank wear rate model

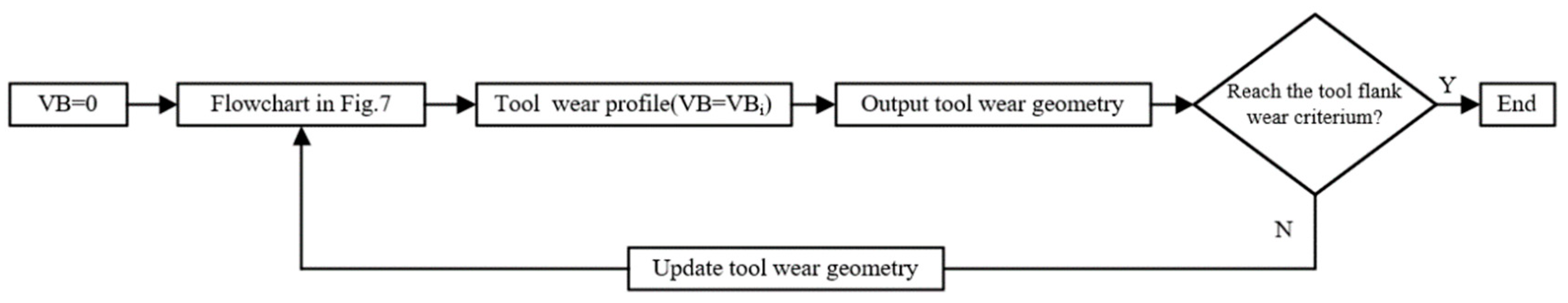

2.2. Tool Wear Prediction

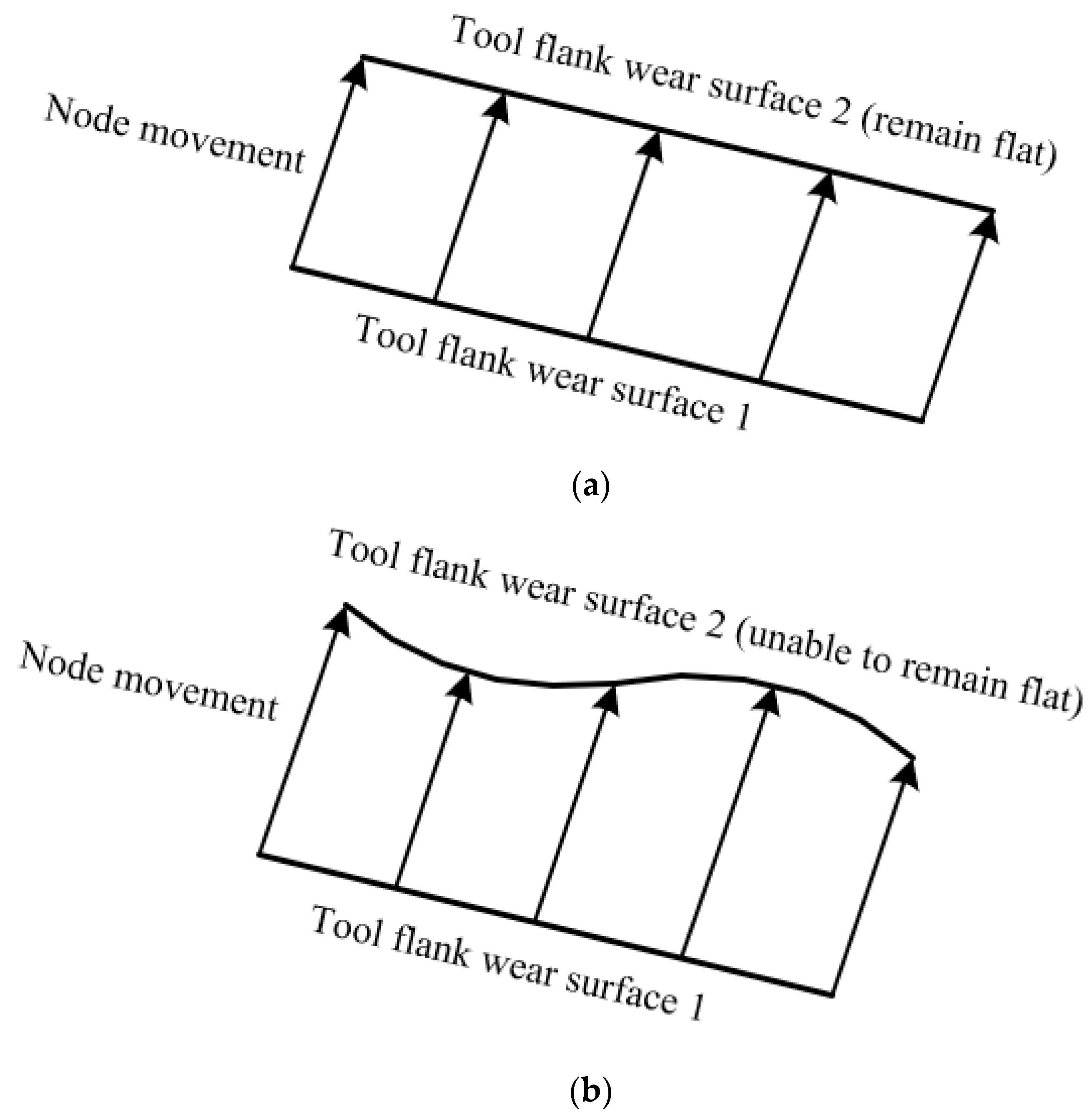

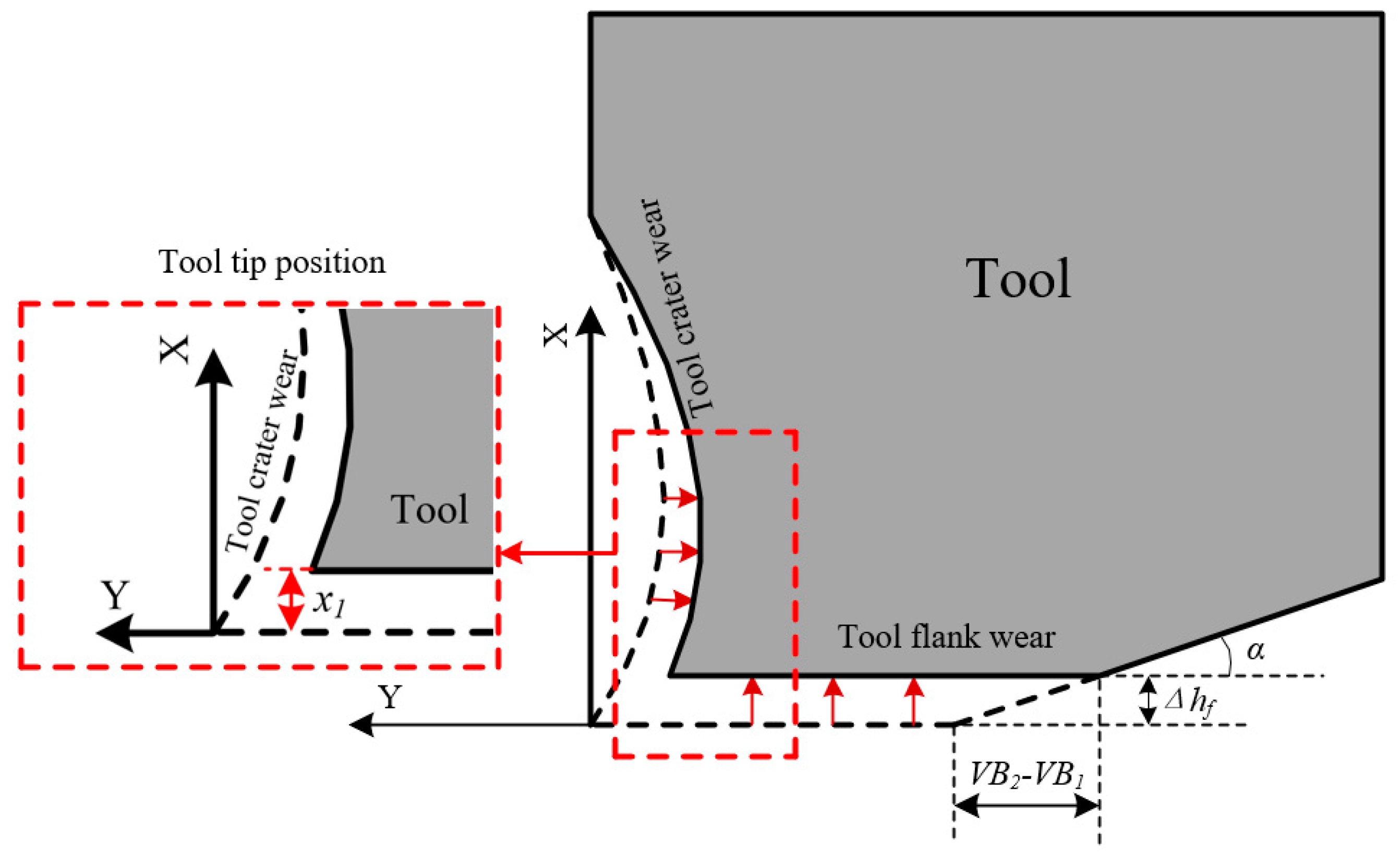

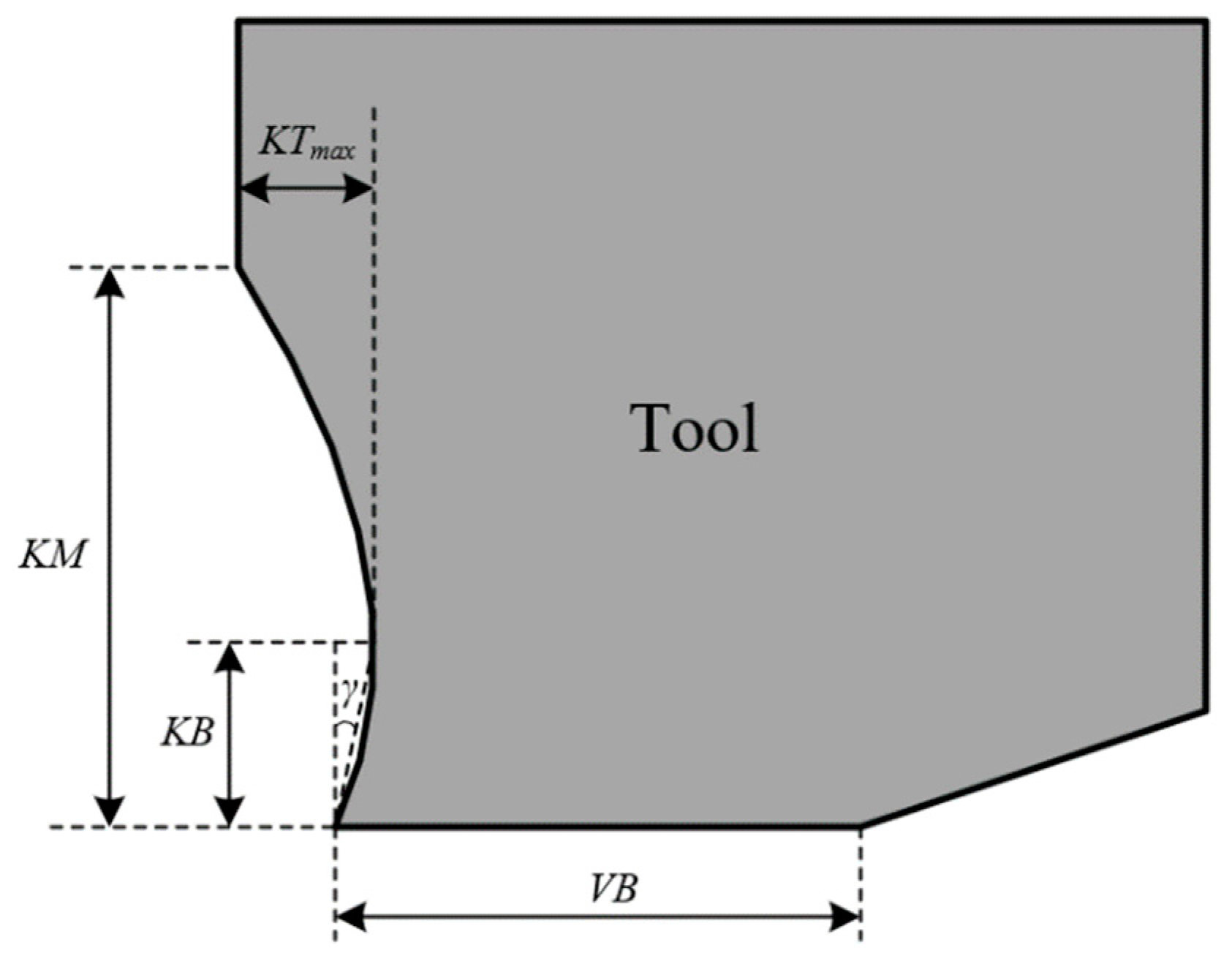

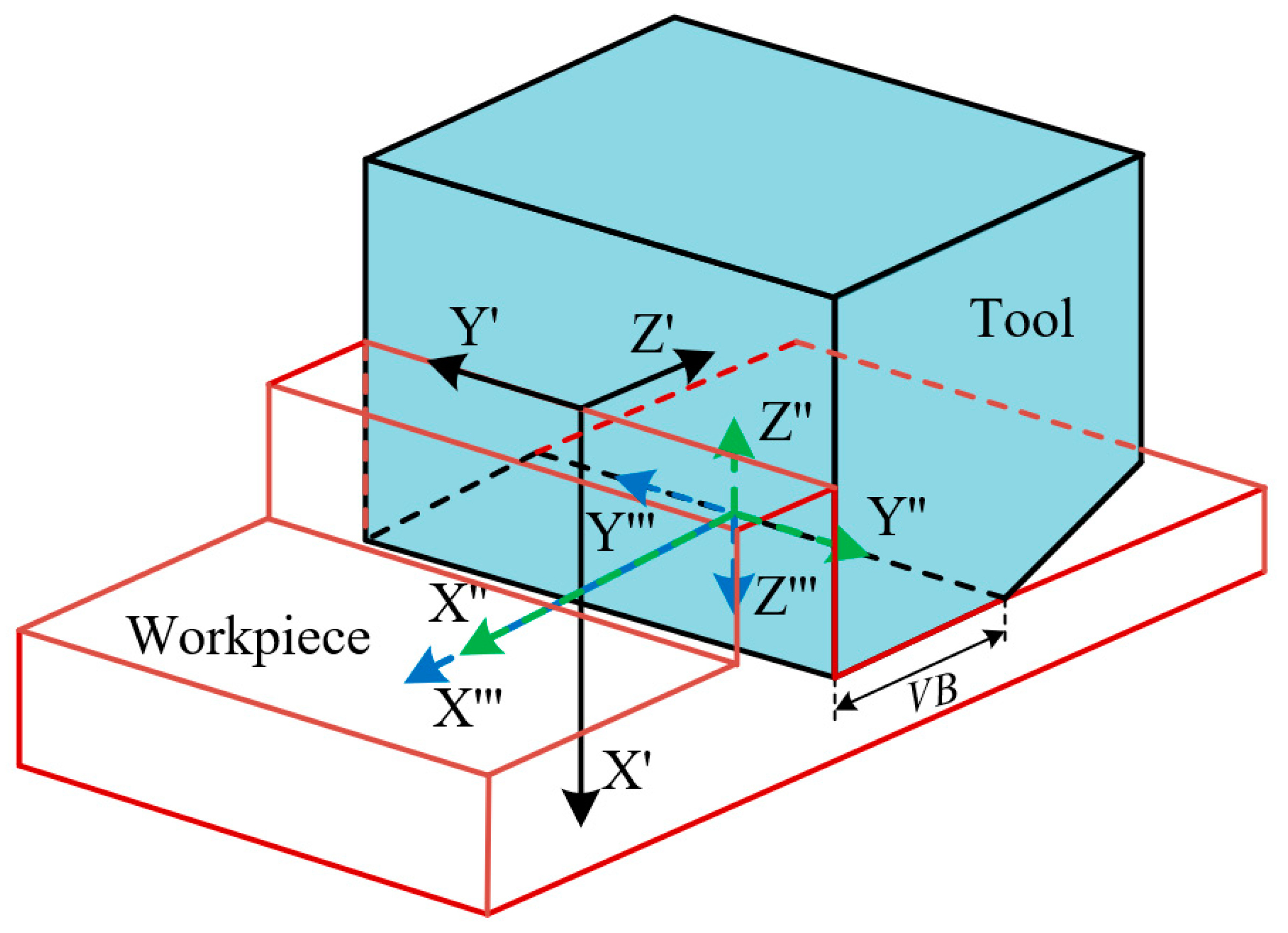

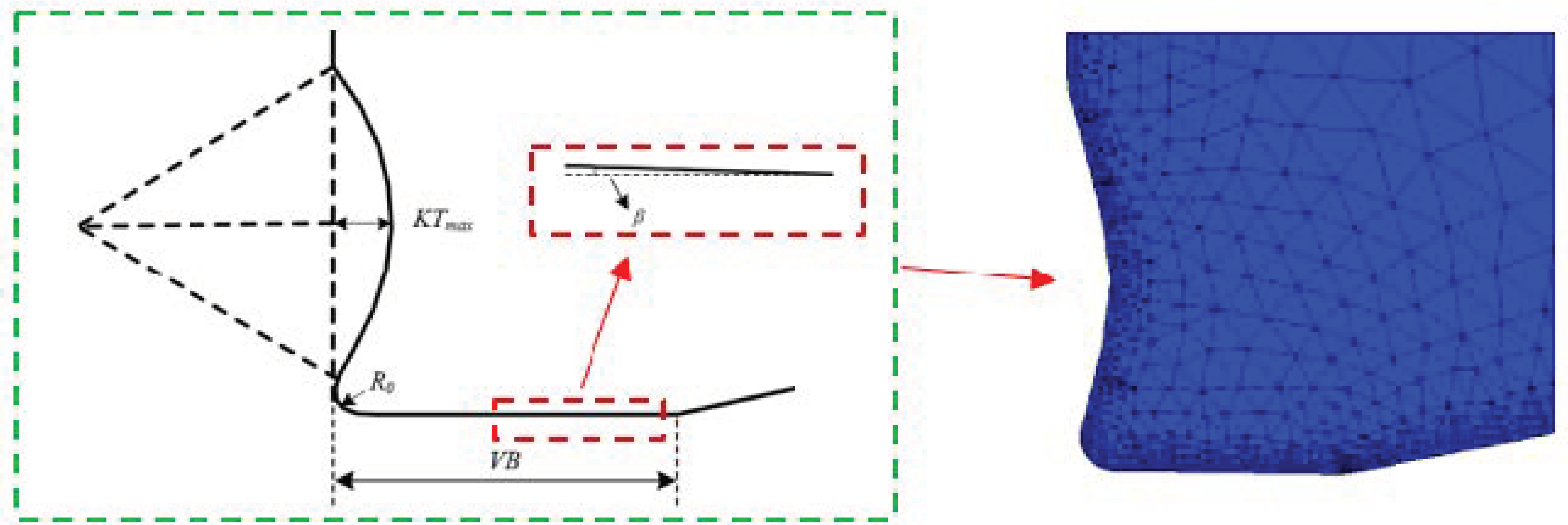

3. Evolution of Tool Geometry during Tool Wear Progress

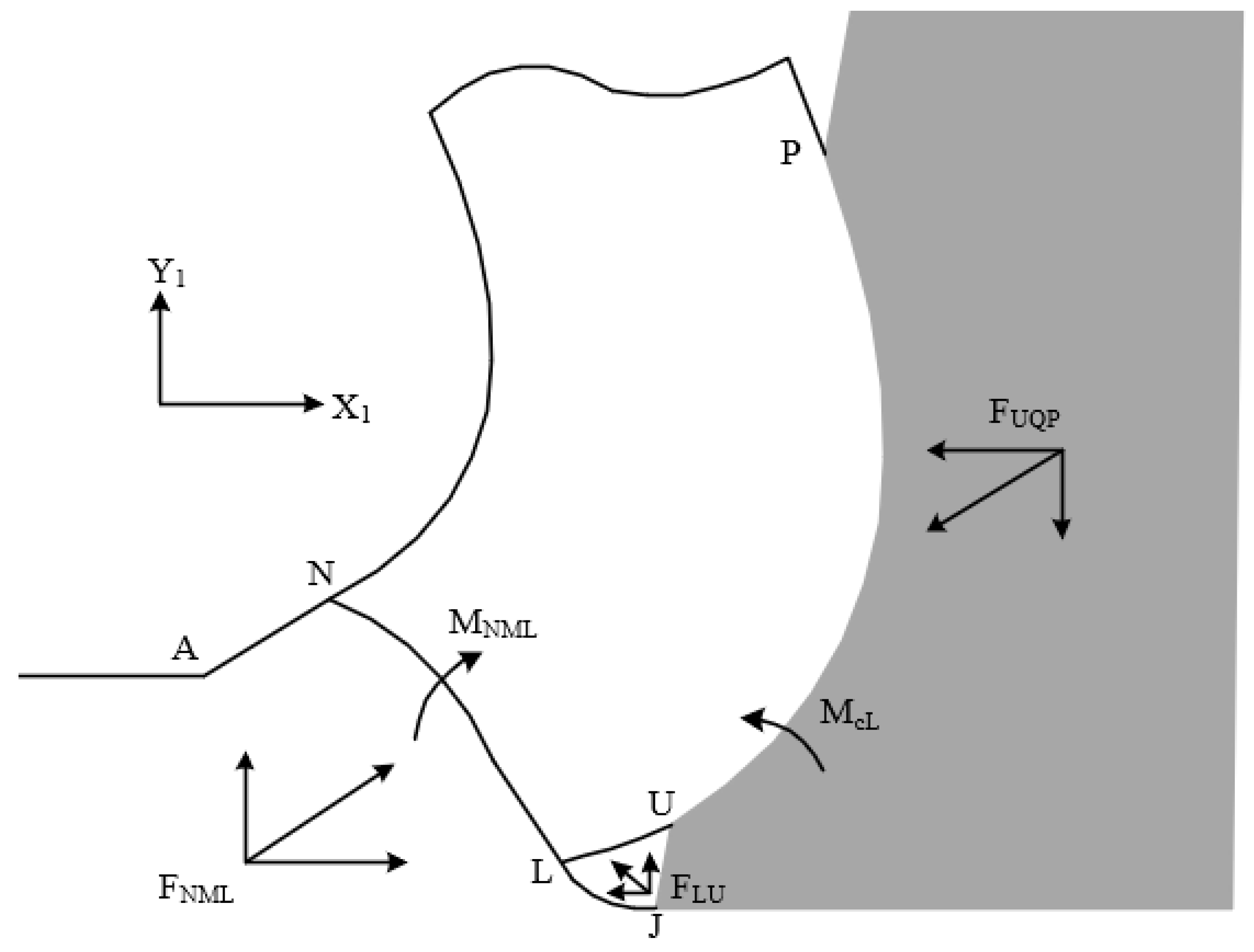

3.1. Evolution of Tool Tip Position

3.2. Tool Rake Angle

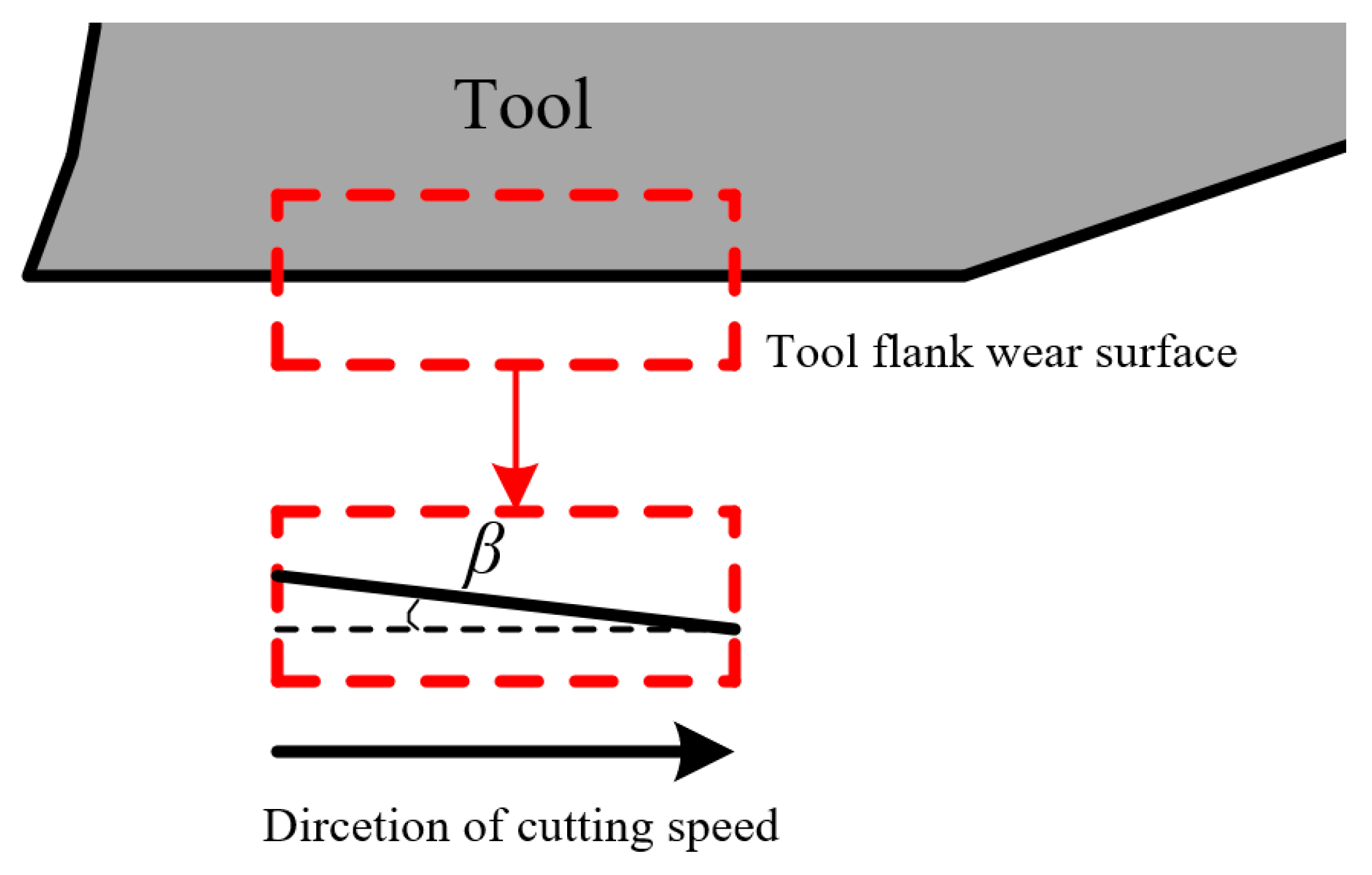

3.3. Tool Flank Rolling Angle

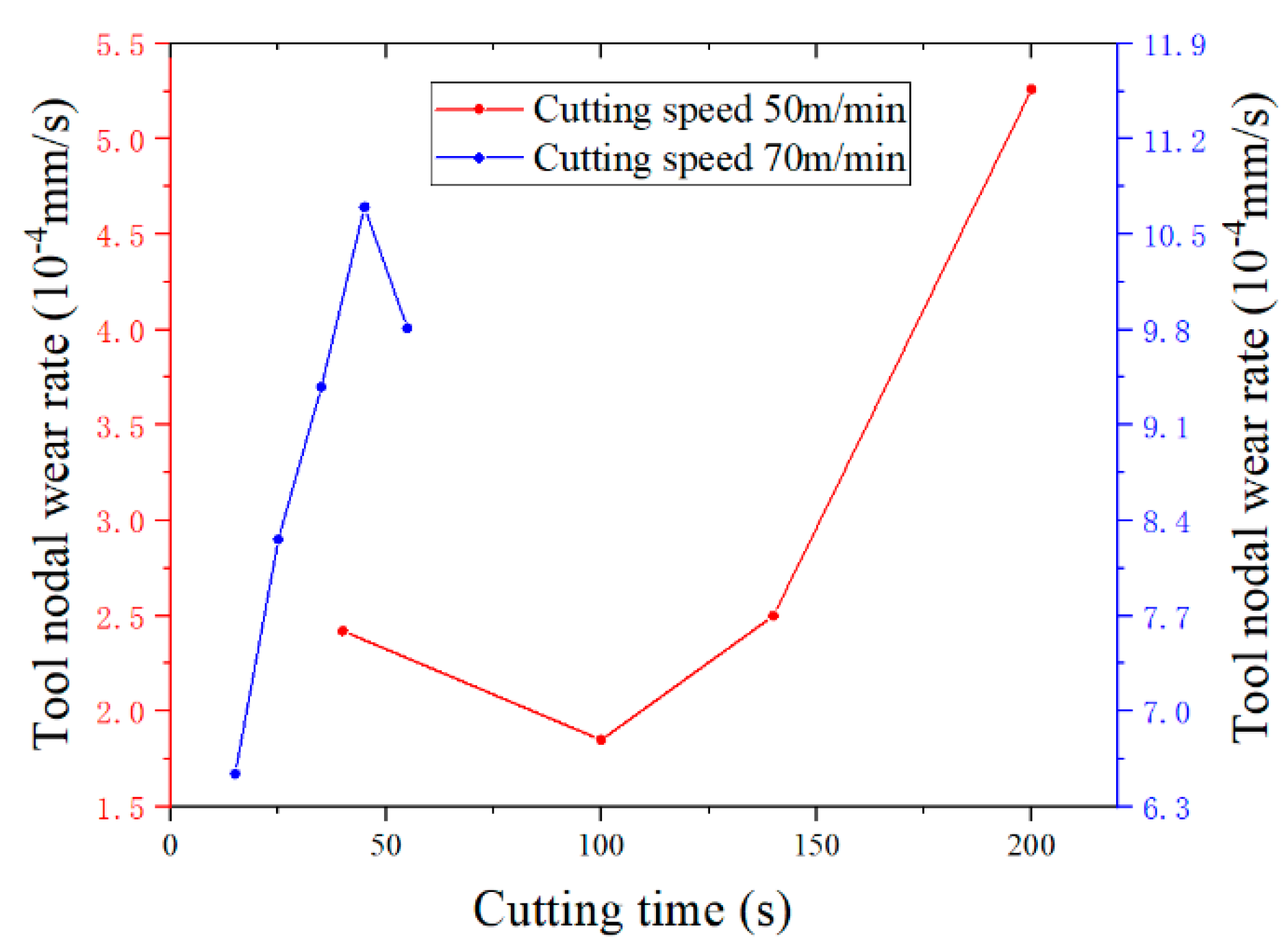

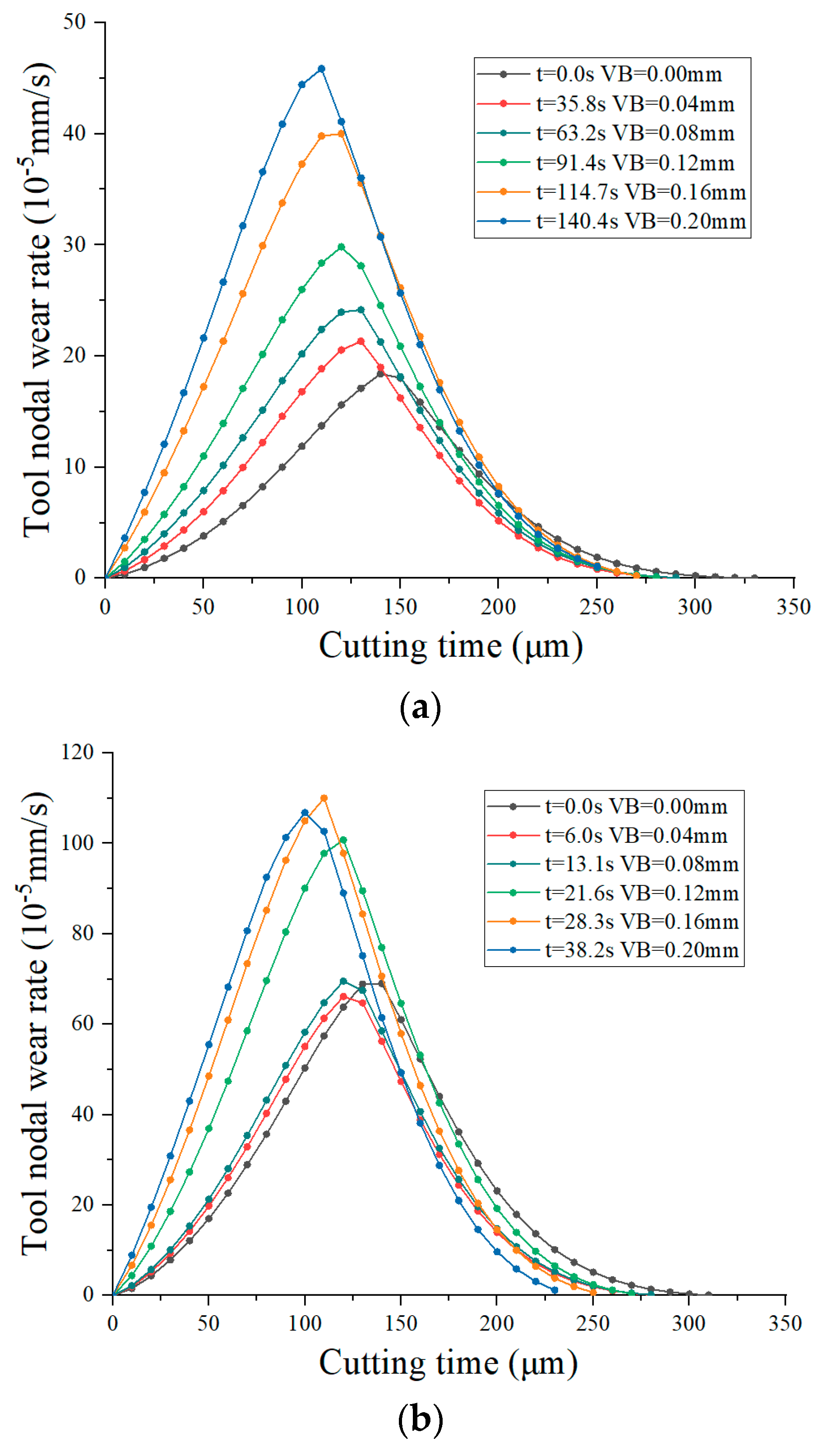

4. Evolution of Tool Wear Rate

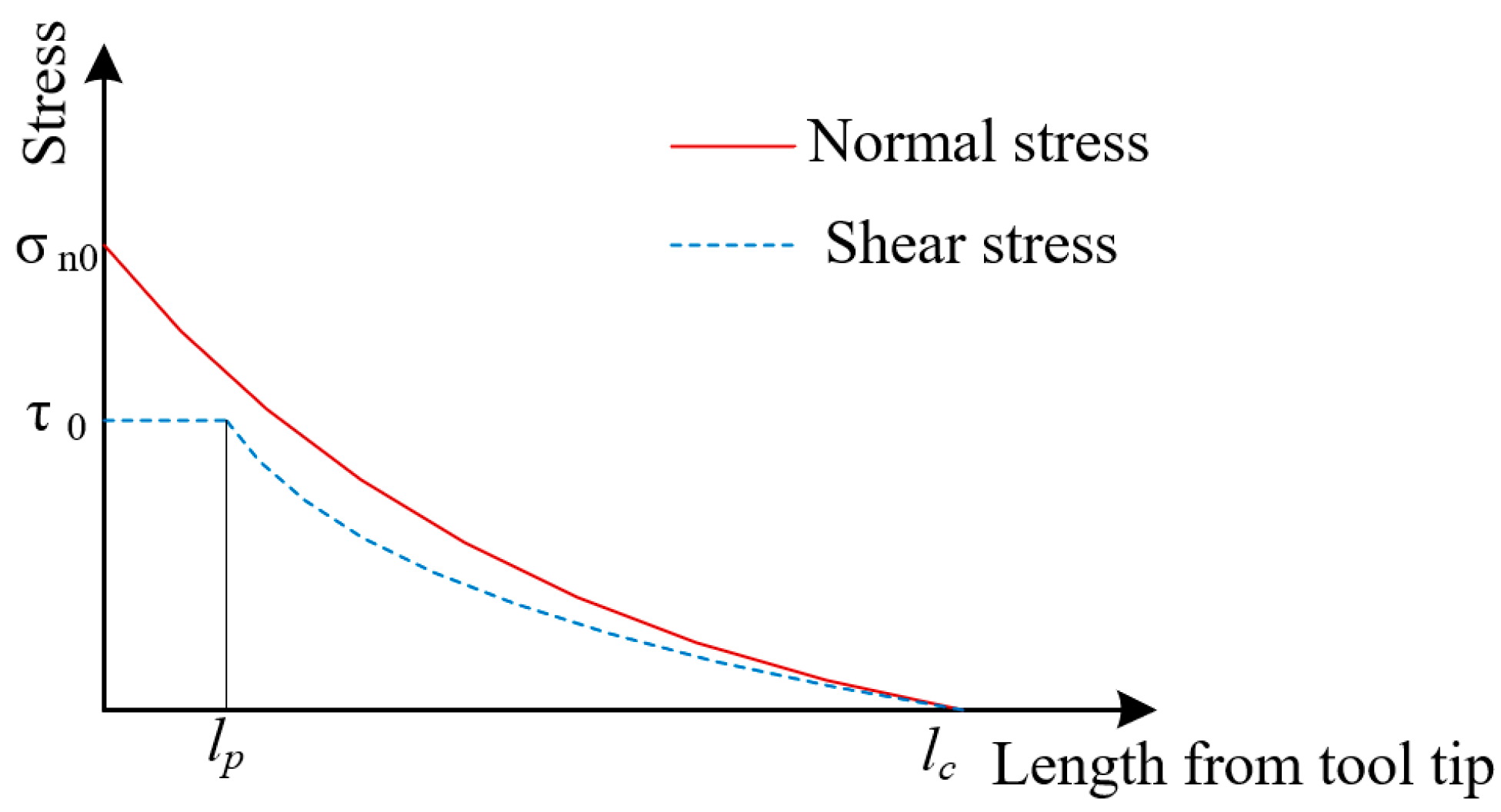

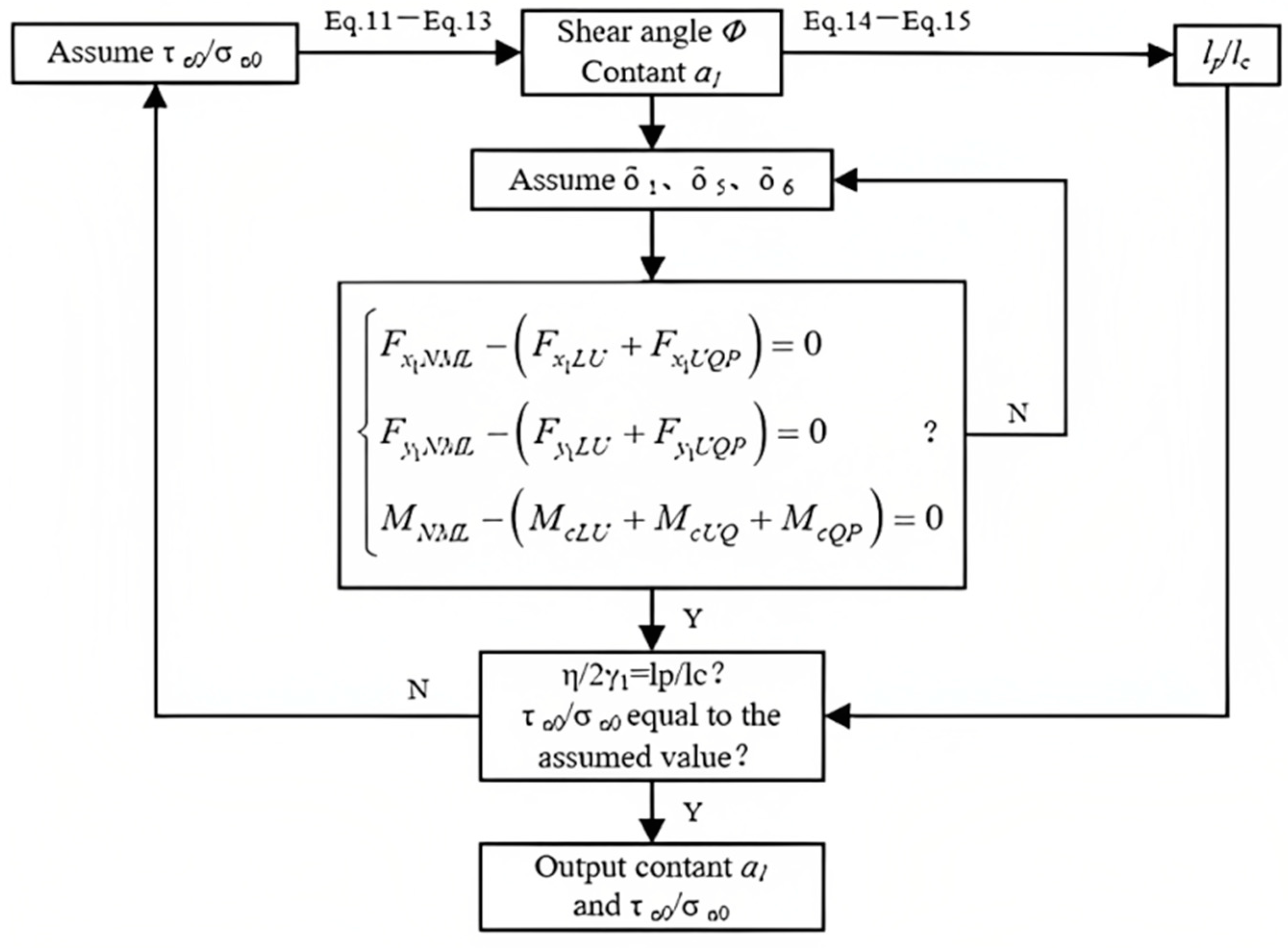

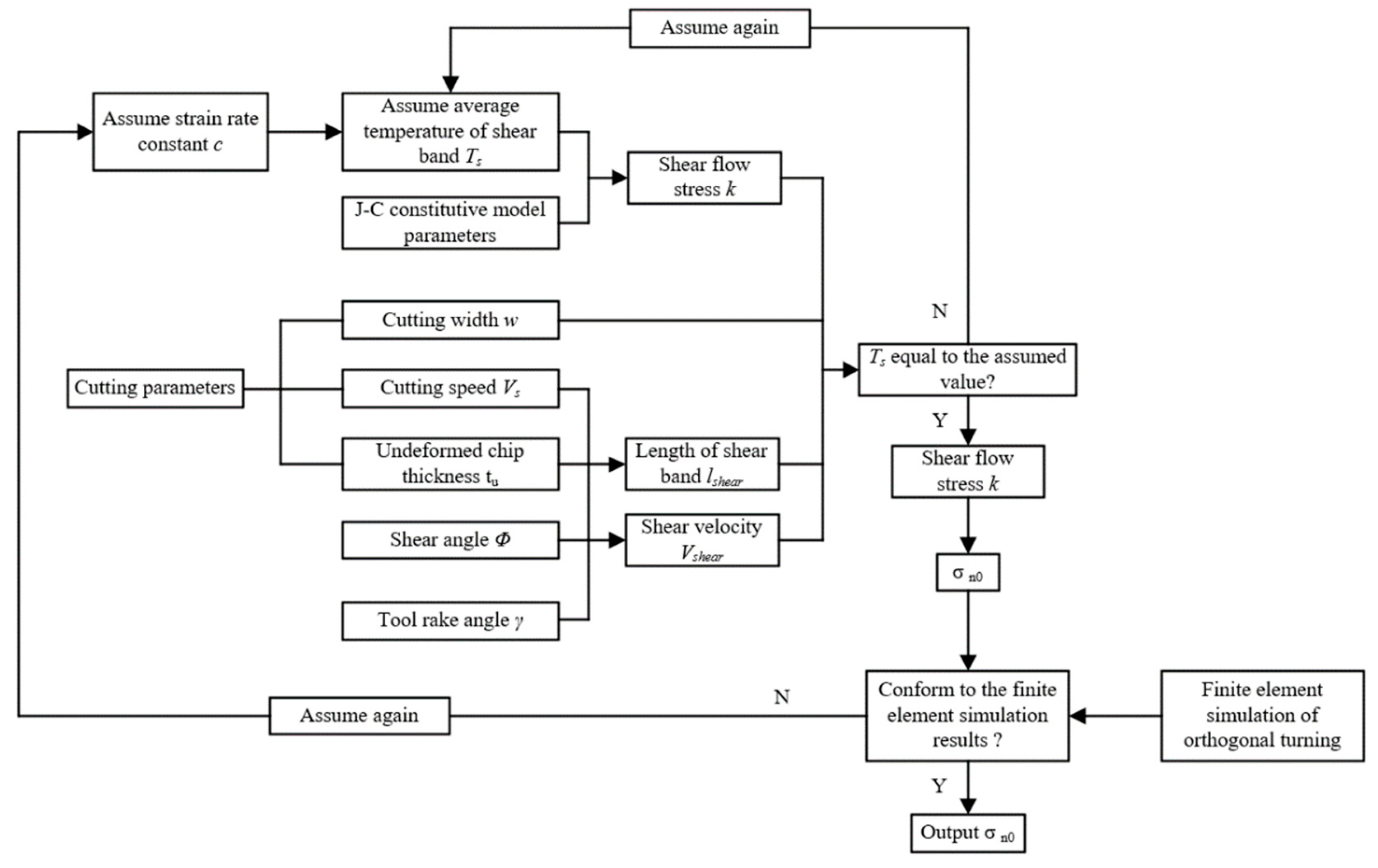

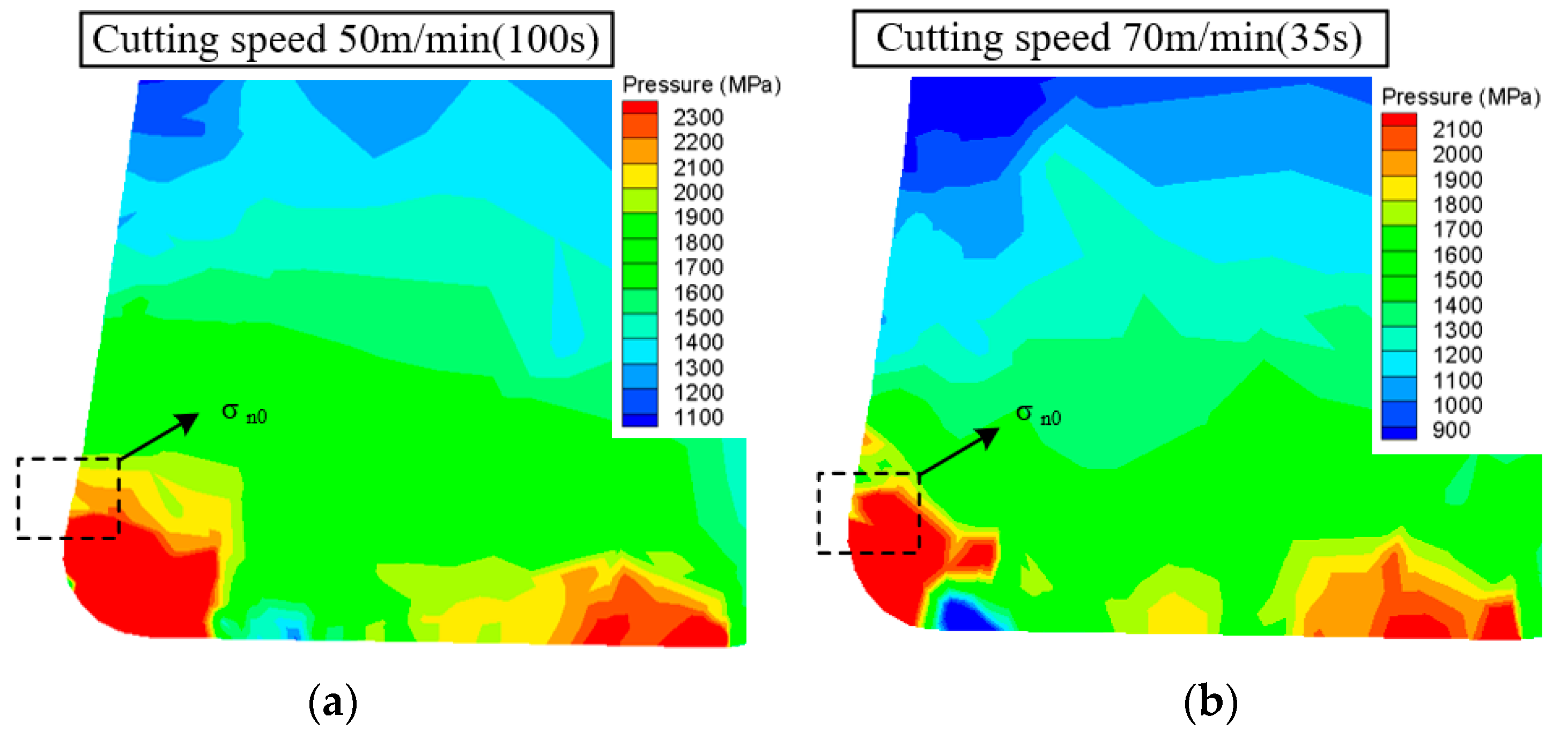

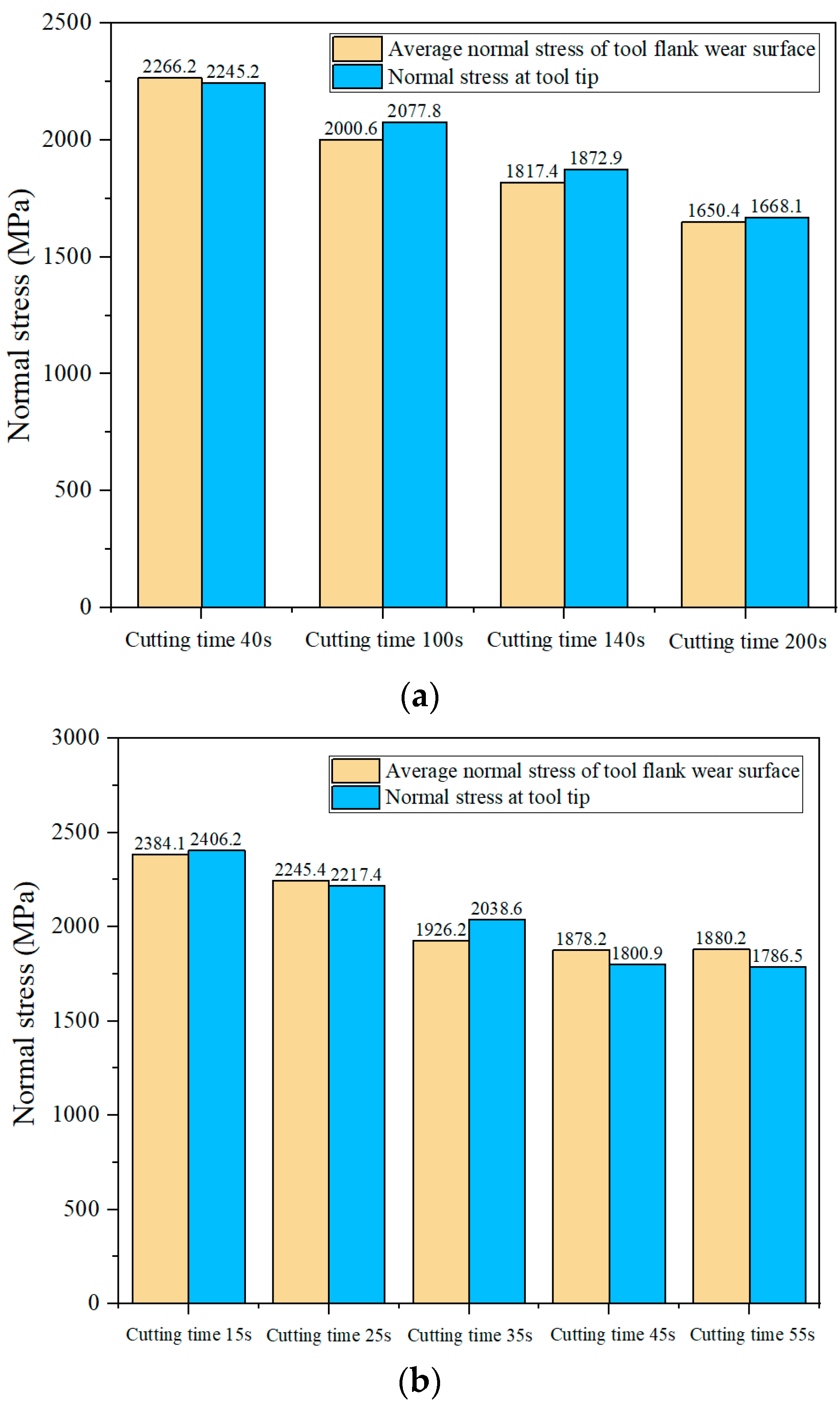

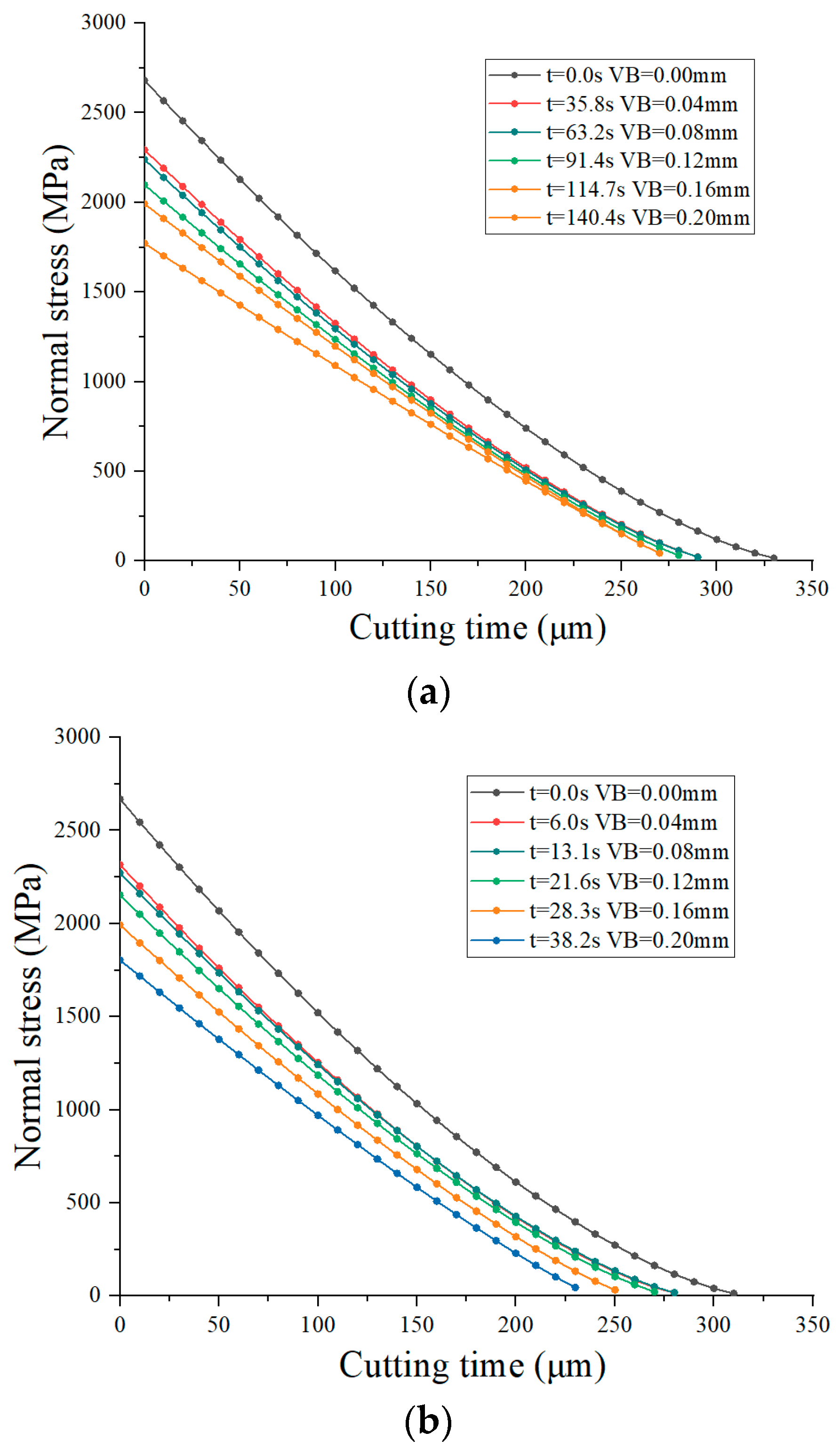

4.1. Normal Stress Distribution on Tool Wear Surface

- (1)

- Normal stress distribution on the tool crater wear surface

- (2)

- Normal stress distribution on the tool flank wear surface

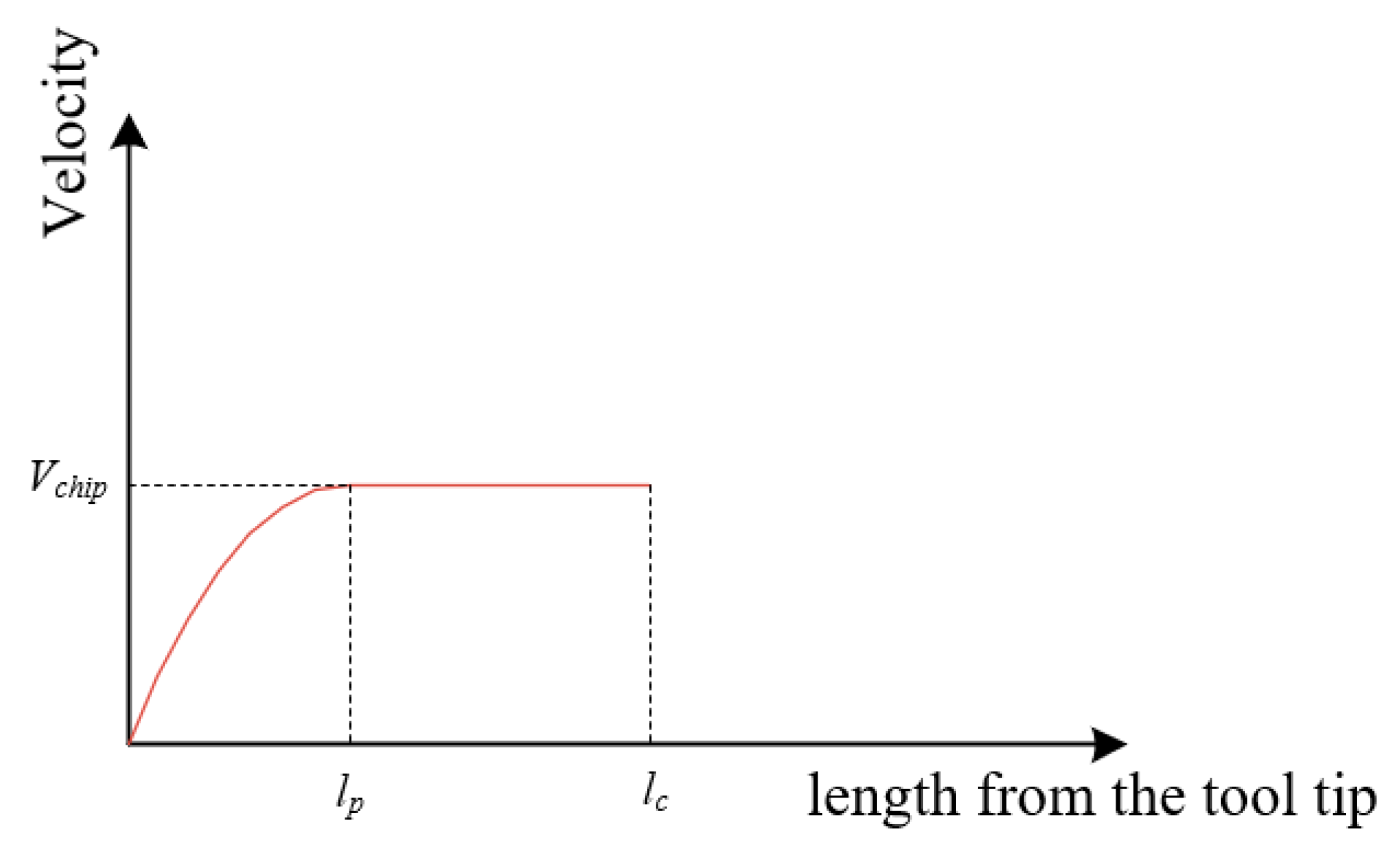

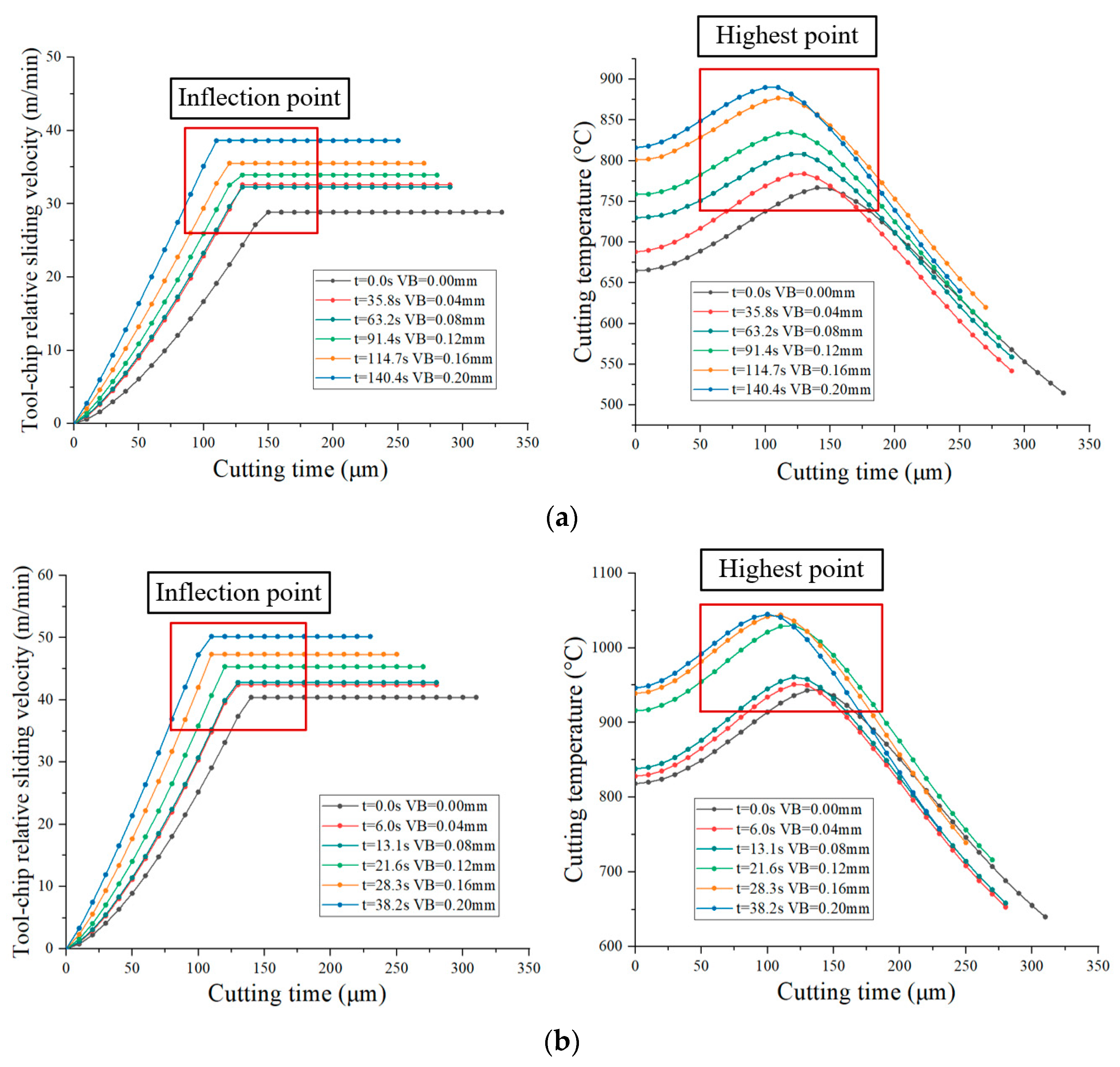

4.2. Tool–Chip Relative Sliding Velocity

4.3. Cutting Temperature Distribution on Tool Wear Surface

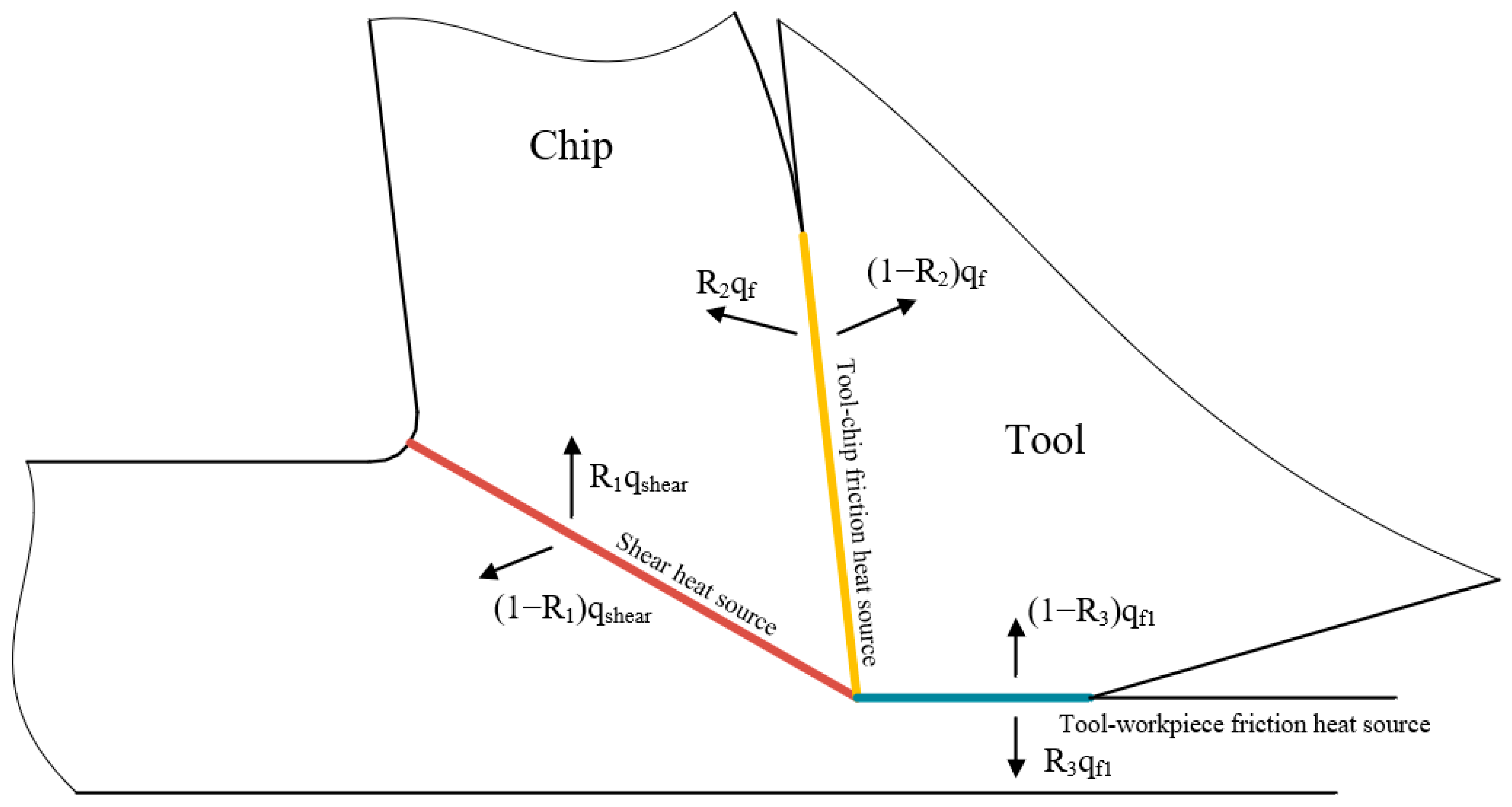

- (1)

- Cutting temperature distribution on the tool crater wear surface

- (2)

- Cutting temperature distribution on the tool flank wear surface

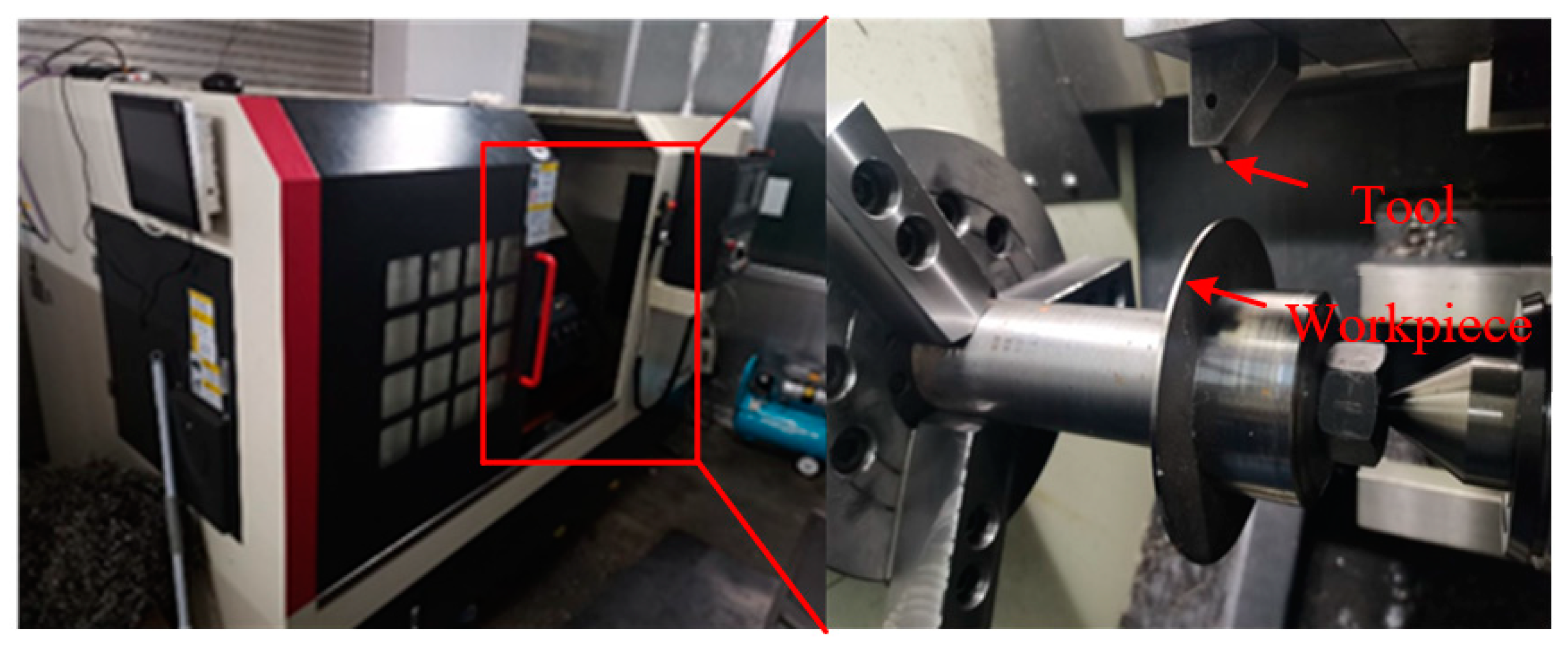

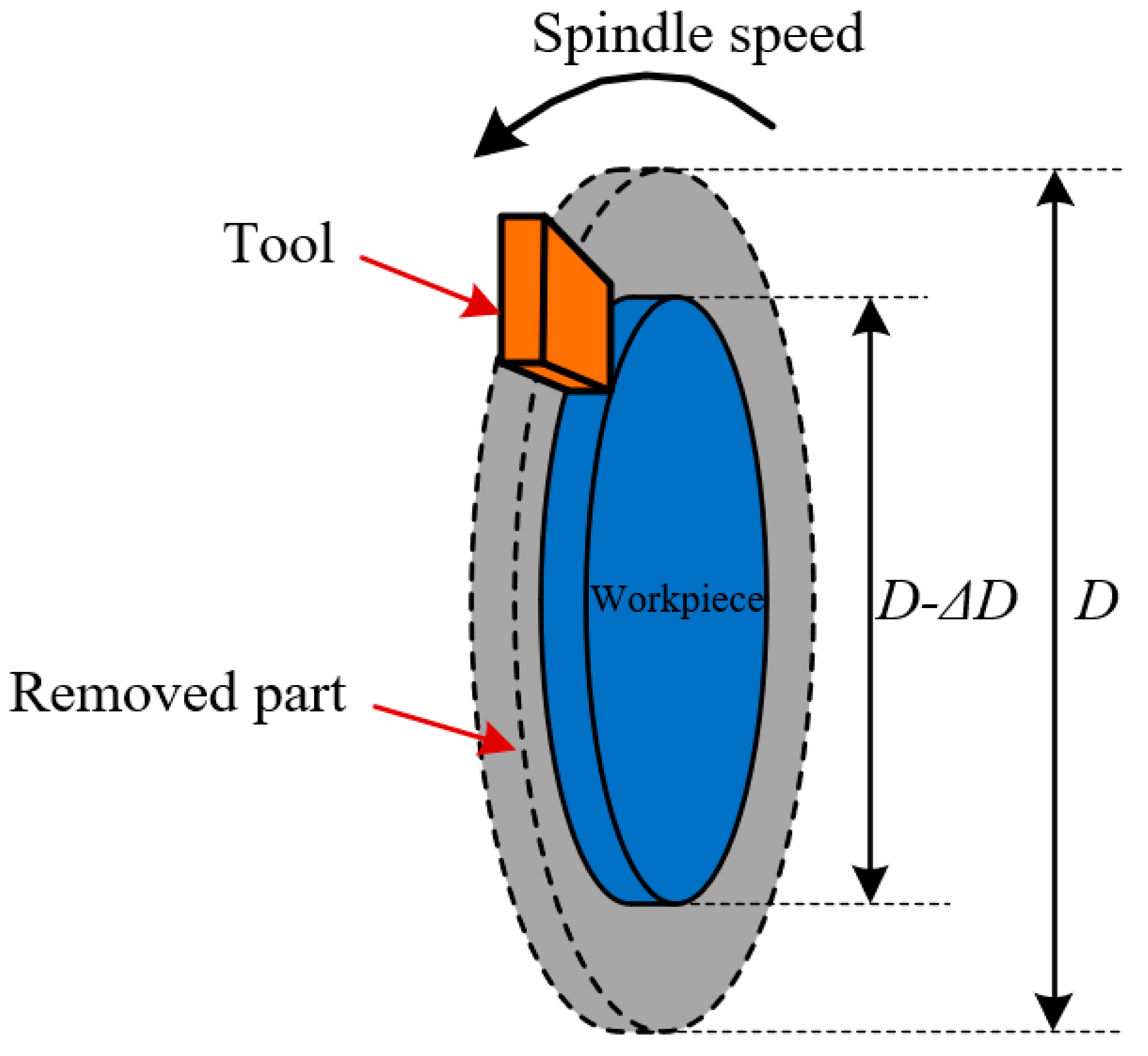

5. Orthogonal Cutting Experiment

6. Finite Element Simulation of Orthogonal Cutting

7. Results and Discussion

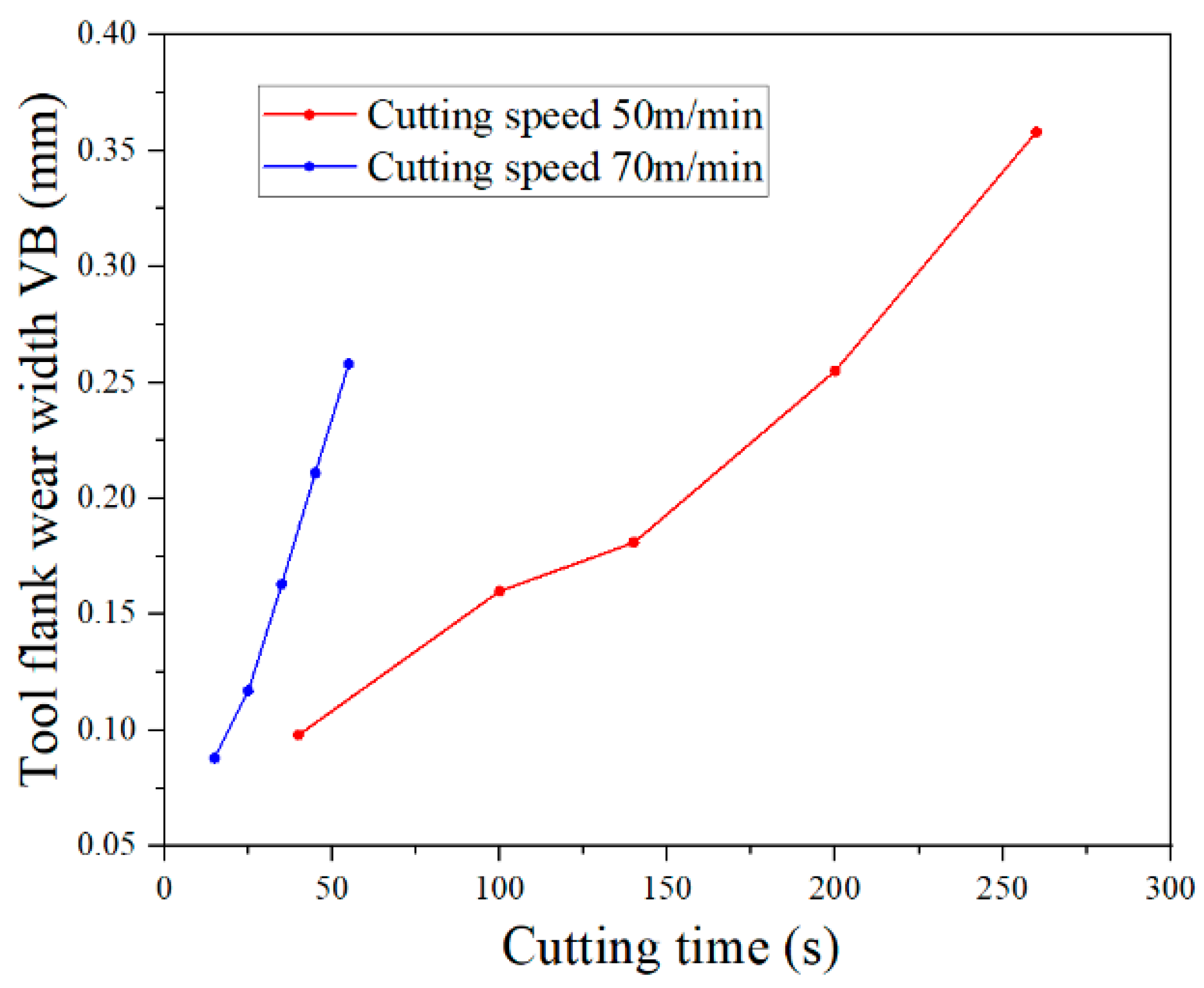

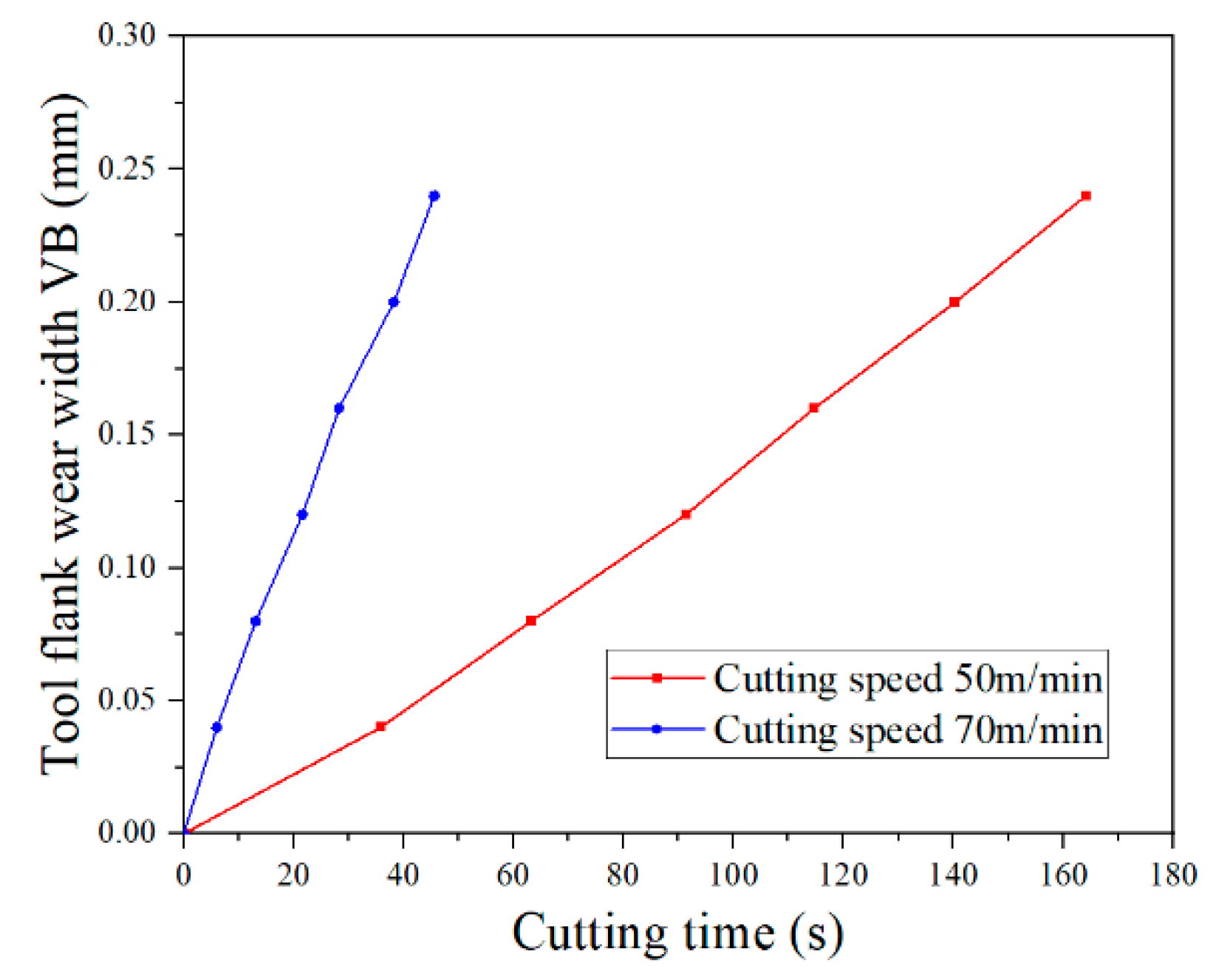

7.1. Results of Orthogonal Cutting Experiment

7.2. Results of Finite Element Simulation

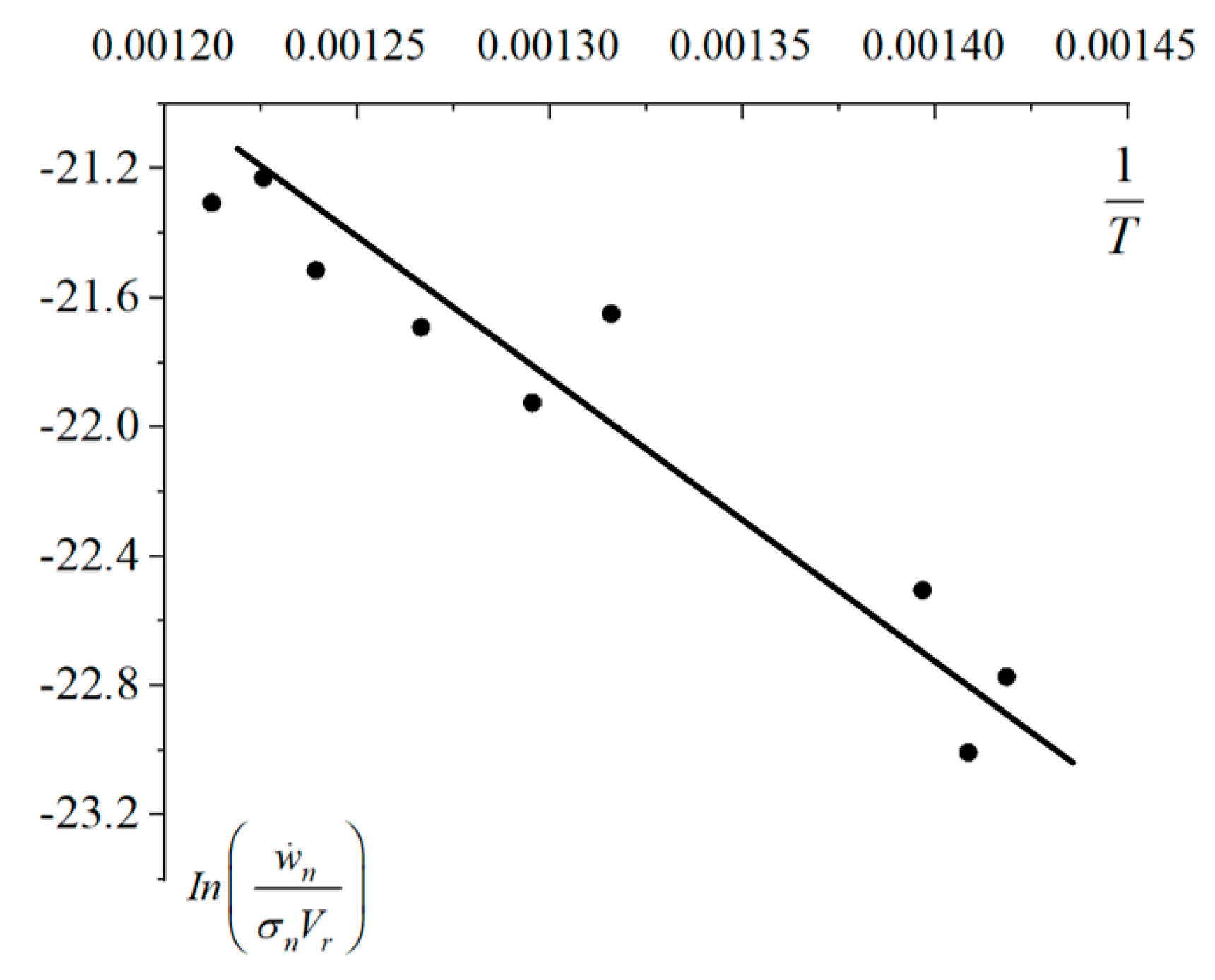

7.3. Solution of Usui Model Constants

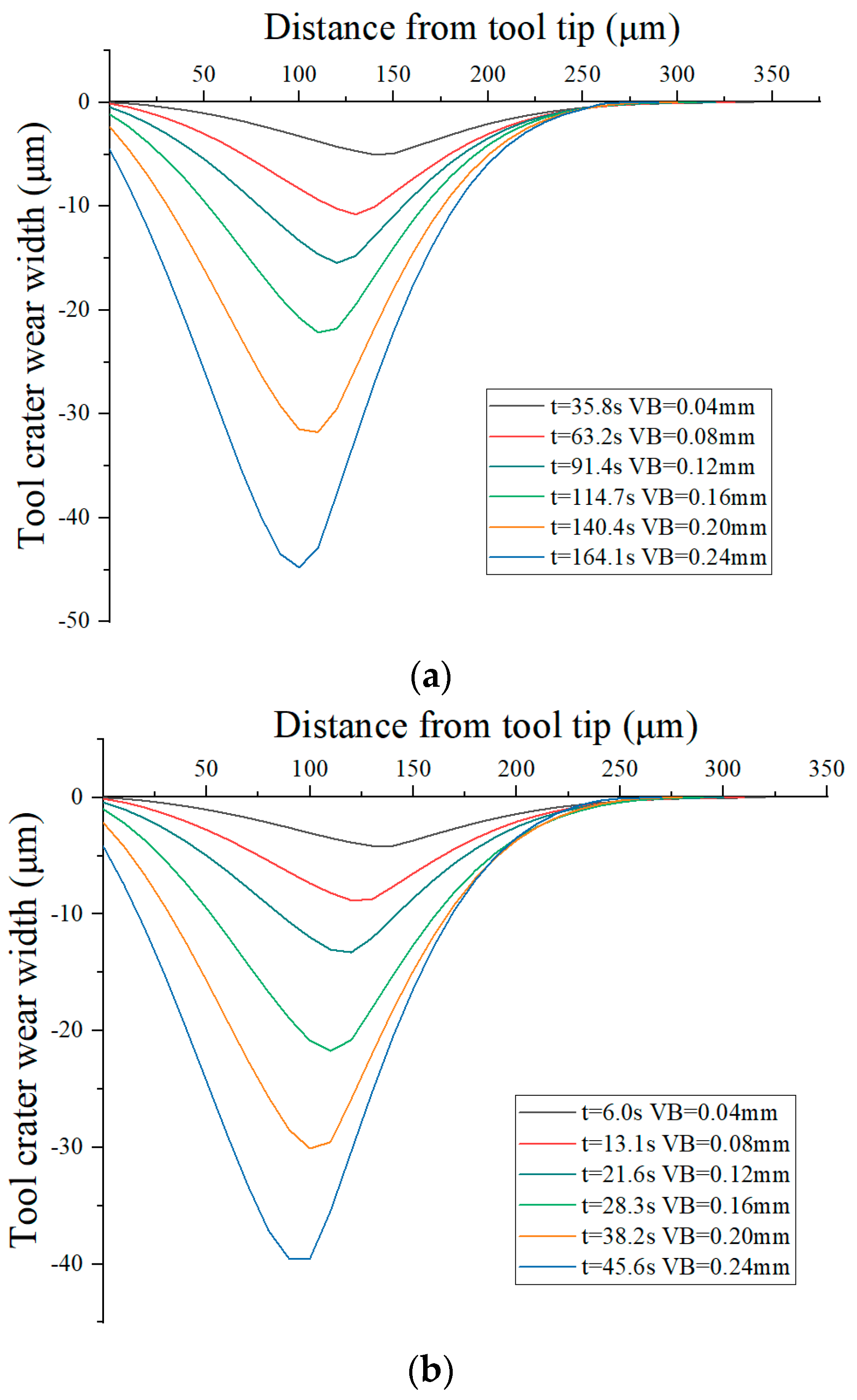

7.4. Predicted Results of Tool Wear

8. Conclusions

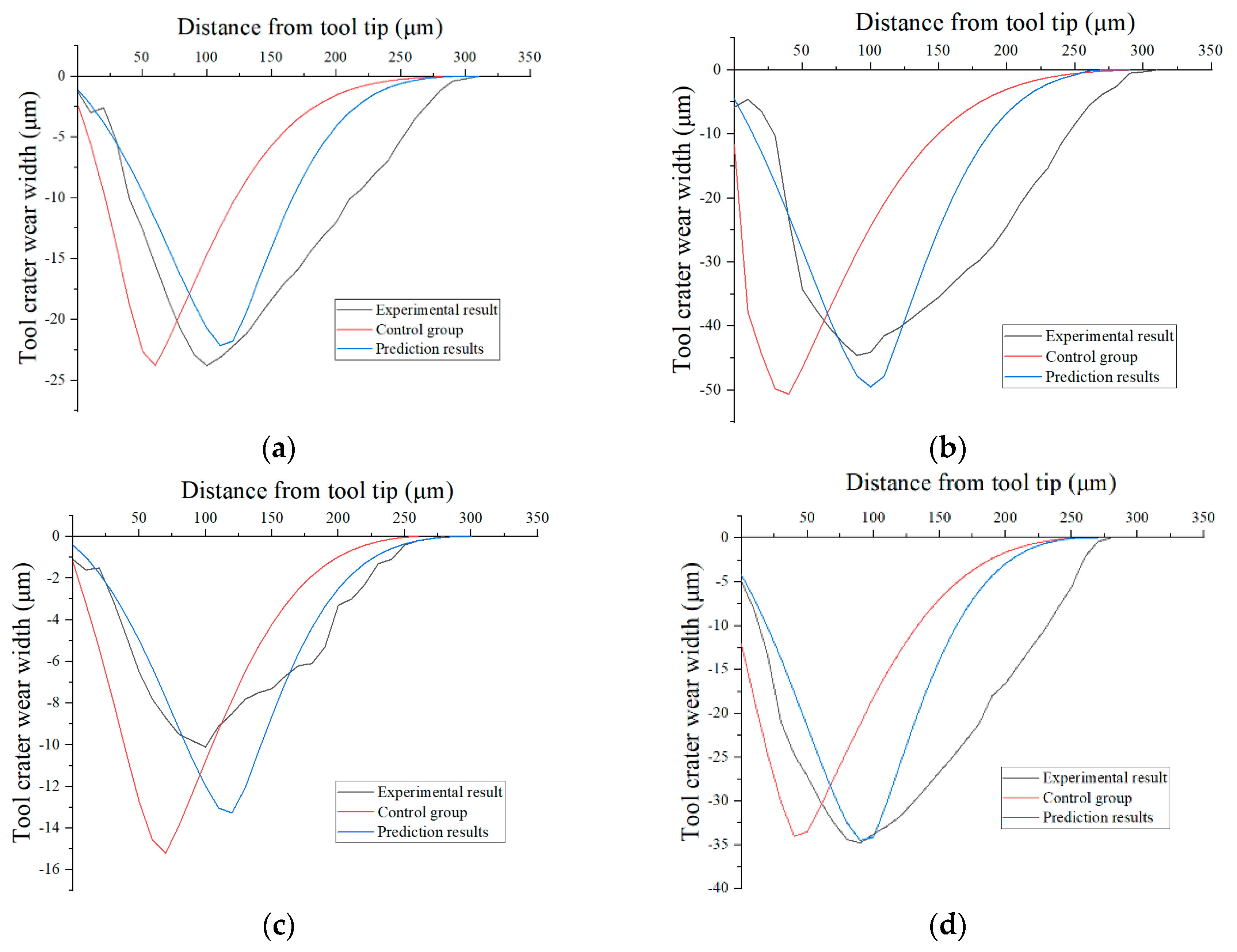

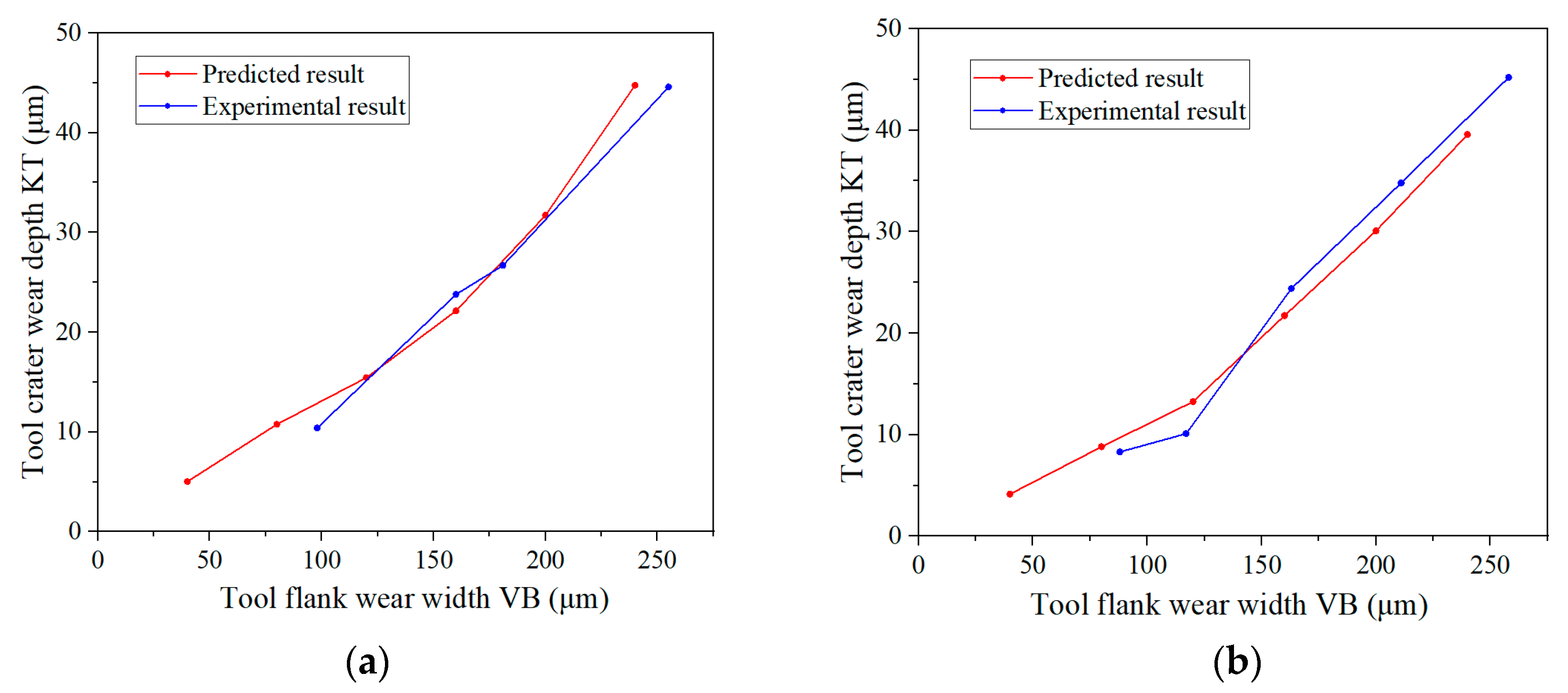

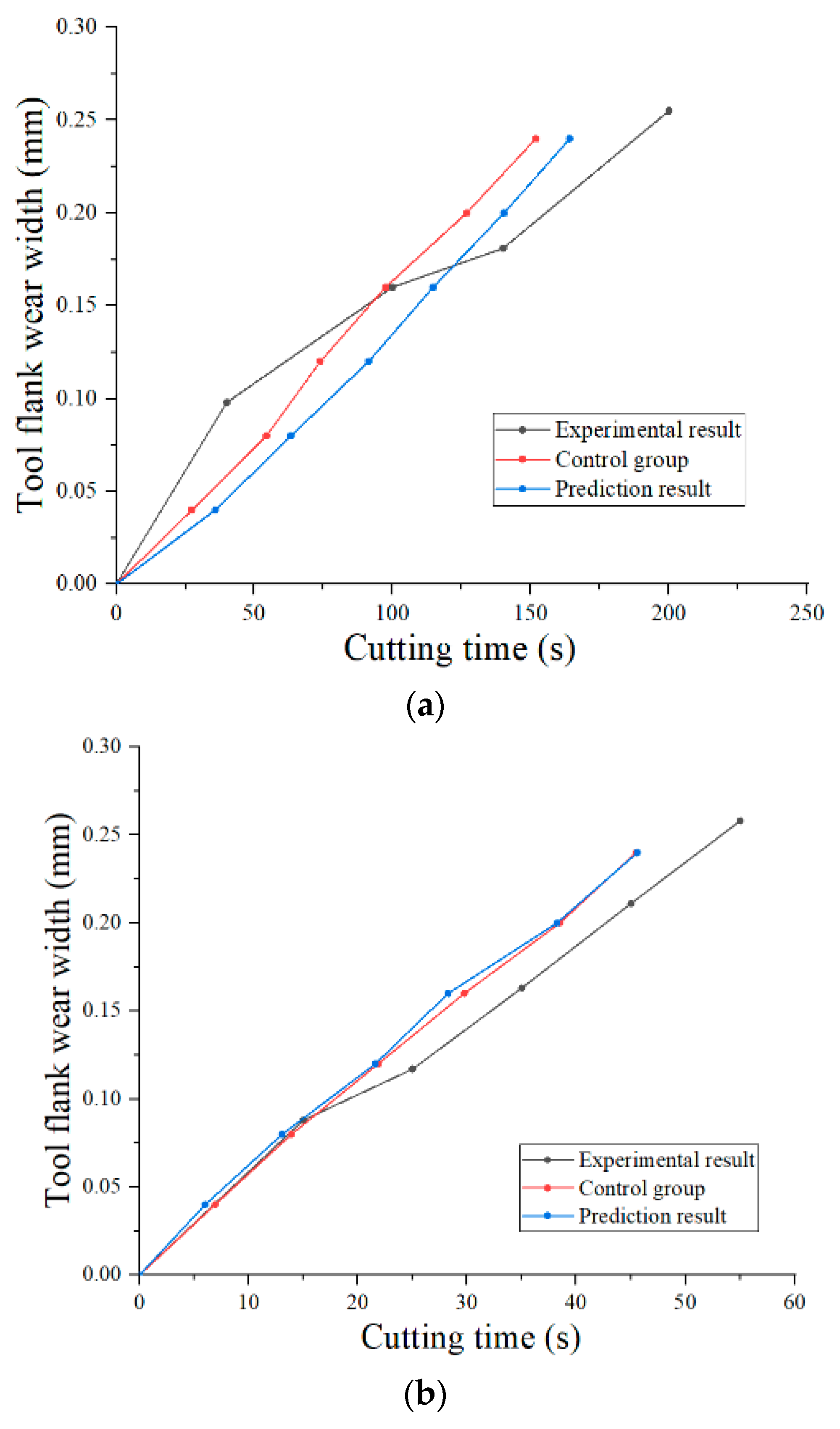

- (1)

- The predicted maximum depth of the tool crater wear profile and the deepest point of tool crater wear profile are consistent with the experimental results. Considering the real-time evolution of shear angle and tool–chip contact length with tool wear is helpful to improve the prediction accuracy of rake face wear profile. The prediction method proposed in this paper is consistent with the experimental results in the prediction of the deepest point of tool crater wear profile, and the prediction error is less than 20%. The prediction results of control group have a large error in the prediction of the deepest point of the tool crater wear profile. The predicted results of the tool flank wear are also consistent with the experimental results. The predicted tool flank wear curves did not follow a conventional tool wear pattern, and the tool wear rate model needs to be further optimized according to the specific machining conditions.

- (2)

- The nodal wear rate distribution of the tool crater wear surface determines the evolution of the tool crater wear profile. The distribution of the nodal wear rate of the tool crater wear surface depends on the distribution of the cutting temperature and the tool–chip relative sliding velocity. The highest point of the cutting temperature and the inflection point of the tool–chip relative sliding velocity coincide with the highest point of the nodal wear rate of the tool crater wear surface.

- (3)

- The forward movement of the deepest point of tool crater wear profile is attributed to the increase in tool wear. The consideration of the interaction between the tool crater wear and tool flank wear can describe the evolution of the tool–chip contact length and rake angle. The tool–chip contact length decreases with the increase in tool flank wear, resulting in a decrease in the length of the sticking zone. The inflection point of the tool–chip relative sliding velocity moves forward, and the highest point of the nodal wear rate of the tool crater wear surface moves forward. The increase in the tool shear angle and tool rake angle leads to the increase in the tool–chip relative sliding velocity. The increase in the tool–chip relative sliding velocity increases the cutting temperature of the tool crater wear surface, the highest point of the cutting temperature coincides with the highest point of the nodal wear rate of the tool crater wear surface, and the nodal wear rate increases. Therefore, the tool crater wear profile deepens.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Taylor, F.W. On the art of cutting metals. Metall. Res. Technol. 1907, 4, 39–65. Available online: http://hdl.handle.net/1957/21006 (accessed on 10 May 2023).

- Li, T.; Shi, T.; Tang, Z. Real-time tool wear monitoring using thin-film thermocouple. J. Mater. Process. Technol. 2020, 288, 116901. [Google Scholar] [CrossRef]

- Sharma, V.K.; Singh, T.; Singh, K.; Kaur, G. MQL assisted face milling of EN-31: Tool wear optimization and its correlation with cutting temperature. Mater. Today Proc. 2022, 71, 346–351. [Google Scholar] [CrossRef]

- Sk, T.; Shankar, S.; Mohanraj, T.; Devendran, K. Tool wear prediction in hard turning of en8 steel using cutting force and surface roughness with artificial neural network. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 329–342. [Google Scholar] [CrossRef]

- Kaya, E.; Kaya, İ. Tool wear progression of PCD and PCBN cutting tools in high speed machining of NiTi shape memory alloy under various cutting speeds. Diam. Relat. Mater. 2020, 105, 107810. [Google Scholar] [CrossRef]

- Olander, P.; Heinrichs, J. On wear of WC–Co cutting inserts in turning of Ti6Al4V—A study of wear surfaces. Tribol.-Mater. Surf. Interfaces 2020, 15, 181–192. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Usui, E.; Shirakashi, T.; Kitagawa, T. Analytical prediction of cutting tool wear. Wear 1984, 100, 129–151. [Google Scholar] [CrossRef]

- Malakizadi, A.; Gruber, H.; Sadik, I.; Nyborg, L. An FEM-based approach for tool wear estimation in machining. Wear 2016, 368, 10–24. [Google Scholar] [CrossRef]

- Binder, M.; Klocke, F.; Lung, D. Tool wear simulation of complex shaped coated cutting tools. Wear 2015, 330, 600–607. [Google Scholar] [CrossRef]

- Haddag, B.; Nouari, M. Tool wear and heat transfer analyses in dry machining based on multi-steps numerical modelling and experimental validation. Wear 2013, 302, 1158–1170. [Google Scholar] [CrossRef]

- Matsumura, T.; Shirakashi, T.; Usui, E. Identification of wear characteristics in tool wear model of cutting process. Int. J. Mater. Form. 2008, 1, 555–558. [Google Scholar] [CrossRef]

- Zhao, H.; Barber, G.C.; Zou, Q. A study of flank wear in orthogonal cutting with internal cooling. Wear 2002, 253, 957–962. [Google Scholar] [CrossRef]

- Sagar, C.K.; Priyadarshini, A.; Gupta, A.K. Experimental investigation of tool wear characteristics and analytical prediction of tool life using a modified tool wear rate model while machining 90 tungsten heavy alloys. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 253, 242–254. [Google Scholar] [CrossRef]

- Elias, J.V.; Asams, S.; Mathew, J. Worn tool geometry–based flank wear prediction in micro turning. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 710–719. [Google Scholar] [CrossRef]

- Nooraie, R.Y.; Safari, M.; Pak, A. Tool wear estimation in machining based on the flank wear inclination angle changes using the FE method. Mach. Sci. Technol. 2019, 24, 425–445. [Google Scholar] [CrossRef]

- Huang, Y.; Chou, Y.K.; Liang, S.Y. CBN tool wear in hard turning: A survey on research progresses. Int. J. Adv. Manuf. Technol. 2007, 35, 443–453. [Google Scholar] [CrossRef]

- Yue, C.; Li, X.; Liu, X.; Du, J.; Liang, S.Y.; Wang, L.; Sun, Y. Wear behavior of tool flank in the side milling of Ti6Al4V: An analytical model and experimental validation. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 1631–1644. [Google Scholar] [CrossRef]

- Huang, Y.; Dawson, T.G. Tool crater wear depth modeling in CBN hard turning. Wear 2005, 258, 1455–1461. [Google Scholar] [CrossRef]

- Zhuang, K.; Li, M.; Lin, F.; Hu, C.; Weng, J.; Gao, Z.; Wu, C. Crater wear prediction in turning Ti6Al4V considering cutting temperature effect. Int. J. Adv. Manuf. Technol. 2022, 121, 6763–6781. [Google Scholar] [CrossRef]

- Olortegui-Yume, J.A.; Kwon, P.Y. Local crater wear prediction using physics-based models. J. Manuf. Sci. Eng 2010, 132, 051007. [Google Scholar] [CrossRef]

- Mishra, S.K.; Ghosh, S.; Aravindan, S. Temporal and spatial crater wear prediction of WC/Co tools during dry turning of Ti6Al4V alloy. Wear 2020, 448, 203229. [Google Scholar] [CrossRef]

- Kursuncu, B.; Caliskan, H.; Guven, S.Y.; Panjan, P. Wear behavior of multilayer nanocomposite TiAlSiN/TiSiN/TiAlN coated carbide cutting tool during face milling of inconel 718 superalloy. J. Nano Res. 2017, 47, 11–16. [Google Scholar] [CrossRef]

- Banda, T.; Ho, K.Y.; Akhavan Farid, A.; Lim, C.S. Characterization of tool wear mechanisms and failure modes of TiAlN-NbN coated carbide inserts in face milling of Inconel 718. J. Mater. Eng. Perform. 2022, 31, 2309–2320. [Google Scholar] [CrossRef]

- Zorev, N.N. Inter-relationship between shear processes occurring along tool face and shear plane in metal cutting. Int. J. Prod. Res. 1963, 49, 143–152. [Google Scholar] [CrossRef]

- Ozlu, E.; Molinari, A.; Budak, E. Two-zone analytical contact model applied to orthogonal cutting. Mach. Sci. Technol. 2010, 14, 323–343. [Google Scholar] [CrossRef]

- Lee, E.H.; Shaffer, B.W. The theory of plasticity applied to a problem of machining. J. Appl. Mech 1951, 18, 405–413. [Google Scholar] [CrossRef]

- Long, Y.; Huang, Y. Combined effects of flank and crater wear on cutting force modeling in orthogonal machining—Part I: Model development. Mach. Sci. Technol. 2010, 14, 1–23. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.; Hou, X.; Zhao, J. Influences of cutting speed and material mechanical properties on chip deformation and fracture during high-speed cutting of Inconel 718. Materials 2018, 11, 461. [Google Scholar] [CrossRef]

- Karpat, Y.; Özel, T. Predictive analytical and thermal modeling of orthogonal cutting process—Part I: Predictions of tool forces, stresses, and temperature distributions. J. Manuf. Sci. Eng. 2006, 128, 435–444. [Google Scholar] [CrossRef]

- Waldorf, D.J. Shearing, Ploughing, and Wear in Orthogonal Machining; University of Illinois at Urbana-Champaign: Champaign County, IL, USA, 1996. [Google Scholar]

- Zhou, J.M.; Andersson, M.; Ståhl, J.E. Cutting tool fracture prediction and strength evaluation by stress identification, part i: Stress model. Int. J. Mach. Tool Manuf. 1997, 37, 1691–1714. [Google Scholar] [CrossRef]

- Zorev, N.N. Metal Cutting Mechanics; Pergamon: London, UK, 1966. [Google Scholar]

- Tay, A.O.; Stevenson, M.G.; de Vahl Davis, G. Using the finite element method to determine temperature distributions in orthogonal machining. Proc. Inst. Mech. Eng. 1974, 188, 627–638. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Wang, B.; Hu, J. PVD AlTiN coating effects on tool-chip heat partition coefficient and cutting temperature rise in orthogonal cutting Inconel 718. Int. J. Heat Mass Transf. 2020, 163, 120449. [Google Scholar] [CrossRef]

- Huang, C.; Zou, B.; Guo, P.; Liu, Y.; Huang, C.; Wang, J. Sliding behavior and wear mechanism of iron and cobalt-based high-temperature alloys against WC and SiC balls. Int. J. Refract. Met. Hard Mater. 2016, 59, 40–55. [Google Scholar] [CrossRef]

| A1/MPa | B1/MPa | C | m | n | Tm/K | |

|---|---|---|---|---|---|---|

| 1200 | 895 | 0.016 | 1.55 | 0.526 | 1573 | 1.001 |

| Density (kg/m3) | Elastic Modulus (GPa) | Thermal Conductivity (W/m·K) | Specific Heat Capacity (J/kg·K) | Temperature Coefficient (10−6 m2/s) |

|---|---|---|---|---|

| 8240 | 206 | 13.4 (20 °C) 15.9 (200 °C) 21.2 (600 °C) 30.4 (1000 °C) | 435 (20 °C) 460 (200 °C) 539 (600 °C) 707 (1000 °C) | 3.74 (20 °C) 4.19 (200 °C) 4.77 (600 °C) 5.22 (1000 °C) |

| Density (g/cm3) | Thermal Conductivity (W/m·K) | Specific Heat Capacity (J/kg·K) | Temperature Coefficient (10−6 m2/s) |

|---|---|---|---|

| 14.32 | 92.42 (25 °C) 79.94 (100 °C) 75.33 (300 °C) 68.14 (500 °C) 68.12 (700 °C) 58.35 (900 °C) | 0.45 (25 °C) 0.29 (100 °C) 0.32 (300 °C) 0.33 (500 °C) 0.56 (700 °C) 0.39 (900 °C) | 13.93 (25 °C) 19.43 (100 °C) 16.41 (300 °C) 14.48 (500 °C) 8.05 (700 °C) 10.05 (900 °C) |

| Density (kg/m3) | Elastic Modulus (GPa) | Thermal Conductivity (W/m·K) | Specific Heat Capacity (J/kg·K) | Temperature Coefficient (10−6 m2/s) |

|---|---|---|---|---|

| 1892 | 370 | 15.41 | 769.46 | 10.59 |

| Cutting Speed (m/min) | Cutting Time (s) | ||||

|---|---|---|---|---|---|

| Group | 1 | 2 | 3 | 4 | 5 |

| 50 | 40 | 100 | 140 | 200 | 260 |

| 70 | 15 | 25 | 35 | 45 | 55 |

| Cutting Time/s | 40 | 100 | 140 | 200 | 260 |

|---|---|---|---|---|---|

| = 50 m/min = 0.1 mm/r) | 1.9 | 1.2 | 0.9 | 0.5 | - |

| Cutting Time/s | 15 | 25 | 35 | 45 | 55 |

|---|---|---|---|---|---|

| = 70 m/min = 0.1 mm/r) | 1.8 | 1.5 | 1.2 | 0.7 | 0.5 |

| Cutting Time (s) | 0.0 | 35.8 | 63.2 | 91.4 | 114.7 | 140.4 |

|---|---|---|---|---|---|---|

| / | 30 | 34 | 35 | 36 | 38 | 42 |

| /mm | 0.34 | 0.30 | 0.30 | 0.29 | 0.28 | 0.26 |

| /mm | 0.146 | 0.130 | 0.128 | 0.124 | 0.118 | 0.110 |

| / | 0 | 3 | 4 | 6 | 12 | 16 |

| Cutting Time (s) | 0.0 | 6.0 | 13.1 | 21.6 | 28.3 | 38.2 |

|---|---|---|---|---|---|---|

| / | 32 | 35 | 36 | 38 | 41 | 44 |

| /mm | 0.32 | 0.29 | 0.29 | 0.28 | 0.26 | 0.24 |

| /mm | 0.137 | 0.126 | 0.124 | 0.119 | 0.110 | 0.104 |

| / | 0 | 3 | 5 | 8 | 13 | 18 |

| = 50 m/min VB = 0.160 mm | = 50 m/min VB = 0.255 mm | = 70 m/min VB = 0.117 mm | = 70 m/min VB = 0.211 mm | |||||

|---|---|---|---|---|---|---|---|---|

| KT | Position of KT | KT | Position of KT | KT | Position of KT | KT | Position of KT | |

| Error 1 | 0.55% | 40.00% | 13.45% | 55.55% | 51.94% | 30.00% | 2.30% | 55.55% |

| Error 2 | 6.97% | 10.00% | 11.01% | 11.11% | 32.46% | 20.00% | 0.91% | 11.11% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Liu, Z.; Ren, X.; Zhao, J. Prediction of Tool Wear Rate and Tool Wear during Dry Orthogonal Cutting of Inconel 718. Metals 2023, 13, 1225. https://doi.org/10.3390/met13071225

Zhang Z, Liu Z, Ren X, Zhao J. Prediction of Tool Wear Rate and Tool Wear during Dry Orthogonal Cutting of Inconel 718. Metals. 2023; 13(7):1225. https://doi.org/10.3390/met13071225

Chicago/Turabian StyleZhang, Ziqi, Zhanqiang Liu, Xiaoping Ren, and Jinfu Zhao. 2023. "Prediction of Tool Wear Rate and Tool Wear during Dry Orthogonal Cutting of Inconel 718" Metals 13, no. 7: 1225. https://doi.org/10.3390/met13071225

APA StyleZhang, Z., Liu, Z., Ren, X., & Zhao, J. (2023). Prediction of Tool Wear Rate and Tool Wear during Dry Orthogonal Cutting of Inconel 718. Metals, 13(7), 1225. https://doi.org/10.3390/met13071225