Pressure Drop and Gas Flow in an Oxygen Blast Furnace Analyzed by a Combination of Experimentation and a Porous Model

Abstract

1. Introduction

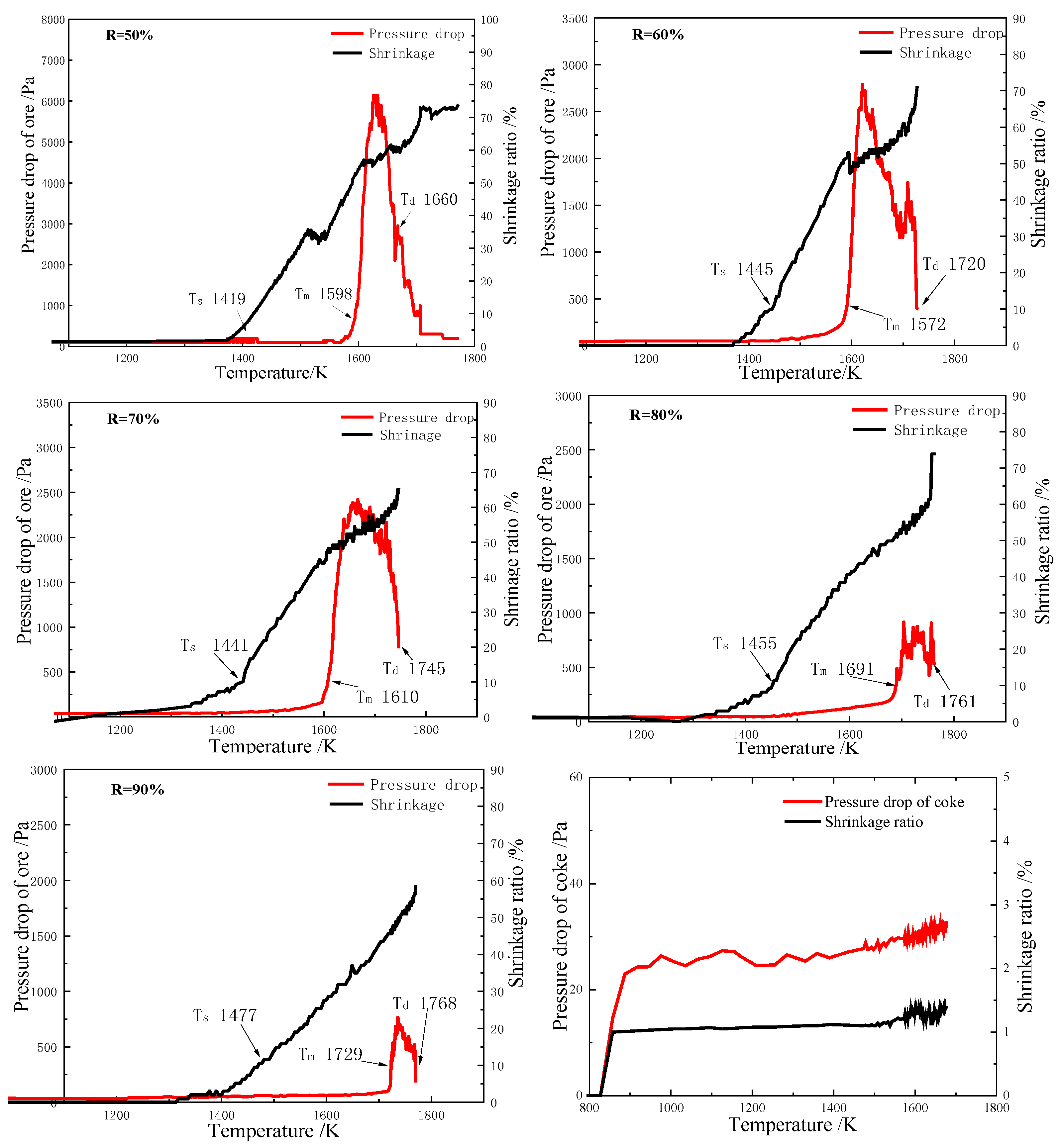

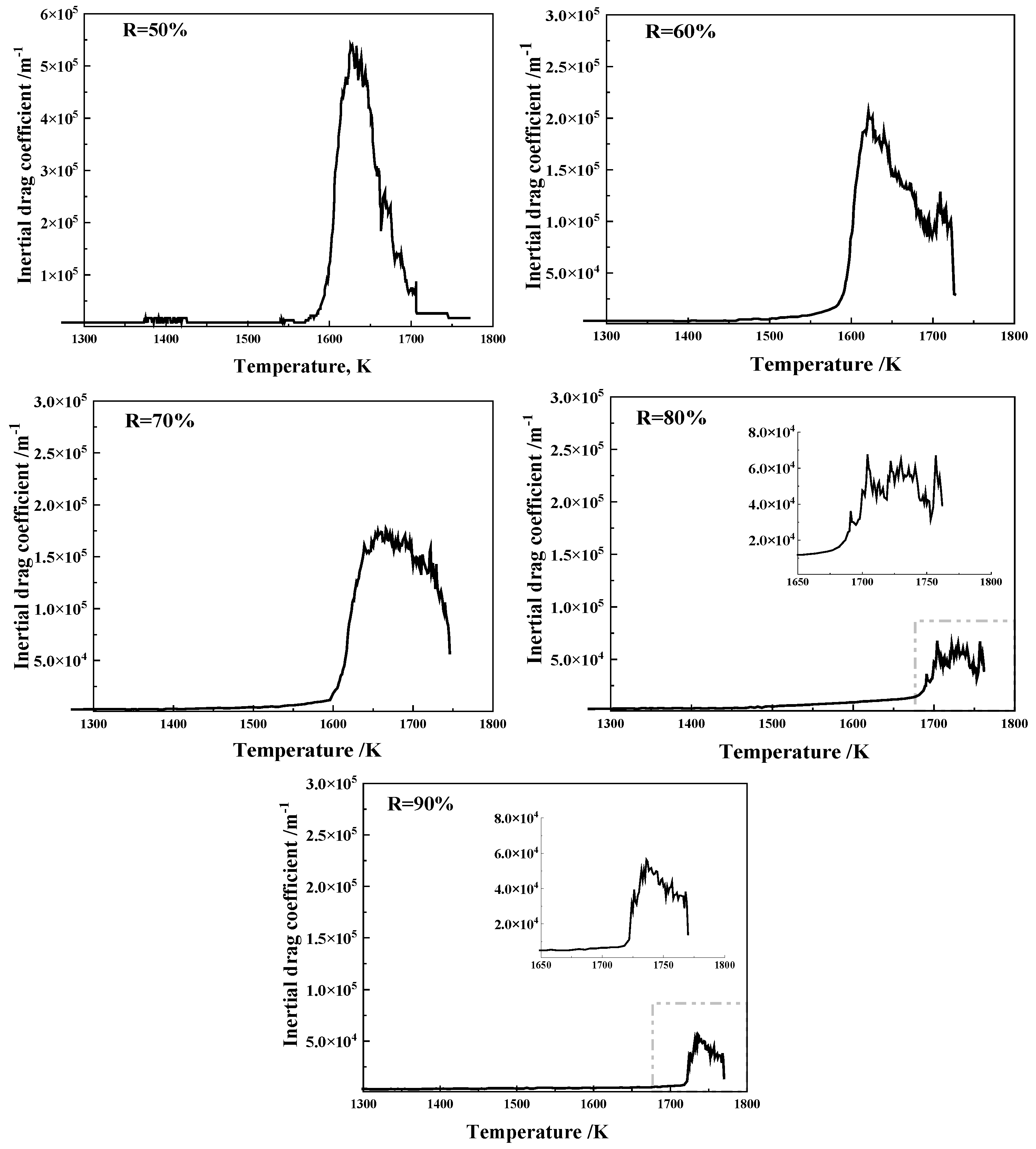

2. Deriving a Resistance Coefficient via Experiment

2.1. Softening and Melting Experiments

2.2. Deriving Resistance Coefficient

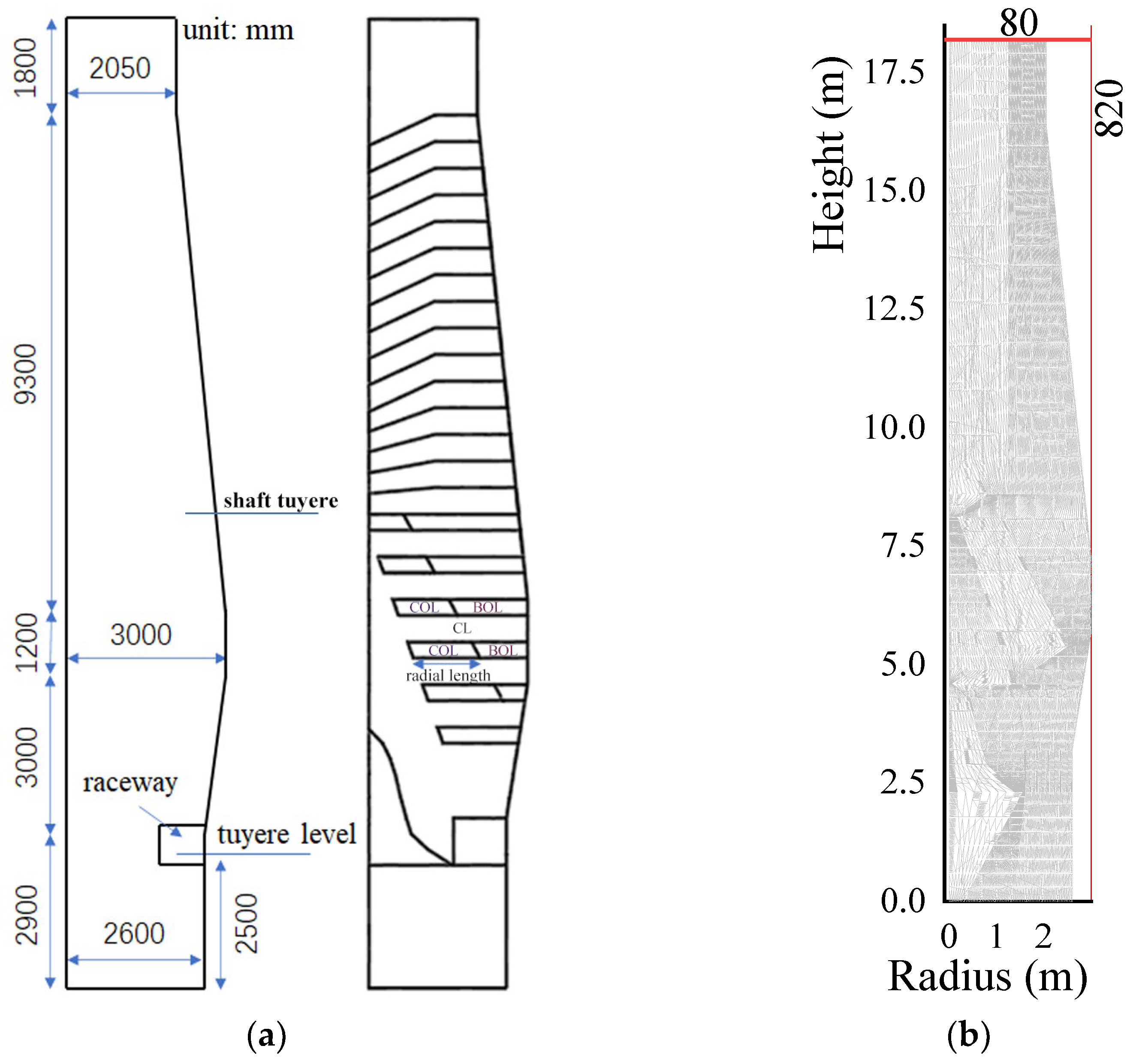

3. Model Description

4. Results and Discussion

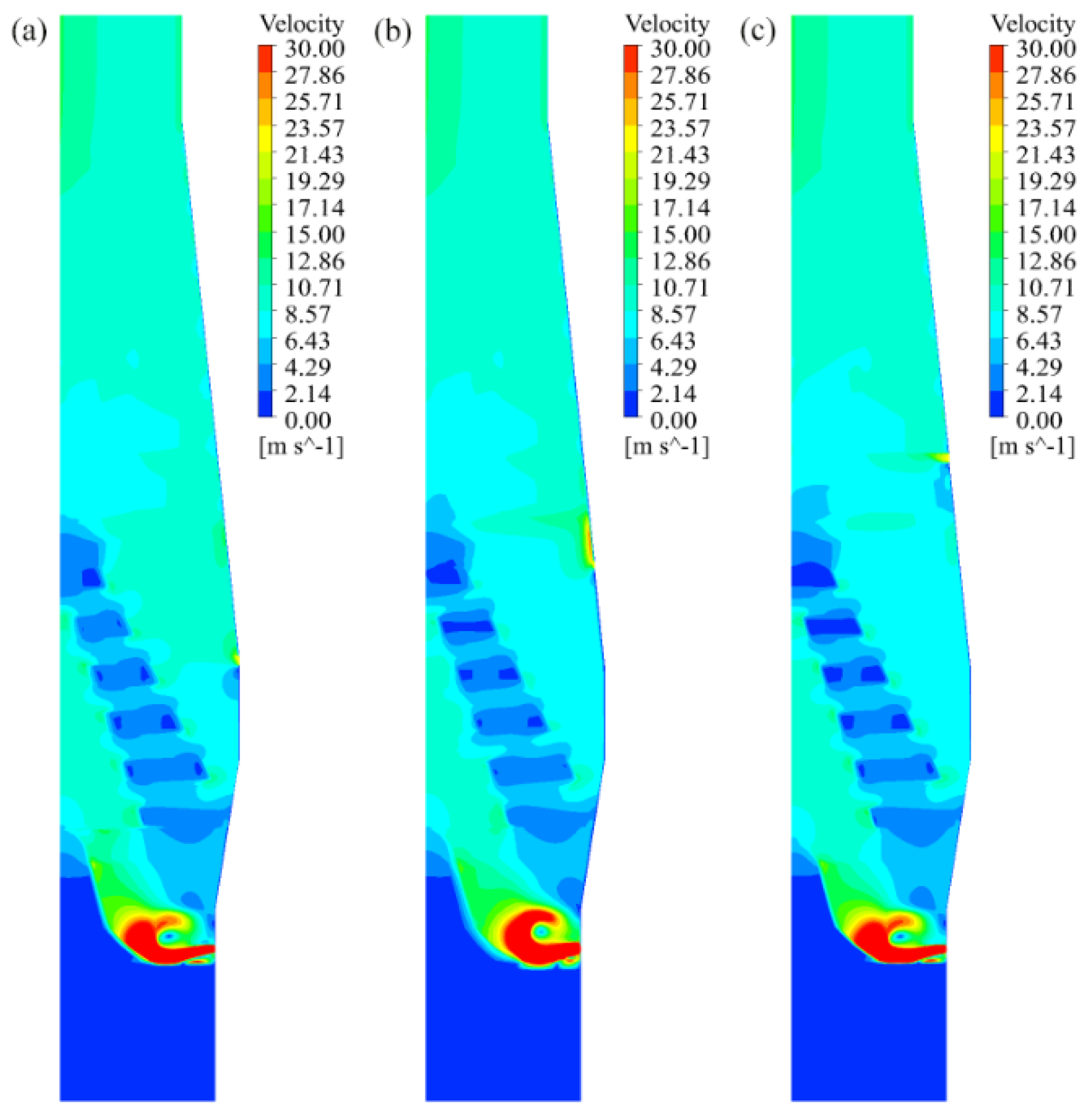

4.1. Conventional BF with Charged Central Coke

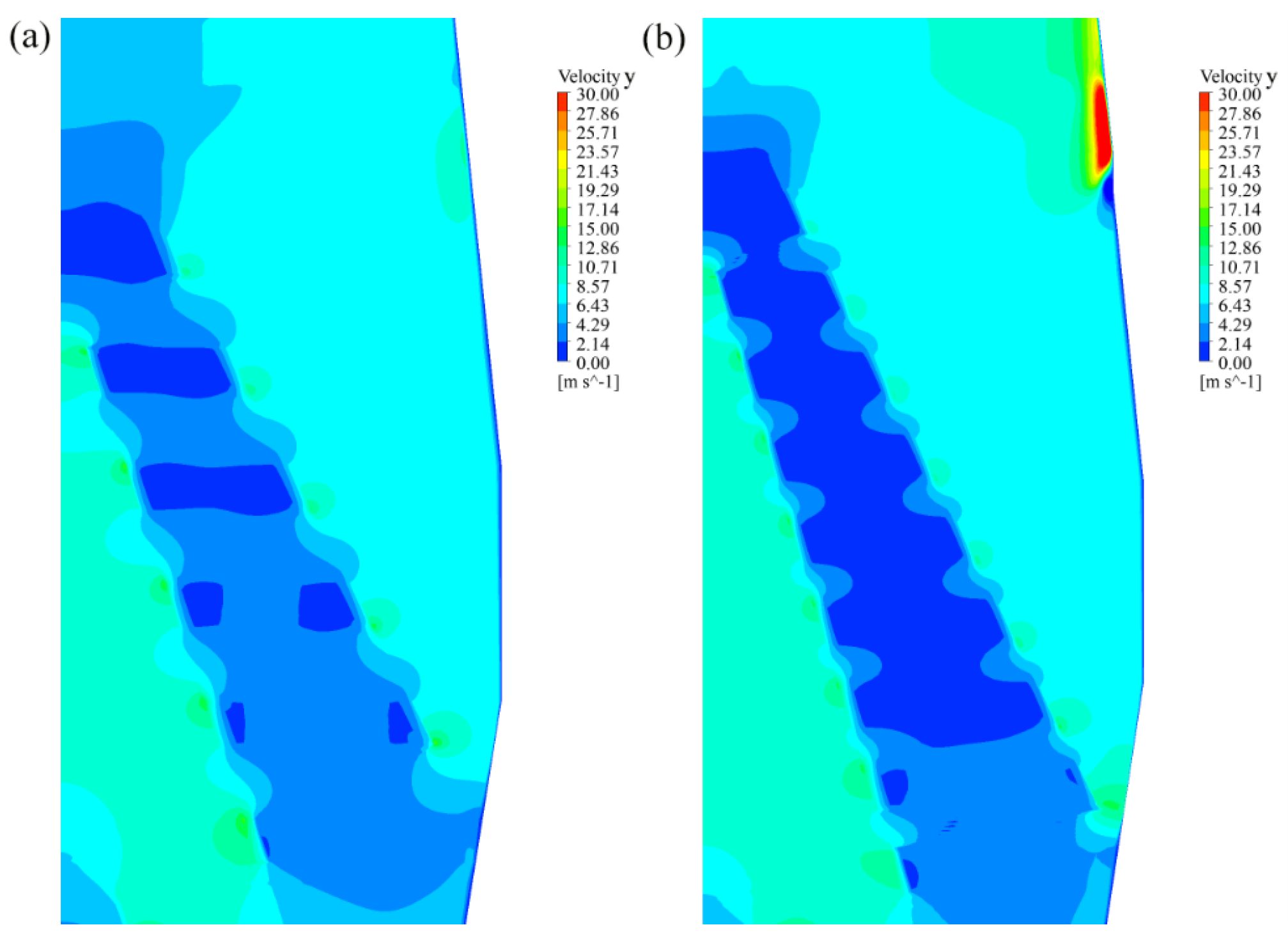

4.2. Influence of Different Stack Tuyere Heights

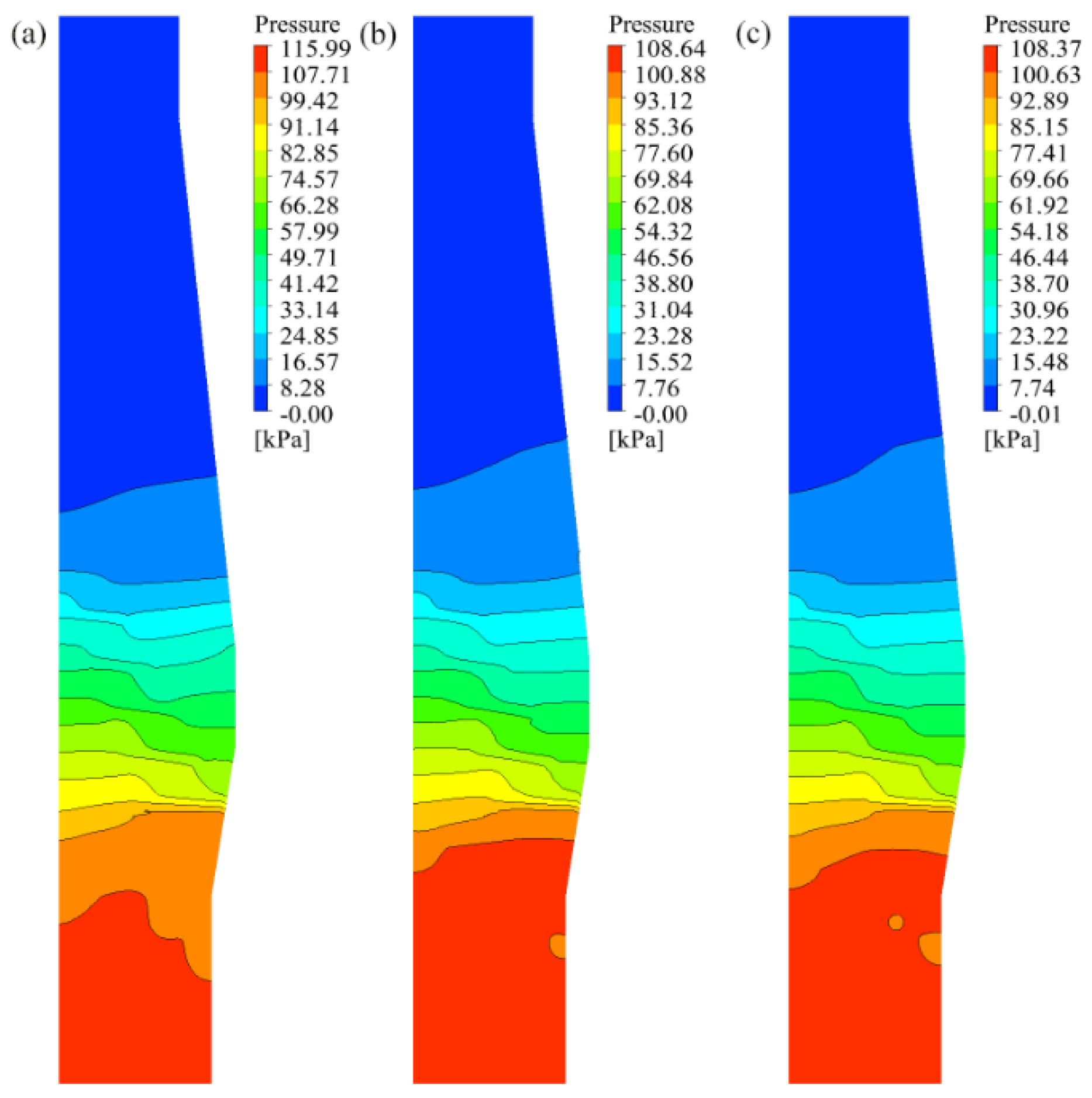

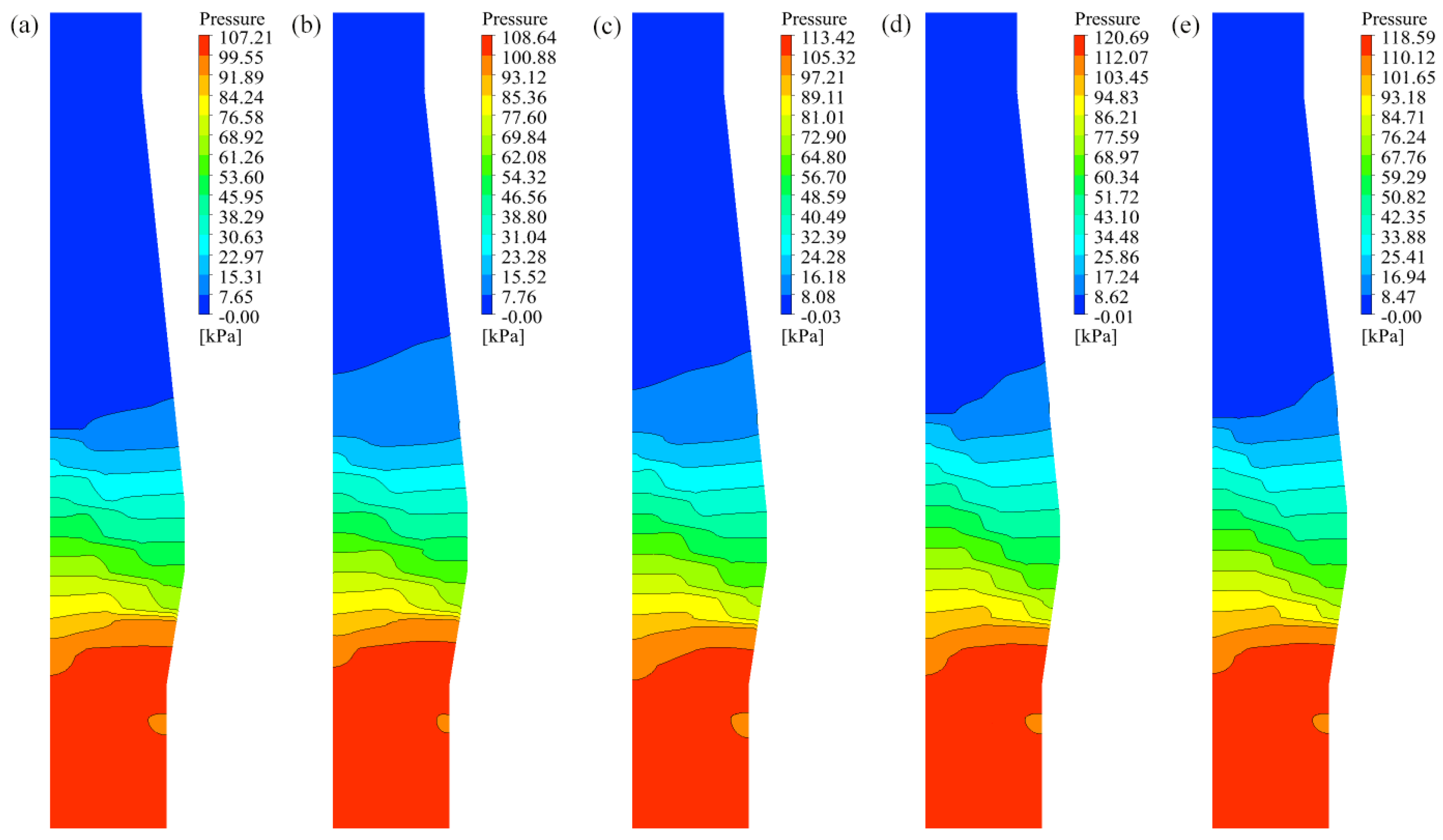

4.3. Pressure Drop and Gas Flow of Different Pre-Reduction Degrees

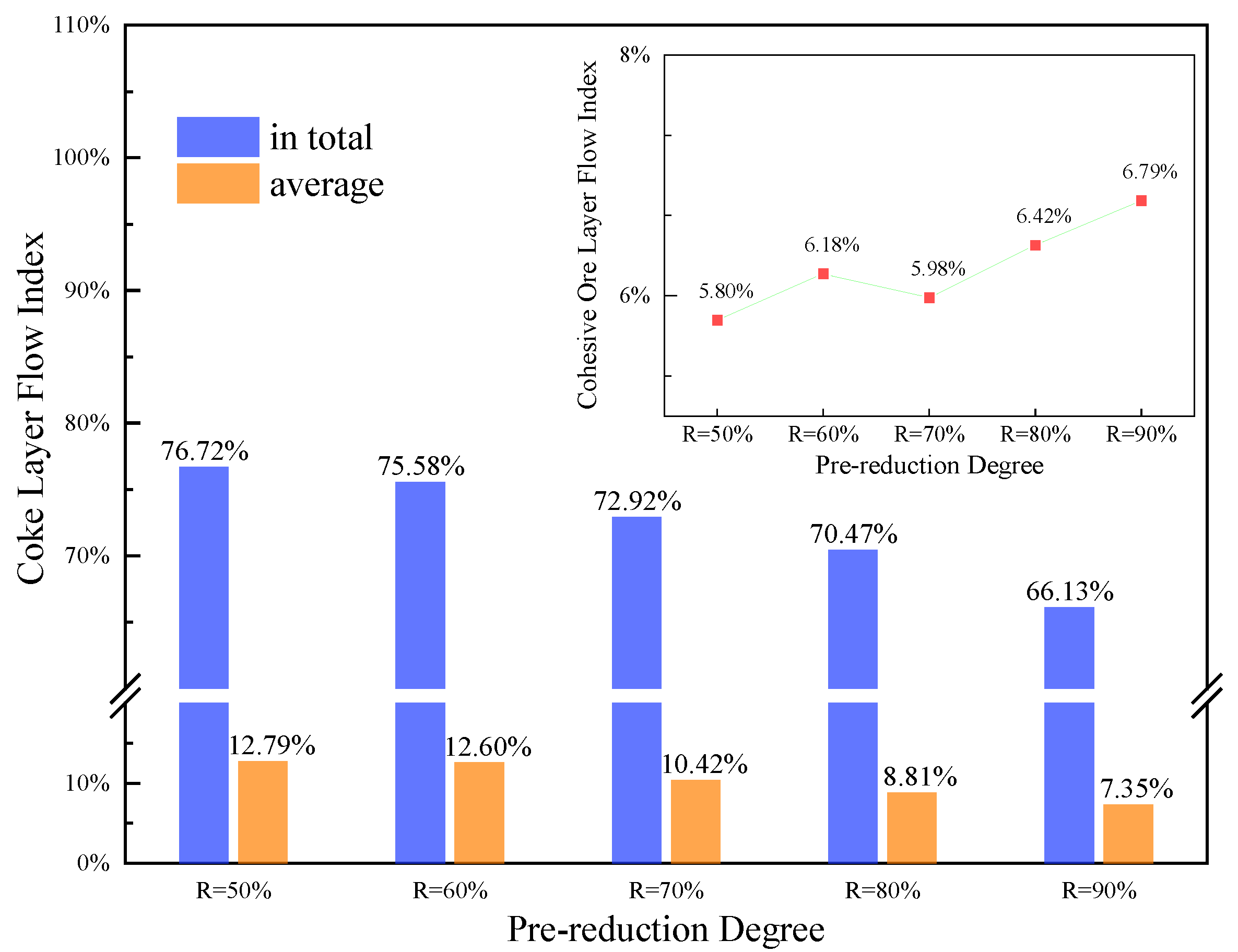

4.4. Index of Coke Layer Flow

5. Conclusions

- (1)

- The pressure drop of the whole furnace without central coke was consistent with industrial BFs of a similar size, which verified the effectiveness and reliability of the model. The high-speed whirling movement in the raceway and in two majority gas flows (central and border) at the outlet were observed. Under the condition of charging central coke, the central gas flow velocity increased significantly. The results also verified the effect of central coke in reducing the pressure difference of a BF.

- (2)

- With the increase in stack tuyere height, the pressure drop of the whole furnace decreased continuously. However, when the stack tuyere height was at the same elevation as the upper edge of the cohesive zone, a further increase in the stack tuyere height had little effect in reducing the in-furnace pressure drop.

- (3)

- The differential pressure of the whole furnace increased generally, although the resistance coefficient of the COL of the high indirect reduction degree was lower. This was because the number of burden layers in the cohesive zone increased, due to the thinning of the coke layer under the condition of 60° inclination. The ratio of the cohesive zone pressure drop to the total pressure drop of the whole furnace was between 75% and ~80%.

- (4)

- The gas flow index was used to quantitatively compare the gas distribution between the CL and the COL. With the increase in the reduction degree, the permeability of the ore layer increased and the proportion of the gas flow through the CL could be reduced by up to 10%. This proved that the cohesive zone could still ensure the in-furnace gas permeability under the condition of a low coke rate in the TGR-OBF.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kuang, S.B.; Li, Z.Y.; Yu, A.B. Review on Modeling and Simulation of Blast Furnace. Steel Res. Int. 2017, 89, 71–96. [Google Scholar] [CrossRef]

- Dong, X.F.; Pinson, D.; Zhang, S.J.; Yu, A.B.; Zulli, P. Gas-powder flow in blast furnace with different shapes of cohesive zone. Appl. Math. Model. 2006, 30, 1293–1309. [Google Scholar] [CrossRef]

- Fu, D.; Chen, Y.; Zhou, C.Q. Mathematical modeling of blast furnace burden distribution with non-uniform descending speed. Appl. Math. Model. 2015, 39, 7554–7567. [Google Scholar] [CrossRef]

- Shen, Y.S.; Guo, B.Y.; Chew, S.; Austin, P.; Yu, A.B. Three-Dimensional Modeling of Flow and Thermochemical Behavior in a Blast Furnace. Metall. Mater. Trans. B 2014, 46, 432–448. [Google Scholar] [CrossRef]

- Li, C.; Pan, Y.Z.; Xu, Z.; Xue, Q.G.; Zuo, H.B.; She, X.F.; Wang, G.; Wang, J.S. Pressure Drop and Gas Flow of Cohesive Zone in Oxygen Blast Furnace Using a Combination of Experimentation and Porous Model. ISIJ Int. 2022, 62, 91–98. [Google Scholar] [CrossRef]

- Rasul, M.G.; Tanty, B.S.; Mohanty, B. Modelling and analysis of blast furnace performance for efficient utilization of energy. Appl. Therm. Eng. 2007, 27, 78–88. [Google Scholar] [CrossRef]

- Liu, L.Z.; Jiang, Z.Y.; Zhang, X.R.; Lu, Y.X.; He, J.K.; Wang, J.S.; Zhang, X.X. Effects of top gas recycling on in-furnace status, productivity, and energy consumption of oxygen blast furnace. Energy 2018, 163, 144–150. [Google Scholar] [CrossRef]

- Zuo, X.J.; Wang, J.S.; An, X.W.; She, X.F.; Xue, Q.G. Reduction behaviors of pellets under different reducing potential. J. Iron Steel Res. Int. 2013, 20, 12–18. [Google Scholar] [CrossRef]

- Mitra, S.; Liu, X.; Honeyands, T.; Evans, G.; O’Dea, D.; Zulli, P. Pressure-drop Modelling in the Softening and Melting Test for Ferrous Burden. ISIJ Int. 2020, 60, 1416–1426. [Google Scholar] [CrossRef]

- Baniasadi, M.; Peters, B.; Pierret, J.C.; Vanderheyden, B.; Ansseau, O. Experimental and numerical investigation into the softening Behavior of a packed bed of iron ore pellets. Powder Technol. 2018, 339, 863–871. [Google Scholar] [CrossRef]

- Fojtik, D.; Tuma, J.; Faruzel, P. Computer modelling of burden distribution in the blast furnace equipped by a bell-less top charging system. Ironmak. Steelmak. 2021, 48, 1226–1238. [Google Scholar] [CrossRef]

- Narita, K.; Inaba, S.; Shimizu, M.; Yamaguchi, A.; Kobayashi, I.; Okimoto, K. Burden and gas distribution considering blast furnace aerodynamics. Trans. ISIJ 1981, 21, 405–413. [Google Scholar] [CrossRef]

- Zhou, C.L.; Li, Y.Z. Research on charging patch and cohesive zone width. Ironmak. Steelmak. 1989, 2, 19–23. [Google Scholar]

- Kurita, K.; Murai, T. Estiamation of the inner states by the use of the burden distribution model based on the profile meter measurements at blast furnce. Tetsu-to-Hagane 1987, 73, 2052–2059. [Google Scholar] [CrossRef] [PubMed]

- Nomura, S. A Simple Treatment on the Geometry of Raceway Zone. Trans. ISIJ 1986, 26, 107–113. [Google Scholar] [CrossRef]

- Kohichi, I.; Kuwabara, M.; Muchi, I. Simulation of solid particle movement in the lower part of blast furnace. Tetsu-to-Hagane 1981, 67, 53. [Google Scholar] [CrossRef]

- Li, J.; Kuang, S.; Zou, R.; Yu, A. Numerical Investigation of Burden Distribution in Hydrogen Blast Furnace. Metall. Mater. Trans. B 2022, 53, 4124–4137. [Google Scholar] [CrossRef]

| Pre-Reduction Degree 1 | R = 50% | R = 60% | R = 70% | R = 80% | R = 90% |

|---|---|---|---|---|---|

| Coke rate (kg/tHM 2) | 480 | 450 | 400 | 330 | 250 |

| Coal rate (kg/tHM) | 120 | 145 | 160 | 180 | 220 |

| Direct reduction degree | 0.5 | 0.4 | 0.3 | 0.2 | 0.1 |

| Utilization coefficient (t/m3·d) | 3 | 3.5 | 3.8 | 4 | 4.2 |

| Air blast volume (m3/tHM) | 1199.62 | 792.39 | 616.30 | 408.38 | 305.40 |

| Blast temperature 3 (K) | 1373 | 973 | 0 | 0 | 0 |

| Oxygen volume fraction | 26.41% | 40% | 50% | 70% | 90% |

| Hearth recycled gas (m3/tHM) | - | 270.00 | 300.00 | 450.00 | 450.00 |

| Representative process | TBF | TGR-OBF | TGR-OBF | TGR-OBF | TGR-OBF |

| - | R = 50% | R = 60% | R = 70% | R = 80% | R = 90% |

|---|---|---|---|---|---|

| 1.02 × 105 | 6.59 × 104 | 6.29 × 104 | 1.77 × 104 | 1.07 × 104 |

| - | Coke | Bulk Burden |

|---|---|---|

| 2.19 × 103 | 3.62 × 103 |

| Ore Batch (t) | Coke Batch (t) | Bulk Ore Layer Thickness (m) | Coke Layer Thickness (m) | Coke Rate (kg/tHM) |

|---|---|---|---|---|

| 15 | 3.5 | 0.5 | 0.5 | 480 |

| Pre-Reduction Degree | Coke Rate kg/tHM | Coke Layer Thickness m | N | Stack Tuyere Height | Cohesive Zone Inclination | Hearth Tuyere Diameter m | Shaft Tuyere Diameter m |

|---|---|---|---|---|---|---|---|

| 50% | 480 | 0.50 | 6 | - | 60° | 0.12 | - |

| 60% | 450 | 0.50 | 6 | from upper edge of stack: 0.0 m | 60° | 0.1 | 0.16 |

| from upper edge of stack: 1.8 m | |||||||

| from upper edge of stack: 3.6 m | |||||||

| 70% | 400 | 0.42 | 7 | upper edge of COL | 60° | 0.1 | 0.23 |

| 80% | 330 | 0.35 | 8 | upper edge of COL | 60° | 0.1 | 0.23 |

| 90% | 250 | 0.26 | 9 | upper edge of COL | 60° | 0.1 | 0.25 |

| Case | R = 50% | R = 60% | R = 70% | R = 80% | R = 90% |

|---|---|---|---|---|---|

| Tuyere gas inlet velocity (m/s) | 180 | 180 | 180 | 180 | 180 |

| Stack gas inlet velocity (m/s) | - | 23 | 23 | 23 | 23 |

| Tuyere gas composition (Mole fraction) | N2: 0.719, O2: 0.264, H2O: 0.017 | N2: 0.546, O2: 0.295, CO: 0.115 H2: 0.013 H2O: 0.017 CO2: 0.015 | N2: 0.453, O2: 0.331, CO: 0.162 H2: 0.021 H2O: 0.010 CO2: 0.020 | N2: 0.276, O2: 0.324, CO: 0.315 H2: 0.046 H2O: 0.008 CO2: 0.030 | N2: 0.123, O2: 0.348, CO: 0.411 H2: 0.076 H2O: 0.007 CO2: 0.034 |

| Stack gas composition (Mole fraction) | - | N2: 0.446, CO: 0.452 H2: 0.052 H2O: 0.006 CO2: 0.045 | N2: 0.390, CO: 0.495 H2: 0.064 H2O: 0.006 CO2: 0.045 | N2: 0.262, CO: 0.601 H2: 0.088 H2O: 0.006 CO2: 0.045 | N2: 0.132, CO: 0.690 H2: 0.128 H2O: 0.006 CO2: 0.045 |

| Gas outlet | Pressure-outlet | Pressure-outlet | Pressure-outlet | Pressure-outlet | Pressure-outlet |

| Pressure Drop of Whole Furnace (kPa) | Pressure Drop of Cohesive Zone (kPa) | Proportion | |

|---|---|---|---|

| R = 50% | 107.21 | 83.60 | 77.98% |

| R = 60% | 108.64 | 81.24 | 74.78% |

| R = 70% | 113.42 | 86.49 | 76.26% |

| R = 80% | 120.69 | 94.83 | 78.57% |

| R = 90% | 118.59 | 92.18 | 77.73% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Xue, Q.; Zuo, H.; Wang, J.; Wang, G. Pressure Drop and Gas Flow in an Oxygen Blast Furnace Analyzed by a Combination of Experimentation and a Porous Model. Metals 2023, 13, 455. https://doi.org/10.3390/met13030455

Li C, Xue Q, Zuo H, Wang J, Wang G. Pressure Drop and Gas Flow in an Oxygen Blast Furnace Analyzed by a Combination of Experimentation and a Porous Model. Metals. 2023; 13(3):455. https://doi.org/10.3390/met13030455

Chicago/Turabian StyleLi, Cong, Qingguo Xue, Haibin Zuo, Jingsong Wang, and Guang Wang. 2023. "Pressure Drop and Gas Flow in an Oxygen Blast Furnace Analyzed by a Combination of Experimentation and a Porous Model" Metals 13, no. 3: 455. https://doi.org/10.3390/met13030455

APA StyleLi, C., Xue, Q., Zuo, H., Wang, J., & Wang, G. (2023). Pressure Drop and Gas Flow in an Oxygen Blast Furnace Analyzed by a Combination of Experimentation and a Porous Model. Metals, 13(3), 455. https://doi.org/10.3390/met13030455