Nb Phase Position Marking for Clarifying the Formation Process of Cu-Al Composite Interfacial Phases in Continuous Composite Casting

Abstract

1. Introduction

2. Materials and Methods

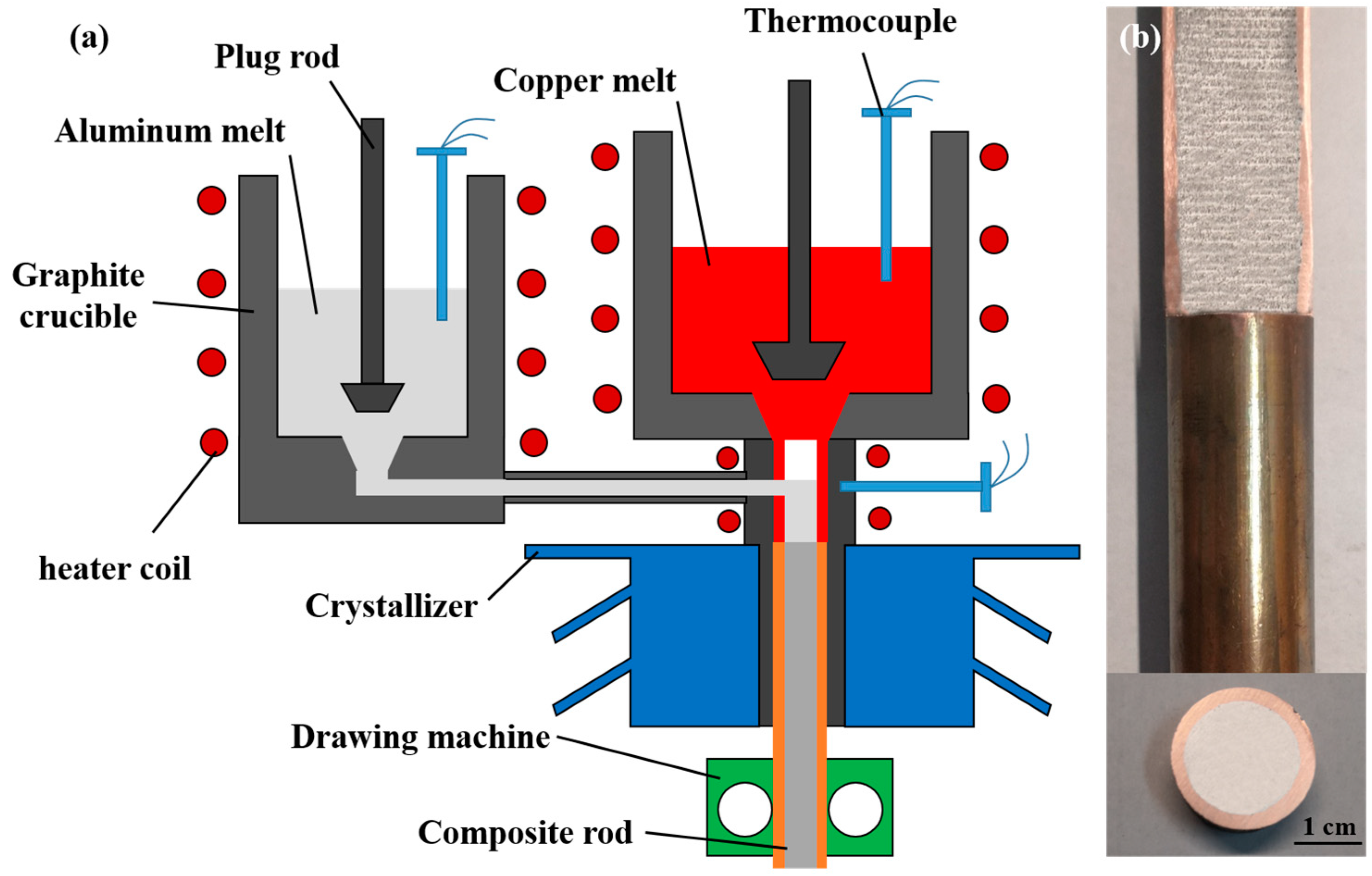

2.1. Continuous Composite Casting

2.2. Microstructure Analysis

2.3. Thermodynamic Calculations

3. Results and Analysis

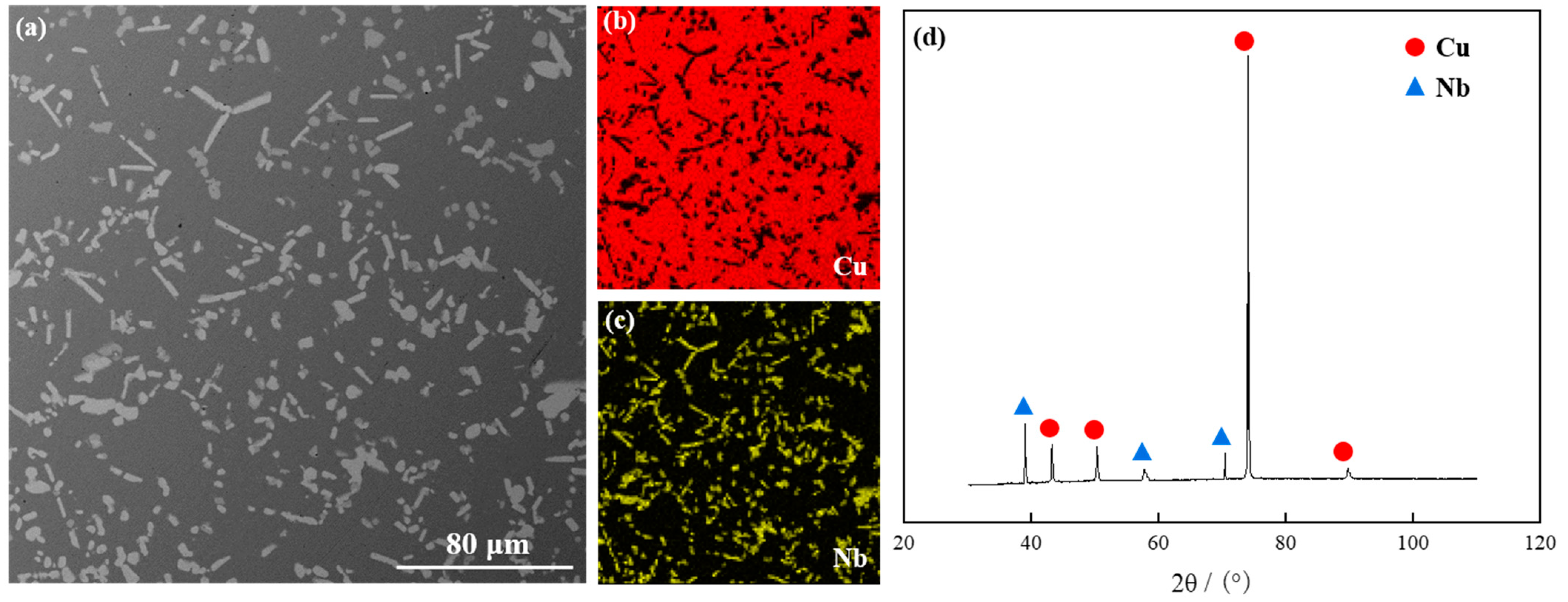

3.1. Microstructure of the Cu-Nb Alloy

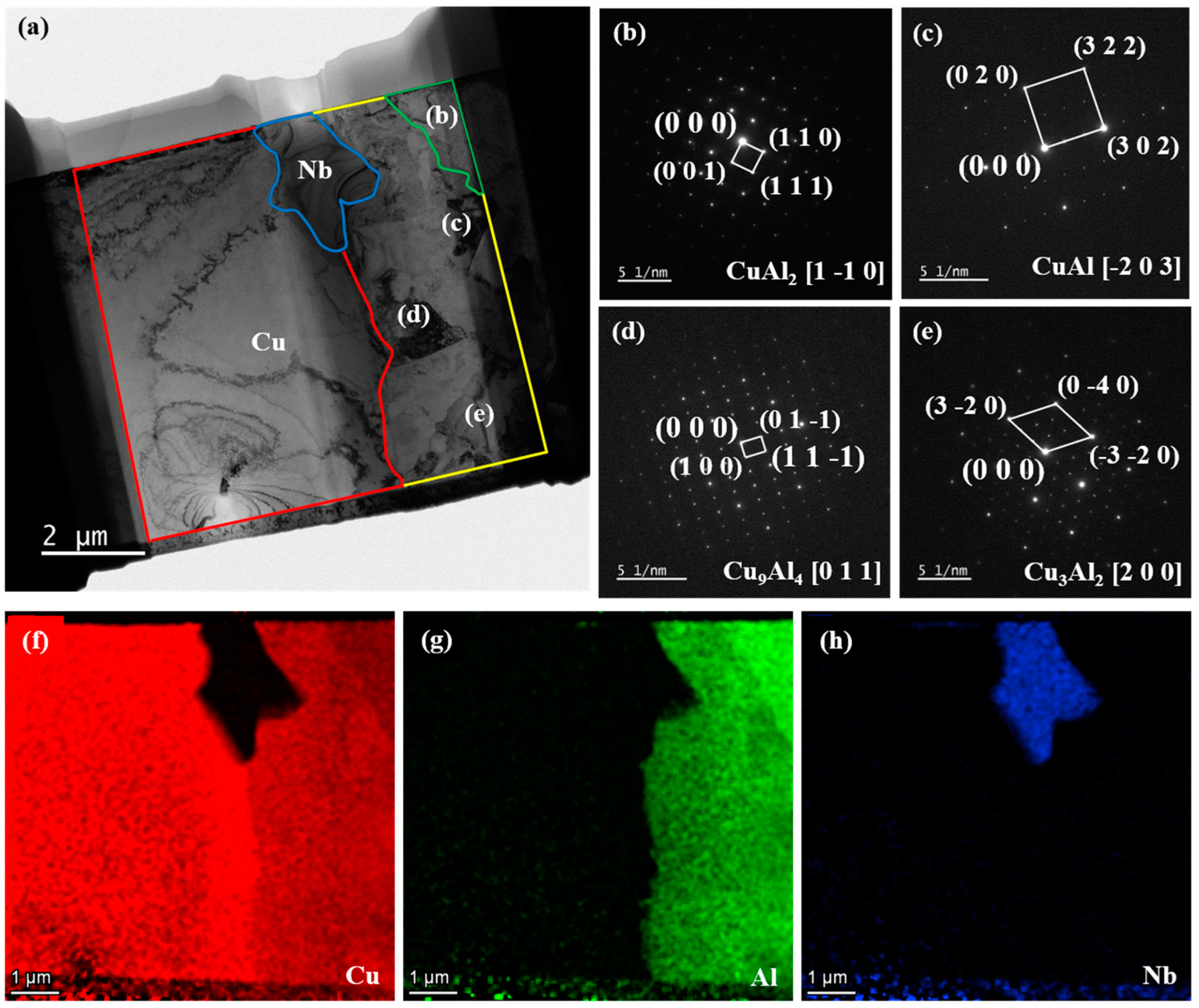

3.2. Interface Morphology of the Cu-Nb/Al Composite

3.3. Thermodynamic Calculation of the Interfacial Phase Formation Sequence

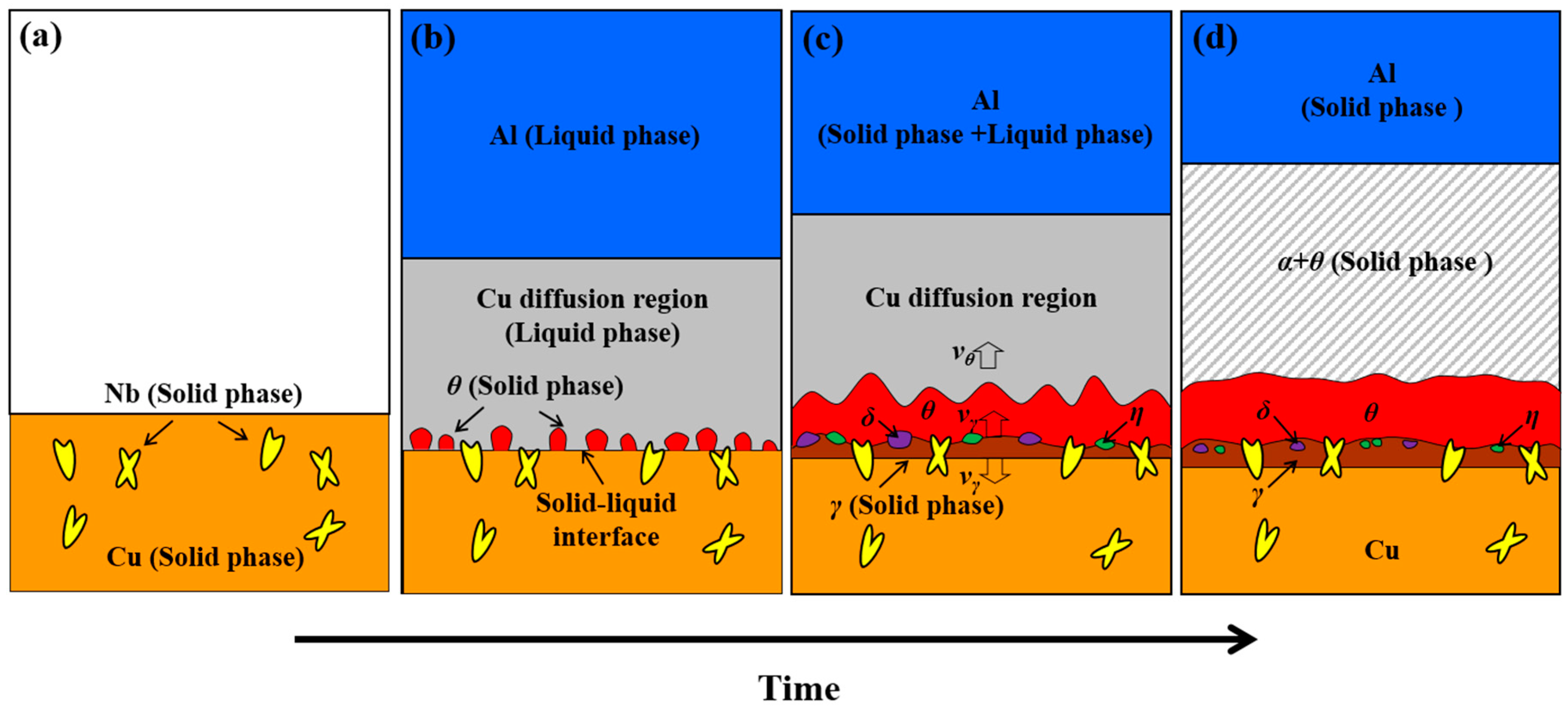

3.4. Interfacial Phase Formation Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, D.G.; Zhang, H.M.; Zhao, D.D.; Liu, Y.Y.; Jiang, Z.Y. Effects of annealing temperature on interface microstructure and element diffusion of ultra-thin Cu/Al composite sheets. Mater. Lett. 2022, 322, 132491. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Yuan, X.G.; Huang, H.J.; Zou, X.J.; Cheng, Y.L. Influence of chloride ion concentration and temperature on the corrosion of Cu–Al composite plates in salt fog. J. Alloys Compd. 2020, 821, 153249. [Google Scholar] [CrossRef]

- Lenka, K.; Radim, K.; Karel, D.; Adéla, M. Rotary swaged laminated Cu-Al composites: Effect of structure on residual stress and mechanical and electric properties. Mater. Sci. Eng. A 2019, 742, 743–750. [Google Scholar]

- Song, H.; Hao, W.X.; Mu, X.W.; Han, T.Z.; Che, C.J.; Geng, G.H. Effect of pulse current-assisted rolling on the interface bonding strength and microstructure of Cu/Al laminated composite. Metals 2020, 11, 1555. [Google Scholar] [CrossRef]

- Gao, L.; Zou, T.J.; Zhang, P.; Sun, L.X.; Cao, F.; Liang, S.H. Interfacial bonding mechanism and mechanical properties of adding CuZn alloy fibre for Cu/Al composite. Mater. Charact. 2022, 188, 111883. [Google Scholar] [CrossRef]

- Radim, K.; Lenka, K.; Casey, F.D.; Terry, C.L.; Ivo, S.; Adéla, M. Deformation behavior of multilayered Al–Cu clad composite during cold-swaging. Mater. Des. 2016, 90, 379–388. [Google Scholar]

- Sealy, C. Polymer composite combines novel properties. Mater. Today 2017, 20, 558–559. [Google Scholar] [CrossRef]

- Gao, H.T.; Li, J.; Lei, G.; Song, L.L.; Kong, C.; Yu, H.L. High strength and thermal stability of multilayered Cu/Al composites fabricated through accumulative roll bonding and cryorolling. Metall. Mater. Trans. A 2022, 53, 1176–1187. [Google Scholar] [CrossRef]

- Kim, I.K.; Hong, S.I. Effect of heat treatment on the bending behavior of tri-layered Cu/Al/Cu composite plates. Mater. Des. 2013, 47, 590–598. [Google Scholar] [CrossRef]

- Liu, S.Y.; Wang, A.Q.; Tian, H.W.; Xie, J.P. The synergetic tensile deformation behavior of Cu/Al laminated composites prepared by twin-roll casting technology. Mater. Res. Express 2019, 6, 016530. [Google Scholar] [CrossRef]

- Chen, S.Y.; Chang, G.W.; Yue, X.D.; Li, Q.C. Solidification process and microstructure of transition layer of Cu-Al composite cast prepared by method of pouring molten aluminum. Trans. Nonferrous Met. Soc. China 2016, 26, 2247–2256. [Google Scholar] [CrossRef]

- Hoseini-Athar, M.M.; Tolaminejad, B. Interface morphology and mechanical properties of Al-Cu-Al laminated composites fabricated by explosive welding and subsequent rolling process. Met. Mater. Int. 2016, 22, 670–680. [Google Scholar] [CrossRef]

- Su, Y.J.; Liu, X.H.; Wu, Y.F.; Huang, H.Y.; Xie, J.X. Numerical simulation of temperature field in horizontal core-filling continuous casting for copper cladding aluminum rods. Int. J. Miner. Metall. Mater. 2013, 20, 684–692. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, F.; Xie, G.L.; Xu, J.X.; Liu, X.H. Hot compressive deformation of eutectic Al–17at% Cu alloy on the interface of the Cu–Al composite plate produced by horizontal continuous casting. Int. J. Miner. Metall. Mater. 2022, 29, 1578–1588. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, F.; Xie, G.L.; Hou, Y.F.; Wang, R.; Liu, X.H. Rolling deformation behaviour and interface evaluation of Cu-Al bimetallic composite plates fabricated by horizontal continuous composite casting. J. Mater. Process. Technol. 2021, 298, 117296. [Google Scholar] [CrossRef]

- Wang, J.; Lei, Y.; Liu, X.H.; Xie, G.L.; Jiang, Y.Q.; Zhang, S. Microstructure and properties of Cu–Al-laminated composites fabricated via formation of a horizontal continuous casting composite. China J. Eng. 2020, 42, 216–224. [Google Scholar]

- Ikeda, Y.; Mancias, J.; Gan, B.; Maass, R. Evidence of room-temperature shear-deformation in a Cu-Al intermetallic. Scr. Mater. 2021, 190, 126–130. [Google Scholar] [CrossRef]

- Liu, S.Y.; Wang, A.Q.; Liang, T.T.; Xie, J.P. Hot deformation behaviour of Cu/Al laminated composites under interface constraint effect. Mater. Res. Express 2018, 5, 066531. [Google Scholar] [CrossRef]

- Guo, Y.J.; Liu, G.W.; Jin, H.Y.; Shi, Z.Q.; Qian, G.J. Intermetallic phase formation in diffusion-bonded Cu/Al laminates. J. Mater. Sci. 2011, 46, 2467–2473. [Google Scholar] [CrossRef]

- Lee, K.S.; Kwon, Y. Solid-state bonding between Al and Cu by vacuum hot pressing. Trans. Nonferrous Met. Soc. China 2013, 23, 341–346. [Google Scholar] [CrossRef]

- Tavassoli, S.; Abbasi, M.; Tahavvori, R. Controlling of IMCs layer formation sequence, bond strength and electrical resistance in Al-Cu bimetal compound casting process. Mater. Des. 2016, 108, 343–353. [Google Scholar] [CrossRef]

- Su, Y.J.; Liu, X.H.; Huang, H.Y.; Liu, X.F.; Xie, J.X. Interfacial microstructure and bonding strength of copper cladding aluminum rods fabricated by horizontal core-filling continuous casting. Met. Mater. Trans. A 2011, 42, 4088–4099. [Google Scholar] [CrossRef]

- Tian, S.K.; Zhao, F.; Liu, X.H. Clarification of the solid-state diffusion behavior of a copper alloy/aluminum alloy composite interface assisted by position marking of the second phases. Mater. Charact. 2022, 192, 112173. [Google Scholar] [CrossRef]

- Liu, X.H.; Fu, H.D.; He, X.Q.; Fu, X.T.; Jiang, Y.Q.; Xie, J.X. Numerical Simulation Analysis of Continuous Casting Cladding Forming for Cu-Al Composites. Acta Metall. Sin. 2018, 54, 470–484. [Google Scholar]

- Pretorius, R.; de Reus, R.; Vredenberg, A.M.; Saris, F.W. Use of the effective heat of formation rule for predicting phase formation sequence in Al−Ni systems. Mater. Lett. 1990, 9, 494–499. [Google Scholar] [CrossRef]

- Pretorius, R.; Vredenberg, A.M.; Saris, F.W.; de Reus, R. Prediction of phase formation sequence and phase stability in binary metal−aluminum thin−film systems using the effective heat of formation rule. J. Appl. Phys. 1991, 70, 3636–3646. [Google Scholar] [CrossRef]

- Buhler, T.; Fries, S.G.; Spencer, P.J.; Lukas, H.L. A thermodynamic assessment of the Al-Cu-Mg ternary system. J. Phase Equilib. 1998, 19, 317–333. [Google Scholar] [CrossRef]

- Cao, F.; Zhang, P.; Zou, J.T.; Wang, T.M. The formation and growth of intermetallic compounds during interdiffusion of Al/Cu bimetals. Mater. Res. Express 2022, 9, 056503. [Google Scholar] [CrossRef]

| Types of Cu-Al Intermetallic Compounds | ∆G (J/mol) |

|---|---|

| CuAl2 | −77,100 + 22.3T |

| Cu9Al4 | −334,000 + 96.1T |

| CuAl | −51,380 + 14.8T |

| Cu3Al2 | −128,440 + 36.9T |

| Phase (IMCs) | Compound Concentration | [28] | Effective Concentration | |

|---|---|---|---|---|

| Limiting Element | ||||

| CuAl2 | Cu0.33Al0.67 | −13.05 | Cu | −6.76 |

| CuAl | Cu0.51Al0.49 | −19.92 | Cu | −6.68 |

| Cu3Al2 | Cu0.605Al0.9.395 | −20.67 | Cu | −5.84 |

| Cu9Al4 | Cu0.66Al0.34 | −21.69 | Cu | −5.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhao, F.; Liu, X. Nb Phase Position Marking for Clarifying the Formation Process of Cu-Al Composite Interfacial Phases in Continuous Composite Casting. Metals 2023, 13, 1045. https://doi.org/10.3390/met13061045

Wang J, Zhao F, Liu X. Nb Phase Position Marking for Clarifying the Formation Process of Cu-Al Composite Interfacial Phases in Continuous Composite Casting. Metals. 2023; 13(6):1045. https://doi.org/10.3390/met13061045

Chicago/Turabian StyleWang, Jun, Fan Zhao, and Xinhua Liu. 2023. "Nb Phase Position Marking for Clarifying the Formation Process of Cu-Al Composite Interfacial Phases in Continuous Composite Casting" Metals 13, no. 6: 1045. https://doi.org/10.3390/met13061045

APA StyleWang, J., Zhao, F., & Liu, X. (2023). Nb Phase Position Marking for Clarifying the Formation Process of Cu-Al Composite Interfacial Phases in Continuous Composite Casting. Metals, 13(6), 1045. https://doi.org/10.3390/met13061045