High-Resolution Characterization of Deformation Induced Martensite in Large Areas of Fatigued Austenitic Stainless Steel Using Deep Learning

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

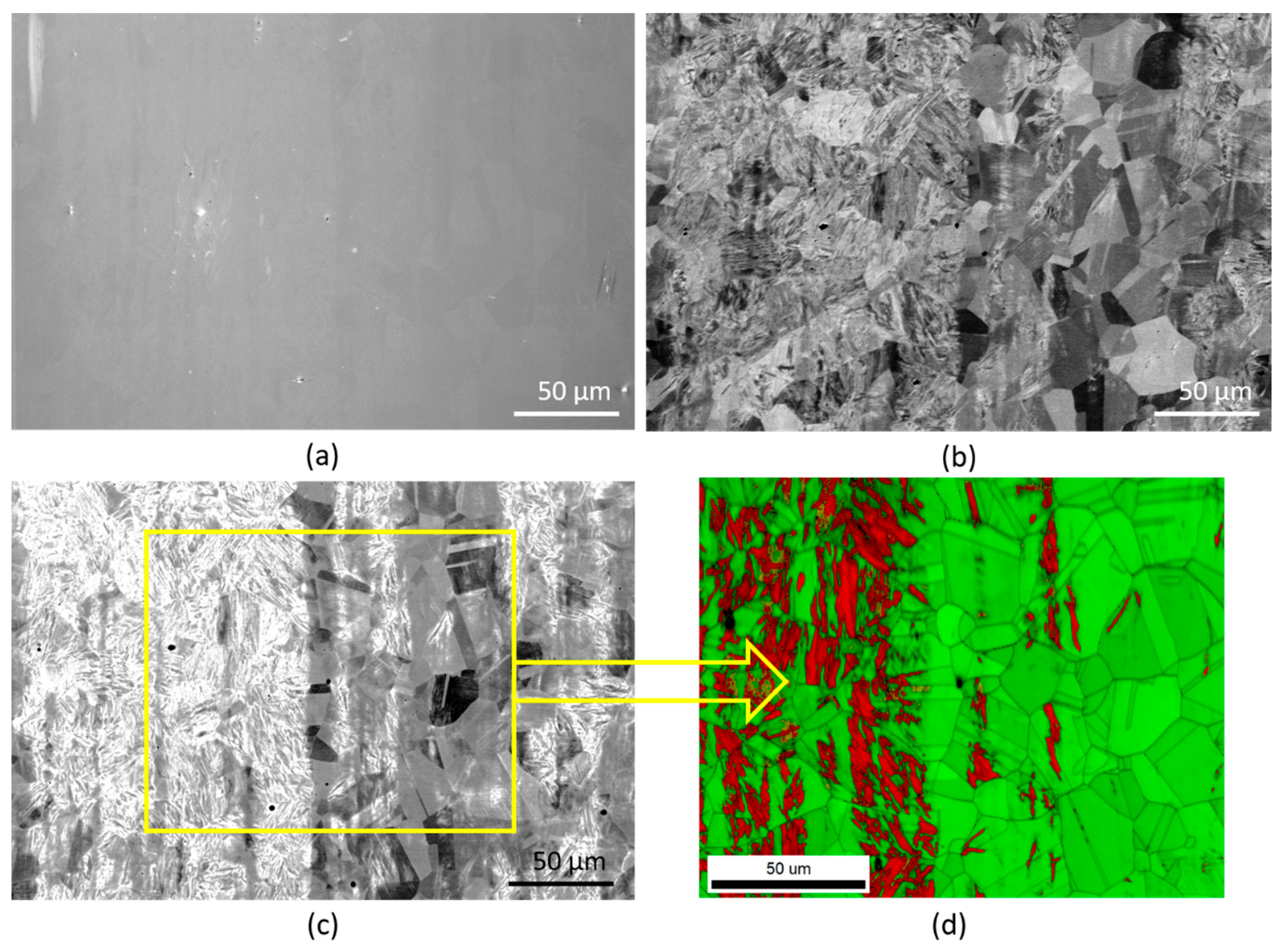

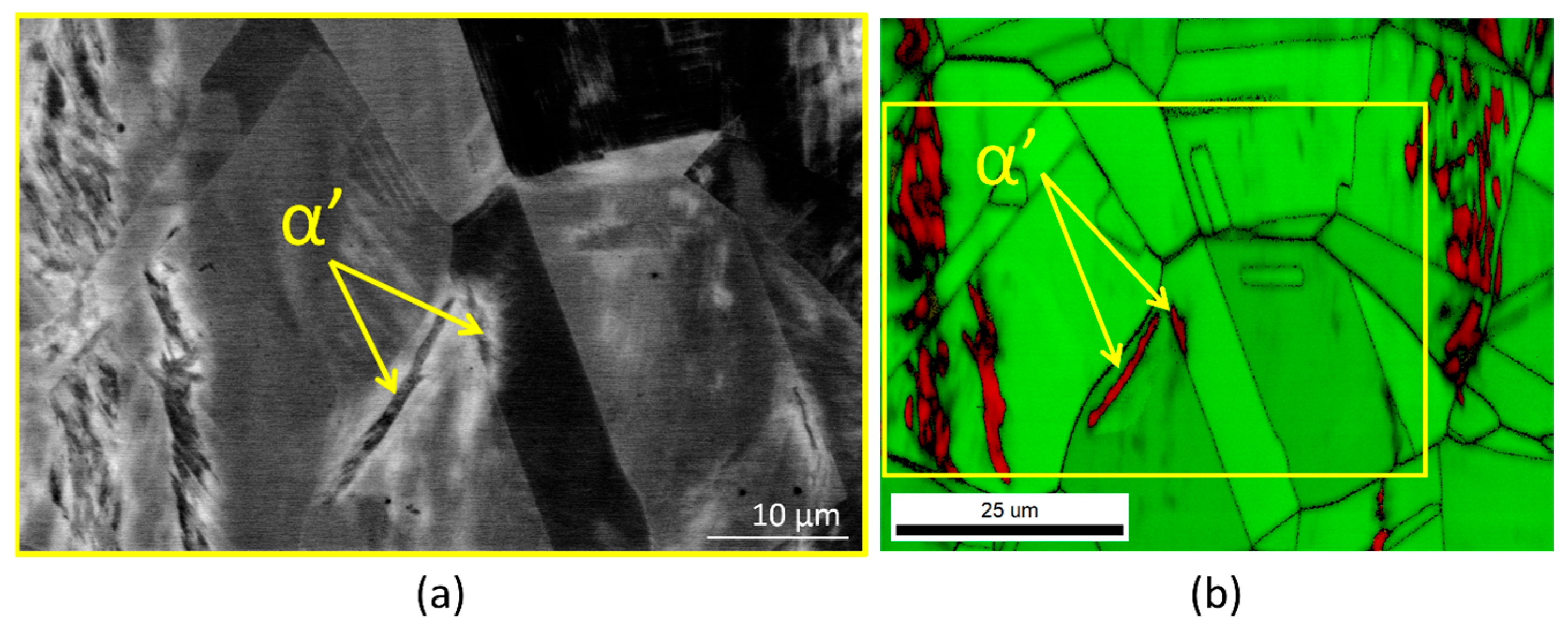

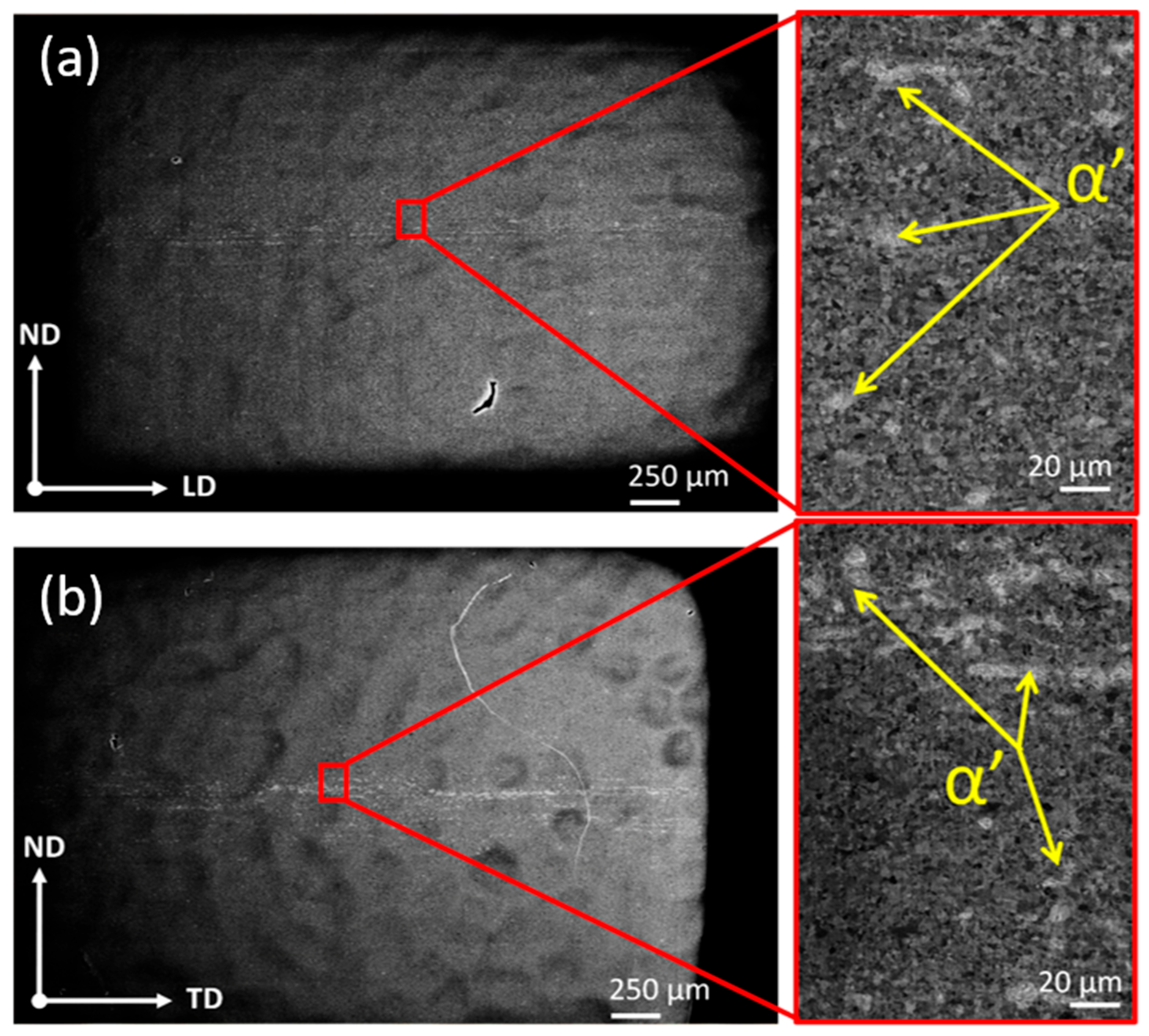

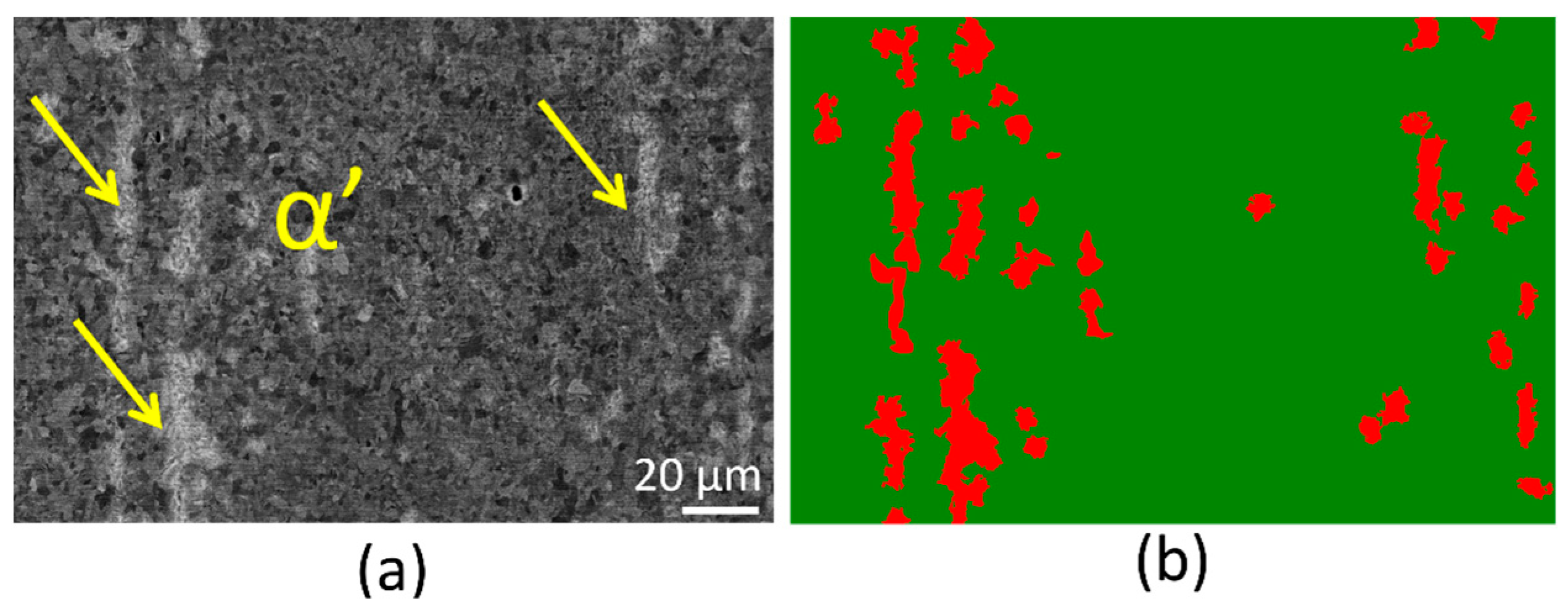

3.1. Visualization of Martensite Phase in SEM Micrographs

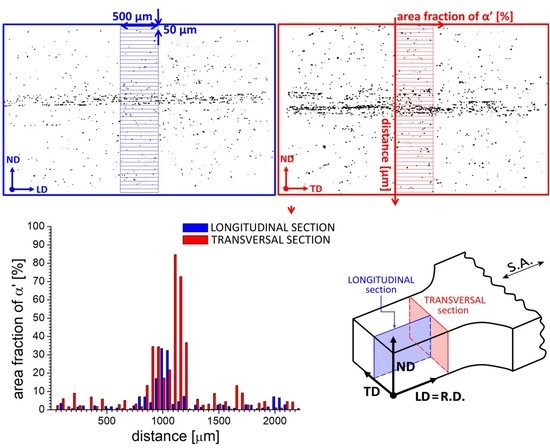

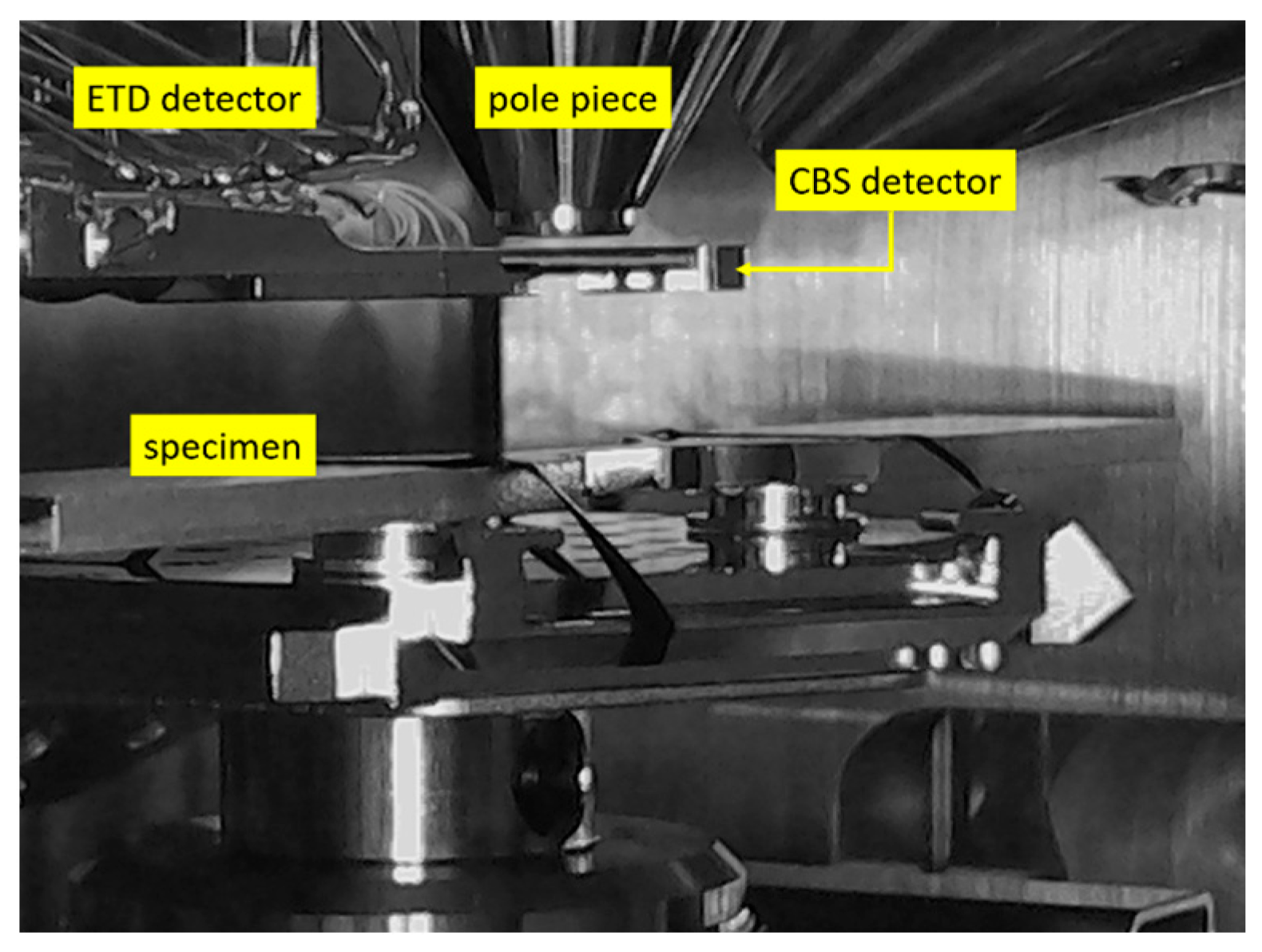

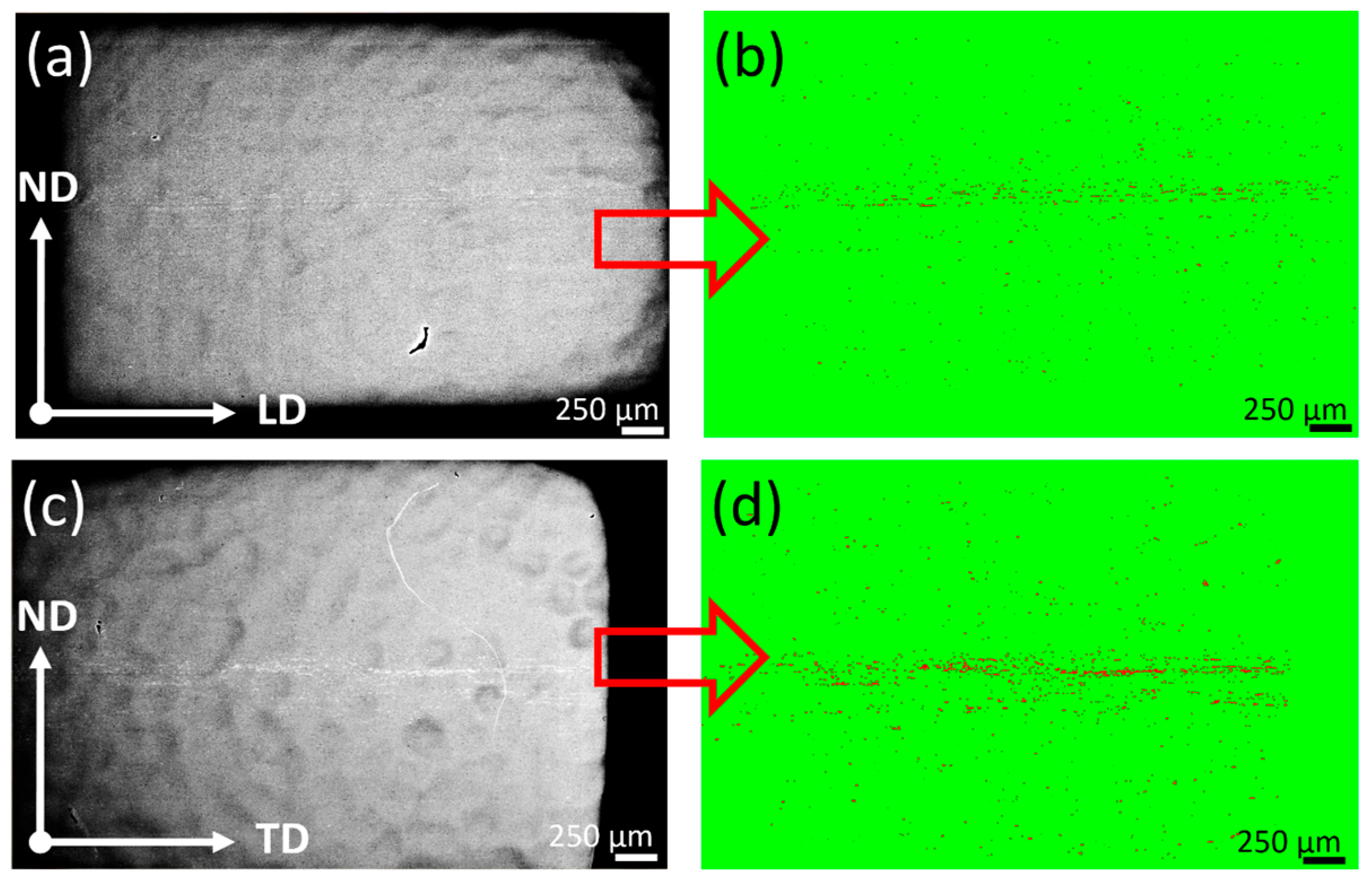

3.2. Large-Area Mapping: Automated Image Acquisition in the SEM

3.3. Deep Learning

4. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boniardi, M.; Casaroli, A. Stainless Steels; Lucefin S.p.A.: Esine, Italy, 2014. [Google Scholar]

- Lacombe, P.; Baroux, B.; Beranger, G. (Eds.) Stainless Steels; Les Editions de Physique: Les Ulis, France, 1993. [Google Scholar]

- McGuire, M.F. Stainless Steels for Design Engineers; ASM International: Materials Park, OH, USA, 2008. [Google Scholar]

- Lo, K.H.; Shek, C.H.; Lai, J.K.L. Recent developments in stainless steels. Mater. Sci. Eng. R Rep. 2009, 65, 39–104. [Google Scholar] [CrossRef]

- Biermann, H.; Aneziris, C.G. (Eds.) Austenitic TRIP/TWIP Steels and Steel-Zirconia Composites; Springer Series in Materials Science 298; Springer Nature: Cham, Switzerland, 2020. [Google Scholar]

- Hedström, P.; Odqvist, J. Deformation-induced martensitic transformation in metastable austenitic stainless steels–Introduction and current perspectives. In Stainless Steel: Microstructure, Mechanical Properties and Methods of Application; Pramanik, A., Basak, A.K., Eds.; Nova Science Publishers: New York, NY, USA, 2015; pp. 81–106. [Google Scholar]

- de Bellefon, G.M.; Van Duysen, J.C. Tailoring plasticity of austenitic stainless steels for nuclear applications: Review of mechanisms controlling plasticity of austenitic steels below 400 °C. J. Nucl. Mater. 2016, 475, 168–191. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Naghizadeh, M.; Mirzadeh, H. Deformation-induced martensite in austenitic stainless steels: A review. Arch. Civ. Mech. Eng. 2020, 20, 124. [Google Scholar] [CrossRef]

- Hahnenberger, F.; Smaga, M.; Eifler, D. Microstructural investigation of the fatigue behavior and phase transformation in metastable austenitic steels at ambient and lower temperatures. Int. J. Fatigue 2014, 69, 36–48. [Google Scholar] [CrossRef]

- Tian, Y.E.; Gorbatov, O.I.; Borgenstam, A.; Ruban, A.V.; Hedström, P. Deformation microstructure and deformation-induced martensite in austenitic Fe-Cr-Ni alloys depending on stacking fault energy. Metall. Mater. Trans. A 2017, 48, 1–7. [Google Scholar] [CrossRef]

- Rafaja, D.; Ullrich, C.; Motylenko, M.; Martin, S. Microstructure aspects of the deformation mechanisms in metastable austenitic steels. In Austenitic TRIP/TWIP Steels and Steel-Zirconia Composites: Design of Tough, Transformation-Strengthened Composites and Structures; Chapter 11; Biermann, H., Aneziris, C.G., Eds.; Springer Series in Materials Science 298; Springer Nature: Cham, Switzerland, 2020; pp. 325–377. [Google Scholar]

- Talonen, J.; Hänninen, H. Formation of shear bands and strain-induced martensite during plastic deformation of metastable austenitic stainless steels. Acta Mater. 2007, 55, 6108–6118. [Google Scholar] [CrossRef]

- Martin, S.; Fabrichnaya, O.; Rafaja, D. Prediction of the local deformation mechanisms in metastable austenitic steels from the local concentration of the main alloying elements. Mater. Lett. 2015, 159, 484–488. [Google Scholar] [CrossRef]

- Walter, M.; Mujica Roncery, L.; Weber, S.; Leich, L.; Theisen, W. XRD measurement of stacking fault energy of Cr–Ni austenitic steels: Influence of temperature and alloying elements. J. Mater. Sci. 2020, 55, 13424–13437. [Google Scholar] [CrossRef]

- Man, J.; Smaga, M.; Kuběna, I.; Eifler, D.; Polák, J. Effect of metallurgical variables on the austenite stability in fatigued AISI 304 type steels. Eng. Fract. Mech. 2017, 185, 139–159. [Google Scholar] [CrossRef]

- Weidner, A. Deformation Processes in TRIP/TWIP Steels: In-Situ Characterization Techniques; Springer Series in Materials Science 295; Springer Nature: Cham, Switzerland, 2020. [Google Scholar]

- Somani, M.C.; Juntunen, P.; Karjalainen, L.P.; Misra, R.D.K.; Kyröläinen, A. Enhanced mechanical properties through reversion in metastable austenitic stainless steels. Metall. Mater. Trans. A 2009, 40, 729–744. [Google Scholar] [CrossRef]

- Järvenpää, A.; Jaskari, M.; Kisko, A.; Karjalainen, P. Processing and properties of reversion-treated austenitic stainless steels. Metals 2020, 10, 281. [Google Scholar] [CrossRef]

- Tobler, R.L.; Nishimura, A.; Yamamoto, J. Design-relevant mechanical properties of 316-type steels for superconducting magnets. Cryogenics 1997, 37, 533–550. [Google Scholar] [CrossRef]

- Nishimura, A.; Ono, Y.; Umezawa, O.; Kumagai, S.; Kato, Y.; Kato, T.; Yuri, T.; Komatsu, M. Study on development policy for new cryogenic structural material for superconducting magnet of fusion reactor. Nucl. Mater. Energy 2022, 30, 101125. [Google Scholar] [CrossRef]

- De Backer, F.; Schoss, V.; Maussner, G. Investigations on the evaluation of the residual fatigue life-time in austenitic stainless steels. Nucl. Eng. Des. 2001, 206, 201–219. [Google Scholar] [CrossRef]

- Leber, H.J.; Niffenegger, M.; Tirbonod, B. Microstructural aspects of low cycle fatigued austenitic stainless tube and pipe steels. Mater. Charact. 2007, 58, 1006–1015. [Google Scholar] [CrossRef]

- Smaga, M.; Walther, F.; Eifler, D. Deformation-induced martensitic transformation in metastable austenitic steels. Mater. Sci. Eng. A 2008, 483–484, 394–397. [Google Scholar] [CrossRef]

- Mishakin, V.; Gonchar, A.; Kurashkin, K.; Kachanov, M. Prediction of fatigue life of metastable austenitic steel by a combination of acoustic and eddy current data. Int. J. Fatigue 2020, 141, 105846. [Google Scholar] [CrossRef]

- Acosta, R.; Heckmann, K.; Sievers, J.; Schopf, T.; Bill, T.; Starke, P.; Donnerbauer, K.; Lücker, L.; Walther, F.; Boller, C. Microstructure-based lifetime assessment of austenitic steel AISI 347 in view of fatigue, environmental conditions and NDT. Appl. Sci. 2021, 11, 11214. [Google Scholar] [CrossRef]

- Guo, X.; Post, J.; Groen, M.; Bleck, W. Stress oriented delayed cracking induced by dynamic martensitic transformation in meta-stable austenitic stainless steels. Steel Res. Int. 2011, 82, 6–13. [Google Scholar] [CrossRef]

- Papula, S.; Talonen, J.; Hänninen, H. Effect of residual stress and strain-induced α′-martensite on delayed cracking of metastable austenitic stainless steels. Metall. Mater. Trans. A 2014, 45, 1238–1246. [Google Scholar] [CrossRef]

- San Marchi, C.; Michler, T.; Nibur, K.A.; Somerday, B.P. On the physical differences between tensile testing of type 304 and 316 austenitic stainless steels with internal hydrogen and in external hydrogen. Int. J. Hydrog. Energy 2010, 35, 9736–9745. [Google Scholar] [CrossRef]

- Egels, G.; Roncery, L.M.; Fussik, R.; Theisen, W.; Weber, S. Impact of chemical inhomogeneities on local material properties and hydrogen environment embrittlement in AISI 304L steels. Int. J. Hydrog. Energy 2018, 43, 5206–5216. [Google Scholar] [CrossRef]

- Izawa, C.; Wagner, S.; Deutges, M.; Weber, S.; Pargeter, R.; Michler, T.; Uchida, H.H.; Gemma, R.; Pundt, A. Relationship between hydrogen embrittlement and Md30 temperature: Prediction of low-nickel austenitic stainless steel’s resistance. Int. J. Hydrog. Energy 2019, 44, 25064–25075. [Google Scholar] [CrossRef]

- Barrera, O.; Bombac, D.; Chen, Y.; Daff, T.D.; Galindo-Nava, E.; Gong, P.; Haley, D.; Horton, R.; Katzarov, I.; Kermode, J.R.; et al. Understanding and mitigating hydrogen embrittlement of steels: A review of experimental, modelling and design progress from atomistic to continuum. J. Mater. Sci. 2018, 53, 6251–6290. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Y.; Yang, H.; Tong, L.; Wang, L. Research progress of cryogenic materials for storage and transportation of liquid hydrogen. Metals 2021, 11, 1101. [Google Scholar] [CrossRef]

- de Abreu, H.F.G.; de Carvalho, S.S.; de Lima Neto, P.; dos Santos, R.P.; Freire, V.N.; de Oliveira Silva, P.M.; Tavares, S.S.M. Deformation induced martensite in an AISI 301LN stainless steel: Characterization and influence on pitting corrosion resistance. Mater. Res. 2007, 10, 359–366. [Google Scholar] [CrossRef]

- Lv, J.; Luo, H. Effects of strain and strain-induced α′-martensite on passive films in AISI 304 austenitic stainless steel. Mater. Sci. Eng. C 2014, 34, 484–490. [Google Scholar] [CrossRef]

- Solomon, N.; Solomon, I. Effect of deformation-induced phase transformation on AISI 316 stainless steel corrosion resistance. Eng. Fail. Anal. 2017, 79, 865–875. [Google Scholar] [CrossRef]

- Silva, P.M.; Filho, M.C.; Cruz, J.A.D.; Sales, A.J.; Sombra, A.S.; Tavares, J.M.R. Influence on pitting corrosion resistance of AISI 301LN and 316L stainless steels subjected to cold-induced deformation. Metals 2023, 13, 443. [Google Scholar] [CrossRef]

- Talonen, J.; Aspegren, P.; Hänninen, H. Comparison of different methods for measuring strain induced α′-martensite content in austenitic steels. Mater. Sci. Technol. 2004, 20, 1506–1512. [Google Scholar] [CrossRef]

- Haušild, P.; Davydov, V.; Drahokoupil, J.; Landa, M.; Pilvin, P. Characterization of strain-induced martensitic transformation in a metastable austenitic stainless steel. Mater. Des. 2010, 31, 1821–1827. [Google Scholar] [CrossRef]

- Celada-Casero, C.; Kooiker, H.; Groen, M.; Post, J.; San-Martin, D. In-situ investigation of strain-induced martensitic transformation kinetics in an austenitic stainless steel by inductive measurements. Metals 2017, 7, 271. [Google Scholar] [CrossRef]

- Carneiro, Í.; Simões, S. Recent advances in EBSD characterization of metals. Metals 2020, 10, 1097. [Google Scholar] [CrossRef]

- Man, J.; Järvenpää, A.; Jaskari, M.; Kuběna, I.; Fintová, S.; Chlupová, A.; Karjalainen, L.P.; Polák, J. Cyclic deformation behaviour and stability of grain-refined 301LN austenitic stainless structure. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 165, p. 06005. [Google Scholar]

- Järvenpää, A.; Jaskari, M.; Man, J.; Karjalainen, L.P. Austenite stability in reversion-treated structures of a 301LN steel under tensile loading. Mater. Charact. 2017, 127, 12–26. [Google Scholar] [CrossRef]

- Järvenpää, A.; Jaskari, M.; Man, J.; Karjalainen, L.P. Stability of grain-refined reversed structures in a 301LN austenitic stainless steel under cyclic loading. Mater. Sci. Eng. A 2017, 703, 280–292. [Google Scholar] [CrossRef]

- FEI Company. MagellanTM XHR SEM User Manual; FEI Company: Hillsboro, OR, USA, 2001. [Google Scholar]

- Šakić, A.; Nanver, L.K.; van Veen, G.; Kooijman, K.; Vogelsamg, P.; Scholtes, T.L.M.; de Boer, W.; Wien, W.H.A.; Milosavljevic, S.; Heerkens, C.T.H.; et al. Versatile silicon photodiode detector technology for scanning electron microscopy with high-efficiency sub-5keV electron detection. In Proceedings of the 2010 International Electron Devices Meeting, San Francisco, CA, USA, 6–8 December 2010; pp. 31.4.1–31.4.4. [Google Scholar] [CrossRef]

- FEI Company. FEI Maps 2.5 SW Application User Guide; FEI Company: Hillsboro, OR, USA, 2016. [Google Scholar]

- Mikmeková, Š.; Yamada, K.; Noro, H. Dual-phase steel structure visualized by extremely slow electrons. Microscopy 2015, 64, 437–443. [Google Scholar] [CrossRef]

- Sato, K.; Sueyoshi, H.; Yamada, K. Characterization of complex phase steel using backscattered electron images with controlled collection angles. Microscopy 2015, 64, 297–304. [Google Scholar] [CrossRef]

- Marshall, P. Austenitic Stainless Steels: Microstructure and Mechanical Properties; Elsevier Applied Science Publishers: London, UK; New York, NY, USA, 1984; p. 29. [Google Scholar]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional networks for biomedical image segmentation. In Proceedings of the 18th International Conference on Medical Image Computing and Computer-Assisted Intervention (MICCAI 2015), Munich, Germany, 5–9 October 2015; Part III 18. Springer International Publishing: Cham, Switzerland, 2015; pp. 234–241. [Google Scholar]

- Gu, J.; Wang, Z.; Kuen, J.; Ma, L.; Shahroudy, A.; Shuai, B.; Liu, T.; Wang, X.; Wang, L.; Wang, G.; et al. Recent advances in convolutional neural networks. Pattern Recognit. 2018, 77, 354–377. [Google Scholar] [CrossRef]

- Li, Z.; Liu, F.; Yang, W.; Peng, S.; Zhou, J. A survey of convolutional neural networks: Analysis, applications, and prospects. IEEE Trans. Neural Netw. Learn. Syst. 2022, 33, 6999–7019. [Google Scholar] [CrossRef]

- Long, J.; Shelhamer, E.; Darrell, T. Fully convolutional networks for semantic segmentation. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVRP 2015), Boston, MA, USA, 7–12 June 2015; pp. 3431–3440. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- Lin, T.-Y.; Dollár, P.; Girshick, R.; He, K.; Hariharan, B.; Belongie, S. Feature pyramid networks for object detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017; pp. 936–944. [Google Scholar]

- Chaurasia, A.; Culurciello, E. LinkNet: Exploiting encoder representations for efficient semantic segmentation. In Proceedings of the 2017 IEEE Visual Communications and Image Processing (VCIP), St. Petersburg, FL, USA, 10–13 December 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Zhao, H.; Shi, J.; Qi, X.; Wang, X.; Jia, J. Pyramid scene parsing network. In Proceedings of the 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 26 July 2017; pp. 6230–6239. [Google Scholar] [CrossRef]

- Russakovsky, O.; Deng, J.; Su, H.; Krause, J.; Satheesh, S.; Ma, S.; Huang, Z.; Karpathy, A.; Khosla, A.; Bernstain, M.; et al. ImageNet large scale visual recognition challenge. Int. J. Comput. Vis. 2015, 115, 211–252. [Google Scholar] [CrossRef]

- Paszke, A.; Gross, S.; Massa, F.; Lerer, A.; Bradbury, J.; Chanan, G.; Kileen, T.; Lin, Z.; Gimelshein, N.; Antiga, L.; et al. PyTorch: An imperative style, high-performance deep learning library. In Advances in Neural Information Processing Systems 32, Proceedings of the Annual Conference on Neural Information Processing Systems 2019, Vancouver, BC, Canada, 8–14 December 2019; NeurIPS 2019; Wallach, H.M., Larochelle, H., Beygelzimer, A., d’Alché-Buc, F., Fox, E.A., Garnett, R., Eds.; Neural Information Processing Systems Foundation, Inc.: La Jolla, CA, USA, 2019; pp. 8024–8035. [Google Scholar]

- Li, X.; Sun, X.; Meng, Y.; Liang, J.; Wu, F.; Li, J. Dice loss for data-imbalanced NLP tasks. In Proceedings of the 58th Annual Meeting of the Association for Computational Linguistics, Online, 5–10 July 2020; Jurafsky, D., Chai, J., Schluter, N., Tetreault, J., Eds.; The Association for Computational Linguistics: Stroudsburg, PA, USA, 2020; pp. 465–476. [Google Scholar]

- Wu, S.; Li, X.; Wang, X. IoU-aware single-stage object detector for accurate localization. Image Vis. Comput. 2020, 97, 103911. [Google Scholar] [CrossRef]

| Model | Best Validation Dice Loss | Best Validation IoU Score |

|---|---|---|

| U-net with ResNet encoder | 0.3639 | 0.5436 |

| FPN | 0.8619 | 0.1379 |

| Link Net | 0.3958 | 0.5258 |

| PSP Net | 0.5853 | 0.3471 |

| Section | Analyzed Area (mm2) | α′-Martensite Fraction |

|---|---|---|

| Longitudinal | 7.97 | 0.931% |

| Transversal | 7.97 | 1.298% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mikmeková, Š.; Man, J.; Ambrož, O.; Jozefovič, P.; Čermák, J.; Järvenpää, A.; Jaskari, M.; Materna, J.; Kruml, T. High-Resolution Characterization of Deformation Induced Martensite in Large Areas of Fatigued Austenitic Stainless Steel Using Deep Learning. Metals 2023, 13, 1039. https://doi.org/10.3390/met13061039

Mikmeková Š, Man J, Ambrož O, Jozefovič P, Čermák J, Järvenpää A, Jaskari M, Materna J, Kruml T. High-Resolution Characterization of Deformation Induced Martensite in Large Areas of Fatigued Austenitic Stainless Steel Using Deep Learning. Metals. 2023; 13(6):1039. https://doi.org/10.3390/met13061039

Chicago/Turabian StyleMikmeková, Šárka, Jiří Man, Ondřej Ambrož, Patrik Jozefovič, Jan Čermák, Antti Järvenpää, Matias Jaskari, Jiří Materna, and Tomáš Kruml. 2023. "High-Resolution Characterization of Deformation Induced Martensite in Large Areas of Fatigued Austenitic Stainless Steel Using Deep Learning" Metals 13, no. 6: 1039. https://doi.org/10.3390/met13061039

APA StyleMikmeková, Š., Man, J., Ambrož, O., Jozefovič, P., Čermák, J., Järvenpää, A., Jaskari, M., Materna, J., & Kruml, T. (2023). High-Resolution Characterization of Deformation Induced Martensite in Large Areas of Fatigued Austenitic Stainless Steel Using Deep Learning. Metals, 13(6), 1039. https://doi.org/10.3390/met13061039