Repair Reliability Analysis of a Special-Shaped Epoxy Steel Sleeve for Low-Strength Tee Pipes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Properties

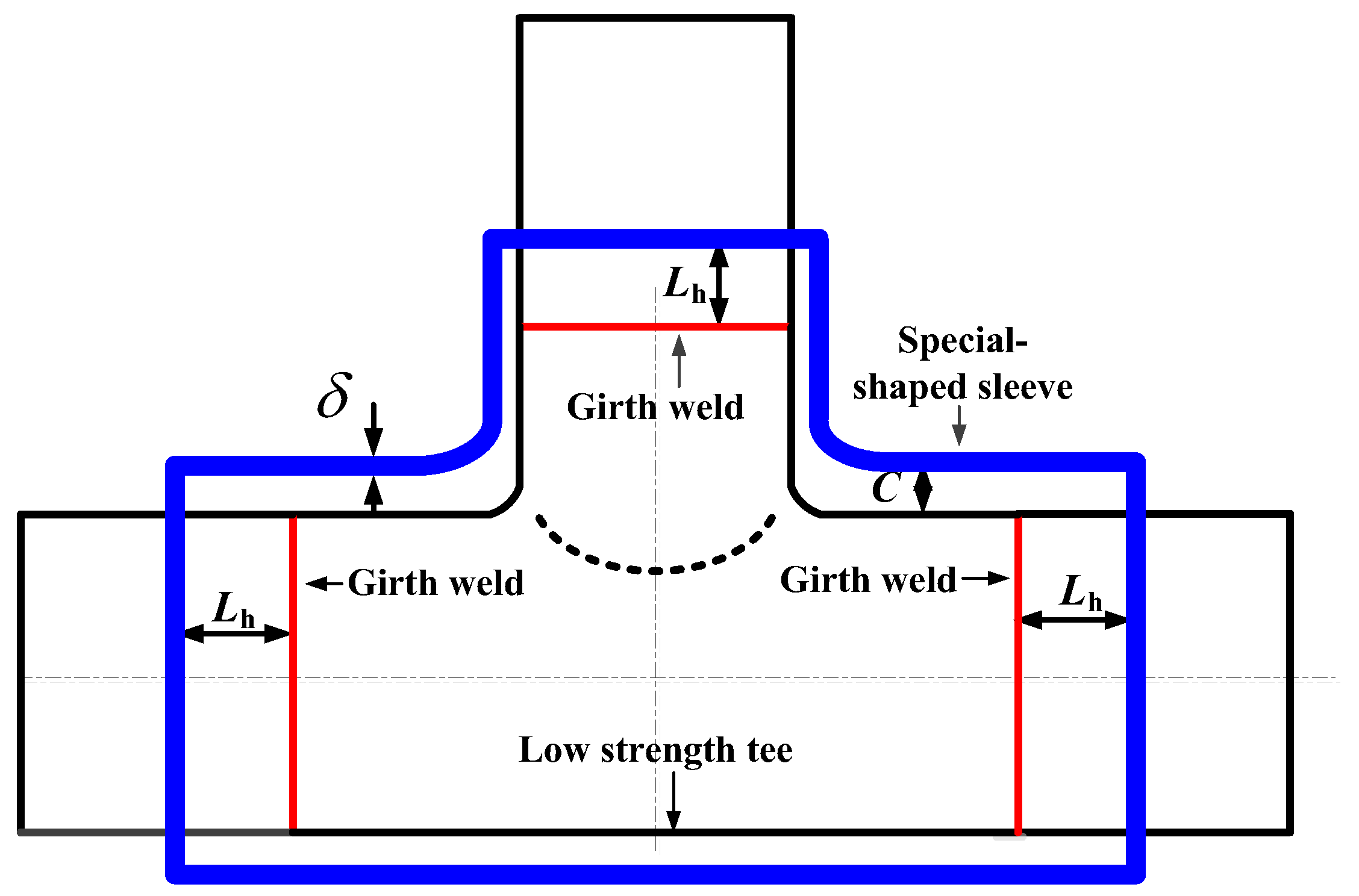

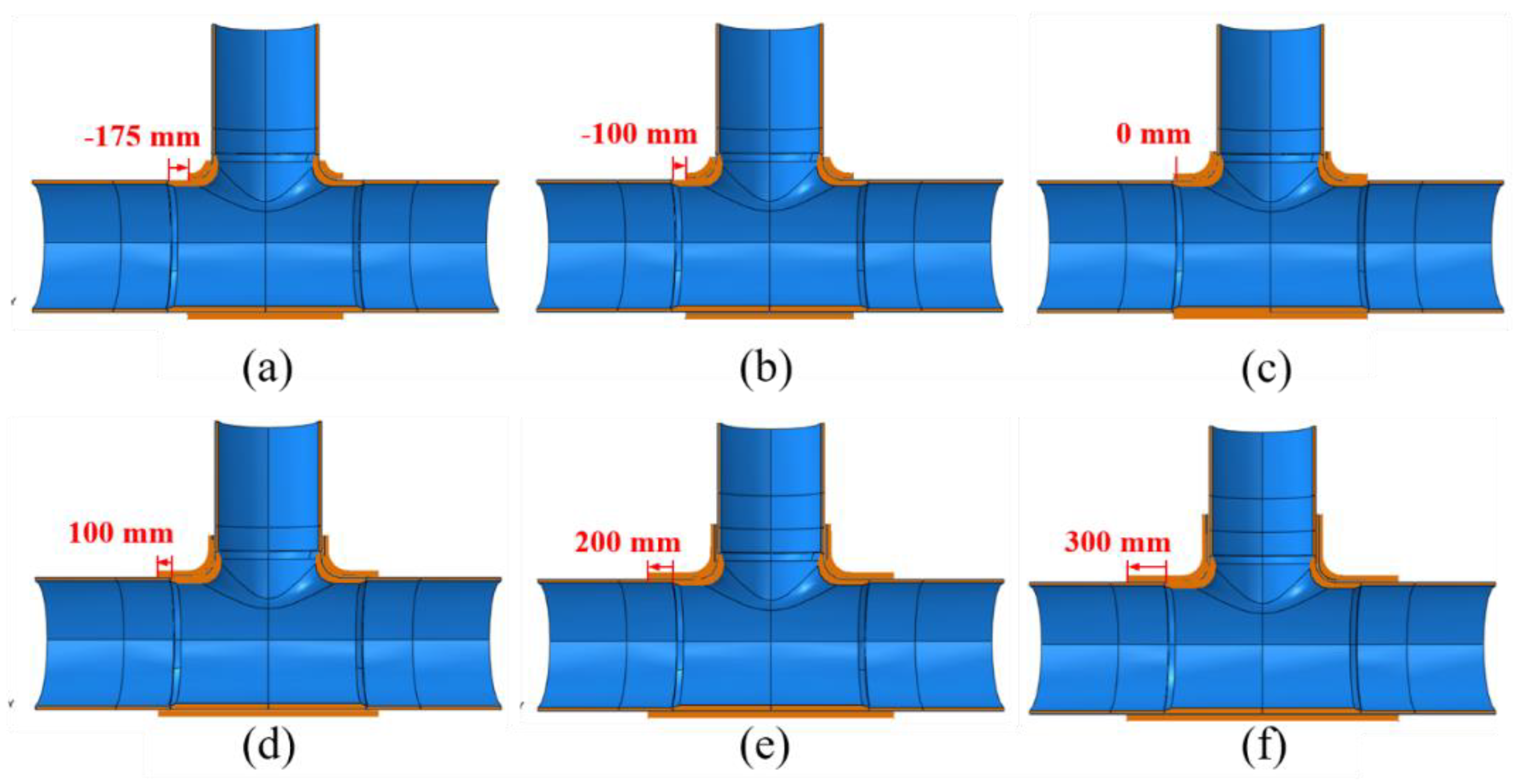

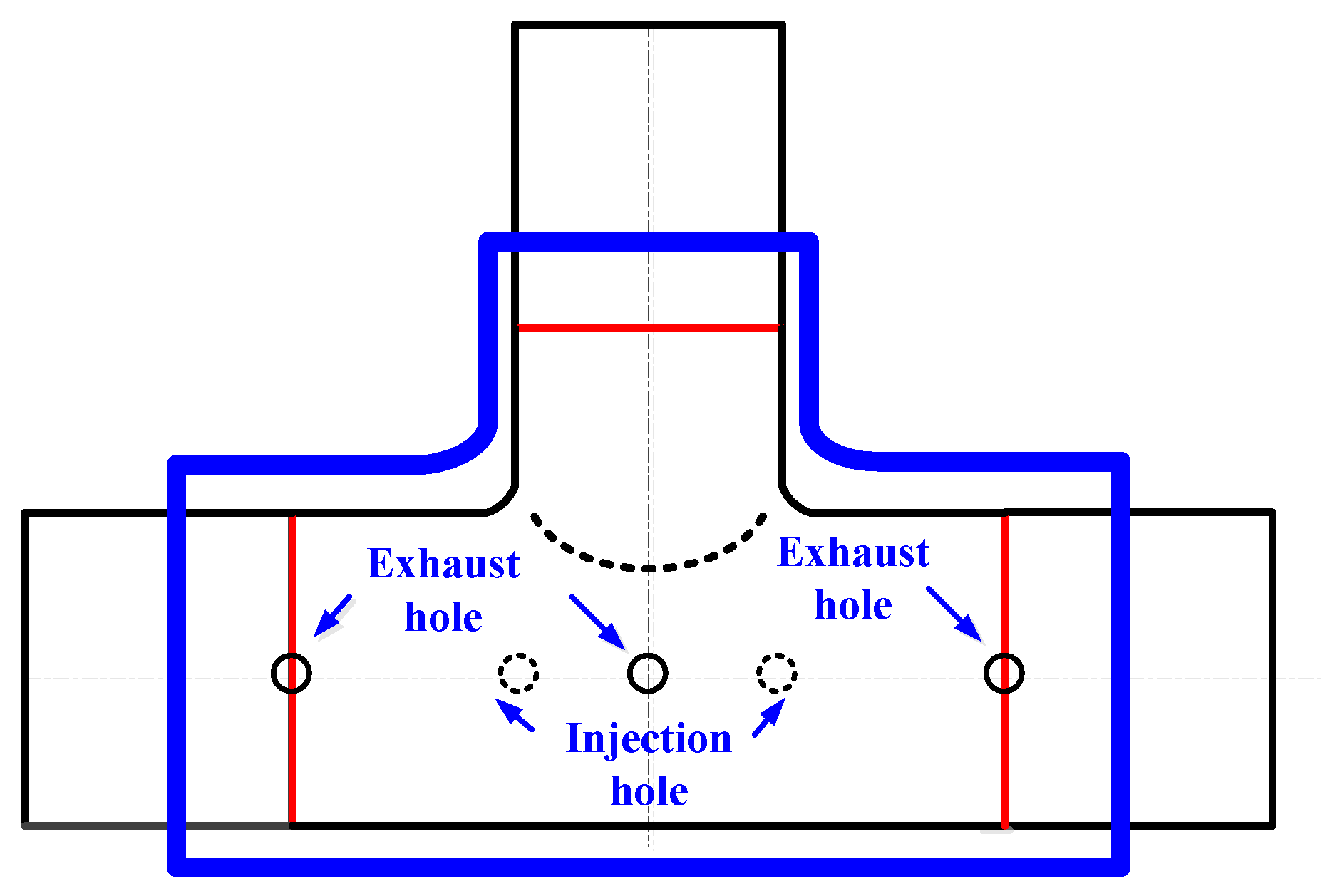

2.2. Design of the Special-Shaped Steel Sleeve

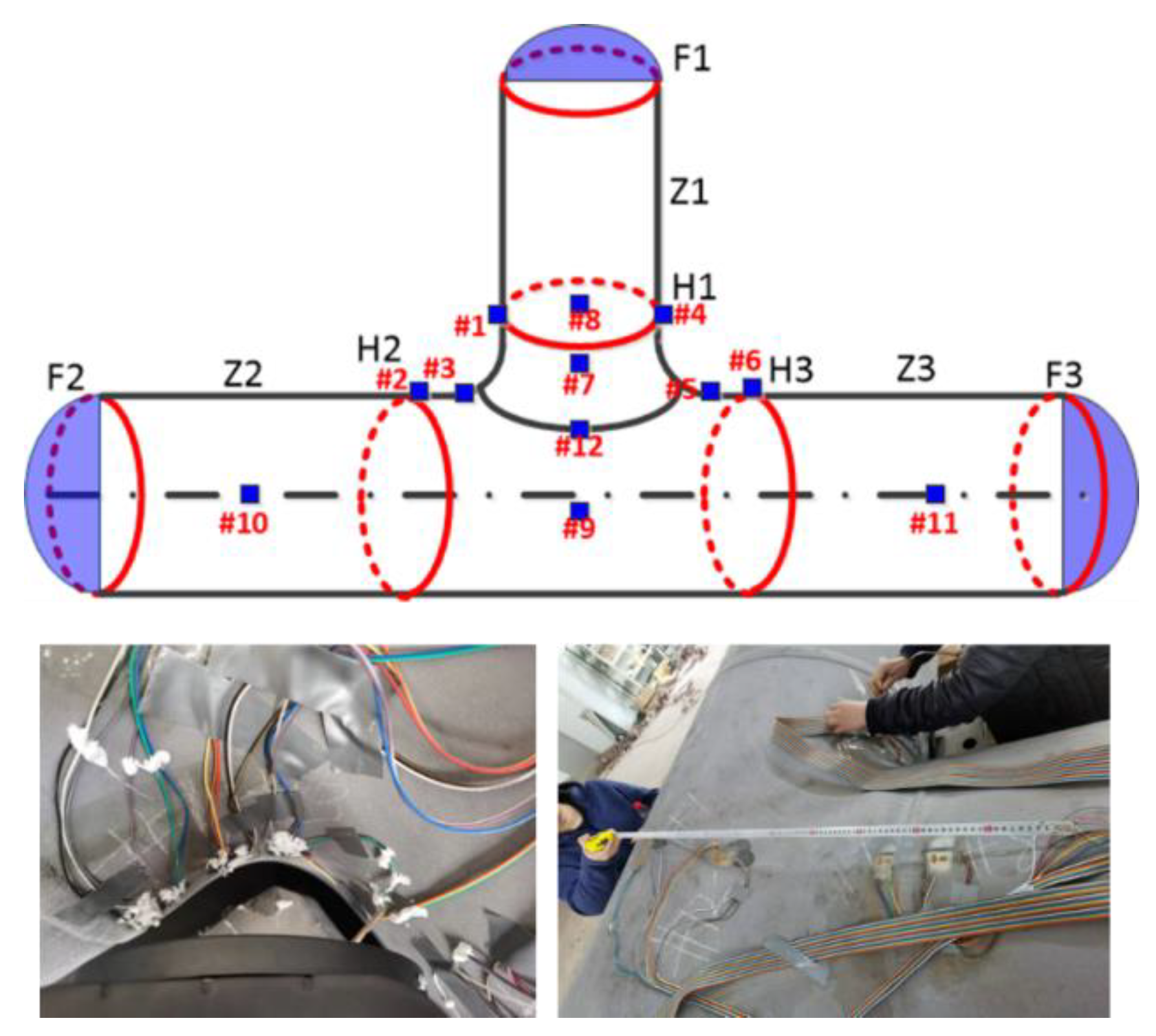

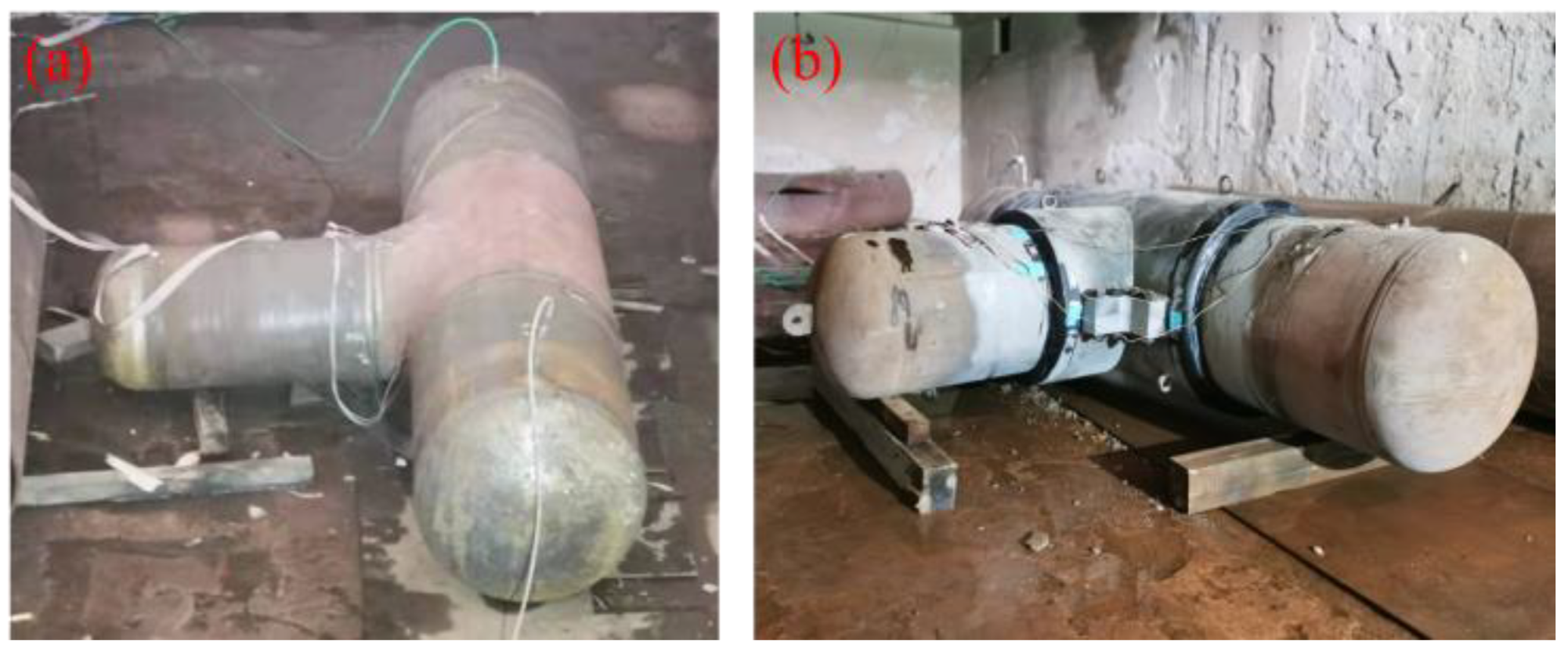

2.3. Repairing Test of SSESS

- Step 1: Surface cleaning and sand-blasting

- Step 2: Experiments with strain monitoring

- Step 3: Installation of a special-shaped steel sleeve

- Step 4: Injecting process

- Step 5: Epoxy resin curing process

2.4. Hydraulic Burst Test

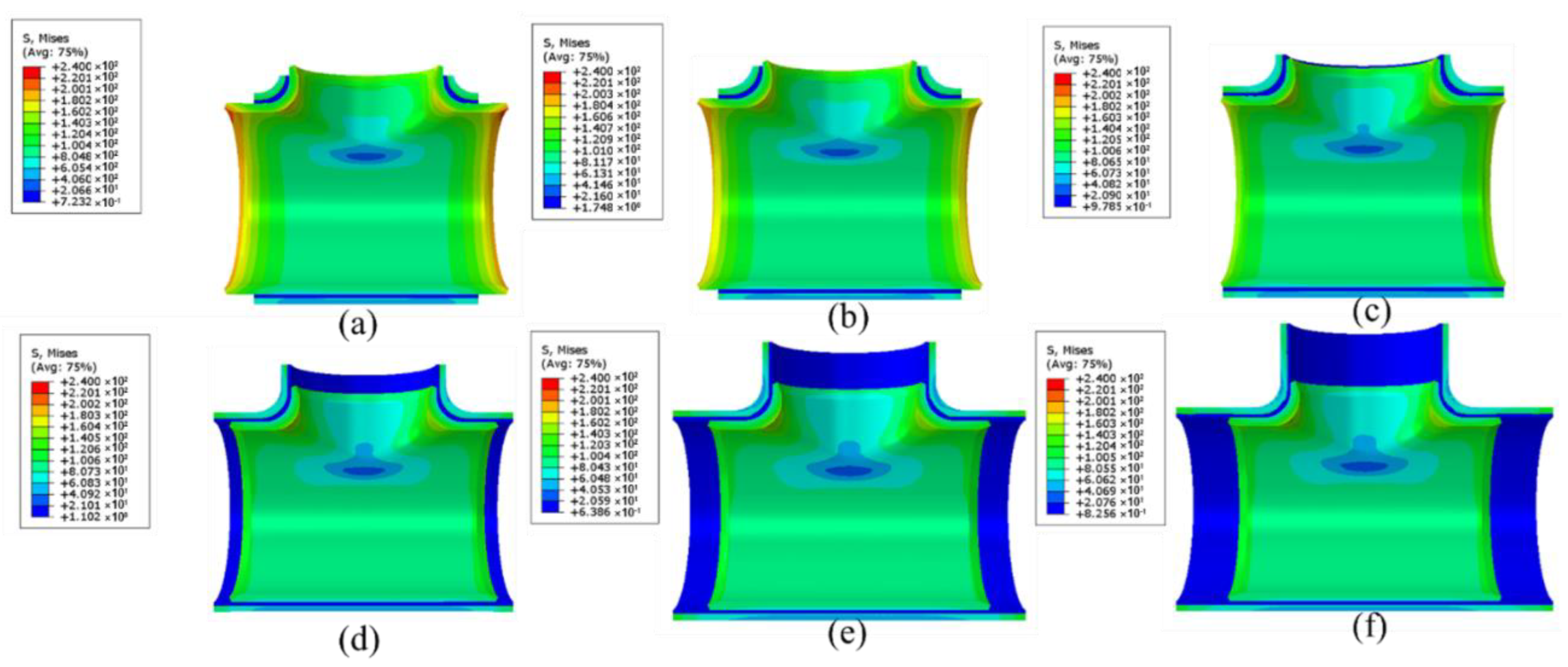

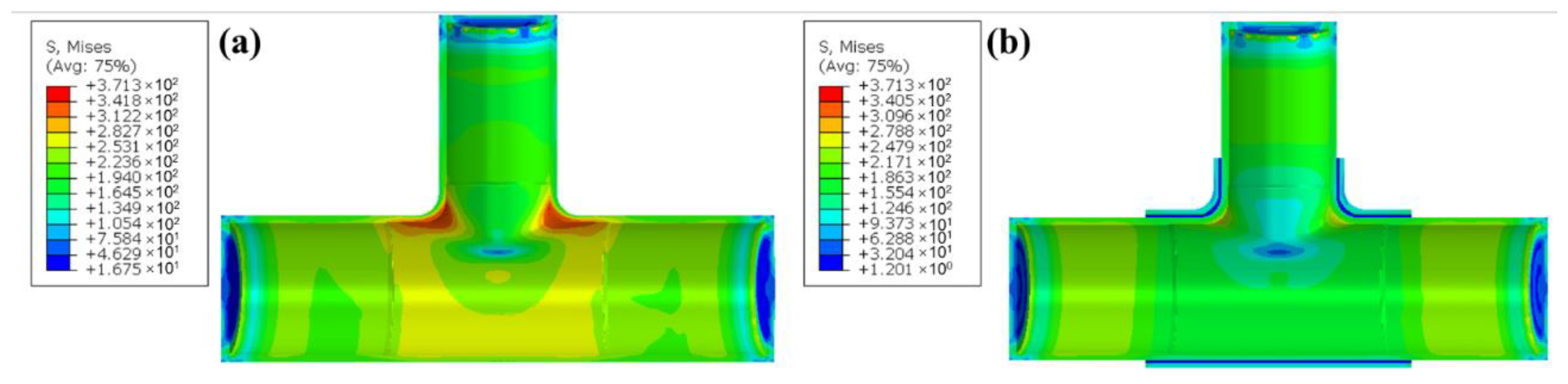

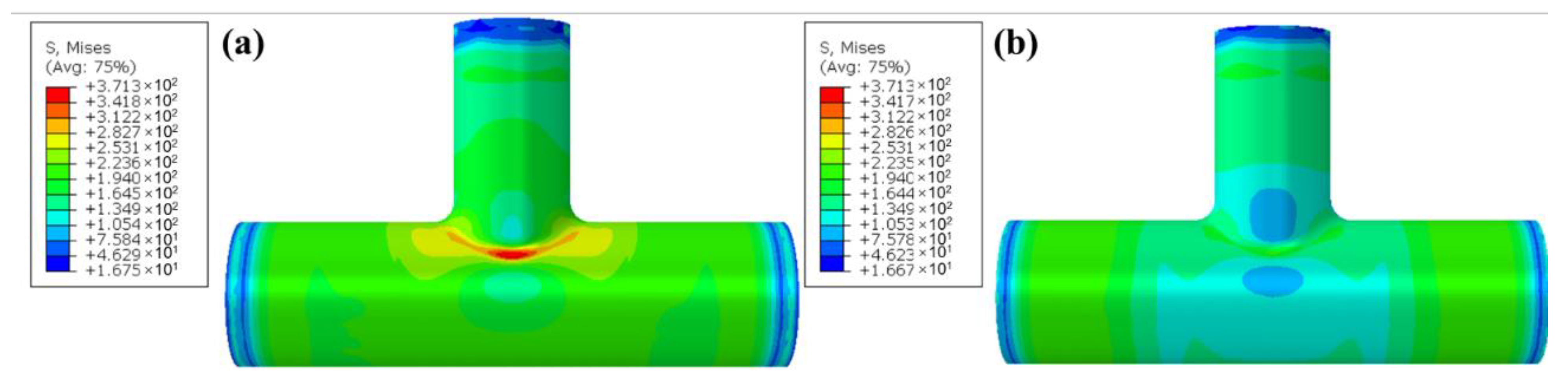

2.5. Simulations

3. Results

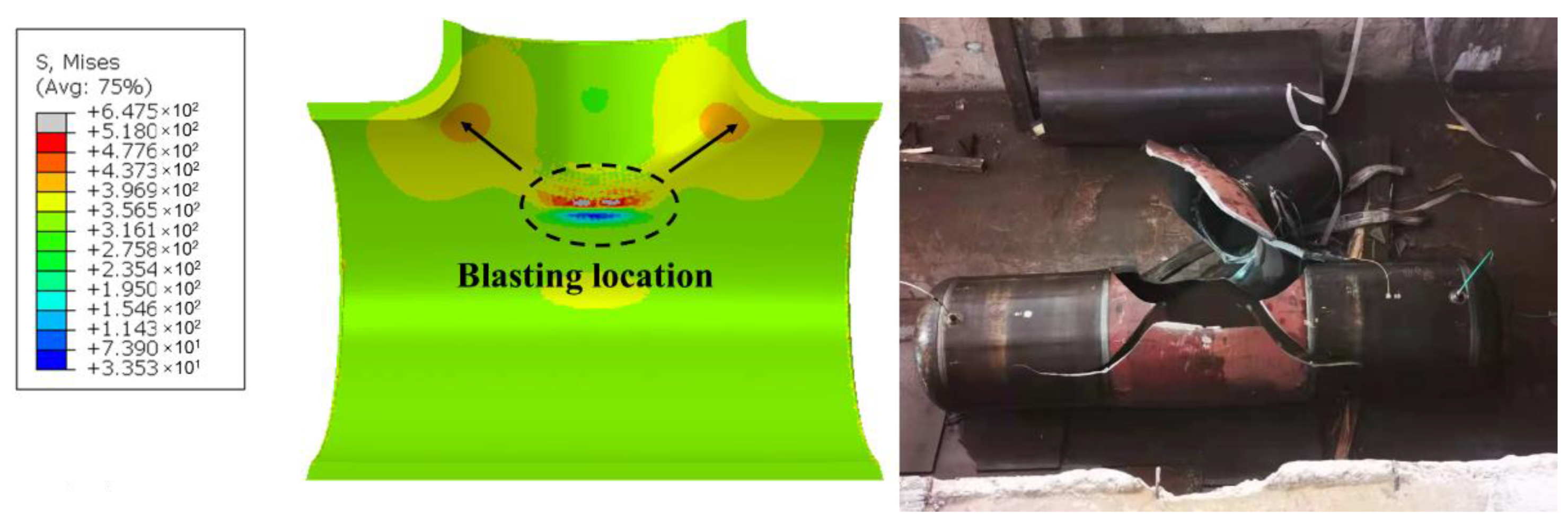

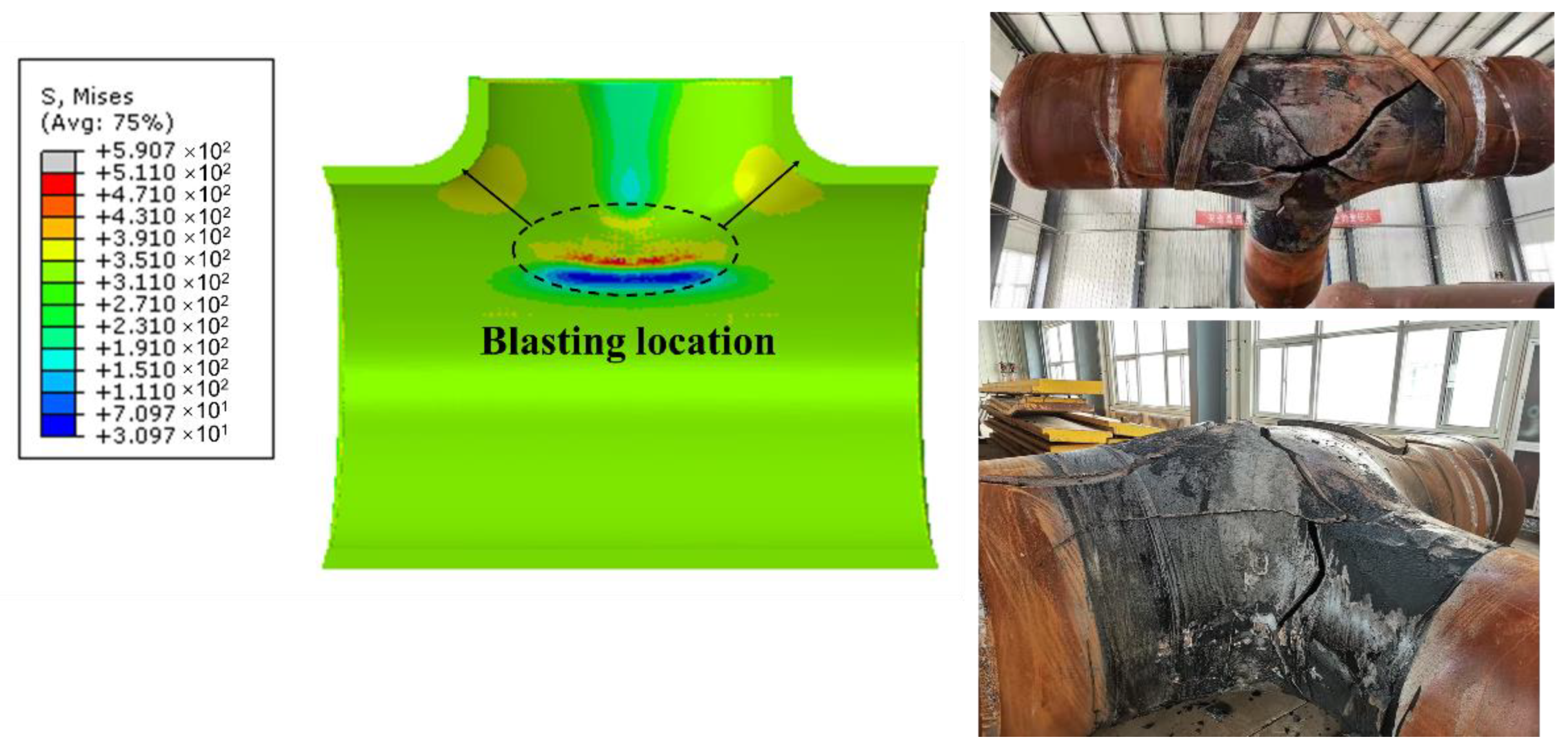

4. Discussion

5. Conclusions

- (1)

- The critical design parameters for the special-shaped sleeve are the minimum thickness, the material properties of the sleeve, the length between the edge of the sleeve and the girth weld, the gap between the sleeve and the tee, and the locations of the injection and exhaust holes.

- (2)

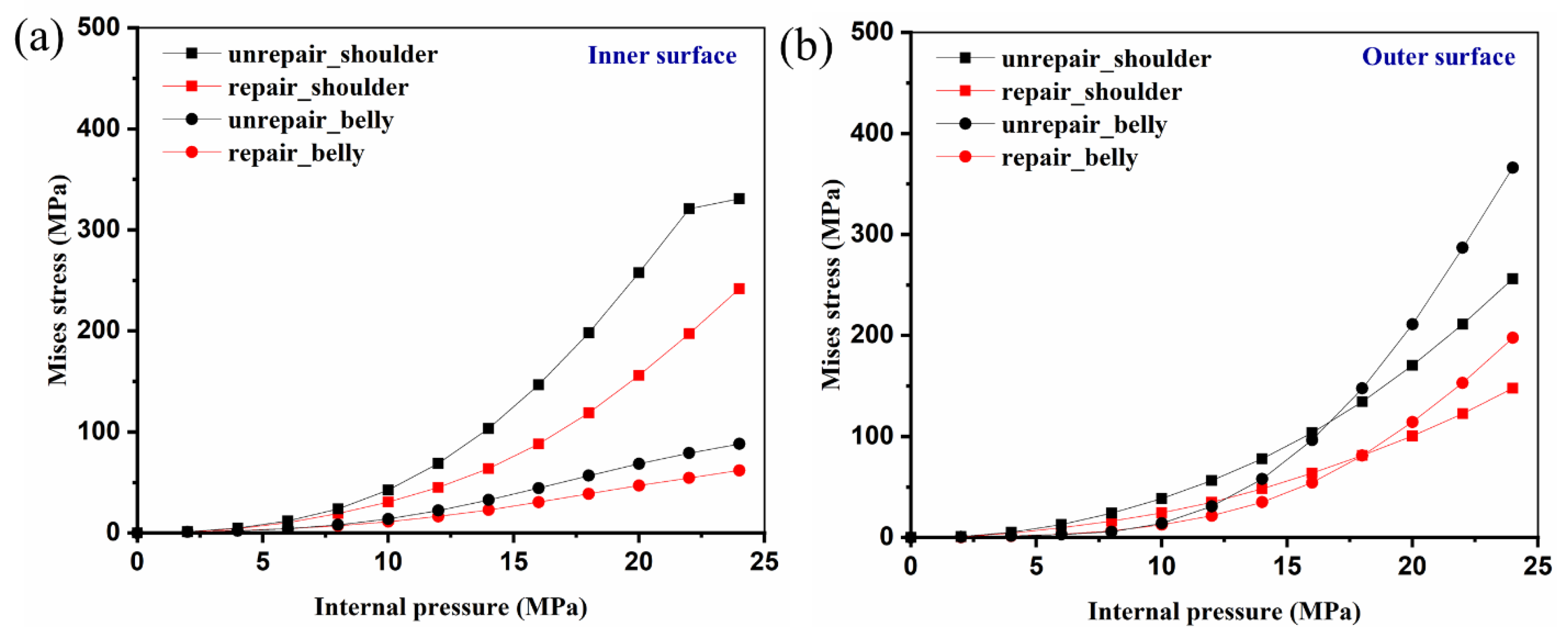

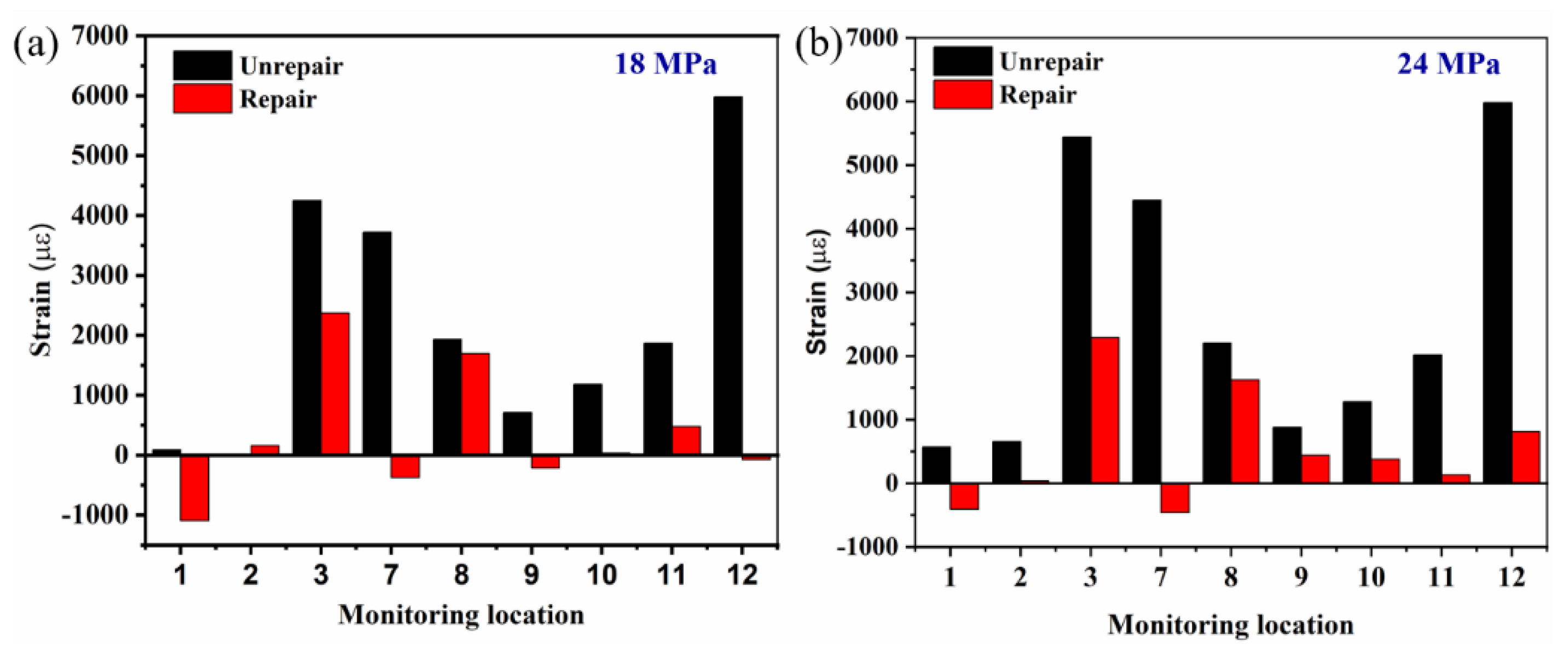

- The strain concentrations of the unrepaired tee were greatly reduced, especially for the belly. The maximum strain was ~0.006 on the outer surface of the belly, and it decreased from ~0.006 to ~0.001 under hydrostatic pressure of 24 MPa, where the decreasing rate was about 80%.

- (3)

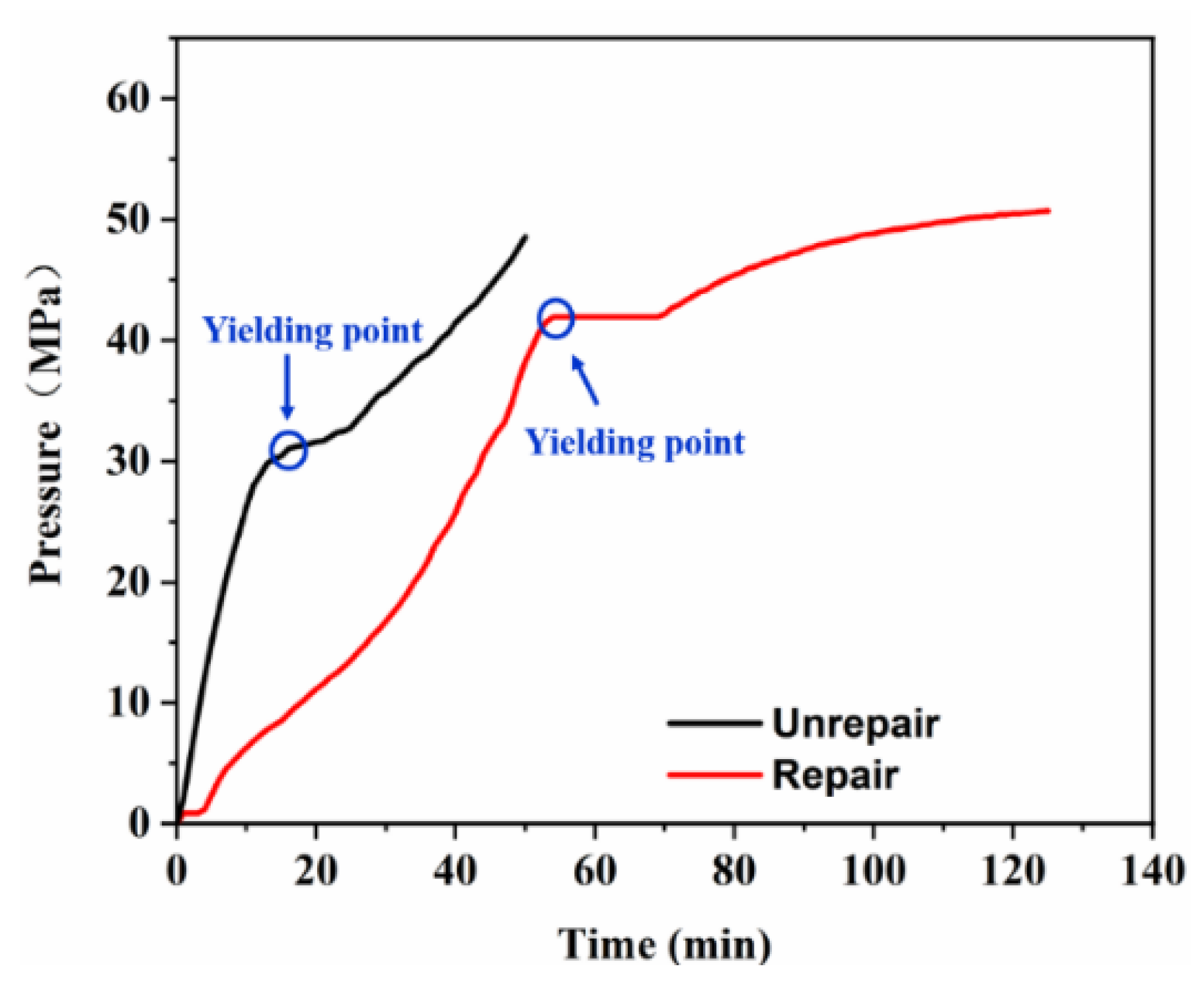

- The yielding and burst pressure was improved from ~32 MPa and ~48.6 MPa to ~42 MPa and ~50.8 MPa, respectively, which demonstrates the good reliability of the special-shaped epoxy resin steel sleeve repairing low-strength tee.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cao, J.; Ma, W.; Pang, G.; Wang, K.; Yao, T. Failure analysis on girth weld cracking of underground tee pipe. Int. J. Press. Vessel. Pip. 2021, 191, 104371. [Google Scholar] [CrossRef]

- Su, W.; Luo, W.; Dong, X.; Liu, R. Ultimate Strength Analysis of Local Thinning Tee Pipe Considering Plastic Strengthening Effect. J. Phys. Conf. Ser. 2020, 1650, 022024. [Google Scholar] [CrossRef]

- Shuai, Y.; Wang, X.; Wang, J.; Yin, H.G.; Cheng, Y.F. Modeling of mechanical behavior of corroded X80 steel pipeline reinforced with type-B repair sleeve. Thin Walled Struct. 2021, 163, 107708. [Google Scholar] [CrossRef]

- Jaske, C.E.; Hart, B.O.; Bruce, W.A. Pipeline Repair Manual; Pipeline Research Council International: Arlington, VA, USA, 2006; pp. 1–196. [Google Scholar]

- American Society of Mechanical Engineers. Repair of Pressure Equipment and Piping; American Society of Mechanical Engineers: New York, NY, USA, 2015. [Google Scholar]

- Lim, K.S.; Azraai, S.; Yahaya, N.; Noor, N.M.; Kim, J. Behaviour of steel pipelines with composite repairs analysed using experimental and numerical approaches. Thin Walled Struct. 2019, 139, 321–333. [Google Scholar] [CrossRef]

- Rinastiti, M. The Effect of Aging on Composite-to-Composite Repair Strength; Citeseer: State College, PA, USA, 2010. [Google Scholar]

- Savari, A.; Rashed, G.; Eskandari, H. Time-Dependent Reliability Analysis of Composite Repaired Pipes Subjected to Multiple Failure Modes. J. Fail. Anal. Prev. 2021, 21, 2234–2246. [Google Scholar] [CrossRef]

- Karpenko, M.; Prentkovskis, O.; Šukevičius, Š. Research on high-pressure hose with repairing fitting and influence on energy parameter of the hydraulic drive. Eksploat. Niezawodn. Maint. Reliab. 2021, 24, 25–32. [Google Scholar] [CrossRef]

- Batisse, R. Review of gas transmission pipeline repair methods. In Safety, Reliability and Risks Associated with Water, Oil and Gas Pipelines; Springer: Berlin/Heidelberg, Germany, 2008; pp. 335–349. [Google Scholar]

- Stephens, D.; Leis, B.; Francini, R. Developments in criteria for repair or replacement decisions for pipeline corrosion defects. In Proceedings of the 3 Congreso y Expo Internacional de Ductos, Monterrey, Mexico, 13–15 December 1998; pp. 268–275. [Google Scholar]

- Wood, A. Evolution of epoxy sleeve pipeline repair technology. Pipes Pipelines Int. 2015, 23, 50–52. [Google Scholar]

- CSA-Z662-2007; Oil and Gas Pipeline Systems. Canadian Standards Association: Toronto, ON, Canada, 2007.

- Novák, P.; Žmindák, M.; Pelagić, Z. High-pressure pipelines repaired by steel sleeve and epoxy composition. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2014; pp. 181–188. [Google Scholar]

- Mazurkiewicz, L.; Tomaszewski, M.; Malachowski, J.; Sybilski, K.; Chebakov, M.; Witek, M.; Yukhymets, P.; Dmitrienko, R. Experimental and numerical study of steel pipe with part-wall defect reinforced with fibre glass sleeve. Int. J. Press. Vessel. Pip. 2017, 149, 108–119. [Google Scholar] [CrossRef]

- Arif, A.; Al-Nassar, Y.N.; Al-Qahtani, H.; Khan, S.; Anis, M.; Eleiche, A.; Inam, M.; Al-Nasri, N.I.; Al-Muslim, H.M. Optimization of pipe repair sleeve design. J. Press. Vessel. Technol. 2012, 134, 51702. [Google Scholar] [CrossRef]

- Jaszak, P.; Skrzypacz, J.; Borawski, A.; Grzejda, R. Methodology of Leakage Prediction in Gasketed Flange Joints at Pipeline Deformations. Materials 2022, 15, 4354. [Google Scholar] [CrossRef] [PubMed]

- Shang-Peng, L.; Lei, Y.; Xuan-Peng, Q.; Xuefei, D.; Weihua, X.; Huatian, X.; Zhenhua, C. The Applicability Study of Special Steel Sleeve Filled with Epoxy Resin for the Leakage of Welding Connection Platform on Brine Pipeline. Total Corros. Control 2016, 8, 57–59. [Google Scholar]

- Ahmad, K.; Baig, Y.; Rahman, H.; Hasham, H. Progressive failure analysis of helicopter rotor blade under aeroelastic loading. Aviation 2020, 24, 33–41. [Google Scholar] [CrossRef]

- Fowler, J.R.; Alexander, C.R. Design Guidelines for High-Strength Pipe Fittings; American Gas Association, Inc.: Arlington, VA, USA; Stress Engineering Services: Houston, TX, USA, 1994. [Google Scholar]

| Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | |

|---|---|---|---|

| S1 (branch pipe) | 343 | 539 | 29.5 |

| S2 (shoulder) | 374 | 502 | 29.5 |

| S3 (main pipe) | 363 | 553 | 27.5 |

| Properties | Unit | Requirements |

|---|---|---|

| Hardness of the resin after curing | Shore D | 80 ± 10 |

| Mass solid content | % | ≥99.5 |

| Curing shrinkage | % | ≤0.4 |

| Compressive strength of the resin after curing | MPa | ≥50 |

| (50% deformation) | MPa | ≥10 |

| Shear strength | MPa | ≥10 |

| Region of Tee | E (GPa) | K (MPa) | n |

|---|---|---|---|

| S1 | 207 | 281.0 | 0.295 |

| S2 | 211 | 183.5 | 0.295 |

| S3 | 209 | 271.0 | 0.275 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, J.; Jia, H.; Ma, W.; Wang, K.; Yao, T.; Ren, J.; Nie, H.; Liang, X.; Dang, W. Repair Reliability Analysis of a Special-Shaped Epoxy Steel Sleeve for Low-Strength Tee Pipes. Metals 2022, 12, 2149. https://doi.org/10.3390/met12122149

Cao J, Jia H, Ma W, Wang K, Yao T, Ren J, Nie H, Liang X, Dang W. Repair Reliability Analysis of a Special-Shaped Epoxy Steel Sleeve for Low-Strength Tee Pipes. Metals. 2022; 12(12):2149. https://doi.org/10.3390/met12122149

Chicago/Turabian StyleCao, Jun, Haidong Jia, Weifeng Ma, Ke Wang, Tian Yao, Junjie Ren, Hailiang Nie, Xiaobin Liang, and Wei Dang. 2022. "Repair Reliability Analysis of a Special-Shaped Epoxy Steel Sleeve for Low-Strength Tee Pipes" Metals 12, no. 12: 2149. https://doi.org/10.3390/met12122149

APA StyleCao, J., Jia, H., Ma, W., Wang, K., Yao, T., Ren, J., Nie, H., Liang, X., & Dang, W. (2022). Repair Reliability Analysis of a Special-Shaped Epoxy Steel Sleeve for Low-Strength Tee Pipes. Metals, 12(12), 2149. https://doi.org/10.3390/met12122149