Abstract

The use of acoustic and magnetic methods of non-destructive testing to detect zones of stable localization of deformation in order to assess and predict the performance of long-term equipment is of scientific and practical interest at present. A structural–mechanical criterion was developed that reflects the relationships between the structural and substructural states, internal stress fields and stable localization of deformations with the characteristics of non-destructive tests in the metal of long-term equipment made of structural 0.2 C steel and heat-resistant 0.12C-1Cr-1Mo-1V steel. The values of the structural–mechanical criteria Ks.-m for structural 0.2 C steel and for heat-resistant 0.12C-1Cr-1Mo-1V steel, corresponding to the moment of stable localization of deformation, are established. At the same time, it is recommended to replace the checked equipment nodes due to the exhaustion of the resource. The proposed and justified approach to assessing and predicting the performance and residual life of long-term power equipment, based on the identified relationships between the structural and substructural states, internal stress fields and stable localization of deformations with the characteristics of non-destructive tests and the calculation of the structural–mechanical criterion, was applied at a number of power plants in the Kemerovo region—Kuzbass. A methodology was developed for evaluating the residual life, based on the identification and use of relationships between structural and substructural states, internal stress fields and stable localization of deformations with the characteristics of non-destructive tests and the calculation of a structural–mechanical criterion.

1. Introduction

Most (more than 80%) of the equipment used in Russian power industry enterprises was put into operation in the period from 1960 to 1985; therefore, its operating time is from 30 to 50 years [1]. After this period, there was a significant slowdown in the commissioning of new generating capacities, with a delay in the development and creation of modern economical equipment for thermal power plant (TPP) [2,3,4], while maintaining regulated requirements for their safety. As a result of a complex of large-scale studies conducted by specialists from many leading organizations of the country, the concept of “park resource” was introduced, which made it possible to increase the service life of the main equipment of TPP by 1.5–2.0 times [4]. The concept of “park resource” was extended to the most critical thermal mechanical equipment of thermal power plants [5], mainly operating under creep conditions or under severe loading conditions, causing potentially dangerous damage to the metal.

This article is a continuation and conclusion based on the materials that were presented in [6]. On the basis of the presented results and their discussion, on the one hand, it can be argued that information on the localization of macrostrain, together with the data of the spectral–acoustic method, can be used to estimate the residual life of long-term power equipment. Studies of the structural-phase state of the metal of samples without operation, after operation without destruction and with destruction from structural and heat-resistant steels in the zone of stable localization of macrodeformations were carried out. A relationship was established between the processes of localization of macrostrains and the evolution of the substructural state for structural and heat-resistant steels.

To establish the characteristics of non-destructive tests that are most suitable for evaluating one or another structural or deformation indicator, using statistical processing of research results based on a comparison of the obtained values of the correlation coefficients for equipment made of structural and heat-resistant steels, the dependences of structural and deformation indicators on acoustic and magnetic characteristics were selected, which made it possible to evaluate the structural and mechanical parameters with a sufficient degree of reliability.

In science and technology, a large number of methods and approaches are used to assess the performance of heat-resistant materials. The basis of these methods was developed in the 1970–1990s by scientists including Allen Forrest, P.A. Antikain, T.G. Berezina, L.R. Botvina, A.A. Bochvar, N.V. Bugay, E.Y. Veksler, S.P. Golyansky, Y.M. Gofman, V.F. Zlepko, V.I. Kovpak, E.I. Krutasova, V.I. Kumanin and N.A. Makhutov [7,8,9,10].

Currently, the issues of assessing creep in heat-resistant steels used in thermal power engineering are of concern not only to legal organizations, but also to research teams led by such scientists as G.M. Khazhinsky, A.M. Lokoshchenko, L.R. Botvina, N. A. Makhutov and others [11,12,13,14,15,16,17,18,19,20,21,22,23,24,25]. In particular, they consider the issues of not only directly conducting long-term tests, but also the development of software products that are close to real processes that occur with the material during long-term operation.

To solve production problems, many of the above methods are often unacceptable due to the long duration of the test. In this regard, in recent years, express methods for assessing heat resistance based on changes in various mechanical, structural and physical characteristics of the material have been widely developed.

One of the shortcomings of express methods is the predominant selection of one or several factors (e.g., the content of alloying elements in the carbide deposit, the density of carbide particles, etc.) from the entire complex of characteristics of the material under study that determine the heat resistance. Thus, the purpose of this work is to assess the residual life of long-term power equipment made of structural and heat-resistant steels, using the structural–mechanical criterion and the results of non-destructive testing, which determines the innovativeness and scientific significance of the work.

2. Materials and Methods

As mentioned in the introduction, this article is a continuation and conclusion based on the materials that were presented in [6]. Samples of structural 0.2 C steel and heat-resistant 0.12C-1Cr-1Mo-1V steel were used for research due to the fact that they are most widely represented at the thermal power plants of the Kemerovo region—Kuzbass. In this case, samples of three batches were used both from structural 0.2 C steel and from heat-resistant 0.12C-1Cr-1Mo-1V steel. Samples were cut from structural 0.2 C steel without operation from the culvert of the front screen of power equipment, after operation for 219,000 h without destruction and for 242,000 h before destruction. Samples were cut from heat-resistant 0.12C-1Cr-1Mo-1V steel without operation from the bend of the steam pipeline in front of the exhaust valve, after operation for 260,000 h without failure and for 263,000 h before failure. The chemical composition of the studied steels is given in Table 1.

Table 1.

Chemical composition (wt. %) of the investigated steels.

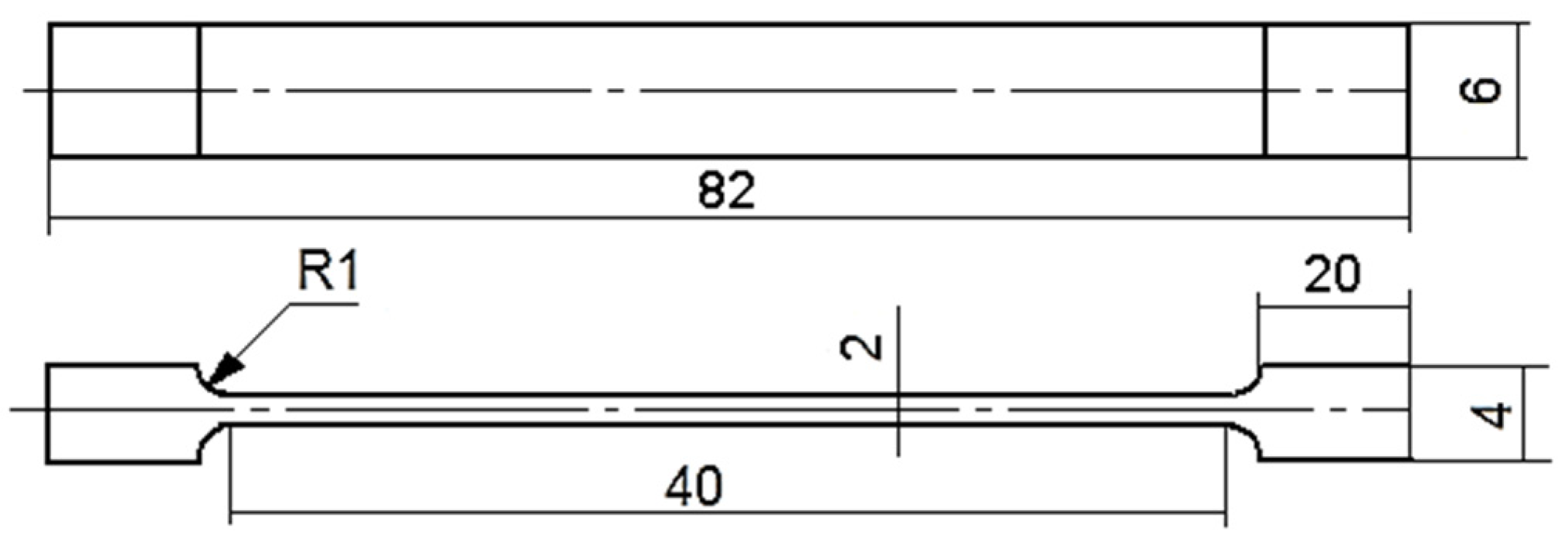

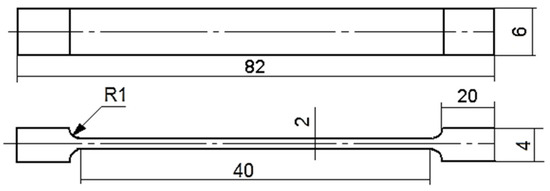

The dimensions of the working part were 40 × 6 × 2 mm for testing samples with a “dog-bone” shape (Figure 1).

Figure 1.

Samples for experimental studies, shape and dimensions.

The microstructure of the samples was studied using a Neophot-21 (Carl Zeiss Jena, Jena, Germany) optical microscope and a UCMOS03100KPA digital technical video camera. The evaluation of mechanical characteristics was carried out for uniaxial tension at a constant rate on a universal testing machine Walter+Bai AG LFM-125 (Walter + Bai AG, Löhningen, Switzerland) under room temperature conditions. In quasi-static tests, the moving gripper travel speed was 0.4 mm/min. The registration of strain localization patterns by digital image correlation (DIC) was performed simultaneously with stretching [22,23,24,25,26]. Digital image correlation (DIC) was carried out using a PL-B781F video camera (Pixelink, Ottawa, ON, Canada) with illumination of the working part with an SNF-xxx-635-30-KB laser. The same experiments were carried out on similar samples obtained from pipes of the same dimensions that were not in operation (initial state) for comparison.

Transmission electron microscopy (TEM) on foils was used to study the fine structure of metal in localized deformation zones using an EM-125 electron microscope (Sumy electronic devices plant, Sumy, Ukraine) [27,28,29,30]. The studies were carried out at a working magnification in the microscope column of 25,000 times and an accelerating voltage of 125 kV.

For each sample, as a result of the research, the phase composition (qualitative and quantitative) was studied, and an assessment was made of parameters of the fine structure, including: structural components of steel and their volume fractions, dislocation densities: scalar and excess, curvature–torsion of the crystal lattice, amplitude of internal stress fields: shear stresses and long-range stresses. The fine structure parameters were evaluated both for each sample as a whole and for each structural component of the steel [31,32,33,34,35,36,37,38].

Tests by non-destructive control methods were performed with samples both before and after plastic deformation. In this case, a spectral–acoustic method (measuring and computing complex “ASTRON” [20,39]) and a magnetic noise method (structure and stress analyzer “Introscan” (NPF Diagnostics LLC, Belarus, Minsk) [20]) were used. At the same time, characteristics such as the intensity of magnetic noise, the speed and delay time of the Rayleigh waves, the attenuation coefficient and the amplitude of the received signal were evaluated.

Processing of the results of studies obtained both during mechanical testing of samples, the study of the microstructure and the values of the characteristics of non-destructive testing was carried out in the “Statistica” program. The algorithm for statistical processing of experimental data included: calculation of sample statistical characteristics; determination of the desired properties of the sample characteristics; elimination of rough observations; testing the hypothesis of normal distribution; construction of dependences by methods of linear and non-linear estimation.

3. Theoretical Part

Approaches to predicting performance and evaluating the residual life are being developed on the basis of non-destructive testing methods related to structuroscopy [40,41,42]. A number of criteria for the limiting state of a long-term operating base metal and welded joints have been developed.

For a more reliable assessment of performance, an integral physical research method is required, based on recording changes in the mechanical and structural characteristics of the metal during long-term operation of power equipment [43,44,45,46,47,48,49,50,51].

The established relationships between the long-term strength of chromium–molybdenum–vanadium steels, determined by the level of local fields of internal stresses, confirmed that for structural steels, the magnitude of internal stresses and the nature of the distribution of their sources is the most important performance indicator for assessing the resource of TPP steam pipelines [1,28].

It is possible to quantify the time, as well as the place of future destruction, by establishing a zone of stable localization of deformations. The scientific team of the Laboratory of Strength Physics, ISPMS SB RAS, has proposed an approach to the observation of Chernov–Luders deformations in the process of uniaxial tension under a laser and during high-speed filming. One of the main advantages of this approach is the fundamental possibility of detecting the place of future destruction of the sample—the zone of stable localization of deformation before the formation of a “neck” (autowave collapse).

Of greater scientific and practical interest is the use of acoustic and magnetic methods of non-destructive testing to detect zones of stable deformation localization in order to assess and predict the performance of long-term equipment [6].

A structural–mechanical criterion has been developed [52] that reflects the revealed relationships between the structural and substructural states, internal stress fields and stable localization of deformations with the characteristics of non-destructive tests in the metal of long-term power equipment made of structural 0.2 C steel and heat-resistant 0.12C-1Cr-1Mo-1V steel.

The current state of the equipment at the time of diagnosis is characterized by the indicator Kt, which can be represented as:

where Kstr—parameters of the metal structure in the current state, determined using metallography; Kfr—operating modes (temperature, pressure [load], cyclicity, environment), Kdef— defects in manufacturing, installation and repair, detected by physical methods of non-destructive testing; Kmech—metal characteristics obtained by destructive tests.

Due to the fact that the previously proposed complex criteria for the degree of damage to the metal in relative units and based on the use of the delay time of the surface acoustic wave (R, ns) cannot be used when the metal is in the region of plastic deformations (σ0.2 < σ < σstr), we propose to introduce into this system Equation (2) for the structural–mechanical criterion of localized deformation of the metal in the current state (Ks.-m), determined by the method of transmission electron microscopy and taking into account deformation indicators, as well as the degree of achievement of a stable zone of localization of deformation (Equation (3)):

where σd—amplitude of internal stress fields, MPa; σl—tangential stresses, MPa; ρ±—excess density of dislocations, cm−2; ρ—scalar density of dislocations, cm−2; a1 and a2—deformation indices reflecting the degree of achievement of a stable zone of deformation localization, σ0.2/δ—ratio of the yield strength to relative elongation (determined at room temperature).

For the studied steels, a structural–mechanical criterion was proposed, which was tested on long-term heat-resistant steels of power equipment at all stages of the life cycle (from the initial state without operation to reaching the limit state and destruction) and which has the following form:

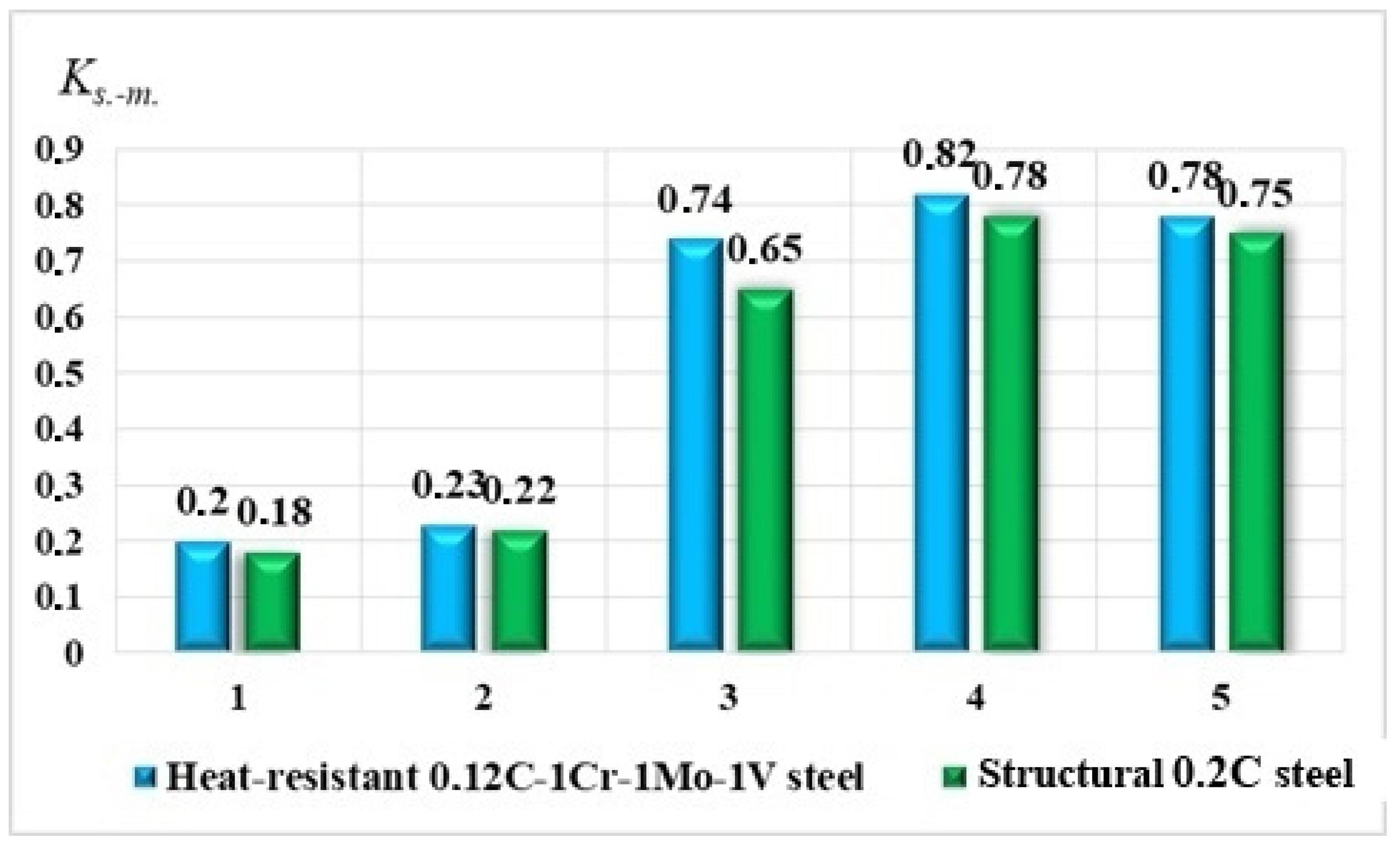

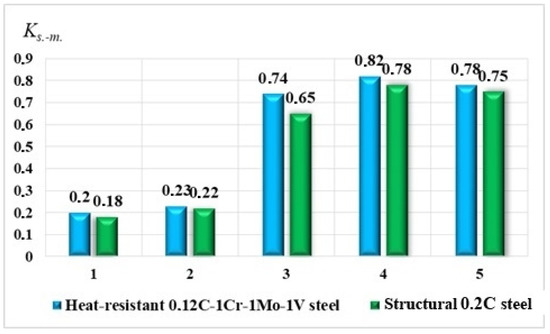

During the calculations, the values of the structural–mechanical criterion were established, corresponding to the moment of stable localization of deformation: for structural 0.2 C steel, with values of Kc.-m ≤ 0.75, it is recommended to replace the checked equipment unit due to the exhaustion of the service life; for heat-resistant 0.12C-1Cr-1Mo-1V steel, it is recommended to replace the tested unit of equipment due to the exhaustion of the service life at values of Kc.-m ≤ 0.78 (Figure 2).

Figure 2.

Calculated values of the structural–mechanical criterion Ks.-m of all groups of the studied samples of power equipment made of structural 0.2 C steel and heat-resistant 0.12C-1Cr-1Mo-1V steel in different states: 1—state without operation; 2—condition after long-term operation (219,000 h—structural 0.2 C steel, 260,000 h—heat-resistant 0.12C-1Cr-1Mo-1V steel) without destruction; 3—condition after long-term operation (242,000 h—structural 0.2 C steel, 263,000 h—heat-resistant 0.12C-1Cr-1Mo-1V steel) and destruction at a distance of 30 mm from the crack; 4—state after long-term operation (242,000 h—structural 0.2 C steel, 263,000 h—heat-resistant 0.12C-1Cr-1Mo-1V steel) and destruction near the crack; 5—deformation localization zone.

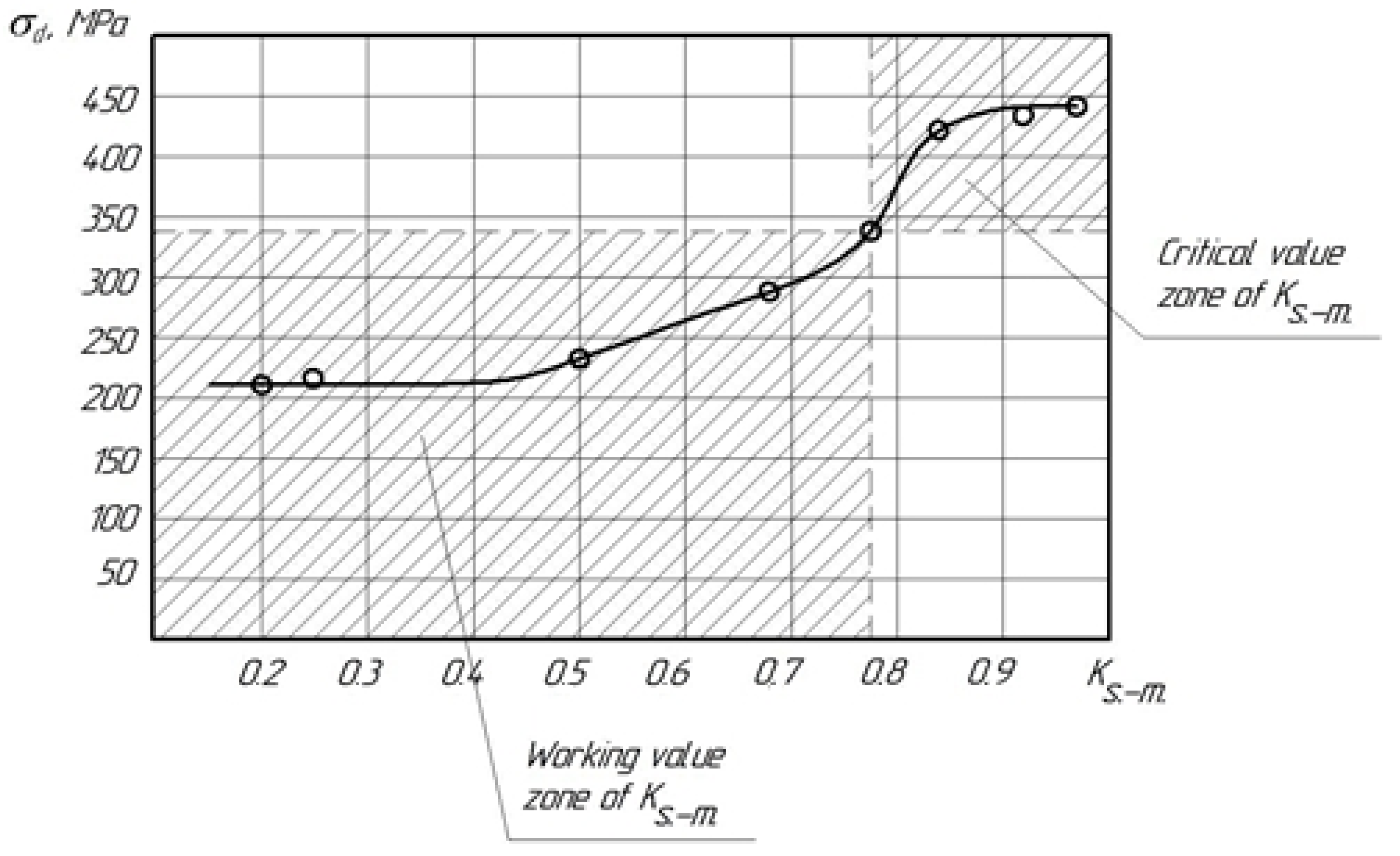

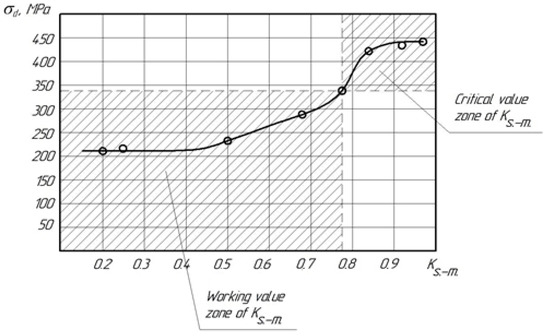

In addition, the values of tangential shear stresses (σd, MPa) were established at certain values of the structural–mechanical criterion (Ks.-m.) for samples of power equipment made of heat-resistant 0.12C-1Cr-1Mo-1V steel (Figure 3).

Figure 3.

Influence of tangential shear stresses (σd, MPa) on the value of the structural–mechanical criterion (Ks.-m.) for samples of power equipment from heat-resistant 0.12C-1Cr-1Mo-1V steel.

The total operating time of any equipment (Equation (5)) is the sum of the operating time of the equipment until the moment of inspection (current state), τcur, and further equipment operation time until the limit state τrem is reached (residual life):

Provided that Kfr and Kdef remain relatively constant throughout the life of the equipment, expressions (1) and (5) can be written as:

where Kl.s—coefficient characterizing the technical condition of the equipment at the moment of reaching the limit state.

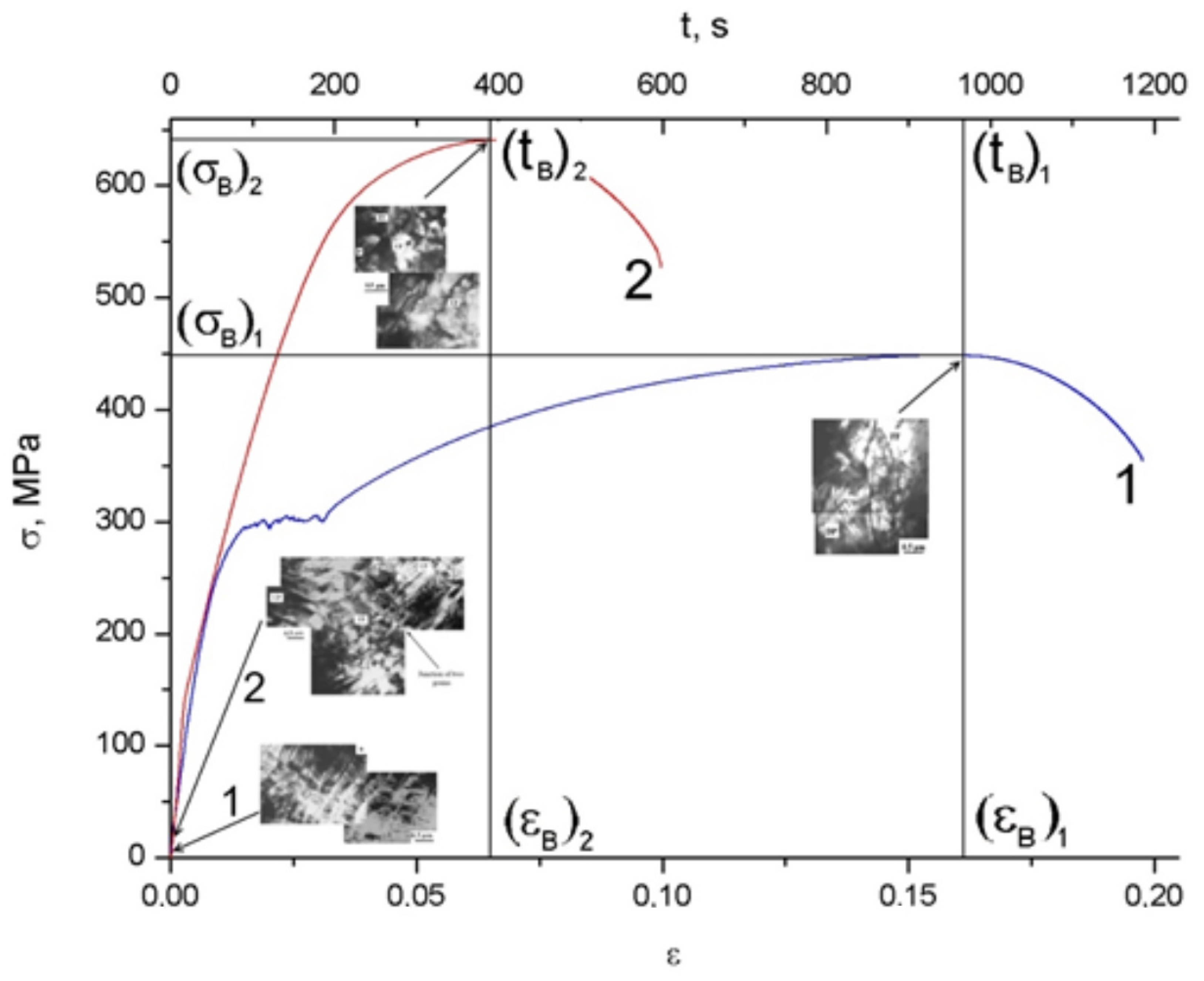

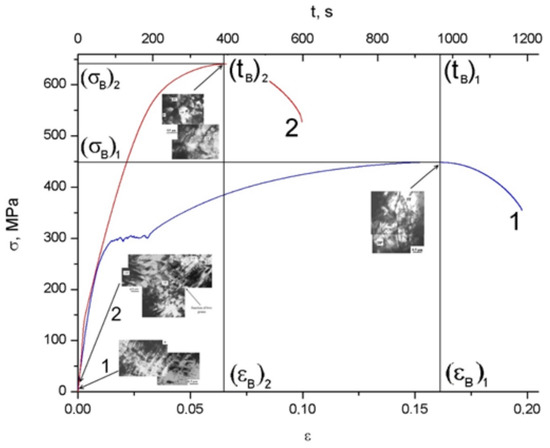

Based on the results of structural studies by transmission electron microscopy and non-destructive tests, loading diagrams were superimposed for specimens in different states (without operation and after long-term operation (219,000 h) with a common start of loading (Figure 4). As a result of superimposing the diagrams, it was found that the time intervals from the beginning of loading to the moment of stable localization of deformation are not equal ((tloc)1 ≠ (tloc)2). However, the time intervals from the moment of stable localization of deformation to the destruction of the samples are equal ((tcrac)1 − (tloc)1 = (tcrac)2 − (tloc)2) for different states (the state without operation and the state after long-term operation (219,000 h).

Figure 4.

Combination of “stress-strain” diagrams of structural 0.2 C steel samples in different states (without operation (1) and after long-term operation (219,000 h) (2)).

The moment of achieving stable localization of deformation can be used to assess and predict the performance and residual life of a technical device. With this in mind, the residual operating time can be divided into the time until stable localization of deformation is reached (τrem.adj—adjusted residual life) and the time from stable localization of deformation to failure (τsld). Then, expression (5) will take the form:

Since the state of stable deformation localization was used instead of the limiting one, Equation (7) will look as follows:

where Ksld—coefficient characterizing the technical condition of the equipment at the moment of achieving stable deformation localization.

From Equation (9), having carried out mathematical transformations and substituting the results of calculations and studies into the formula, the desired result is obtained—the residual operating time of the equipment.

4. Calculation of the Structural–Mechanical Criterion and Residual Operating Time

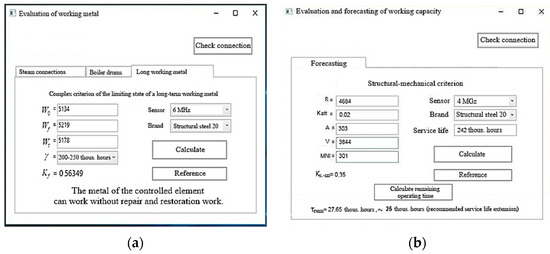

The process of calculating the structural–mechanical criterion and predicting performance on its basis requires high qualification of the operator and takes a relatively long time. Therefore, to simplify the calculation process and reduce labor intensity, an automated system for evaluating and predicting the performance of long-term power equipment based on the limit state criteria and the structural–mechanical criterion was developed. The software module for assessing the state of long-term power equipment was developed on the basis of the spectral–acoustic method of control and, accordingly, the measuring and computing complex “ASTRON”. The operation of the hardware part of the complex is based on the method of taking into account the entire series of reflected acoustic pulses for its subsequent processing by means of the software of the complex. In the processing part of the system, the oscillogram of reflected pulses is sequentially converted with a certain sampling step from the moment of probing the material under study until the arrival of the nth reflected pulse to transmit primary acoustic information. With the MKK “ASTRON” surface wave converters are used, which are a wave emitter and receiver made in one housing. In this work, a 4 MHz transducer with an 18 mm base was used.

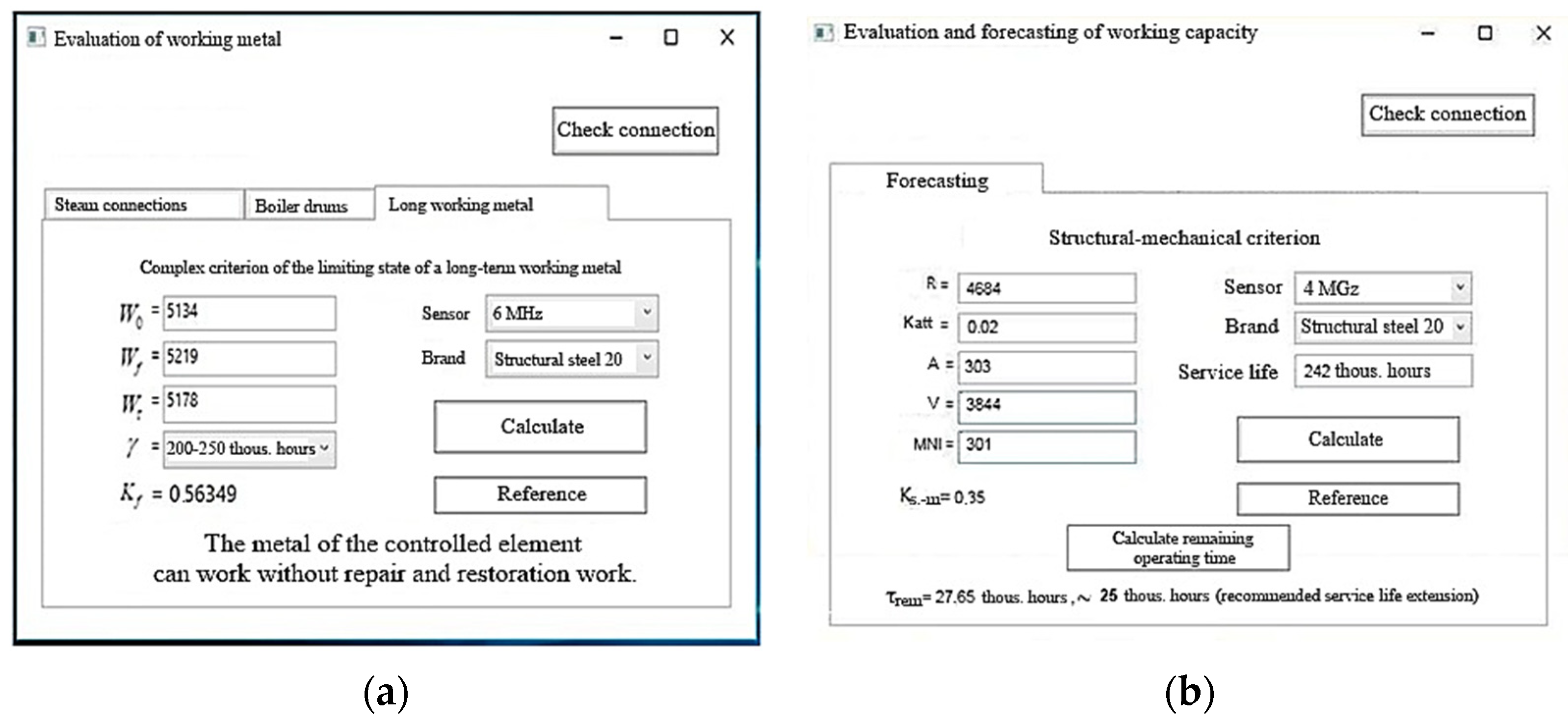

The application “Assessment and prediction of health” uses a form with the “Forecast” tab (Figure 5b) and is designed to assess both the current state of the metal of welded joints of power equipment operated for a long time in difficult stressful conditions and forecasting residual resource.

Figure 5.

Automated evaluation and forecasting system health: (a) an example of calculating the complex criterion of the limiting state of a long-term metal that can operate without repair and restoration work; tab = “Evaluation of working metal”; (b) calculation of the remaining operating time; tab = “Evaluation and forecasting of working capacity”.

The algorithm for working with the “Main” tab is to select the type of sensor, i.e., 4 or 6 MHz, and the appropriate steel grade and service life in hours. After selecting these parameters, the values of the characteristics taken from the device R (ns) and Kzat (1/µs) are then manually entered. The calculation of the structural–mechanical criterion is launched and the result of the calculation is displayed—the metal can work without repair and restoration work, or the metal needs to be repaired and restored. In the latter case, the recommended number of hours is given for which the resource can be extended.

The “Database” tab, which is planned to be added, will allow accessing the results of previous measurements for structural 0.2 C steel and heat-resistant 0.12C-1Cr-1Mo-1V steel. In addition, it will be possible to add new measurement results to the database both for structural 0.2 C steel and heat-resistant 0.12C-1Cr-1Mo-1V steel, and for new steels for which measurements are made. At the same time, in order to obtain adequate calculation results, it is necessary to enter data on steels in at least two states: in the initial (without operation) and after long-term operation until failure. Pressing the “Help” button (Figure 5b) provides theoretical information on the values used in the calculations.

The automated performance evaluation and forecasting system was tested under industrial conditions on a number of sections of steam and hot water steam pipelines made of structural 0.2 C steel and heat-resistant 0.12C-1Cr-1Mo-1V steel. For 36 steam pipes made of structural 0.2 C steel, after 219,000–242,000 h of operation, the residual life was estimated, which showed that for 70% of the pipes, the residual life was 50,000–75,000 h; for 20% of the pipes it was 25,000–50,000 h; and for 10%, replacement is necessary due to the exhaustion of the service life. For 29 steam and hot water pipelines made of heat-resistant 0.12C-1Cr-1Mo-1V steel after 180,000–263,000 h of operation, the calculation showed that for 60% of the steam pipelines, the residual life was 50,000–70,000 h; for 25% it was 25,000–50,000 h; and for 15% replacement is necessary due to the exhaustion of the service life (Figure 5b; Table 2).

Table 2.

Comparison of the values of the residual life of pipes of steam boilers made of 0.2 C steel and 0.12C-1Cr-1Mo-1V steel, calculated using an automated system and an expert organization.

The results of the calculation of the residual life according to the structural–mechanical criterion were compared with the results obtained by the expert organization during the examination of industrial safety. The coincidence of the residual life assessment results was 95% (Table 2). Thus, the reliability of calculations increased by 3.1%, while reducing the duration of the assessment by 37%.

The results of the implementation of the developed solutions for predicting the performance and evaluating the residual life of long-term operating power equipment in industry in the form of an automated system are presented.

The process of calculating the structural–mechanical criterion and predicting performance on its basis requires high qualification of the operator and takes a relatively long time. Therefore, to simplify the calculation process and reduce labor intensity, an automated system for evaluating and predicting the performance of long-term power equipment based on the limit state criteria and the structural–mechanical criterion was developed (Figure 5).

5. Discussion

When comparing the results of calculating the residual life of power equipment in an automated system, a high convergence was established with the results obtained by directly calculating the parameters of the microstructure (electron microscopy) and deformation parameters. Comparison with the results obtained by the expert organization when applying the industrial safety expertise showed a higher reliability in the assessment of the residual life according to the calculation of the structural–mechanical criterion.

The proposed and justified approach to assessing and predicting the performance and residual life of long-term power equipment, based on the identified relationships between the structural and substructural states, internal stress fields and stable localization of deformations with the characteristics of non-destructive tests and the calculation of the structural–mechanical criterion, was applied at a number of power plants in the Kemerovo region—Kuzbass.

6. Conclusions

- A structural–mechanical criterion Ks.-m was developed based on the established relationships between the structural state, internal stress fields and stable localization of deformations with the characteristics of non-destructive tests in the metal of long-term power equipment made of structural 0.2 C steel and heat-resistant 0.12C-1Cr-1Mo-1V steel.

- It has been established that with the values of the structural–mechanical criterion Ks.-m ≤ 0.75 for structural steel 20 and Ks.-m ≤ 0.78 for heat-resistant 0.12C-1Cr-1Mo-1V steel, corresponding to the moment of stable deformation localization, it is recommended to replace the checked equipment components due to the exhaustion of the resource. However, the structural–mechanical criterion requires a large number of calculations that can be automated using intelligent systems.

- The proposed and justified approach to assessing and predicting the performance and residual life of long-running power equipment, based on the identified relationships between the structural and substructural states, internal stress fields and stable localization of deformations with the characteristics of non-destructive tests and the calculation of the structural–mechanical criterion, was applied at a number of power plants in the Kemerovo region—Kuzbass.

- When comparing the results of calculating the residual life of power equipment in an automated system, a high convergence was established with the results obtained when directly calculating the parameters of the microstructure (electron microscopy) and deformation parameters.

- An automated system for predicting the performance and evaluating the residual life of long-term power equipment has been developed, the basis of which is the structural–mechanical criterion, and has been tested in industrial conditions on a number of sections of steam and hot water steam pipelines made of structural 0.2 C steel and heat-resistant 0.12C-1Cr-1Mo-1V steel. The results of the calculation of the residual life according to the structural–mechanical criterion were compared with the results obtained by the expert organization during the examination of industrial safety. The discrepancy between the residual life assessment results did not exceed 5%.

Author Contributions

Conceptualization, N.A.; methodology, V.D.; software, A.S.; validation, N.A.; formal analysis, V.D.; investigation, N.A.; resources, A.S.; data curation, N.A.; writing—original draft preparation, A.S.; writing—review and editing, V.D.; visualization, N.A.; supervision, A.S.; project administration, N.A.; funding acquisition, A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Russian Science Foundation, agreement No. 22-29-20192, a grant from the Kemerovo Region—Kuzbass, agreement No 16 and by the Government research assignment for ISPMS SB RAS, project FWRW-2021–0011.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rezinskikh, V.F.; Grin, E.A. Modern problems concerned with ensuring safe operation of heat-generating and mechanical equipment in extending its lifetime. Therm. Eng. 2013, 60, 16–23. [Google Scholar] [CrossRef]

- Chrysochoos, A.; Louche, H. An infrared image processing to analyse the calorific effects accompanying strain localisation. Int. J. Eng. Sci. 2000, 38, 1759–1788. [Google Scholar] [CrossRef]

- Sun, H.B.; Yoshida, F.; Ohmori, M.; Ma, X. Effect of strain rate on Luders band propagating velocity and Luders strain for an-nealed mild steel under uniaxial tension. Mater. Lett. 2003, 57, 4535–4539. [Google Scholar] [CrossRef]

- Avril, S.; Pierron, F.; Sutton, M.A.; Yan, J. Identification of elasto-viscoplastic parameters and characterization of Lüders behavior using digital image correlation and the virtual fields method. Mech. Mater. 2008, 40, 729–742. [Google Scholar] [CrossRef]

- Makhutov, N.; Gadenin, M.; Reznikov, D.; Nadein, V. Risk and industrial safety. Reliab. Theory Appl. 2022, 17, 138–143. [Google Scholar]

- Ababkov, N.; Smirnov, A.; Danilov, V.; Zuev, L.; Popova, N.; Nikonenko, E. Structural-Phase State, Mechanical Properties, Acoustic and Magnetic Characteristics in the Sustainable Deformation Localization Zones of Power Equipment Made of Structural and Heat Resistant Steels. Metals 2021, 11, 1638. [Google Scholar] [CrossRef]

- Antikain, P.A. Metals and Calculation of the Strength of Boilers and Pipelines; Energoservis: Moscow, Russia, 2001. [Google Scholar]

- Tyutin, M.R.; Botvina, L.R.; Sinev, I.O. Changes in the physical properties and the damage of low- and medium-carbon steels during tension. Russ. Metall. 2018, 2018, 671–676. [Google Scholar] [CrossRef]

- Botvina, L.R.; Sinev, I.O.; Zavyalov, A.D. On the time dependences of the fracture concentration parameter estimated by dif-ferent methods. Dokl. Earth Sci. 2021, 496, 80–85. [Google Scholar] [CrossRef]

- Makhutov, N.A.; Gadenin, M.M. Analysis and Control of the Strength, Useful Life, and Safe Operation Risks of Power Plants with Various Kinds of Energy Commodities. J. Mach. Manuf. Reliab. 2022, 51, 37–45. [Google Scholar] [CrossRef]

- Basalov, Y.G.; Lokoshchenko, A.M.; Teraud, V.V. Modeling of Creep and Long-Term Strength of Rods at Alternating Stresses. Mech. Solids 2020, 55, 589–594. [Google Scholar] [CrossRef]

- Larin, N.S.; Lokoshchenko, A.M.; Fomin, L. Dependence of Creep-Rupture Lifetime for Rods under Tension in an Aggressive Environment on the Shape of a Single-Cell Cross-Section. Mech. Solids 2019, 54, 1042–1050. [Google Scholar] [CrossRef]

- Fomin, L.V.; Basalov, Y.; Lokoshchenko, A.M. On accouning the influence of corrosion processes on delayed fracture of a rod under creep condition. Mech. Compos. Mater. Struct. 2019, 25, 327. [Google Scholar]

- Syromyatnikova, A.S.; Gulyaeva, E.M.; Alekseeva, K.I. Computational-Experimental Estimation of Strength Properties of the Metal of Long-Operating Gas Pipeline. Russ. Metall. 2016, 2016, 10. [Google Scholar] [CrossRef]

- Botvina, L.R.; Tyutin, M.R.; Levin, V.P.; Ioffe, A.V.; Perminova, Y.S.; Prosvirnin, D.V. Mechanical and Physical Properties, Fracture Mechanisms, and Residual Strength of 15Kh2GMF Steel for Oil Sucker Rods. Russ. Metall. 2021, 2021, 546–558. [Google Scholar] [CrossRef]

- Zharkova, N.A.; Botvina, L.R.; Tyutin, M. Damage accumulation stages in a low-carbon steel during uniaxial tension. Russ. Metall. 2007, 2007, 223–229. [Google Scholar] [CrossRef]

- Tyutin, M.R.; Botvina, L.R.; Zharkova, N.A.; Petersen, T.B.; Hudson, J.A. Evolution of Damage Accumulation in Low-Carbon Steel in Tension Condition. Strength Fract. Complex. 2005, 3, 73–80. [Google Scholar] [CrossRef]

- Botvina, L.R.; Tyutin, M.R.; Petersen, T.B.; Levin, V.P.; Soldatenkov, A.P.; Prosvirnin, D.V. Residual Strength, Microhardness, and Acoustic Properties of Low-Carbon Steel after Cyclic Loading. J. Mach. Manuf. Reliab. 2018, 47, 516–524. [Google Scholar] [CrossRef]

- Demina, Y.A.; Tyutin, M.R.; Marchenkov, A.Y.; Levin, V.P.; Botvina, L.R. Effect of Long-Term Operation on the Physical and Mechanical Properties and the Fracture Mechanisms of X70 Pipeline Steels. Russ. Metall. 2022, 2022, 452–462. [Google Scholar] [CrossRef]

- Botvina, L.R.; Tyutin, M.R.; Bolotnikov, A.I.; Petersen, T.B. Effect of Preliminary Cycling on the Acoustic Emission Characteristics of Structural 15Kh2GMF Steel. Russ. Metall. 2021, 2021, 32–41. [Google Scholar] [CrossRef]

- Botvina, L.R.; Kushnarenko, V.M.; Tyutin, M.R.; Levin, V.P.; Morozov, A.E.; Bolotnikov, A.I. Fracture Stages and Residual Strength of Pipe Steel after Long-Term Operation. Phys. Mesomech. 2021, 24, 475–485. [Google Scholar] [CrossRef]

- Danilov, V.I.; Smirnov, A.N.; Gorbatenko, V.V.; Orlova, D.V.; Danilova, L. Luders Deformation in Weld Joints. Steel Transl. 2018, 48, 87–92. [Google Scholar] [CrossRef]

- Makhutov, N.A.; Gadenin, M.M.; Cherniavsky, O.F.; Cherniavsky, A.O. Study of Material Properties under Complex Conditions of Low-Cycle Deformation. Inorg. Mater. 2022, 58, 1563–1570. [Google Scholar] [CrossRef]

- Makhutov, N.A. Generalized regularities of deformation and fracture processes. Her. Russ. Acad. Sci. 2017, 87, 217–228. [Google Scholar] [CrossRef]

- Makhutov, N.A.; Lepikhin, A.M.; Leshchenko, V.V. Scientific and Methodological Provision of Safety of Offshore Subsea Pipelines with Defects according to Risk Criteria. Inorg. Mater. 2022, 58, 1556–1562. [Google Scholar] [CrossRef]

- Barnett, M.R.; Nave, M.D.; Ghaderi, A. Yield point elongation due to twinning in a magnesium alloy. Acta Mater. 2012, 60, 1433–1443. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; Huang, M. Kinematic and thermal characteristics of Lüders and Portevin-Le Châtelier bands in a medium Mn transformation-induced plasticity steel. Acta Mater. 2017, 124, 17–29. [Google Scholar] [CrossRef]

- Pchelintsev, A.V.; Rezinskikh, V.F. Studying the damageability and short-term mechanical properties of grade 10Kh9V2MFBR-Sh steel during its combined thermal and mechanical loading. Therm. Eng. 2011, 58, 170–173. [Google Scholar] [CrossRef]

- Grote, K.E. Antonsson Handbook of Mechanical Engineering; Springer: New York, NY, USA, 2008. [Google Scholar]

- Bayatanova, L.; Rakhadilov, B.; Kurbanbekov, S.; Skakov, M.; Popova, N. Fine structure of low-carbon steel after electrolytic plasma treatment. Materialpruefung 2021, 63, 842–847. [Google Scholar] [CrossRef]

- Segal, V.M.; Noskova, N.I.; Mulyukov, R.R. Severe Plastic Deformation: Toward Bulk Production of Nanostructured Materials; Nova Science Publishers, Inc.: New York, NY, USA, 2006. [Google Scholar]

- Gorbatenko, V.; Danilov, V.; Zuev, L. Elastoplastic transition in the material with sharp yield point. AIP Conf. Proc. 2015, 1683, 020058. [Google Scholar] [CrossRef]

- Murav’eva, O.V.; Muraviev, M.A.; Sintsov, M.A.; Volkova, L.V. Detecting Flaws in Pumping-Compressor Pipe Couplings by Magnetic, Eddy Current, and Ultrasonic Multiple-Shadow Testing Methods. Russ. J. Nondestruct. Test. 2022, 58, 248–258. [Google Scholar] [CrossRef]

- Danilov, V.; Orlova, D.; Zuev, L. On the kinetics of localized plasticity domains emergent at the pre-failure stage of deformation process. Mater. Des. 2011, 32, 1554–1558. [Google Scholar] [CrossRef]

- Zuev, L.B.; Gorbatenko, V.V.; Danilova, L.V. Model of plastic deformation and failure of solids. Russ. Phys. J. 2022, 64, 1666–1675. [Google Scholar] [CrossRef]

- Zuev, L.B. Chernov–Luders and Portevin–Le Chatelier deformations in active deformable media of different nature. J. Appl. Mech. Tech. Phys. 2017, 58, 328–334. [Google Scholar] [CrossRef]

- Campbell, F. Elements of Metallurgy and Engineering Alloys; ASM International: Novelty, OH, USA, 2008. [Google Scholar]

- Brent, F.; James, H. Transmission Electron Microscopy and Diffractometry of Materials; Springer: New York, NY, USA, 2013. [Google Scholar]

- Getsov, L.; Rybnikov, A.; Semenov, A.; Semenov, S.; Tikhomirova, E. Thermal fatigue of singlecrystal superalloys: Experiments, crack-initiation and crack-propagation criteria. Mater. Tehnol. 2015, 49, 773–778. [Google Scholar] [CrossRef]

- Gromov, V.E.; Yur’ev, A.B.; Morozov, K.V.; Ivanov, Y.F.; Alsaraeva, K.V. Structure, phase composition, and defect substructure of differentially quenched rail. Steel Transl. 2014, 44, 883–885. [Google Scholar] [CrossRef]

- Popova, N.A.; Nikonenko, E.L.; Klopotov, A.A.; Potekaev, A.I.; Bayatanova, L.B.; Nikonenko, A.V.; Kislitsin, S.B. Phase Composition and Thin Structure of Steel Surface after Plasma Electrolytic Carbonitriding. Russ. Phys. J. 2020, 62, 1794–1800. [Google Scholar] [CrossRef]

- Kozlov, E.; Zhdanov, A.; Popova, N.; Pekarskaya, E.; Koneva, N. Subgrain structure and internal stress fields in UFG materials: Problem of Hall–Petch relation. Mater. Sci. Eng. A 2004, 1–2, 789–794. [Google Scholar] [CrossRef]

- Botvina, L.; Tyutin, M. New acoustic parameter characterizing loading history effects. Eng. Fract. Mech. 2019, 210, 358–366. [Google Scholar] [CrossRef]

- Botvina, L.R.; Soldatenkov, A.; Levin, V.P.; Tyutin, M.R.; Demina, Y.A.; Petersen, T.B.; Dubov, A.; Semashko, N.A. Assessment of mild steel damage characteristics by physical methods. Russ. Metall. 2016, 2016, 23–33. [Google Scholar] [CrossRef]

- Botvina, L.R.; Petersen, T.B.; Soldatenkov, A.P.; Tyutin, M.R. Time dependences of acoustic signal characteristics during fracture of metal samples. Dokl. Earth Sci. 2015, 462, 475–478. [Google Scholar] [CrossRef]

- Wu, K.-T.; Jen, C.-K.; Kobayashi, M.; Blouin, A. Integrated Piezoelectric Ultrasonic Receivers for Laser Ultrasound in Non-destructive Testing of Metals. J. Nondestruct. Eval. 2012, 30, 1–8. [Google Scholar] [CrossRef]

- Labergere, C.; Rassineux, A.; Saanouni, K. Numerical simulation of continuous damage and fracture in metal-forming processes with 2D mesh adaptive methodology. Finite Elem. Anal. Des. 2014, 82, 46–61. [Google Scholar] [CrossRef]

- Yang, J.; Wang, G.; Xuan, F.; Tu, S.; Liu, C. Out-of-plane constraint effect on local fracture resistance of a dissimilar metal welded joint. Mater. Des. 2014, 55, 542–550. [Google Scholar] [CrossRef]

- Osovski, S.; Nahmany, Y.; Rittel, D.; Landau, P.; Venkert, A. On the dynamic character of localized failure. Scr. Mater. 2012, 67, 693–695. [Google Scholar] [CrossRef]

- Khokhlov, M.; Fischer, A.; Rittel, D. Multi-Scale Stereo-Photogrammetry System for Fractographic Analysis Using Scanning Electron Microscopy. Exp. Mech. 2012, 52, 975–991. [Google Scholar] [CrossRef]

- Pokluda, J.; Pippan, R.; Vojtek, T.; Hohenwarter, A. Near-threshold behaviour of shear-mode fatigue cracks in metallic materials. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 232–254. [Google Scholar] [CrossRef]

- Ababkov, N.V.; Smirnov, A.N.; Nikitenko, M.S.; Pimonov, M.V.; Teleguz, A.S.; Nesterenko, K.S.; Medvedchikov, M.N. Software module for assessing the state of mining equipment based on regularities of changes in the structural-phase state and fields of metal internal stress. Bull. Kuzbass State Tech. Univ. 2022, 6, 50–58, (In Russian, abstract in English). [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).