Control of the Microstructure in a Al5Co15Cr30Fe25Ni25 High Entropy Alloy through Thermo-Mechanical and Thermal Treatments

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

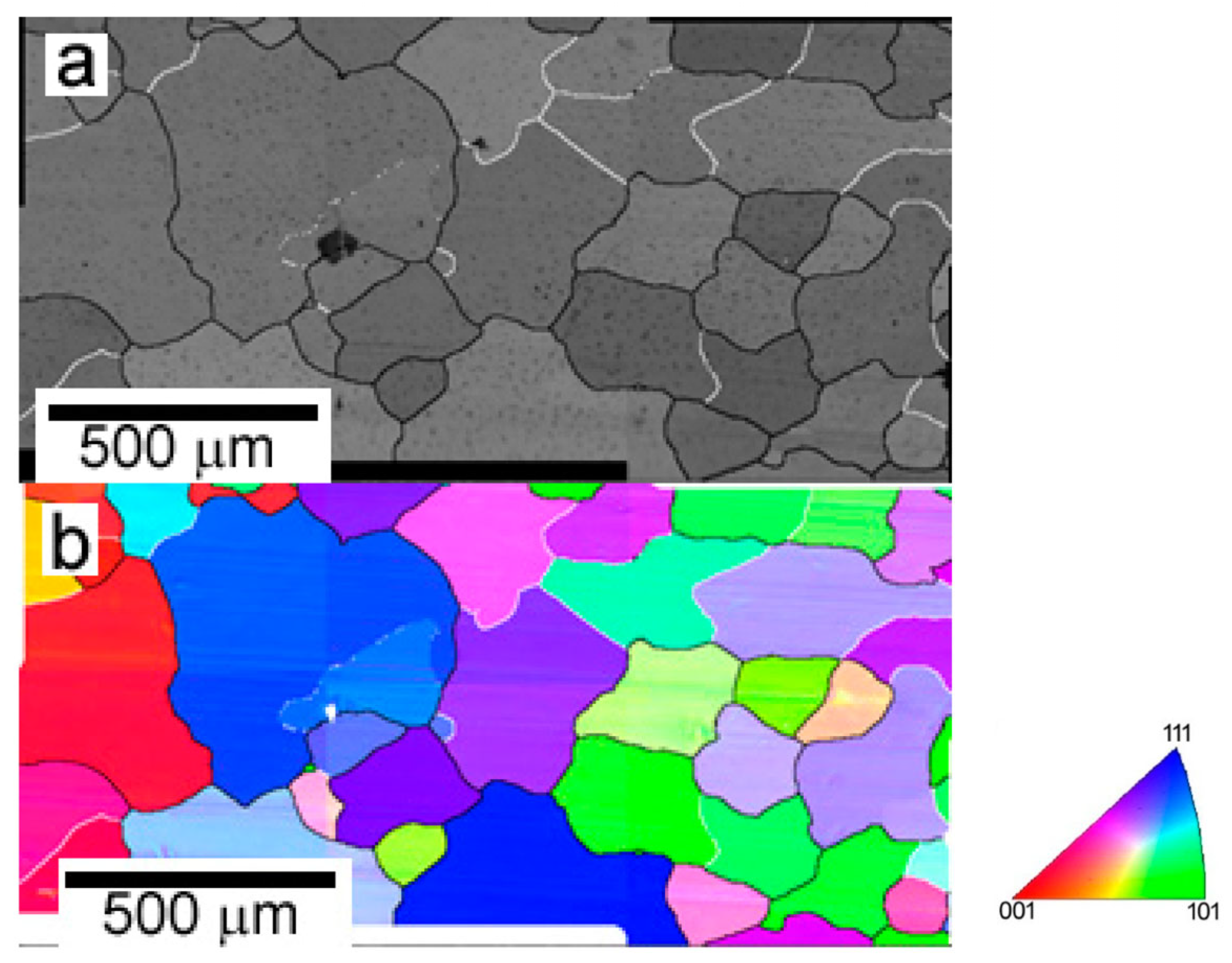

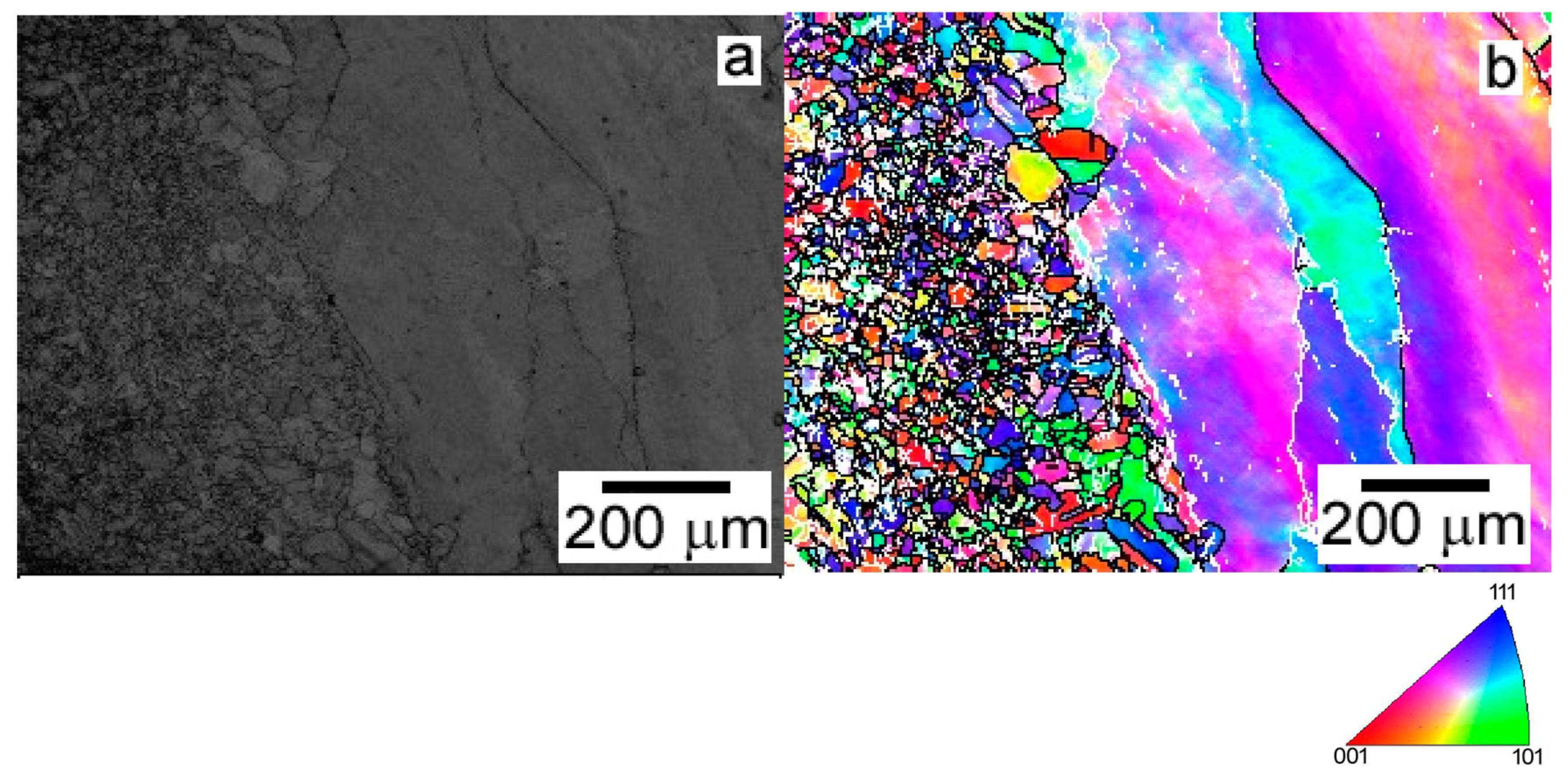

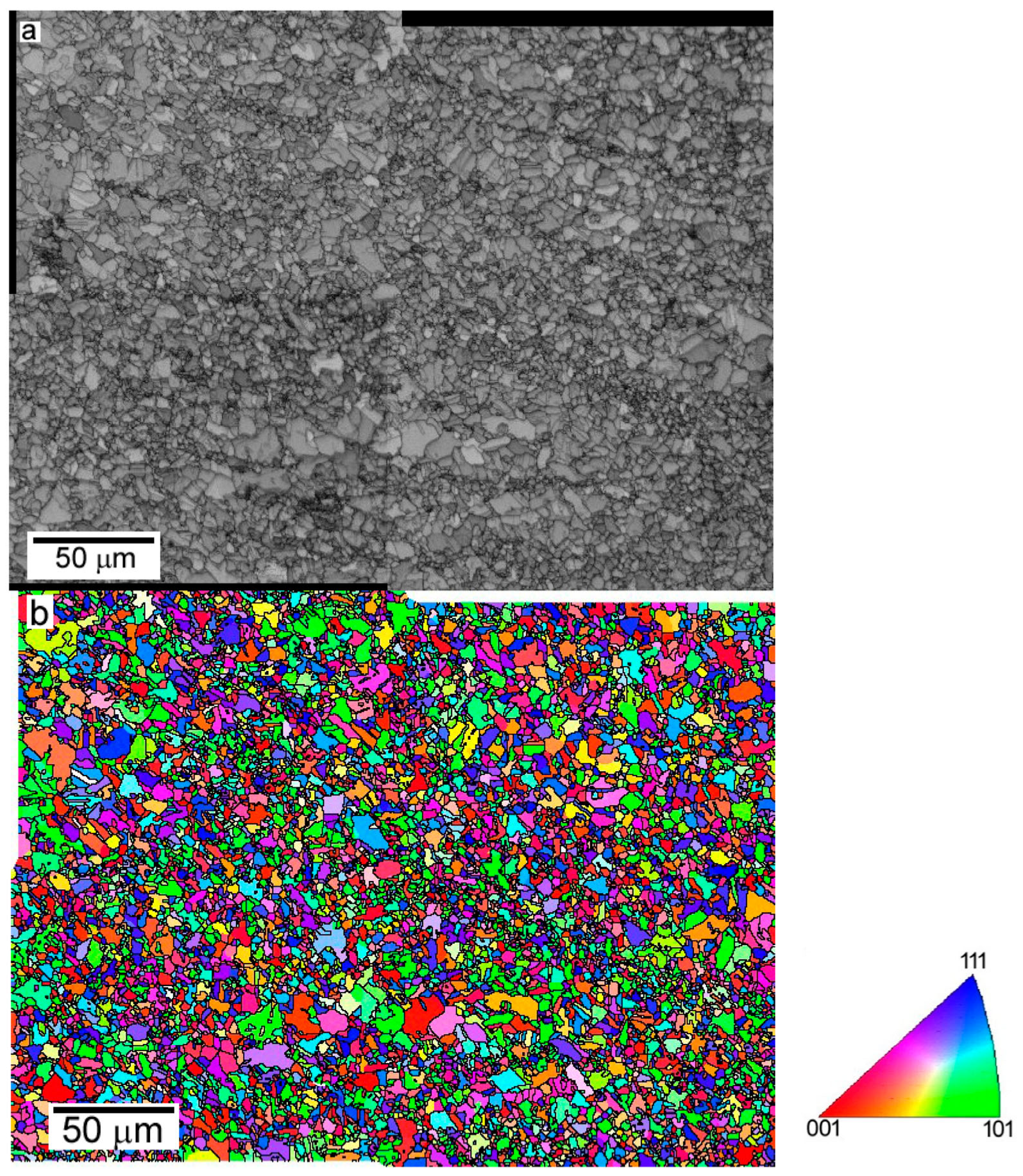

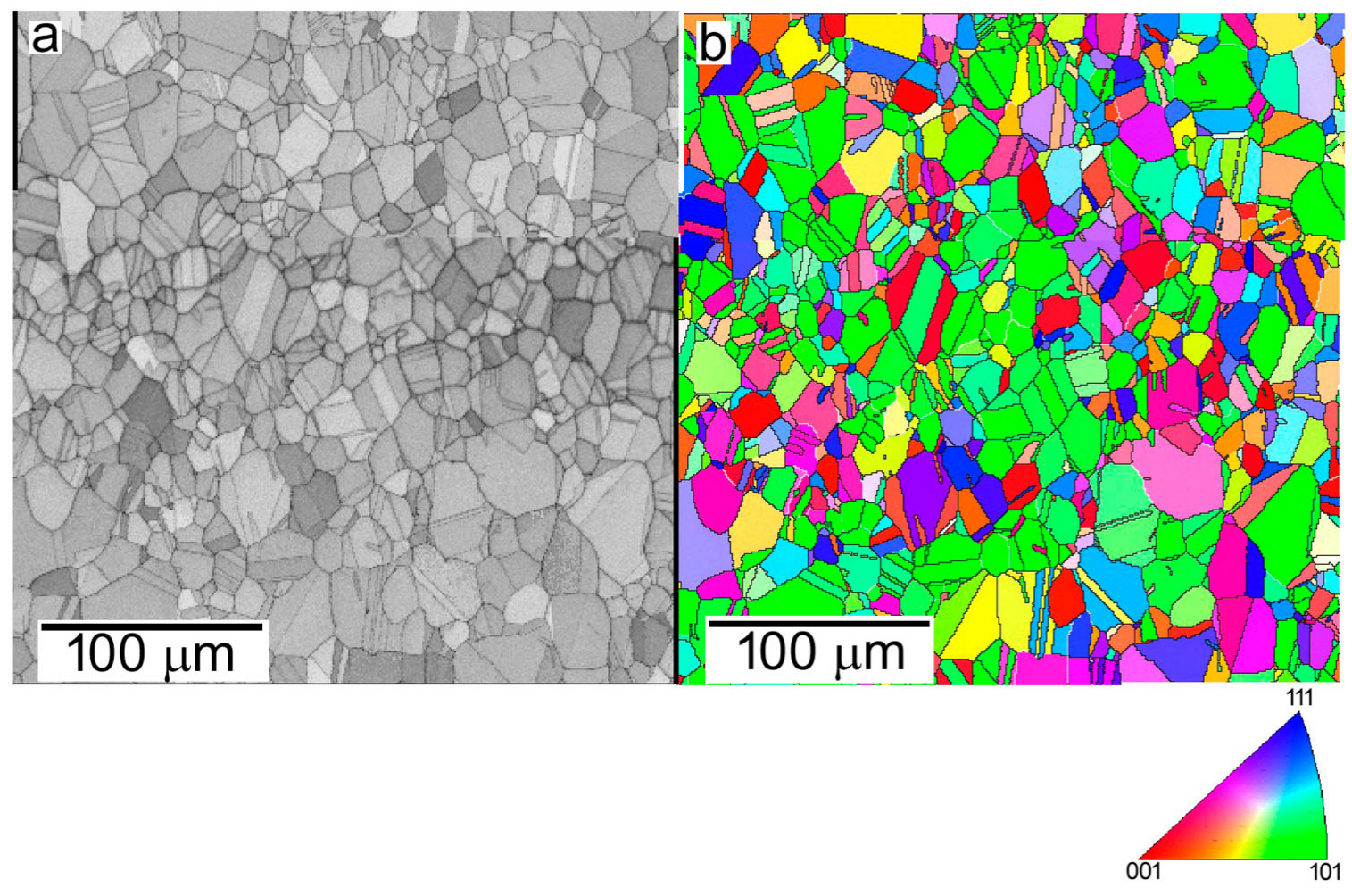

3.1. As-Cast Material

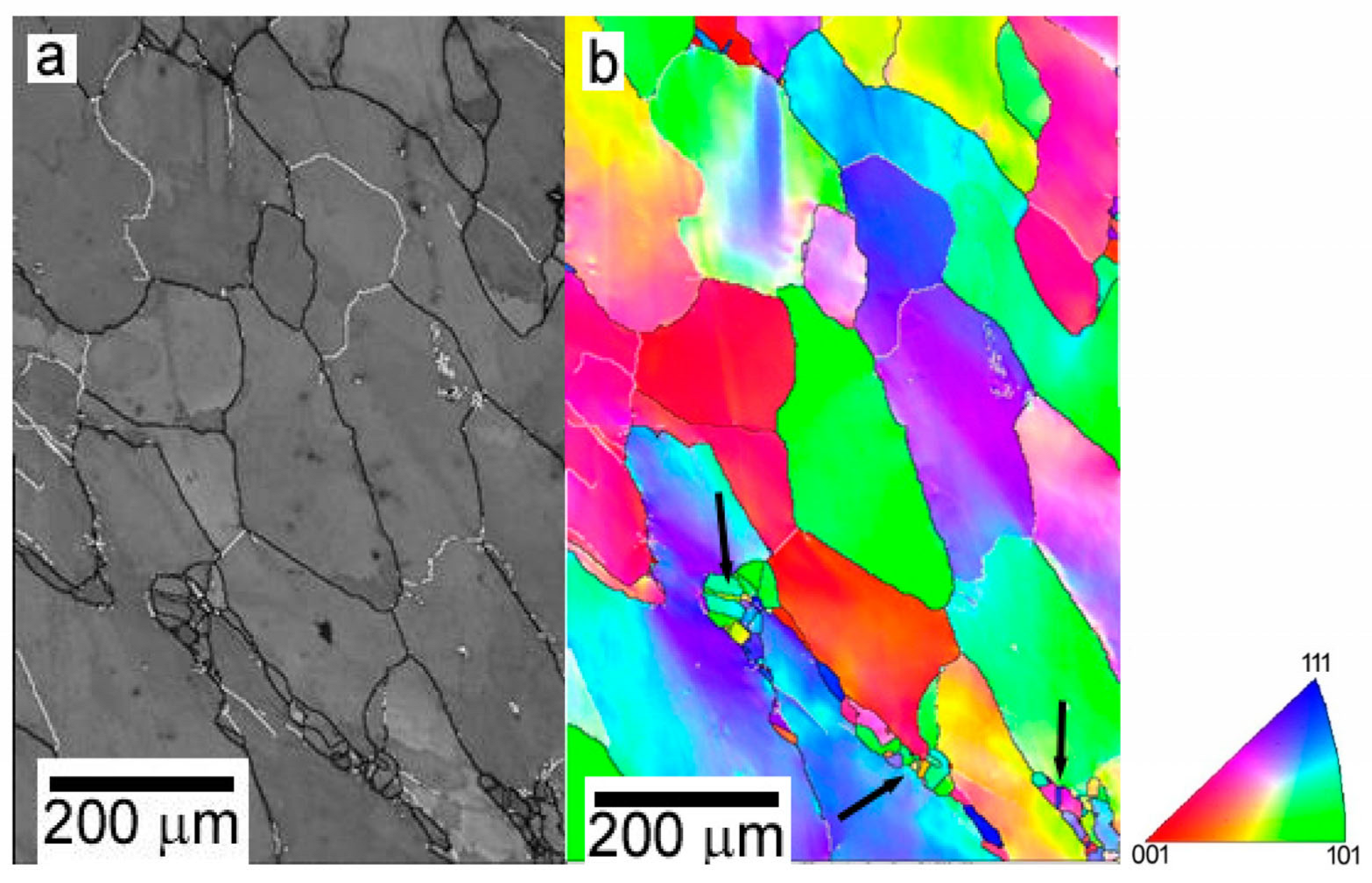

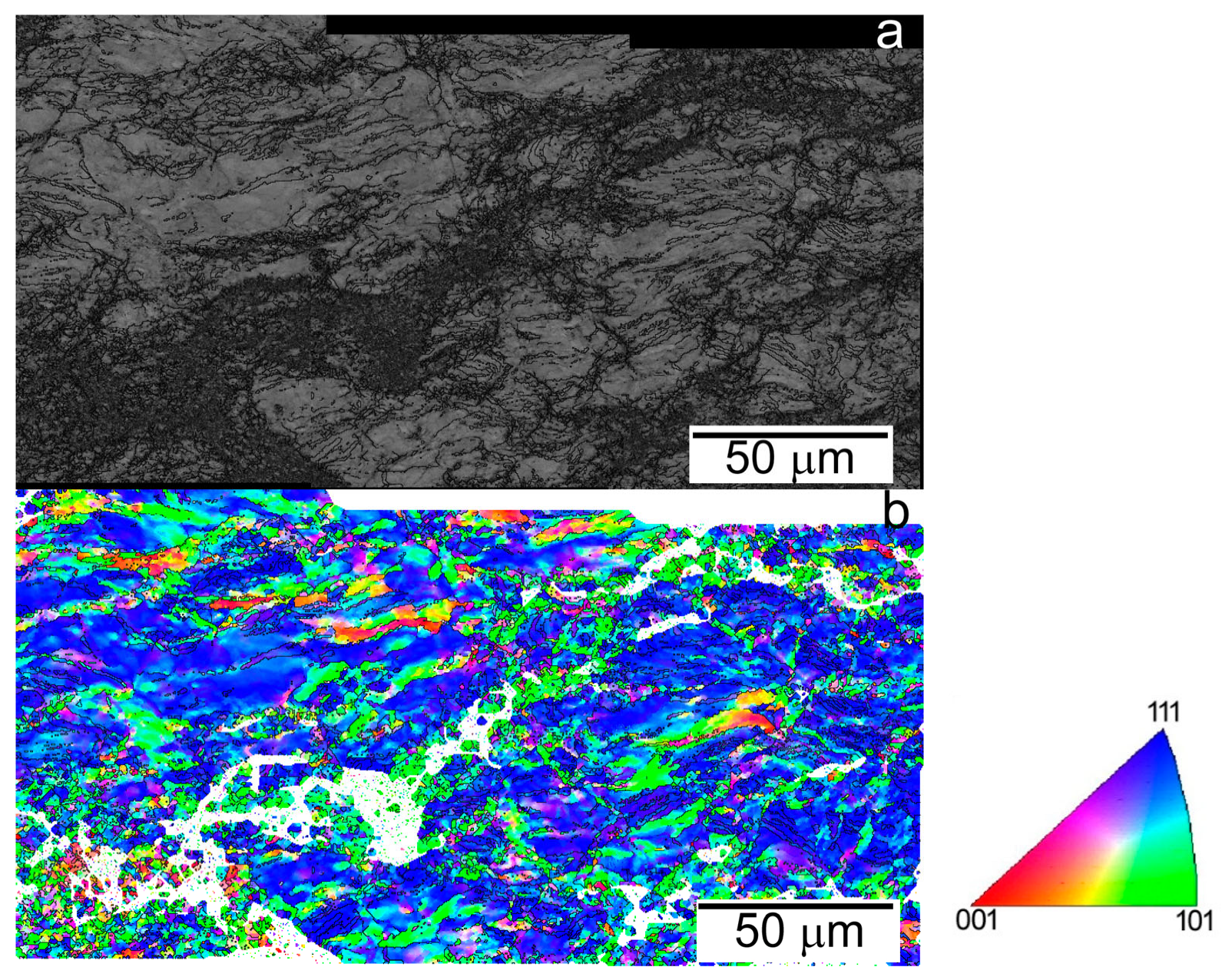

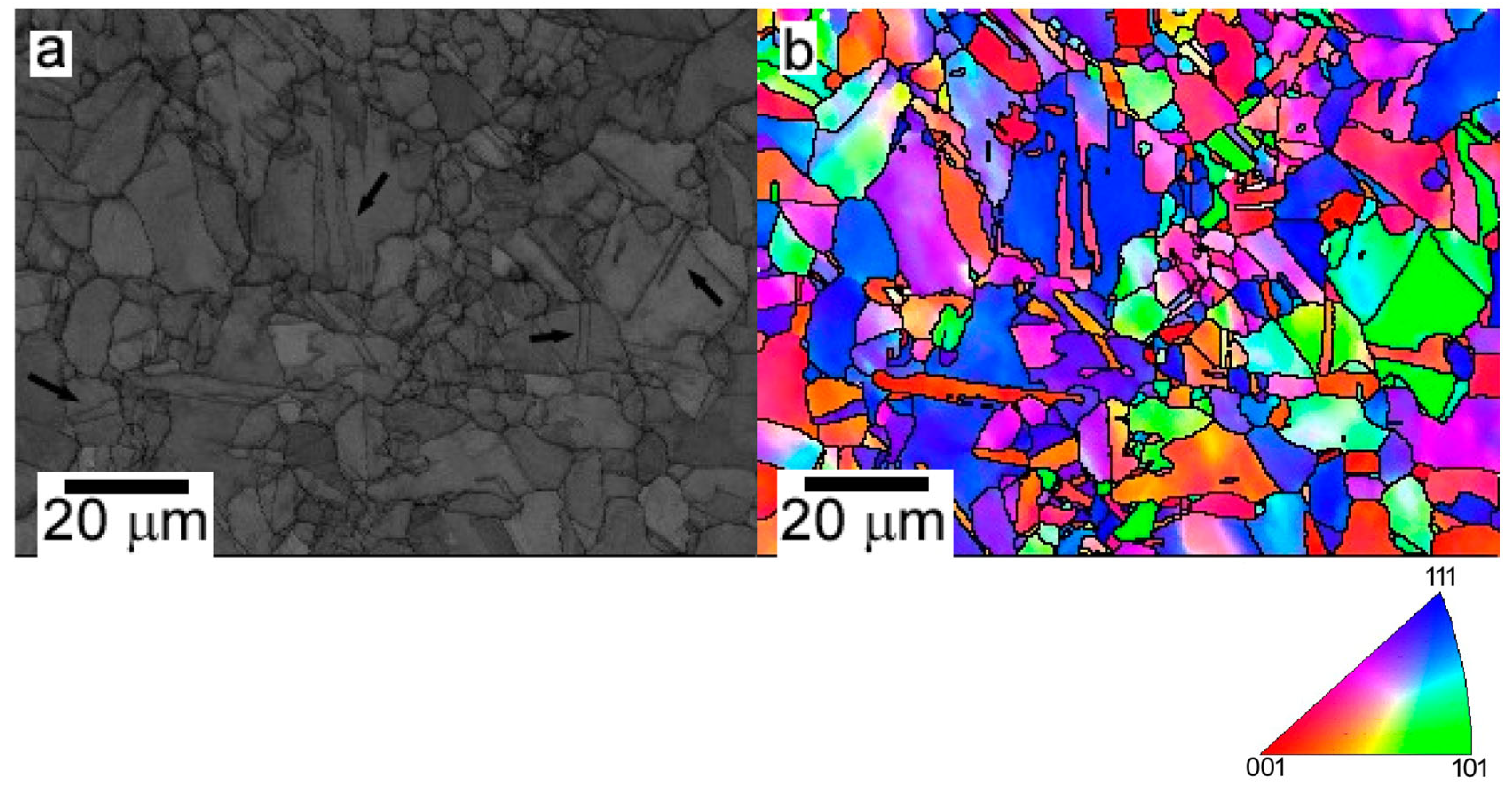

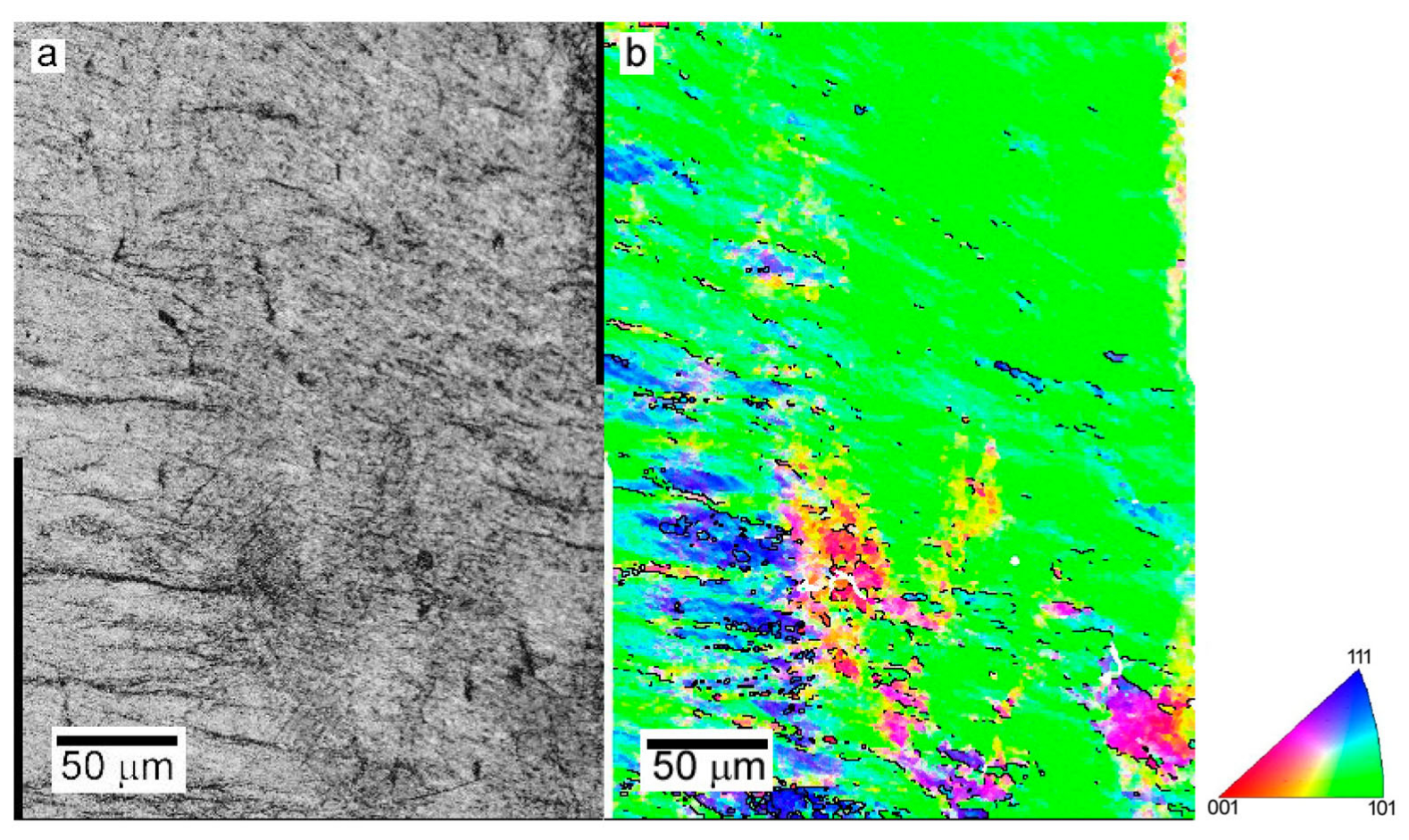

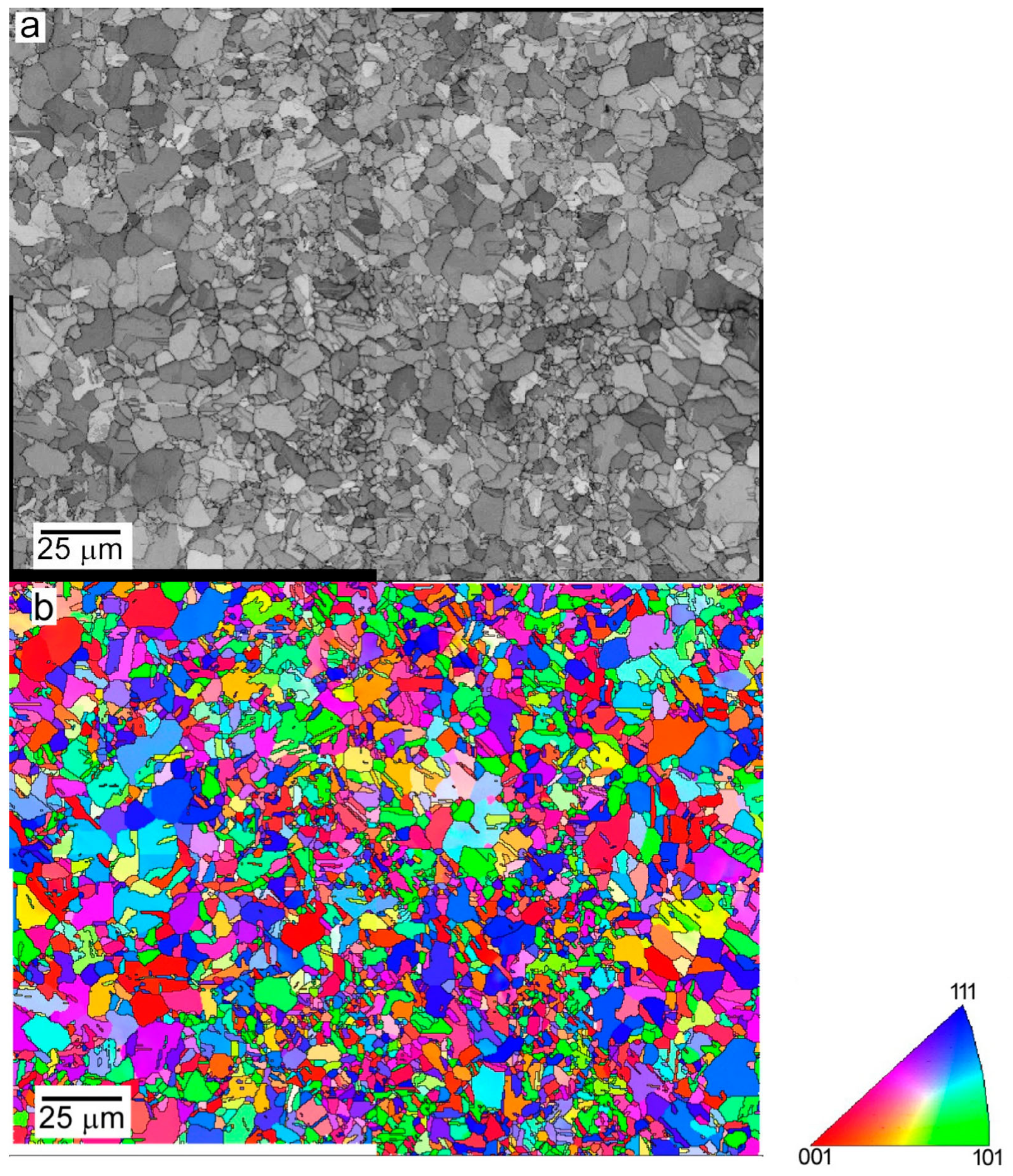

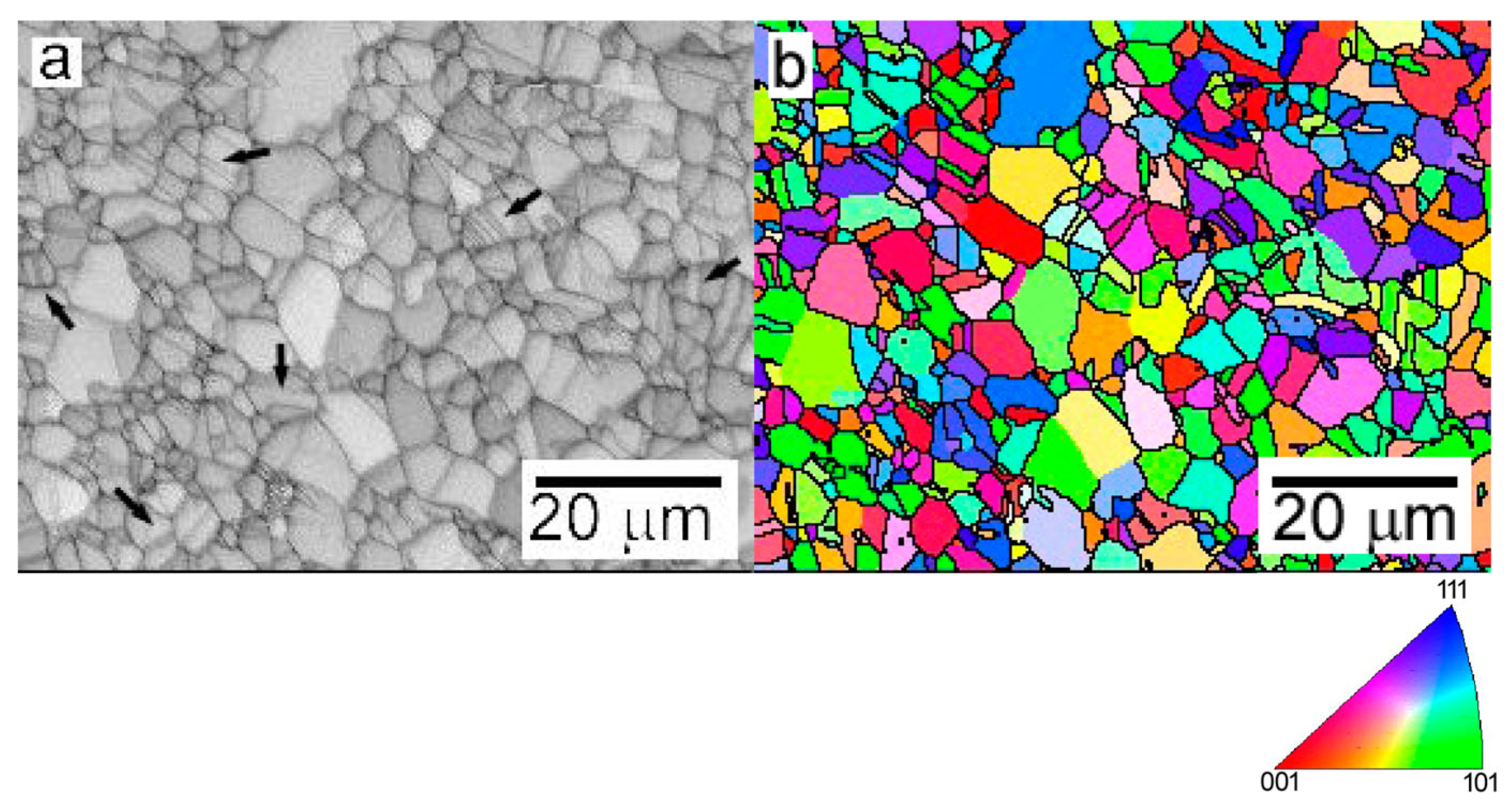

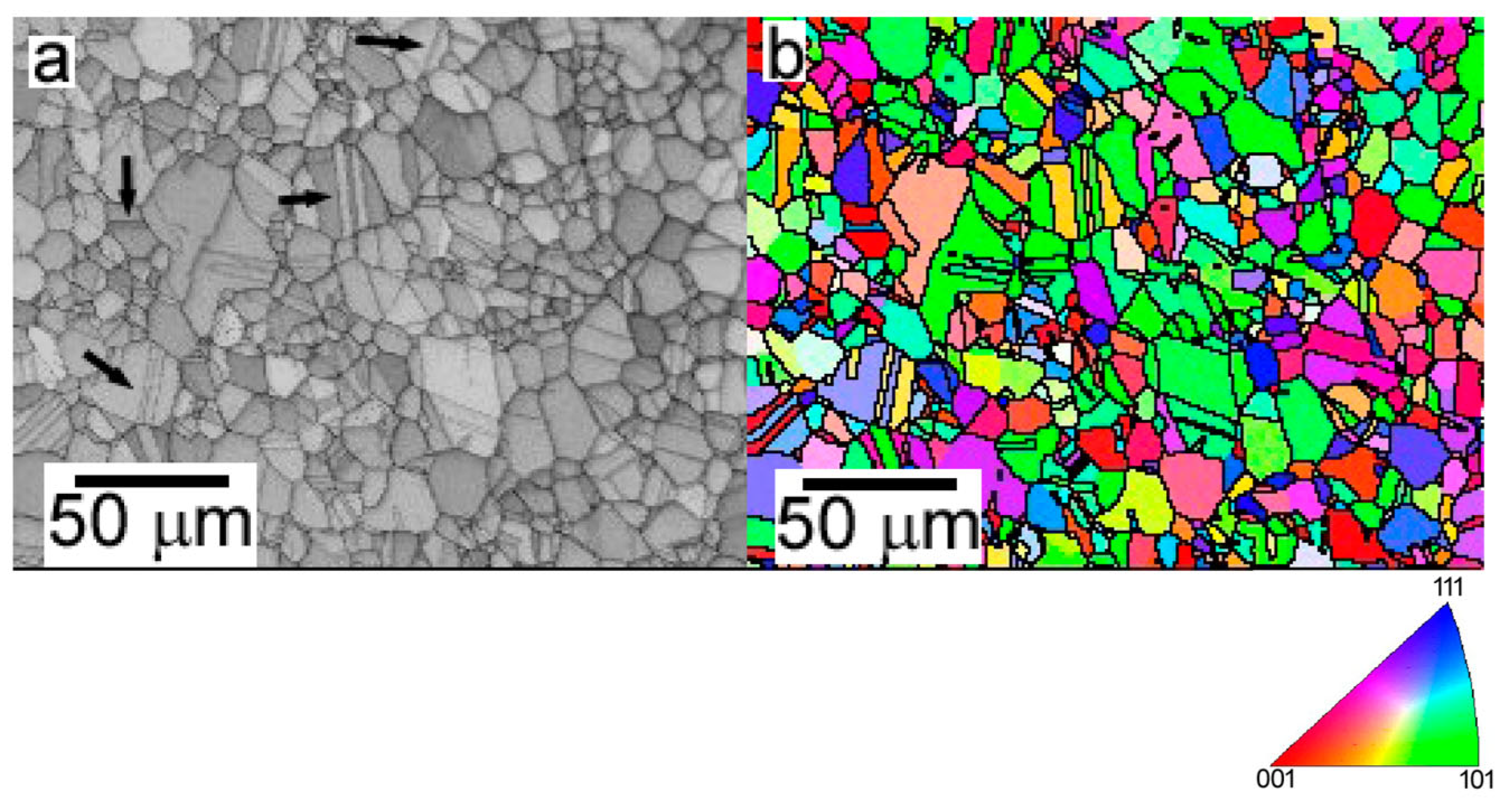

3.2. Thermomechanical Processing

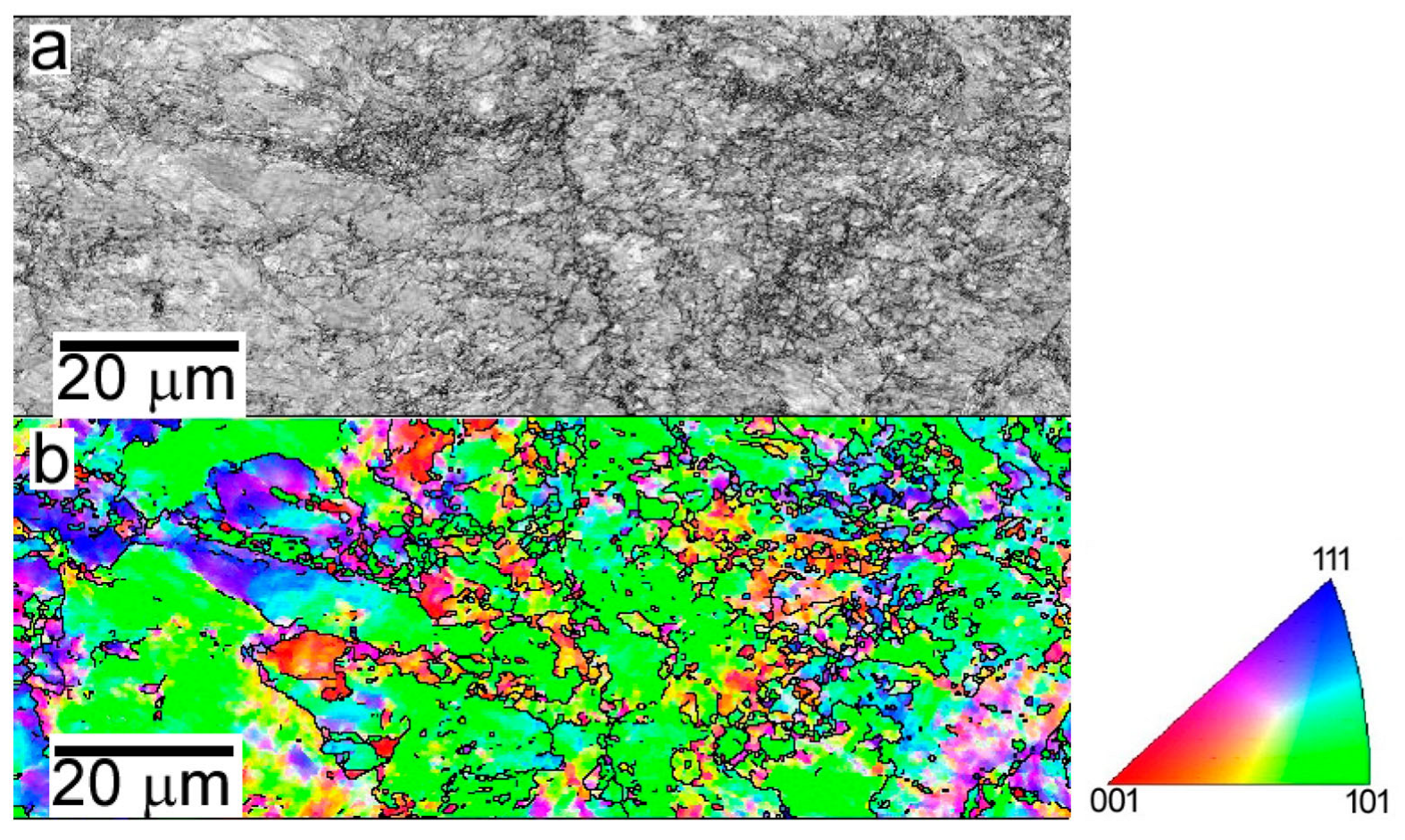

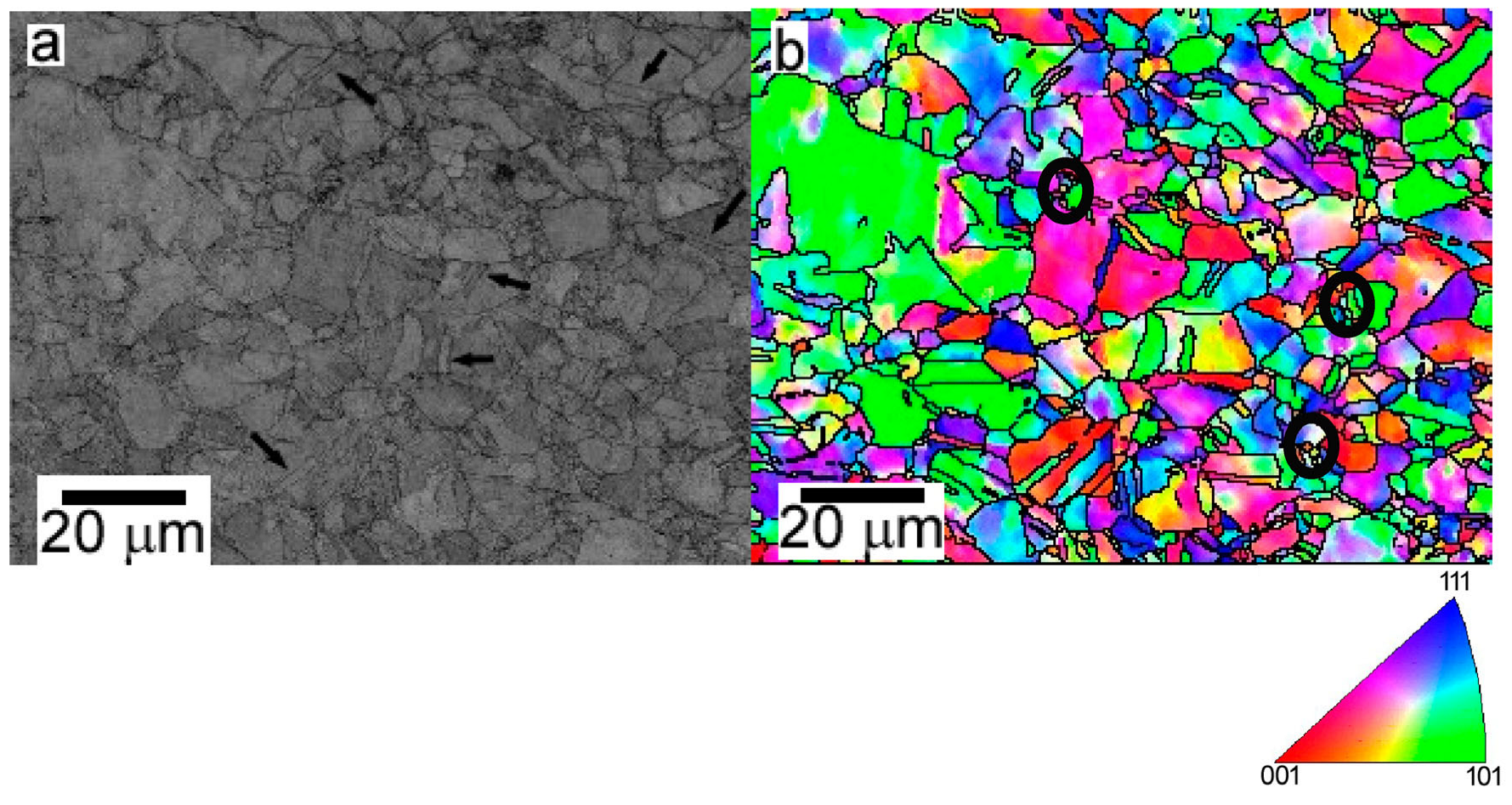

3.3. Annealing of CR Sheets

3.4. Microhardness

4. Conclusions

- (1)

- The microstructure of the single-phase fcc-based Al5Co15Cr30Fe25Ni25 HEA can be tuned through the proper choice of the thermo-mechanical processing and thermal treatments in such a way that hardness can be increased up to three times that of the as-cast alloy.

- (2)

- The occurrence or not of recrystallization during thermo-mechanical and annealing treatments determines the mechanical strength of the HEA. Complete recrystallization of annealed samples is attained after 1 h of exposure at 700 °C, inducing considerable softening.

- (3)

- The degree of recrystallization during thermo-mechanical processing of Al5Co15Cr30Fe25Ni25 HEA depends on the reduction applied to the material and the orientation of parent grains in the as-cast alloy.

- (4)

- Maximum hardening is found for the alloy warm rolled at 450 °C and the cold-rolled alloy annealed at 500 °C for 1 h. This indicates that thermo-mechanical processing or annealing treatments below 600 °C induce an additional hardening associated with the pinning effect of solute atoms located at the core of dislocations.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Yang, X.; Liaw, P.K. Alloy design and properties optimization of high-entropy alloys. JOM 2012, 64, 830–838. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Pickering, E.J.; Jones, N.G. High-entropy alloys: A critical assessment of their founding principles and future prospects. Int. Mater. Rev. 2016, 61, 183–202. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Gorsse, S.; Nguyen, M.H.; Senkov, O.N.; Miracle, D.B. Database on the mechanical properties of high entropy alloys and complex concentrated alloys. Data Br. 2018, 21, 2664–2678. [Google Scholar] [CrossRef]

- Munitz, A.; Salhov, S.; Hayun, S.; Frage, N. Heat treatment impacts the micro-structure and mechanical properties of AlCoCrFeNi high entropy alloy. J. Alloy Compd. 2016, 683, 221–230. [Google Scholar] [CrossRef]

- Hachet, D.; Gorsse, S.; Godet, S. Microstructure study of cold rolled Al0.32CoCrFeMnNi high-entropy alloy: Interactions between recrystallization and precipitation. Mater. Sci. Eng. A 2021, 802, 140452. [Google Scholar] [CrossRef]

- Wu, Y.; Jin, X.; Zhang, M.; Yang, H.; Qiao, J.; Wu, Y. Yield strength-ductility trade-off breakthrough in Co-free Fe40Mn10Cr25Ni25 high-entropy alloys with partial recrystallization. Mater. Today Commun. 2021, 28, 102718. [Google Scholar] [CrossRef]

- Sabban, R.; Dash, K.; Suwas, S.; Murty, B.S. Strength–Ductility synergy in high entropy alloys by tuning the thermo-mechanical process parameters: A comprehensive review. J. Indian Inst. Sci. 2022, 102, 91–116. [Google Scholar] [CrossRef]

- Mahmoud, E.R.I.; Shaharoun, A.; Gepreel, M.A.; Ebied, S. Studying the effect of cold rolling and heat treatment on the microstructure and mechanical properties of the Fe36Mn20Ni20Cr16Al5Si3 High Entropy Alloy. Entropy 2022, 24, 1040. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Zhang, S.Z.; Huo, J.T.; Zhang, C.J.; Zheng, L.W.; Kong, F.T.; Li, H. Heterogeneous precipitation strengthened non-equiatomic NiCoFeAlTi medium entropy alloy with excellent mechanical properties. Mater. Sci. Eng. A 2022, 834, 142617. [Google Scholar] [CrossRef]

- Liu, Z.; Xiong, Z.; Chen, K.; Cheng, X. Large-size high-strength and high-ductility AlCoCrFeNi2.1 eutectic high-entropy alloy produced by hot-rolling and subsequent aging. Mater. Lett. 2022, 315, 131933. [Google Scholar] [CrossRef]

- Huang, X.; Miao, J.; Li, S.; Taylor, C.D.; Luo, A.A. Co-free CuFeMnNi high-entropy alloy with tunable tensile properties by thermomechanical processing. J. Mater. Sci. 2021, 56, 7670–7680. [Google Scholar] [CrossRef]

- Yi, H.; Xie, R.; Zhang, Y.; Wang, L.; Tan, M.; Li, T.; Wei, D. Tuning Microstructure and Mechanical Performance of a Co-Rich Transformation-Induced Plasticity High Entropy Alloy. Materials 2022, 15, 4611. [Google Scholar] [CrossRef]

- Yang, Z.; Yan, D.; Lu, W.; Li, Z. A TWIP-TRIP quinary high-entropy alloy: Tuning phase stability and microstructure for enhanced mechanical properties. Mater. Sci. Eng. A 2021, 801, 140441. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Wu, Z.; Zhao, S.; Zhang, W.; Bei, H.; Gao, Y. Strengthening in Al-, Mo- or Ti-doped CoCrFeNi high entropy alloys: A parallel comparison. J. Mater. Sci. Tech. 2021, 94, 264–274. [Google Scholar] [CrossRef]

- Mohammad-Ebrahimi, M.H.; Zarei-Hanzaki, A.; Abedi, H.R.; Vakili, S.M.; Soundararajan, C.K. Decelerated grain growth kinetic and effectiveness of Hall-Petch relationship in a cold-rolled non-equiatomic high entropy alloy. J. Alloy Compd. 2021, 874, 159849. [Google Scholar] [CrossRef]

- Rajendrachari, S. An Overview of high-entropy alloys prepared by mechanical alloying followed by the characterization of their microstructure and various properties. Alloys 2022, 1, 116–132. [Google Scholar] [CrossRef]

- Rajendrachari, S.; Adimule, V.; Gulen, M.; Khosravi, F.; Somashekharappa, K.K. Synthesis and Characterization of High Entropy Alloy 23Fe-21Cr-18Ni20Ti-18Mn for Electrochemical Sensor Applications. Materials 2022, 15, 7591. [Google Scholar] [CrossRef]

- Gangireddy, S.; Whitaker, D.; Mishra, R.S. Significant contribution to strength enhancement from deformation twins in thermomechanically processed Al0.1CoCrFeNi microstructures. J. Mater. Eng. Perf. 2019, 28, 1661–1667. [Google Scholar] [CrossRef]

- Haase, C.; Barrales-Mora, L.A. Influence of deformation and annealing twinning on the microstructure and texture evolution of face-centered cubic high entropy alloys. Acta Mater. 2018, 150, 88–103. [Google Scholar] [CrossRef]

- Santos, L.A.; Singh, S.; Rollett, A.D. Microstructure and texture evolution during thermomechanical processing of Al0.25CoCrFeNi high-entropy alloy. Met. Mater. Trans. A 2019, 50, 5433–5444. [Google Scholar] [CrossRef]

- Gourdet, S.; Montheillet, F. A model of continuous dynamic recrystallization. Acta Mater. 2003, 51, 2685–2699. [Google Scholar] [CrossRef]

- Jin, Y.; Lin, B.; Bernacki, M.; Rohrer, G.S.; Rollet, A.D.; Bozzolo, N. Annealing twin development during recrystallization and grain growth in pure nickel. Mater. Sci. Eng. A 2014, 597, 295–303. [Google Scholar] [CrossRef]

- Field, D.P.; Bradford, L.T.; Nowell, M.M.; Lillo, T.M. The role of annealing twins during recrystallization of Cu. Acta Mater. 2007, 55, 4233–4241. [Google Scholar] [CrossRef]

- Otto, F.; Hanold, N.L.; George, E.P. Microstructural evolution after thermomechanical processing in an equiatomic, single-phase CoCrFeMnNi high-entropy alloy with special focus on twin boundaries. Intermetallics 2014, 54, 39–48. [Google Scholar] [CrossRef]

- Tsai, C.W.; Lee, C.; Lin, P.T.; Xie, X.; Chen, S.; Carroll, R.; LeBlanc, M.; Brinkman, B.A.W.; Liaw, P.K.; Dahmen, K.A.; et al. Portevin-Le Chatelier mechanism in face-centered-cubic metallic alloys from low to high entropy. Int. J. Plast. 2019, 122, 212–224. [Google Scholar] [CrossRef]

- Chen, S.Y.; Wang, L.; Li, W.D.; Tong, Y.; Tseng, K.K.; Tsai, C.W.; Yeh, J.W.; Ren, Y.; Guo, W.; Poplawsky, J.D.; et al. Peierls barrier characteristic and anomalous strain hardening provoked by dynamic-strain-aging strengthening in a body-centered-cubic high-entropy alloy. Mater. Res. Lett. 2019, 7, 475–481. [Google Scholar] [CrossRef]

| Composition | Al | Co | Cr | Co | Ni |

|---|---|---|---|---|---|

| Nominal | 5 | 15 | 30 | 25 | 25 |

| Real | 4.6 ± 0.1 | 15.9 ± 0.3 | 31.1 ± 0.3 | 24.1 ± 0.1 | 24.3 ± 0.2 |

| Condition | Temperature (°C) | Designation | Reduction (%) | Final Thickness (mm) |

|---|---|---|---|---|

| Forging | 1200 | FG1200 | 50 (1 step) | 30 |

| Cold rolling | 25 | CR | 86 (0.5 mm per pass) | 1 |

| Warm rolling | 450 | WR450-2 | 83 (1 mm per pass) | 2 |

| Hot rolling | 850 | HR850-6 | 50 (1.5 mm per pass) | 6 |

| Hot rolling | 850 | HR850-2 | 83 (1.5 mm per pass) | 2 |

| Temperature (°C) | Designation |

|---|---|

| 400 | CR + TT400 |

| 500 | CR + TT500 |

| 600 | CR + TT600 |

| 700 | CR + TT700 |

| 800 | CR + TT800 |

| 850 | CR + TT850 |

| 900 | CR + TT900 |

| 950 | CR + TT950 |

| Material | Microhardness Vickers (kg/mm2) |

|---|---|

| As cast | 121 ± 5 |

| FG1200 | 157 ± 6 |

| HR850-6 | 267 ± 2 |

| HR850-2 | 309 ± 5 |

| WR450-2 | 363 ± 5 |

| CR | 318 ± 9 |

| CR + TT400 | 342 ± 9 |

| CR + TT500 | 380 ± 6 |

| CR + TT600 | 339 ± 12 |

| CR + TT700 | 203 ± 6 |

| CR + TT800 | 190 ± 8 |

| CR + TT850 | 165 ± 4 |

| CR + TT900 | 144 ± 2 |

| CR +TT950 | 127 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez, P.; Medina, J.; Vega, M.F.; Garcés, G.; Adeva, P. Control of the Microstructure in a Al5Co15Cr30Fe25Ni25 High Entropy Alloy through Thermo-Mechanical and Thermal Treatments. Metals 2023, 13, 180. https://doi.org/10.3390/met13010180

Pérez P, Medina J, Vega MF, Garcés G, Adeva P. Control of the Microstructure in a Al5Co15Cr30Fe25Ni25 High Entropy Alloy through Thermo-Mechanical and Thermal Treatments. Metals. 2023; 13(1):180. https://doi.org/10.3390/met13010180

Chicago/Turabian StylePérez, Pablo, Judit Medina, María Fernanda Vega, Gerardo Garcés, and Paloma Adeva. 2023. "Control of the Microstructure in a Al5Co15Cr30Fe25Ni25 High Entropy Alloy through Thermo-Mechanical and Thermal Treatments" Metals 13, no. 1: 180. https://doi.org/10.3390/met13010180

APA StylePérez, P., Medina, J., Vega, M. F., Garcés, G., & Adeva, P. (2023). Control of the Microstructure in a Al5Co15Cr30Fe25Ni25 High Entropy Alloy through Thermo-Mechanical and Thermal Treatments. Metals, 13(1), 180. https://doi.org/10.3390/met13010180