Identifying Optimal Hot Forming Conditions for AA6010 Alloy by Means of Elevated Temperature Tensile Testing

Abstract

1. Introduction

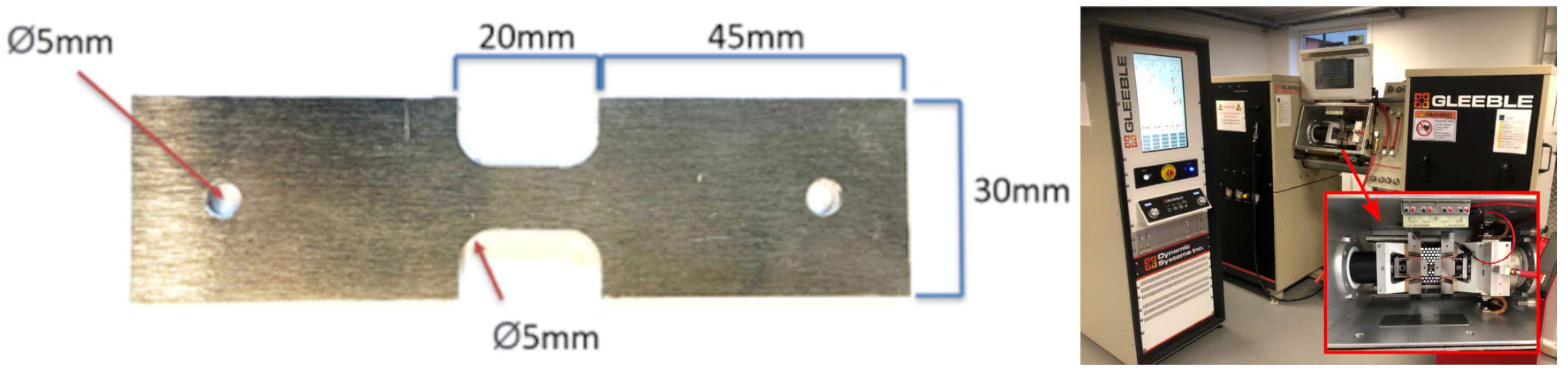

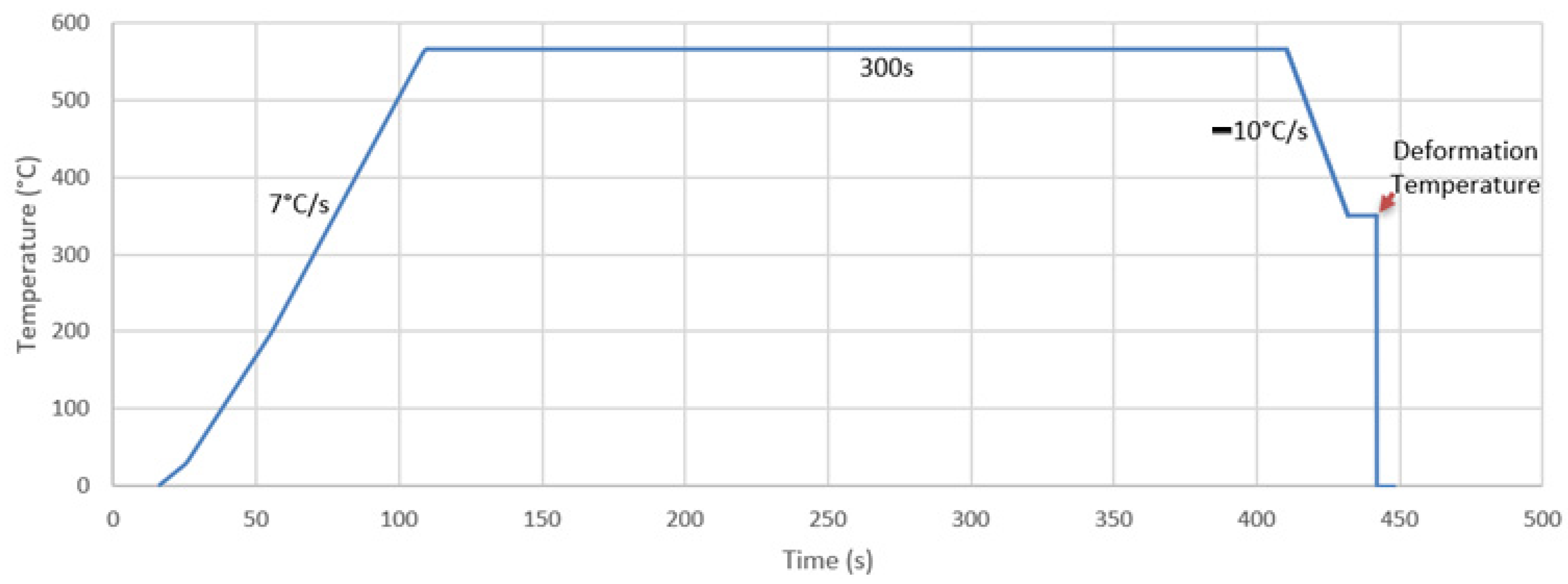

2. Materials and Methods

3. Results

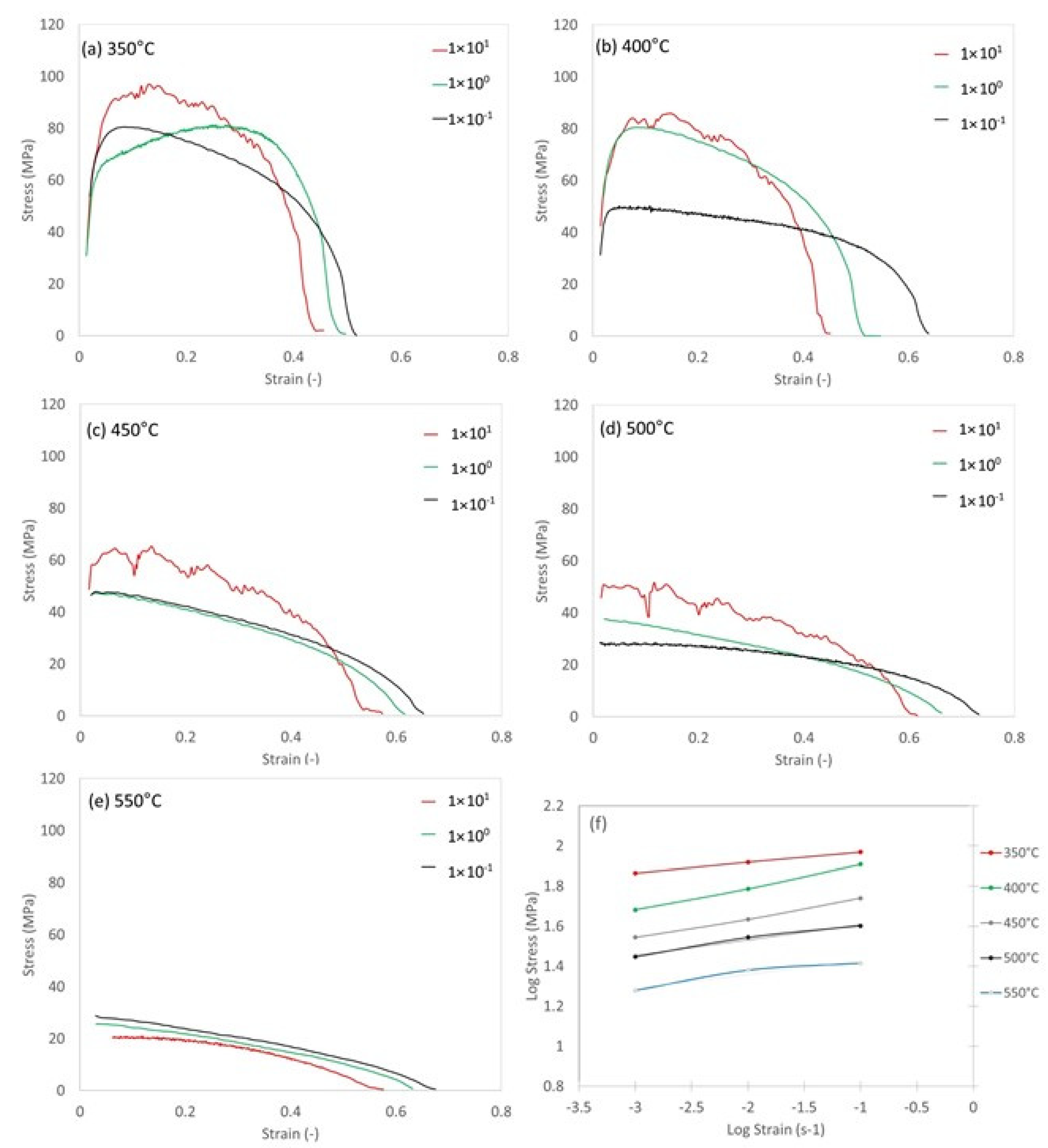

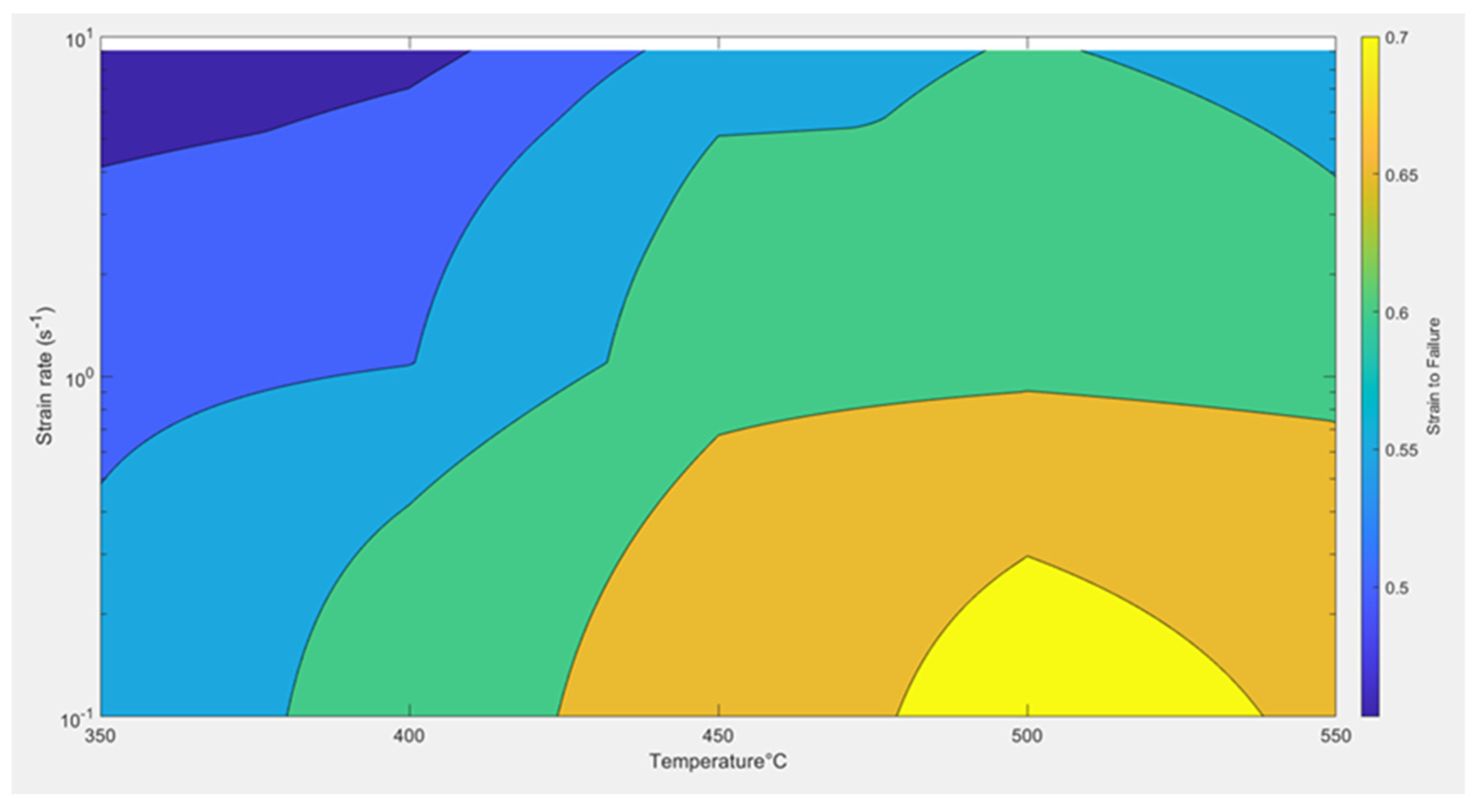

3.1. Elevated Temperature Formability

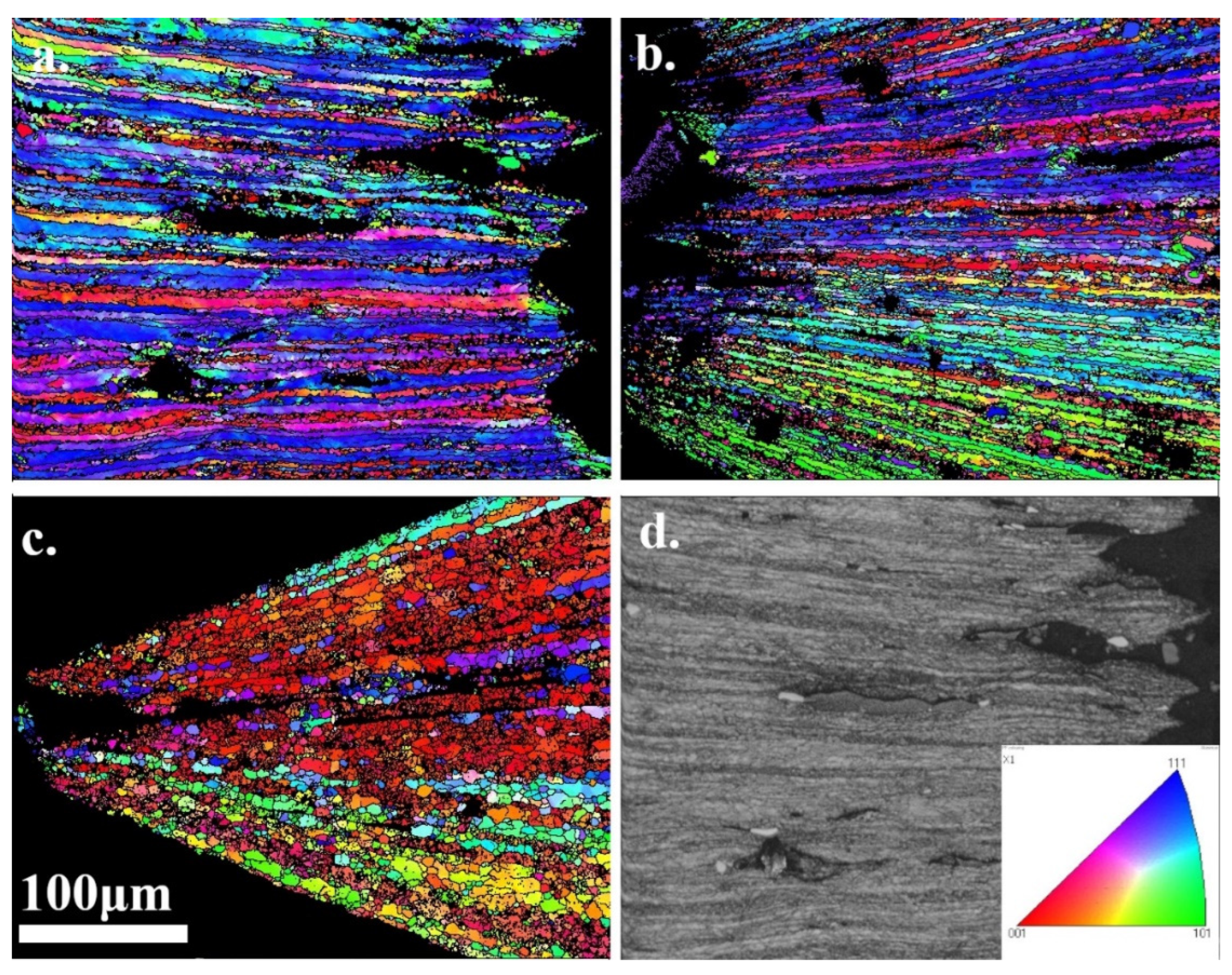

3.2. EBSD Analysis of Deformed Specimens

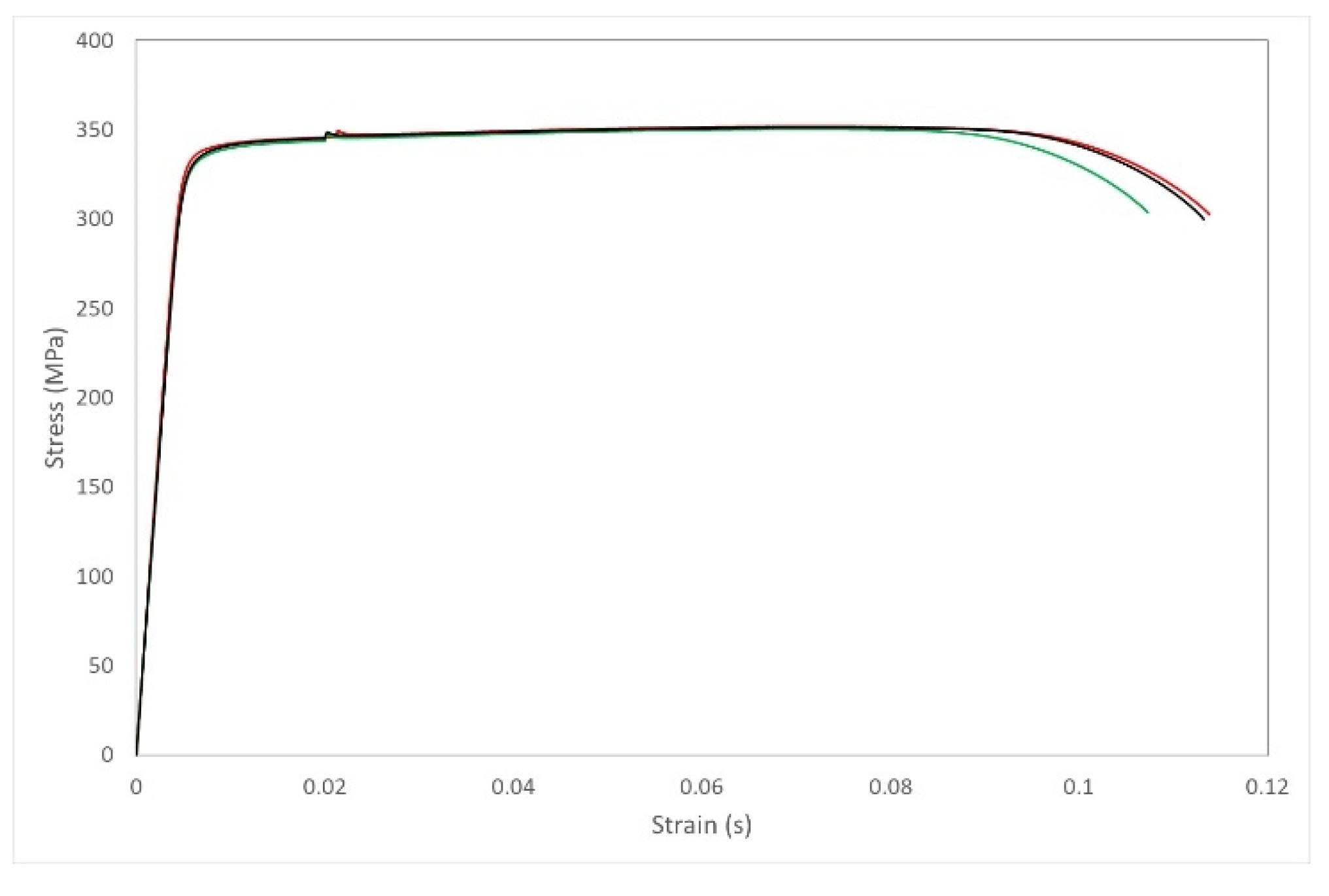

3.3. Post-Forming Heat Treatment

4. Discussion

5. Conclusions

- Optimal forming conditions for AA6010 in terms of peak ductility were established as 500 °C and 1 × 10−1 s−1 achieving a strain to failure of 0.7.

- Industrially usable levels of deformation are achievable under sub-optimal conditions at 450 °C and 1 × 101 s−1 achieving a strain to failure of 0.55.

- Dislocation creep and dynamic recrystallization are the dominant deformation mechanisms within AA6010 during HFQ like deformation.

- Following rapid aging treatments the material can achieve a yield strength of 335 MPa.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Czerwinski, F. Current Trends in Automotive Lightweighting Strategies and Materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef]

- Milovanoff, A.; Posen, I.D.; MacLean, H.L. Electrification of Light-Duty Vehicle Fleet Alone Will Not Meet Mitigation Targets. Nat. Clim. Chang. 2020, 10, 1102–1107. [Google Scholar] [CrossRef]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent Development in Aluminium Alloys for the Automotive Industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Long, R.S.; Boettcher, E.; Crawford, D. Current and Future Uses of Aluminum in the Automotive Industry. JOM 2017, 69, 2635–2639. [Google Scholar] [CrossRef]

- Hirsch, J. Recent Development in Aluminium for Automotive Applications. Trans. Nonferrous Met. Soc. China 2014, 24, 1995–2002. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Wang, L.; Wang, K.; Zhu, B.; Zhang, Y. Hot Stamping of a B-Pillar Reinforced Panel with 7075 Aluminum Alloy and the Feasibility Study of Short-Time Aging. Front. Mater. 2021, 7, 444. [Google Scholar] [CrossRef]

- Zheng, K.; Politis, D.J.; Wang, L.; Lin, J. A Review on Forming Techniques for Manufacturing Lightweight Complex—Shaped Aluminium Panel Components. Int. J. Light. Mater. Manuf. 2018, 1, 55–80. [Google Scholar] [CrossRef]

- Krajewski, P.E.; Schroth, J.G. Overview of Quick Plastic Forming Technology. Mater. Sci. Forum 2007, 551–552, 3–12. [Google Scholar] [CrossRef]

- Dunwoody, B.J. The Production of Automotive Body Panels in 5083 SPF Aluminium Alloy. In Proceedings of the Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2001; Volume 357–359, pp. 59–64. [Google Scholar]

- Meng, Q.; Wang, B.; Fu, L.; Zhou, J.; Lin, J. The Influence of Process Parameters during Hot Stamping of Aa6111 Aluminum Alloy Sheet. In Proceedings of the Advanced Materials Research; Trans Tech Publications: Bäch, Switzerland, 2012; Volume 572, pp. 255–260. [Google Scholar]

- Rader, K.E.; Carter, J.T.; Hector, L.G.; Taleff, E.M. Plastic Deformation and Ductility of AA7075 and AA6013 at Warm Temperatures Suitable to Retrogression Forming. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2021, 52, 4003–4017. [Google Scholar] [CrossRef]

- El-Danaf, E.A.; Almajid, A.A.; Soliman, M.S. Hot Deformation of AA6082-T4 Aluminum Alloy. J. Mater. Sci. 2008, 43, 6324–6330. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, Z.; Wang, Z.; Zhu, B.; Wang, Y.; Zhang, Y. Formability and Lubrication of a B-Pillar in Hot Stamping with 6061 and 7075 Aluminum Alloy Sheets. In Proceedings of the Procedia Engineering; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; Volume 207, pp. 723–728. [Google Scholar]

- Ma, W.Y.; Wang, B.Y.; Fu, L.; Zhou, J.; Huang, M.D. Influence of Process Parameters on Deep Drawing of AA6111 Aluminum Alloy at Elevated Temperatures. J. Cent. South Univ. 2015, 22, 1167–1174. [Google Scholar] [CrossRef]

- Di Ciano, M.; DiCecco, S.; Esmaeili, S.; Wells, M.A.; Worswick, M.J. Coarsening of AA6013-T6 Precipitates during Sheet Warm Forming Applications. J. Mater. Eng. Perform. 2018, 27, 939–947. [Google Scholar] [CrossRef]

- EPO—European Publication Server. Available online: https://data.epo.org/publication-server/document?iDocId=6324311&iFormat=0 (accessed on 3 March 2022).

- Li, N.; Shao, Z.; Lin, J.; Dean, T.A. Investigation of Uniaxial Tensile Properties of AA6082 under HFQ® Conditions. Key Eng. Mater. 2016, 716, 337–344. [Google Scholar] [CrossRef]

- Mohamed, M.S.; Foster, A.D.; Lin, J.; Balint, D.S.; Dean, T.A. Investigation of Deformation and Failure Features in Hot Stamping of AA6082: Experimentation and Modelling. Int. J. Mach. Tools Manuf. 2012, 53, 27–38. [Google Scholar] [CrossRef]

- Liu, X.; Fakir, O.E.; Meng, L.; Sun, X.; Li, X.; Wang, L.L. Effects of Lubricant on the IHTC during the Hot Stamping of AA6082 Aluminium Alloy: Experimental and Modelling Studies. J. Mater. Process. Technol. 2018, 255, 175–183. [Google Scholar] [CrossRef]

- Barnes, A.J. Industrial Applications of Superplastic Forming: Trends and Prospects. In Proceedings of the Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2001; Volume 357–359, pp. 3–16. [Google Scholar]

- The Aluminum Association, Teal Seets. Available online: https://www.aluminum.org/sites/default/files/2021-10/Teal%20Sheet.pdf (accessed on 3 March 2022).

- Jia, X.D.; Wang, Y.N.; Zhou, Y.; Cao, M.Y. The Study on Forming Property at High Temperature and Processing Map of 2219 Aluminum Alloy. Metals 2021, 11, 77. [Google Scholar] [CrossRef]

- Wang, P.L.; Jiang, H.T.; Zhang, R.J.; Huang, S.Y. Study of Hot Deformation Behavior of 6082 Aluminum Alloy. In Proceedings of the Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2017; Volume 877, pp. 340–346. [Google Scholar]

- Taylor, S.; Kotadia, H.R. Microstructural Evolution of 316L Austenitic Stainless Steel during In-Situ Biaxial Deformation and Annealing. Mater. Charact. 2020, 163, 110288. [Google Scholar] [CrossRef]

- Sherby, O.D.; Wadsworth, J. Superplasticity-Recent Advances and Future Directions. Prog. Mater. Sci. 1989, 33, 169–221. [Google Scholar] [CrossRef]

- Chen, X.; Peng, Y.; Peng, S.; Yao, S.; Chen, C.; Xu, P. Flow and Fracture Behavior of Aluminum Alloy 6082-T6 at Different Tensile Strain Rates and Triaxialities. PLoS ONE 2017, 12, e0181983. [Google Scholar] [CrossRef] [PubMed]

| Element | Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Wt% | Balance | 0.8–1.2 | 0.5 | 0.15–0.6 | 0.2–0.8 | 0.6–1.0 | 0.1 | 0.25 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taylor, S.; Dhara, S.; Slater, C.; Kotadia, H. Identifying Optimal Hot Forming Conditions for AA6010 Alloy by Means of Elevated Temperature Tensile Testing. Metals 2023, 13, 76. https://doi.org/10.3390/met13010076

Taylor S, Dhara S, Slater C, Kotadia H. Identifying Optimal Hot Forming Conditions for AA6010 Alloy by Means of Elevated Temperature Tensile Testing. Metals. 2023; 13(1):76. https://doi.org/10.3390/met13010076

Chicago/Turabian StyleTaylor, Scott, Sisir Dhara, Carl Slater, and Hiren Kotadia. 2023. "Identifying Optimal Hot Forming Conditions for AA6010 Alloy by Means of Elevated Temperature Tensile Testing" Metals 13, no. 1: 76. https://doi.org/10.3390/met13010076

APA StyleTaylor, S., Dhara, S., Slater, C., & Kotadia, H. (2023). Identifying Optimal Hot Forming Conditions for AA6010 Alloy by Means of Elevated Temperature Tensile Testing. Metals, 13(1), 76. https://doi.org/10.3390/met13010076