Effect of Laser Shock Peening on High-Cycle Fatigue Performance of 1Cr18Ni9Ti/GH1140 Weld

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Laser Shock Process

2.2. Residual Stress and Microhardness Measurements

2.3. Microstructural Characterization

2.4. High-Cycle Fatigue Tests

3. Results and Discussion

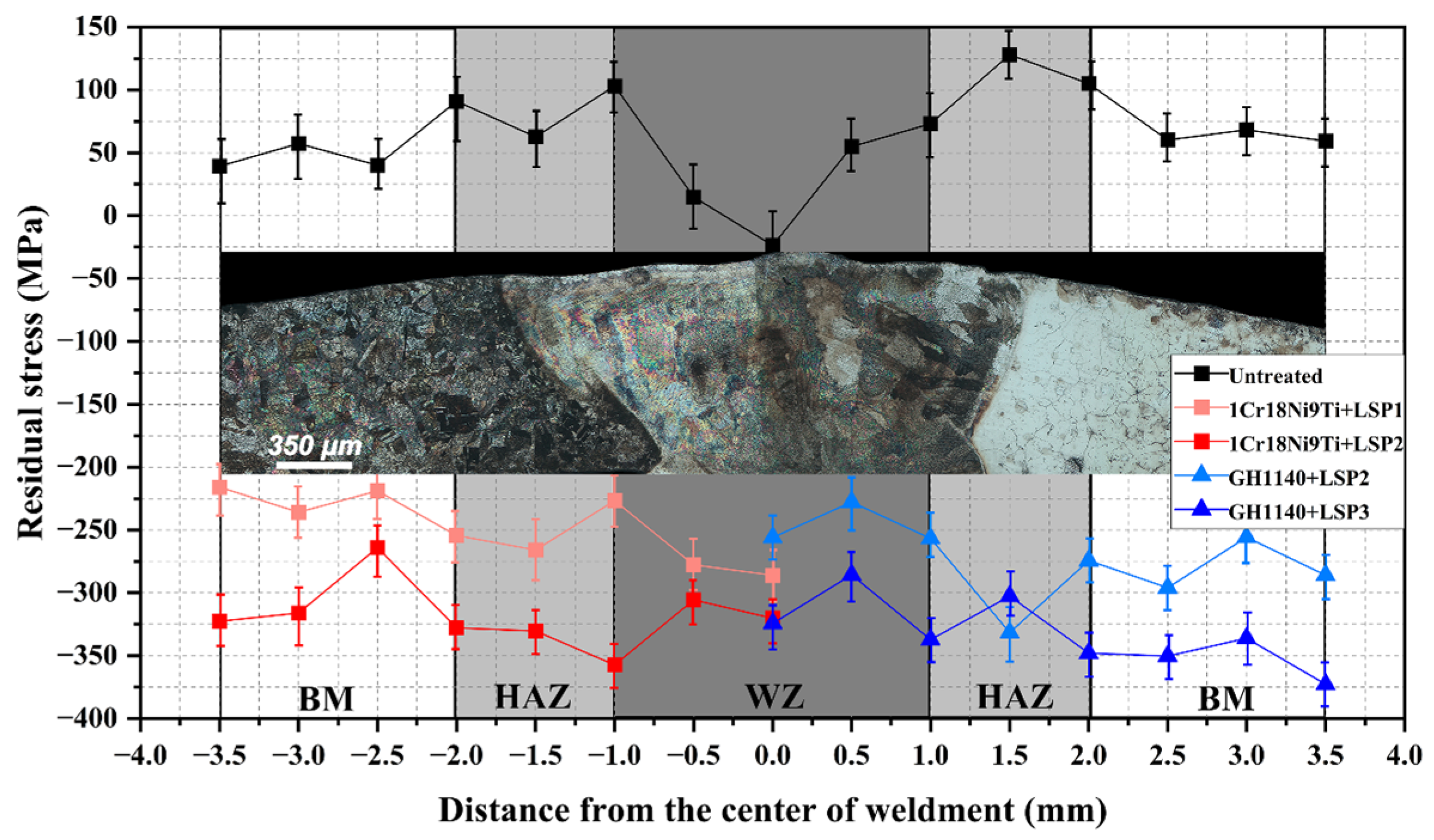

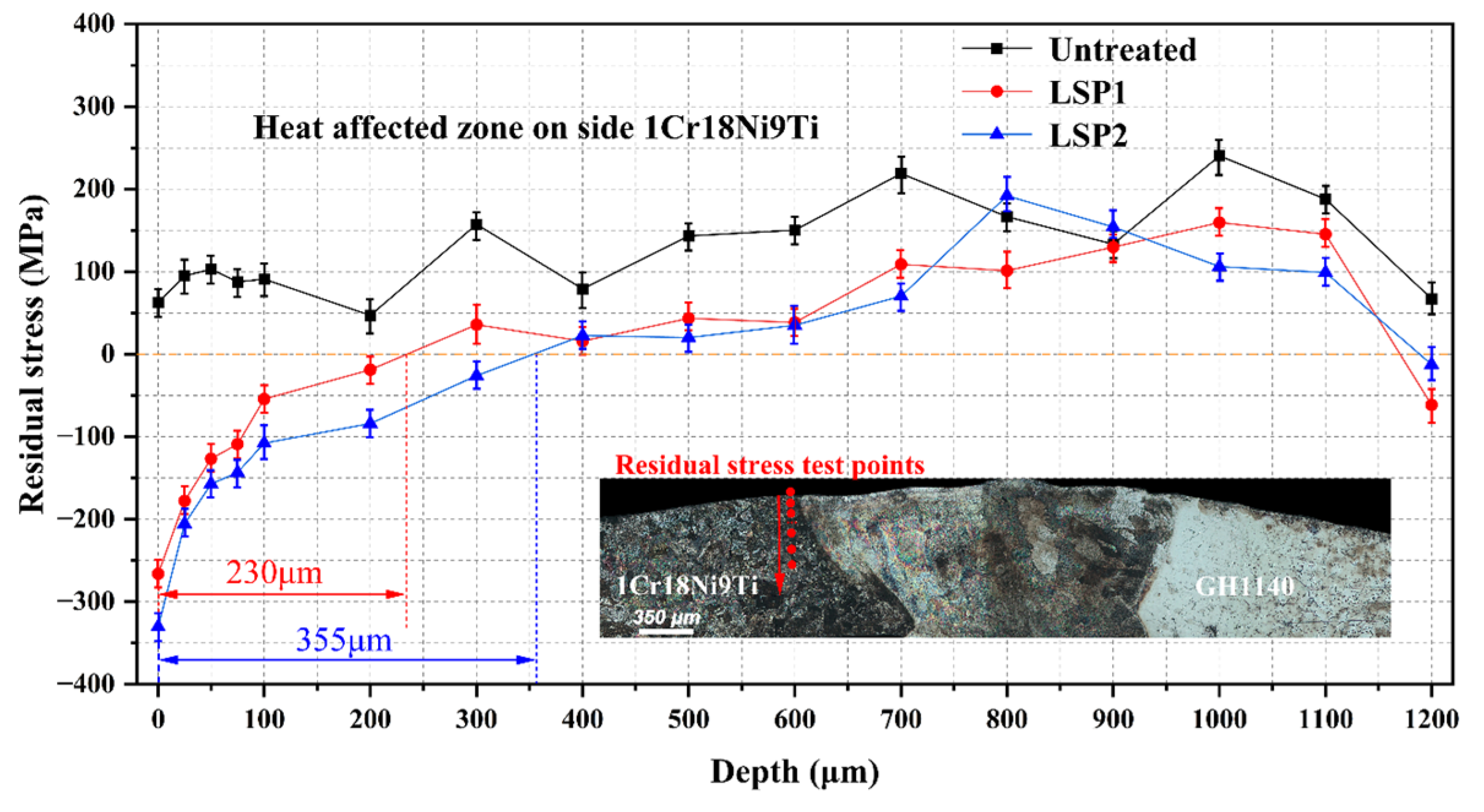

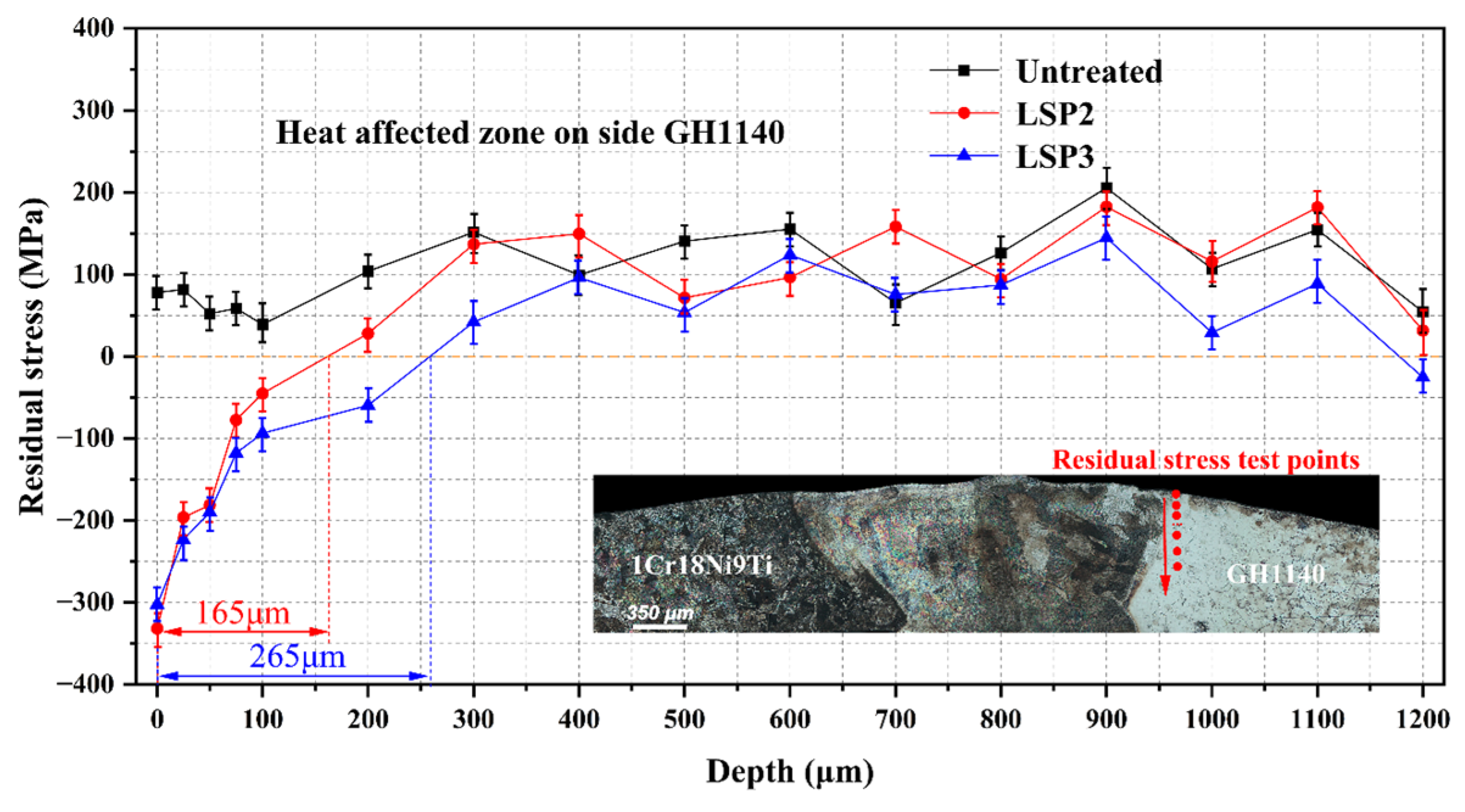

3.1. Residual Stress Distribution

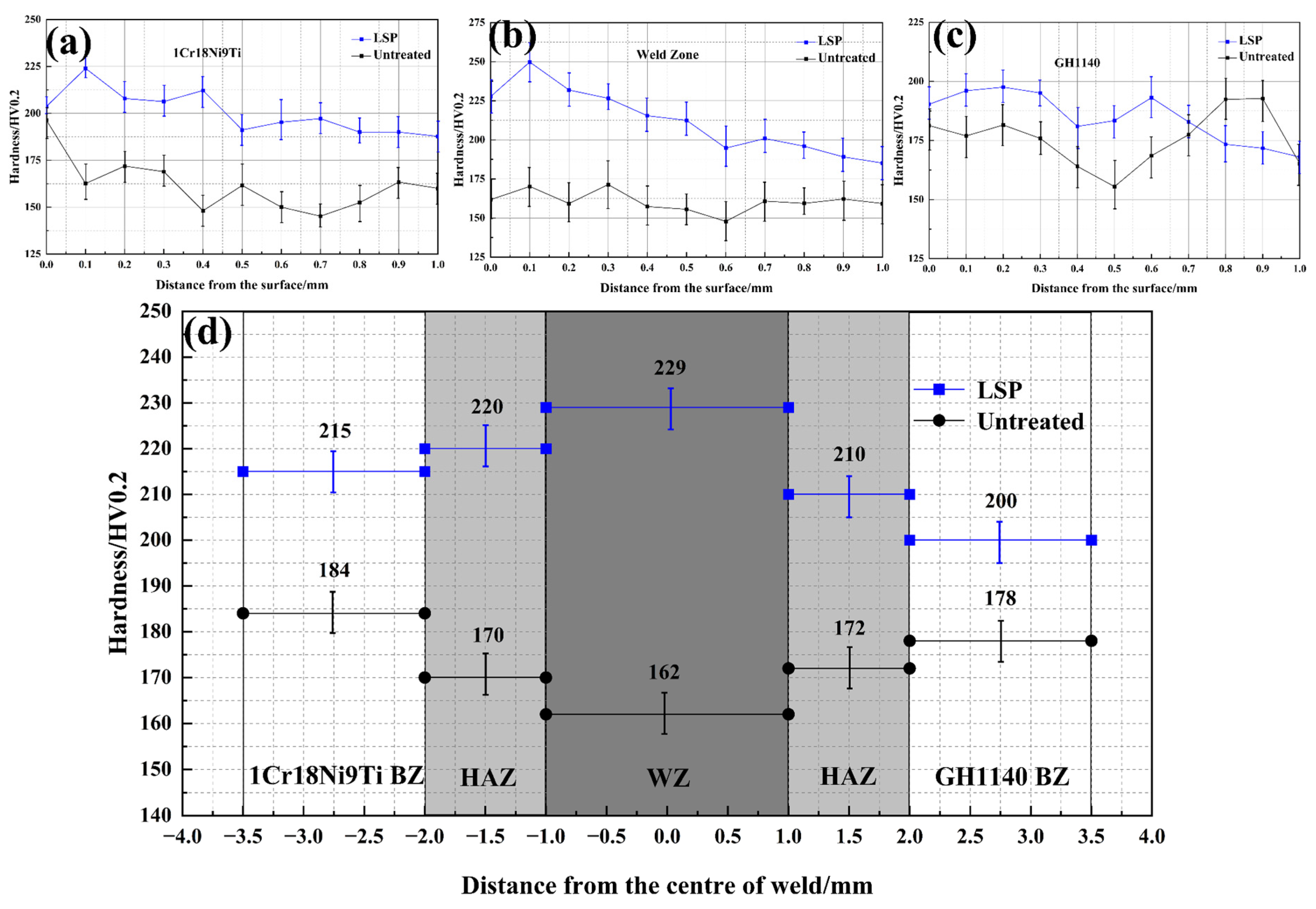

3.2. Microhardness Analysis

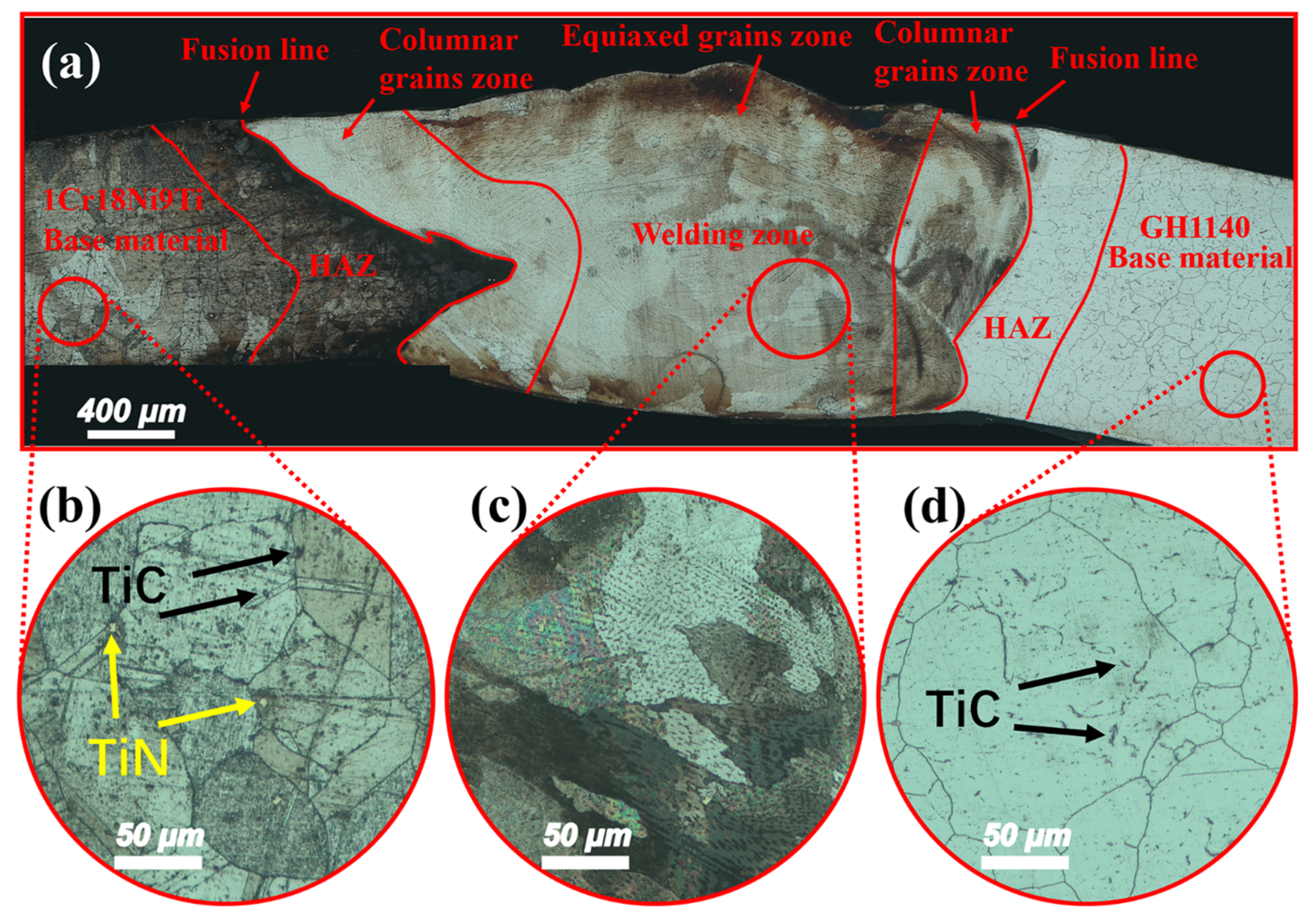

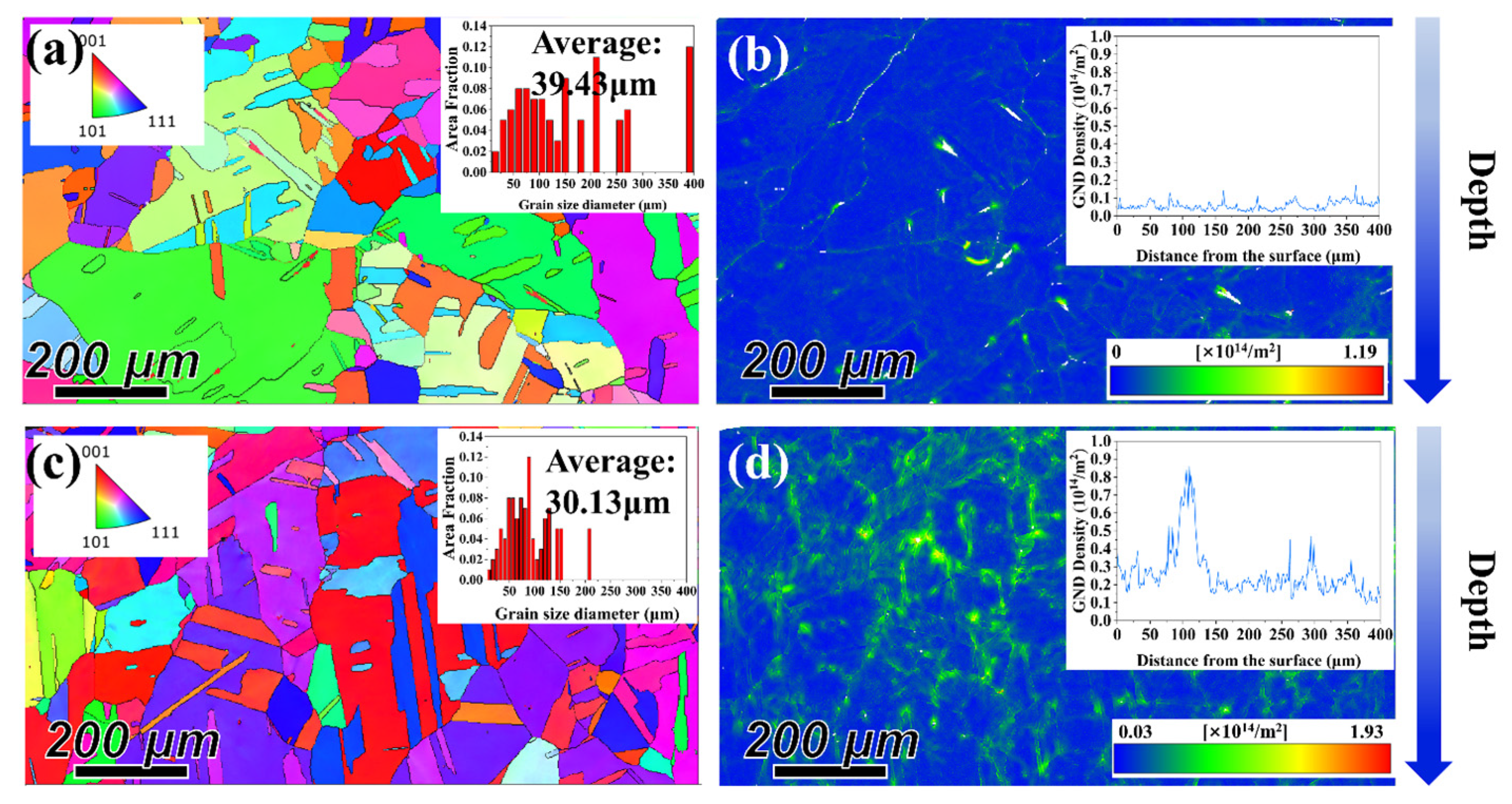

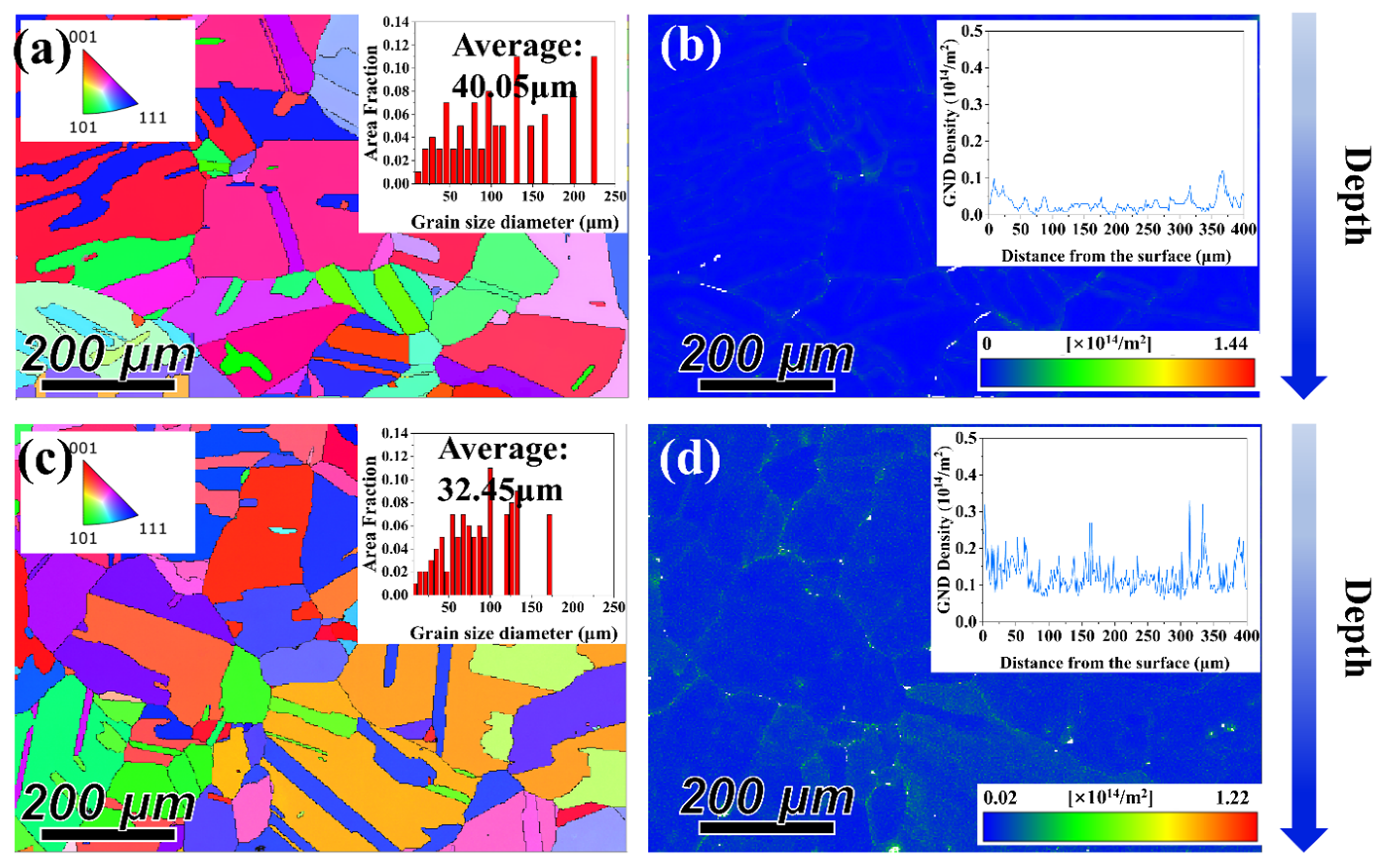

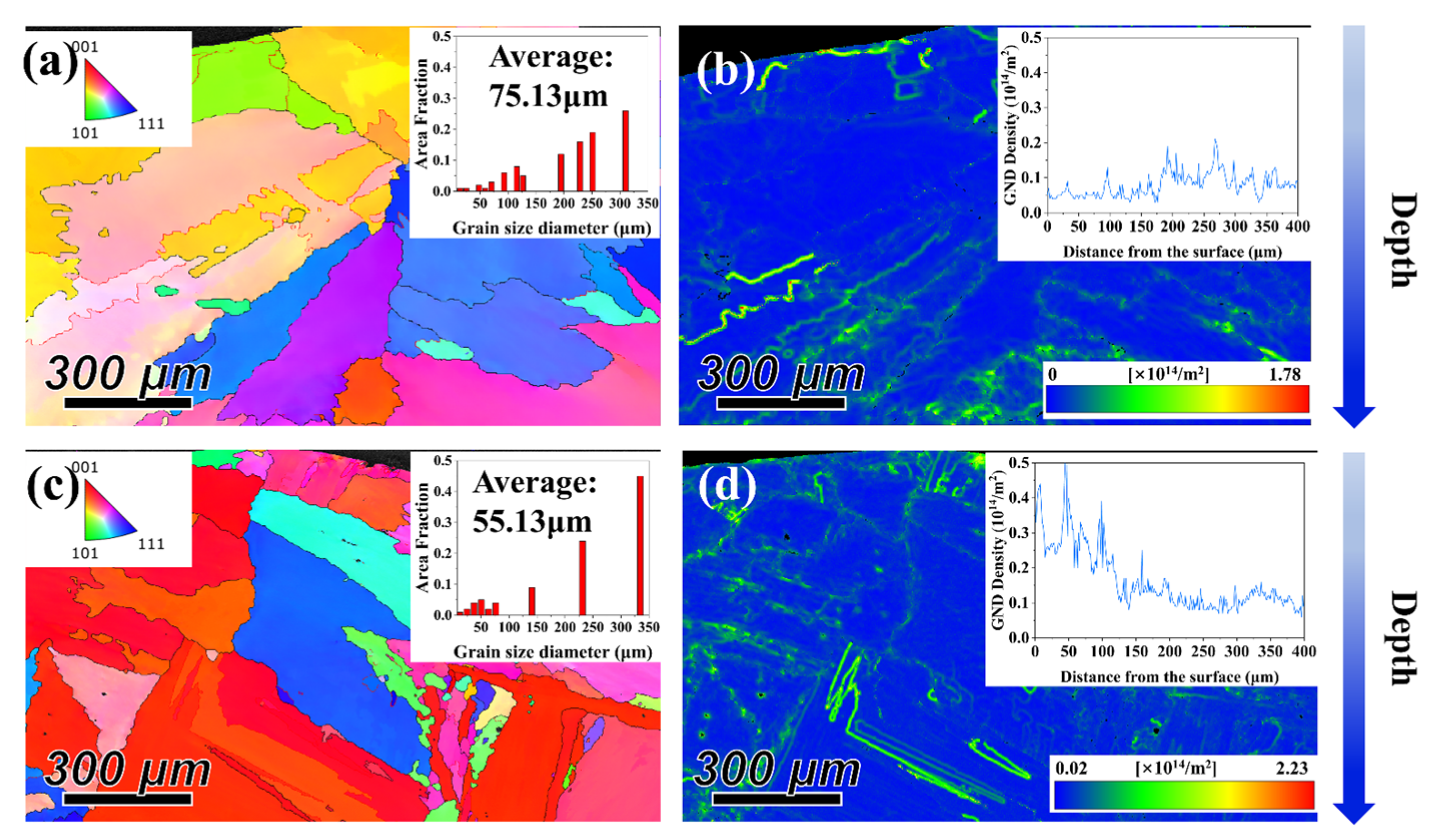

3.3. Microstructural Evolution

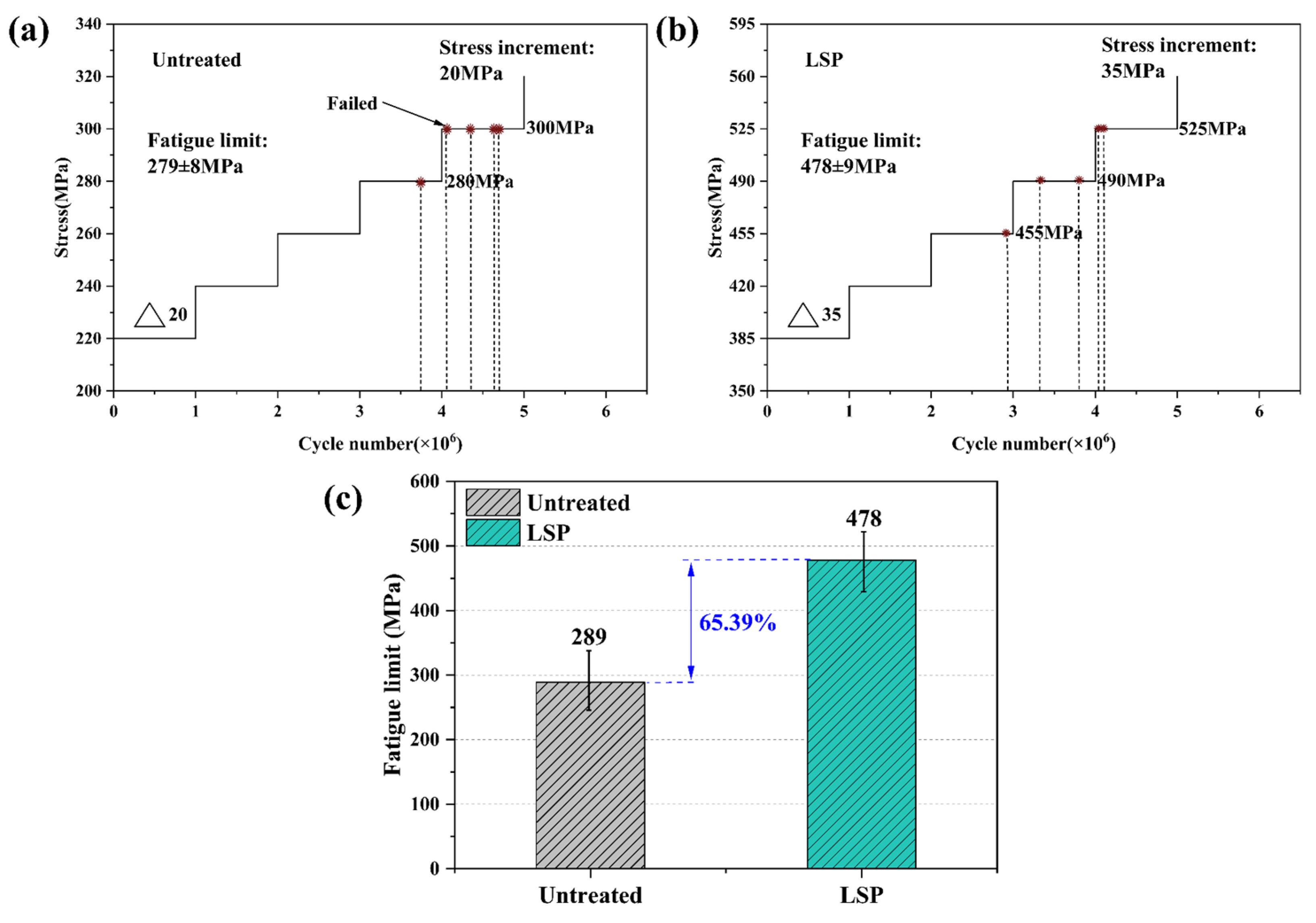

3.4. High-Cycle Fatigue Performance

4. Conclusions

- (1)

- The welding residual stress changes from the original residual tensile stress to the high-amplitude residual compressive stress. The average value of residual compressive stress is about −300 MPa and the depth of the influence layer of residual compressive stress in HAZ of 1Cr18Ni9Ti side reaches 355 μm. The influence layer depth of residual compressive stress in HAZ of GH1140 reaches 265 μm.

- (2)

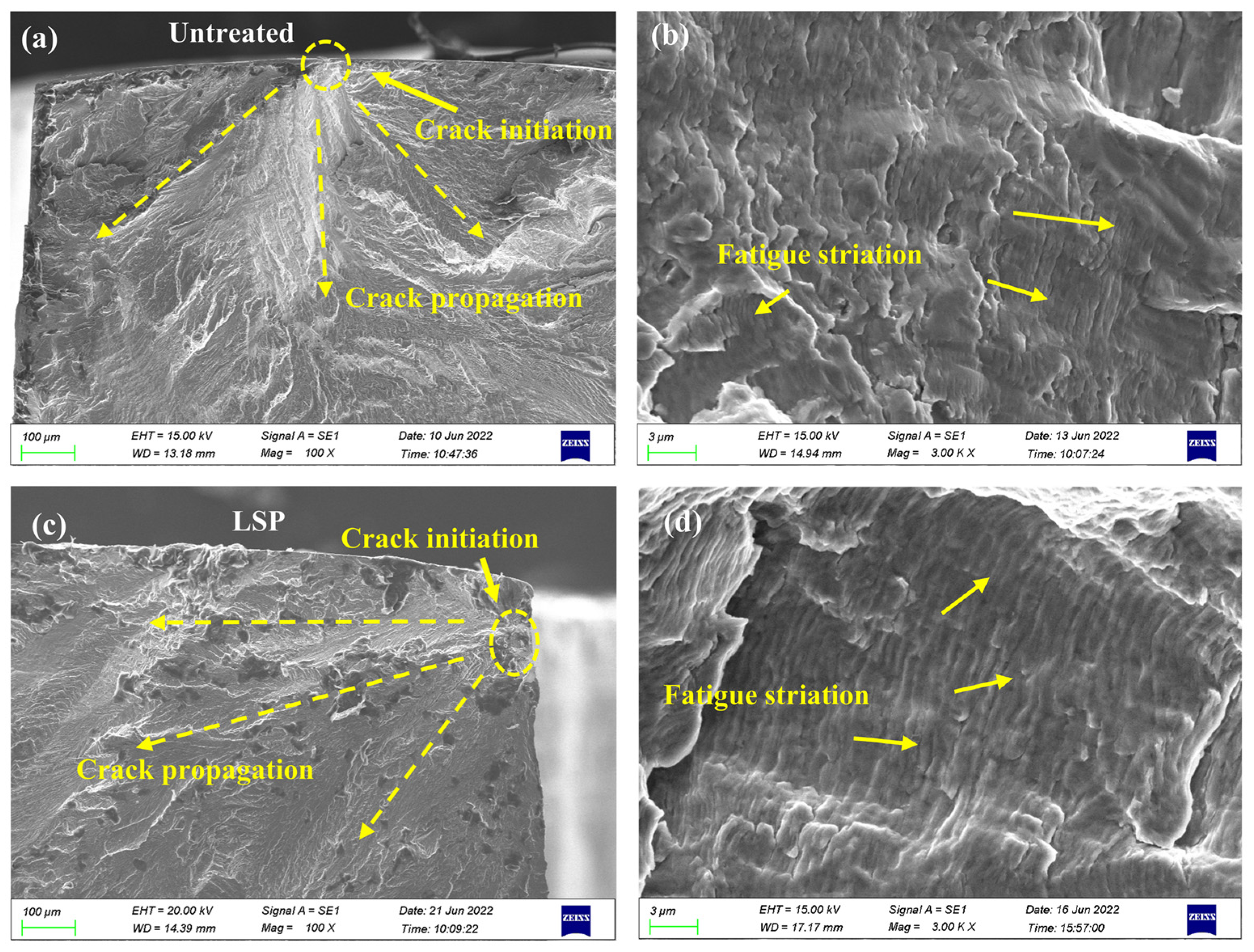

- The grain refinement, gradient plastic deformation in the depth direction and dislocation structure of the surface material induced by laser shock peening can increase the resistance of fatigue crack initiation and propagation, thus improving the fatigue performance.

- (3)

- The high-cycle tensile–tensile fatigue limit of the 1CR18NI9TI/GH1140 welded joint was increased from 289 to 478 MPa. It is considered that this is the result of the interaction of high-amplitude residual compressive stress, grain refinement and gradient plasticity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramkumar, K.D.; Arivazhagan, N.; Narayanan, S. Effect of filler materials on the performance of gas tungsten arc welded AISI 304 and Monel 400. Mater. Des. 2012, 40, 70–79. [Google Scholar] [CrossRef]

- Mortezaie, A.; Shamanian, M. An assessment of microstructure, mechanical properties and corrosion resistance of dissimilar welds between Inconel 718 and 310S austenitic stainless steel. Int. J. Press. Vessel. Pip. 2014, 116, 37–46. [Google Scholar] [CrossRef]

- Naffakh, H.; Shamanian, M.; Ashrafizadeh, F. Dissimilar welding of AISI 310 austenitic stainless steel to nickel-based alloy Inconel 657. J. Mater. Process. Technol. 2009, 209, 3628–3639. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Patel, S.D.; Praveen, S.S.; Choudhury, D.J.; Prabaharan, P.; Arivazhagan, N.; Xavior, M.A. Influence of filler metals and welding techniques on the structure-property relationships of Inconel 718 and AISI 316L dissimilar weldments. Mater. Des. 2014, 62, 175–188. [Google Scholar] [CrossRef]

- Chen, F.; Lv, Y.; Zhuang, X.; Zhong, G.; He, Y.; Yin, C. Effects of laser shock strengthening on performance of dissimilar metal welded joint. Hot Work. Technol. 2016, 45, 192–194. [Google Scholar]

- Ramkumar, K.D.; Sridhar, R.; Periwal, S.; Oza, S.; Saxena, V.; Hidad, P.; Arivazhagan, N. Investigations on the structure—Property relationships of electron beam welded Inconel 625 and UNS 32205. Mater. Des. 2015, 68, 158–166. [Google Scholar] [CrossRef]

- Neves, M.D.M.d.; Lotto, A.; Berretta, J.R.; de Rossi, W.; Junior, N.D.V. Microstructure development in Nd:YAG laser welding of AISI 304 and Inconel 600. Soldag. Insp. 2009, 14, 104–113. [Google Scholar] [CrossRef]

- Hosseini, H.S.; Shamanian, M.; Kermanpur, A. Characterization of microstructures and mechanical properties of Inconel 617/310 stainless steel dissimilar welds. Mater. Charact. 2011, 62, 425–431. [Google Scholar] [CrossRef]

- Jeng, S.L.; Lee, H.T.; Weirich, T.E.; Rebach, W.P. Microstructual study of the dissimilar joints of alloy 690 and SUS 304L stainless steel. Mater. Trans. 2007, 48, 481–489. [Google Scholar] [CrossRef]

- Yeh, T.-K.; Huang, G.-R.; Wang, M.-Y.; Tsai, C.-H. Stress corrosion cracking in dissimilar metal welds with 304L stainless steel and Alloy 82 in high temperature water. Prog. Nucl. Energy 2013, 63, 7–11. [Google Scholar] [CrossRef]

- Hassan, K.S.; Hanash, K.E.; Razooqi, A.I. Influence of shot peening on bending forces for MIG dissimilar welding joint aluminum alloys. In Proceedings of the 2nd International Conference on Sustainable Engineering Techniques (ICSET), Baghdad, Iraq, 6–7 March 2019. [Google Scholar]

- Logesh, M.; Selvabharathi, R.; Thangeeswari, T.; Palani, S. Influence of severe double shot peening on microstructure properties of Ti 6Al-4V and Titanium Grade 2 dissimilar joints using laser beam welding. Opt. Laser Technol. 2020, 123, 105883. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Kumar, P.S.G.; Krishna, V.R.; Chandrasekhar, A.; Dev, S.; Abraham, W.S.; Prabhakaran, S.; Kalainathan, S.; Sridhar, R. Influence of laser peening on the tensile strength and impact toughness of dissimilar welds of Inconel 625 and UNS 532205. Mater. Sci. Eng. A 2016, 676, 88–99. [Google Scholar] [CrossRef]

- Ghorbani, S.; Ghasemi, R.; Ebrahimi-Kahrizsangi, R.; Hojjati-Najafabadi, A. Effect of post weld heat treatment (PWHT) on the microstructure, mechanical properties, and corrosion resistance of dissimilar stainless steels. Mater. Sci. Eng. A 2017, 688, 470–479. [Google Scholar] [CrossRef]

- Leo, P.; D’Ostuni, S.; Nobile, R.; Mele, C.; Tarantino, A.; Casalino, G. Analysis of the process parameters, post-weld heat treatment and peening effects on microstructure and mechanical performance of Ti-Al dissimilar laser weldings. Metals 2021, 11, 1257. [Google Scholar] [CrossRef]

- Benchouia, S.; Merakeb, N.; Adjel, S.; Ehlers, S.; Baccouche, M.; Kaddour, A. Fatigue life enhancement of TIG-welded 304L stainless steels by shot peening. Int. J. Adv. Manuf. Technol. 2019, 100, 2885–2893. [Google Scholar] [CrossRef]

- Fu, Z.; Ji, B.; Kong, X.; Chen, X. Effects of Hammer Peening on Fatigue Performance of Roof and U-Rib Welds in Orthotropic Steel Bridge Decks. J. Mater. Civ. Eng. 2018, 30, 04018306. [Google Scholar] [CrossRef]

- Fueki, R.; Takahashi, K. Improving the fatigue limit and rendering a defect harmless by laser peening for a high strength steel welded joint. Opt. Laser Technol. 2021, 134, 106605. [Google Scholar] [CrossRef]

- Fueki, R.; Takahashi, K.; Handa, M. Fatigue Limit Improvement and Rendering Defects Harmless by Needle Peening for High Tensile Steel Welded Joint. Metals 2019, 9, 143. [Google Scholar] [CrossRef]

- Hensel, J.; Eslami, H.; Nitschke-Pagel, T.; Dilger, K. Fatigue Strength Enhancement of Butt Welds by Means of Shot Peening and Clean Blasting. Metals 2019, 9, 744. [Google Scholar] [CrossRef]

- Kinoshita, K.; Banno, Y.; Ono, Y.; Yamada, S.; Handa, M. Fatigue Strength Improvement of Welded Joints of Existing Steel Bridges by Shot-Peening. Int. J. Steel Struct. 2019, 19, 495–503. [Google Scholar] [CrossRef]

- Lago, J.; Trsko, L.; Jambor, M.; Novy, F.; Bokuvka, O.; Mician, M.; Pastorek, F. Fatigue Life Improvement of the High Strength Steel Welded Joints by Ultrasonic Impact Peening. Metals 2019, 9, 619. [Google Scholar] [CrossRef] [Green Version]

- Sano, T.; Eimura, T.; Hirose, A.; Kawahito, Y.; Katayama, S.; Arakawa, K.; Masaki, K.; Shiro, A.; Shobu, T.; Sano, Y. Improving Fatigue Performance of Laser-Welded 2024-T3 Aluminum Alloy Using Dry Laser Peening. Metals 2019, 9, 1192. [Google Scholar] [CrossRef]

- Soyama, H. Laser Cavitation Peening and Its Application for Improving the Fatigue Strength of Welded Parts. Metals 2021, 11, 531. [Google Scholar] [CrossRef]

- Soyama, H.; Simoncini, M.; Cabibbo, M. Effect of Cavitation Peening on Fatigue Properties in Friction Stir Welded Aluminum Alloy AA5754. Metals 2021, 11, 59. [Google Scholar] [CrossRef]

- Chattopadhyay, A.; Muvvala, G.; Sarkar, S.; Racherla, V.; Nath, A.K. Effect of laser shock peening on microstructural, mechanical and corrosion properties of laser beam welded commercially pure titanium. Opt. Laser Technol. 2021, 133, 106527. [Google Scholar] [CrossRef]

- Feng, X.; Pan, X.; He, W.; Liu, P.; An, Z.; Zhou, L. Improving high cycle fatigue performance of gas tungsten arc welded Ti6Al4V titanium alloy by warm laser shock peening. Int. J. Fatigue 2021, 149, 106270. [Google Scholar] [CrossRef]

- Shi, X.; Feng, X.; Teng, J.; Zhang, K.; Zhou, L. Effect of laser shock peening on microstructure and fatigue properties of thin-wall welded Ti-6Al-4V alloy. Vacuum 2021, 184, 109986. [Google Scholar] [CrossRef]

- Jiang, W.; Chen, W.; Woo, W.; Tu, S.-T.; Zhang, X.-C.; Em, V. Effects of low-temperature transformation and transformation-induced plasticity on weld residual stresses: Numerical study and neutron diffraction measurement. Mater. Des. 2018, 147, 65–79. [Google Scholar] [CrossRef]

- Ahn, J.; He, E.; Chen, L.; Wimpory, R.C.; Dear, J.P.; Davies, C.M. Prediction and measurement of residual stresses and distortions in fibre laser welded Ti-6Al-4V considering phase transformation. Mater. Des. 2017, 115, 441–457. [Google Scholar] [CrossRef]

- Dhakal, B.; Swaroop, S. Review: Laser shock peening as post welding treatment technique. J. Manuf. Processes 2018, 32, 721–733. [Google Scholar] [CrossRef]

- Becker, N.; Gauthier, D.; Vidal, E.E. Fatigue properties of steel to aluminum transition joints produced by explosion welding. Int. J. Fatigue 2020, 139, 105736. [Google Scholar] [CrossRef]

- Sanchez, A.G.; You, C.; Leering, M.; Glaser, D.; Furfari, D.; Fitzpatrick, M.E.; Wharton, J.; Reed, P.A.S. Effects of laser shock peening on the mechanisms of fatigue short crack initiation and propagation of AA7075-T651. Int. J. Fatigue 2021, 143, 106025. [Google Scholar] [CrossRef]

- Praveen, T.R.; Nayaka, H.S.; Swaroop, S. Influence of equal channel angular pressing and laser shock peening on fatigue behaviour of AM80 alloy. Surf. Coat. Technol. 2019, 369, 221–227. [Google Scholar] [CrossRef]

- Nie, X.; He, W.; Zhou, L.; Li, Q.; Wang, X. Experiment investigation of laser shock peening on TC6 titanium alloy to improve high cycle fatigue performance. Mater. Sci. Eng. A 2014, 594, 161–167. [Google Scholar] [CrossRef]

- Hatamleh, O.; Lyons, J.; Forman, R. Laser and shot peening effects on fatigue crack growth in friction stir welded 7075-T7351 aluminum alloy joints. Int. J. Fatigue 2007, 29, 421–434. [Google Scholar] [CrossRef]

- Sano, Y.; Masaki, K.; Gushi, T.; Sano, T. Improvement in fatigue performance of friction stir welded A6061-T6 aluminum alloy by laser peening without coating. Mater. Des. 2012, 36, 809–814. [Google Scholar] [CrossRef]

- Hatamleh, O. Effects of peening on mechanical properties in friction stir welded 2195 aluminum alloy joints. Mater. Sci. Eng. A 2008, 492, 168–176. [Google Scholar] [CrossRef]

- Hatamleh, O. A comprehensive investigation on the effects of laser and shot peening on fatigue crack growth in friction stir welded AA 2195 joints. Int. J. Fatigue 2009, 31, 974–988. [Google Scholar] [CrossRef]

| Materials | C | Si | Mn | P | S | Ni | Cr | Ti | W | Mo | Al | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1Cr18Ni9Ti | 0.11 | 0.96 | 1.97 | <0.035 | <0.030 | 9.66 | 18.54 | 0.78 | 0 | 0 | 0 | Bal |

| GH1140 | 0.08 | 0.3 | 0.3 | 0 | 0 | 40 | 21 | 1.0 | 1.4 | 2.1 | 0.3 | Bal |

| A202 | 0.08 | 0.8 | 1.5 | 0.02 | 0.03 | 14 | 20 | 1.0 | 0 | 2.0 | 0.3 | Bal |

| Properties | 1Cr18Ni9Ti | GH1140 |

|---|---|---|

| Yield strength σ0.2 (MPa) | 205 | — |

| Ultimate tensile strength σb (MPa) | 520 | 635 |

| Elongation rate δ (%) | 40 | 40 |

| Elastic modulus (GPa) | 206 | — |

| Specimen | Wavelength (nm) | Lapping Rate | Spot Diameter (mm) | Energy (J) | Power Density (GW/cm2) | Laser Impacts |

|---|---|---|---|---|---|---|

| LSP1 | 1064 | 50% | 2.2 | 2 | 2.63 | 1 |

| LSP2 | 1064 | 50% | 2.2 | 3 | 3.94 | 1 |

| LSP3 | 1064 | 50% | 2.2 | 5 | 6.57 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Zhao, T.; Yu, Y.; Liu, P.; Pan, X. Effect of Laser Shock Peening on High-Cycle Fatigue Performance of 1Cr18Ni9Ti/GH1140 Weld. Metals 2022, 12, 1495. https://doi.org/10.3390/met12091495

Zhou L, Zhao T, Yu Y, Liu P, Pan X. Effect of Laser Shock Peening on High-Cycle Fatigue Performance of 1Cr18Ni9Ti/GH1140 Weld. Metals. 2022; 12(9):1495. https://doi.org/10.3390/met12091495

Chicago/Turabian StyleZhou, Liucheng, Tianxiao Zhao, Yanqing Yu, Ping Liu, and Xinlei Pan. 2022. "Effect of Laser Shock Peening on High-Cycle Fatigue Performance of 1Cr18Ni9Ti/GH1140 Weld" Metals 12, no. 9: 1495. https://doi.org/10.3390/met12091495

APA StyleZhou, L., Zhao, T., Yu, Y., Liu, P., & Pan, X. (2022). Effect of Laser Shock Peening on High-Cycle Fatigue Performance of 1Cr18Ni9Ti/GH1140 Weld. Metals, 12(9), 1495. https://doi.org/10.3390/met12091495