The Effect of Strain Rate on the Deformation Behavior of Fe-30Mn-8Al-1.0C Austenitic Low-Density Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

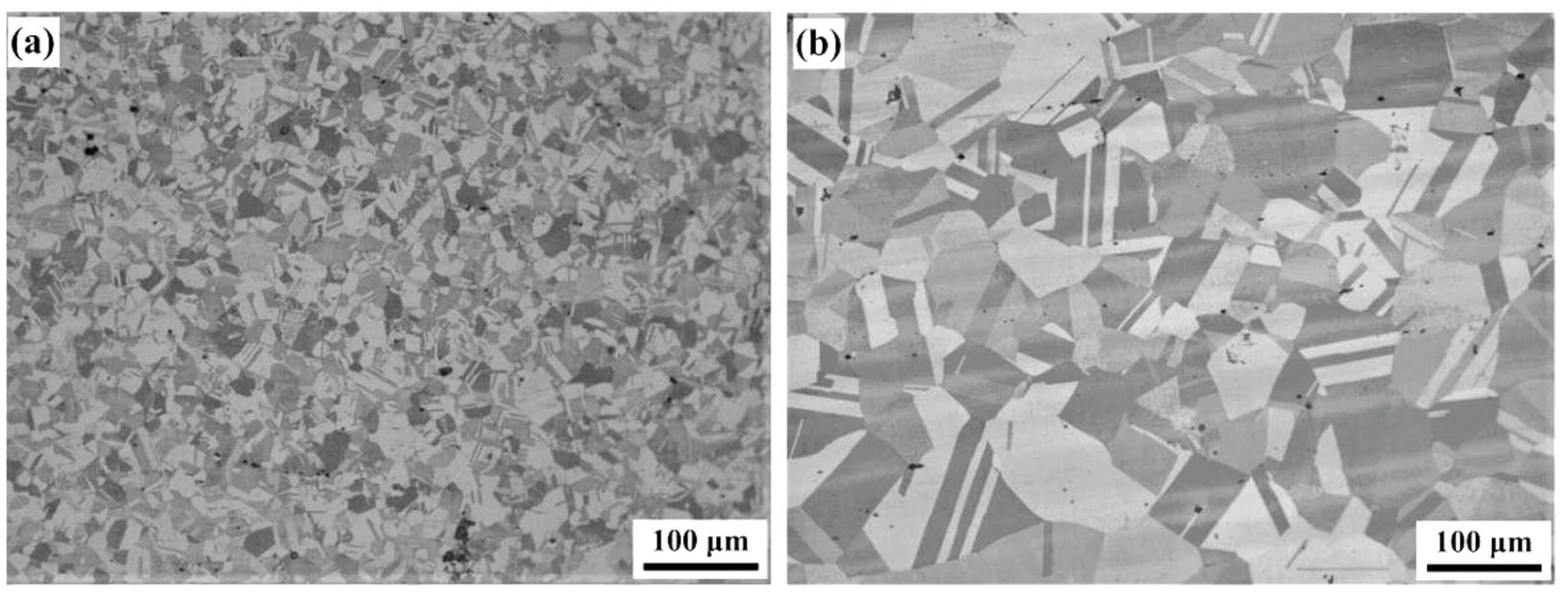

3.1. Initial Solution-Treated Microstructure

3.2. Tensile Properties

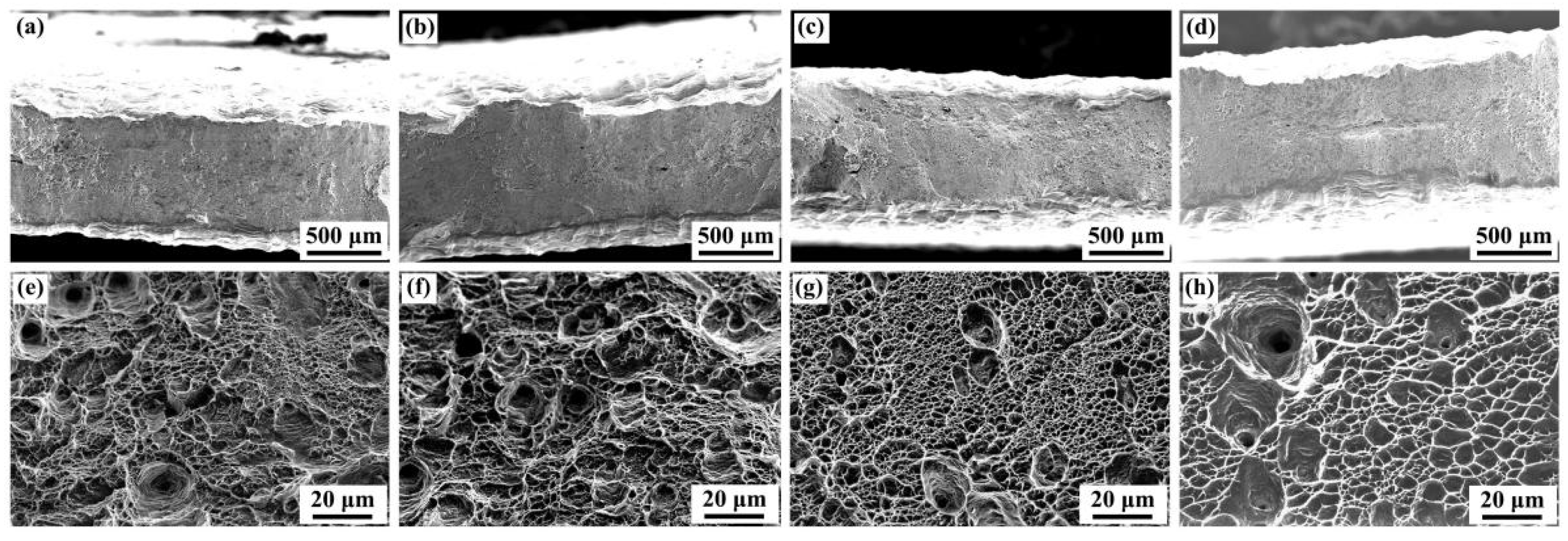

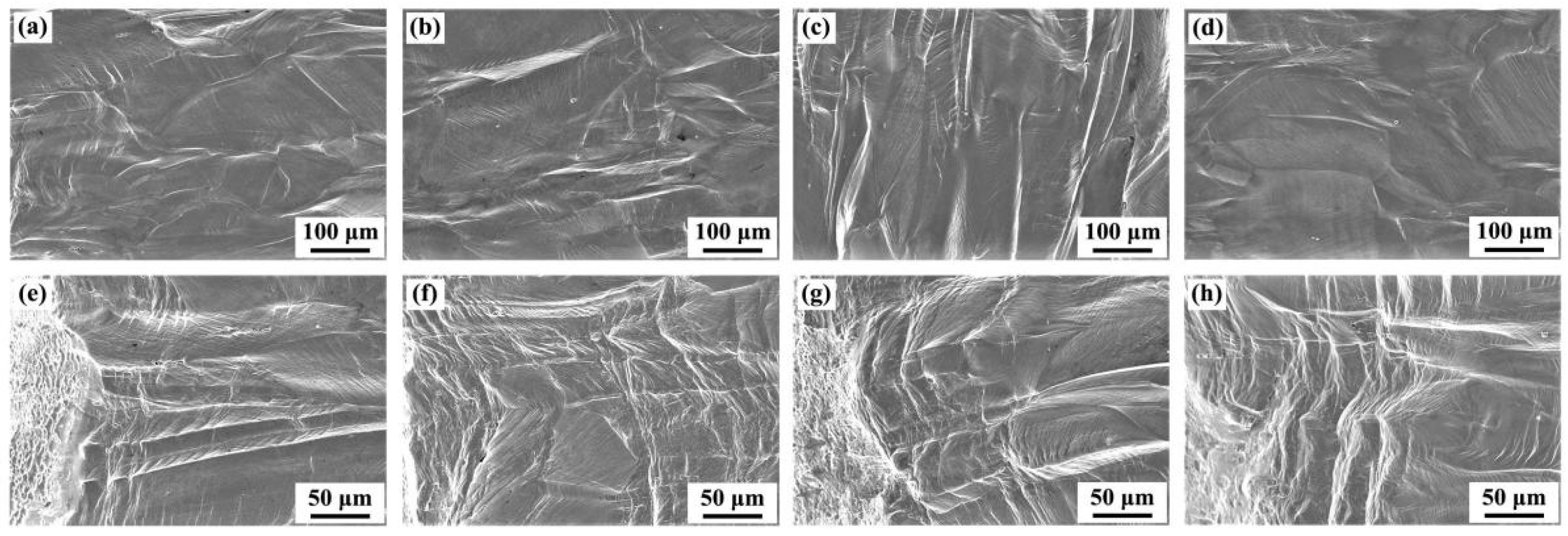

3.3. Morphologies of Deformation and Fracture

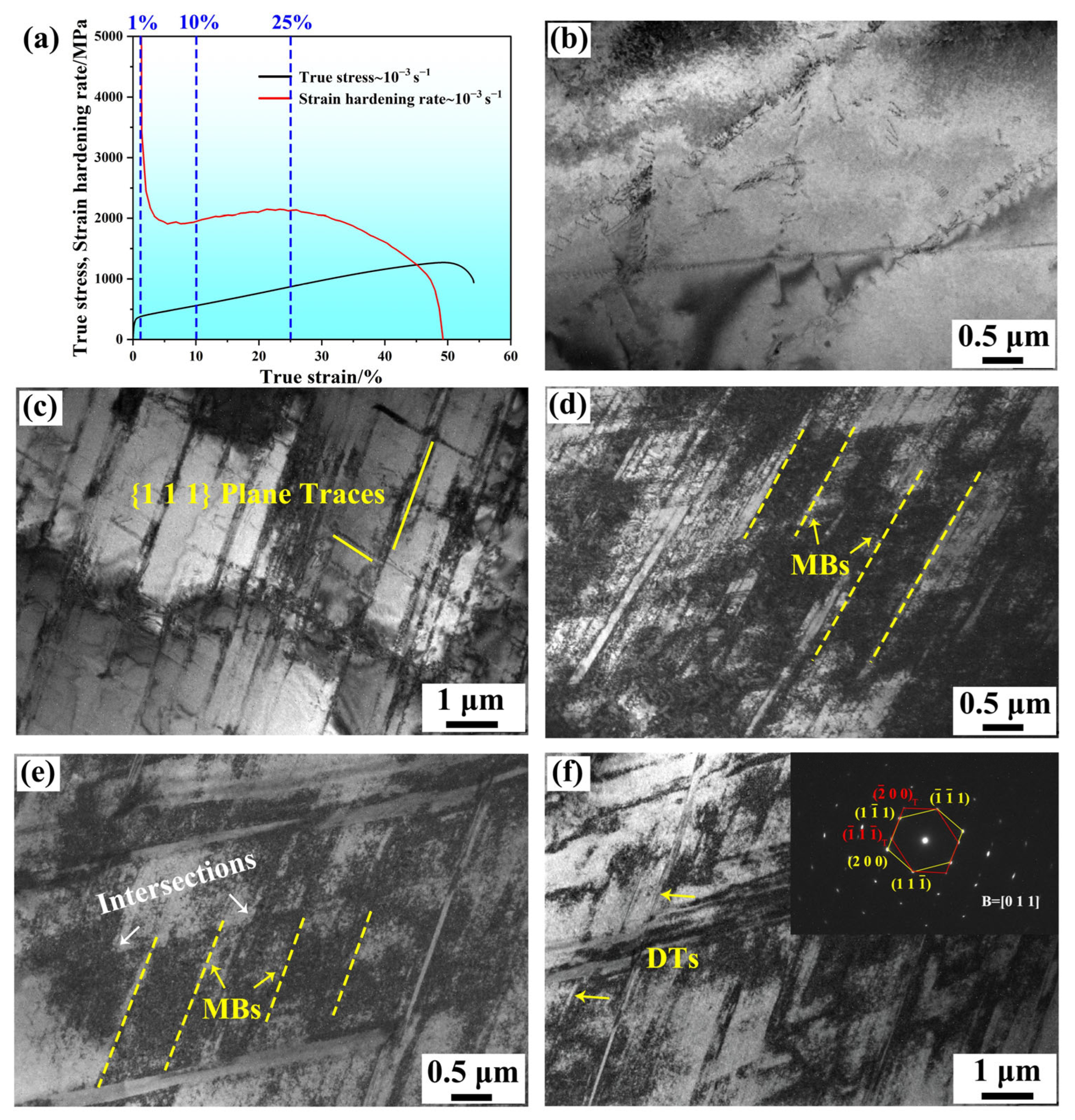

3.4. Microstructure Evolution during Deformation

4. Conclusions

- (1)

- With the increase in strain rate, the yield strength increases from 301 MPa to 381 MPa, and the ultimate tensile strength reaches the maximum of 801 MPa at 10−2 s−1. The recovery of work hardening rate of studied steel is the most remarkable at the strain rate of 10−3 s−1, and its elongation reaches as high as 72%. The deterioration of its mechanical properties at 10−1 s−1 might be related to thermal softening effect and the inhibition of TWIP effect.

- (2)

- During the tensile deformation at the strain rate of 10−3 s−1, dislocation arrays, Taylor lattices, microbands and deformation twins can be observed in sequence with increasing strain. This indicates that the continuous strain hardening results from both MBIP and TWIP, and a good combination of strength and ductility is thus achieved.

- (3)

- Adiabatic heating that leads to the increase in SFE and inhibits the TWIP effect, as well as thermal softening occurring at the high strain rate of 10−1 s−1 jointly induces an anomalous decrease in tensile strength at such a high strain rate.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Park, K.T. Tensile deformation of low-density Fe–Mn–Al–C austenitic steels at ambient temperature. Scr. Mater. 2013, 68, 375–379. [Google Scholar] [CrossRef]

- Sutou, Y.; Kamiya, N.; Umino, R.; Ohnuma, I.; Ishida, K. High-strength Fe–20Mn–Al–C-based Alloys with Low Density. ISIJ Int. 2010, 50, 893–899. [Google Scholar] [CrossRef]

- Choo, W.K.; Kim, J.H.; Yoon, J.C. Microstructural change in austenitic Fe-30.0wt%Mn-7.8wt%Al-1.3wt%C initiated by spinodal decomposition and its influence on mechanical properties. Acta Mater. 1997, 45, 4877–4885. [Google Scholar] [CrossRef]

- Frommeyer, G.; Brüx, U. Microstructures and Mechanical Properties of High-Strength Fe-Mn-Al-C Light-Weight TRIPLEX Steels. Steel Res. Int. 2006, 77, 627–633. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. High strength and ductile low density austenitic FeMnAlC steels: Simplex and alloys strengthened by nanoscale ordered carbides. Mater. Sci. Technol. 2014, 30, 1099–1104. [Google Scholar] [CrossRef]

- Chen, S.; Rana, R.; Haldar, A.; Ray, R.K. Current state of Fe-Mn-Al-C low density steels. Prog. Mater. Sci. 2017, 89, 345–391. [Google Scholar] [CrossRef]

- Yao, M.J.; Dey, P.; Seol, J.-B.; Choi, P.; Herbig, M.; Marceau, R.K.W.; Hickel, T.; Neugebauer, J.; Raabe, D. Combined atom probe tomography and density functional theory investigation of the Al off-stoichiometry of κ-carbides in an austenitic Fe–Mn–Al–C low density steel. Acta Mater. 2016, 106, 229–238. [Google Scholar] [CrossRef]

- Ren, P.; Chen, X.P.; Cao, Z.X.; Mei, L.; Li, W.J.; Cao, W.Q.; Liu, Q. Synergistic strengthening effect induced ultrahigh yield strength in lightweight Fe30Mn11Al-1.2C steel. Mater. Sci. Eng. A 2019, 752, 160–166. [Google Scholar] [CrossRef]

- Moon, J.; Park, S.-J.; Jang, J.H.; Lee, T.-H.; Lee, C.-H.; Hong, H.-U.; Han, H.N.; Lee, J.; Lee, B.H.; Lee, C. Investigations of the microstructure evolution and tensile deformation behavior of austenitic Fe-Mn-Al-C lightweight steels and the effect of Mo addition. Acta Mater. 2018, 147, 226–235. [Google Scholar] [CrossRef]

- Yoo, J.D.; Hwang, S.W.; Park, K.-T. Factors influencing the tensile behavior of a Fe–28Mn–9Al–0.8C steel. Mater. Sci. Eng. A 2009, 508, 234–240. [Google Scholar] [CrossRef]

- Yang, H.K.; Zhang, Z.J.; Dong, F.Y.; Duan, Q.Q.; Zhang, Z.F. Strain rate effects on tensile deformation behaviors for Fe–22Mn–0.6C–(1.5Al) twinning-induced plasticity steel. Mater. Sci. Eng. A 2014, 607, 551–558. [Google Scholar] [CrossRef]

- Leslie, W.C.; Rauch, G.C. Precipitation of carbides in low-carbon Fe-AI-C alloys. Metall. Mater. Trans. A 1987, 9, 343–349. [Google Scholar] [CrossRef]

- Talonen, J.; Hänninen, H.; Nenonen, P.; Pape, G. Effect of strain rate on the strain-induced γ → α′-martensite transformation and mechanical properties of austenitic stainless steels. Metall. Mater. Trans. A 2005, 36, 421–432. [Google Scholar] [CrossRef]

- Kundu, A.; Chakraborti, P.C. Effect of strain rate on quasistatic tensile flow behaviour of solution annealed 304 austenitic stainless steel at room temperature. J. Mater. Sci. 2010, 45, 5482–5489. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.-T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 2010, 58, 5129–5141. [Google Scholar] [CrossRef]

- Gerold, V.; Karnthaler, H.P. On the origin of planar slip in f.c.c. alloys. Acta Metall. 1989, 37, 2177–2183. [Google Scholar] [CrossRef]

- Han, D.; Zhang, Y.J.; Li, X.W. A crucial impact of short-range ordering on the cyclic deformation and damage behavior of face-centered cubic alloys: A case study on Cu-Mn alloys. Acta Mater. 2021, 205, 116559. [Google Scholar] [CrossRef]

- Liu, R.T. Failure Analysis of Mechanical Parts, 1st ed.; Harbin Institute of Technology Press: Harbin, China, 2003; pp. 103–104. [Google Scholar]

- Wang, R.; Lu, C.; Tieu, K.A.; Gazder, A.A. Slip system activity and lattice rotation in polycrystalline copper during uniaxial tension. J. Mater. Res. Technol. 2022, 18, 508–519. [Google Scholar] [CrossRef]

- Kim, C.; Terner, M.; Hong, H.-U.; Lee, C.-H.; Park, S.-J.; Moon, J. Influence of inter/intra-granular κ-carbides on the deformation mechanism in lightweight Fe-20Mn-11.5Al-1.2C steel. Mater. Charact. 2020, 161, 110142. [Google Scholar] [CrossRef]

- Liu, J.; Wu, H.; He, J.; Yang, S.; Ding, C. Effect of κ-carbides on the mechanical properties and superparamagnetism of Fe–28Mn–11Al-1.5/1.7C–5Cr lightweight steels. Mater. Sci. Eng. A 2022, 849, 143462. [Google Scholar] [CrossRef]

- Cheng, W.-C.; Cheng, C.-Y.; Hsu, C.-W.; Laughlin, D.E. Phase transformation of the L12 phase to kappa-carbide after spinodal decomposition and ordering in an Fe–C–Mn–Al austenitic steel. Mater. Sci. Eng. A 2015, 642, 128–135. [Google Scholar] [CrossRef]

- Chen, P.; Fu, J.; Xu, X.; Lin, C.; Pang, J.C.; Li, X.W.; Misra, R.D.K.; Wang, G.D.; Yi, H.L. A high specific Young’s modulus steel reinforced by spheroidal kappa-carbide. Mater. Sci. Technol. 2021, 87, 54–59. [Google Scholar] [CrossRef]

- Chen, P.; Xiong, X.C.; Wang, G.D.; Yi, H.L. The origin of the brittleness of high aluminum pearlite and the method for improving ductility. Scr. Mater. 2016, 124, 42–46. [Google Scholar] [CrossRef]

- Chen, P.; Li, X.; Yi, H. The κ-Carbides in Low-Density Fe-Mn-Al-C Steels: A Review on Their Structure, Precipitation and Deformation Mechanism. Metals 2020, 10, 1021. [Google Scholar] [CrossRef]

- Yao, M.J.; Welsch, E.; Ponge, D.; Haghighat, S.M.H.; Sandlöbes, S.; Choi, P.; Herbig, M.; Bleskov, I.; Hickel, T.; Lipinska-Chwalek, M.; et al. Strengthening and strain hardening mechanisms in a precipitation-hardened high-Mn lightweight steel. Acta Mater. 2017, 140, 258–273. [Google Scholar] [CrossRef]

- Kimura, Y.; Handa, K.; Hayashi, K.; Mishima, Y. Microstructure control and ductility improvement of the two-phase γ-Fe/κ-(Fe, Mn)3AlC alloys in the Fe–Mn–Al–C quaternary system. Intermetallics 2004, 12, 607–617. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Han, D.; Li, X.W. A unique two-stage strength-ductility match in low solid-solution hardening Ni-Cr alloys: Decisive role of short range ordering. Scr. Mater. 2020, 178, 269–273. [Google Scholar] [CrossRef]

- Han, D.; Wang, Z.Y.; Yan, Y.; Shi, F.; Li, X.W. A good strength-ductility match in Cu-Mn alloys with high stacking fault energies: Determinant effect of short range ordering. Scr. Mater. 2017, 133, 59–64. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Multistage strain hardening through dislocation substructure and twinning in a high strength and ductile weight-reduced Fe–Mn–Al–C steel. Acta Mater. 2012, 60, 5791–5802. [Google Scholar] [CrossRef]

- Kuhlmann-Wilsdorf, D. Theory of plastic deformation:—properties of low energy dislocation structures. Mater. Sci. Eng. A 1989, 113, 1–41. [Google Scholar] [CrossRef]

- Canadinc, D.; Sehitoglu, H.; Maier, H.J.; Niklasch, D.; Chumlyakov, Y.I. Orientation evolution in Hadfield steel single crystals under combined slip and twinning. Int. J. Sol. Struct. 2007, 44, 34–50. [Google Scholar] [CrossRef]

- Ma, B.; Li, C.; Zheng, J.; Song, Y.; Han, Y. Strain hardening behavior and deformation substructure of Fe–20/27Mn–4Al–0.3C non-magnetic steels. Mater. Des. 2016, 92, 313–321. [Google Scholar] [CrossRef]

- Yoo, J.D.; Hwang, S.W.; Park, K.-T. Origin of Extended Tensile Ductility of a Fe-28Mn-10Al-1C Steel. Metall. Mater. Trans. A 2009, 40, 1520–1523. [Google Scholar] [CrossRef]

- Yoo, J.D.; Park, K.-T. Microband-induced plasticity in a high Mn–Al–C light steel. Mater. Sci. Eng. A 2008, 496, 417–424. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Y.; Wang, Y.; Chen, J.; Bai, R.; Gao, L.; Xu, Z.; Wang, W.Y.; Tan, C.; Hui, X. Enhanced dynamic deformability and strengthening effect via twinning and microbanding in high density NiCoFeCrMoW high-entropy alloys. J. Mater. Sci. Technol. 2022, 127, 164–176. [Google Scholar] [CrossRef]

- Yao, K.; Min, X. Static and dynamic Hall–Petch relations in {332}<113> TWIP Ti–15Mo alloy. Mater. Sci. Eng. A 2021, 827, 142044. [Google Scholar] [CrossRef]

| Strain Rate/s−1 | Yield Strength/MPa | Ultimate Tensile Strength/MPa | Total Elongation/% |

|---|---|---|---|

| 10−4 | 301 ± 30 | 761 ± 35 | 59 ± 2 |

| 10−3 | 329 ± 20 | 789 ± 25 | 72 ± 3 |

| 10−2 | 378 ± 5 | 801 ± 12 | 61 ± 1 |

| 10−1 | 381 ± 8 | 738 ± 9 | 56 ± 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, J.; Chen, P.; Guan, X.; Cai, J.; Peng, Q.; Lin, C.; Li, X. The Effect of Strain Rate on the Deformation Behavior of Fe-30Mn-8Al-1.0C Austenitic Low-Density Steel. Metals 2022, 12, 1374. https://doi.org/10.3390/met12081374

Du J, Chen P, Guan X, Cai J, Peng Q, Lin C, Li X. The Effect of Strain Rate on the Deformation Behavior of Fe-30Mn-8Al-1.0C Austenitic Low-Density Steel. Metals. 2022; 12(8):1374. https://doi.org/10.3390/met12081374

Chicago/Turabian StyleDu, Jiahui, Peng Chen, Xianjun Guan, Jiawei Cai, Qian Peng, Chuang Lin, and Xiaowu Li. 2022. "The Effect of Strain Rate on the Deformation Behavior of Fe-30Mn-8Al-1.0C Austenitic Low-Density Steel" Metals 12, no. 8: 1374. https://doi.org/10.3390/met12081374

APA StyleDu, J., Chen, P., Guan, X., Cai, J., Peng, Q., Lin, C., & Li, X. (2022). The Effect of Strain Rate on the Deformation Behavior of Fe-30Mn-8Al-1.0C Austenitic Low-Density Steel. Metals, 12(8), 1374. https://doi.org/10.3390/met12081374