Conceptual Analysis on Severe Plastic Deformation Processes of Shape Memory Alloys: Mechanical Properties and Microstructure Characterization

Abstract

1. Introduction

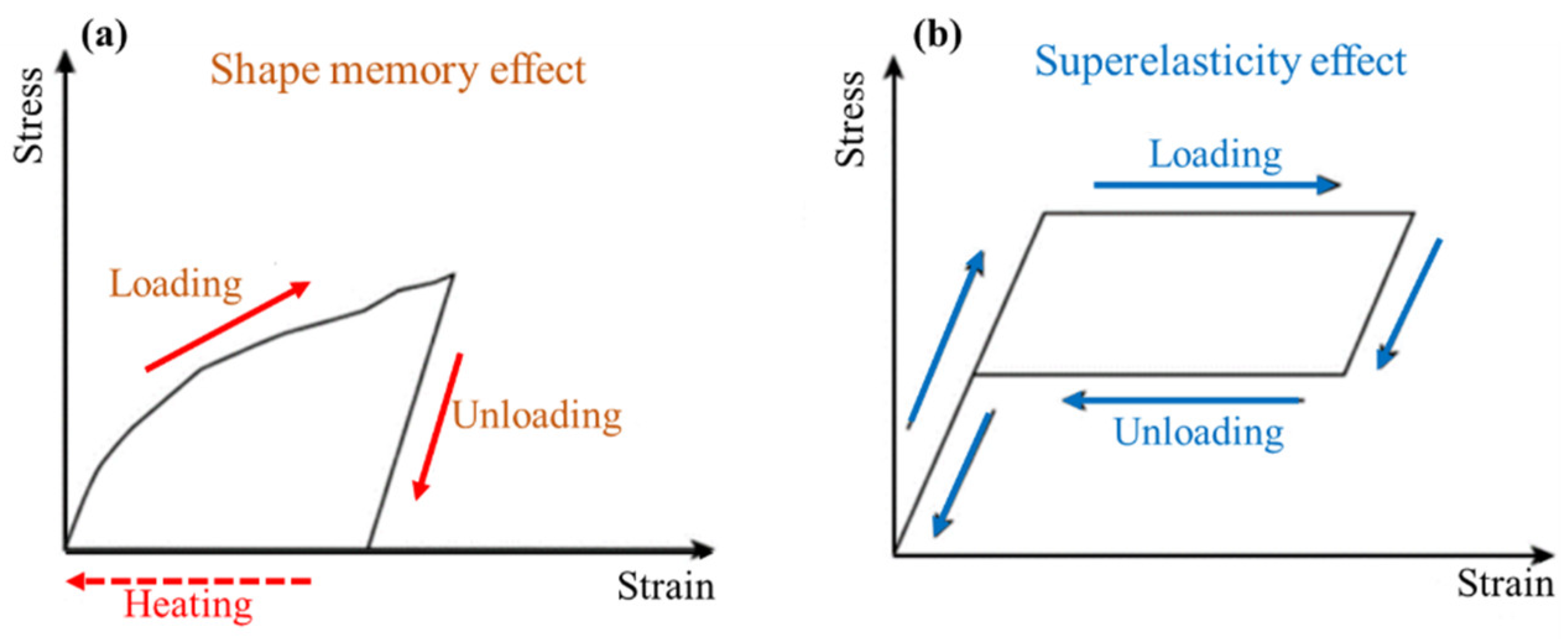

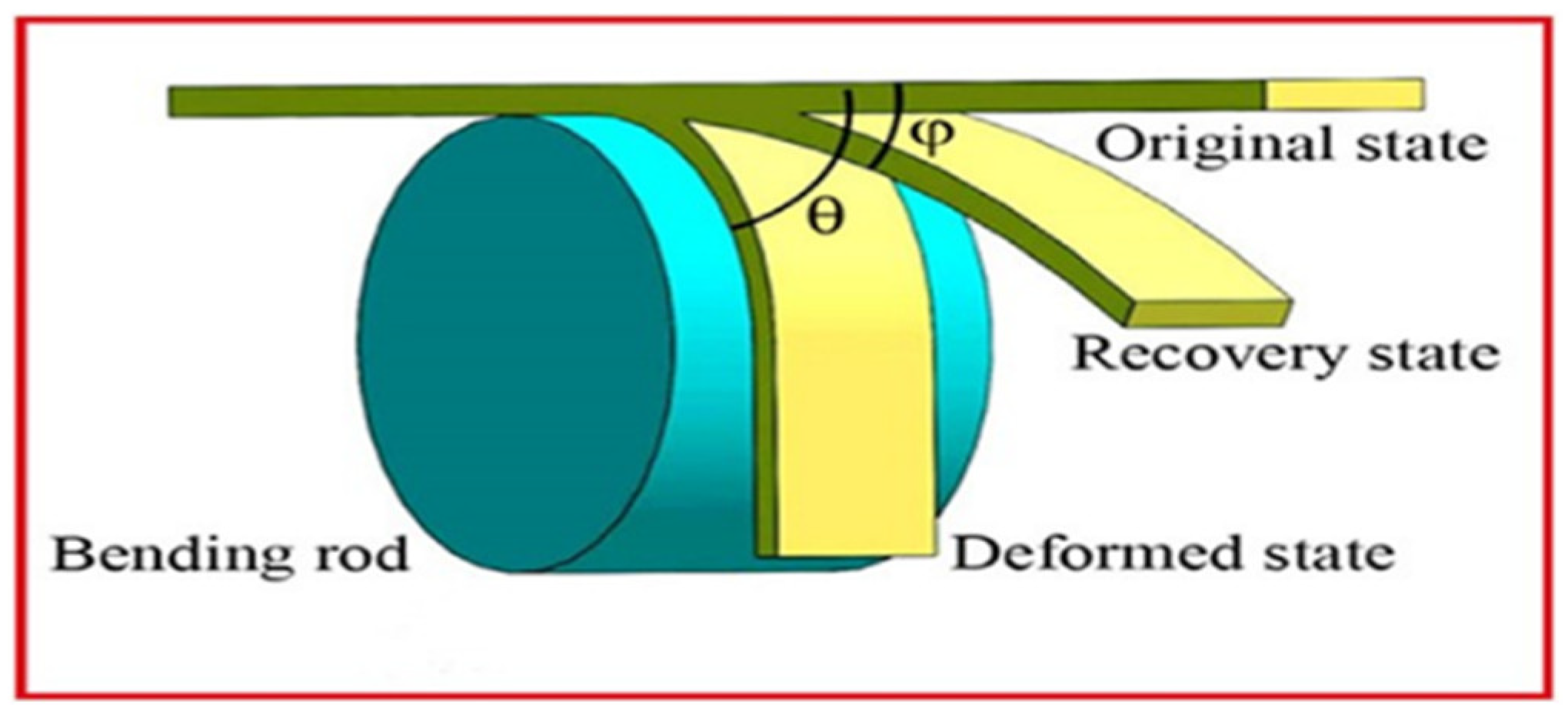

2. Influence of SPD Processing on the Shape Memory Effect

3. Effect of Different SPD Techniques on the Behavior of SMAs

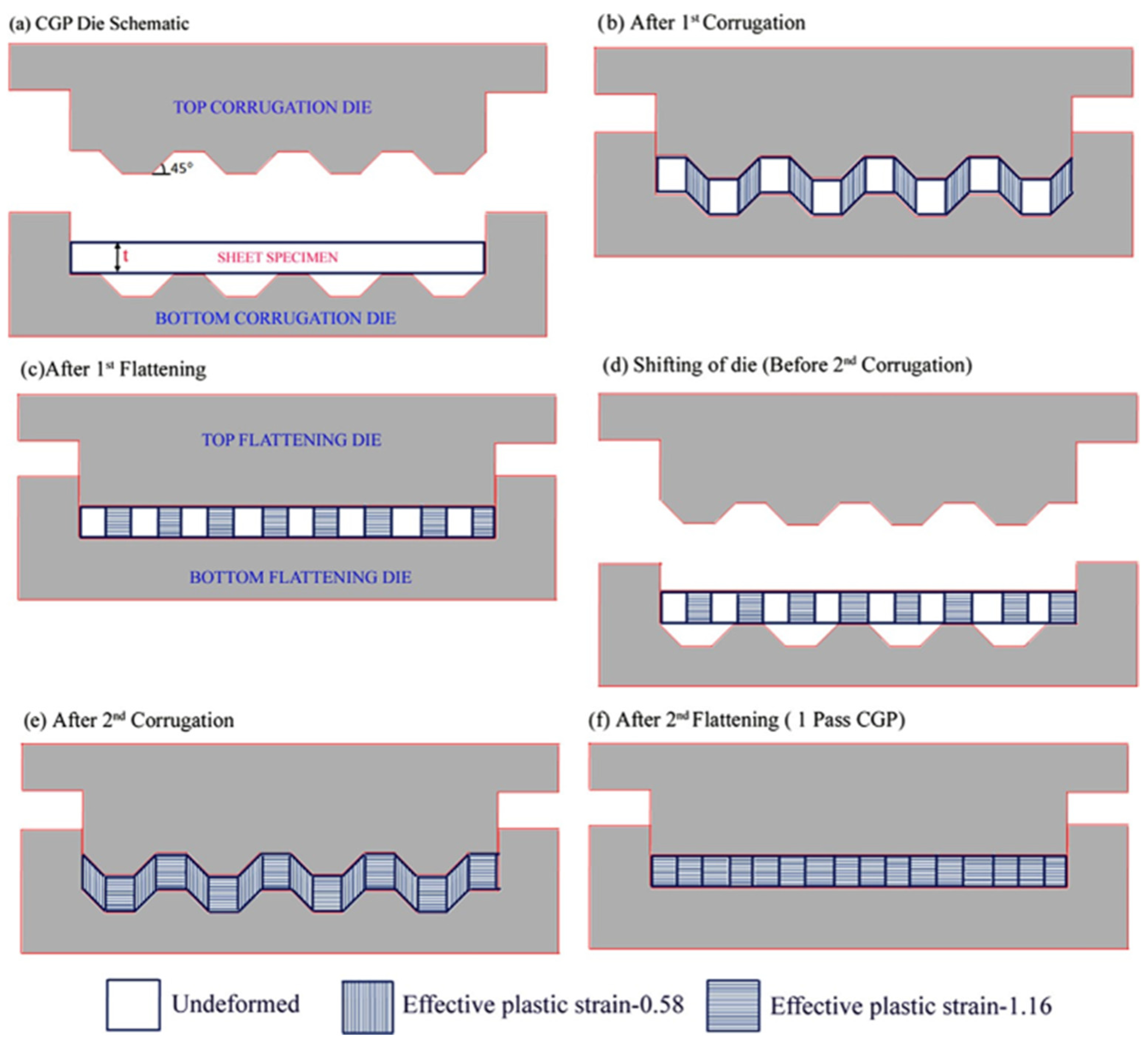

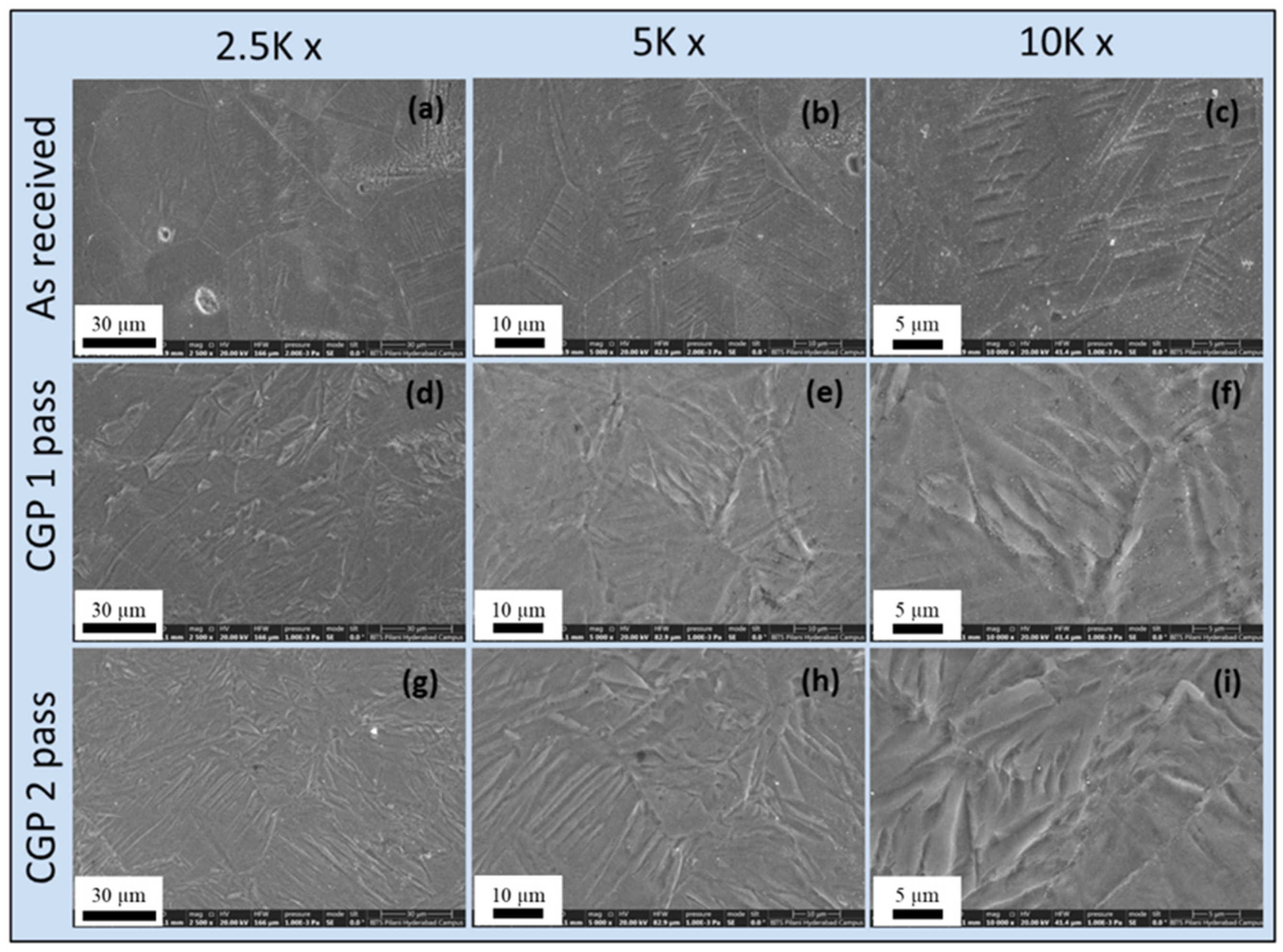

3.1. Constrained Groove Pressing (CGP)

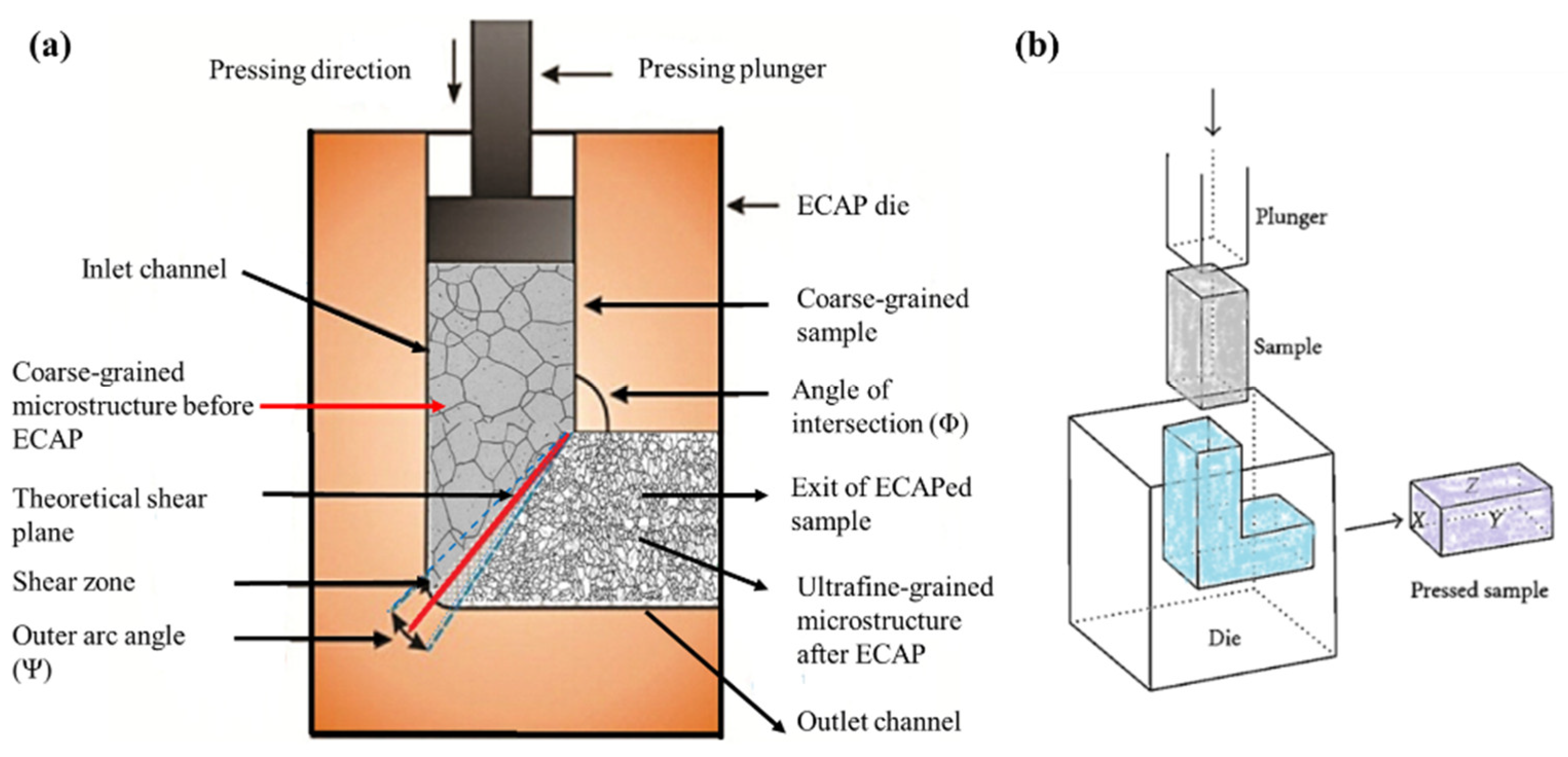

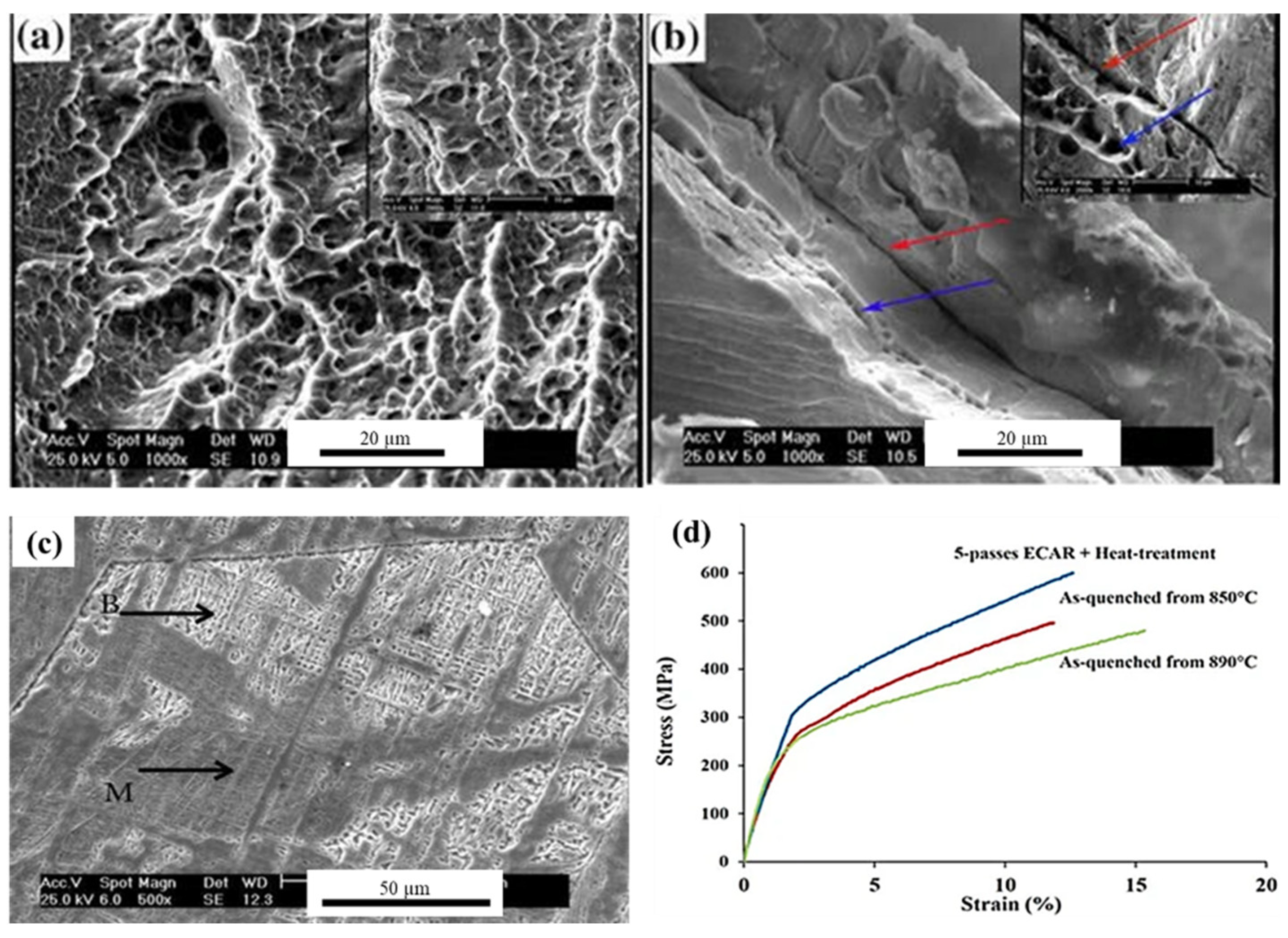

3.2. Equal-Channel Angular Pressing/Extrusion (ECAP/E)

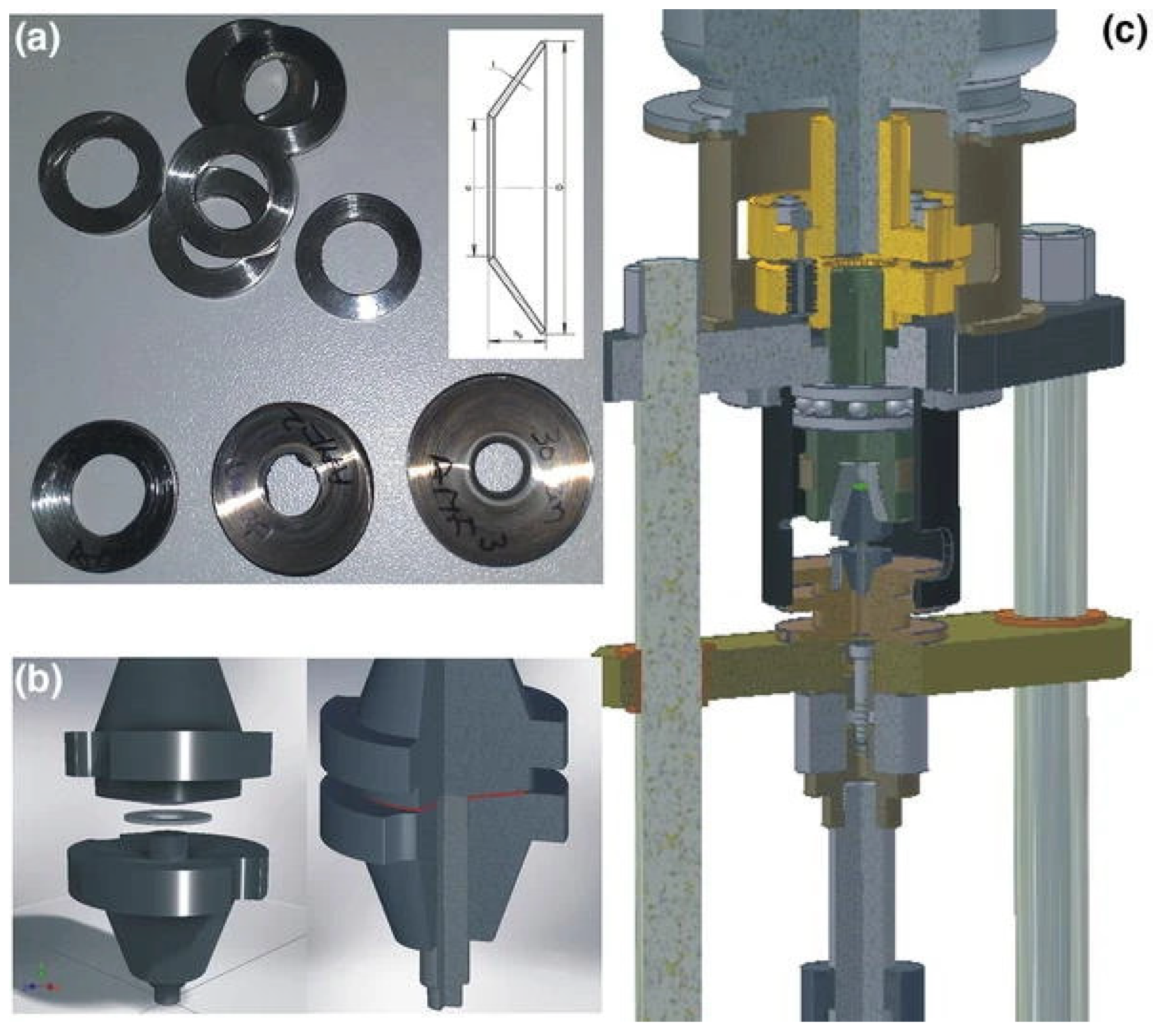

3.3. High-Speed High-Pressure Torsion (HSHPT)

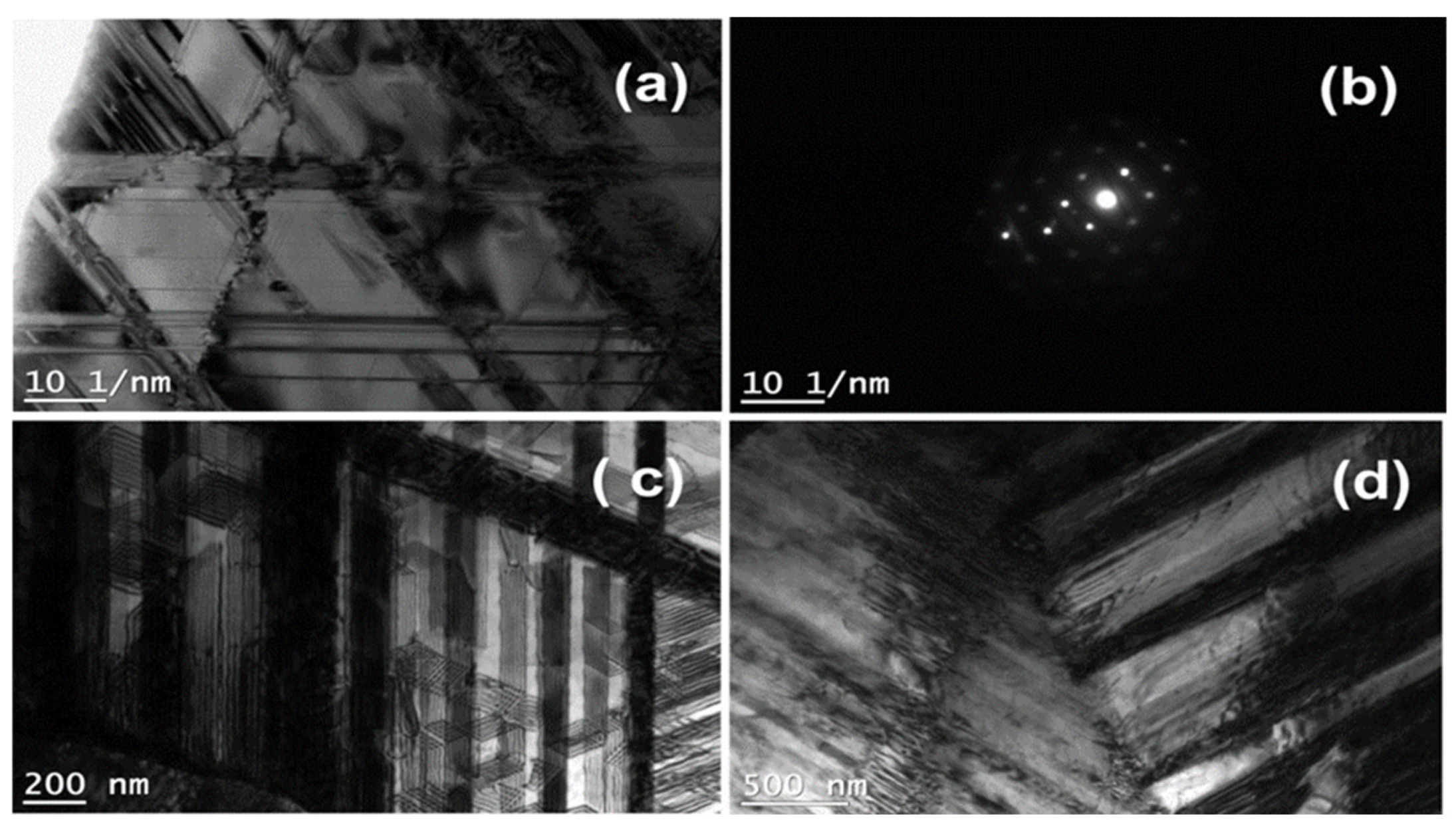

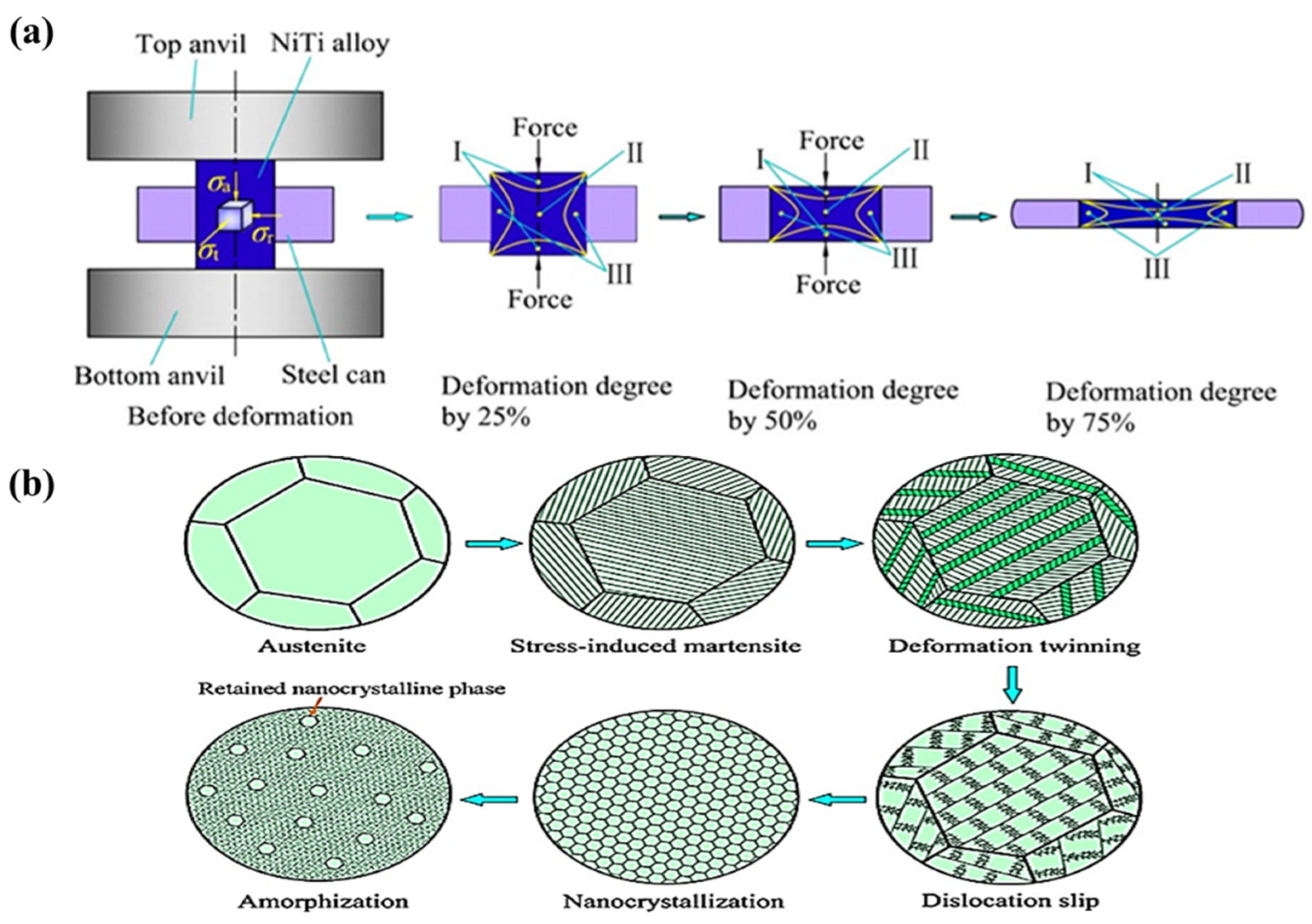

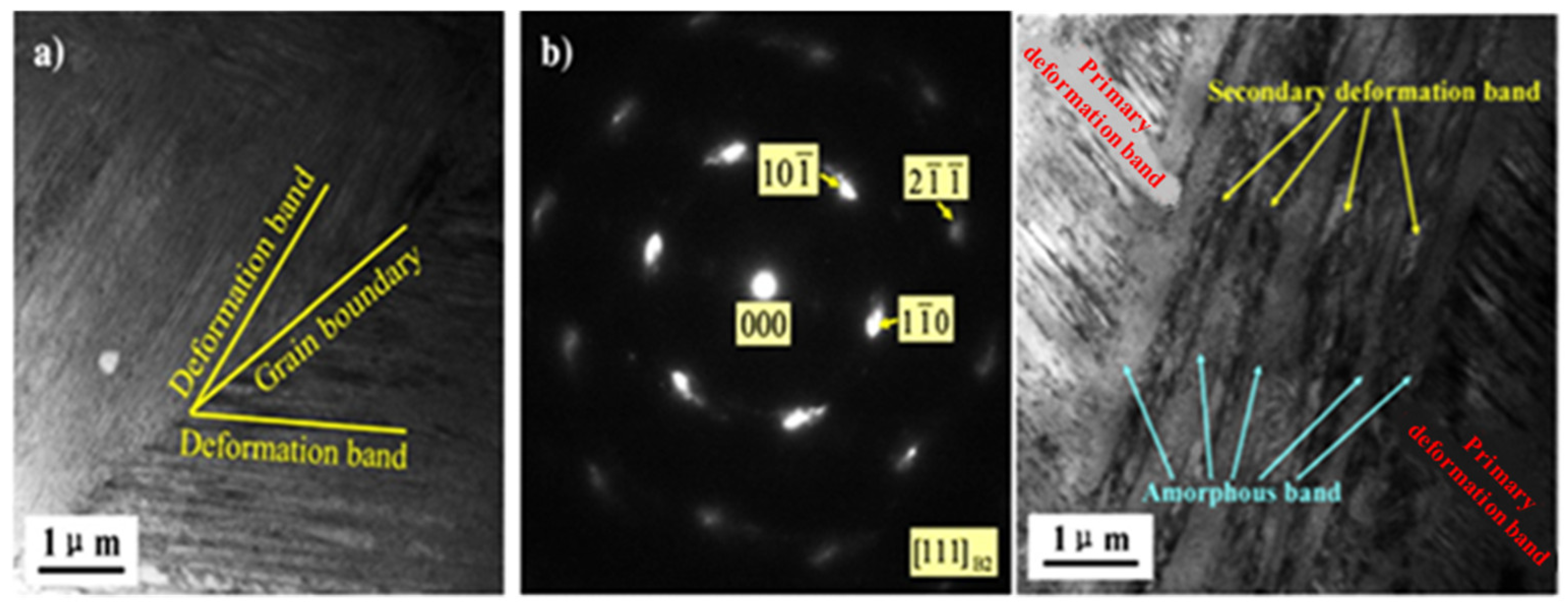

3.4. Local Canning Compression (LCC)

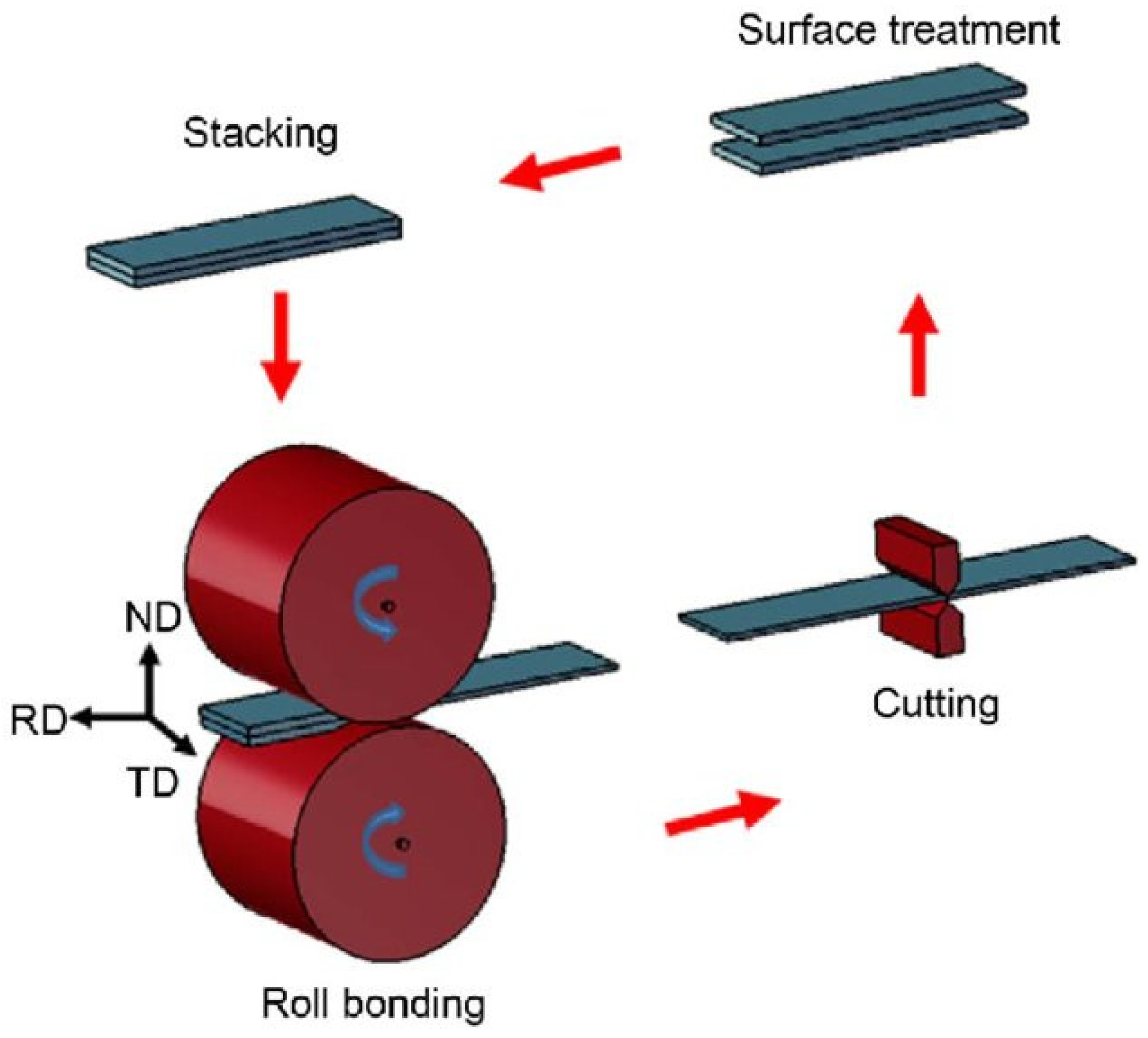

3.5. Accumulative Roll-Bonding (ARB)

4. Conclusions and Future Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ebrahimi, M.; Wang, Q.; Attarilar, S. A comprehensive review of magnesium-based alloys and composites processed by cyclic extrusion compression and the related techniques. Prog. Mater. Sci. 2023, 131, 101016. [Google Scholar] [CrossRef]

- Langdon, T.G. Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement. Acta Mater. 2013, 61, 7035–7059. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z. A review on high-pressure torsion (HPT) from 1935 to 1988. Mater. Sci. Eng. A 2016, 652, 325–352. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Djavanroodi, F.; Omranpour, B.; Ebrahimi, M.; Sedighi, M. Designing of ECAP parameters based on strain distribution uniformity. Prog. Nat. Sci. Mater. Int. 2012, 22, 452–460. [Google Scholar] [CrossRef]

- Attarilar, S.; Salehi, M.T.; Djavanroodi, F. Microhardness evolution of pure titanium deformed by equal channel angular extrusion. Metall. Res. Technol. 2019, 116, 1–10. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Djavanroodi, F.; Tiji, S.; Gholipour, H.; Gode, C. Experimental Investigation of the Equal Channel Forward Extrusion Process. Metals 2015, 5, 471–483. [Google Scholar] [CrossRef]

- Wu, J.; Ebrahimi, M.; Attarilar, S.; Gode, C.; Zadshakoyan, M. Cyclic Extrusion Compression Process for Achieving Ultrafine-Grained 5052 Aluminum Alloy with Eminent Strength and Wear Resistance. Metals 2022, 12, 1627. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Wang, Q. Accumulative roll-bonding of aluminum alloys and composites: An overview of properties and performance. J. Mater. Res. Technol. 2022, 19, 4381–4403. [Google Scholar] [CrossRef]

- Fan, R.; Attarilar, S.; Shamsborhan, M.; Ebrahimi, M.; Gode, C.; Özkavak, H.V. Enhancing mechanical properties and corrosion performance of AA6063 aluminum alloys through constrained groove pressing technique. Trans. Nonferrous Met. Soc. China 2020, 30, 1790–1802. [Google Scholar] [CrossRef]

- Djavanroodi, F.; Ebrahimi, M.; Nayfeh, J.F. Tribological and mechanical investigation of multi-directional forged nickel. Sci. Rep. 2019, 9, 241. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimi, M.; Par, M.A. Twenty-year uninterrupted endeavor of friction stir processing by focusing on copper and its alloys. J. Alloys Compd. 2019, 781, 1074–1090. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Shamsborhan, M. Monotonic and dynamic mechanical properties of PTCAE aluminum. J. Alloys Compd. 2017, 705, 28–37. [Google Scholar] [CrossRef]

- Ebrahimi, M. Fatigue Behaviors of Materials Processed by Planar Twist Extrusion. Metall. Mater. Trans. A 2017, 48, 6126–6134. [Google Scholar] [CrossRef]

- Mohd, J.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Liang, L.; Xu, M.; Chen, Y.; Zhang, T.; Tong, W.; Liu, H.; Wang, H.; Li, H. Effect of welding thermal treatment on the microstructure and mechanical properties of nickel-based superalloy fabricated by selective laser melting. Mater. Sci. Eng. A 2021, 819, 141507. [Google Scholar] [CrossRef]

- Miyazaki, S.; Otsuka, K. Development of Shape Memory Alloys. ISIJ Int. 1989, 29, 353–377. [Google Scholar] [CrossRef]

- Ölander, A. An electrochemical investigation of solid cadmium-gold alloys. J. Am. Chem. Soc. 1932, 54, 3819–3833. [Google Scholar] [CrossRef]

- Buehler, W.J.; Gilfrich, J.V.; Wiley, R.C. Effect of Low-Temperature Phase Changes on the Mechanical Properties of Alloys near Composition TiNi. J. Appl. Phys. 1963, 34, 1475. [Google Scholar] [CrossRef]

- Furuya, Y.; Shimada, H. Shape memory actuators for robotic applications. Mater. Des. 1991, 12, 21–28. [Google Scholar] [CrossRef]

- Babacan, N.; Atli, K.C.; Turkbas, O.S.; Karaman, I.; Kockar, B. The effect of dynamic aging on the cyclic stability of Cu73Al16Mn11 shape memory alloy. Mater. Sci. Eng. A 2017, 701, 352–358. [Google Scholar] [CrossRef]

- Humbeeck, J. Van Non-medical applications of shape memory alloys. Mater. Sci. Eng. A 1999, 273–275, 134–148. [Google Scholar] [CrossRef]

- Hartl, D.J.; Lagoudas, D.C. Aerospace applications of shape memory alloys. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2007, 221, 535–552. [Google Scholar] [CrossRef]

- Bil, C.; Massey, K.; Abdullah, E.J. Wing morphing control with shape memory alloy actuators. J. Intell. Mater. Syst. Struct. 2013, 24, 879–898. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A. Shape memory alloys in automotive applications. Appl. Mech. Mater. 2014, 663, 248–253. [Google Scholar] [CrossRef]

- Qi, Y.; Lapovok, R.; Estrin, Y. Microstructure and electrical conductivity of aluminium/steel bimetallic rods processed by severe plastic deformation. J. Mater. Sci. 2016, 51, 6860–6875. [Google Scholar] [CrossRef]

- Zehetbauer, M.; Grössinger, R.; Krenn, H.; Krystian, M.; Pippan, R.; Rogl, P.; Waitz, T.; Würschum, R. Bulk nanostructured functional materials by severe plastic deformation. Adv. Eng. Mater. 2010, 12, 692–700. [Google Scholar] [CrossRef]

- Guillem-Martí, J.; Herranz-Díez, C.; Shaffer, J.E.; Gil, F.J.; Manero, J.M. Mechanical and microstructural characterization of new nickel-free low modulus β-type titanium wires during thermomechanical treatments. Mater. Sci. Eng. A 2015, 636, 507–515. [Google Scholar] [CrossRef]

- He, J.; Zhu, S.; Luo, C.; Niu, X.; Wang, Q. Size effect in fatigue modelling of defective materials: Application of the calibrated weakest-link theory. Int. J. Fatigue 2022, 165, 107213. [Google Scholar] [CrossRef]

- Xu, H.; He, T.; Zhong, N.; Zhao, B.; Liu, Z. Transient thermomechanical analysis of micro cylindrical asperity sliding contact of SnSbCu alloy. Tribol. Int. 2022, 167, 107362. [Google Scholar] [CrossRef]

- Sathish, S.; Mallik, U.S.; Raju, T.N. Microstructure and Shape Memory Effect of Cu-Zn-Ni Shape Memory Alloys. J. Miner. Mater. Charact. Eng. 2014, 2, 71–77. [Google Scholar] [CrossRef]

- Liu, J.L.; Huang, H.Y.; Xie, J.X. Superelastic anisotropy characteristics of columnar-grained Cu-Al-Mn shape memory alloys and its potential applications. Mater. Des. 2015, 85, 211–220. [Google Scholar] [CrossRef]

- Huang, W. On the selection of shape memory alloys for actuators. Mater. Des. 2002, 23, 11–19. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Gupta, A.K.; Padisala, S.K.; Poluri, K. Characterization of mechanical and microstructural properties of constrained groove pressed nitinol shape memory alloy for biomedical applications. Mater. Sci. Eng. C 2019, 102, 730–742. [Google Scholar] [CrossRef]

- Sun, L.; Huang, W.M.; Ding, Z.; Zhao, Y.; Wang, C.C.; Purnawali, H.; Tang, C. Stimulus-responsive shape memory materials: A review. Mater. Des. 2012, 33, 577–640. [Google Scholar] [CrossRef]

- Sakon, T.; Nagashio, H.; Sasaki, K.; Susuga, S.; Numakura, D.; Abe, M.; Endo, K.; Yamashita, S.; Nojiri, H.; Kanomata, T. Thermal strain and magnetization of the ferromagnetic shape memory alloy Ni52Mn25Ga23 in a magnetic field. J. Phys. Chem. Solids 2013, 74, 158–165. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, C.; Liang, T.; Ma, Y.; Xu, H. Martensitic transformation and magnetization of Ni–Fe–Ga ferromagnetic shape memory alloys. Scr. Mater. 2003, 48, 1255–1258. [Google Scholar] [CrossRef]

- Namvari, M.; Laitinen, V.; Sozinov, A.; Saren, A.; Ullakko, K. Effects of 1 at.% additions of Co, Fe, Cu, and Cr on the properties of Ni-Mn-Ga-based magnetic shape memory alloys. Scr. Mater. 2023, 224, 115116. [Google Scholar] [CrossRef]

- Dan, N.H.; Hau, K.X.; Yen, N.H.; Thi Thanh, P.; Ngoc, N.H.; Anh, T.V.; Nguyet Nga, N.T.; Anh, D.T.K. Structure and magnetic properties of Ni50−xCoxMn50−yAly (x = 5–9, y = 18–19) shape memory alloy ribbons. J. Alloys Compd. 2022, 916, 165470. [Google Scholar] [CrossRef]

- Amako, Y.; Tanaka, S.; Nakashima, M.; Eto, T.; Adachi, Y.; Kanomata, T. 119Sn Mössbauer and magnetization studies of the Heusler alloy Ni2Mn1.48Sn0.52. J. Phys. Chem. Solids 2023, 172, 111101. [Google Scholar] [CrossRef]

- Heczko, O.; Straka, L. Compositional dependence of structure, magnetization and magnetic anisotropy in Ni–Mn–Ga magnetic shape memory alloys. J. Magn. Magn. Mater. 2004, 272–276, 2045–2046. [Google Scholar] [CrossRef]

- Wang, S.; Yang, R.; Lu, G.; Yi, L.; Liu, M.; Xu, Y.; Pan, L. Atomic occupation and role of Cr atoms in Cr-doped Ni43Co7Mn39Sn11 magnetic shape memory alloys. J. Alloys Compd. 2022, 929, 167315. [Google Scholar] [CrossRef]

- Yang, H.; An, K.; Nie, Z.H.; Wang, Y.D.; Tang, B.; Peng, T. The anomalous staircase-like magnetization behavior and giant magnetocaloric effect in a Fe–Mn-Ga magnetic shape memory alloy. Intermetallics 2020, 127, 106975. [Google Scholar] [CrossRef]

- Gao, W.; Yi, X.; Sun, B.; Fu, Y.; Meng, X. Low-cost (ZrCu)50-xTax high temperature shape memory alloys showing excellent shape memory effect. Prog. Nat. Sci. Mater. Int. 2022, 32, 369–374. [Google Scholar] [CrossRef]

- Montecinos, S.; Cuniberti, A.; Sepúlveda, A. Grain size and pseudoelastic behaviour of a Cu–Al–Be alloy. Mater. Charact. 2008, 59, 117–123. [Google Scholar] [CrossRef]

- Casciati, F.; Faravelli, L. Experimental characterisation of a Cu-based shape memory alloy toward its exploitation in passive control devices. J. Phys. IV 2004, 115, 299–306. [Google Scholar] [CrossRef]

- Torra, V.; Isalgue, A.; Lovey, F.C.; Martorell, F.; Molina, F.J.; Sade, M.; Tachoire, H. Shape memory alloys: From the physical properties of metastable phase transitions to dampers for civil engineering applications. J. Phys. IV 2004, 113, 85–90. [Google Scholar] [CrossRef]

- Figueroa, C.G.; Garcia-Castillo, F.N.; Jacobo, V.H.; Cortés-Pérez, J.; Schouwenaars, R. Microstructural and superficial modification in a Cu-Al-Be shape memory alloy due to superficial severe plastic deformation under sliding wear conditions. IOP Conf. Ser. Mater. Sci. Eng. 2017, 194, 012011. [Google Scholar] [CrossRef]

- Zhang, Y.; He, X.; Xu, K.; Kang, Y.; Sun, H.; Liu, H.; Cao, Y.; Wei, S.; Li, Z.; Jing, C. Structural ordering, magnetic and electrical transport properties in Ni60-Fe13+Ga27 Heusler alloys. J. Alloys Compd. 2023, 936, 168242. [Google Scholar] [CrossRef]

- Nikolaev, V.I.; Stepanov, S.I.; Yakushev, P.N.; Krymov, V.M.; Kustov, S.B. Burst-like shape recovery and caloric effects in Ni–Fe–Ga–Co single crystalline shape memory alloys. Intermetallics 2020, 119, 106709. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Li, S.; Niu, Y.; Yin, T.; Song, C.; Lang, R.; Cong, D.; Li, S.; Wang, Y.-D. Enhanced cyclability of superelasticity and elastocaloric effect in Cu and B co-doped Co-Ni-Ga shape memory alloys. J. Alloys Compd. 2022, 918, 165633. [Google Scholar] [CrossRef]

- Mendonça, A.A.; Ghivelder, L.; Bernardo, P.L.; Cohen, L.F.; Gomes, A.M. Low hysteretic magnetostructural transformation in Cr-doped Ni-Mn-Ga Heusler alloy. J. Alloys Compd. 2023, 938, 168444. [Google Scholar] [CrossRef]

- Tavares, S.; Yang, K.; Meyers, M.A. Heusler alloys: Past, properties, new alloys, and prospects. Prog. Mater. Sci. 2023, 132, 101017. [Google Scholar] [CrossRef]

- Cao, P.; Tian, F.; Li, W.; Vitos, L.; Wang, Y. Ideal superelasticity in Ni-based Heusler alloys. Acta Mater. 2021, 210, 116816. [Google Scholar] [CrossRef]

- Gurau, G.; Gurau, C.; Sampath, V.; Bujoreanu, L.G. Investigations of a nanostructured FeMnSi shape memory alloy produced via severe plastic deformation. Int. J. Miner. Metall. Mater. 2016, 23, 1315–1322. [Google Scholar] [CrossRef]

- Jiang, S.; Hu, L.; Zhang, Y.; Liang, Y. Nanocrystallization and amorphization of NiTi shape memory alloy under severe plastic deformation based on local canning compression. J. Non-Cryst. Solids 2013, 367, 23–29. [Google Scholar] [CrossRef]

- Sun, D.; Jiang, S.; Zhang, Y.; Yan, B.; Yu, J. Influence of annealing on incomplete detwinning and deformation twinning in equiatomic NiTi shape memory alloy undergoing severe plastic deformation. J. Alloys Compd. 2021, 871, 159550. [Google Scholar] [CrossRef]

- Hu, L.; Jiang, S.; Zhang, Y.; Zhao, Y.; Liu, S.; Zhao, C. Intermetallics Multiple plastic deformation mechanisms of NiTi shape memory alloy based on local canning compression at various temperatures. Intermetallics 2016, 70, 45–52. [Google Scholar] [CrossRef]

- Gunderov, D.V.; Kuranova, N.N.; Luk’Yanov, A.V.; Uksusnikov, A.N.; Prokof’Ev, E.A.; Yurchenko, L.I.; Valiev, R.Z.; Pushin, V.G. Application of severe plastic deformation by torsion to form amorphous and nanocrystalline states in large-size TiNi alloy sample. Phys. Met. Metallogr. 2009, 108, 131–138. [Google Scholar] [CrossRef]

- Jiang, S.Y.; Zhao, Y.N.; Zhang, Y.Q.; Tang, M.; Li, C.F. Equal channel angular extrusion of NiTi shape memory alloy tube. Trans. Nonferrous Met. Soc. China 2013, 23, 2021–2028. [Google Scholar] [CrossRef]

- Pushin, V.G.; Stolyarov, V.V.; Valiev, R.Z.; Lowe, T.C.; Zhu, Y.T. Nanostructured TiNi-based shape memory alloys processed by severe plastic deformation. Mater. Sci. Eng. A 2005, 411, 386–389. [Google Scholar] [CrossRef]

- Zhang, X.; Xia, B.; Song, J.; Chen, B.; Tian, X.; Hao, Y.; Xie, C. Effects of equal channel angular extrusion and aging treatment on R phase transformation behaviors and Ti3Ni4 precipitates of Ni-rich TiNi alloys. J. Alloys Compd. 2011, 509, 6296–6301. [Google Scholar] [CrossRef]

- Song, J.; Wang, L.M.; Zhang, X.N.; Sun, X.G.; Jiang, H.; Fan, Z.G.; Xie, C.Y.; Wu, M.H. Effects of second phases on mechanical properties and martensitic transformations of ECAPed TiNi and Ti-Mo based shape memory alloys. Trans. Nonferrous Met. Soc. China 2012, 22, 1839–1848. [Google Scholar] [CrossRef]

- Fan, Z.G.; Xie, C.Y. Shape Memory Behavior of Ti-50.9at%Ni Alloy after ECAE Processes. Mater. Sci. Forum 2007, 561–565, 2313–2316. [Google Scholar] [CrossRef]

- Zhang, X.; Song, J.; Huang, C.; Xia, B.; Chen, B.; Sun, X.; Xie, C. Microstructures evolution and phase transformation behaviors of Ni-rich TiNi shape memory alloys after equal channel angular extrusion. J. Alloys Compd. 2011, 509, 3006–3012. [Google Scholar] [CrossRef]

- Zhang, X.; Song, J.; Jiang, H.; Sun, X.; Xie, C. Effects of ECAE and aging on phase transformations and superelasticity of a Ni-rich TiNi SMA. Mater. Sci. Forum 2011, 682, 185–191. [Google Scholar] [CrossRef]

- Pushin, V.G.; Stolyarov, V.V.; Valiev, R.Z.; Kourov, N.I.; Kuranova, N.N.; Prokofiev, E.A.; Yurchenko, L.I. Features of structure and phase transformations in shape memory TiNi-based alloys after severe plastic deformation. Ann. Chim. Sci. Matériaux 2002, 27, 77–88. [Google Scholar] [CrossRef]

- Arockiakumar, R.; Park, J.K. Effect of α-precipitation on the superelastic behavior of Ti-40 wt.%Nb-0.3 wt.%O alloy processed by equal channel angular extrusion. Mater. Sci. Eng. A 2010, 527, 2709–2713. [Google Scholar] [CrossRef]

- Zhang, P.; Ma, A.; Lu, S.; Lin, P.; Jiang, J.; Ma, H.; Chu, C. Effect of equal channel angular pressing and heat treatment on the microstructure of Cu-Al-Be-B shape memory alloy. Mater. Lett. 2009, 63, 2676–2679. [Google Scholar] [CrossRef]

- Alizadeh, M.; Avazzadeh, M. Evaluation of Cu-26Zn-5Al shape memory alloy fabricated by accumulative roll bonding process. Mater. Sci. Eng. A 2019, 757, 88–94. [Google Scholar] [CrossRef]

- Alizadeh, M.; Dashtestaninejad, M.K. Fabrication of manganese-aluminum bronze as a shape memory alloy by accumulative roll bonding process. Mater. Des. 2016, 111, 263–270. [Google Scholar] [CrossRef]

- Ostovari Moghaddam, A.; Mazinani, A.; Ketabchi, M. Effect of Accumulative Roll Bonding and Equal Channel Angular Rolling on Microstructural and Mechanical Properties of Cu–Al–Mn Shape Memory Alloys. Trans. Indian Inst. Met. 2017, 70, 1901–1909. [Google Scholar] [CrossRef]

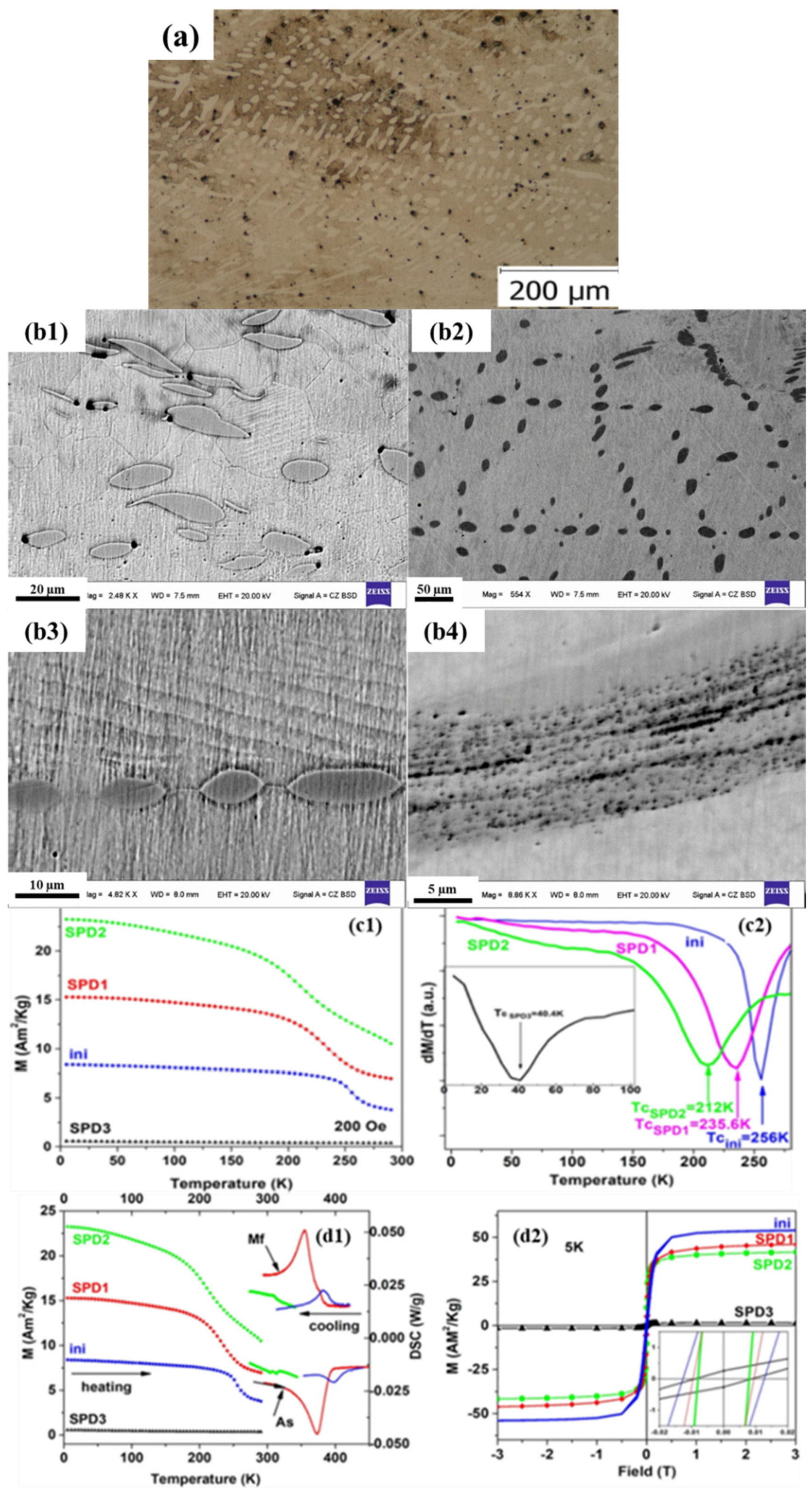

- Gurau, G.; Gurau, C.; Tolea, F.; Valeanu, M.; Sampath, V.; Bujoreanu, L.G. Effect of Severe Plastic Deformation on the Structure and Magnetic Behaviour of an Fe-Mn-Si Shape Memory Alloy. Adv. Mater. Res. 2017, 1143, 240–246. [Google Scholar] [CrossRef]

- Popescu, B.; Gurau, C.; Gurau, G.; Tolea, M.; Sofronie, M.; Tolea, F. Martensitic Transformation and Magnetic Properties of Ni57Fe18Ga25 Shape Memory Alloy Subjected to Severe Plastic Deformation. Trans. Indian Inst. Met. 2021, 74, 2491–2498. [Google Scholar] [CrossRef]

- Gurau, C.; Gurau, G.; Tolea, F.; Sampath, V. Structural evolution of the niti/nifega smart hybrid material during severe plastic deformation. Dig. J. Nanomater. Biostructures 2019, 14, 539–546. [Google Scholar]

- Waitz, T.; Antretter, T.; Fischer, F.D.; Karnthaler, H.P. Size effects on martensitic phase transformations in nanocrystalline NiTi shape memory alloys. Mater. Sci. Technol. 2008, 24, 934–940. [Google Scholar] [CrossRef]

- Sun, Q.P.; He, Y.J. A multiscale continuum model of the grain-size dependence of the stress hysteresis in shape memory alloy polycrystals. Int. J. Solids Struct. 2008, 45, 3868–3896. [Google Scholar] [CrossRef]

- Meng, Q.; Rong, Y.; Hsu, T.Y. Nucleation barrier for phase transformations in nanosized crystals. Phys. Rev. B 2002, 65, 174118. [Google Scholar] [CrossRef]

- Meng, Q.; Zhou, N.; Rong, Y.; Chen, S.; Hsu (Xu Zuyao), T.Y.; Zuyao, X. Size effect on the Fe nanocrystalline phase transformation. Acta Mater. 2002, 50, 4563–4570. [Google Scholar] [CrossRef]

- Lee, T.-J.; Kim, W.-J. Effect of Severe Plastic Deformation and Post-Deformation Heat Treatment on the Microstructure and Superelastic Properties of Ti-50.8 at.% Ni Alloy. Materials 2022, 15, 7822. [Google Scholar] [CrossRef]

- Satheesh Kumar, S.S.; Raghu, T. Structural and mechanical behaviour of severe plastically deformed high purity aluminium sheets processed by constrained groove pressing technique. Mater. Des. 2013, 57, 114–120. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Attarilar, S.; Djavanroodi, F.; Gode, C.; Kim, H.S. Wear properties of brass samples subjected to constrained groove pressing process. Mater. Des. 2014, 63, 531–537. [Google Scholar] [CrossRef]

- Garudapalli, A.; Bhardwaj, A.; Oswal, K.; Mathur, D.; Gupta, A.K. Microstructural, Mechanical, and Superelastic Behavior of Thermo-Mechanically Processed Nitinol Alloy. Shape Mem. Superelasticity 2021, 7, 503–514. [Google Scholar] [CrossRef]

- Rohatgi, A.; Vecchio, K.S.; Gray, G.T. The influence of stacking fault energy on the mechanical behavior of Cu and Cu-Al alloys: Deformation twinning, work hardening, and dynamic recovery. Metall. Mater. Trans. A 2001, 32, 135–145. [Google Scholar] [CrossRef]

- Vercammen, S.; Blanpain, B.; De Cooman, B.C.; Wollants, P. Cold rolling behaviour of an austenitic Fe–30Mn–3Al–3Si TWIP-steel: The importance of deformation twinning. Acta Mater. 2004, 52, 2005–2012. [Google Scholar] [CrossRef]

- Xiao, G.H.; Tao, N.R.; Lu, K. Effects of strain, strain rate and temperature on deformation twinning in a Cu–Zn alloy. Scr. Mater. 2008, 59, 975–978. [Google Scholar] [CrossRef]

- Attarilar, S.; Djavanroodi, F.; Ebrahimi, M.; Al-Fadhalah, K.J.; Wang, L.; Mozafari, M. Hierarchical Microstructure Tailoring of Pure Titanium for Enhancing Cellular Response at Tissue-Implant Interface. J. Biomed. Nanotechnol. 2021, 17, 115–130. [Google Scholar] [CrossRef]

- Duerig, T.W.; Melton, K.N.; Stöckel, D. Engineering Aspects of Shape Memory Alloys; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Shaeri, M.H.; Shaeri, M.; Ebrahimi, M.; Salehi, M.T.; Seyyedein, S.H. Effect of ECAP temperature on microstructure and mechanical properties of Al-Zn-Mg-Cu alloy. Prog. Nat. Sci. Mater. Int. 2016, 26, 182–191. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Shaeri, M.H.; Gode, C.; Armoon, H.; Shamsborhan, M. The synergistic effect of dilute alloying and nanostructuring of copper on the improvement of mechanical and tribological response. Compos. Part B Eng. 2019, 164, 508–516. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, L. The Ultrafine-Grained Titanium and Biomedical Titanium Alloys Processed by Severe Plastic Deformation (SPD). SOJ Mater. Sci. Eng. 2013, 1, 1. [Google Scholar] [CrossRef]

- Djavanroodi, F.; Ebrahimi, M.; Rajabifar, B.; Akramizadeh, S. Fatigue design factors for ECAPed materials. Mater. Sci. Eng. A 2010, 528, 745–750. [Google Scholar] [CrossRef]

- Sutou, Y.; Omori, T.; Yamauchi, K.; Ono, N.; Kainuma, R.; Ishida, K. Effect of grain size and texture on pseudoelasticity in Cu-Al-Mn-based shape memory wire. Acta Mater. 2005, 53, 4121–4133. [Google Scholar] [CrossRef]

- Hsu, C.A.; Wang, W.H.; Hsu, Y.F.; Rehbach, W.P. The refinement treatment of martensite in Cu-11.38 wt.%Al-0.43 wt.%Be shape memory alloys. J. Alloys Compd. 2009, 474, 455–462. [Google Scholar] [CrossRef]

- Sergueeva, A.V.; Song, C.; Valiev, R.Z.; Mukherjee, A.K. Structure and properties of amorphous and nanocrystalline NiTi prepared by severe plastic deformation and annealing. Mater. Sci. Eng. A 2003, 339, 159–165. [Google Scholar] [CrossRef]

- Gurău, G.; Gurău, C.; Potecaşu, O.; Alexandru, P.; Bujoreanu, L.-G. Novel High-Speed High Pressure Torsion Technology for Obtaining Fe-Mn-Si-Cr Shape Memory Alloy Active Elements. J. Mater. Eng. Perform. 2014, 23, 2396–2402. [Google Scholar] [CrossRef]

- Gurau, G.; Gurau, C.; Tolea, F.; Sampath, V. Structural Change in Ni-Fe-Ga Magnetic Shape Memory Alloys after Severe Plastic Deformation. Materials 2019, 12, 1939. [Google Scholar] [CrossRef]

- Panigrahi, A.; Sulkowski, B.; Waitz, T.; Ozaltin, K.; Chrominski, W.; Pukenas, A.; Horky, J.; Lewandowska, M.; Skrotzki, W.; Zehetbauer, M. Mechanical properties, structural and texture evolution of biocompatible Ti–45Nb alloy processed by severe plastic deformation. J. Mech. Behav. Biomed. Mater. 2016, 62, 93–105. [Google Scholar] [CrossRef]

- An, X.H.; Lin, Q.Y.; Sha, G.; Huang, M.X.; Ringer, S.P.; Zhu, Y.T.; Liao, X.Z. Microstructural evolution and phase transformation in twinning-induced plasticity steel induced by high-pressure torsion. Acta Mater. 2016, 109, 300–313. [Google Scholar] [CrossRef]

- Sun, D.; Jiang, S.; Xing, X.; Yan, B.; Yu, J.; Zhang, Y. Microstructures and Mechanical Properties of Equiatomic NiTi Shape Memory Alloy Undergoing Local Canning Compression and Subsequent Annealing. Met. Mater. Int. 2021, 27, 4901–4910. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, S.; Hu, L. Investigation of Dynamic Recrystallization of NiTi Shape Memory Alloy Subjected to Local Canning Compression. Metals 2017, 7, 208. [Google Scholar] [CrossRef]

- Nishida, M.; Ii, S.; Kitamura, K.; Furukawa, T.; Chiba, A.; Hara, T.; Hiraga, K. New deformation twinning mode of B19′ martensite in Ti-Ni shape memory alloy. Scr. Mater. 1998, 39, 1749–1754. [Google Scholar] [CrossRef]

- Hua, P.; Wang, B.; Yu, C.; Han, Y.; Sun, Q. Shear-induced amorphization in nanocrystalline NiTi micropillars under large plastic deformation. Acta Mater. 2022, 241, 118358. [Google Scholar] [CrossRef]

- Ko, W.-S.; Choi, W.S.; Xu, G.; Choi, P.-P.; Ikeda, Y.; Grabowski, B. Dissecting functional degradation in NiTi shape memory alloys containing amorphous regions via atomistic simulations. Acta Mater. 2021, 202, 331–349. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, S.; Wang, M. Atomistic investigation on superelasticity of NiTi shape memory alloy with complex microstructures based on molecular dynamics simulation. Int. J. Plast. 2020, 125, 27–51. [Google Scholar] [CrossRef]

- Ko, W.-S.; Jeon, J.B. Atomistic simulations on orientation dependent martensitic transformation during nanoindentation of NiTi shape-memory alloys. Comput. Mater. Sci. 2021, 187, 110127. [Google Scholar] [CrossRef]

- Tsuji, N.; Saito, Y.; Utsunomiya, H.; Tanigawa, S. Ultra-fine grained bulk steel produced by accumulative roll-bonding (ARB) process. Scr. Mater. 1999, 40, 795–800. [Google Scholar] [CrossRef]

- Lim, Y.G.; Han, S.H.; Choi, E.; Kim, W.J. Shape memory and superelasticity of nanograined Ti-51.2 at.% Ni alloy processed by severe plastic deformation via high-ratio differential speed rolling. Mater. Charact. 2018, 145, 284–293. [Google Scholar] [CrossRef]

- Kahani Khabushan, J.; Bazzaz Bonabi, S. Investigating of the Microstructure and Mechanical Properties of Al-Based Composite Reinforced with Nano-Trioxide Tungsten via Accumulative Roll Bonding Process. Open J. Met. 2017, 07, 9–23. [Google Scholar] [CrossRef]

| No. | Type of SMAs | Type of SPD Technique | Application/Feature | Ref. |

|---|---|---|---|---|

| 1 | Ti–Ni | Local canning compression | Amorphous structures | [56] |

| 2 | Ti–Ni | Local canning compression | Effect of the twins on the transformation behavior of the nanocrystalline NiTi | [57] |

| 3 | Ti–Ni | Local canning compression | Mechanisms of amorphization of NiTi SMA | [58] |

| 4 | Ti–Ni | High-pressure torsion | Structural investigations of nanostructured NiTi SMA | [59] |

| 5 | Ti–Ni | Equal-channel angular pressing | Viscoplastic FEM simulation, microstructural observation | [60] |

| 6 | Ti–Ni | High-pressure torsion Equal-channel angular pressing | Phase transformation sequence, microstructural studies | [61] |

| 7 | Ti–Ni | Equal-channel angular pressing | Phase transformation and precipitates’ behavior | [62] |

| 8 | Ti–Ni | Equal-channel angular pressing | Martensitic transformations and effect of second phases | [63] |

| 9 | Ti–Ni | Equal-channel angular pressing | Transformation behavior and effect of pass numbers | [64] |

| 10 | Ti–Ni | Equal-channel angular pressing | Phase transformation, microstructural observation | [65] |

| 11 | Ti–Ni | Equal-channel angular pressing | phase transformations and superelasticity | [66] |

| 12 | Ti50–Ni50, Ti49.5–Ni50.5, Ti50–Ni49–Fe1 | High-speed high-pressure torsion Equal-channel angular pressing | Phase transformation behavior | [67] |

| 13 | Ti–Nb–O | Equal-channel angular pressing | Superelastic behavior and precipitation effects | [68] |

| 14 | Ti–Mo | Equal-channel angular pressing | Martensitic transformations and effect of second phases | [63] |

| 15 | Cu–Al–Be–B | Equal-channel angular pressing | Microstructural observation | [69] |

| 16 | Cu–26Zn–5Al | Accumulative roll-bonding | Shape memory effect and phase distribution | [70] |

| 17 | Cu–Zn–Ni | Accumulative roll-bonding | Martensitic transformation and SMA behavior, microstructural observation | [31] |

| 18 | Cu–Al–Mn | Accumulative roll-bonding | Microstructure, phase formation, corrosion | [71] |

| 19 | Cu–Al–Mn alloys Cu–9.5Al–8.2Mn Cu–8.3Al–8Mn | Accumulative roll-bonding Equal-channel angular rolling | - | [72] |

| 20 | Fe–Mn–Si | High-speed high-pressure torsion | Magnetism | [73] |

| 21 | Fe–Mn–Si | High-speed high-pressure torsion | Actuator | [55] |

| 22 | Ni50.5–Ti49.5 | Constrained groove pressing | Biomedical | [34] |

| 23 | Ni57–Fe18–Ga25 | High-speed high-pressure torsion | Amorphization and magnetism | [74] |

| 24 | Ni50.3–Ti49.7 | High-speed high-pressure torsion | Smart hybrid material | [75] |

| 25 | Ni–Fe–Ga Ni57–Fe18–Ga25 | High-speed high-pressure torsion | Smart hybrid material | [75] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ebrahimi, M.; Attarilar, S.; Gode, C.; Kandavalli, S.R.; Shamsborhan, M.; Wang, Q. Conceptual Analysis on Severe Plastic Deformation Processes of Shape Memory Alloys: Mechanical Properties and Microstructure Characterization. Metals 2023, 13, 447. https://doi.org/10.3390/met13030447

Ebrahimi M, Attarilar S, Gode C, Kandavalli SR, Shamsborhan M, Wang Q. Conceptual Analysis on Severe Plastic Deformation Processes of Shape Memory Alloys: Mechanical Properties and Microstructure Characterization. Metals. 2023; 13(3):447. https://doi.org/10.3390/met13030447

Chicago/Turabian StyleEbrahimi, Mahmoud, Shokouh Attarilar, Ceren Gode, Sumanth Ratna Kandavalli, Mahmoud Shamsborhan, and Qudong Wang. 2023. "Conceptual Analysis on Severe Plastic Deformation Processes of Shape Memory Alloys: Mechanical Properties and Microstructure Characterization" Metals 13, no. 3: 447. https://doi.org/10.3390/met13030447

APA StyleEbrahimi, M., Attarilar, S., Gode, C., Kandavalli, S. R., Shamsborhan, M., & Wang, Q. (2023). Conceptual Analysis on Severe Plastic Deformation Processes of Shape Memory Alloys: Mechanical Properties and Microstructure Characterization. Metals, 13(3), 447. https://doi.org/10.3390/met13030447