Dynamic Behavior of Additively Manufactured FeCoCrNi High Entropy Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results

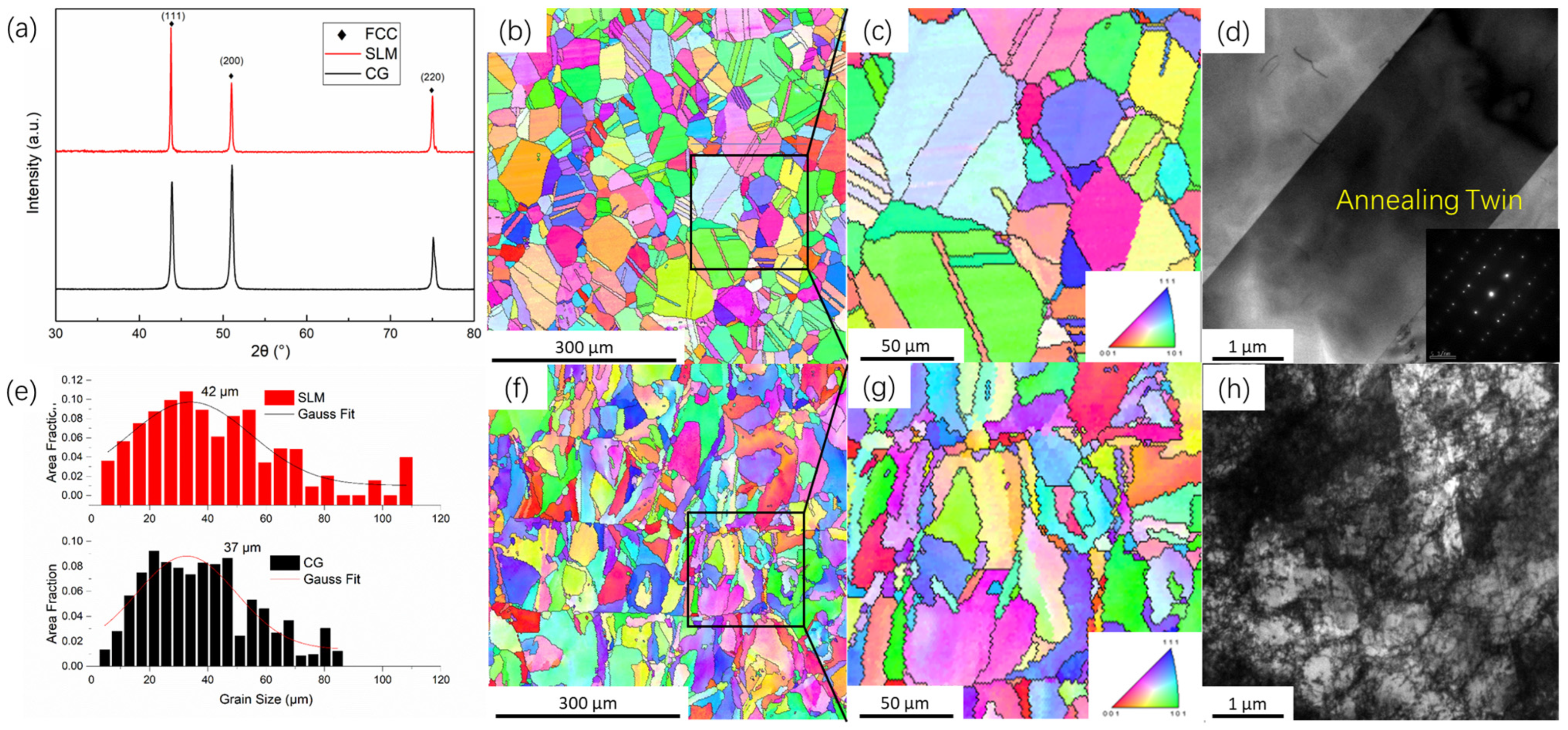

3.1. Microstructures

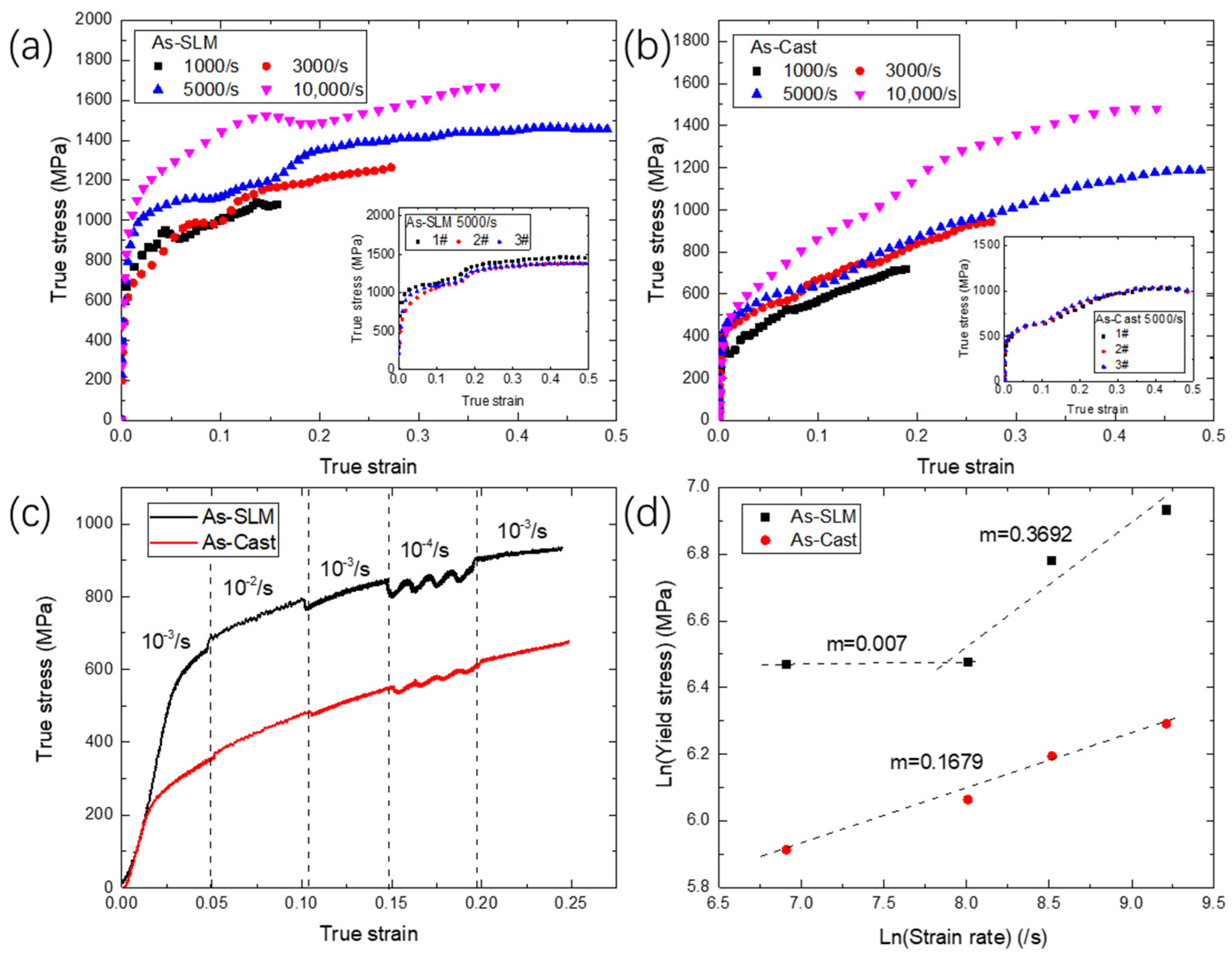

3.2. Mechanical Properties

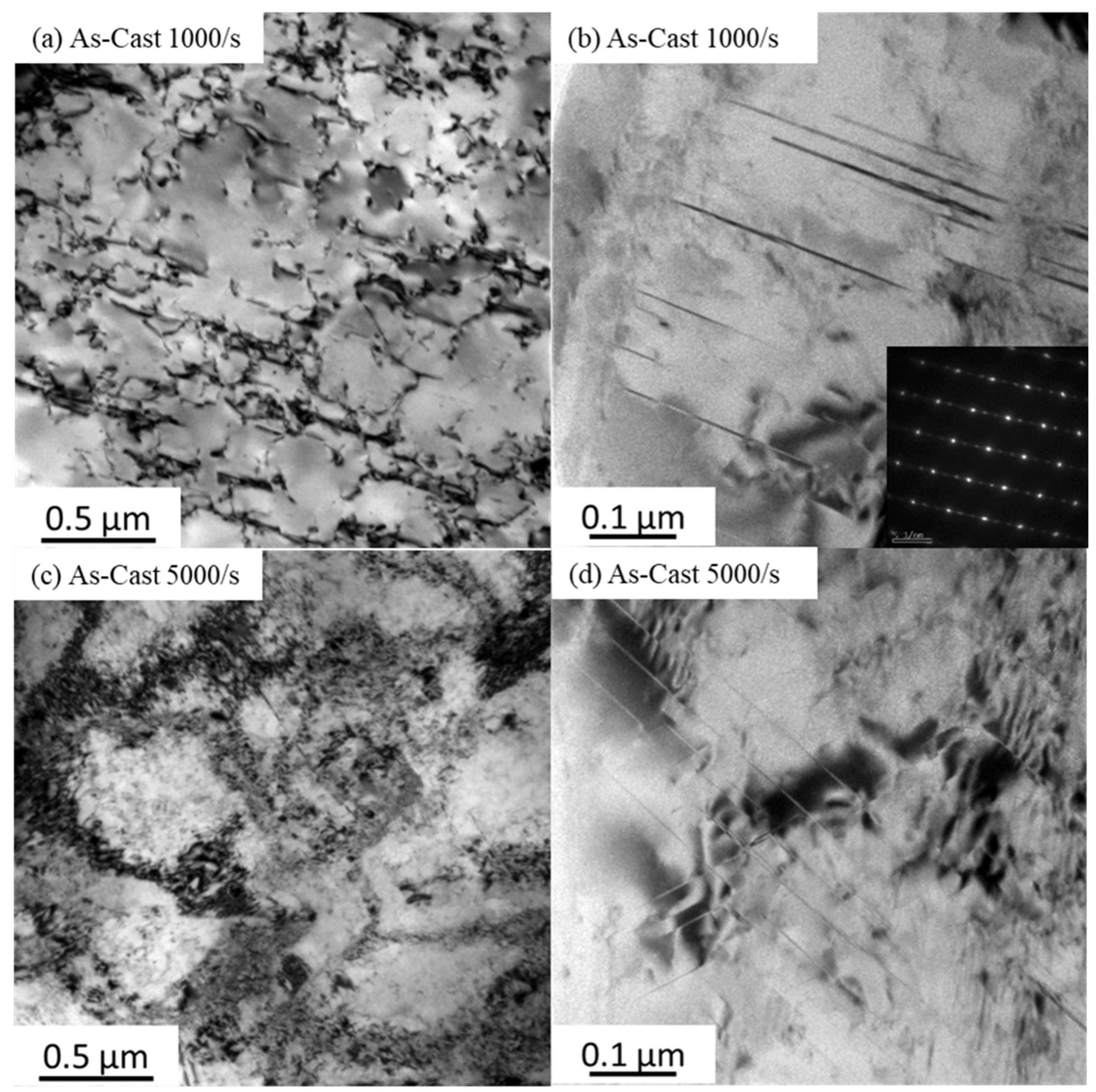

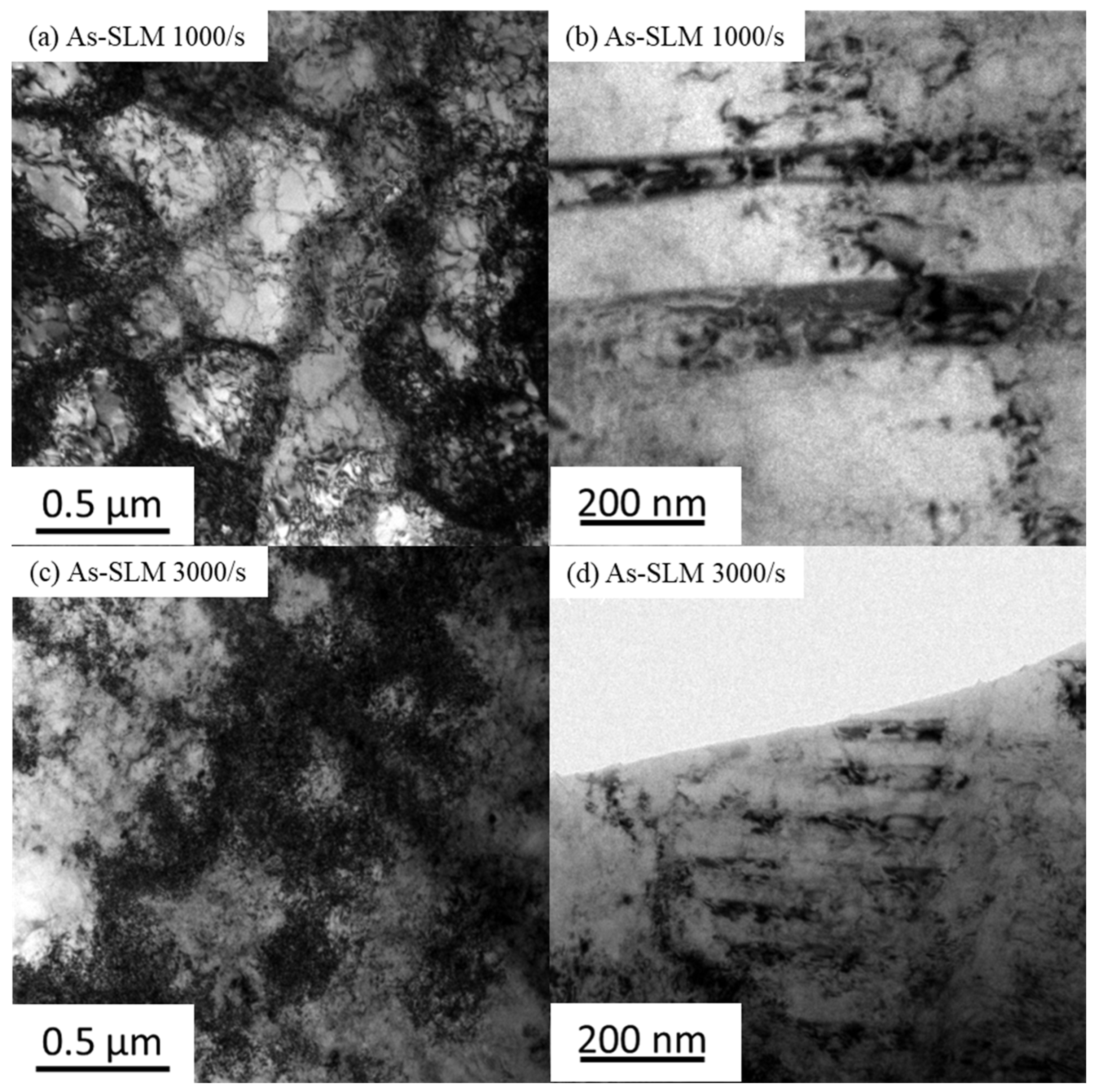

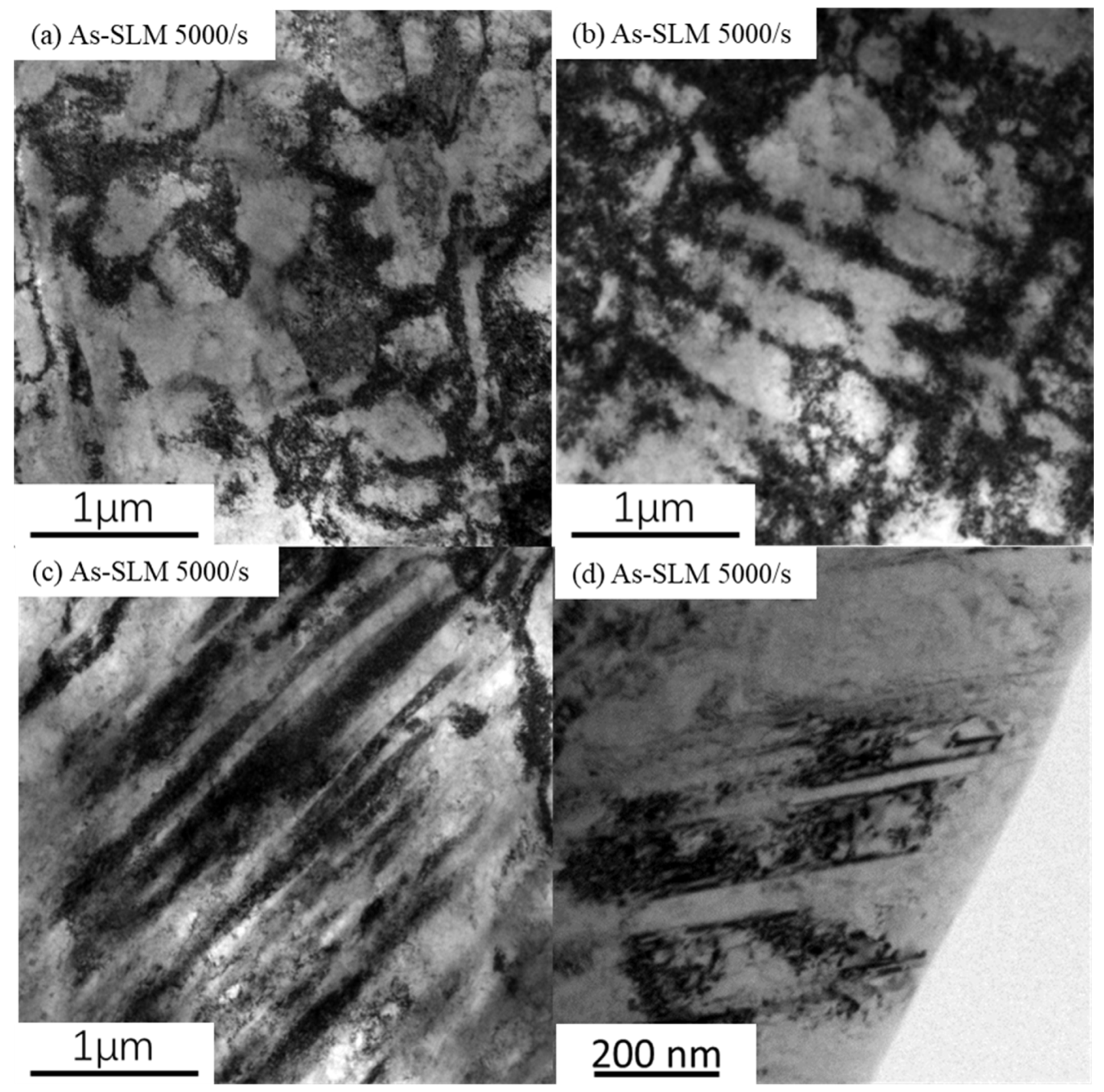

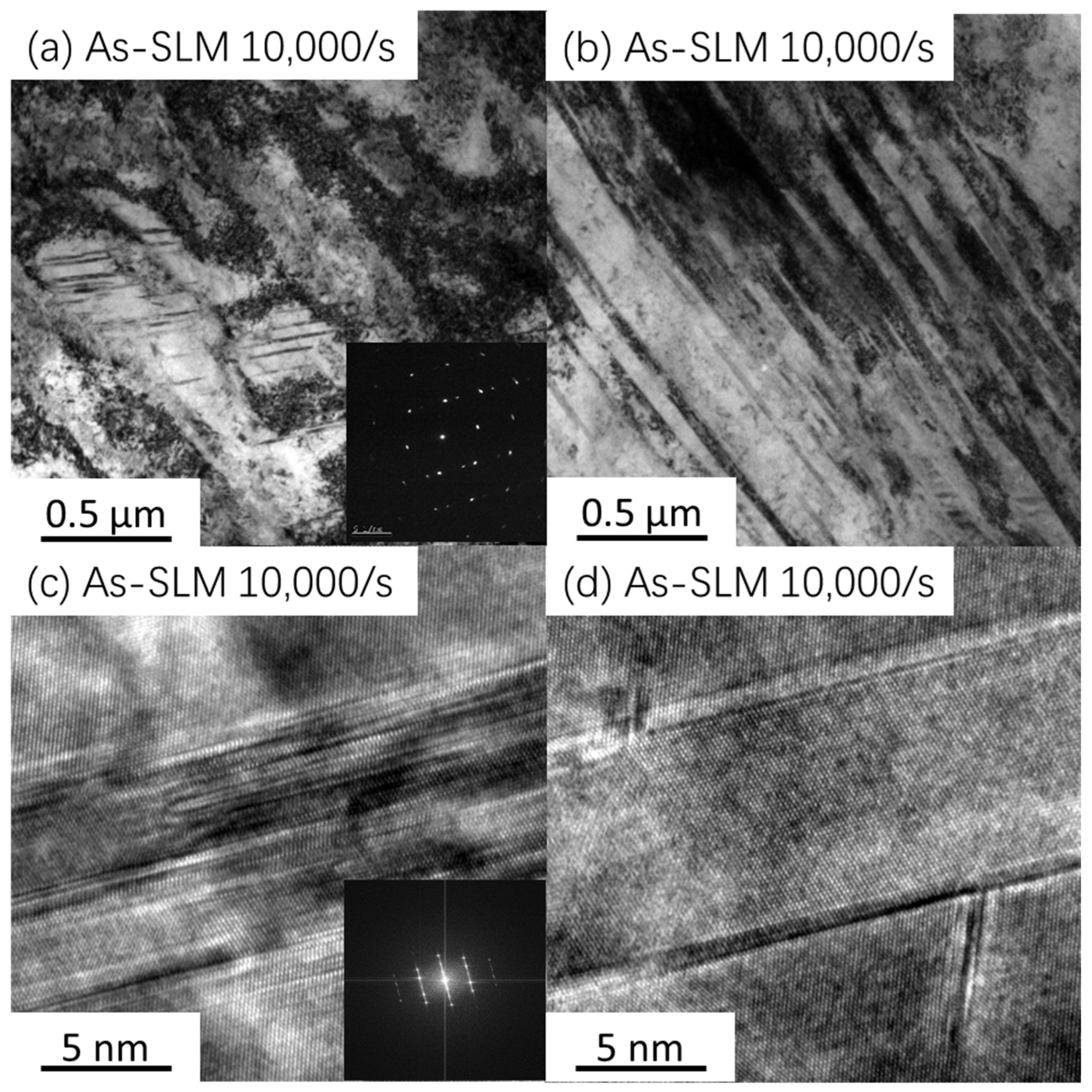

3.3. Deformed Microstructure

4. Discussion

4.1. Strain Rate Sensitivity

4.2. Microstructural Evolution

4.3. Dynamic Behavior

5. Conclusions

- (1)

- The As-SLM FeCoCrNi HEA showed a more excellent combination of toughness and yield stress than previously reported alloys due to the high density of deformation microbands and twins.

- (2)

- The dislocation cell structures contributed to high local stress concentration and facilitated the formation of microbands at strain rates of 1000/s and 3000/s. With further increase of strain rate, the deformation mechanism changed to twins.

- (3)

- The AS-SLM HEA showed a low strain rate sensitivity between strain rates of 1000/s and 3000/s due to the collective dislocation nucleation mechanism. At higher strain rates, the strain rate sensitivity increased rapidly.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; Zhao, S.; Ritchie, R.O.; Meyers, M.A. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater. Sci. 2019, 102, 296–345. [Google Scholar] [CrossRef]

- Lei, Z.; Liu, X.; Wu, Y.; Wang, H.; Jiang, S.; Wang, S.; Hui, X.; Wu, Y.; Gault, B.; Kontis, P.; et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature 2018, 563, 546–550. [Google Scholar] [CrossRef] [PubMed]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef]

- Zhang, T.W.; Ma, S.G.; Zhao, D.; Wu, Y.; Zhang, Y.C.; Wang, Z.H.; Qiao, J.W. Simultaneous enhancement of strength and ductility in a NiCoCrFe high-entropy alloy upon dynamic tension: Micromechanism and constitutive modeling. Int. J. Plast. 2020, 124, 226–246. [Google Scholar] [CrossRef]

- Zhao, S.; Li, Z.; Zhu, C.; Yang, W.; Zhang, Z.; Armstrong, D.E.; Grant, P.S.; Ritchie, R.O.; Meyers, M.A. Amorphization in extreme deformation of the CrMnFeCoNi high-entropy alloy. Sci. Adv. 2021, 7, eabb3108. [Google Scholar] [CrossRef] [PubMed]

- Sathiyamoorthi, P.; Kim, H. High-entropy alloys with heterogeneous microstructure: Processing and mechanical properties. Prog. Mater. Sci. 2022, 123, 100709. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef]

- Liu, L.; Ding, Q.; Zhong, Y.; Zou, J.; Wu, J.; Chiu, Y.-L.; Li, J.; Zhang, Z.; Yu, Q.; Shen, Z. Dislocation network in additive manufactured steel breaks strength–ductility trade-off. Mater. Today 2018, 21, 354–361. [Google Scholar] [CrossRef]

- Brif, Y.; Thomas, M.; Todd, I. The use of high-entropy alloys in additive manufacturing. Scripta Mater. 2015, 99, 93–96. [Google Scholar] [CrossRef]

- Zhu, Z.G.; Nguyen, Q.B.; Ng, F.L.; An, X.H.; Liao, X.Z.; Liaw, P.K.; Nai, S.M.L.; Wei, J. Hierarchical microstructure and strengthening mechanisms of a CoCrFeNiMn high entropy alloy additively manufactured by selective laser melting. Scripta Mater. 2018, 154, 20–24. [Google Scholar] [CrossRef]

- Song, M.; Zhou, R.; Gu, J.; Wang, Z.; Ni, S.; Liu, Y. Nitrogen induced heterogeneous structures overcome strength-ductility trade-off in an additively manufactured high-entropy alloy. Appl. Mater. Today 2020, 18, 100498. [Google Scholar] [CrossRef]

- Verleysen, P.; Degrieck, J. Experimental investigation of the deformation of Hopkinson bar specimens. Int. J. Impact Eng. 2004, 30, 239–253. [Google Scholar] [CrossRef]

- Ramachandramoorthy, R.; Kalácska, S.; Poras, G.; Schwiedrzik, J.; Edwards, T.; Maeder, X.; Merle, T.; Ercolano, G.; Koelmans, W.; Michler, J. Anomalous high strain rate compressive behavior of additively manufactured copper micropillars. Appl. Mater. Today 2022, 27, 101415. [Google Scholar] [CrossRef]

- He, J.; Wang, Q.; Zhang, H.; Dai, L.; Mukai, T.; Wu, Y.; Liu, X.; Wang, H.; Nieh, T.-G.; Lu, Z. Dynamic deformation behavior of a face-centered cubic FeCoNiCrMn high-entropy alloy. Sci. Bull. 2018, 63, 362–368. [Google Scholar] [CrossRef]

- Gangireddy, S.; Gwalani, B.; Mishra, R.S. Grain size dependence of strain rate sensitivity in a single phase FCC high entropy alloy Al0.3CoCrFeNi. Mater. Sci. Eng. A 2018, 736, 344–348. [Google Scholar] [CrossRef]

- He, Z.F.; Jia, N.; Wang, H.W.; Liu, Y.; Li, D.Y.; Shen, Y.F. The effect of strain rate on mechanical properties and micro structure of a metastable FeMnCoCr high entropy alloy. Mater. Sci. Eng. A 2020, 776, 138982. [Google Scholar] [CrossRef]

- Li, Z.; He, B.; Guo, Q. Strengthening and hardening mechanisms of additively manufactured stainless steels: The role of cell sizes. Scripta Mater. 2020, 177, 17–21. [Google Scholar] [CrossRef]

- Raturi, A.; Biswas, K.; Gurao, N.P. A mechanistic perspective on the kinetics of plastic deformation in FCC High Entropy Alloys: Effect of strain, strain rate and temperature. Scripta Mater. 2021, 197, 113809. [Google Scholar] [CrossRef]

- Güden, M.; Enser, S.; Bayhan, M.; Taşdemirci, A.; Yavaş, H. The strain rate sensitive flow stresses and constitutive equations of a selective-laser-melt and an annealed-rolled 316L stainless steel: A comparative study. Mater. Sci. Eng. A 2022, 838, 142743. [Google Scholar] [CrossRef]

- Jennings, A.T.; Li, J.; Greer, J. Emergence of strain-rate sensitivity in Cu nanopillars: Transition from dislocation multiplication to dislocation nucleation. Acta Mater. 2011, 59, 5627–5637. [Google Scholar] [CrossRef]

- Khantha, M.; Vitek, V.; Pope, D.P. Strain-rate dependent mechanism of cooperative dislocation generation: Application to the brittle-ductile transition. Mat. Sci. Eng. A-Struct. 2001, 319, 484–489. [Google Scholar] [CrossRef][Green Version]

- Lee, W.S.; Lin, C.F. Comparative study of the impact response and microstructure of 304L stainless steel with and without prestrain. Metall. Mater. Trans. A 2002, 33, 2801–2810. [Google Scholar] [CrossRef]

- Foley, D.L.; Huang, S.H.; Anber, E.; Shanahan, L.; Shen, Y.; Lang, A.C.; Barr, C.M.; Spearot, D.; Lamberson, L.; Taheri, M.L. Simultaneous twinning and microband formation under dynamic compression in a high entropy alloy with a complex energetic landscape. Acta Mater. 2020, 200, 1–11. [Google Scholar] [CrossRef]

- Rahman, K.M.; Vorontsov, V.A.; Dye, D. The effect of grain size on the twin initiation stress in a TWIP steel. Acta Mater. 2015, 89, 247–257. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, Z.; Xie, Y.; Chan, S.L.I.; Liang, J.; Wang, J. Multiple deformation mechanisms induced by pre-twin ning in CoCrFeNi high entropy alloy. Scripta Mater. 2022, 207, 114266. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, B.; Yan, K.; Wang, M.; Kabra, S.; Chiu, Y.-L.; Dye, D.; Lee, P.; Liu, Y.; Cai, B. Probing deformation mechanisms of a FeCoCrNi high-entropy alloy at 293 and 77 K using in situ neutron diffraction. Acta Mater. 2018, 154, 79–89. [Google Scholar] [CrossRef]

- Wu, Z.; Gao, Y.; Bei, H. Thermal activation mechanisms and Labusch-type strengthening analysis for a family of high-entropy and equiatomic solid-solution alloys. Acta Mater. 2016, 120, 108–119. [Google Scholar] [CrossRef]

- Wang, Z.; Bei, H.; Baker, I. Microband induced plasticity and the temperature dependence of the mechanical prop erties of a carbon-doped FeNiMnAlCr high entropy alloy. Mater. Character. 2018, 139, 373–381. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, Y.L.; Tong, Y.; Jiao, Z.B.; Wei, J.; Cai, J.X.; Han, X.D.; Chen, D.; Hu, A.; Kai, J.J.; et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 2018, 362, 933–937. [Google Scholar] [CrossRef]

- Li, N.; Chen, W.; He, J.; Gu, J.; Wang, Z.; Li, Y.; Song, M. Dynamic deformation behavior and microstructure evolution of CoCrNiMox medium entropy alloys. Mater. Sci. Eng. A 2021, 827, 142048. [Google Scholar] [CrossRef]

- Huang, J.C.; Gray, G.T., III. Microband formation in shock-loaded and quasi-statically deformed metals. Acta Metall. 1989, 37, 3335–3347. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Multistage strain hardening through dislocation substructure and twinning in a high strength and ductile weight-reduced Fe–Mn–Al–C steel. Acta Mater. 2012, 60, 5791–5802. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Microbanding mechanism in an Fe–Mn–C high-Mn twinning-induced plasticity steel. Scripta Mater. 2013, 69, 53–56. [Google Scholar] [CrossRef]

- Tsai, S.-P.; Tsai, Y.-T.; Chen, Y.-W.; Chen, P.-J.; Chiu, P.-H.; Chen, C.-Y.; Lee, W.-S.; Yeh, J.-W.; Yang, J.-R. High-entropy CoCrFeMnNi alloy subjected to high-strain-rate compressive deformation. Mater. Character. 2019, 147, 193–198. [Google Scholar] [CrossRef]

- Sonkusare, R.; Jain, R.; Biswas, K.; Parameswaran, V.; Gurao, N.P. High strain rate compression behaviour of single phase CoCuFeMnNi high entropy alloy. J. Alloys Compd. 2020, 823, 153763. [Google Scholar] [CrossRef]

- Kumar, N.; Ying, Q.; Nie, X.; Mishra, R.S.; Tang, Z.; Liaw, P.K.; Brennan, R.E.; Doherty, K.J.; Cho, K.C. High strain-rate compressive deformation behavior of the Al0.1CrFeCoNi high entropy alloy. Mater. Design 2015, 86, 598–602. [Google Scholar] [CrossRef]

- Wang, L.; Qiao, J.W.; Ma, S.G.; Jiao, Z.M.; Zhang, T.W.; Chen, G.; Zhao, D.; Zhang, Y.; Wang, Z.H. Mechanical response and deformation behavior of Al0.6CoCrFeNi high-entropy alloys upon dynamic loading. Mater. Sci. Eng. A 2018, 727, 208–213. [Google Scholar] [CrossRef]

- Wu, X.; Li, L.; Liu, W.; Li, S.; Zhang, L.; He, H. Development of adiabatic shearing bands in 7003-T4 aluminum alloy under high strain rate impacting. Mater. Sci. Eng. A 2018, 732, 91–98. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Amirkhiz, B.S.; Odeshi, A.; Li, J.; Mohammadi, M. Role of hierarchical microstructure of ad ditively manufactured AlSi10Mg on dynamic loading behavior. Addit. Manuf. 2019, 28, 1–13. [Google Scholar]

- Oguocha, I.N.A.; Tiamiyu, A.A.; Rezaei, M.; Odeshi, A.G.; Szpunar, J.A. Experimental investigation of the dynamic impact responses of as-cast and homogenized A535 aluminum alloy. Mater. Sci. Eng. A 2020, 771, 138536. [Google Scholar] [CrossRef]

- Zhou, T.; Wu, J.; Che, J.; Wang, Y.; Wang, X. Dynamic shear characteristics of titanium alloy Ti-6Al-4V at large strain rates by the split Hopkinson pressure bar test. Int. J. Impact Eng. 2017, 109, 167–177. [Google Scholar] [CrossRef]

- Shi, X.; Zhao, C.; Cao, Z.; Zhang, T.; Wang, Z.; Qiao, J. Mechanical behavior of a near α titanium alloy under dynamic compression: Characterization and modeling. Prog. Nat. Sci. Mater. Int. 2019, 29, 432–439. [Google Scholar] [CrossRef]

- Chen, J.; Wei, H.; Bao, K.; Zhang, X.; Cao, Y.; Peng, Y.; Kong, J.; Wang, K. Dynamic mechanical properties of 316L stainless steel fabricated by an additive manufacturing process. J. Mater. Res. Technol. 2021, 11, 170–179. [Google Scholar] [CrossRef]

- Zhu, L.; Wen, C.; Gao, C.; Guo, X.; Lu, J. A study of dynamic plasticity in austenite stainless steels with a gradient distribution of nanoscale twins. Scripta Mater. 2017, 133, 49–53. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, M.; Liu, B.; Liu, Y.; Yang, Y. Dynamic Behavior of Additively Manufactured FeCoCrNi High Entropy Alloy. Metals 2023, 13, 75. https://doi.org/10.3390/met13010075

Du M, Liu B, Liu Y, Yang Y. Dynamic Behavior of Additively Manufactured FeCoCrNi High Entropy Alloy. Metals. 2023; 13(1):75. https://doi.org/10.3390/met13010075

Chicago/Turabian StyleDu, Meng, Bin Liu, Yong Liu, and Yong Yang. 2023. "Dynamic Behavior of Additively Manufactured FeCoCrNi High Entropy Alloy" Metals 13, no. 1: 75. https://doi.org/10.3390/met13010075

APA StyleDu, M., Liu, B., Liu, Y., & Yang, Y. (2023). Dynamic Behavior of Additively Manufactured FeCoCrNi High Entropy Alloy. Metals, 13(1), 75. https://doi.org/10.3390/met13010075