Analysis on the Quenching Deformation Characteristics of Light Cast Aluminum Alloy Wheels and Their Control Strategies

Abstract

1. Introduction

2. Mathematical Model of Multi-Phase Coupled Heat Exchange

3. Establishment and Calculation of Fluid Calculation Domain Model

3.1. Fluid Area Gridding

3.2. Setup of Workbench Model

3.3. Fluid Properties and Boundary Conditions

3.4. Solid Properties and Boundary Conditions

4. Analysis of Simulation Results

4.1. Analysis of Heat Transfer Characteristics of Inflow Flow

4.2. Analysis of Heat Exchange Characteristics on Wheel Surface

4.3. Analysis of Quenching Deformation Mechanism

5. Tests and Measurements

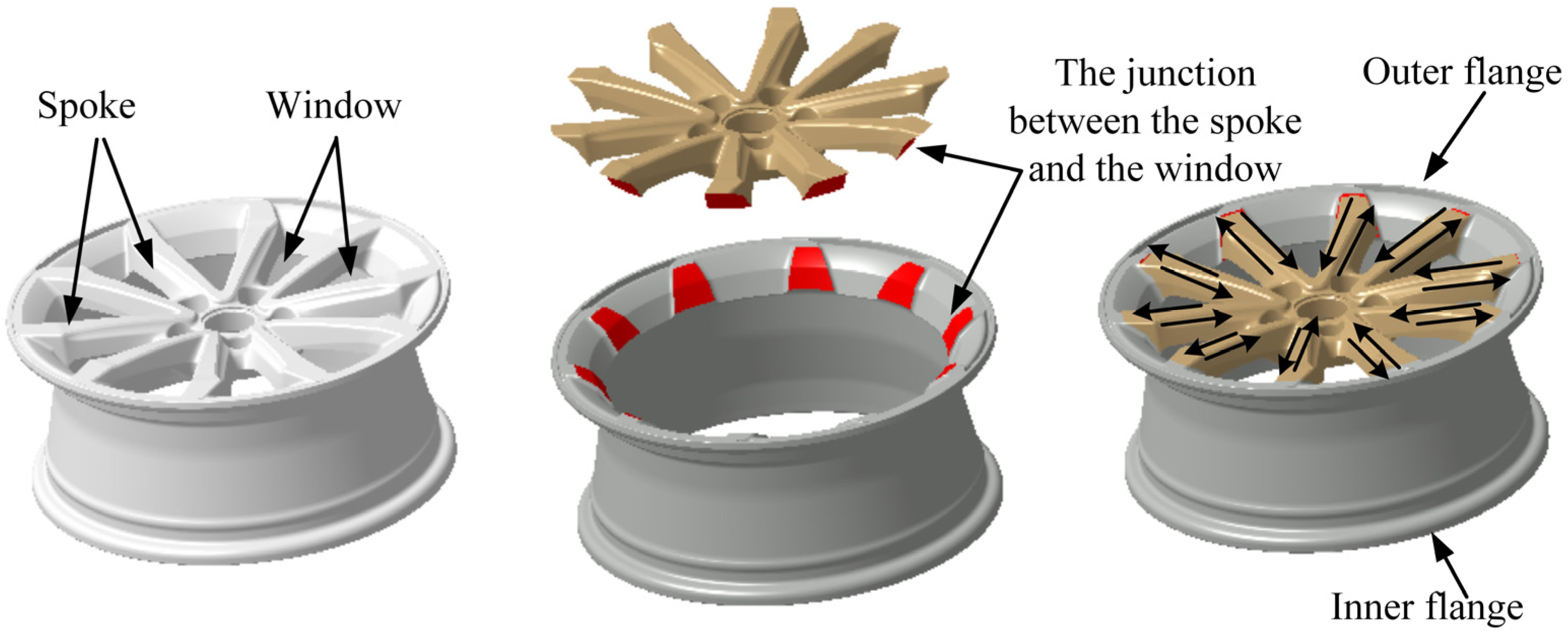

5.1. Introduction to Test Wheel and Heat Treatment Platform

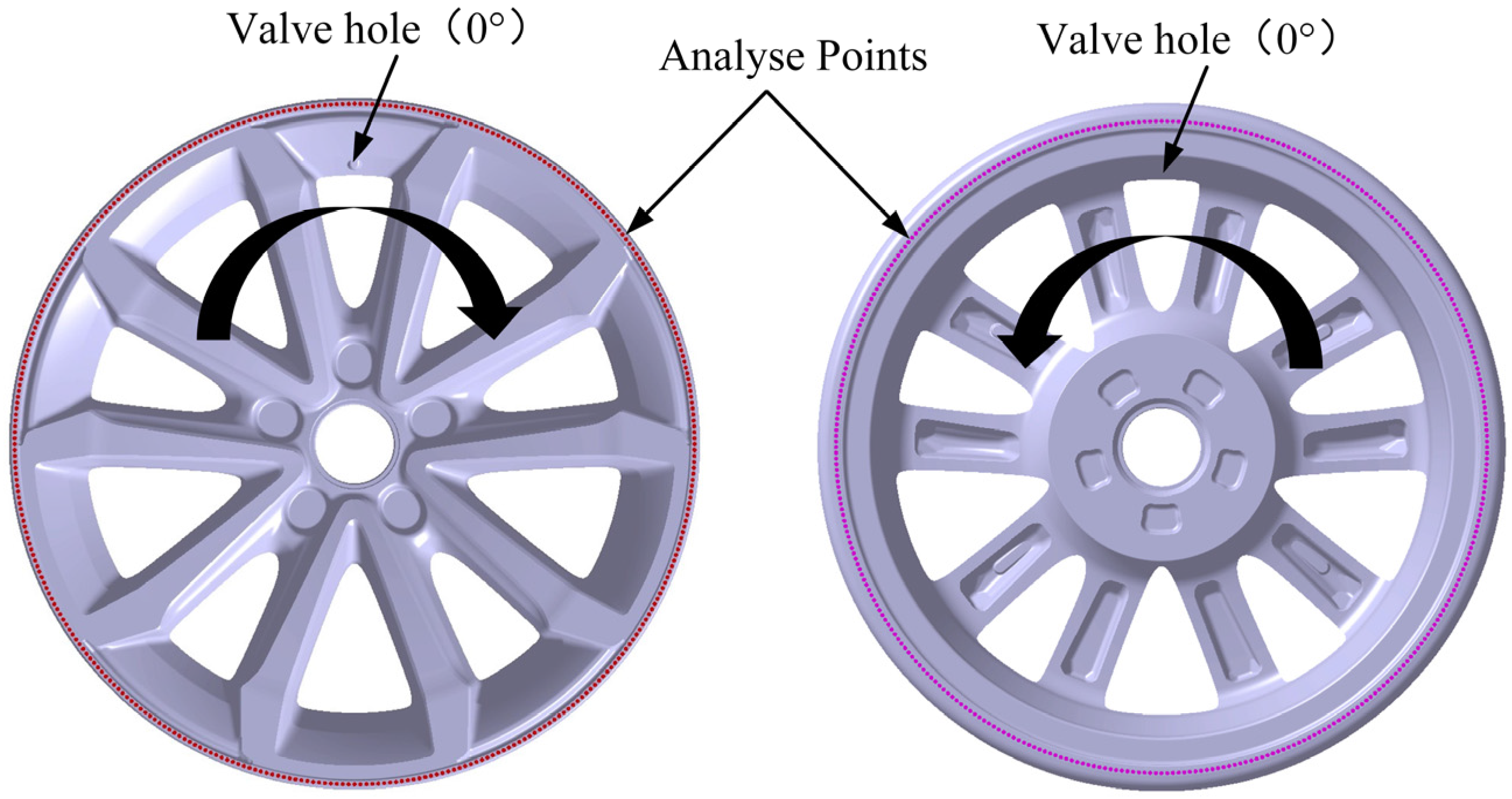

5.2. Wheel Deformation Measurement

5.3. Control Strategy for Wheel Deformation

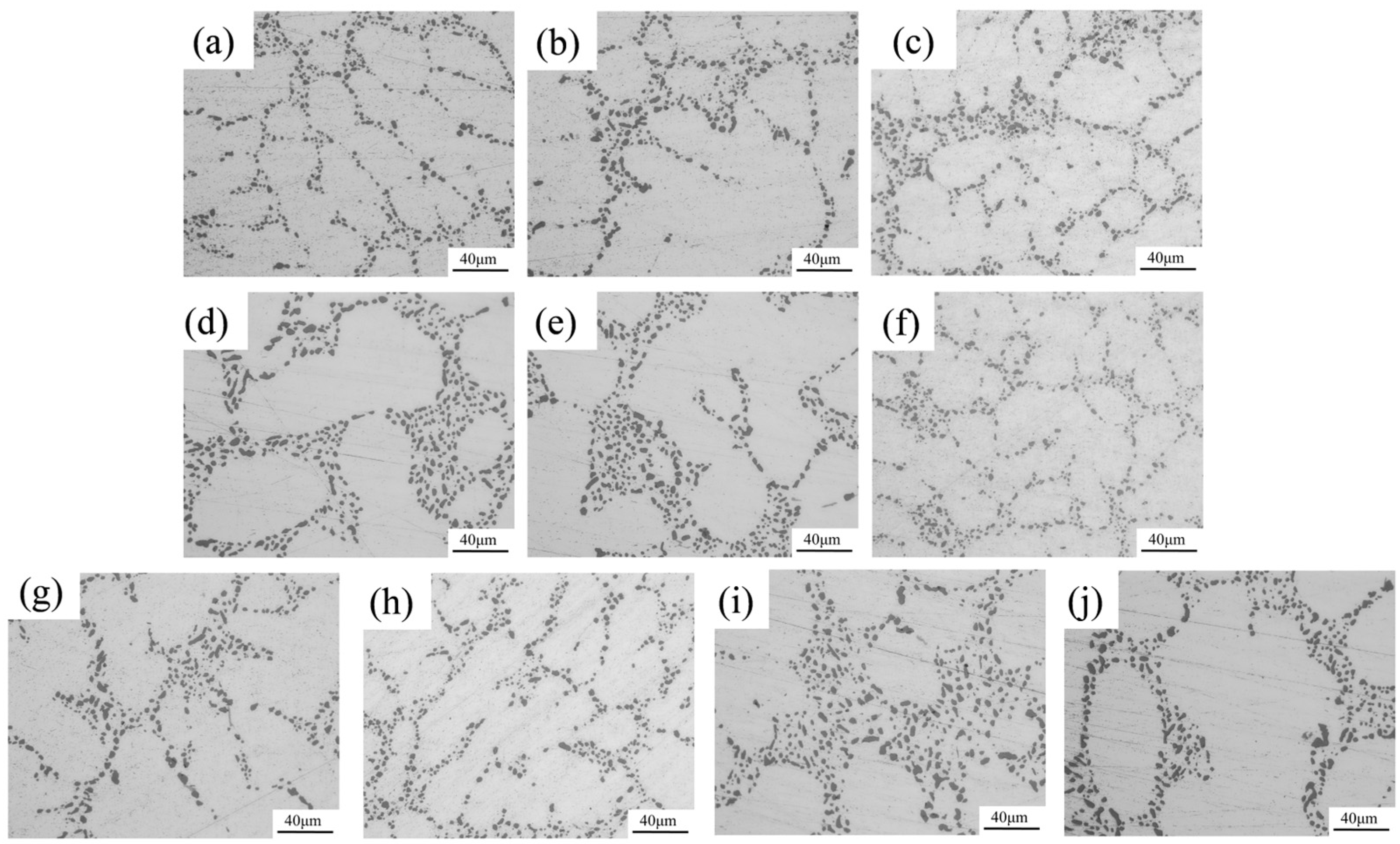

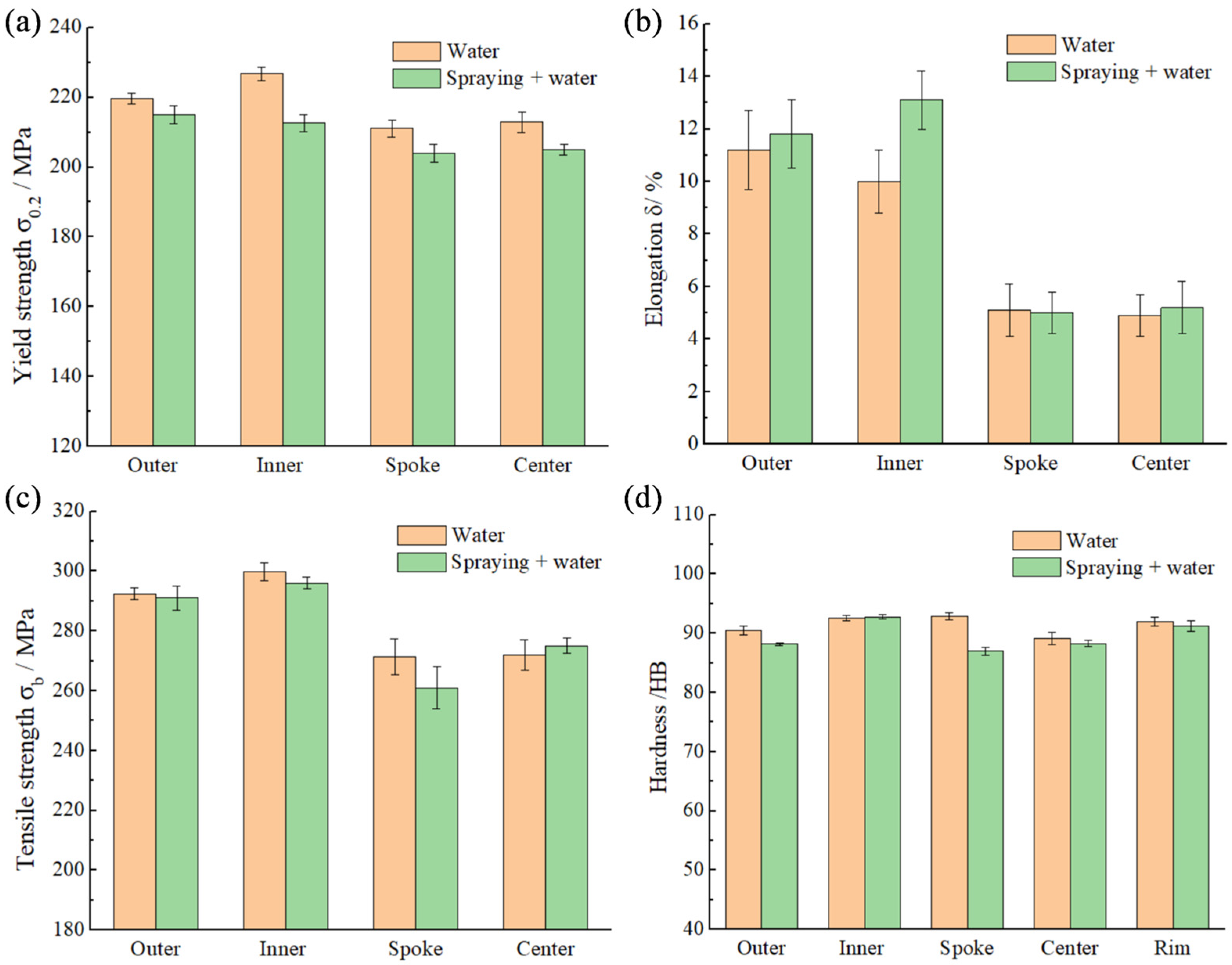

5.4. Analysis of Structure and Mechanical Properties of Wheels

6. Conclusions

- (1)

- Based on Workbench platform, the immersion quenching process was simulated by multi-physical field coupling, and the change characteristics of physical fields and the heat treatment deformation mechanism during the whole quenching process were revealed.

- (2)

- The deformation characteristics of the inner/outer rim end face are affected by the stiffness of the wheel structure, and the deformation of the inner rim presents the deformation characteristics following with the outer rim. However, affected by the uneven heat exchange of the wheel and internal structure defects, the overall deformation presents the characteristics of double-peak and trough.

- (3)

- The mechanical properties and hardness indexes of each monitoring point of the new graded zone quenching process spraying 15 s and water immersion can meet the automobile factories’ requirements for an aluminum alloy wheel. The maximum reduction of the wheel end deformation is 39.2%, which can be used as a new direction of integrated regulation and control of heat treatment formality.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclatures

| u | The velocity vector of flow field, m/s |

| Flux of flow field | |

| The source term of the mass conservation equation | |

| Γ | Diffusion coefficients of the k-ɛ equations, m2/s |

| Thermal conductivity, W/(m·°C) | |

| Density, kg/m3 | |

| Specific heat capacity, J/(kg·°C) | |

| Transient temperature of the object, °C | |

| Time, s | |

| Heat flux density, W/m2 | |

| Normal temperature gradient of the boundary layer | |

| Surface temperature of the boundary layer, °C | |

| Temperature of the flowing fluid, °C | |

| Heat exchange coefficient, W/(m2·°C) |

References

- Liang, Z.L.; Li, W.T.; Zhu, B.G.; Niu, L.Q. Modelling Dynamic Recrystallization of A356 Aluminum Alloy during Hot Deformation. Metals 2022, 12, 1407. [Google Scholar] [CrossRef]

- Li, P.; Maijer, D.M.; Lindley, T.C.; Lee, P.D. Simulating the Residual Stress in an A356 Automotive Wheel and Its Impact on Fatigue Life. Metall. Mater. Trans. B 2007, 38, 505–515. [Google Scholar] [CrossRef]

- Hu, P.; Yang, H.; Tan, H.; Yang, L.; Sun, X. Optimization of Low Pressure Die Casting Process for Alloy Wheels with Complex Wheel Faces. Spec. Cast. Nonferrous Alloys 2018, 38, 402–405. [Google Scholar]

- Gholamreza, K.; Mohammad, J.K.; Ali, N. Microstructure and hot deformation behavior of AlMg6 alloy produced by equal-channel angular pressing. Mater. Sci. Eng. A 2012, 542, 15–20. [Google Scholar]

- Estey, C.M.; Cockcroft, S.L.; Maijer, D.M.; Hermesmann, C. Constitutive behaviour of A356 during the quenching operation. Mater. Sci. Eng. A 2004, 383, 245–251. [Google Scholar] [CrossRef]

- Zhao, Y.T.; Lu, S.P.; Chen, G. Manufacturing Technology of Light-Alloy Wheels; China Machine Press: Beijing, China, 2018; p. 108. [Google Scholar]

- Deng, Y.L.; Zhang, X.M. Development of aluminium and aluminium alloy. Chin. J. Nonferrous Met. 2019, 29, 2115–2141. [Google Scholar]

- Huo, Y.C.; Liu, Y.; Huang, L.N.; Li, Q. Quenching stress at inner surface of hollow cylinders. Trans. Mater. Heat Treat. 2022, 43, 157–166. [Google Scholar]

- Wang, W.; Zhou, J.X.; Yin, Y.J.; Shen, X.; Ji, X.Y. Simulation of Thermal Stress and Distortion during Heat treatment process of Swing at Fixed End. In Proceedings of the 2017 China Foundry Activity Week Proceedings, Soochow, China, 14 November 2017; pp. 498–504. [Google Scholar]

- Li, H.W.; Gao, Y.F.; Du, C.H.; Hong, W.P. Numerical study on swirl cooling flow, heat transfer and stress characteristics based on fluid-structure coupling method under different swirl chamber heights and Reynolds numbers. Int. J. Heat Mass Transf. 2021, 173, 121228. [Google Scholar] [CrossRef]

- Yan, M.; Fan, Y.R.; Yue, M.; Wei, J.N.; Lin, H.F.; Li, S.G. Heat-mass transfer coupling effects in water-ice phase transformation of water-bearing coal frozen with liquid nitrogen. Appl. Therm. Eng. 2022, 215, 118902. [Google Scholar] [CrossRef]

- Peng, C.T.; Luo, Y.; Jin, Y. Thermal Fluid-Solid Coupling and Thermal Stress Analysis of Vacuum Valve Based on CFD. In Proceedings of the Seventh Asia International Symposium on Mechatronics; Springer: Singapore, 2 September 2020; pp. 85–94. [Google Scholar]

- Ying, L.; Gao, T.H.; Dai, M.H.; Hu, P.; Teng, H. Experimental and numerical investigation on temperature field and tailored mechanical properties distribution of 22MnB5 steel in spray quenching process. J. Manuf. Process. 2020, 57, 930–956. [Google Scholar] [CrossRef]

- Hu, H.; Yang, L.Z.; Guo, Y.F.; Chen, F.; Wang, S.; Zheng, F.Q.; Li, B. Numerical Simulation of Bottom-Blowing Stirring in Different Smelting Stages of Electric Arc Furnace Steelmaking. Metals 2021, 11, 799. [Google Scholar] [CrossRef]

- Song, J.S.; Zhang, W.L.; Li, X.J.; Chen, R.Z.; Luo, P. Numerical simulation of dynamic quenching process of forged aluminum alloy wheel hub. Heat Treat. Met. 2019, 44, 213–217. [Google Scholar]

- Meng, T.; Zhang, J.Y.; Li, T. Numerical Simulation and Optimization for the Temperature Field of the Coach in the Sleeping EMU. J. Mech. Eng. 2018, 54, 17–22. [Google Scholar] [CrossRef]

- Liu, Z.W.; Yi, J.; Li, S.K.; Nie, W.J.; Li, L.X.; Wang, G. Study on inhomogeneous cooling behavior of extruded profile with unequal and large thicknesses during quenching using thermo-mechanical coupling model. Trans. Nonferrous Met. Soc. China 2020, 30, 1211–1226. [Google Scholar] [CrossRef]

- Wang, C.T.; Li, Z.C. Numerical Simulation Research of Sequential Fluid-solid Coupling Heat Transfer of Exhaust Turbine. J. Mech. Eng. 2017, 53, 156–164. [Google Scholar] [CrossRef]

- Roy, M.J.; Maijer, D.M.; Dancoine, L. Constitutive behavior of as-cast A356. Mater. Sci. Eng. A 2012, 548, 195–205. [Google Scholar] [CrossRef]

- Popiel, C.O.; Wojtkowiak, J. Simple Formulas for Thermophysical Properties of Liquid Water for Heat Transfer Calculations (from 0 °C to 150 °C). Heat Transf. Eng. 1998, 19, 87–101. [Google Scholar] [CrossRef]

- Kang, L.; Zhao, G.; Tian, N.; Zhang, H.T. Computation of synthetic surface heat transfer coefficient of 7B50 ultra-high-strength aluminum alloy during spray quenching. Trans. Nonferrous Met. Soc. China 2018, 28, 989–997. [Google Scholar] [CrossRef]

- Pouraliakbar, H.; Firooz, S.; Jandaghi, M.R.; Khalaj, G.; Ali, N. Predicting the ultimate grain size of aluminum sheets undergone constrained groove pressing. Int. J. Adv. Manuf. Technol. 2016, 86, 1639–1658. [Google Scholar] [CrossRef]

| Chemical Element | Al | Si | Fe | Cu | Mn | Mg | Zn | Ti | Sr |

|---|---|---|---|---|---|---|---|---|---|

| Standard | ≥90 | 6.5~7.5 | ≤0.20 | ≤0.10 | ≤0.10 | 0.25~0.45 | ≤0.10 | 0.08~0.20 | 0.008~0.20 |

| Measured | 92.7 | 6.73 | 0.11 | 0.004 | 0.002 | 0.278 | 0.005 | 0.115 | 0.001 |

| Parameter | Functional Relationship | R-Square |

|---|---|---|

| Specific heat capacity (J/(kg·°C)) | 873.7 + 0.6764 T − 9.9866 × 10−4 T2 + 1.1926 × 10−6 T3 | 0.99991 |

| Density (kg/m3) | 2685.6 − 0.1683 T − 6.3294 × 10−5 T2 | 1 |

| Thermal conductivity (W/(m·°C)) | 183.25 + 4.50 × 10−2 T − 2.1161 × 10−4 T2 + 1.5977 ×1 0−7 T3 | 0.99931 |

| Poisson’s ratio | 0.3305 + 3.3373 × 10−5 T + 3.7497 × 10−8 T2 | 1 |

| Young’s modulus (MPa) | 71,642.9 − 31.7224 T − 2.19 × 10−2 T2 | 1 |

| Technics Number | Quenching Processes | Transfer Time/s | Average Deformation/μm | Relative Improvement/% | Numbers of Wheel | Wheel Number |

|---|---|---|---|---|---|---|

| 1 | Water | 25 | 470 | Baseline | 3 | 1#, 2#, 3# |

| 2 | Spraying 15 s + water | 40 | 275 | 39.2 | 3 | 4#, 5#, 6# |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chi, H.; Yan, M.; Xu, Z.; Xiang, P.; An, Z.; Huang, H. Analysis on the Quenching Deformation Characteristics of Light Cast Aluminum Alloy Wheels and Their Control Strategies. Metals 2023, 13, 128. https://doi.org/10.3390/met13010128

Chi H, Yan M, Xu Z, Xiang P, An Z, Huang H. Analysis on the Quenching Deformation Characteristics of Light Cast Aluminum Alloy Wheels and Their Control Strategies. Metals. 2023; 13(1):128. https://doi.org/10.3390/met13010128

Chicago/Turabian StyleChi, Hui, Meng Yan, Zhengqi Xu, Pengfei Xiang, Zijun An, and Huagui Huang. 2023. "Analysis on the Quenching Deformation Characteristics of Light Cast Aluminum Alloy Wheels and Their Control Strategies" Metals 13, no. 1: 128. https://doi.org/10.3390/met13010128

APA StyleChi, H., Yan, M., Xu, Z., Xiang, P., An, Z., & Huang, H. (2023). Analysis on the Quenching Deformation Characteristics of Light Cast Aluminum Alloy Wheels and Their Control Strategies. Metals, 13(1), 128. https://doi.org/10.3390/met13010128