Strain-Rate Effect on Anisotropic Deformation Characterization and Material Modeling of High-Strength Aluminum Alloy Sheet

Abstract

:1. Introduction

2. Experimental Procedure

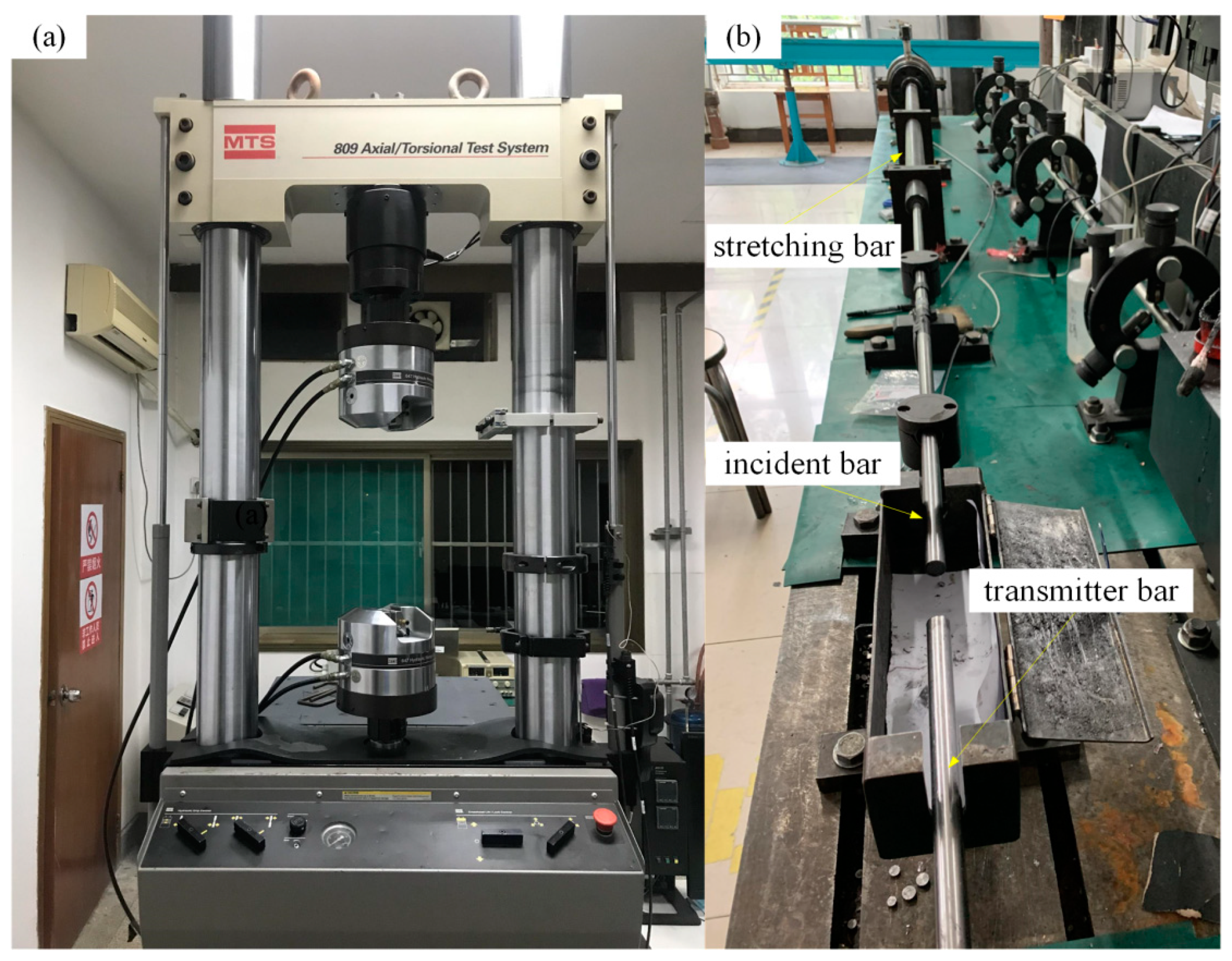

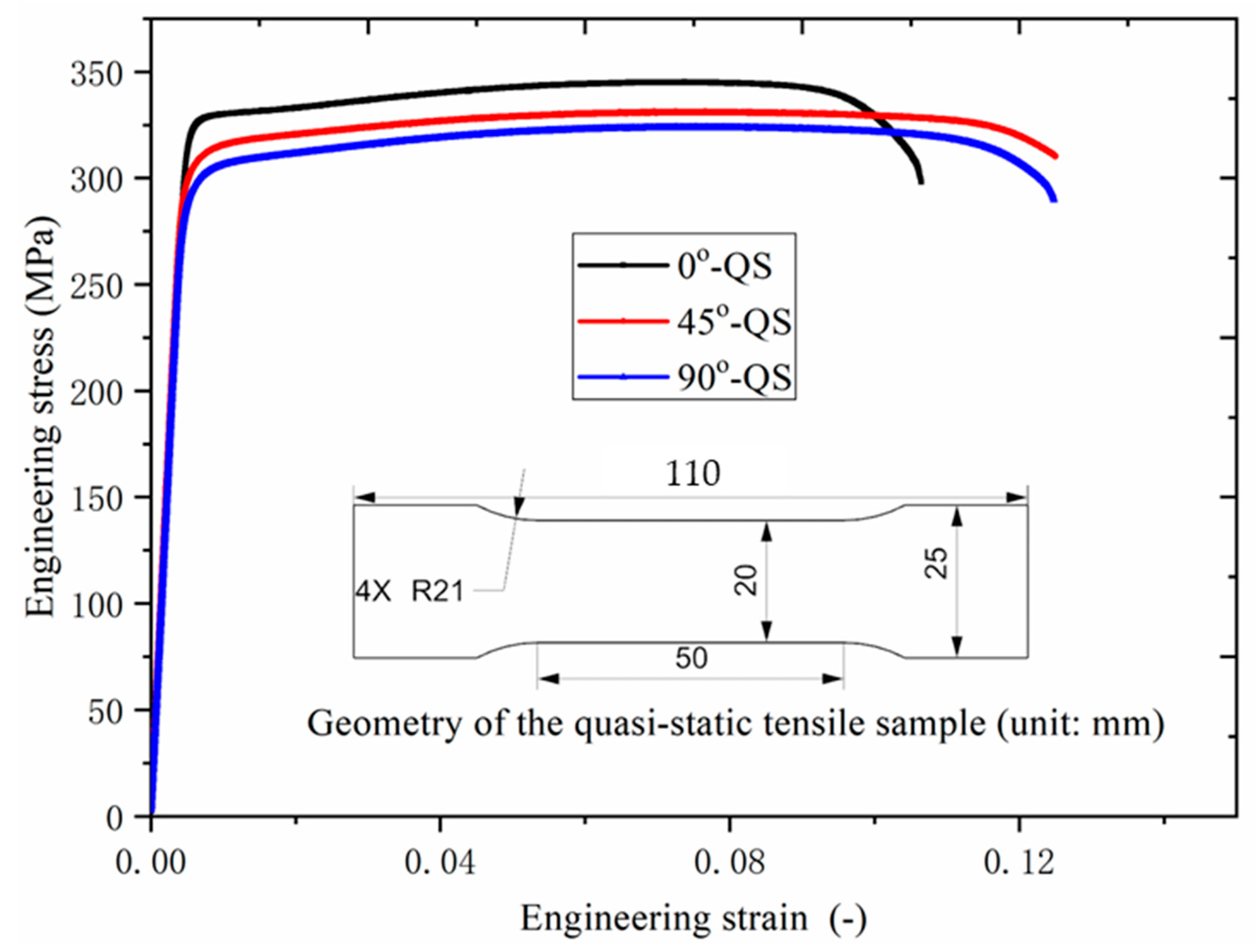

2.1. Uniaxial Tensile Test at Quasi-Static Condition

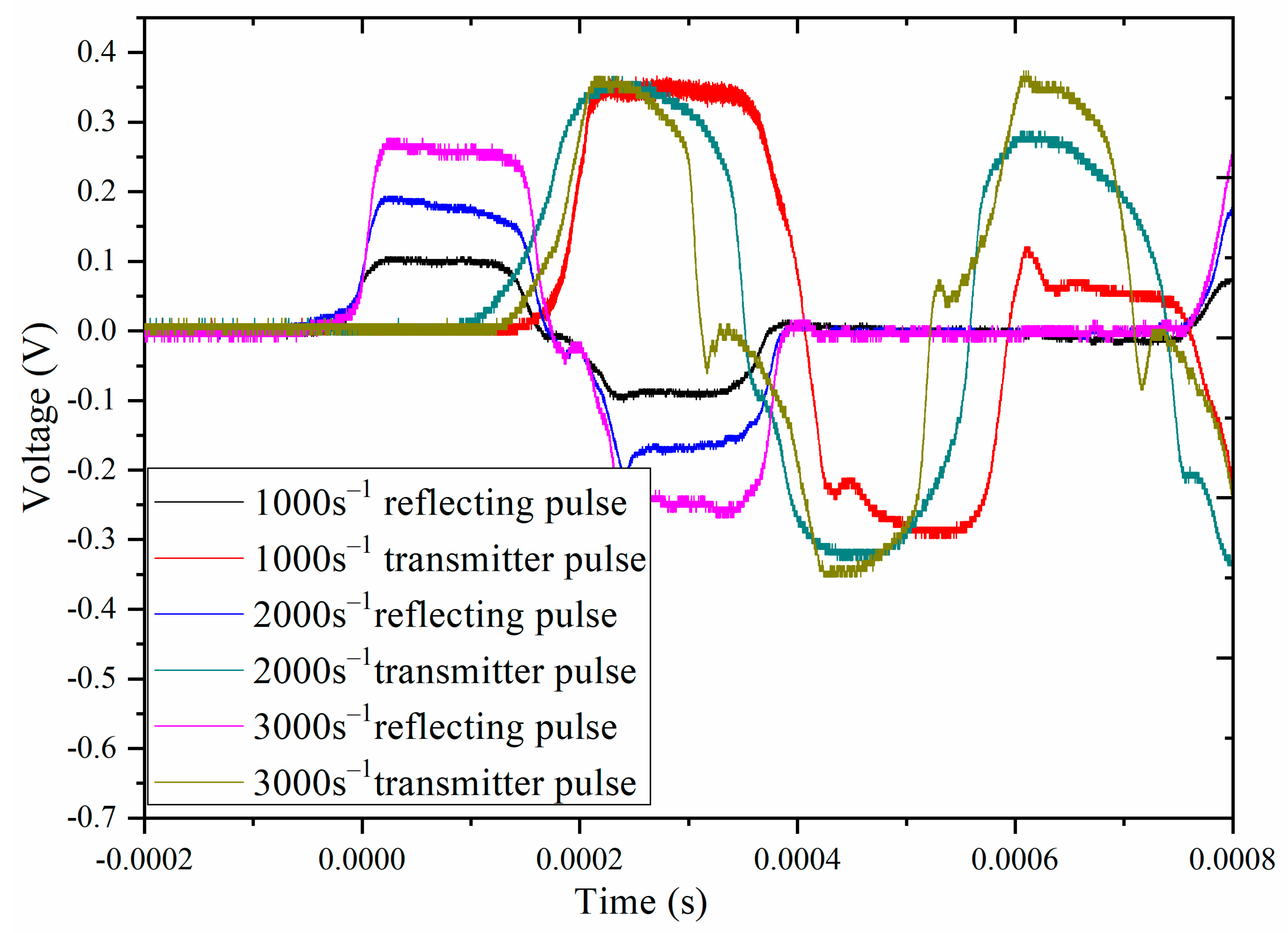

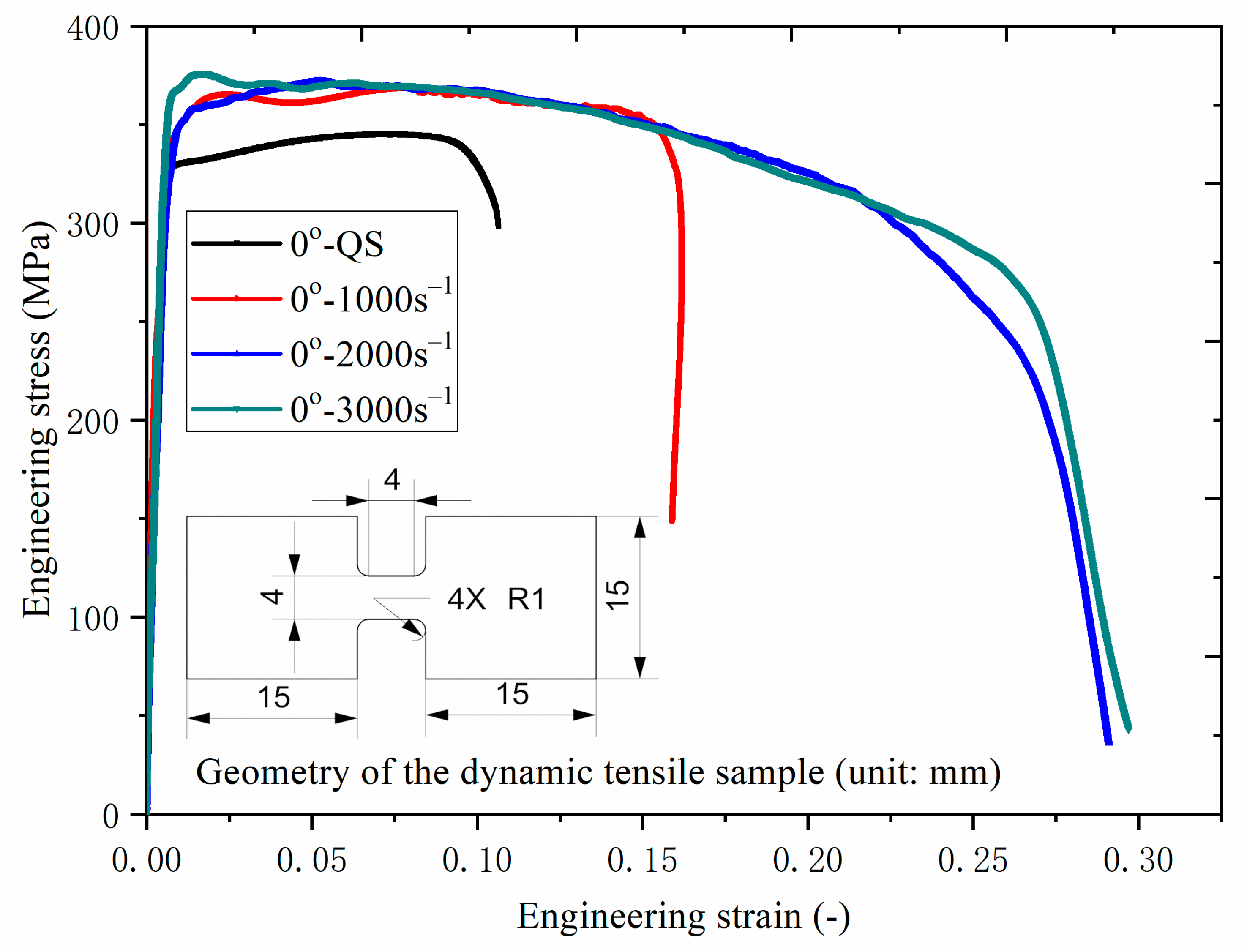

2.2. SHTB Tests at Various High Strain Rate Conditions

3. Material Modeling Analysis

3.1. Stress-Strain Hardening Model

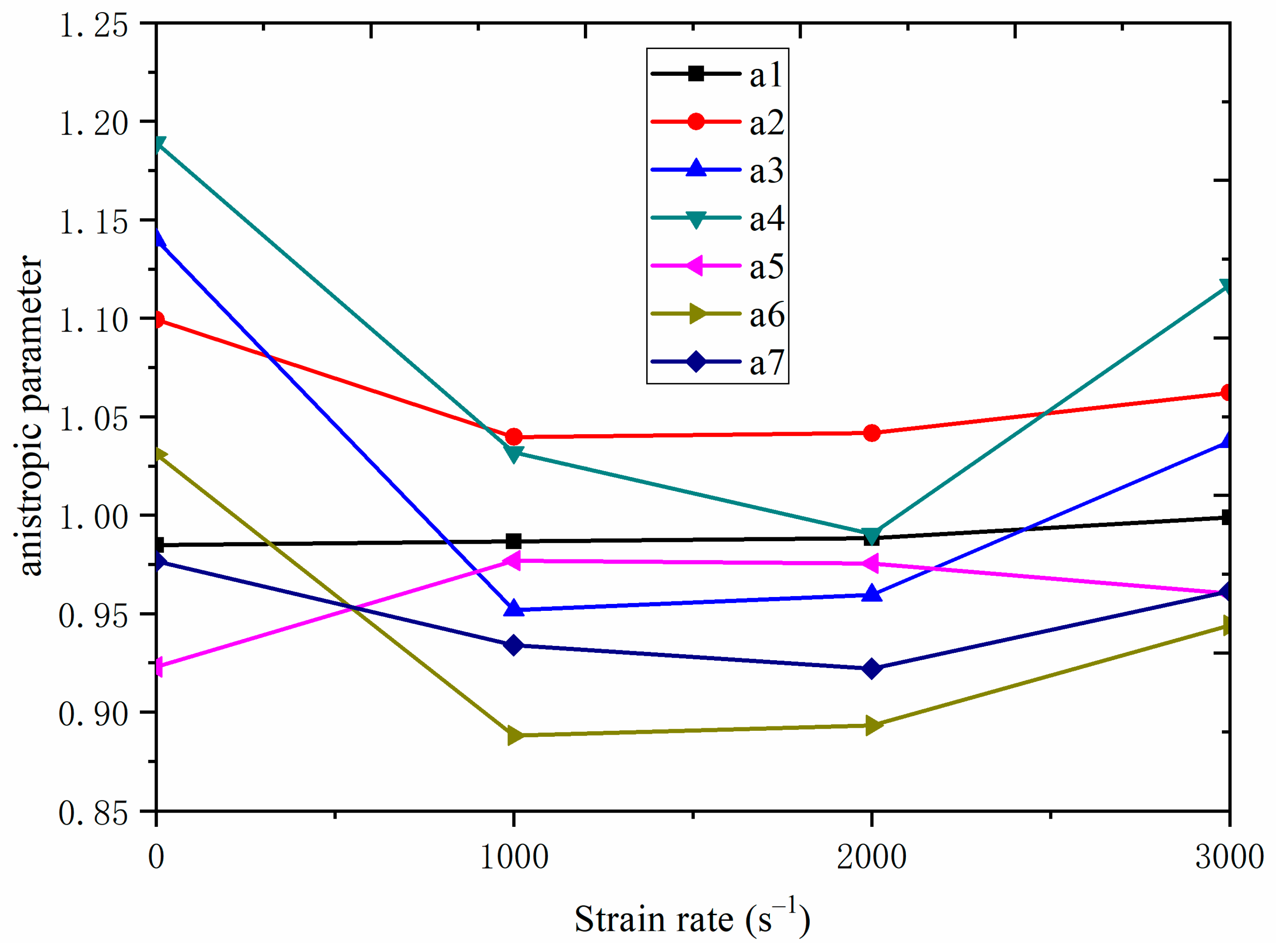

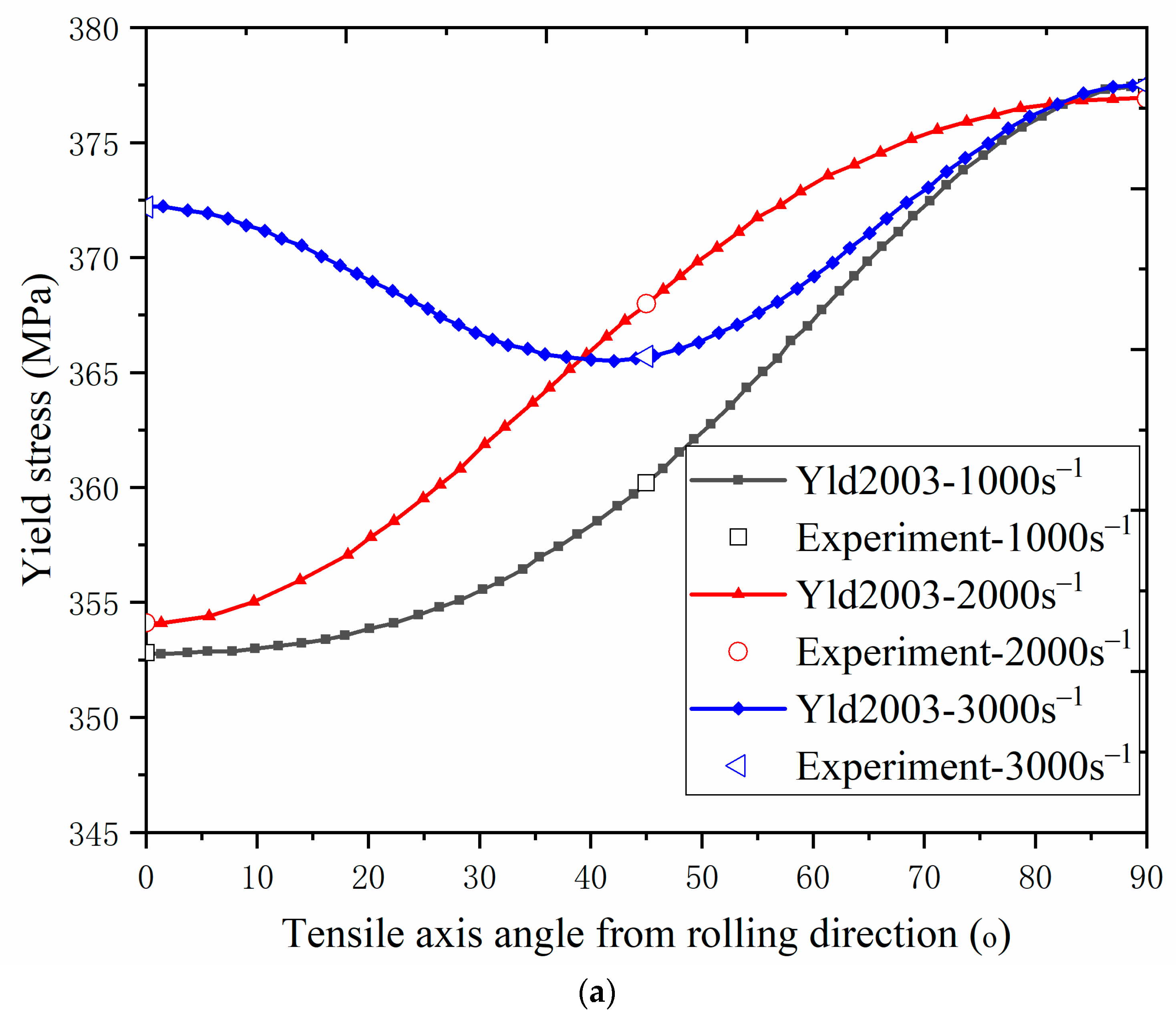

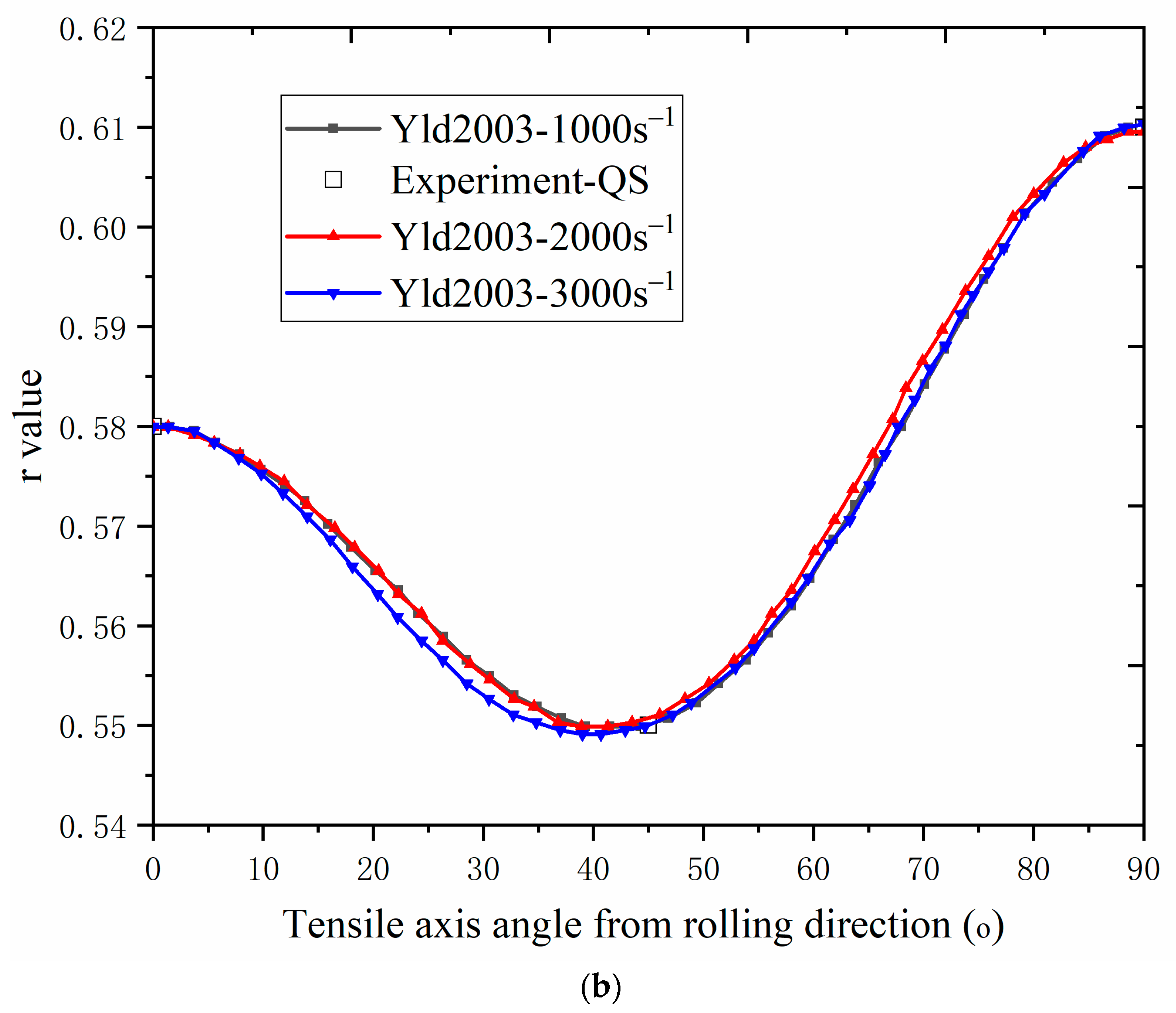

3.2. Anistropic Yield Function

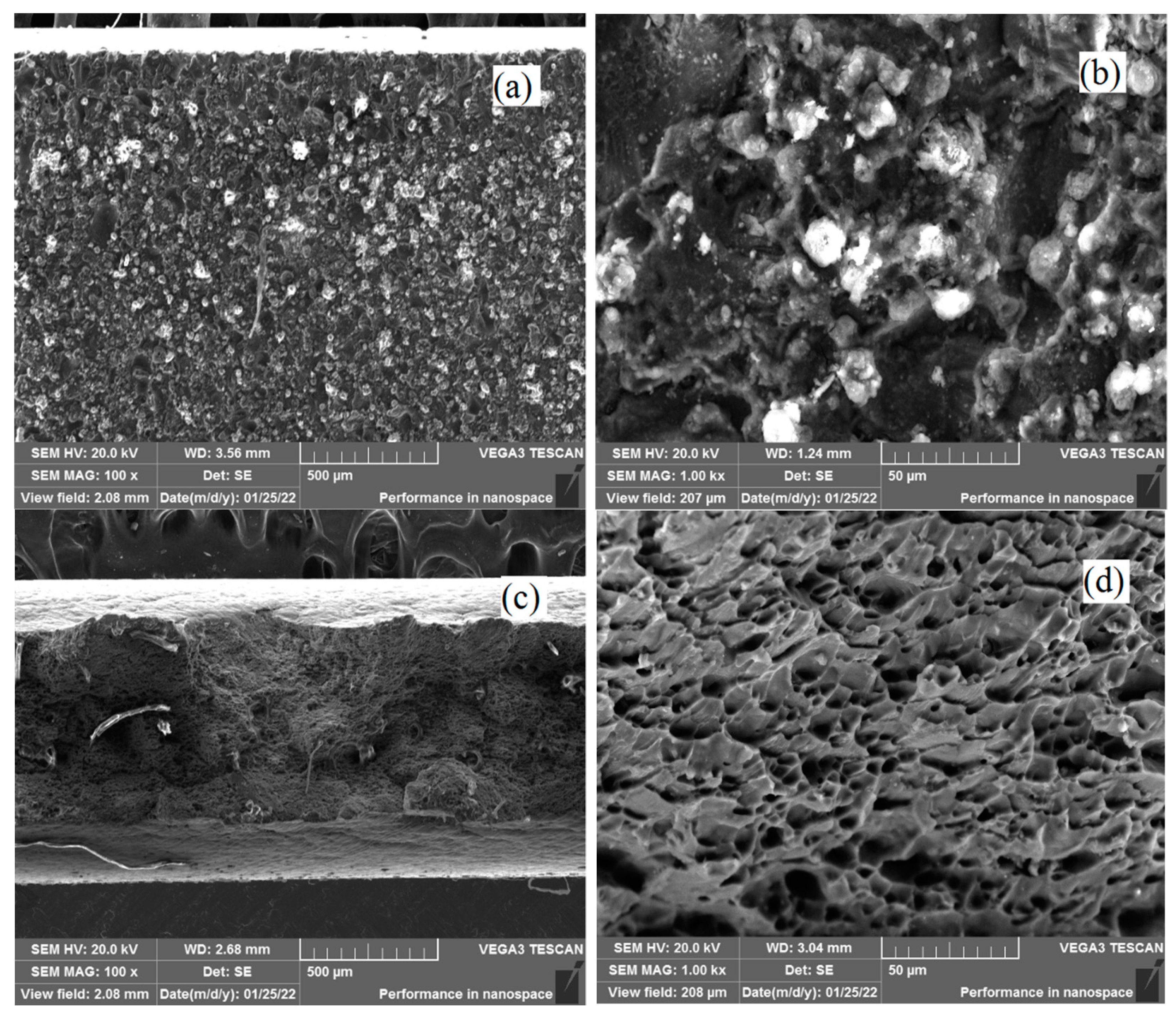

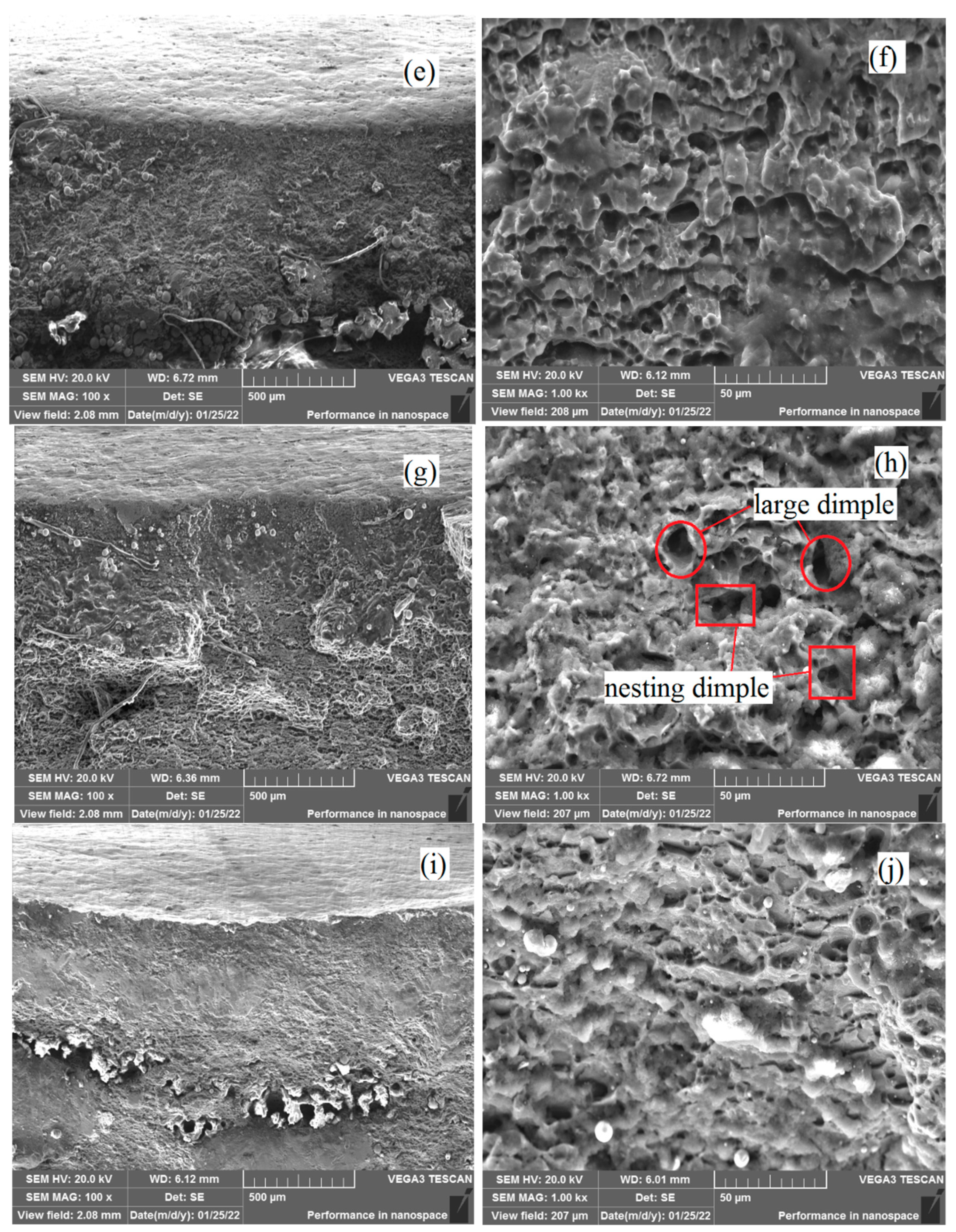

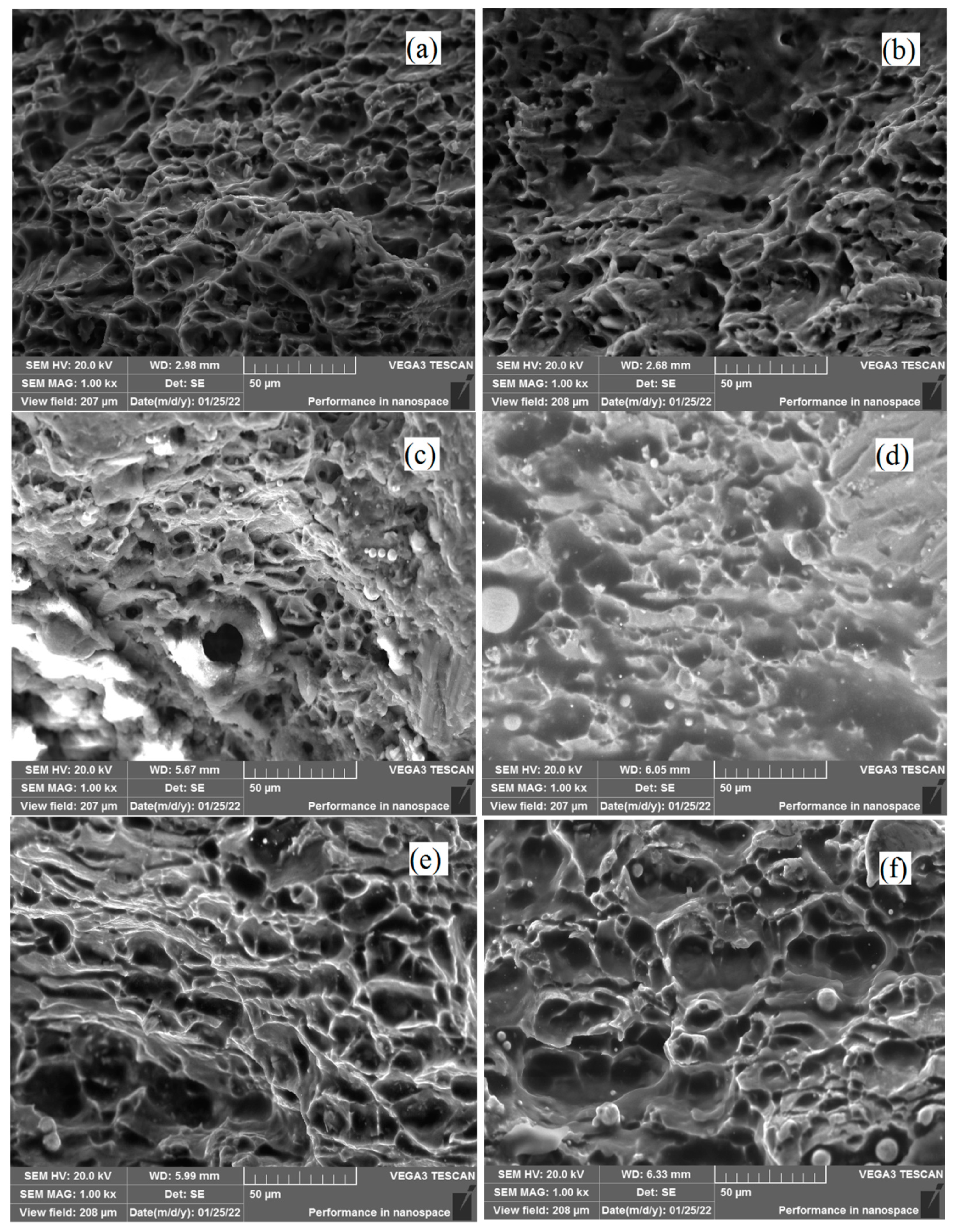

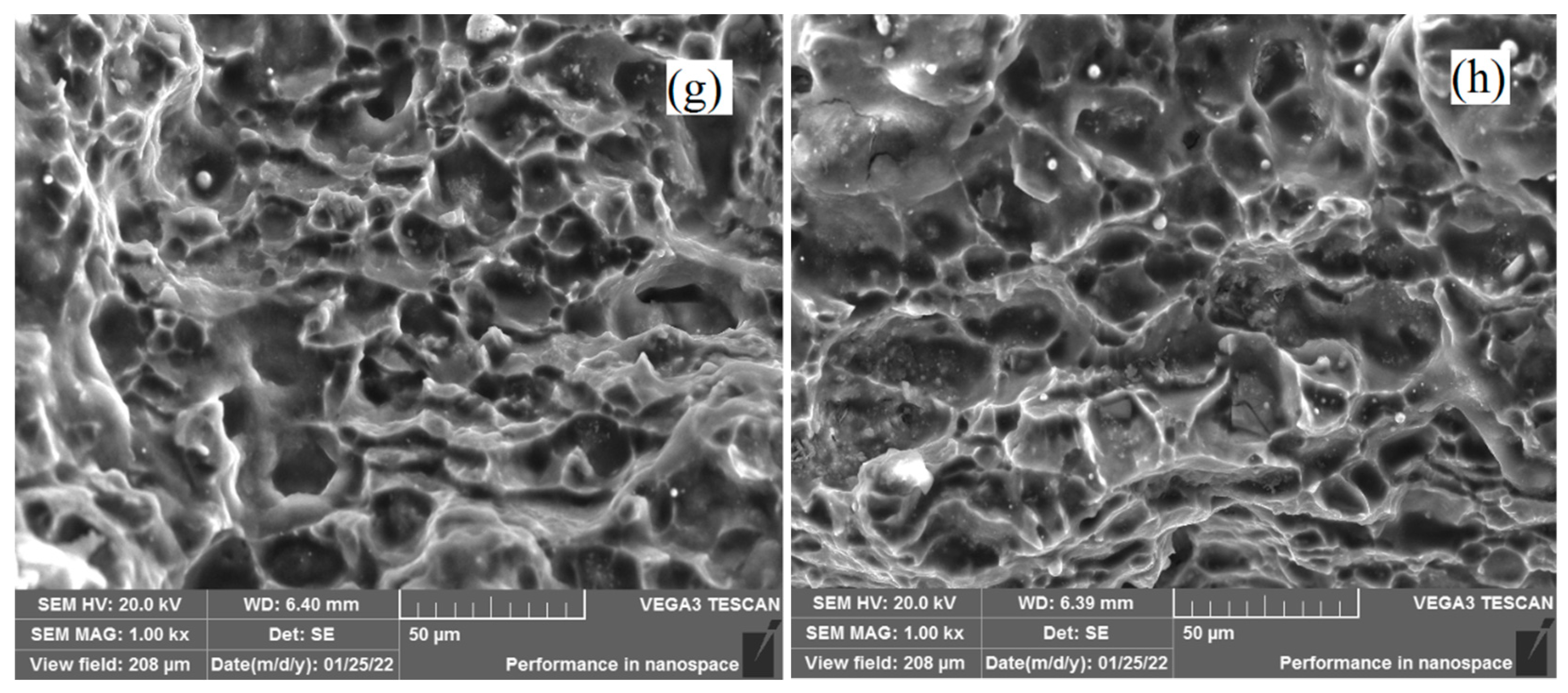

4. Microstructure Analysis

5. Conclusions

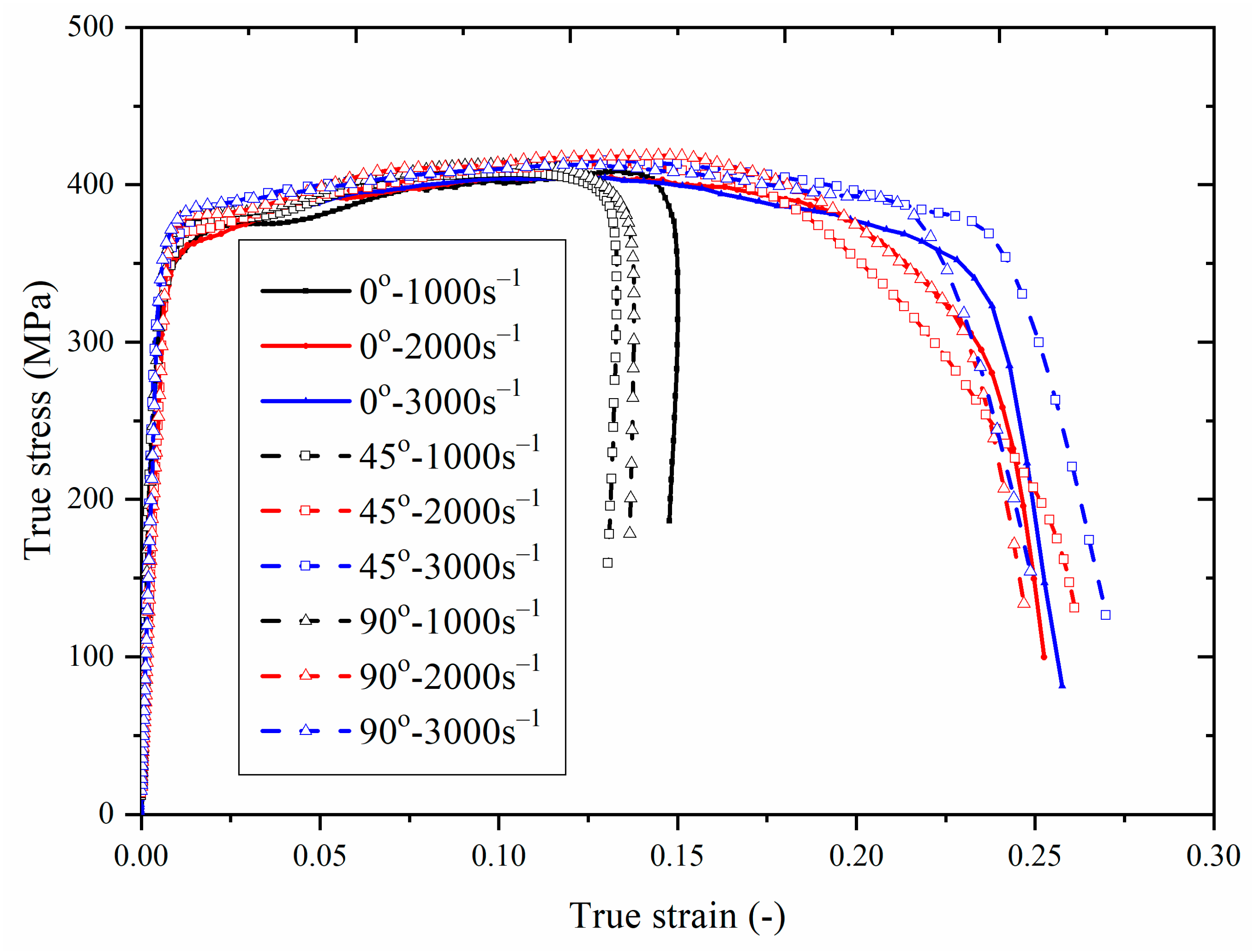

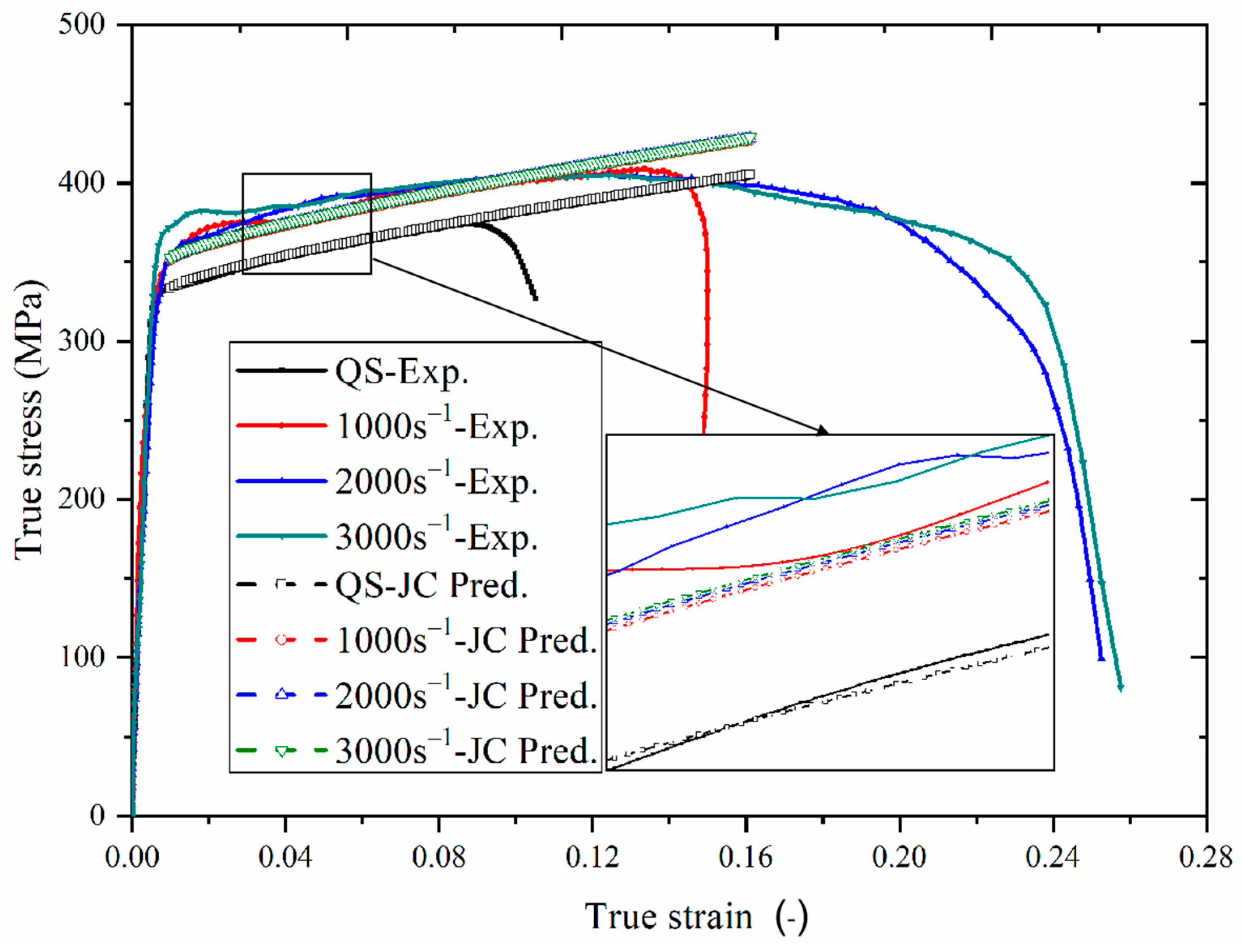

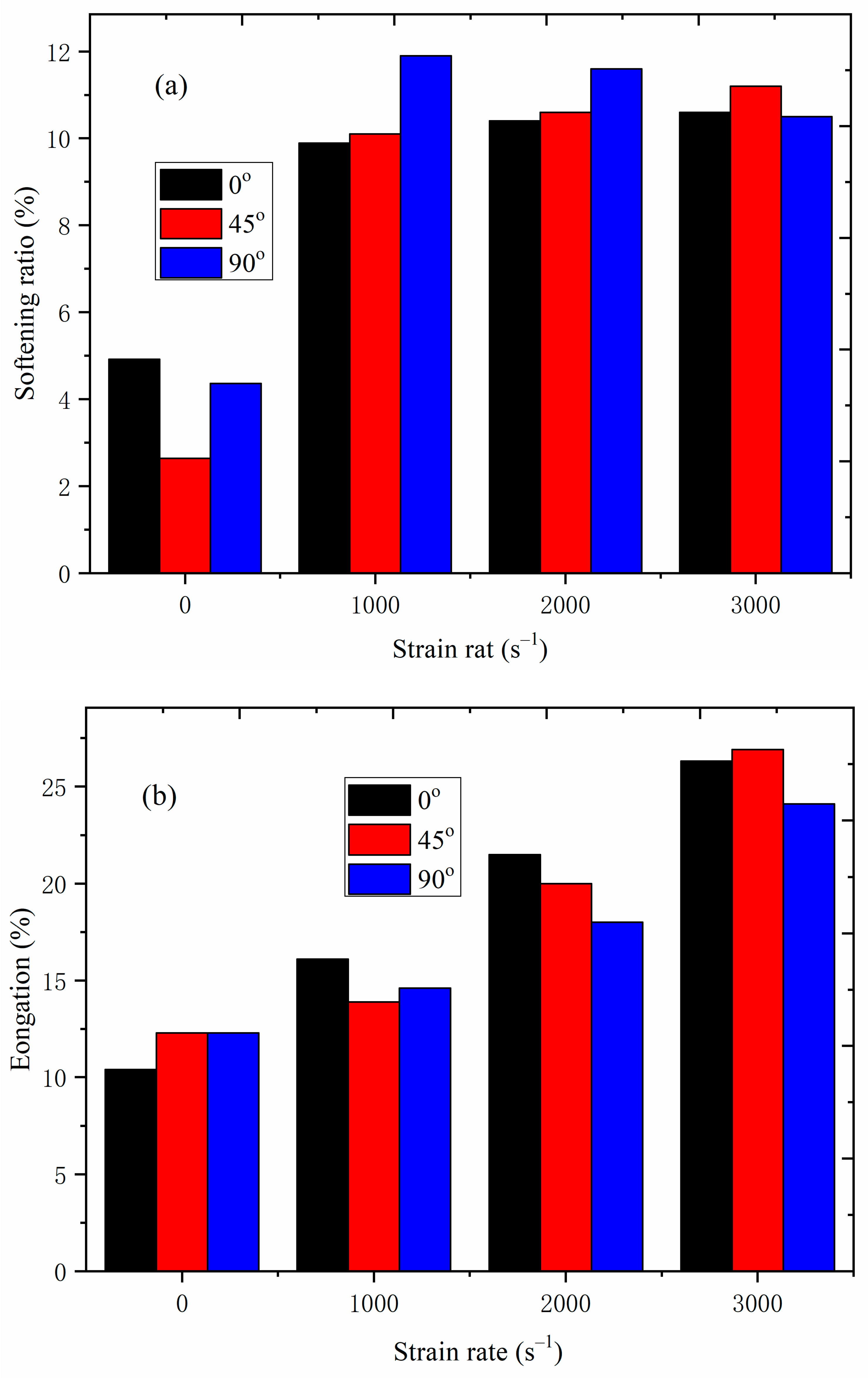

- 6XXX aluminum alloy sheet has obvious strain-rate-dependent and certain anisotropic characteristics. The Johnson–Cook model can describe the stress–strain characterization of the aluminum alloy at both quasi-static condition and high strain rate condition quite well.

- The yield stress, tensile strength, maximum strain (or ductility) and the softening degree of 6XXX aluminum alloy sheet increase greatly with the increase of strain rate.

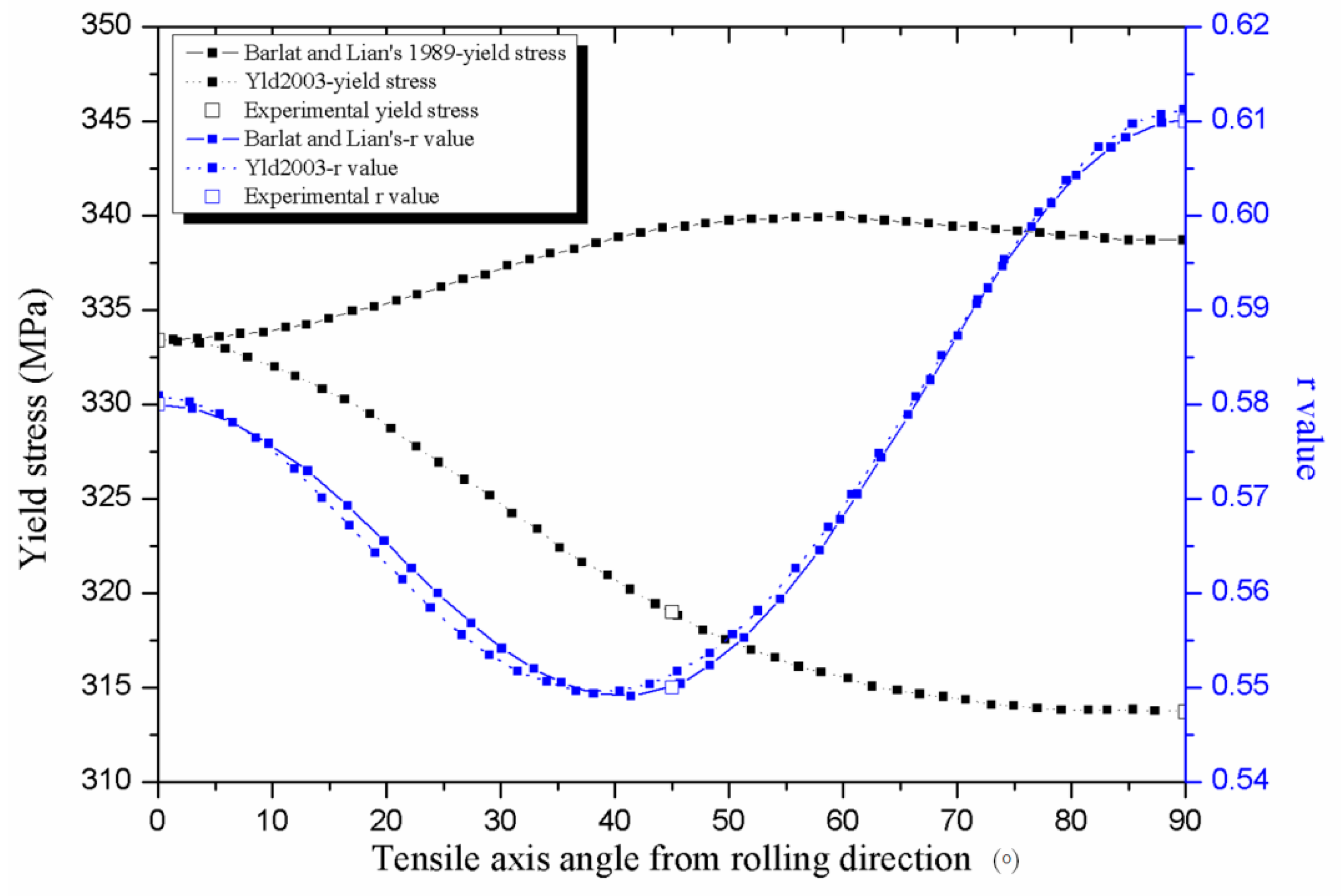

- Compared with Barlat and Lian’s 1989 yield function, the Yld2003 yield function with variable anisotropic parameters associated with strain rate can better predict the yielding behavior of the aluminum alloy under quasi-static condition and high strain rate conditions. In addition, the stress anisotropic behavior of this aluminum alloy sheet is changed from the quasi-static condition to the dynamic condition.

- The fracture morphology of this aluminum alloy is significantly different under quasi-static and high strain rate conditions. From quasi-static condition to the high strain rate condition, the fracture mode is changed from ductile fracture to the mixture of ductile fracture and shear fracture. In addition, there is no significant difference of the fracture morphology for the high strain rate cases along different tensile directions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Joost, W.J. Reducing vehicle weight and improving U.S. energy efficiency using integrated computational materials engineering. JOM 2012, 64, 1032–1038. [Google Scholar] [CrossRef]

- Georgantzia, E.; Gkantou, M.; Kamaris, G.S. Aluminium alloys as structural material: A review of research. Eng. Struct. 2021, 227, 111372. [Google Scholar] [CrossRef]

- Chen, L.; Fang, S.; Zhao, K.; Xiao, R.; Zhao, H. Forming limit prediction using an integrated model for 7075 aluminum alloy sheets at an elevated temperature. Int. J. Solids Struct. 2020, 202, 475–485. [Google Scholar] [CrossRef]

- Balanethiram, V.S.; Daehn, G.S. Enhanced formability of interstitial free iron at high strain rates. Scripta Metall. Mater. 1992, 27, 1783–1788. [Google Scholar] [CrossRef]

- Imbert, J.M.; Winkler, S.L.; Worswick, M.J.; Oliveira, D.A.; Golovashchenko, S. The effect of tool-sheet interaction on damage evolution in electromagnetic forming of aluminum alloy sheet. J. Eng. Mater. Technol. 2005, 127, 145–153. [Google Scholar] [CrossRef]

- Ahmed, M.; Kumar, D.R.; Nabi, M. Enhancement of formability of AA5052 alloy sheets by electrohydraulic forming process. J. Mater. Eng. Perform. 2017, 26, 439–452. [Google Scholar] [CrossRef]

- Khan, A.S.; Suh, Y.S.; Chen, X.; Takacs, L.; Zhang, H. Nanocrystalline aluminum and iron: Mechanical behavior at quasi-static and high strain rates, and constitutive modeling. Int. J. Plast. 2006, 22, 195–209. [Google Scholar] [CrossRef]

- Cheng, T.C.; Lee, R.S. The influence of grain size and strain rate effects on formability of aluminium alloy sheet at high-speed forming. J. Mater. Process. Techol. 2018, 253, 134–159. [Google Scholar] [CrossRef]

- Adesola, A.O.; Odeshi, A.G.; Lanke, U.D. The effects of aging treatment and strain rates on damage evolution in AA 6061 aluminum alloy in compression. Mater. Des. 2013, 45, 212–221. [Google Scholar] [CrossRef]

- Braun, R. Effect of thermal exposure on the microstructure, tensile properties and the corrosion behavior of 6061 aluminum alloy sheet. Mater. Corros. 2005, 56, 159–162. [Google Scholar] [CrossRef]

- Yu, H.; Jin, Y.; Hu, L.; Wang, Y. Mechanical properties of the solution treated and quenched Al-Cu-Li alloy (AA2195) sheet during high strain rate deformation at room temperature. Mater. Sci. Eng. A 2020, 793, 139880. [Google Scholar] [CrossRef]

- Jenab, A.; Sarraf, I.S.; Green, D.E.; Rahmaan, T.; Worswick, M.J. The use of genetic algorithm and neural network to predict rate-dependent tensile flow behavior of AA5182-O sheets. Mater. Des. 2016, 94, 62–273. [Google Scholar] [CrossRef]

- Zhang, C.; Chu, X.; Guines, D.; Leotoing, L.; Ding, J.; Zhao, G. Effects of temperature and strain rate on the forming limit curves of Aa5086 sheet. In Proceedings of the 11th International Conference on Technology of Plasticity, ICTP 2014, Nagoya, Japan, 19–24 October 2014. [Google Scholar] [CrossRef]

- Lee, W.S.; Tang, Z.C. Relationship between mechanical properties and microstructural response of 6061-T6 aluminum alloy-impacted at elevated temperature. Mater. Des. 2014, 58, 116–124. [Google Scholar] [CrossRef]

- Lee, W.S.; Shyu, J.C.; Chiou, S.T. Effect of strain rate on impact response and dislocation substructure of 6061-T6 aluminum alloy. Scripta Mater. 2000, 42, 51–56. [Google Scholar] [CrossRef]

- Owolabi, G.M.; Odeshi, A.G.; Singh, M.N.K.; Bassim, M.N. Dynamic shear band formation in aluminum 6061-T6 and aluminum 6061-T6/Al2O3 composites. Mater. Sci. Eng. A 2007, 457, 114–119. [Google Scholar] [CrossRef]

- Gupta, M.K. Numerical simulation of AA7075 under high strain rate with different shape of striker of split Hopkinson pressure bar. Mater. Today Commun. 2021, 26, 102178. [Google Scholar] [CrossRef]

- Yan, S.L.; Yang, H.; Li, H.W.; Ren, G.Y. Experimental study of macro-micro dynamic behaviors of 5A0X aluminum alloys in high velocity deformation. Mater. Sci. Eng. A 2014, 598, 197–206. [Google Scholar] [CrossRef]

- Ji, C.; Li, Z.; Liu, J. Development of an improved MMC-based fracture function characterizing the anisotropic and strain rate-dependent behavior of 6061-T5 aluminum alloy. Mech. Mater. 2020, 150, 103598. [Google Scholar] [CrossRef]

- Chen, D.Y.; Xu, Y.; Zhang, S.H.; Ma, Y.; El-Aty, A.A.; Banabic, D.; Pokrovsky, A.I.; Bakinovskaya, A.A. A novel method to evaluate the high strain rate formability of sheet metals under impact hydroforming. J. Mater. Process. Technol. 2021, 287, 116553. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, J.; Chen, J.; Zhu, X. Forming limit model evaluation for anisotropic sheet metals under through-thickness normal stress. Int. J. Mech. Sci. 2014, 89, 40–46. [Google Scholar] [CrossRef]

- Forni, D.; Chiaia, B.; Cadoni, E. Strain rate behavior in tension of S355 steel: Base for progressive collapse analysis. Eng. Struct. 2016, 119, 164–173. [Google Scholar] [CrossRef]

- Zhong, T.; Zhong, Z.Y.; Huang, J.W.; Sun, T.; Fezzaa, K.; Huang, J.Y.; Luo, S.N. Rate-dependent phase transition of high density polyethylene. Materialia 2019, 6, 100274. [Google Scholar] [CrossRef]

- Jin, H.; Sanborn, B.; Lu, W.Y.; Song, B. Mechanical characterization of 304L-VAR stainless steel in tension with a full coverage of low, intermediate, and high strain rates. Mech. Mater. 2021, 152, 103654. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates, and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Tang, W.; Liu, S.; Liu, Z.; Kang, S.; Mao, P.; Zhou, L.; Wang, Z. Microstructure evoluation and constitutive relation establishment of Mg-7Gd-5Y-1.2Nd-0.5Zr alloy under high strain rate after severe multi-directional deformation. Mater. Sci. Eng. A 2021, 809, 140994. [Google Scholar] [CrossRef]

- Cadoni, E.; Forni, D. Mechanical behaviour of B500A rebars: Effect of elevated temperature and high strain-rate. Fire Saf. J. 2021, 122, 103321. [Google Scholar] [CrossRef]

- Barlat, F.; Lian, J. Plastic behavior and stretchability of sheet metals. Part I: A yield function for orthotropic sheet under plane stress conditions. Int. J. Plast. 1989, 5, 51–66. [Google Scholar] [CrossRef]

- Aretz, H. Applications of a new plane stress yield function to orthotropic steel and aluminum sheet metals. Model. Simul. Mater. Sci. Eng. 2004, 12, 491–509. [Google Scholar] [CrossRef]

- Li, F.Q.; Mo, J.H.; Li, J.J.; Huang, L.; Zhou, H.Y. Formability of Ti-6Al-4V titanium alloy sheet in magnetic pulse bulging. Mater. Des. 2013, 52, 337–344. [Google Scholar] [CrossRef]

| Element | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Al | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard | Min. | 0.4 | - | 0.15 | - | 0.8 | 0.04 | - | - | - | - | Bal. |

| Max. | 0.8 | 0.7 | 0.4 | 0.15 | 1.2 | 0.35 | - | 0.25 | 0.15 | - | Bal. | |

| Actual | 0.63 | 0.39 | 0.22 | 0.02 | 1.0 | 0.1 | - | 0.06 | 0.32 | - | Bal. | |

| Strain Rate (s−1) | Yield Stress (MPa) | Ultimate Tensile Stress (MPa) | ||||

|---|---|---|---|---|---|---|

| 0° | 45° | 90° | 0° | 45° | 90° | |

| QS | 333.4 | 319 | 313.7 | 374.3 | 363.6 | 358 |

| 1000 s−1 | 352.8 | 360.2 | 377.4 | 408.2 | 407.9 | 412.7 |

| 2000 s−1 | 354.1 | 368 | 376.9 | 405.2 | 413.7 | 418.7 |

| 3000 s−1 | 372.2 | 365.7 | 377.5 | 405.1 | 415.3 | 412.7 |

| 1.2541 | 0.7459 | 0.9843 | 0.978 |

| 0.9848 | 1.0994 | 1.1933 | 1.1891 | 0.9229 | 1.0311 | 0.9765 | 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; He, K.; Li, Z.; Huang, B. Strain-Rate Effect on Anisotropic Deformation Characterization and Material Modeling of High-Strength Aluminum Alloy Sheet. Metals 2022, 12, 1430. https://doi.org/10.3390/met12091430

Zhang F, He K, Li Z, Huang B. Strain-Rate Effect on Anisotropic Deformation Characterization and Material Modeling of High-Strength Aluminum Alloy Sheet. Metals. 2022; 12(9):1430. https://doi.org/10.3390/met12091430

Chicago/Turabian StyleZhang, Feifei, Kai He, Zheng Li, and Bo Huang. 2022. "Strain-Rate Effect on Anisotropic Deformation Characterization and Material Modeling of High-Strength Aluminum Alloy Sheet" Metals 12, no. 9: 1430. https://doi.org/10.3390/met12091430

APA StyleZhang, F., He, K., Li, Z., & Huang, B. (2022). Strain-Rate Effect on Anisotropic Deformation Characterization and Material Modeling of High-Strength Aluminum Alloy Sheet. Metals, 12(9), 1430. https://doi.org/10.3390/met12091430