Stiffness and Strength of Square Hollow Section Tubes under Localised Transverse Actions

Abstract

:1. Introduction

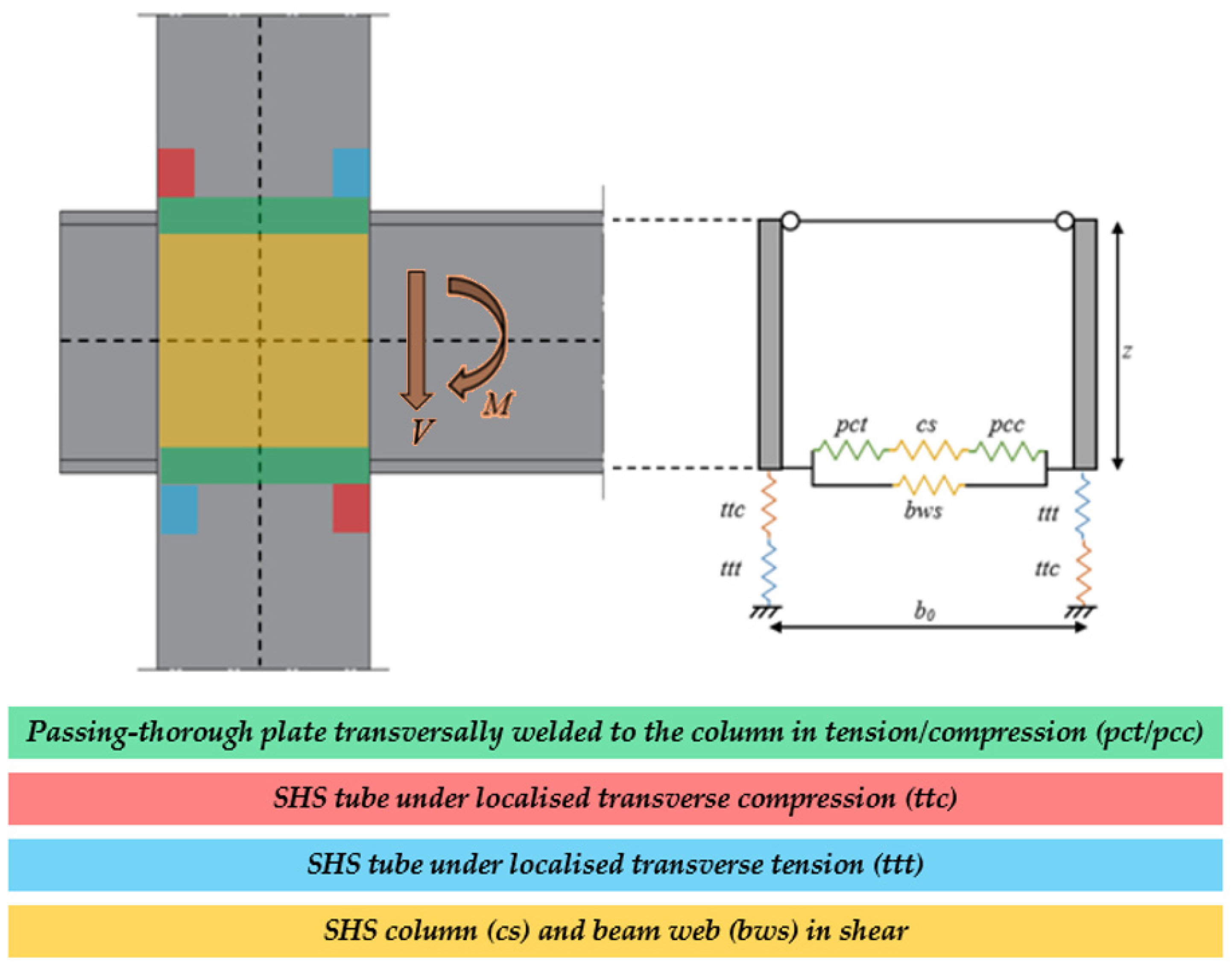

- (i)

- Identification of strength and deformability sources. In this initial phase, the various sources of strength and deformability within the connection, which are essentially the joint components, are identified. This identification process relies on a combination of experimental data, engineering judgment, and Finite Element (FE) modelling.

- (ii)

- Mechanical modelling of individual components, which consists of the mechanical modelling of each of the identified components, considering their respective strength and stiffness characteristics.

- (iii)

- Assembly of a mechanical spring model that accurately represents the behaviour of the entire connection. This model is constructed by combining the responses of the individual components, resulting in a comprehensive representation of the joint’s stiffness and strength.

- -

- The passing-through plate transversally welded to the column in tension/compression (pcc/pct), which is representative of the behaviour of the attachment between the flanges of the beam and the SHS profile.

- -

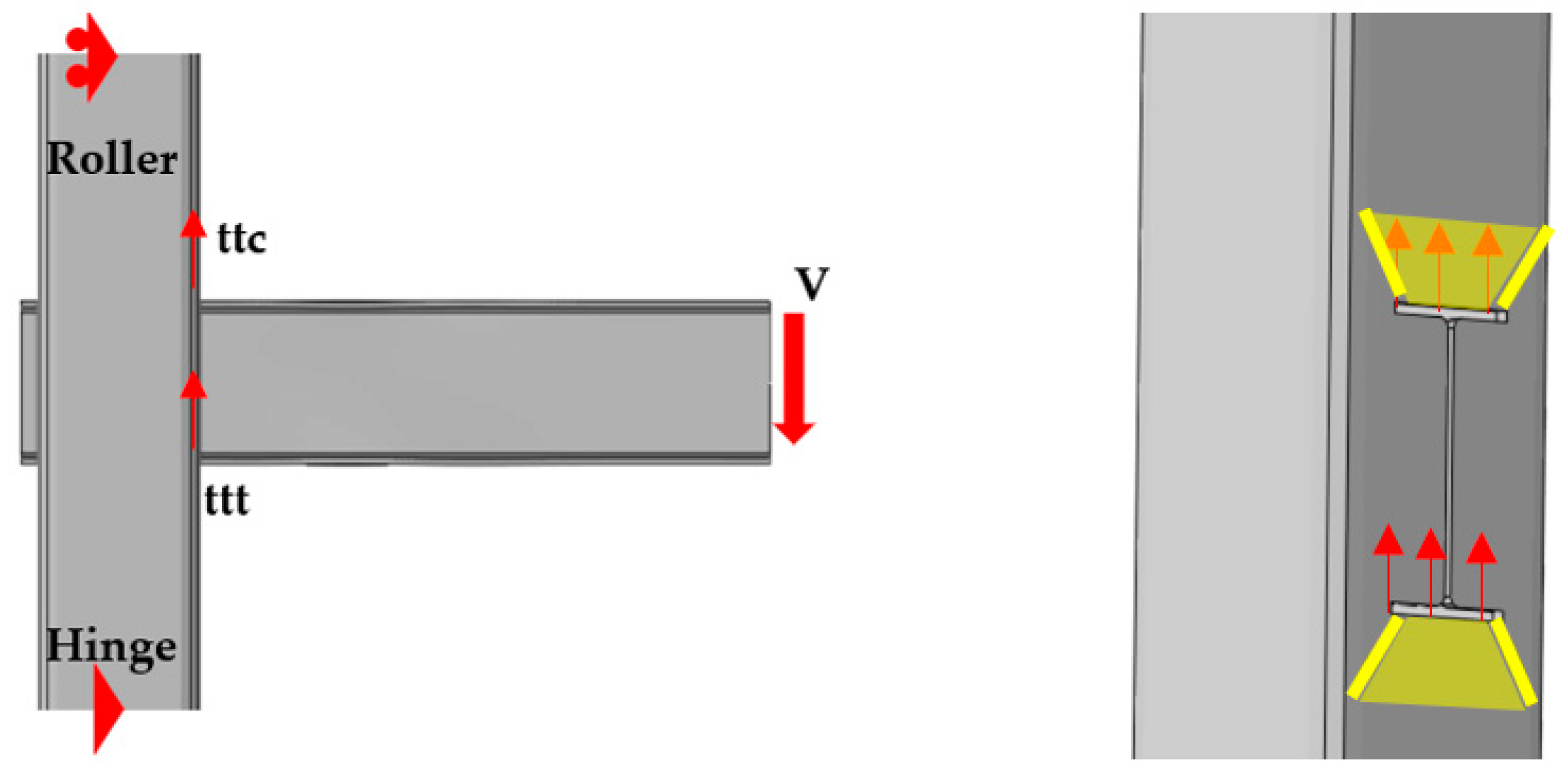

- The column in transverse tension or compression stresses (ttt/ttc). These components are crucial, particularly concerning the overall stiffness of the connection because the rigid rotation of the beam induces localised stresses at the junctions between the flanges of the IPE profile and the sections of the hollow profile adjacent to the hollow section.

- -

- The column and the beam web in shear (cs stands for the column in shear, while bws is the acronym of beam web in shear).

2. Aim of This Research

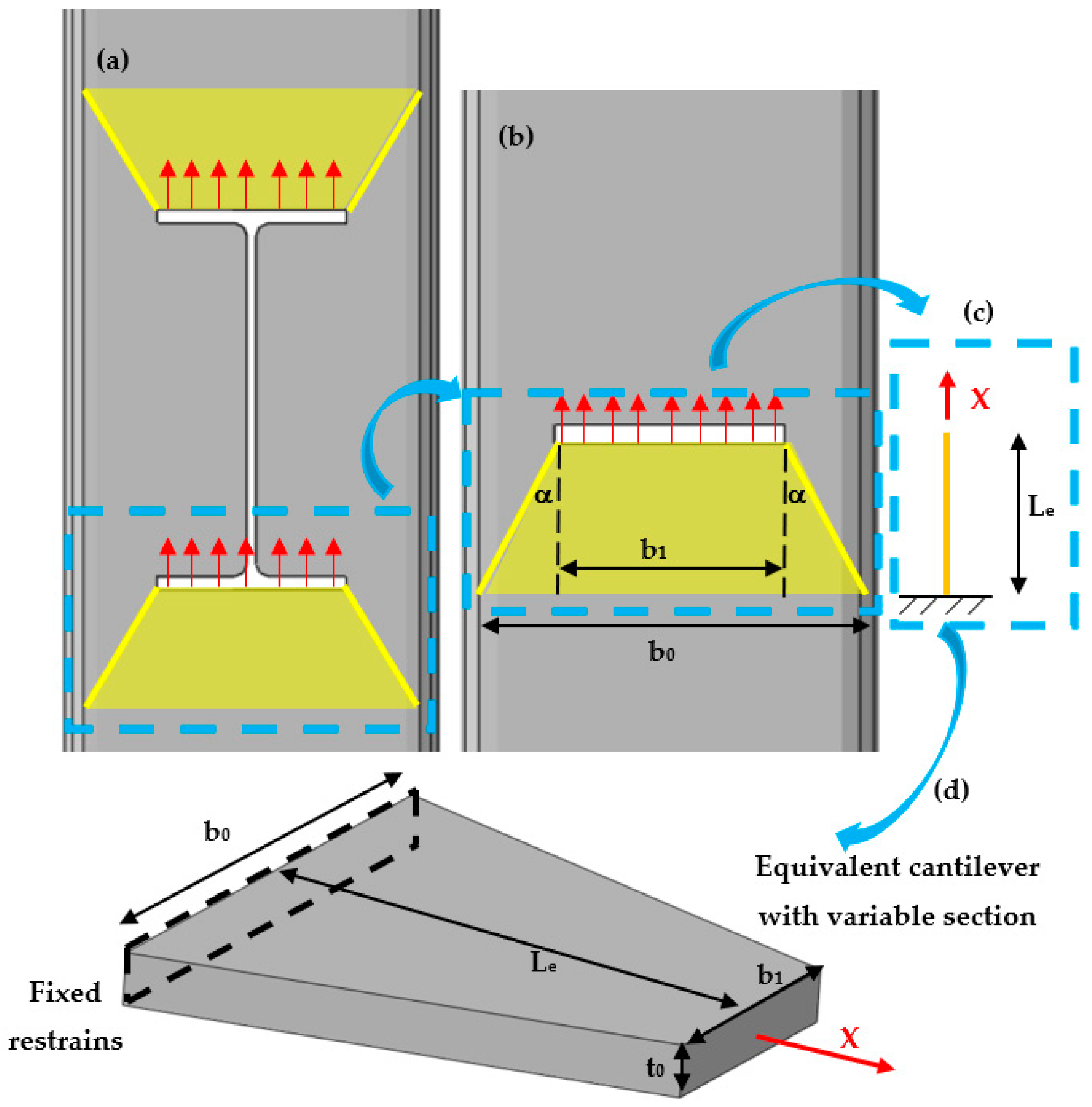

3. Analytical Activity to Characterise the Stiffness and Strength of the ttt/ttc Components

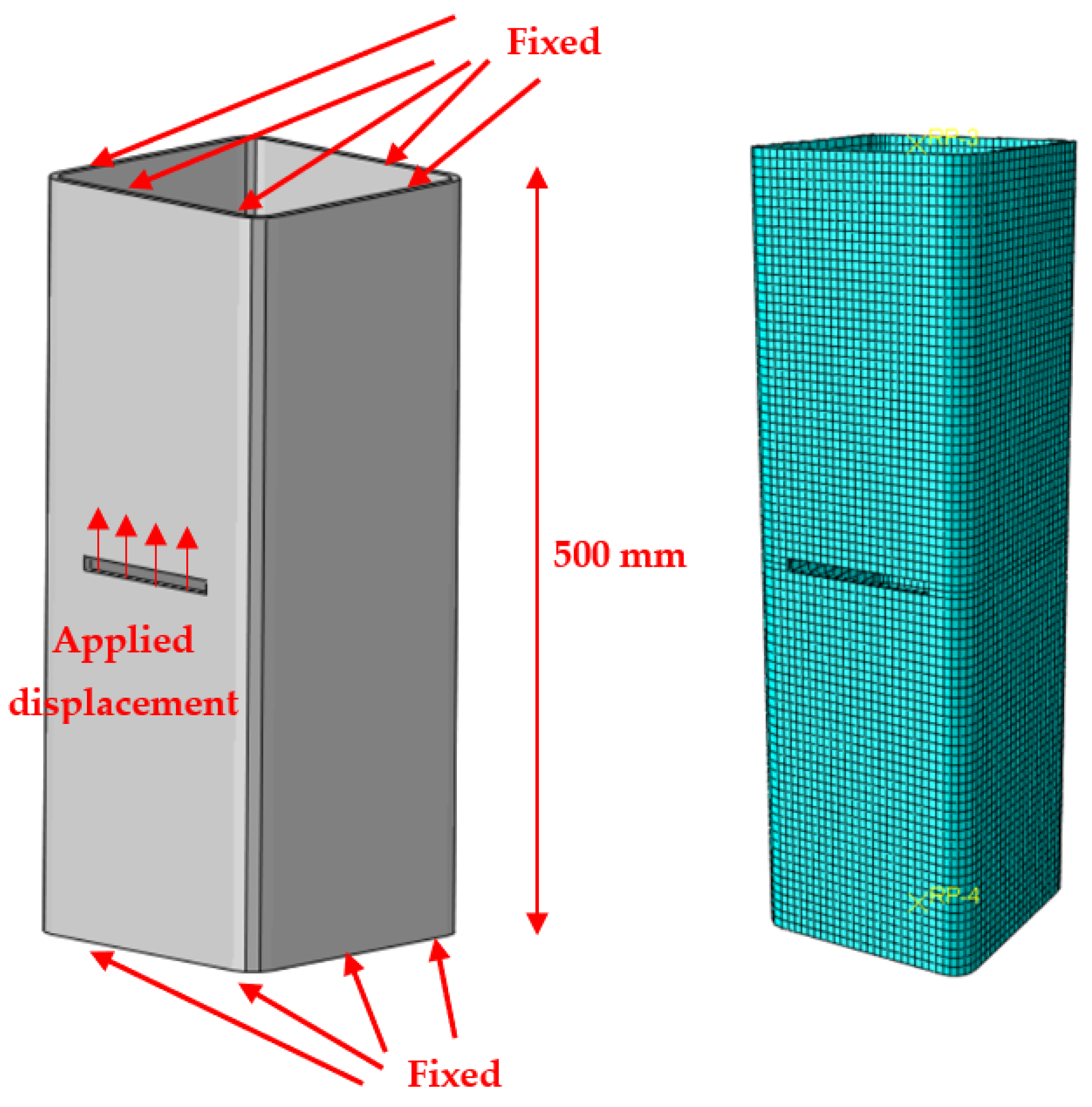

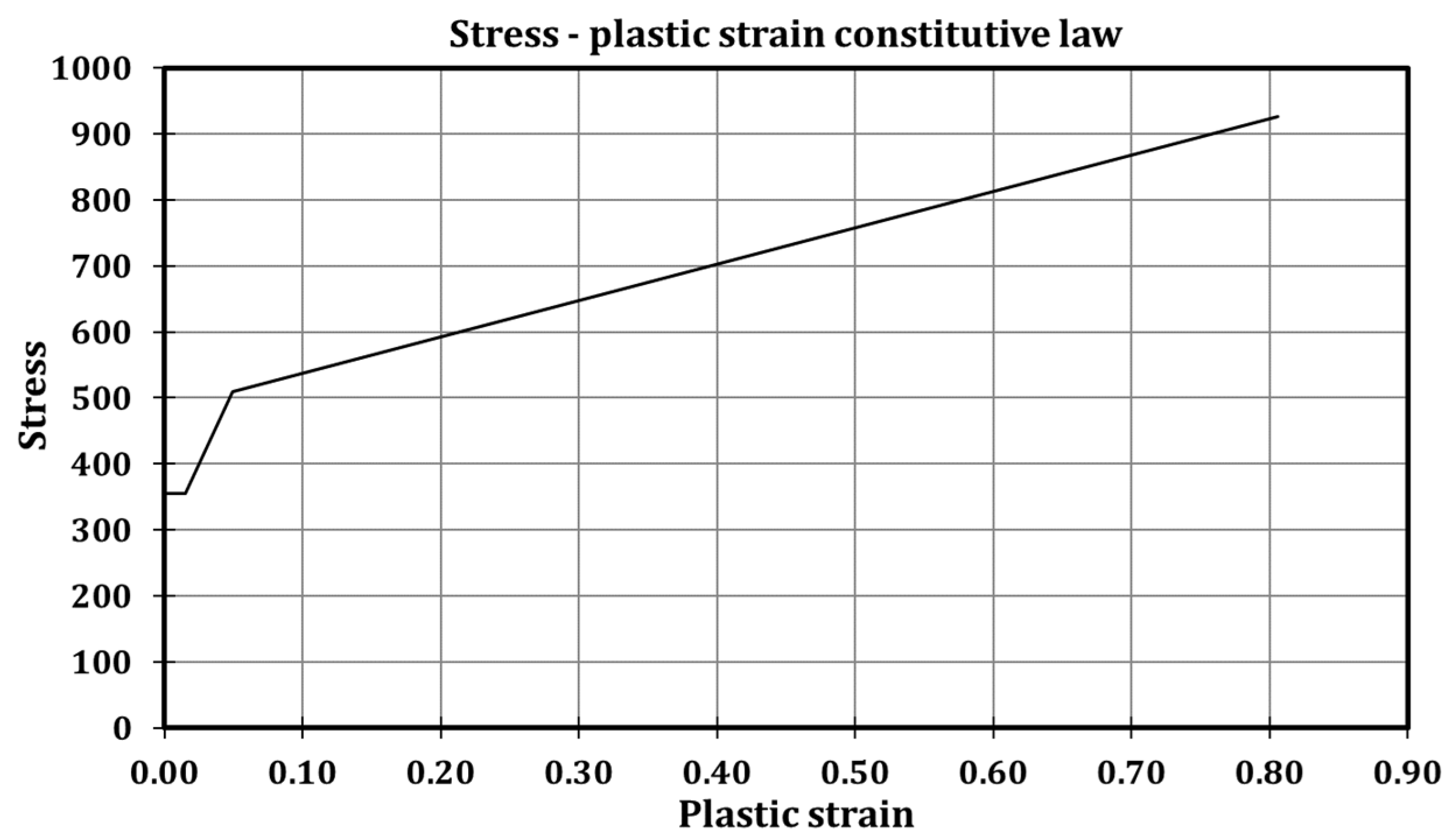

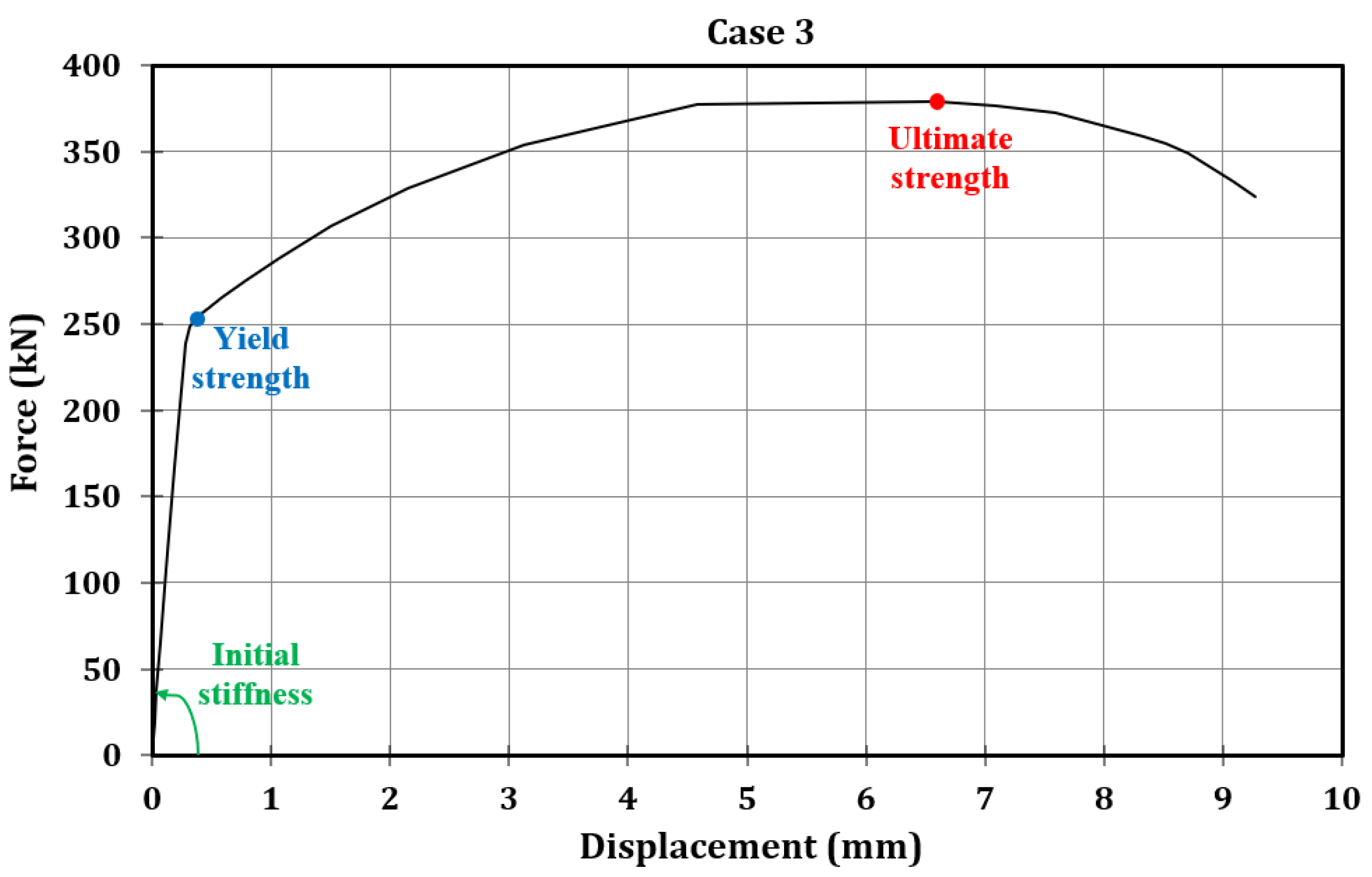

4. Finite Element (FE) Simulations

5. Discussion

6. Conclusions

- -

- By applying principles of elasticity to structural elements, analytical formulations ware developed to predict the initial stiffness and yield strength of the ttt/ttc components.

- -

- The need to validate the derived formulations led to a parametric analysis involving 27 geometrical configurations of Square Hollow Section (SHS) profiles with rectangular holes subjected to displacements along the axis of the hollow profile; the parametric analysis was conducted through numerical simulations using Finite Element software.

- -

- The primary parameters obtained from the numerical simulations included initial stiffness, yield strength, and ultimate strength of the analysed ttt/ttc components; these parameters revealed a consistent relationship between yield and ultimate strength, maintaining a ratio of 1:1.5.

- -

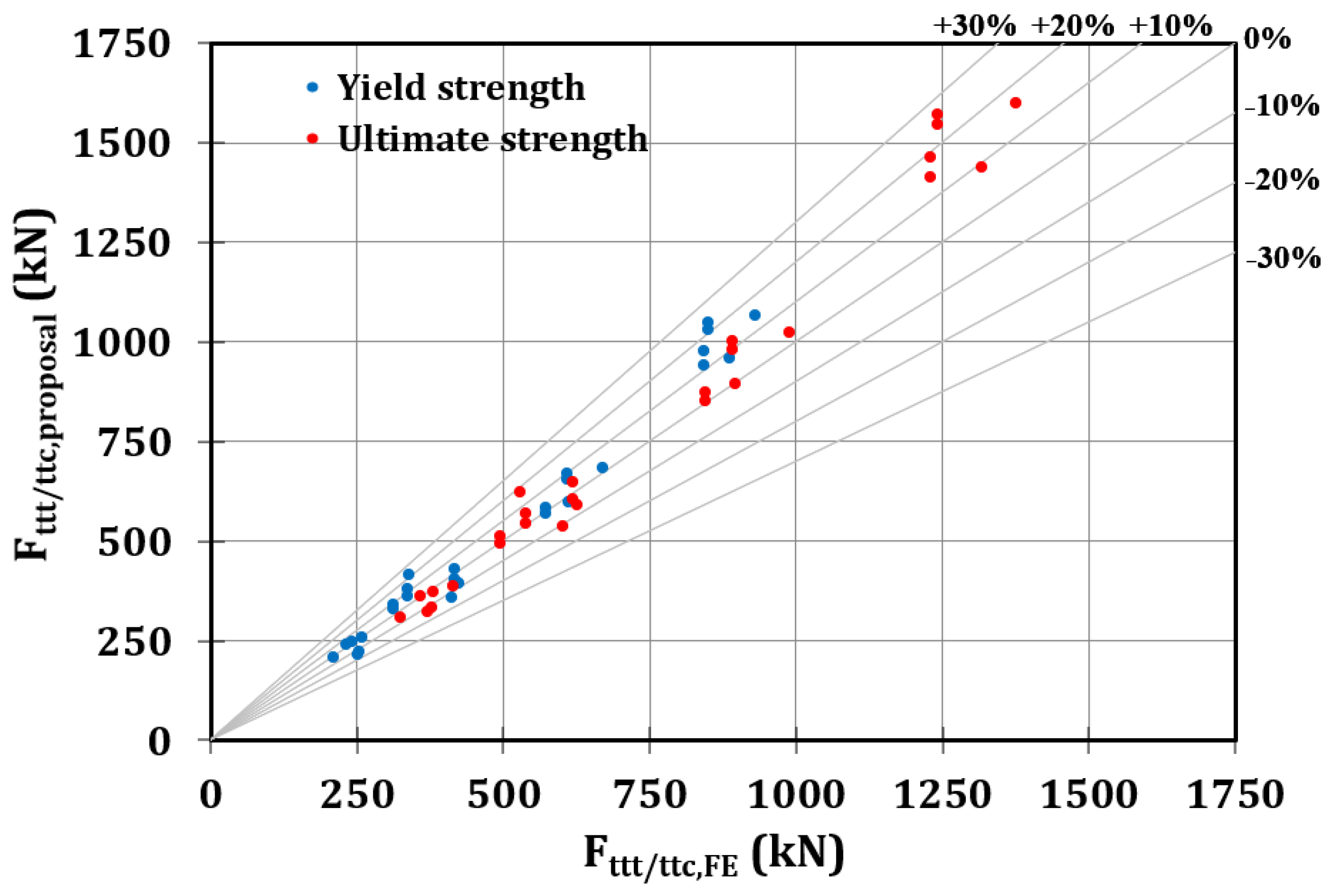

- The stiffness and strength values obtained from the 27 numerical simulations were compared with those derived from the analytical formulations developed in the initial phase of this study; the comparisons demonstrated the effectiveness of the proposed formulations since the average ratio between the analytical predictions and the numerical simulations was approximately 1.00 (with a coefficient of variation of about 10% in relation to the initial stiffness), while the average was approximately 1.04 (with a coefficient of variation of about 10% in relation to the yield and ultimate strength).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kanakubo, T.; Yonemaru, K.; Fukuyama, H.; Fujisawa, M.; Sonobe, Y. Bond performance of concrete members reinforced with FRP bars. Am. Concr. Inst. ACI Spec. Publ. 1993, 138, 767–788. [Google Scholar]

- Cucuzza, R.; Domaneschi, M.; Camata, G.; Marano, G.C.; Formisano, A.; Brigante, D. FRCM retrofitting techniques for masonry walls: A literature review and some laboratory tests. Procedia Struct. Integr. 2023, 44, 2190–2197. [Google Scholar] [CrossRef]

- Narayanan, P.; Deivanayagam, M. Retrofitting and rehabilitation of masonry structures using FRP composites. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Wu, C.; Ma, G.; Hwang, H.J. Bond performance of spliced GFRP bars in pre-damaged concrete beams retrofitted with CFRP and UHCP. Eng. Struct. 2023, 292, 116523. [Google Scholar] [CrossRef]

- Pall, A.C.; Marsh, C. Response of Friction Damped Braced Frames. J. Struct. Div. 1982, 108, 1313–1323. [Google Scholar] [CrossRef]

- Grigorian, C.E.; Popov, E.P. Energy Dissipation with Slotted Bolted Connections; Earthquake Engineering Research Centre: Berkley, CA, USA, 1994. [Google Scholar]

- Yang, T.S.; Popov, E.P. Experimental and Analytical Studies of Steel Connections and Energy Dissipators; UCB/EERC-95/13; Earthquake Engineering Research Center: Berkley, CA, USA, 1995. [Google Scholar]

- Ricles, J.M.; Sause, R.; Peng, S.W.; Lu, L.W. Experimental evaluation of earthquake resistant posttensioned steel connections. J. Struct. Eng. 2002, 128, 850–859. [Google Scholar] [CrossRef]

- Khoo, H.H.; Clifton, C.; Butterworth, J.; MacRae, G. Experimental study of full-scale self-centring sliding hinge joint connections with friction ring springs. J. Earthq. Eng. 2013, 17, 972–997. [Google Scholar] [CrossRef]

- Latour, M.; Piluso, V.; Rizzano, G. Free from damage beam-to-column joints: Testing and design of DST connections with friction pads. Eng. Struct. 2015, 85, 219–233. [Google Scholar] [CrossRef]

- Freddi, F.; Galasso, C.; Cremen, G.; Dall’Asta, A.; Di Sarno, L.; Giaralis, A.; Gutiérrez-Urzúa, F.; Málaga-Chuquitaype, C.; Mitoulis, S.A.; Petrone, C.; et al. Innovations in earthquake risk reduction for resilience: Recent advances and challenges. Int. J. Disaster Risk Reduct. 2021, 60, 102267. [Google Scholar] [CrossRef]

- Fang, C.; Wang, W.; Qiu, C.; Hu, S.; Macrae, G.A.; Eatherton, M.R. Seismic resilient steel structures: A review of research, practice, challenges and opportunities. J. Constr. Steel Res. 2022, 191, 107172. [Google Scholar] [CrossRef]

- Castiglioni, C.A.; Kanyilmaz, A.; Salvatore, W.; Morelli, F.; Piscini, A.; Hjiaj, M.; Couchaux, M.; Calado, L.; Jorge Proenca Sio, J.; Raso, S.; et al. EU-RFS Project LASTEICON 709807, 2016–2020. Available online: www.lasteicon.eu (accessed on 1 January 2023).

- Makino, Y.; Kurobane, Y.; Paul, J.C.; Orita, Y.; Hiraishi, K. Ultimate capacity of gusset plate-to-tube joints under axial and in plane bending loads. In Proceedings of the 4th International Symposium on Tubular Structues, Delft, The Netherlands, 26–28 June 1991; pp. 424–434. [Google Scholar]

- Makino, Y.; Kurobane, Y.; Ochi, K.; van der Vegte, G.; Wilmshurst, S.R. Database of test and numerical analysis results for unstiffened tubular joints. IIW Doc. 1996, XV-E-96-220. [Google Scholar]

- EN 1993-1-8; Eurocode 3: Design of Steel Structures; Part 1–8: Design of Joints. CEN European Committee for Standardization: Brussels, Belgium, 2005.

- AIJ. Recommendations for the Design and Fabrication of Tubular Truss Structures in Steel; Architectural Institute of Japan: Shiba, Japan, 2002. [Google Scholar]

- Sawada, Y.; Idogaki, S.; Skeia, K. Static and fatigue tests on T-joints stiffened by an internal ring. In Proceedings of the Offshore Technology Conference OTC 3422, Houston, TX, USA, April 1979. [Google Scholar]

- Khador, M.; Chan, T. Cyclic behaviour of external diaphragm joint to CHS column with built-in replaceable links. Steel Constr. 2016, 9, 331–338. [Google Scholar] [CrossRef]

- Li, L.; Wang, W.; Chen, Y.; Lu, Y. Experimental investigation of beam-to-tubular column moment connections under column removal scenario. J. Constr. Steel Res. 2013, 88, 244–255. [Google Scholar] [CrossRef]

- Wang, W.; Chen, Y.; Li, W. Bidirectional seismic performance of steel beam to circular tubular column connections with outer diaphragm. Eartq. Eng. Struct. Dyn. 2011, 40, 1063–1081. [Google Scholar] [CrossRef]

- Zhao, X.L.; Packer, J.A. Tests and design of concrete-filled elliptical hollow section stub columns. Thin-Walled Struct. 2009, 47, 617–628. [Google Scholar] [CrossRef]

- Alostaz, Y.M.; Schneider, S.P. Connections to concrete-filled steel tubes. In Structural Engineering; Series No. 613; University of Illinois at Urbana-Champaign: Champaign, IL, USA, 1996. [Google Scholar]

- Quan, C.; Wang, W.; Zhou, J. Cyclic behavior of stiffened joints between concrete-filled steel tubular column and steel beam with narrow outer diaphragm and partial joint penetration welds. Front. Struct. Civ. Eng. 2016, 10, 333–344. [Google Scholar] [CrossRef]

- Li, X.; Xiao, Y.; Wu, Y.T. Seismic behavior of exterior connections with steel beams bolted to CFT columns. J. Constr. Steel Res. 2009, 65, 1438–1446. [Google Scholar] [CrossRef]

- Voth, A.; Packer, J.A. Branch Plate-to-Circular Hollow Structural Section Connections. I: Experimental Investigation and Finite-Element Modeling. J. Struct. Eng. 2012, 138, 995–1006. [Google Scholar] [CrossRef]

- Kanyilmaz, A.; Castiglioni, C.; Brambilla, G.; Gjoka, K.; Galazzi, A.; Raso, S.; Valli, A.; Brugnolli, M.; Hojda, R. Experimental assessment of tolerances for the fabrication of laser-cut steel joints. Ce/Pap. 2017, 1, 776–785. [Google Scholar] [CrossRef]

- Kanyilmaz, A. The problematic nature of steel hollow section joint fabrication, and a remedy using laser cutting technology: A review of research, applications, opportunities. Eng. Struct. 2019, 183, 1027–1048. [Google Scholar] [CrossRef]

- De Winkel, G.D. The Static Strength of I-Beam to Circular Hollow Section. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1998. [Google Scholar]

- Voth, A. Branch Plate-to-Circular Hollow Structural Section Connections. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2020. [Google Scholar]

- Das, R.; Castiglioni, C.A.; Couchaux, M.; Hoffmeister, B.; Degee, H. Design and analysis of laser-cut based moment resisting passing-through I-beam-to-CHS column joints. J. Constr. Steel Res. 2020, 169, 106015. [Google Scholar] [CrossRef]

- Couchaux, M.; Vyhlas, V.; Kanyilmaz, A.; Hjiaj, M. Passing-through I-beam-to-CHS column joints made by laser cutting technology: Experimental tests and design model. J. Constr. Steel Res. 2021, 176, 106298. [Google Scholar] [CrossRef]

- Di Benedetto, S.; Latour, M.; Rizzano, G. Chord failure resistance of 3D cut welded connections with CHS columns and through I-BEAMS. Thin-Walled Struct. 2020, 154, 106821. [Google Scholar] [CrossRef]

- Di Benedetto, S.; Latour, M.; Rizzano, G. Assessment of the stiffness of 3D cut welded connections with CHS columns and through I-BEAMS. Structures 2020, 27, 247–258. [Google Scholar] [CrossRef]

- Di Benedetto, S.; Latour, M.; Rizzano, G. Stiffness Prediction of Connections between CHS Tubes and Externally Welded I-Beams: FE Analyses and Analytical Study. Materials 2020, 13, 3030. [Google Scholar] [CrossRef] [PubMed]

- Latour, M.; Di Benedetto, S.; Saldutti, A.; Rizzano, G.; Kanyilmaz, A.; Castiglioni, C.A. Component modelling of 3D laser cut joints with CHS columns and through-all members. Thin-Walled Struct. 2023, 182, 110238. [Google Scholar] [CrossRef]

- Latour, M.; Di Benedetto, S.; Francavilla, A.B.; Saldutti, A.; Rizzano, G. Mechanical Modelling of the Strength and Stiffness of Circular Hollow Section Tube under Localised Transverse Compression and Tension. Materials 2023, 16, 2641. [Google Scholar] [CrossRef]

- Steenhuis, M.; Jaspart, J.P.; Gomes, F.; Leino, T. Application of the component method to steel joints. In Proceedings of the Control of the Semi-Rigid Behaviour of Civil Engineering Structural Connections Conference, Liege, Belgium, 17–19 September 1998. [Google Scholar]

- Tschemmernegg, F.; Rubin, A.; Pavlov, A. Application of the component method to composite joints. In Proceedings of the Control of the Semi-Rigid Behaviour of Civil Engineering Structural Connections Conference, Liege, Belgium, 17–19 September 1998. [Google Scholar]

- Wald, F.; Gresnigt, A.M.; Weynand, K.; Jaspart, J.P. Application of the component method to column bases. In Proceedings of the Control of the Semi-Rigid Behaviour of Civil Engineering Structural Connections Conference, Liege, Belgium, 17–19 September 1998. [Google Scholar]

- da Silva, L.S.; Santiago, A.; Vila Real, P. Application of the Component Method to Steel Joints under Fire Loading; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar] [CrossRef]

- Faella, C.; Piluso, V.; Rizzano, G. Structural Steel Semirigid Connections; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Sato, A.; Latour, M.; de la Peña, A.; Di Benedetto, S.; Francavilla, A.B.; Rizzano, G. Strength of connections between SHS columns and through plates. Ce/Papers 2023, 6, 1470–1475. [Google Scholar] [CrossRef]

- Abaqus. Analysis User’s Manual Version 6.17; Abaqus Inc.: Palo Alto, CA, USA, 2017. [Google Scholar]

- Faralli, A.C. Large Deformation of T-Stub Connection in Bolted Steel Joints. Ph.D. Thesis, University College of London, London, UK, 2019. [Google Scholar]

- Pavlovic, M.; Markovic, Z.; Veljkovic, M.; Budevac, D. Bolted shear connectors vs. headed studs behaviour in push-out tests. J. Constr. Steel Res. 2013, 88, 134–149. [Google Scholar] [CrossRef]

- EN 1993-1-5; Eurocode 3: Design of Steel Structures; Part 1–5: Piling. CEN European Committee for Standardization: Brussels, Belgium, 2006.

| Case | b0 (mm) | t0 (mm) | b1 (mm) | t1 (mm) | β = b1/b0 | γ = b0/(2t0) | τ = t1/t0 |

|---|---|---|---|---|---|---|---|

| 1 | 150.00 | 5.00 | 82.00 | 7.40 | 0.55 | 15.00 | 1.48 |

| 2 | 150.00 | 5.00 | 91.00 | 8.00 | 0.61 | 15.00 | 1.60 |

| 3 | 150.00 | 5.00 | 100.00 | 8.50 | 0.67 | 15.00 | 1.70 |

| 4 | 180.00 | 5.00 | 91.00 | 8.00 | 0.51 | 18.00 | 1.60 |

| 5 | 180.00 | 5.00 | 100.00 | 8.50 | 0.56 | 18.00 | 1.70 |

| 6 | 180.00 | 5.00 | 110.00 | 9.20 | 0.61 | 18.00 | 1.84 |

| 7 | 200.00 | 6.00 | 110.00 | 9.20 | 0.55 | 16.67 | 1.53 |

| 8 | 200.00 | 6.00 | 120.00 | 9.80 | 0.60 | 16.67 | 1.63 |

| 9 | 200.00 | 6.00 | 135.00 | 10.20 | 0.68 | 16.67 | 1.70 |

| 10 | 220.00 | 6.00 | 120.00 | 9.80 | 0.55 | 18.33 | 1.63 |

| 11 | 220.00 | 6.00 | 135.00 | 10.20 | 0.61 | 18.33 | 1.70 |

| 12 | 220.00 | 6.00 | 150.00 | 10.70 | 0.68 | 18.33 | 1.78 |

| 13 | 250.00 | 6.30 | 110.00 | 9.20 | 0.44 | 19.84 | 1.46 |

| 14 | 250.00 | 6.30 | 120.00 | 9.80 | 0.48 | 19.84 | 1.56 |

| 15 | 250.00 | 6.30 | 135.00 | 10.20 | 0.54 | 19.84 | 1.62 |

| 16 | 250.00 | 8.00 | 150.00 | 10.70 | 0.60 | 15.63 | 1.34 |

| 17 | 250.00 | 8.00 | 160.00 | 11.50 | 0.64 | 15.63 | 1.44 |

| 18 | 250.00 | 8.00 | 170.00 | 12.70 | 0.68 | 15.63 | 1.59 |

| 19 | 300.00 | 8.00 | 160.00 | 11.50 | 0.53 | 18.75 | 1.44 |

| 20 | 300.00 | 8.00 | 170.00 | 12.70 | 0.57 | 18.75 | 1.59 |

| 21 | 300.00 | 8.00 | 180.00 | 13.50 | 0.60 | 18.75 | 1.69 |

| 22 | 350.00 | 10.00 | 180.00 | 13.50 | 0.51 | 17.50 | 1.35 |

| 23 | 350.00 | 10.00 | 190.00 | 14.60 | 0.54 | 17.50 | 1.46 |

| 24 | 350.00 | 10.00 | 200.00 | 16.00 | 0.57 | 17.50 | 1.60 |

| 25 | 400.00 | 10.00 | 180.00 | 13.50 | 0.45 | 20.00 | 1.35 |

| 26 | 400.00 | 10.00 | 190.00 | 14.60 | 0.48 | 20.00 | 1.46 |

| 27 | 400.00 | 10.00 | 200.00 | 16.00 | 0.50 | 20.00 | 1.60 |

| Case | kttt/ttc,Abaqus (N/mm) | Fy,ttt/ttc,Abaqus (kN) | Fu,ttt/ttc,Abaqus (kN) | Case | kttt/ttc,Abaqus (N/mm) | Fy,ttt/ttc,Abaqus (kN) | Fu,ttt/ttc,Abaqus (kN) |

|---|---|---|---|---|---|---|---|

| 1 | 3375498 | 211 | 325 | 15 | 4229122 | 418 | 618 |

| 2 | 3895147 | 252 | 371 | 16 | 6137837 | 573 | 844 |

| 3 | 4272330 | 254 | 379 | 17 | 6137837 | 573 | 844 |

| 4 | 3107079 | 231 | 358 | 18 | 6751198 | 612 | 895 |

| 5 | 3385264 | 242 | 380 | 19 | 5362997 | 610 | 891 |

| 6 | 3815627 | 259 | 415 | 20 | 5362997 | 610 | 891 |

| 7 | 4095428 | 314 | 495 | 21 | 6159641 | 670 | 988 |

| 8 | 4095428 | 314 | 495 | 22 | 6561348 | 844 | 1231 |

| 9 | 5445403 | 412 | 602 | 23 | 6993271 | 888 | 1317 |

| 10 | 4081222 | 337 | 539 | 24 | 6561348 | 844 | 1231 |

| 11 | 4081223 | 337 | 539 | 25 | 5856770 | 852 | 1242 |

| 12 | 5328507 | 425 | 626 | 26 | 5856770 | 852 | 1242 |

| 13 | 4247004 | 418 | 618 | 27 | 6529677 | 930 | 1377 |

| 14 | 3481750 | 340 | 529 |

| Angle (°) | Mean (kproposal/kAbaqus) | Angle (°) | Mean (kproposal/kAbaqus) | Angle (°) | Mean (kproposal/kAbaqus) |

|---|---|---|---|---|---|

| 30 | 0.64 | 36 | 0.80 | 42 | 0.99 |

| 31 | 0.66 | 37 | 0.83 | 43 | 1.03 |

| 32 | 0.69 | 38 | 0.86 | 44 | 1.06 |

| 33 | 0.71 | 39 | 0.89 | 45 | 1.10 |

| 34 | 0.74 | 40 | 0.92 | ||

| 35 | 0.77 | 41 | 0.96 |

| Case | t0 (mm) | β | kttt/ttc,FE (N/mm) | kttt/ttc,proposal (N/mm) | kttt/ttc,proposal/kttt/ttc,FE |

|---|---|---|---|---|---|

| 1 | 5.00 | 0.55 | 3375498 | 3256461 | 0.96 |

| 2 | 5.00 | 0.61 | 3895147 | 3902905 | 1.00 |

| 3 | 5.00 | 0.67 | 4272330 | 4784420 | 1.12 |

| 4 | 5.00 | 0.51 | 3107079 | 2913450 | 0.94 |

| 5 | 5.00 | 0.56 | 3385264 | 3351959 | 0.99 |

| 6 | 5.00 | 0.61 | 3815626 | 3902905 | 1.02 |

| 7 | 6.00 | 0.55 | 4095428 | 3907754 | 0.95 |

| 8 | 6.00 | 0.60 | 4095428 | 4538036 | 1.11 |

| 9 | 6.00 | 0.68 | 5445403 | 5956173 | 1.09 |

| 10 | 6.00 | 0.55 | 4081222 | 3907754 | 0.96 |

| 11 | 6.00 | 0.61 | 4081223 | 4683486 | 1.15 |

| 12 | 6.00 | 0.68 | 5328507 | 5956173 | 1.12 |

| 13 | 6.30 | 0.44 | 4247004 | 3063175 | 0.72 |

| 14 | 6.30 | 0.48 | 3481750 | 3390437 | 0.97 |

| 15 | 6.30 | 0.54 | 4229122 | 3988046 | 0.94 |

| 16 | 8.00 | 0.60 | 6137837 | 6050715 | 0.99 |

| 17 | 8.00 | 0.64 | 6137837 | 6891092 | 1.12 |

| 18 | 8.00 | 0.68 | 6751198 | 7941564 | 1.18 |

| 19 | 8.00 | 0.53 | 5362997 | 4924252 | 0.92 |

| 20 | 8.00 | 0.57 | 5362997 | 5523037 | 1.03 |

| 21 | 8.00 | 0.60 | 6159641 | 6050715 | 0.98 |

| 22 | 10.00 | 0.51 | 6561347 | 5826900 | 0.89 |

| 23 | 10.00 | 0.54 | 6993271 | 6330232 | 0.91 |

| 24 | 10.00 | 0.57 | 6561347 | 6903796 | 1.05 |

| 25 | 10.00 | 0.45 | 5856770 | 4984964 | 0.85 |

| 26 | 10.00 | 0.48 | 5856770 | 5381646 | 0.92 |

| 27 | 10.00 | 0.50 | 6529677 | 5672545 | 0.87 |

| Mean | 0.99 | ||||

| Standard deviation | 0.10 | ||||

| Coefficient of variation | 0.10 | ||||

| Case | Fy,ttt/ttc,FE (kN) | Fy,ttt/ttc,proposal (kN) | Fy,ttt/ttc,proposal/Fy,ttt/ttc,FE | Fu,ttt/ttc,FE (kN) | Fu,ttt/ttc,proposal (kN) | Fu,ttt/ttc,proposal/Fu,ttt/ttc,FE |

|---|---|---|---|---|---|---|

| 1 | 211 | 206 | 0.97 | 325 | 309 | 0.95 |

| 2 | 252 | 214 | 0.85 | 371 | 321 | 0.87 |

| 3 | 254 | 222 | 0.87 | 379 | 333 | 0.88 |

| 4 | 231 | 241 | 1.04 | 358 | 361 | 1.01 |

| 5 | 242 | 249 | 1.03 | 380 | 373 | 0.98 |

| 6 | 259 | 257 | 0.99 | 415 | 386 | 0.93 |

| 7 | 314 | 330 | 1.05 | 495 | 495 | 1.00 |

| 8 | 314 | 341 | 1.09 | 495 | 511 | 1.03 |

| 9 | 412 | 357 | 0.87 | 602 | 535 | 0.89 |

| 10 | 337 | 362 | 1.07 | 539 | 543 | 1.01 |

| 11 | 337 | 378 | 1.12 | 539 | 567 | 1.05 |

| 12 | 425 | 394 | 0.93 | 626 | 591 | 0.94 |

| 13 | 418 | 403 | 0.96 | 618 | 604 | 0.98 |

| 14 | 340 | 414 | 1.22 | 529 | 621 | 1.17 |

| 15 | 418 | 431 | 1.03 | 618 | 646 | 1.04 |

| 16 | 573 | 568 | 0.99 | 844 | 852 | 1.01 |

| 17 | 573 | 582 | 1.02 | 844 | 873 | 1.03 |

| 18 | 612 | 596 | 0.97 | 895 | 895 | 1.00 |

| 19 | 610 | 653 | 1.07 | 891 | 980 | 1.10 |

| 20 | 610 | 667 | 1.09 | 891 | 1001 | 1.12 |

| 21 | 670 | 682 | 1.02 | 988 | 1022 | 1.03 |

| 22 | 844 | 941 | 1.11 | 1230 | 1411 | 1.15 |

| 23 | 888 | 959 | 1.08 | 1316 | 1438 | 1.09 |

| 24 | 844 | 976 | 1.16 | 1230 | 1464 | 1.19 |

| 25 | 852 | 1030 | 1.21 | 1242 | 1544 | 1.24 |

| 26 | 852 | 1047 | 1.23 | 1242 | 1571 | 1.26 |

| 27 | 930 | 1065 | 1.15 | 1377 | 1598 | 1.16 |

| Mean | 1.04 | 1.04 | ||||

| Standard deviation | 0.10 | 0.10 | ||||

| Coefficient of variation | 0.10 | 0.10 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Latour, M.; Di Benedetto, S.; Francavilla, A.B.; Elettore, G.; Rizzano, G. Stiffness and Strength of Square Hollow Section Tubes under Localised Transverse Actions. Metals 2023, 13, 1767. https://doi.org/10.3390/met13101767

Latour M, Di Benedetto S, Francavilla AB, Elettore G, Rizzano G. Stiffness and Strength of Square Hollow Section Tubes under Localised Transverse Actions. Metals. 2023; 13(10):1767. https://doi.org/10.3390/met13101767

Chicago/Turabian StyleLatour, Massimo, Sabatino Di Benedetto, Antonella Bianca Francavilla, Giuseppe Elettore, and Gianvittorio Rizzano. 2023. "Stiffness and Strength of Square Hollow Section Tubes under Localised Transverse Actions" Metals 13, no. 10: 1767. https://doi.org/10.3390/met13101767

APA StyleLatour, M., Di Benedetto, S., Francavilla, A. B., Elettore, G., & Rizzano, G. (2023). Stiffness and Strength of Square Hollow Section Tubes under Localised Transverse Actions. Metals, 13(10), 1767. https://doi.org/10.3390/met13101767