The Magnetocaloric Behaviors of Gd-based Microwire Arrays with Different Curie Temperatures

Abstract

:1. Introduction

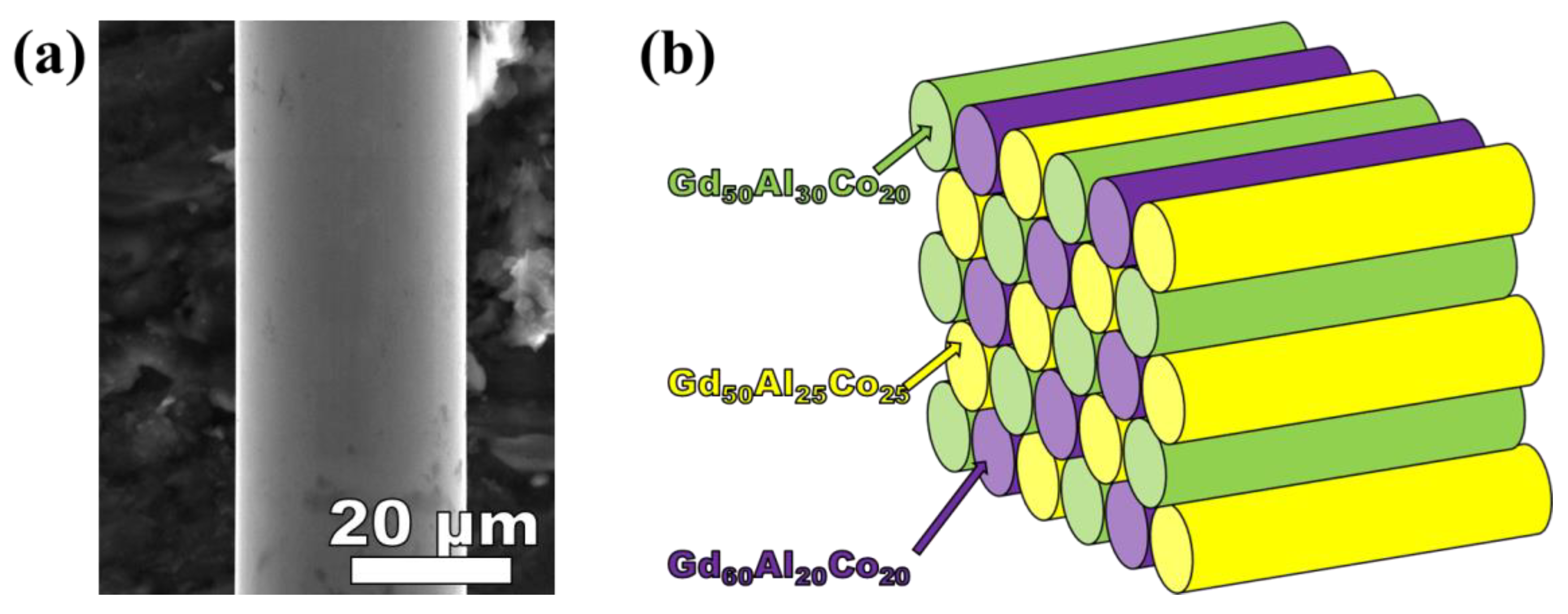

2. Materials and Methods

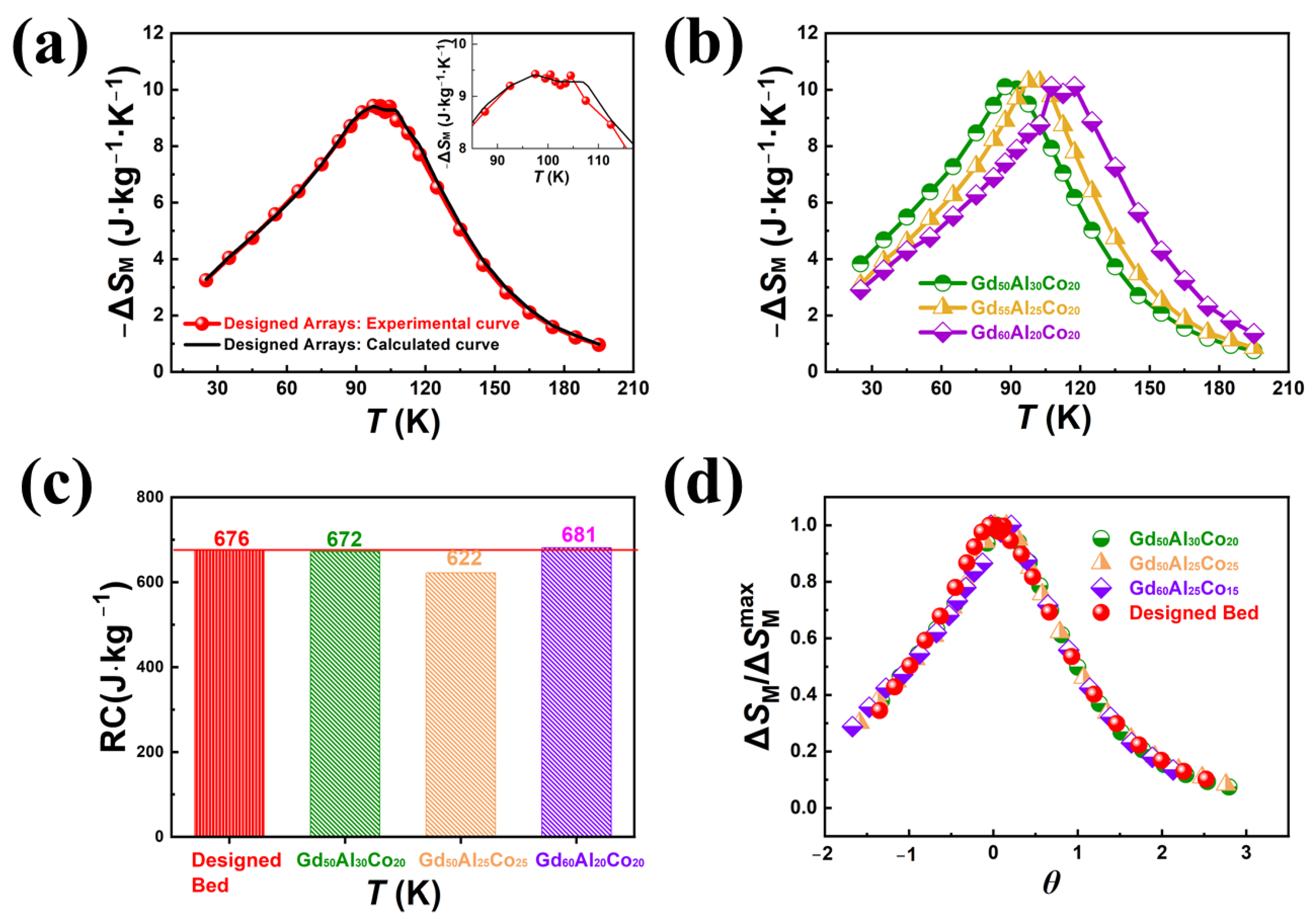

3. Results and Discussion

3.1. Magnetocaloric Performance

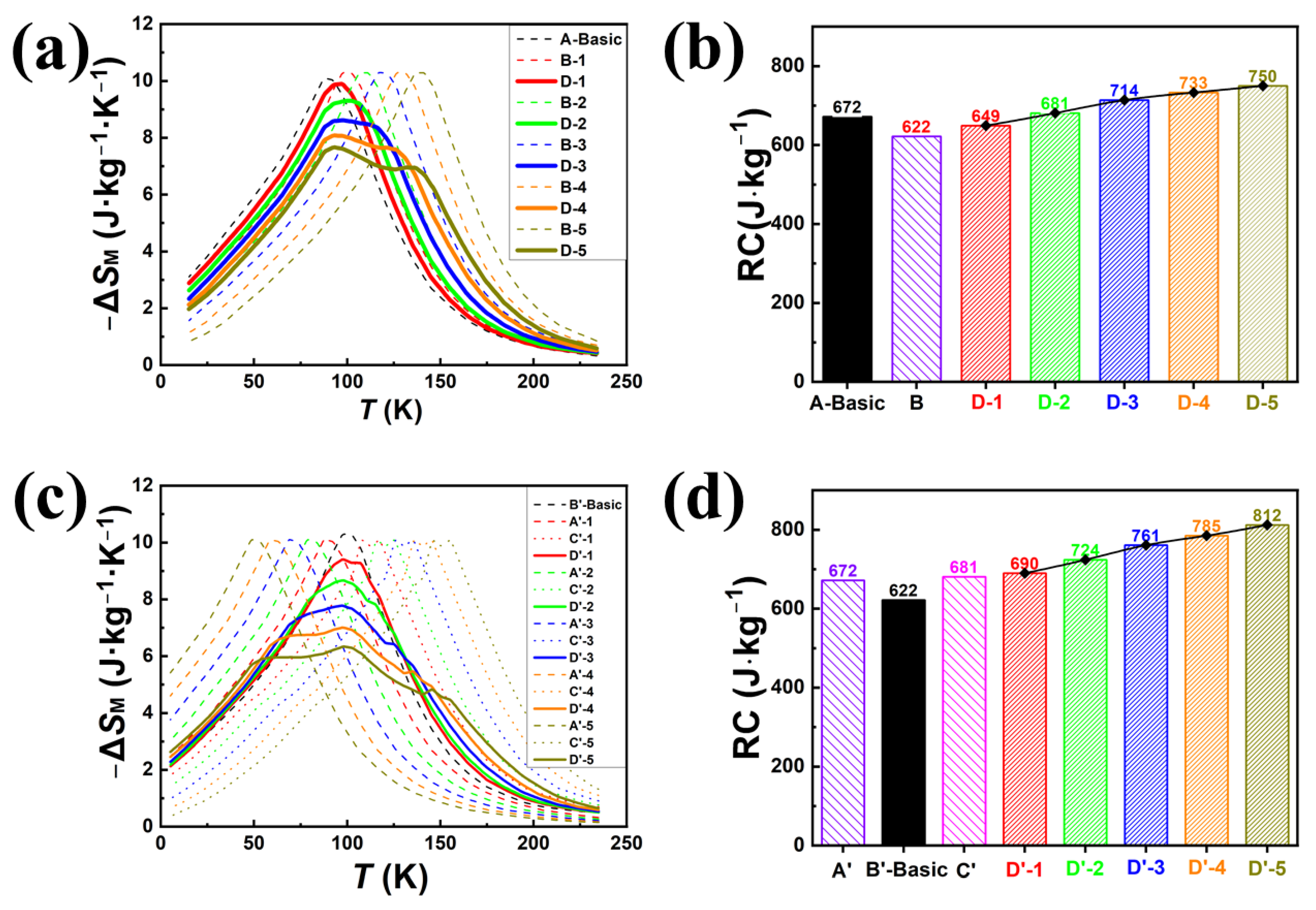

3.2. The Impact of TC Interval on MCE

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, X.; Wang, Q.; Pan, L.; Ding, D.; Tang, B.; Yu, P.; Yao, J.; Xia, L. Effect of Minor Co Substitution for Fe on the Formability and Magnetic and Magnetocaloric Properties of the Amorphous Fe88Ce7B5 Alloy. Metals 2022, 12, 589. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Tang, B.; Ding, D.; Cui, L.; Xia, L. Effect of Mn Substitution Fe on the Formability and Magnetic Properties of Amorphous Fe88Zr8B4 Alloy. Metals 2021, 11, 1577. [Google Scholar] [CrossRef]

- Zhong, X.-C.; Dong, X.-T.; Huang, J.-H.; Liu, C.-L.; Zhang, H.; Huang, Y.-L.; Yu, H.-Y.; Ramanujan, R.V. One-Step Sintering Process for the Production of Magnetocaloric La(Fe,Si)13-Based Composites. Metals 2022, 12, 112. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Y.; Zhang, Z.; Tan, J.; Zhang, X.; Peng, H.; Xiang, X.; Li, H.; Xia, A.; Li, W. Influence of Covalent Element B and Si Addition on Magnetocaloric Properties of Gd-Co-Fe-(B,Si) Amorphous Alloys. Metals 2022, 12, 386. [Google Scholar] [CrossRef]

- Balfour, E.A.; Fu, H.; Ma, Z.; Zhang, X.J.; Wang, D.H.; Teng, B.H. Table-like magnetocaloric effect in the Gd-Co-Al alloys with multi-phase structure. Appl. Phys. Lett. 2014, 104, 072401. [Google Scholar] [CrossRef]

- Franco, V.; Conde, A. Magnetic refrigerants with continuous phase transitions: Amorphous and nanostructured materials. Scr. Mater. 2012, 67, 594–599. [Google Scholar] [CrossRef]

- Li, L.; Niehaus, O.; Kersting, M.; Pöttgen, R. Reversible table-like magnetocaloric effect in Eu4PdMg over a very large temperature span. Appl. Phys. Lett. 2014, 104, 092416. [Google Scholar] [CrossRef]

- Mbarek, H.; M’Nasri, R.; Cheikhrouhou-Koubaa, W.; Cheikhrouhou, A. Magnetocaloric effect near room temperature in (1 − y)La0.8Ca0.05K0.15MnO3/yLa0.8K0.2MnO3 composites. Phys. Status Solidi A 2014, 211, 975–979. [Google Scholar] [CrossRef]

- Romero-Muñiz, C.; Franco, V.; Conde, A. Influence of magnetic interactions between phases on the magnetocaloric effect of composites. Appl. Phys. Lett. 2013, 102, 082402. [Google Scholar] [CrossRef]

- Paticopoulos, S.; Caballero-Flores, R.; Franco, V.; Blázquez, J.; Conde, A.; Knipling, K.; Willard, M. Enhancement of the magnetocaloric effect in composites: Experimental validation. Solid State Commun. 2012, 152, 1590–1594. [Google Scholar] [CrossRef]

- Álvarez, P.; Gorria, P.; Llamazares, J.L.S.; Blanco, J.A. Searching the conditions for a table-like shape of the magnetic entropy in magneto-caloric materials. J. Alloys Compd. 2013, 568, 98–101. [Google Scholar] [CrossRef]

- Álvarez, P.; Llamazares, J.L.S.; Gorria, P.; Blanco, J.A. Enhanced refrigerant capacity and magnetic entropy flattening using a two-amorphous FeZrB(Cu) composite. Appl. Phys. Lett. 2011, 99, 232501. [Google Scholar] [CrossRef]

- Chaturvedi, A.; Stefanoski, S.; Phan, M.-H.; Nolas, G.S.; Srikanth, H. Table-like magnetocaloric effect and enhanced refrigerant capacity in Eu8Ga16Ge30-EuO composite materials. Appl. Phys. Lett. 2011, 99, 162513. [Google Scholar] [CrossRef]

- Kuz’Min, M.D. Factors limiting the operation frequency of magnetic refrigerators. Appl. Phys. Lett. 2007, 90, 251916. [Google Scholar] [CrossRef]

- Vuarnoz, D.; Kawanami, T. Numerical analysis of a reciprocating active magnetic regenerator made of gadolinium wires. Appl. Therm. Eng. 2012, 37, 388–395. [Google Scholar] [CrossRef]

- Khovaylo, V.V.; Rodionova, V.V.; Shevyrtalov, S.N.; Novosad, V. Magnetocaloric effect in “reduced” dimensions: Thin films, ribbons, and microwires of Heusler alloys and related compounds. Phys. Status Solidi B 2014, 251, 2104–2113. [Google Scholar] [CrossRef]

- Bingham, N.S.; Wang, H.; Qin, F.; Peng, H.-X.; Sun, J.F.; Franco, V.; Srikanth, H.; Phan, M.H. Excellent magnetocaloric properties of melt-extracted Gd-based amorphous microwires. Appl. Phys. Lett. 2012, 101, 102407. [Google Scholar] [CrossRef]

- Qin, F.; Bingham, N.; Wang, H.; Peng, H.; Sun, J.; Franco, V.; Yu, S.; Srikanth, H.; Phan, M. Mechanical and magnetocaloric properties of Gd-based amorphous microwires fabricated by melt-extraction. Acta Mater. 2013, 61, 1284–1293. [Google Scholar] [CrossRef]

- Shen, H.; Wang, H.; Jingshun, L.; Cao, F.; Qin, F.; Xing, D.; Chen, D.; Liu, Y.; Sun, J. Enhanced magnetocaloric properties of melt-extracted GdAlCo metallic glass microwires. J. Magn. Magn. Mater. 2014, 372, 23–26. [Google Scholar] [CrossRef]

- Shen, H.; Wang, H.; Liu, J.; Xing, D.; Qin, F.; Cao, F.; Chen, D.; Liu, Y.; Sun, J. Enhanced magnetocaloric and mechanical properties of melt-extracted Gd55Al25Co20 micro-fibers. J. Alloys Compd. 2014, 603, 167–171. [Google Scholar] [CrossRef]

- Xing, D.; Shen, H.; Jiang, S.; Liu, J.; Phan, M.-H.; Wang, H.; Qin, F.; Chen, D.; Liu, Y.; Sun, J. Magnetocaloric effect and critical behavior in melt-extracted Gd60Co15Al25microwires. Phys. Status Solidi A 2015, 212, 1905–1910. [Google Scholar] [CrossRef]

- Xing, D.; Shen, H.; Liu, J.; Wang, H.; Cao, F.; Qin, F.; Chen, D.; Liu, Y.; Sun, J. Magnetocaloric Effect in Uncoated Gd55Al20Co25 Amorphous Wires. Mater. Res. 2015, 18, 49–54. [Google Scholar] [CrossRef]

- Shen, H.X.; Xing, D.W.; Llamazares, J.L.S.; Valdés, C.F.S.; Belliveau, H.; Wang, H.; Qin, F.X.; Liu, Y.F.; Sun, J.F.; Srikanth, H.; et al. Enhanced refrigerant capacity in Gd-Al-Co microwires with a biphase nanocrystalline/amorphous structure. Appl. Phys. Lett. 2016, 108, 092403. [Google Scholar] [CrossRef]

- Belliveau, H.; Yu, Y.; Luo, Y.; Qin, F.; Wang, H.; Shen, H.; Sun, J.; Yu, S.; Srikanth, H.; Phan, M. Improving mechanical and magnetocaloric responses of amorphous melt-extracted Gd-based microwires via nanocrystallization. J. Alloys Compd. 2016, 692, 658–664. [Google Scholar] [CrossRef]

- Bao, Y.; Shen, H.; Xing, D.; Jiang, S.; Sun, J.; Phan, M.-H. Enhanced Curie temperature and cooling efficiency in melt-extracted Gd50(Co69.25Fe4.25Si13B13.5)50 microwires. J. Alloys Compd. 2017, 708, 678–684. [Google Scholar] [CrossRef]

- Duc, N.; Shen, H.; Clements, E.; Thiabgoh, O.; Llamazares, J.S.; Sanchez-Valdes, C.; Huong, N.; Sun, J.; Srikanth, H.; Phan, M. Critical magnetic and magnetocaloric behavior of amorphous melt-extracted Gd50(Co69.25Fe4.25Si13B13.5)50 microwires. Intermetallics 2019, 110, 106479. [Google Scholar] [CrossRef]

- Duc, N.; Shen, H.; Clements, E.; Thiabgoh, O.; Llamazares, J.S.; Sanchez-Valdes, C.; Huong, N.; Sun, J.; Srikanth, H.; Phan, M. Enhanced refrigerant capacity and Curie temperature of amorphous Gd60Fe20Al20 microwires. J. Alloys Compd. 2019, 807, 151694. [Google Scholar] [CrossRef]

- Duc, N.; Shen, H.; Thiabgoh, O.; Huong, N.; Sun, J.; Phan, M. Melt-extracted Gd73.5Si13B13.5/GdB6 ferromagnetic/antiferromagnetic microwires with excellent magnetocaloric properties. J. Alloys Compd. 2019, 818, 153333. [Google Scholar] [CrossRef]

- Shen, H.; Luo, L.; Bao, Y.; Yin, H.; Jiang, S.; Zhang, L.; Huang, Y.; Feng, S.; Xing, D.; Liu, J.; et al. New DyHoCo medium entropy amorphous microwires of large magnetic entropy change. J. Alloys Compd. 2020, 837, 155431. [Google Scholar] [CrossRef]

- Sun, H.; Ning, Z.; Wang, G.; Liang, W.; Shen, H.; Sun, J.; Xue, X. Tensile Strength Reliability Analysis of Cu48Zr48Al4 Amorphous Microwires. Metals 2016, 6, 296. [Google Scholar] [CrossRef] [Green Version]

- Shen, H.; Luo, L.; Xing, D.; Jiang, S.; Liu, J.; Huang, Y.; Guo, S.; Sun, H.; Liu, Y.; Sun, J.; et al. The Magnetocaloric Composite Designed by Multi-Gd-Al-Co Microwires with Close Performances. Phys. Status Solidi A 2019, 216. [Google Scholar] [CrossRef]

- Franco, V.; Blazquez, J.S.; Conde, A. Field dependence of the magnetocaloric effect in materials with a second order phase transition: A master curve for the magnetic entropy change. Appl. Phys. Lett. 2006, 89, 222512. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, H.; Luo, L.; Belliveau, H.; Jiang, S.; Liu, J.; Zhang, L.; Huang, Y.; Sun, J.; Phan, M.-H. The Magnetocaloric Behaviors of Gd-based Microwire Arrays with Different Curie Temperatures. Metals 2022, 12, 1417. https://doi.org/10.3390/met12091417

Shen H, Luo L, Belliveau H, Jiang S, Liu J, Zhang L, Huang Y, Sun J, Phan M-H. The Magnetocaloric Behaviors of Gd-based Microwire Arrays with Different Curie Temperatures. Metals. 2022; 12(9):1417. https://doi.org/10.3390/met12091417

Chicago/Turabian StyleShen, Hongxian, Lin Luo, Hillary Belliveau, Sida Jiang, Jingshun Liu, Lunyong Zhang, Yongjiang Huang, Jianfei Sun, and Manh-Huong Phan. 2022. "The Magnetocaloric Behaviors of Gd-based Microwire Arrays with Different Curie Temperatures" Metals 12, no. 9: 1417. https://doi.org/10.3390/met12091417

APA StyleShen, H., Luo, L., Belliveau, H., Jiang, S., Liu, J., Zhang, L., Huang, Y., Sun, J., & Phan, M.-H. (2022). The Magnetocaloric Behaviors of Gd-based Microwire Arrays with Different Curie Temperatures. Metals, 12(9), 1417. https://doi.org/10.3390/met12091417