Abstract

Post annealing treatment is generally needed for additively manufactured titanium alloy to decompose metastable phases, alleviate residual stress, and improve ductility. In this work, in-situ electrical resistivity and line profile analysis of X-ray diffraction were utilized for monitoring phase transformation behaviors and dislocation evolutions of a laser powder bed fusion-built Ti-6Al-4V alloy under post annealing treatment. Besides, hardness and tensile tests were adopted for revealing the effects of phase transformation and dislocation evolutions on the mechanical properties. The results indicated that post annealing treatment decomposed martensitic α′ into lamellar α + β and eliminated dislocations efficiently. The martensite decomposition rate increased with the annealing temperature. Annealing at 700 °C for 4 h eliminated 98% of the dislocations, and further annealing has only a limited influence on the dislocation density. Annealing at 700 °C for 16 h is beneficial for achieving a high ductility of 10.3% owing to the favorable equilibrium lamellar α + β microstructure. These findings provide valuable insights for optimizing post annealing treatment procedures to enhance the mechanical properties of additively manufactured Ti-6Al-4V alloys.

1. Introduction

Additive manufacturing (AM), known as three-dimensional (3D) printing, is an advanced manufacturing method that provides unprecedented advantages (e.g., short manufacturing lead time and high processing flexibility) in fabricating 3D parts or components [1,2]. Laser additive manufacturing (LAM) is a promising technique for fabricating high-performance metallic parts. Compared with electron beam melting and wire-arc additive manufacturing, the LAM approach can offer better dimensional accuracy. Laser powder bed fusion (LPBF) is one of the mainstream LAM technologies for the fabrication of metallic parts [3]. Owing to the high local energy density and ultra-high cooling rate, high-performance metallic parts with a refined microstructure can be obtained using LPBF [4].

Titanium (Ti) alloy is the chief metal for LPBF thanks to its superior specific strength, low density, high corrosion resistance, and biocompatibility [5,6]. More importantly, the low thermal conductivity and low coefficient of thermal expansion of Ti alloys make them less prone to cracking during LPBF. Thanks to these merits, LPBF-built Ti alloys have been widely adopted in the aerospace and biomedical sectors [6,7]. Ti-6Al-4V is the famous work-horse Ti alloy, accounting for more than 50% of Ti alloy production. With a narrow solidification temperature (~3 K) [8], the Ti-6Al-4V alloy exhibits excellent printability, making it highly sought after in the field of LAM. Owing to the ultra-high cooling rate and high thermal gradient of LPBF, the microstructure LPBF-built Ti-6Al-4V alloy generally consists of acicular martensitic α′ along with columnar prior-β grain boundary. Compared with the conventional processed Ti-6Al-4V alloy (e.g., casting and forging), the LPBF-built Ti-6Al-4V alloy generally possesses higher mechanical strength, while the ductility and fracture toughness are lower owing to the full martensite microstructure.

Post heat treatment (post-HT) is generally needed for the LPBF-fabricated Ti alloys to decompose metastable phases (e.g., martensitic α′); alleviate residual stress; and improve ductility, fracture toughness, and fatigue performance [9,10]. As the work-horse Ti alloy, numerous works have been carried out to investigate the effects of post-HTs on the microstructure, residual stress, and mechanical properties of the LPBF-built Ti-6Al-4V alloy [11,12]. Cao et al. [13] reported that annealing at 700 °C and 800 °C transformed the martensitic α′ into the equilibrium lamellar α + β microstructure, hereby improving the ductility of the alloy significantly, and the related microstructural coarsening mechanism is the bulk diffusion [14]. Wang et al. [15] reported that a non-equilibrium αHME (high in Mo eq) phase exists during the post annealing treatment of the LPBF-built Ti-6Al-4V alloy. Specifically, the α′ → α + β phase transformation occurs in two steps: α′ → α + αHME and αHME → β. Moreover, proper annealing treatments have been proven to be an effective approach for enhancing the fracture toughness and fatigue crack growth resistance of LPBF-built Ti-6Al-4V alloy owing to the favorable lamellar α + β microstructure [16]. Notably, the dislocations will also be annihilated during the annealing treatment. The decrease in dislocation density would also affect the mechanical properties through the dislocation strengthening effect. However, the dislocation density evolutions of the LPBF-built Ti-6Al-4V alloy under post annealing treatment and their effects on mechanical properties are seldom reported. Meanwhile, the underlying relationships between phase transformation behaviors, dislocation evolutions, and mechanical performance are still not clear.

In this work, in situ electrical resistivity and line-profile analysis (LPA) of X-ray diffraction (XRD) measurements were applied to investigate the phase transformation behaviors and dislocation evolutions of an LPBF-built Ti-6Al-4V alloy under post annealing treatments, respectively, which could provide new insights and understanding for post-HTs behaviors of additively manufactured Ti alloys. Besides, the microstructural evolutions were characterized by light optical microscope (LOM), scanning electron microscope (SEM), and electron backscatter diffraction (EBSD). Hardness and tensile tests were implemented to reveal the effects of annealing treatment on the mechanical properties.

2. Materials and Methods

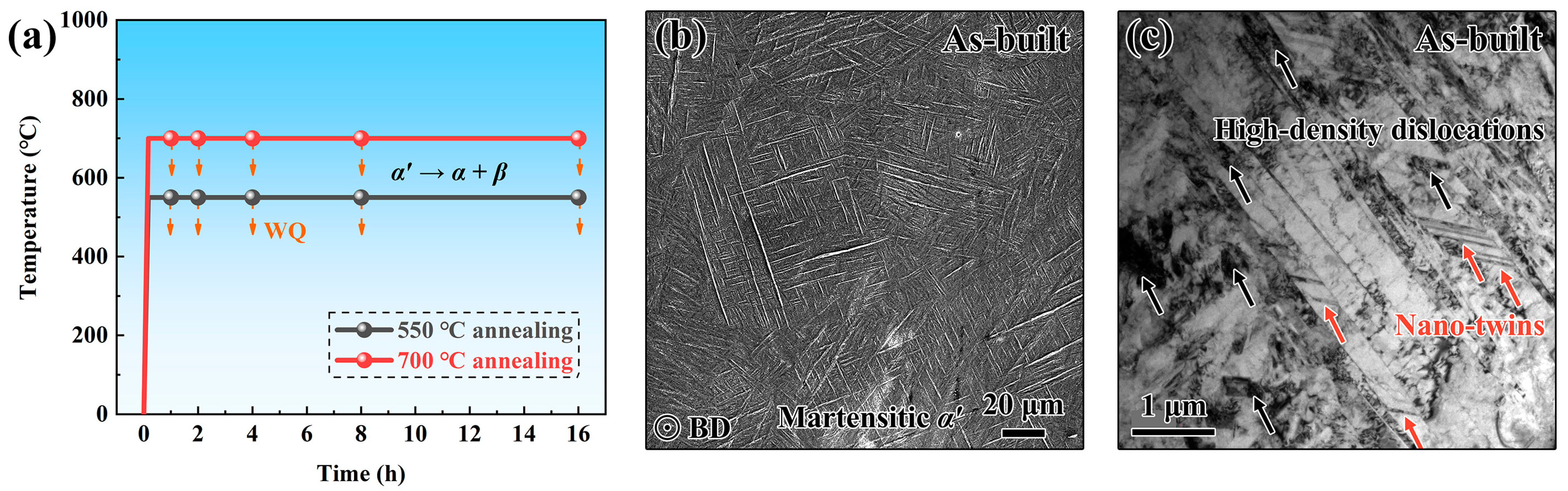

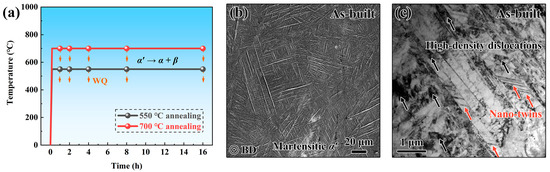

The Ti-6Al-4V alloy block with a size of 65 × 15 × 15 mm was built using a powder bed fusion using a laser beam (PBF-LB) AM machine (EOS M280). The composition of raw powder is 6.18 Al, 4.06 V, 0.17 Fe, 0.09 O, 0.0058 N, 0.011 C, and balance Ti (wt. %). The processing parameters are as follows: laser power 280 W, scan speed 1200 mm/s, hatch space 0.14 mm, and layer thickness 0.03 mm. A raster scan pattern with 67-degree rotation per layer was adopted. The original porosity of the Ti-6Al-4V bulky sample is less than 0.01%. Post annealing treatments were utilized for decomposing metastable phases (martensitic α′) and metastable factors (nano-twins and dislocations), as shown in Figure 1. To avoid the excessive coarsening of α lath and massive formation of brittle Ti3Al phase, the post annealing treatments are held at 550 °C and 700 °C, respectively. The heat treatments are held under the argon protective atmosphere to avoid oxidation. Different from the conventional annealing treatment, which only lasts for 1–4 h, the annealing duration is prolonged to 16 h to decompose the martensitic α′ sufficiently.

Figure 1.

Experimental details: (a) heat treatment procedure and (b) SEM and (c) transmission electron microscope (TEM) images of the as-built Ti-6Al-4V alloy.

In situ electrical resistivity measurement is a powerful tool for studying the phase transformation kinetics of alloys [17,18]. In this work, the in situ electrical resistivity measurement was used for monitoring the phase transformation behavior of the as-built Ti-6Al-4V alloy under the annealing treatments. The principle of the in situ electrical resistivity equipment is provided in [19]. Besides, the dislocation densities of the heat-treated samples were evaluated by LPA of XRD. Mechanical polishing and electrolytic polishing were performed to remove the mechanically affected layers before the XRD tests. To ensure the accuracy of LPA, the step size and scan speed of XRD were set as 0.02 and 1.2 °/min, respectively. A well-annealed pure Ti sample with extremely low dislocation density was used for eliminating the instrumental effects of XRD. The evaluation of dislocation density was based on the modified Williamson–Hall and modified Warren–Averbach (mWH/mWA) method [20,21], and the calculation process has been discussed in our previous works [9,22]. In addition, to reveal the alloying elements’ diffusion behaviors during the annealing treatment, a diffusion-controlled reaction (DICTRA) simulation was implemented on the Thermo-Calc software. The initial simulation cell consists of α′ + β dual-phase, and the thickness of α′ and β are set as 1 μm and 0.1 μm, respectively. The sizes of the phases and the microstructure are set based on the reported experimental results [23,24].

For microstructural observations, the samples were grinded with silicate paper (up to 2000 grit) and then polished with oxide polishing suspension (OP-S) solutions. The Kroll regent (1 mL HF + 2 mL HNO3 + 25 mL H2O) was utilized to reveal the grain boundary. LOM, SEM, and EBSD were adopted to investigate the microstructure evolutions. The mechanical properties were characterized through hardness and tensile tests. For the Vickers hardness test, a load of 2 Newtons-force and a holding duration of 15 s were adopted, and 10 points were measured for each condition. Dog-bone-shaped tensile samples with a gauge length of 20 × 5 × 2 mm were adopted for the tensile tests. The tensile tests were performed on an Instron 3382 machine with a cross head speed of 1 mm/min. After the tensile tests, the fracture morphology and side section of the fractured samples were observed by SEM to reveal the underlying fracture mechanisms.

3. Results

3.1. Microstructure and Mechanical Properties’ Evolutions

3.1.1. Microstructure

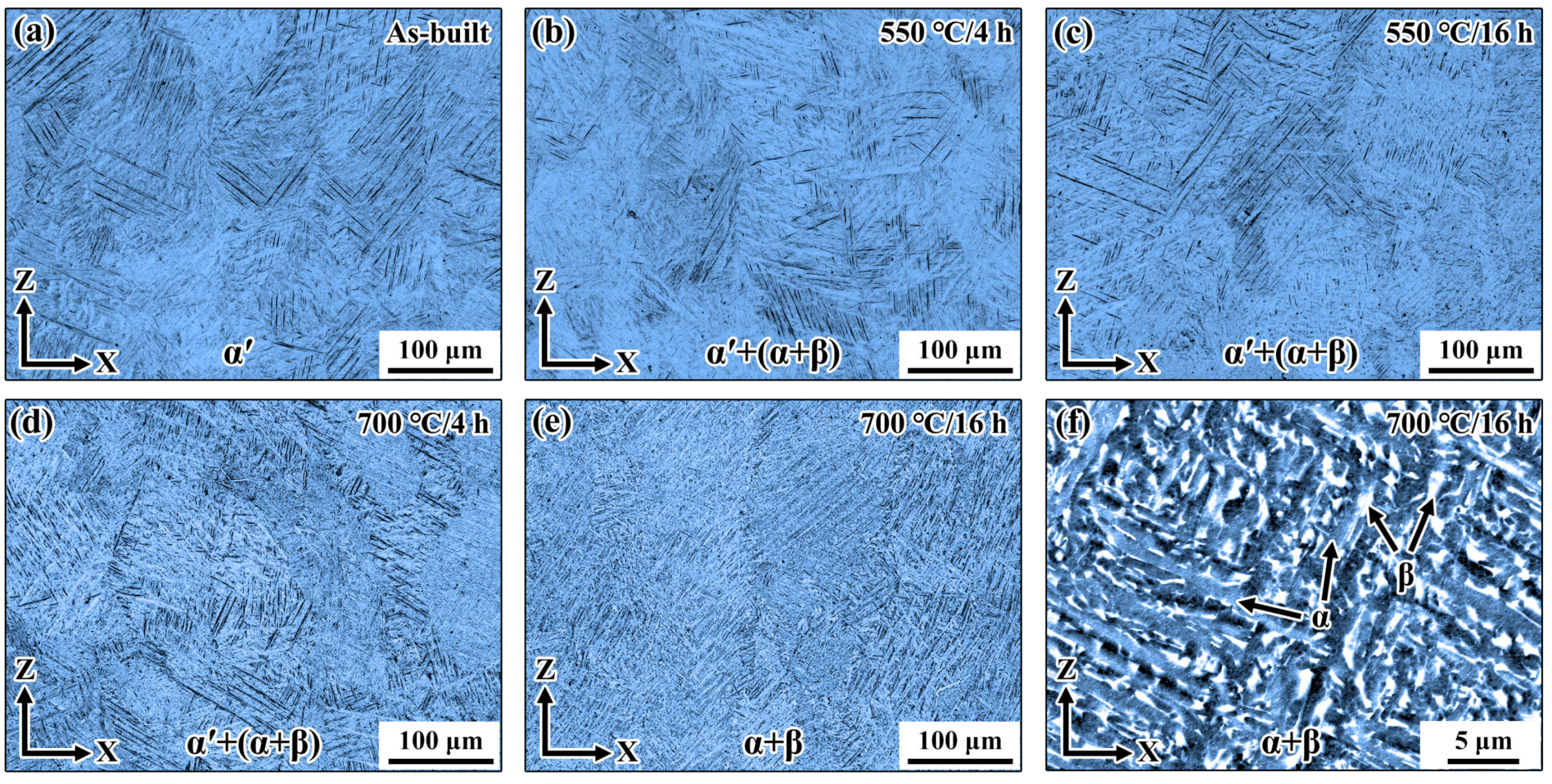

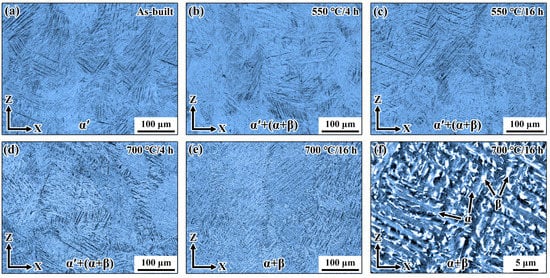

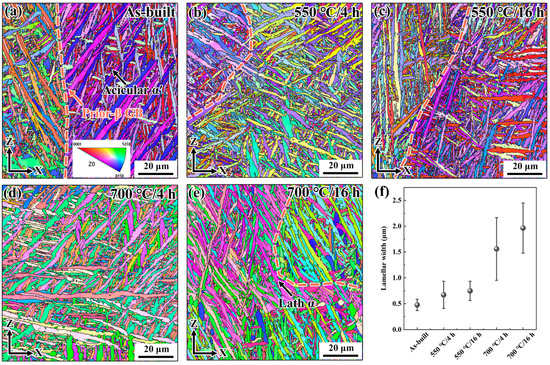

Figure 2a indicates that the main microstructural feature of the as-built Ti-6Al-4V alloy is the acicular martensitic α′ along with the columnar prior-β grains. After annealing at 550 °C for 4 h and 16 h, some acicular region can still be found (Figure 2b,c). Under this circumstance, it can be inferred that the martensitic α′ is only partially decomposed, and the obtained microstructure is α′ + (α + β). After annealing at 700 °C for 16 h, no acicular microstructure can be found, indicating that the martensitic α′ is fully decomposed and a lamellar α + β microstructure is obtained, as shown in Figure 2e,f. The β phase (the bright area) is distributed at the boundary of α lath (the dark area).

Figure 2.

LOM images of the (a) as-built, (b) 550 °C/4 h, (c) 550 °C/16 h, (d) 700 °C/4 h, and (e) 700 °C/16 h samples; (f) enlarged SEM image of the 700 °C/16 h sample.

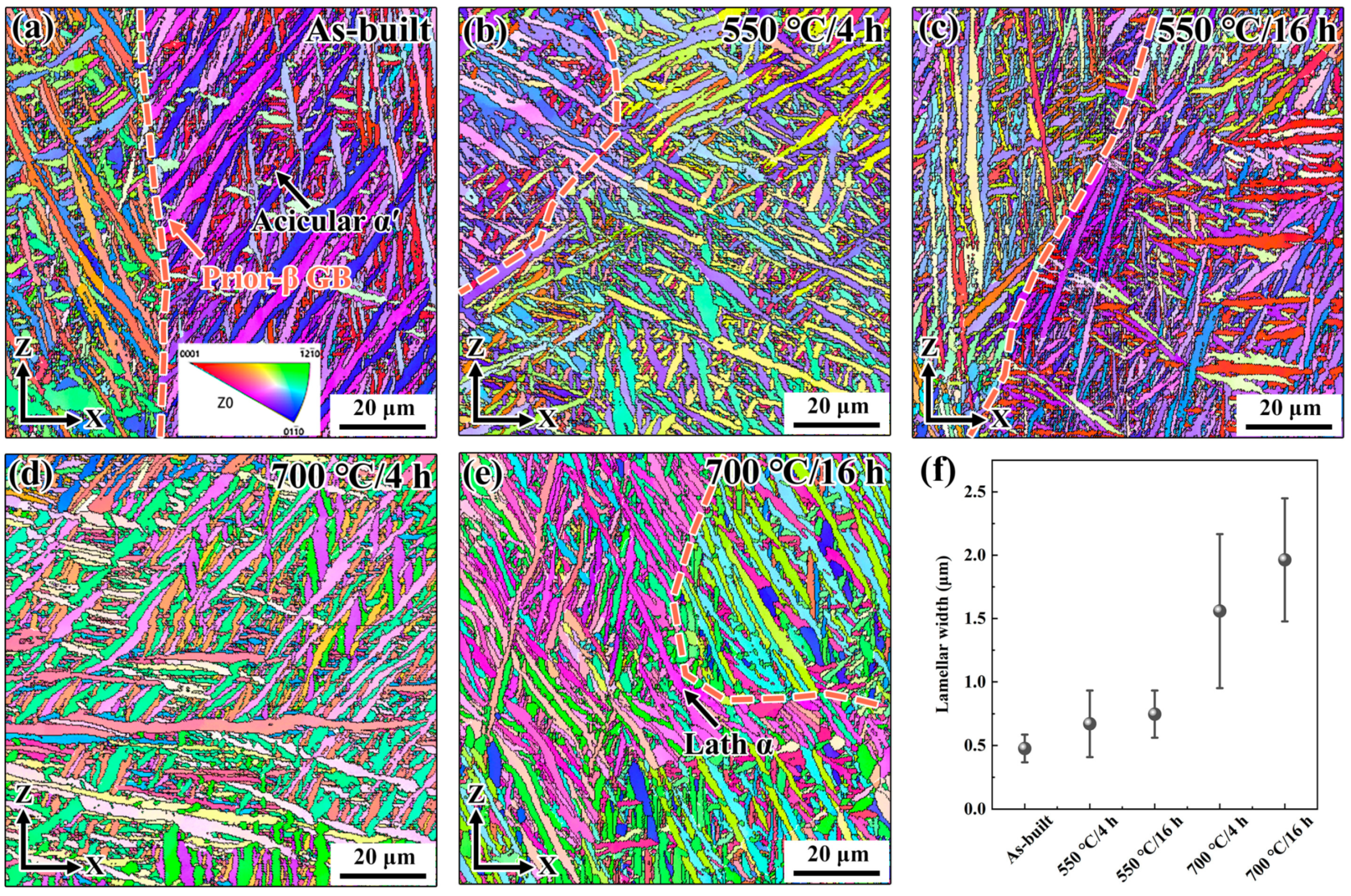

The EBSD inverse pole figure (IPF) orientation maps of the as-built and heat-treated Ti-6Al-4V alloys are presented in Figure 3. Overall, annealing at 550 °C only has a marginal influence on the microstructural morphology, while annealing at 700 °C coarsened the microstructure significantly (Figure 3f). Notably, the acicular morphology in the as-built state (Figure 3a) was transformed into the lath morphology (Figure 3e) after annealing at 700 °C for 16 h. The altered phase morphology could be beneficial for achieving higher work-hardening capacity, because the stress concentration at the acicular tip can be avoided during deformation. Meanwhile, this indicated that the martensite was fully decomposed after the 700 °C annealing treatment.

Figure 3.

EBSD IPF orientation maps of the (a) as-built, (b) 550 °C/4 h, (c) 550 °C/16 h, (d) 700 °C/4 h, and (e) 700 °C/16 h samples; (f) lamellar width of the samples.

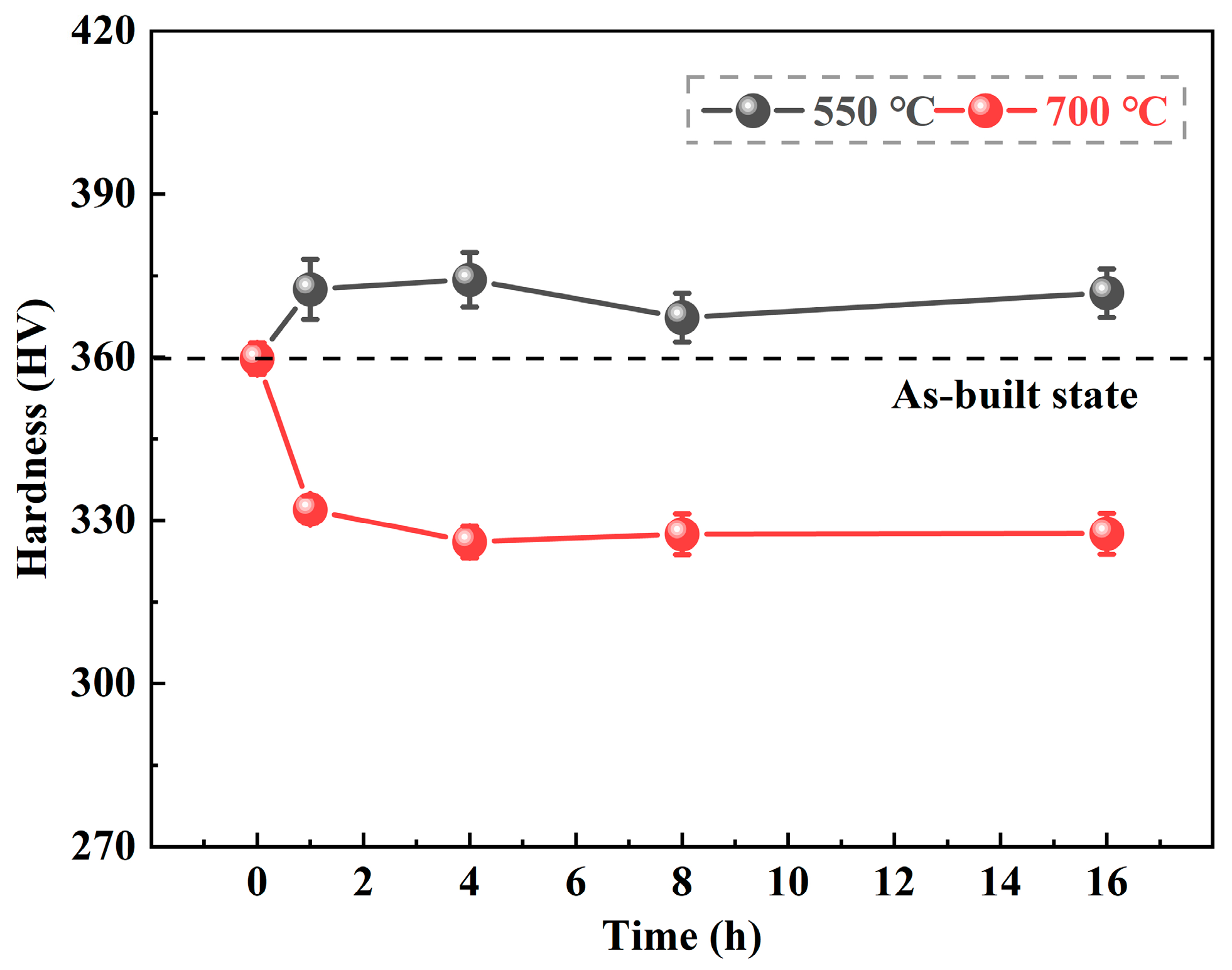

3.1.2. Mechanical Properties

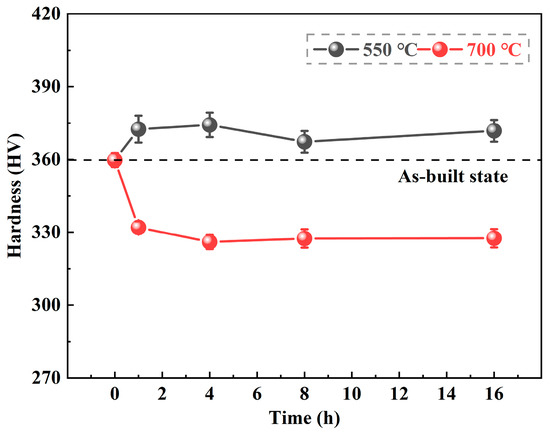

The micro-hardness of the as-built and heat-treated Ti-6Al-4V alloys are presented in the Figure 4 and Table 1. Annealing at 550 °C increases the hardness of the as-built alloy slightly, which could be related to the formation of nano-sized β and Ti3Al precipitates during the 550 °C annealing [25]. In contrast, annealing at 700 °C for 4 h reduces the hardness of the alloy by ~30 HV. Further prolonging the annealing time to 8 h and 16 h does not affect the hardness anymore. A similar phenomenon has also been observed in a β-quenched Ti-6Al-4V alloy [23].

Figure 4.

Micro-hardness evolutions of the as-built Ti-6Al-4V alloy during the annealing treatments.

Table 1.

Hardness values of the as-built Ti-6Al-4V alloy subjected to various annealing treatments.

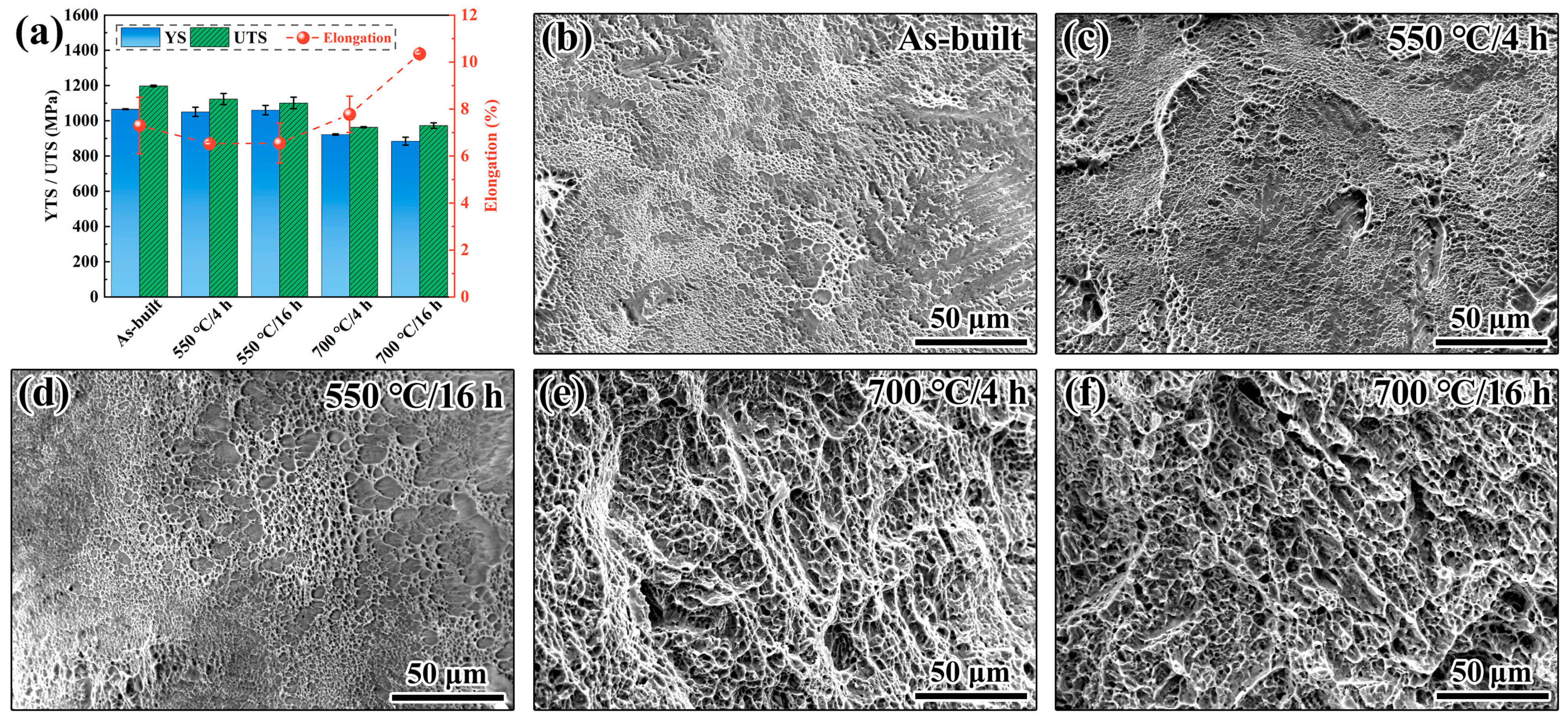

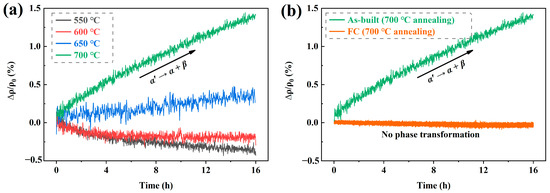

The tensile properties of the as-built and heat-treated samples are listed in Figure 5a and Table 2. Annealing at 550 °C only has a marginal influence on the yield strength (YS) of the alloy, while the ultimate tensile strength (UTS) and the elongation at break (εf) were decreased by 96 MPa and 0.6%, respectively, under annealing at 550 °C for 16 h. The decrease in UTS and εf could be related to the formation of the brittle Ti3Al phase, which is harmful to the work-hardening capacity of the alloy. After annealing at 700 °C for 4 h and 16 h, the ductility of the alloy was increased significantly. After annealing at 700 °C for 16 h, the εf of the alloy reached 10.4%, which meets the requirement for wrought Ti-6Al-4V alloy. Interestingly, compared with the 700 °C/4 h sample, the 700 °C/16 h sample possesses both higher UTS and higher εf, indicating that the work-hardening capacity was increased with a prolonged annealing duration.

Figure 5.

Tensile properties and fracture morphology: (a) tensile properties of the as-built Ti-6Al-4V alloy subjected to various annealing treatments; fracture morphologies of the (b) as-built, (c) 550 °C/4 h, (d) 550 °C/16 h, (e) 700 °C/4 h, and (f) 700 °C/16 h samples.

Table 2.

Tensile properties of the as-built Ti-6Al-4V alloy subjected to various annealing treatments.

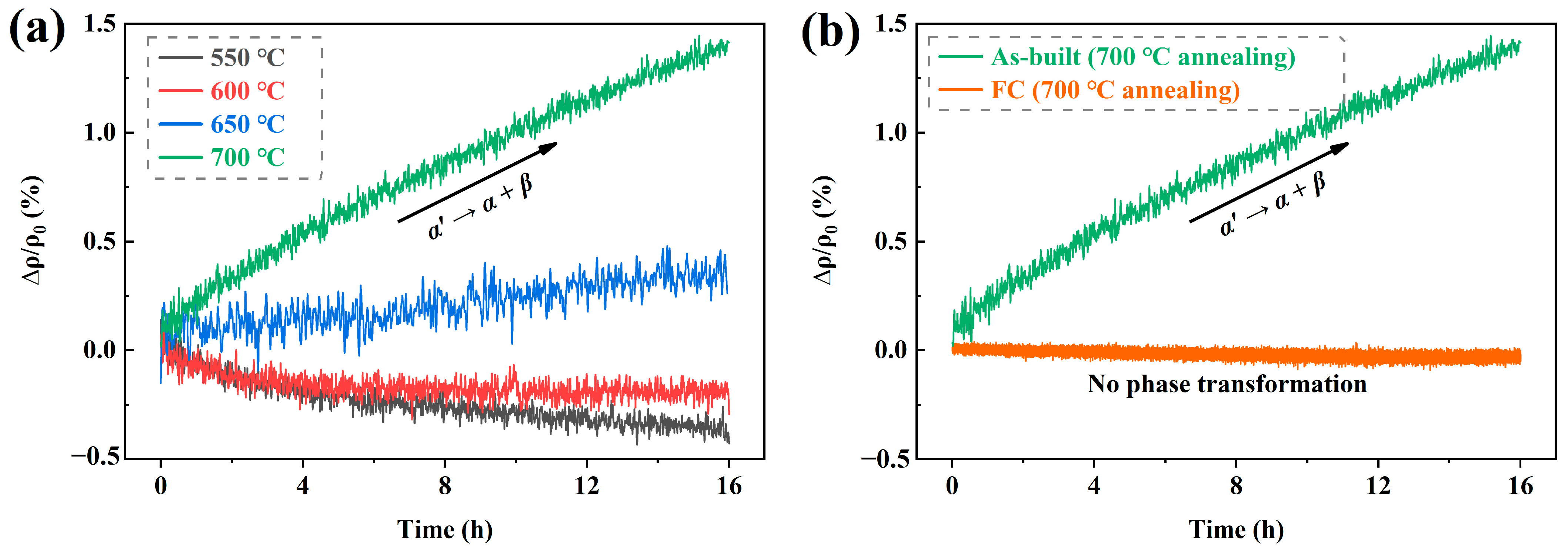

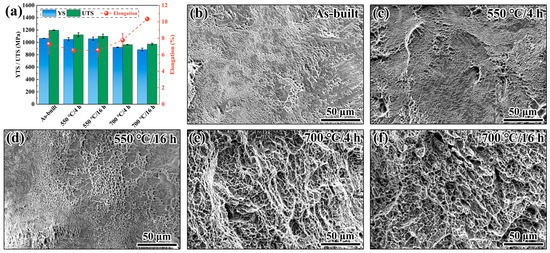

3.2. In Situ Electrical Resistivity Measurement

The in situ electrical resistivity measurement was adopted for monitoring the phase transformation behaviors during the annealing treatments, as shown in Figure 6. Surprisingly, the relative increase of the resistivity increased gradually with increasing annealing temperature. This reflects that the martensite decomposition rate increases with the annealing temperature. In contrast, annealing at 550 °C and 600 °C reduced the electrical resistivity slightly, which could be related to the annihilation of dislocations [26] and formation of Ti3Al precipitates [27]. To demonstrate the effects of martensite decomposition on electrical resistivity, an FC-treated (1050 °C/1 h + furnace cooling) Ti-6Al-4V sample with equilibrium coarse lamellar α + β microstructure was adopted for comparison. Under 700 °C annealing, no phase transformation exists in the FC sample owing to the initial equilibrium α + β microstructure. Interestingly, the electrical resistivity of the FC sample remained constant during annealing, further demonstrating that the increase in electrical resistivity is affected by the martensite decomposition. Overall, the in situ electrical resistivity measurement indicated that the martensite decomposition dominates the annealing behavior at 700 °C, while annealing at 550 °C has only a limited influence on the martensite decomposition, which corresponds well with the microstructural observations.

Figure 6.

In situ electrical resistivity results: (a) the relative increase in the resistivity of the as-built Ti-6Al-4V alloy subjected to various annealing treatments; (b) comparison of the in situ electrical resistivity curves of the as-built Ti-6Al-4V alloy and the FC-treated Ti-6Al-4V alloy under annealing at 700 °C/16 h.

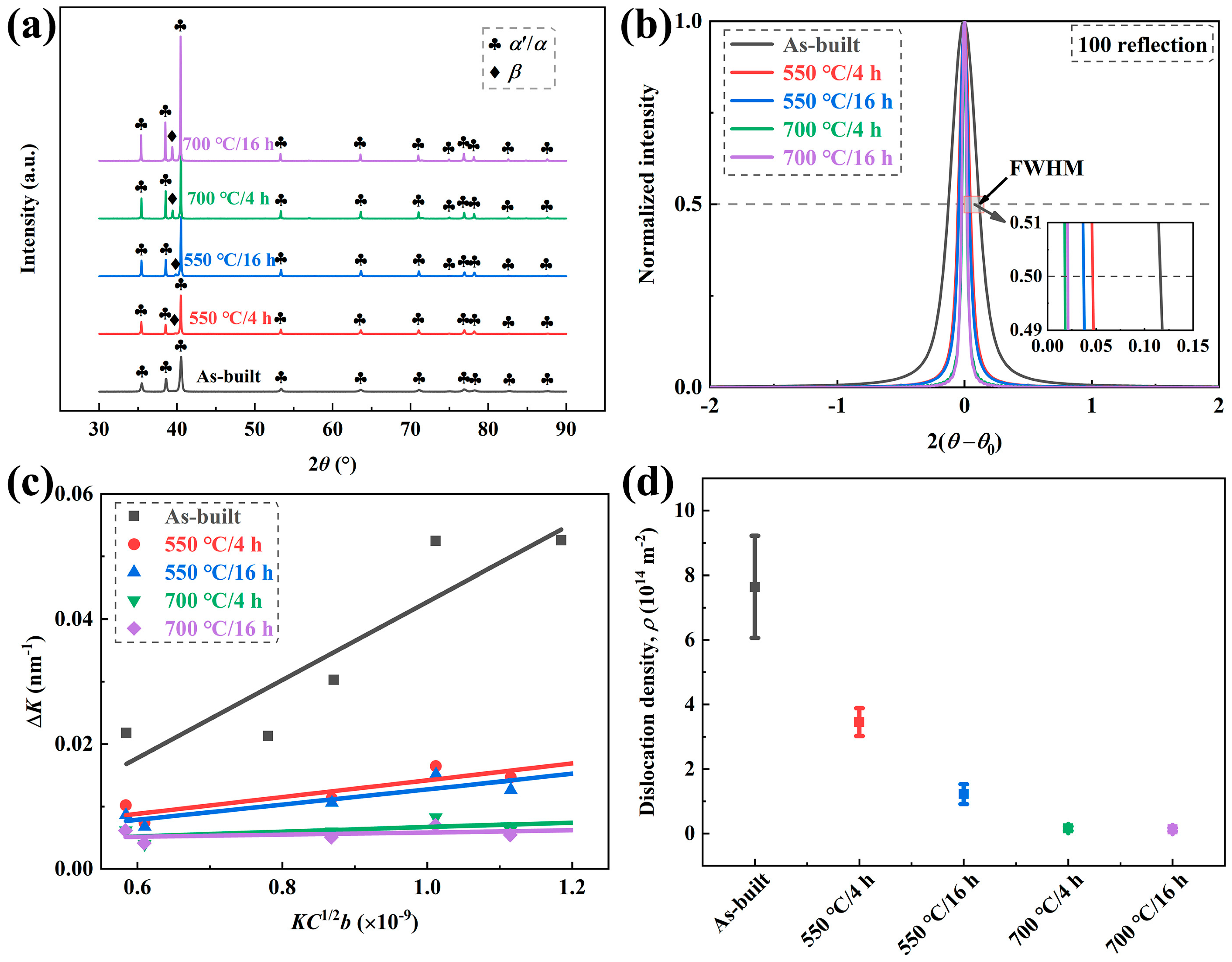

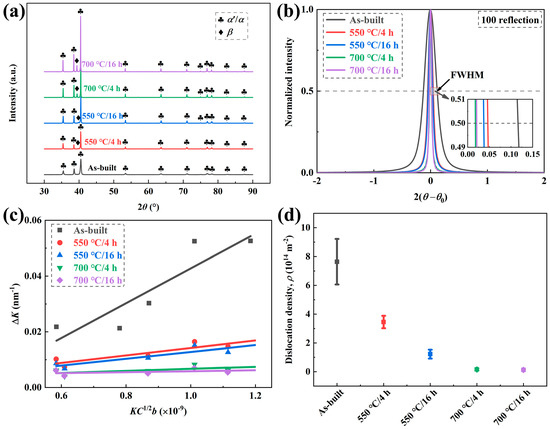

3.3. Line Profile Analysis of XRD

During the annealing treatments, the dislocations evolutions also play a significant role in controlling the mechanical behavior on the alloys [28]. In this section, the LPA of XRD is used to investigate the dislocation density evolutions of the alloy. The phase identification is based on the standard XRD diffraction pattern: JCPDS file #44-1294 (the hexagonal α-Ti) and JCPDS file #44-1288 (the cubic β-Ti). As presented in the XRD patterns in Figure 7, the peak of β phase (~39.4°) became obvious with the annealing treatment. In the as-built state, only peaks of α′ can be found, indicating the microstructure is full martensitic α′. Under annealing at 700 °C for 16 h, the intensity of the β phase peak is the highest among these samples, indicating the highest fraction of β phase. The co-occurrence of α and β phase peaks indicates that a dual-phase α + β microstructure is obtained, which corresponds with the microstructural observations in Figure 2 and Figure 3. The normalized 100 reflection of all of the alloy samples is presented in Figure 7b. Obviously, the FWHM of the as-built alloy is much higher than that of other heat-treated alloys, indicating the highest dislocation density. The mWH plot in Figure 7c further demonstrates this trend, because the slope of the mWH line is positively related to the dislocation density [23]. Notably, the measured dislocation density only takes the α′/α phase into consideration, and the β phase is not considered owing to the negligible dislocation density in the newly formed β phase. Annealing at 700 °C reduced the dislocation density of the as-built alloy significantly. After annealing at 700 °C for 4 h, 98% of the dislocations were eliminated, thus further prolonging the annealing time only has a marginally influence on the dislocation density. The reduced dislocation density in the α lath could provide space for storage of dislocations, which is beneficial for achieving high work-hardening capacity and superior ductility.

Figure 7.

Line profile analysis of XRD: (a) XRD patterns of the as-built Ti-6Al-4V alloy subjected to various annealing treatments; (b) the normalized 100 reflection; (c) the mWH plot; (d) dislocation density evolutions.

4. Discussion

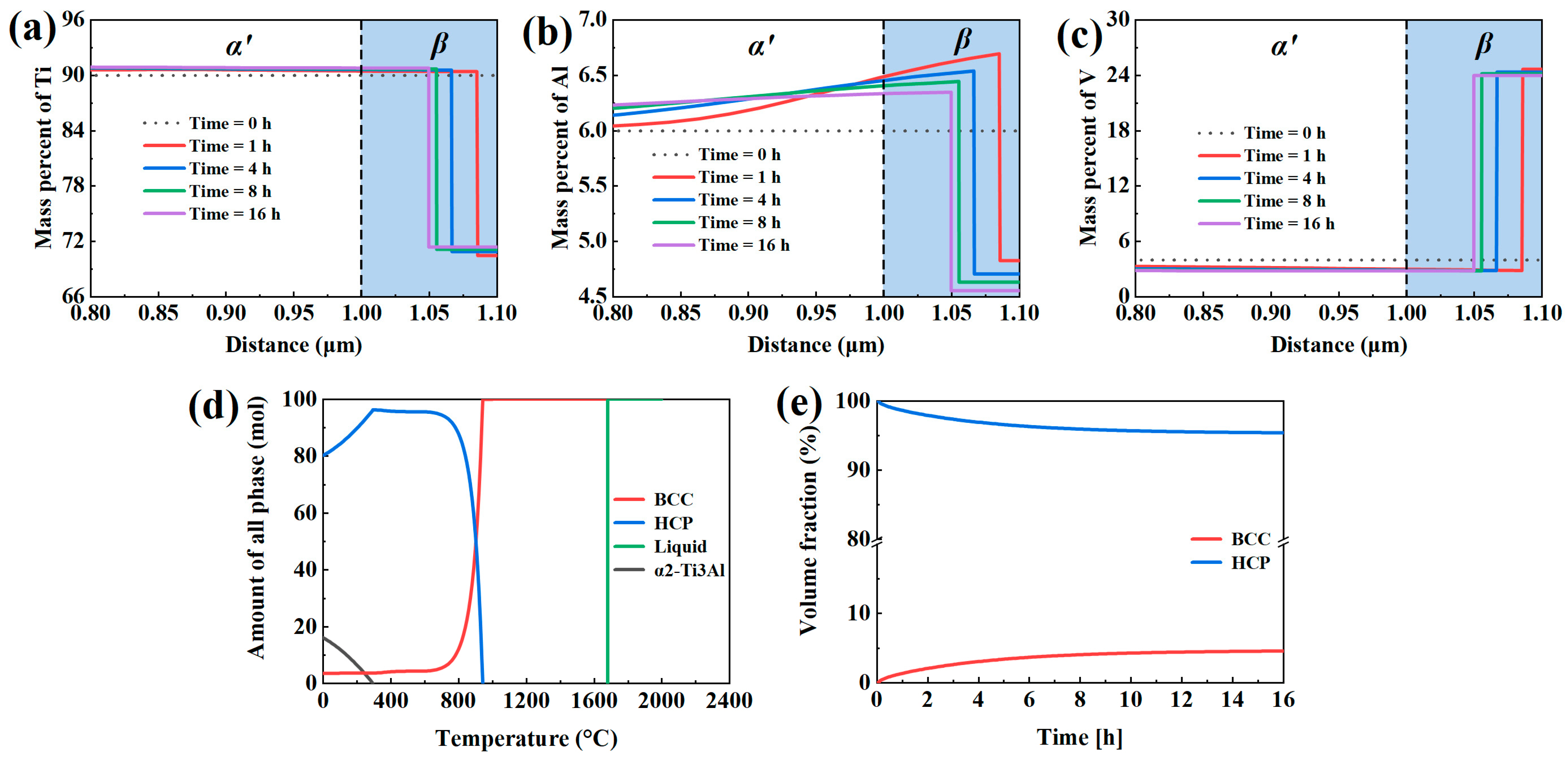

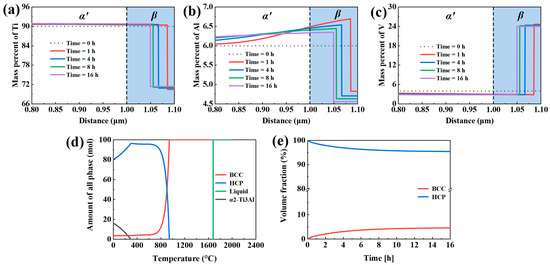

As presented above, the martensitic α′ of the as-built Ti-6Al-4V alloy was decomposed into the lamellar α + β after post annealing treatments. Fundamentally, the phase transformation behavior is dominated by the partitioning of the alloying elements (i.e., Al and V). Because the phase transformation is more obvious at 700 °C annealing, the DICTRA simulation is performed at 700 °C for 0–16 h to reveal the alloying elements’ partitioning behavior during the annealing treatment. Obviously, the V elements were accumulated into the β phase gradually under annealing, while the Ti and Al elements were depleted from the β phase, as shown in Figure 8. During annealing at 700 °C, the mass percent of V at the α′/β phase boundary is stable (Figure 8c). Further annealing leads to the gradual segregation of V into the β phase. In contrast, the Al contents at the α′/β phase boundary are gradient during annealing at 700 °C for 0–16 h (Figure 8b), which could be related to the faster diffusion rate of Al than that of V [29]. Overall, these phenomena indicated that the Al depletion and V segregation stabilized the β phase, thereby promoting the decomposition of martensitic α′ (Figure 8e).

Figure 8.

Thermo-Calc thermodynamic calculations: DICTRA simulation of the composition profiles of (a) Ti, (b) Al, and (c) V across the α′/β microstructure interface under annealing at 700 °C for various times; (d) one-axis equilibrium of the Ti-6Al-4V alloy; (e) phase evolutions during 700 °C annealing.

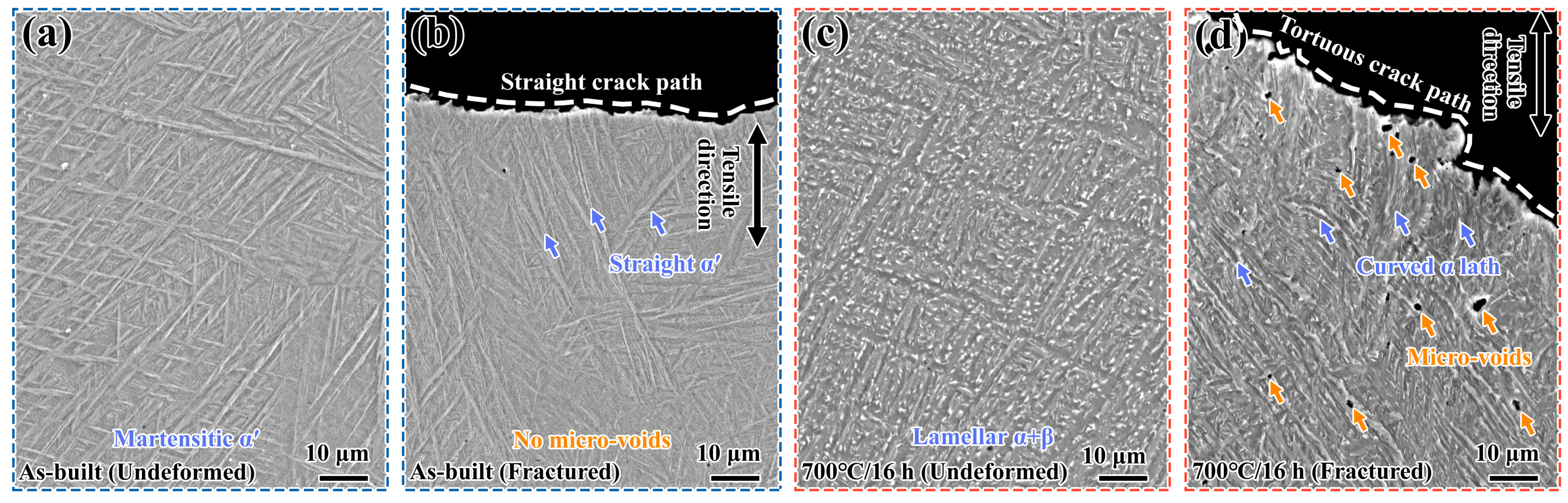

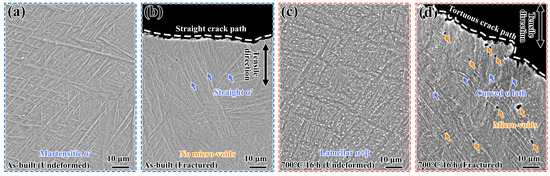

Figure 9 presents the side surface of the fractured tensile samples of the as-built and 700 °C/16 h alloy samples. For the as-built alloy, the microstructure of the fractured region is dominated by the straight acicular α′ (Figure 9b), which is similar to the undeformed state (Figure 9a). This indicated that the hard martensitic α′ phase almost cannot be deformed during the tensile deformation, which corresponds to the poor ductility (~7.3%). Meanwhile, the fracture crack path is relatively straight and no micro-voids can be found in the fractured sample, indicating a typical brittle fracture mechanism. In contrast, the curved α lath and numerous micro-voids can be observed in the fractured 700 °C/16 h tensile sample, indicating that the β phase accommodated the plastic deformation during the tensile test [30]; thus, the work-hardening capacity was improved. Besides, the crack path exhibited a tortuous morphology (Figure 9d), representing that the α/β phase boundary effectively inhibited the propagation of the crack path [31].

Figure 9.

Microstructural deformation features: (a) as-built (undeformed); (b) as-built (fractured); (c) 700 °C/16 h (undeformed); (d) 700 °C/16 h (fractured).

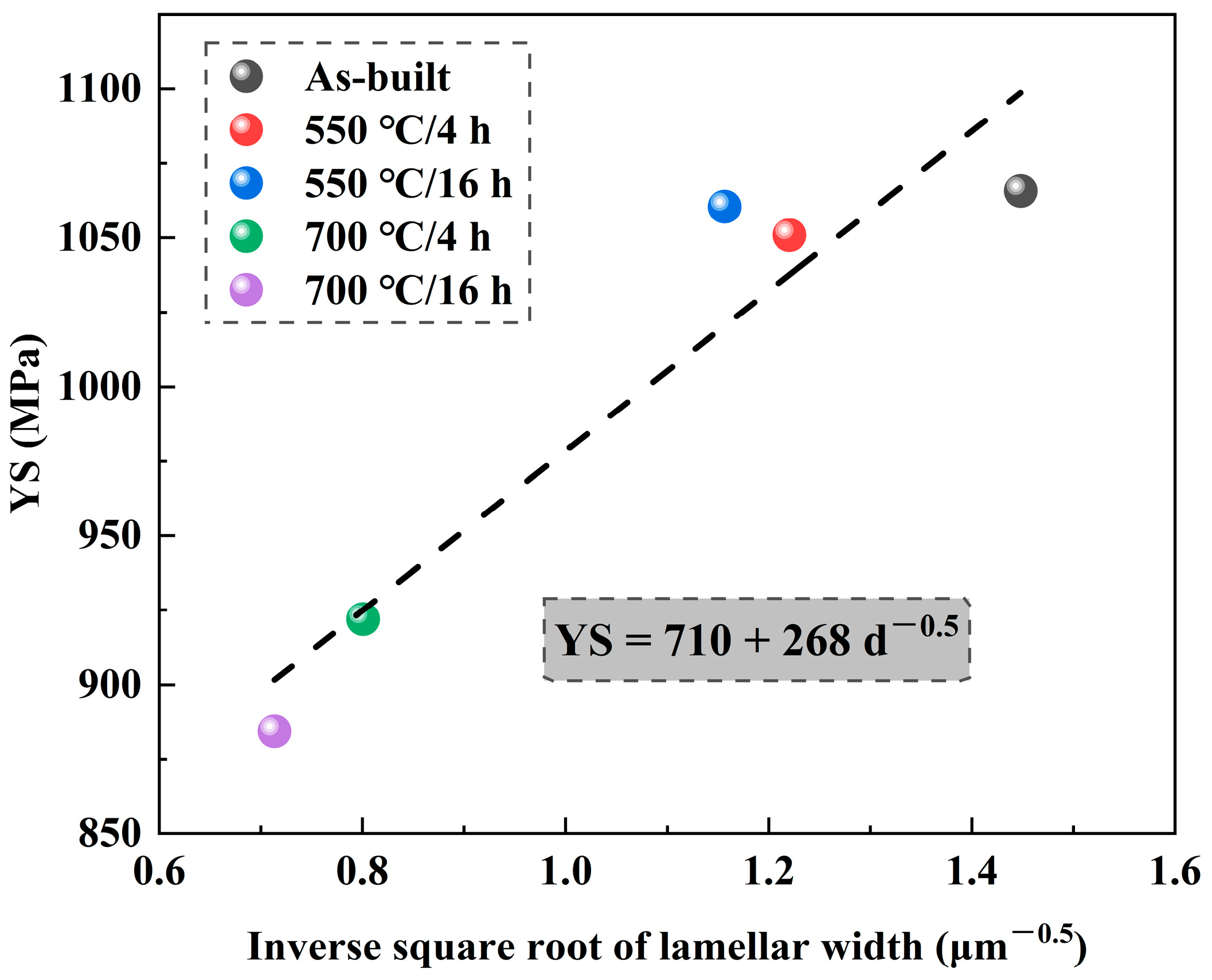

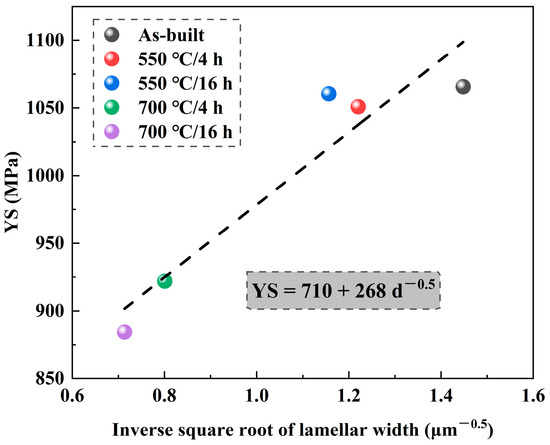

Figure 10 presents the relationship between the yield strength with the inverse square root of lamellar width of α′/α lath. Obviously, a Hall–Petch relationship can be found between the YS and the lamellar width, which has also been reported in other works [13,23]. This indicates that the grain boundary strengthening plays a major role in determining the YS of the alloy. The decrease in dislocation density does not affect the YS significantly. The reason can be attributed to the fact that the dislocations formed by the martensite transformation are mainly mobile dislocations, which has only marginally contributions to the overall YS [9,23]. In addition, the ductility of the as-built Ti-6Al-4V alloy was increased by 700 °C annealing. After annealing at 700 °C for 16 h, the ductility of the alloy reached 10.3%. The in-depth mechanisms for ductility improvements are as follows: (i) the reduced dislocations in the α lath provided substantial space for storage of dislocations during deformation; (ii) the β phase formation induced by alloying element partition accommodated the strain, thereby further increasing the ductility; and (iii) the acicular α′ transformed into lath α + β after the annealing treatment, which could avoid the stress concentration at the acicular tip during the tensile deformation.

Figure 10.

The Hall–Petch plot between YS and lamellar width of α′/α lath.

Overall, the dislocation evolutions and phase transformation both affect the mechanical behavior of the LPBF-built Ti-6Al-4V alloy significantly. The degree of martensite decomposition and the lamellar width of α′/α lath are dominant factors for the yield strength of the Ti-6Al-4V alloy. The dislocation density mainly affects the work-hardening behavior of the alloy, thereby influencing the ductility. Owing to the mobile characteristics of dislocations formed by martensite transformation in the LPBF-built Ti-6Al-4V alloy, the annihilation of dislocations seems to have only a limited influence on the yield strength of the alloy. Note that the β phase formed in the alloy could accommodate the strain and delay the fracture process during the tensile test, which is also favorable for improving the ductility and ultimate tensile strength. The competitive effects of these two factors, martensite decomposition and dislocation evolutions, dominate the mechanical behavior of the alloy.

5. Conclusions

In this work, in situ electrical resistivity and line profile analysis of X-ray diffraction measurements were implemented on an LPBF-built Ti-6Al-4V alloy to investigate the phase transformation behaviors and the dislocation evolutions under post annealing treatments (550/700 °C, 0–16 h). Besides, the relationships between phase transformation, dislocation evolutions, and mechanical properties were discussed intensively. The following main conclusions could be drawn.

- (1)

- The in situ electrical resistivity measurement was implemented to investigate the martensite decomposition behavior of the LPBF-built Ti-6Al-4V alloy under post annealing treatment. The relative increase of the electrical resistivity increased gradually with the increasing annealing temperature, representing that the martensite decomposition rate increases with the annealing temperature.

- (2)

- The dislocations in the as-built Ti-6Al-4V alloy were eliminated efficiently by the post annealing treatments. After annealing at 700 °C for 4 h, 98% of the dislocations were eliminated, and further prolonging the annealing time has only a marginal influence on the dislocation density. The reduced dislocations in the α lath provided space for storage of dislocations, which is beneficial for achieving high work-hardening capacity and superior ductility.

- (3)

- A linear relationship exists between the yield strength and the inverse square root of the lamellar width of α′/α lath, indicating that the grain boundary strengthening plays a major role in controlling the yield strength of the alloy. After annealing at 700 °C for 4 h and 16 h, the ductility of the alloy was increased to 7.8% and 10.3%, respectively. The improvement in ductility can be attributed to the integrated effects of the reduced dislocations, formed β phase, and varied phase morphology.

Author Contributions

Conceptualization, X.J. and J.S.; Formal analysis, X.J. and B.G.; Funding acquisition, X.J., J.S. and F.J.; Investigation, X.J. and H.X.; Methodology, X.J. and H.X.; Resources, F.J., J.T. and H.Z.; Supervision, J.T. and H.Z.; Writing—original draft, X.J. and J.S.; Writing—review and editing, F.J. and B.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the project (J2019-VIII-0002-0163), the State Key Laboratory of Powder Metallurgy of Central South University, and Post-graduate Scientific Research Innovation Project of Hunan Province (CX20220416).

Data Availability Statement

The data used to support the findings of this study are included within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tan, C.; Weng, F.; Sui, S.; Chew, Y.; Bi, G. Progress and Perspectives in Laser Additive Manufacturing of Key Aeroengine Materials. Int. J. Mach. Tools Manuf. 2021, 170, 103804. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, C.-T. Design of Titanium Alloys by Additive Manufacturing: A Critical Review. Adv. Powder Mater. 2021, 100014. [Google Scholar] [CrossRef]

- Lu, J.; Zhuo, L. Additive Manufacturing of Titanium Alloys via Selective Laser Melting: Fabrication, Microstructure, Post-Processing, Performance and Prospect. Int. J. Refract. Met. Hard Mater. 2023, 111, 106110. [Google Scholar] [CrossRef]

- Cao, S.; Zou, Y.; Lim, C.V.S.; Wu, X. Review of Laser Powder Bed Fusion (LPBF) Fabricated Ti-6Al-4V: Process, Post-Process Treatment, Microstructure, and Property. Light Adv. Manuf. 2021, 2, 20. [Google Scholar] [CrossRef]

- Alipour, S.; Moridi, A.; Liou, F.; Emdadi, A. The Trajectory of Additively Manufactured Titanium Alloys with Superior Mechanical Properties and Engineered Microstructures. Addit. Manuf. 2022, 60, 103245. [Google Scholar] [CrossRef]

- Teixeira, Ó.; Silva, F.J.G.; Ferreira, L.P.; Atzeni, E. A Review of Heat Treatments on Improving the Quality and Residual Stresses of the Ti-6Al-4V Parts Produced by Additive Manufacturing. Metals 2020, 10, 1006. [Google Scholar] [CrossRef]

- Huang, S.; Narayan, R.L.; Tan, J.H.K.; Sing, S.L.; Yeong, W.Y. Resolving the Porosity-Unmelted Inclusion Dilemma during in-Situ Alloying of Ti34Nb via Laser Powder Bed Fusion. Acta Mater. 2021, 204, 116522. [Google Scholar] [CrossRef]

- Sui, S.; Chew, Y.; Weng, F.; Tan, C.; Du, Z.; Bi, G. Achieving Grain Refinement and Ultrahigh Yield Strength in Laser Aided Additive Manufacturing of Ti−6Al−4V Alloy by Trace Ni Addition. Virtual Phys. Prototyp. 2021, 16, 417–427. [Google Scholar] [CrossRef]

- Su, J.; Jiang, F.; Li, J.; Tan, C.; Xu, Z.; Xie, H.; Liu, J.; Tang, J.; Fu, D.; Zhang, H.; et al. Phase Transformation Mechanisms, Microstructural Characteristics and Mechanical Performances of an Additively Manufactured Ti-6Al-4V Alloy under Dual-Stage Heat Treatment. Mater. Des. 2022, 223, 111240. [Google Scholar] [CrossRef]

- Sui, S.; Chew, Y.; Hao, Z.; Weng, F.; Tan, C.; Du, Z.; Bi, G. Effect of Cyclic Heat Treatment on Microstructure and Mechanical Properties of Laser Aided Additive Manufacturing Ti-6Al-2Sn-4Zr-2Mo Alloy. Adv. Powder Mater. 2022, 1, 100002. [Google Scholar] [CrossRef]

- Beese, A.M.; Carroll, B.E. Review of Mechanical Properties of Ti-6Al-4V Made by Laser-Based Additive Manufacturing Using Powder Feedstock. JOM 2016, 68, 724–734. [Google Scholar] [CrossRef]

- Azarniya, A.; Colera, X.G.; Mirzaali, M.J.; Sovizi, S.; Bartolomeu, F.; St Weglowski, M.K.; Wits, W.W.; Yap, C.Y.; Ahn, J.; Miranda, G.; et al. Additive Manufacturing of Ti-6Al-4V Parts through Laser Metal Deposition (LMD): Process, Microstructure, and Mechanical Properties. J. Alloys Compd. 2019, 804, 163–191. [Google Scholar] [CrossRef]

- Cao, S.; Chu, R.; Zhou, X.; Yang, K.; Jia, Q.; Lim, C.V.S.; Huang, A.; Wu, X. Role of Martensite Decomposition in Tensile Properties of Selective Laser Melted Ti-6Al-4V. J. Alloys Compd. 2018, 744, 357–363. [Google Scholar] [CrossRef]

- Cao, S.; Hu, Q.; Huang, A.; Chen, Z.; Sun, M.; Zhang, J.; Fu, C.; Jia, Q.; Lim, C.V.S.; Boyer, R.R.; et al. Static Coarsening Behaviour of Lamellar Microstructure in Selective Laser Melted Ti-6Al-4V. J. Mater. Sci. Technol. 2019, 35, 1578–1586. [Google Scholar] [CrossRef]

- Wang, H.; Chao, Q.; Chen, H.S.; Chen, Z.B.; Primig, S.; Xu, W.; Ringer, S.P.; Liao, X.Z. Formation of a Transition V-Rich Structure during the α’ to α + β Phase Transformation Process in Additively Manufactured Ti-6Al-4V. Acta Mater. 2022, 235. [Google Scholar] [CrossRef]

- Kumar, P.; Ramamurty, U. Microstructural Optimization through Heat Treatment for Enhancing the Fracture Toughness and Fatigue Crack Growth Resistance of Selective Laser Melted Ti-6Al-4V Alloy. Acta Mater. 2019, 169, 45–59. [Google Scholar] [CrossRef]

- Malinov, S.; Markovsky, P.; Sha, W.; Guo, Z. Resistivity Study and Computer Modelling of the Isothermal Transformation Kinetics of Ti-6Al-4V and Ti–6Al–2Sn–4Zr–2Mo–0.08Si Alloys. J. Alloys Compd. 2001, 314, 181–192. [Google Scholar] [CrossRef]

- Malinov, S.; Markovsky, P.; Sha, W. Resistivity Study and Computer Modelling of the Isothermal Transformation Kinetics of Ti–8Al–1Mo–1V Alloy. J. Alloys Compd. 2002, 333, 122–132. [Google Scholar] [CrossRef]

- Tang, L.; Bo, G.; Jiang, F.; Xu, S.; Teng, J.; Fu, D.; Zhang, H. Unravelling the Precipitation Evolutions of AZ80 Magnesium Alloy during Non-Isothermal and Isothermal Processes. J. Mater. Sci. Technol. 2021, 75, 184–195. [Google Scholar] [CrossRef]

- Williamson, G.; Hall, W. X-Ray Line Broadening from Filed Aluminium and Wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Warren, B.E.; Averbach, B.L. The Effect of Cold-Work Distortion on X-ray Patterns. J. Appl. Phys. 1950, 21, 595–599. [Google Scholar] [CrossRef]

- Su, J.; Jiang, F.; Tan, C.; Weng, F.; Ng, F.L.; Goh, M.H.; Xie, H.; Liu, J.; Chew, Y.; Teng, J. Additive Manufacturing of Fine-Grained High-Strength Titanium Alloy via Multi-Eutectoid Elements Alloying. Compos. Part B Eng. 2023, 249, 110399. [Google Scholar] [CrossRef]

- Su, J.; Ji, X.; Liu, J.; Teng, J.; Jiang, F.; Fu, D.; Zhang, H. Revealing the Decomposition Mechanisms of Dislocations and Metastable α’ Phase and Their Effects on Mechanical Properties in a Ti-6Al-4V Alloy. J. Mater. Sci. Technol. 2021, 107, 136–148. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Sha, G.; Jin, S.; Hou, Z.; Bayat, M.; Yang, N.; Tan, Q.; Yin, Y.; Liu, S.; et al. Designing against Phase and Property Heterogeneities in Additively Manufactured Titanium Alloys. Nat. Commun. 2022, 13, 4660. [Google Scholar] [CrossRef] [PubMed]

- Carreon, H.; Ruiz, A.; Santoveña, B. Study of Aging Effects in a Ti-6AL-4V Alloy with Widmanstätten and Equiaxed Microstructures by Non-Destructive Means. AIP Conf. Proc. 2014, 1581, 739–745. [Google Scholar] [CrossRef]

- Jiang, F.; Zurob, H.S.; Purdy, G.R.; Zhang, H. Characterizing Precipitate Evolution of an Al-Zn-Mg-Cu-Based Commercial Alloy during Artificial Aging and Non-Isothermal Heat Treatments by in Situ Electrical Resistivity Monitoring. Mater. Charact. 2016, 117, 47–56. [Google Scholar] [CrossRef]

- Su, J.; Xie, H.; Tan, C.; Xu, Z.; Liu, J.; Jiang, F.; Tang, J.; Fu, D.; Zhang, H.; Teng, J. Microstructural Characteristics and Tribological Behavior of an Additively Manufactured Ti-6Al-4V Alloy under Direct Aging and Solution-Aging Treatments. Tribol. Int. 2022, 175, 107763. [Google Scholar] [CrossRef]

- Yamanaka, K.; Kuroda, A.; Ito, M.; Mori, M.; Bian, H.; Shobu, T.; Sato, S.; Chiba, A. Quantifying the Dislocation Structures of Additively Manufactured Ti-6Al-4V Alloys Using X-Ray Diffraction Line Profile Analysis. Addit. Manuf. 2020, 37. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Brown, T.M.; Goff, T.A.; Fagin, P.N.; Barker, D.R.; Turner, R.E.; Murry, J.M.; Miller, J.D.; Zhang, F. Diffusion Coefficients for Modeling the Heat Treatment of Ti-6Al-4V. Metall. Mater. Trans. A 2004, 35, 3015–3018. [Google Scholar] [CrossRef]

- Sui, S.; Chew, Y.; Weng, F.; Tan, C.; Du, Z.; Bi, G. Study of the Intrinsic Mechanisms of Nickel Additive for Grain Refinement and Strength Enhancement of Laser Aided Additively Manufactured Ti-6Al-4V. Int. J. Extrem. Manuf. 2022, 4, 035102. [Google Scholar] [CrossRef]

- Zheng, X.; Zheng, S.; Wang, J.; Ma, Y.; Wang, H.; Zhou, Y.; Shao, X.; Zhang, B.; Lei, J.; Yang, R.; et al. Twinning and Sequential Kinking in Lamellar Ti-6Al-4V Alloy. Acta Mater. 2019, 181, 479–490. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).