Rheological Behavior of Inconel 718 Powder for Electron-Beam Melting

Abstract

1. Introduction

2. Materials and Methods

3. Results

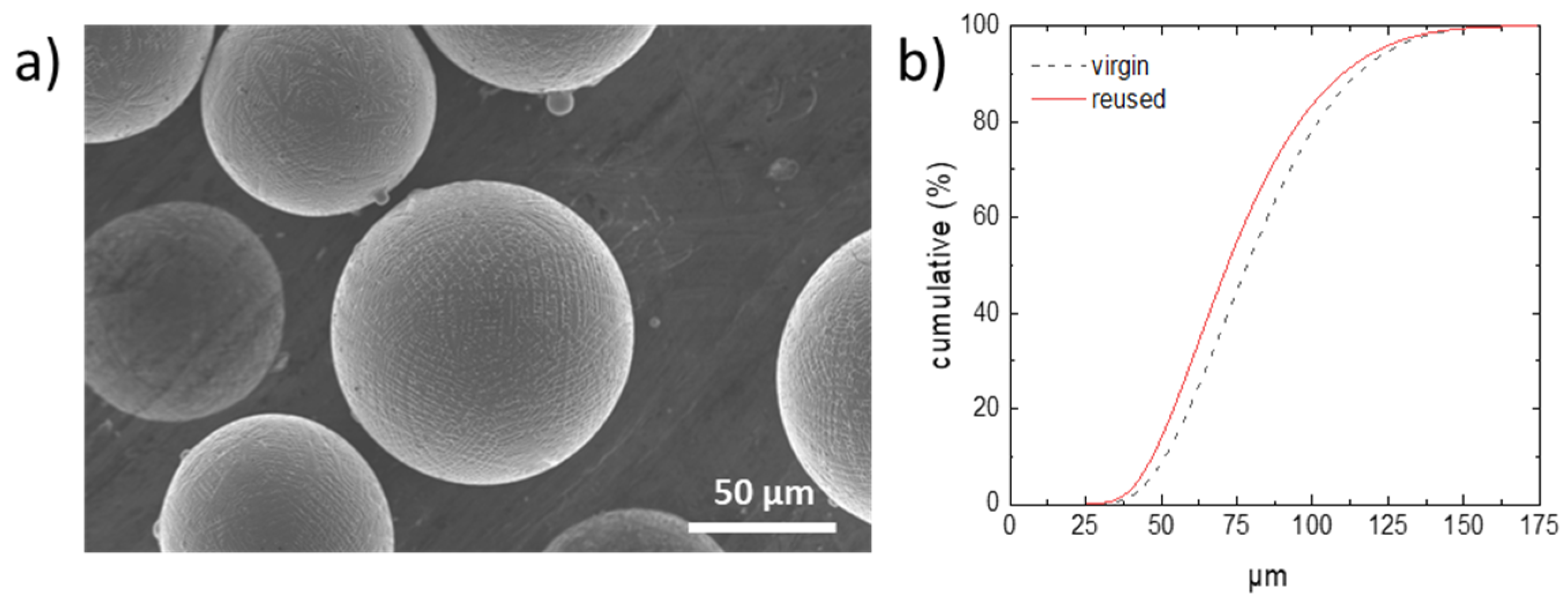

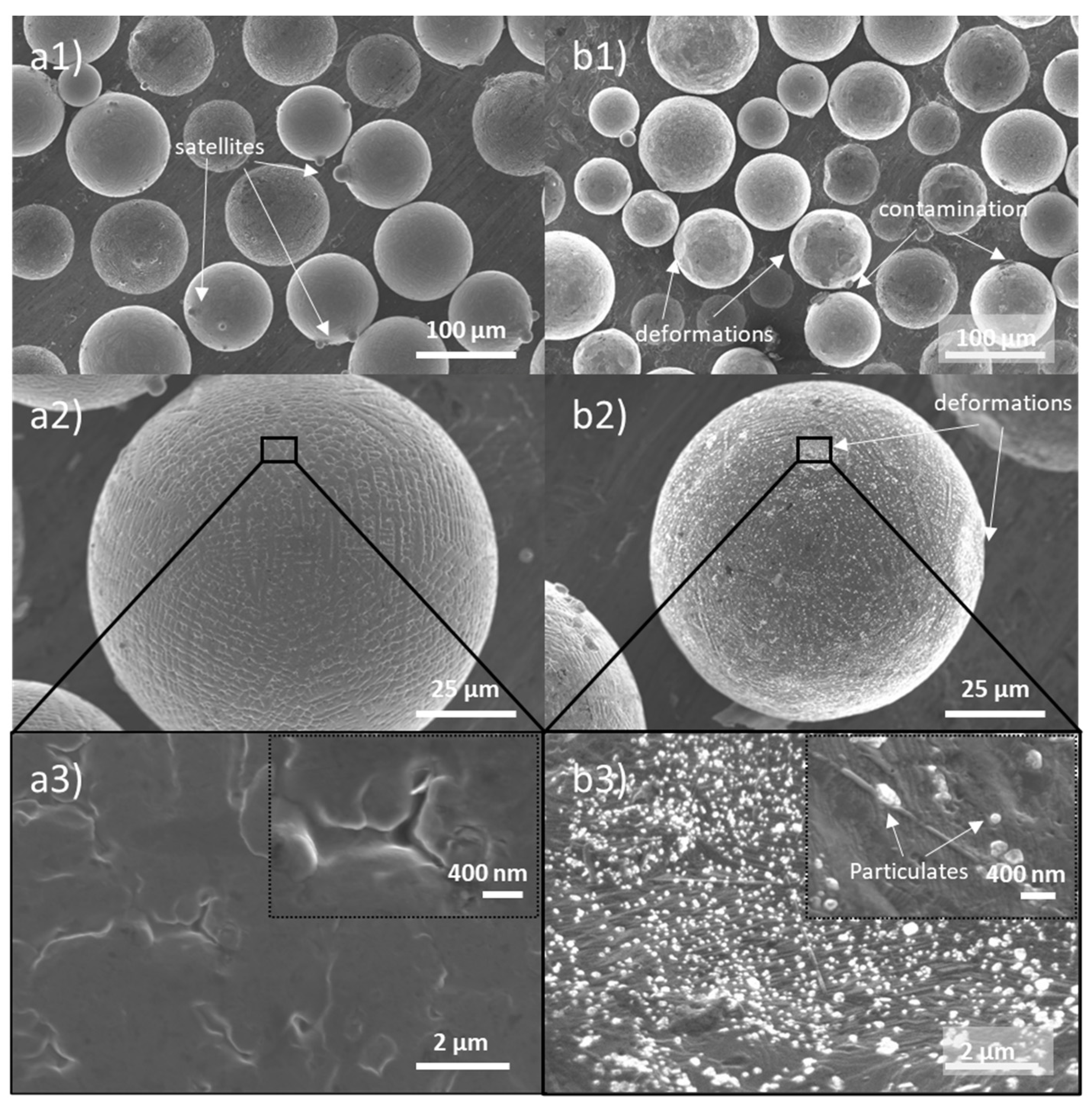

3.1. Morphological Characterization

3.2. Bulk Chemical Analysis and Particle Size Distribution

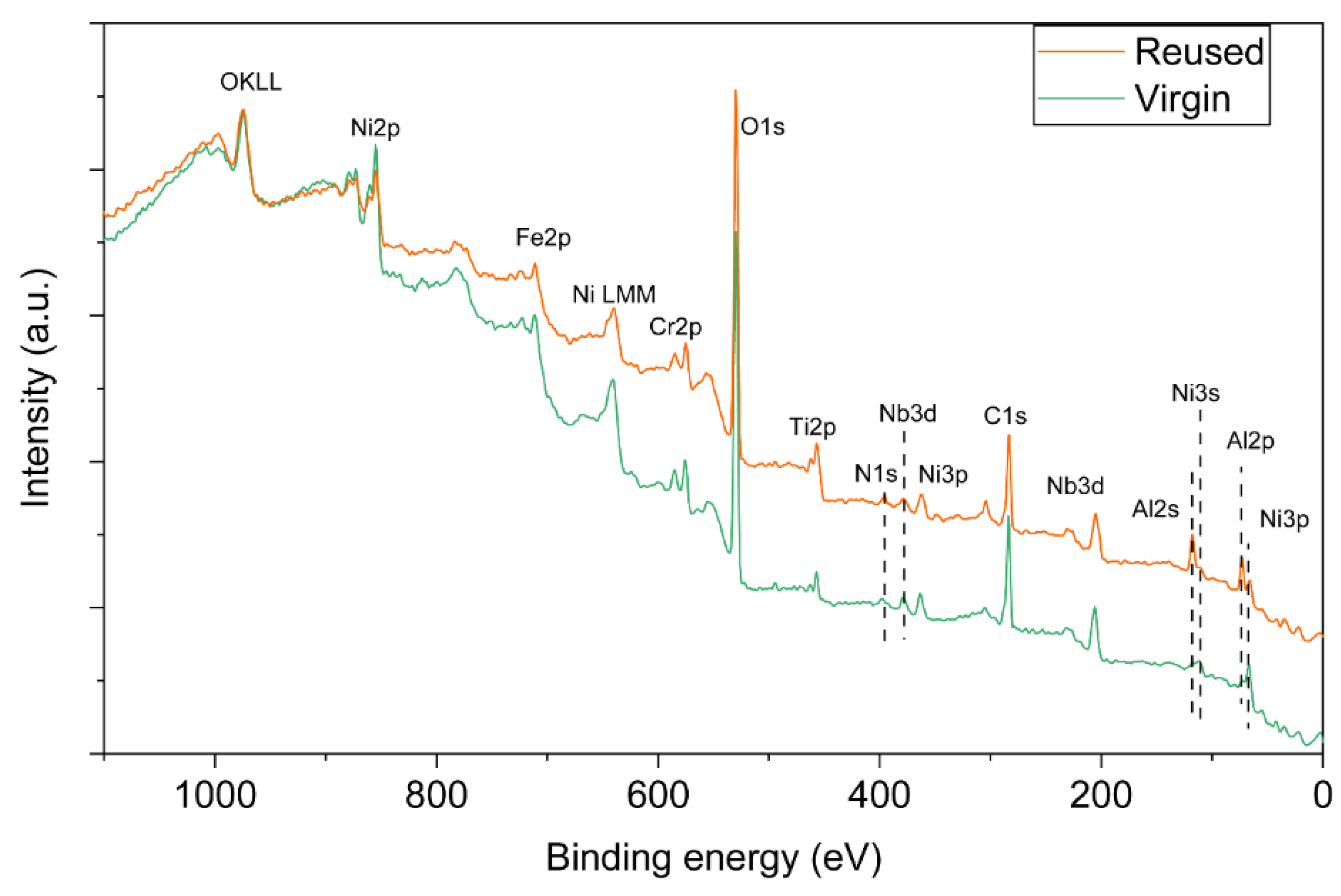

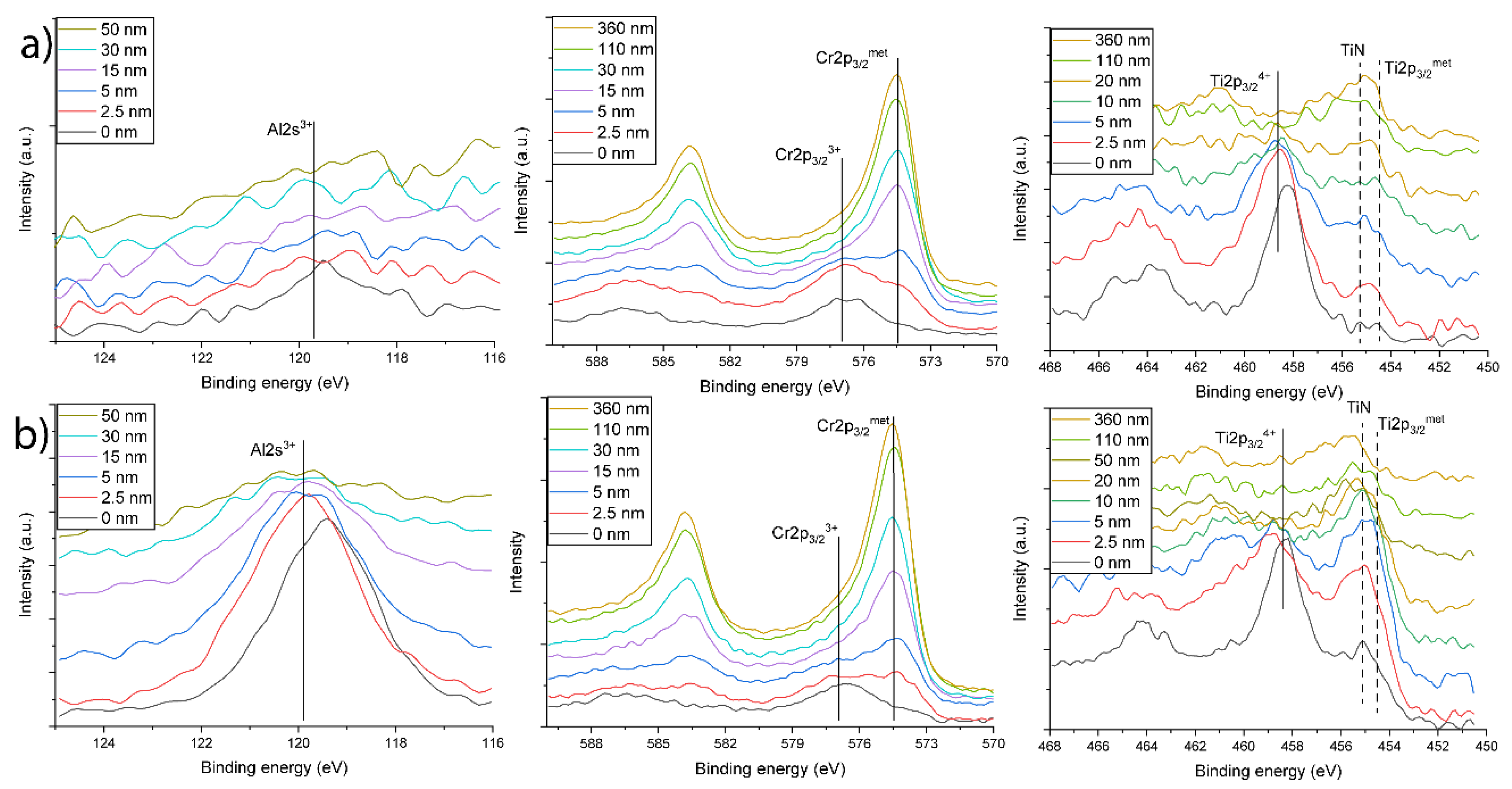

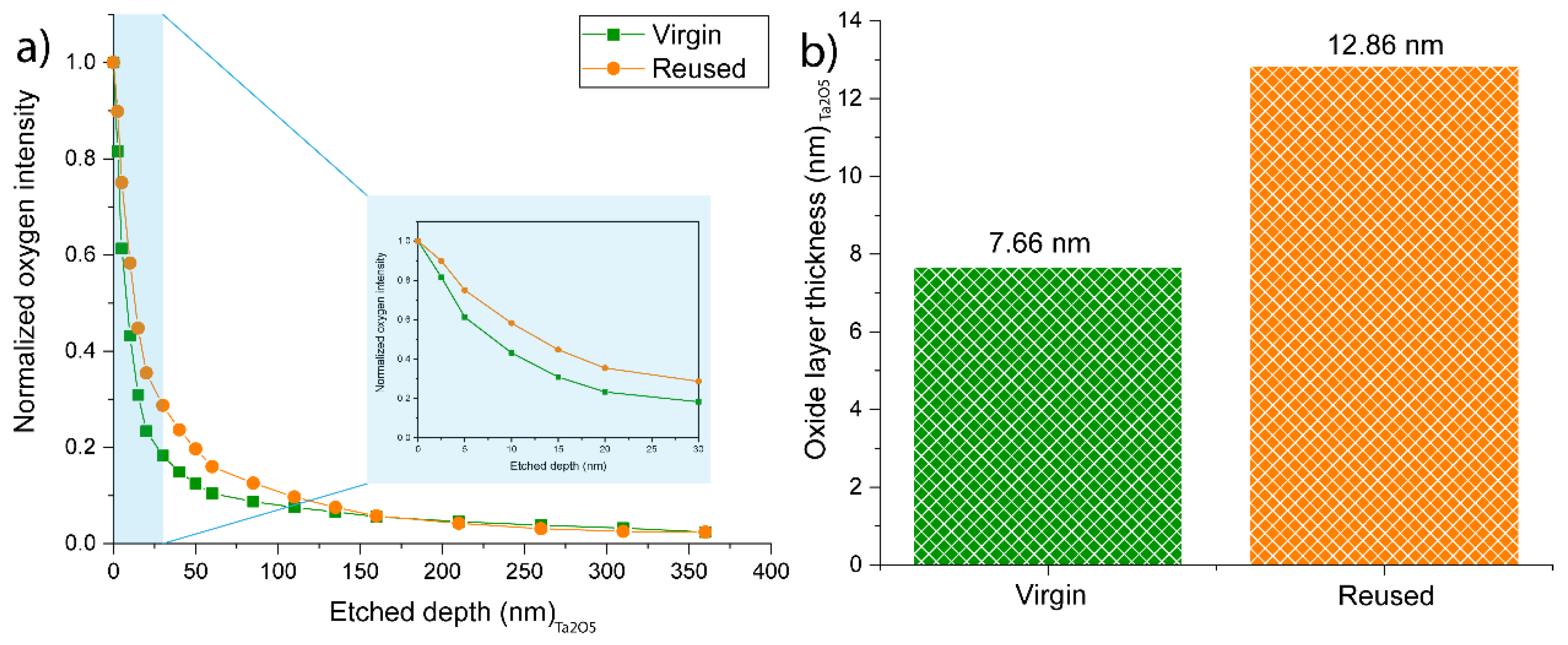

3.3. Surface Chemical Analysis

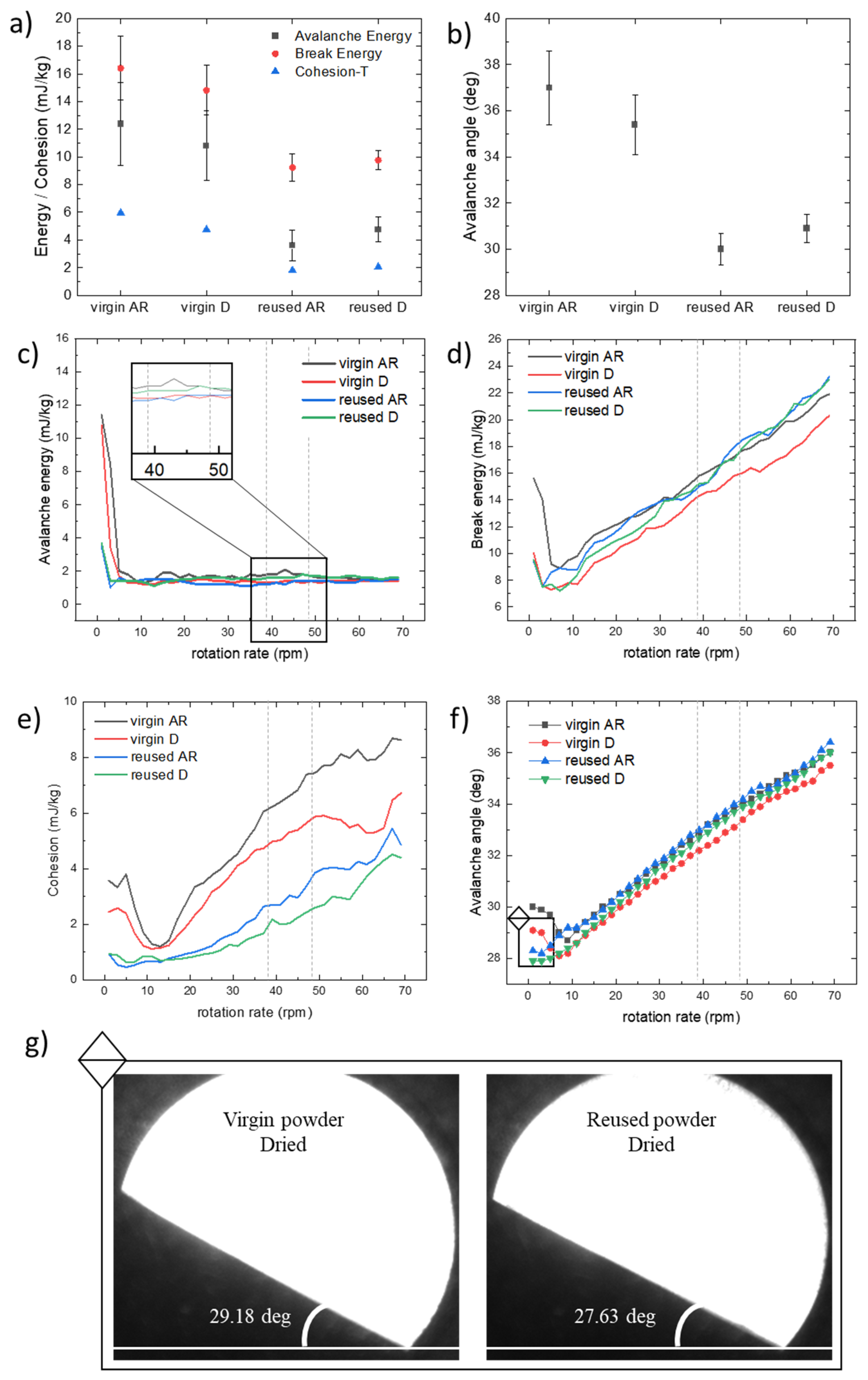

3.4. Rheological Behavior

3.5. Tap and Apparent Density

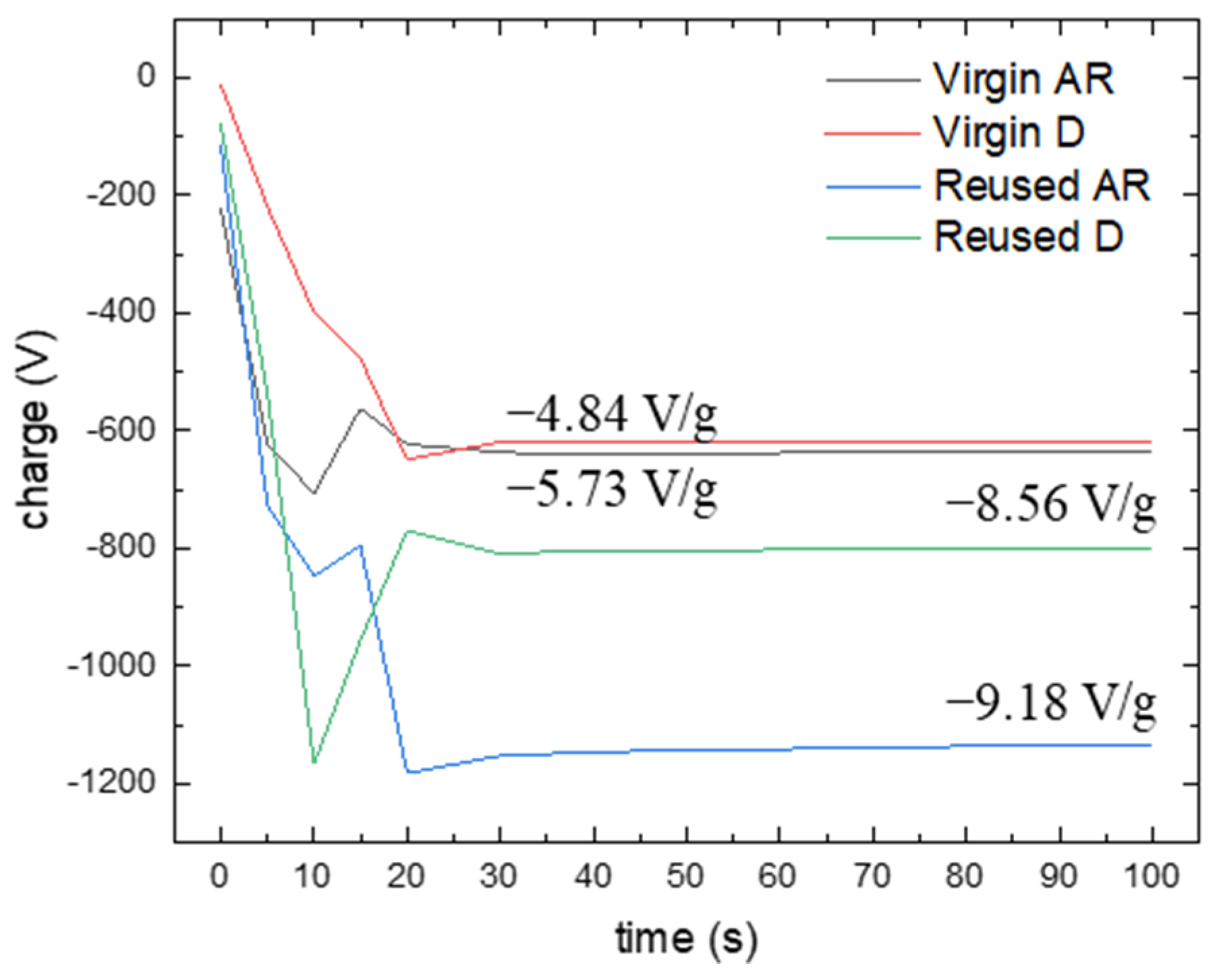

3.6. Charging

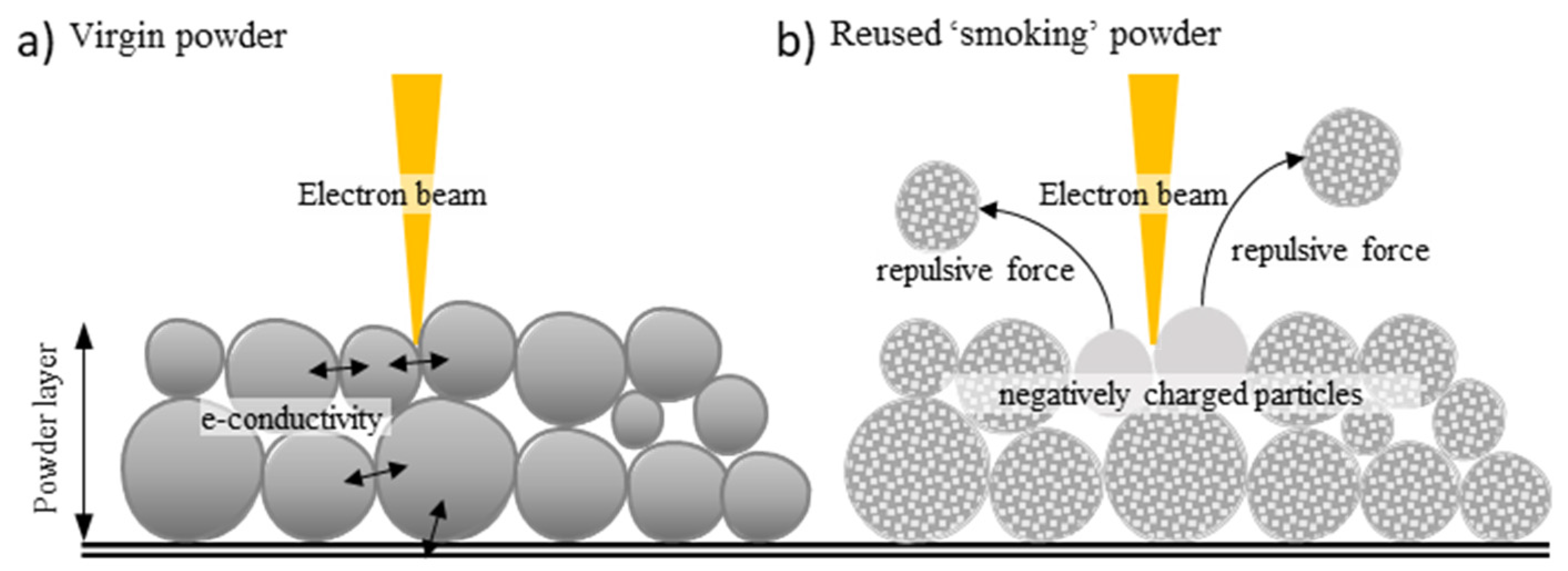

4. Discussion

4.1. Physical Properties of Reused Powder

4.2. Challenges in Processibility and Mitigation Actions

5. Conclusions

- The morphology and particle size of the powder is mildly impacted by reuse and handling. A shift of circa 8% towards lower particle size values is observed. The morphology of reused powders exhibits less satellites and deformations from blasting.

- The bulk oxygen content of the powder increased by 20% upon reuse.

- The nature of the oxide layer and thickness varies from virgin to reused powder. Virgin powder was covered by a thin homogeneous oxide layer, formed preferably by Ni and Cr-oxide. In the case of reused powder, the powder surface was covered with Al-rich oxide particulates with average thicknesses around 13 nm according to XPS analysis.

- Reused powder exhibits better flowability motivated by changes in the oxide layer, measured by dynamic flowability metrics using the RPA. The loose volume fraction, equivalent to the packing density, is circa 57% and 56% for virgin and reused powders, respectively. When tapping, the packed volume fraction increased to 60% in virgin powders and to 57% in reused powder, the particulates and different surface roughness of the reused powder could be hindering a further packing, which could affect the thermal properties and, therefore, quality of the prints.

- The charging behavior of the powder varies in the reuse powders (−9.18 V/g) in comparison with the virgin powders (−5.84 V/g); it potentially offers less electrical conductivity, which is associated to smoking in the powder bed.

- No large differences were observed in rheological and charging behavior upon drying, confirmed by similar estimation of moisture by thermogravimetric analysis in both virgin and reused powders.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Matz, J.E.; Eagar, T.W. Carbide formation in alloy 718 during electron-beam solid freeform fabrication. Met. Mater. Trans. A 2002, 33, 2559–2567. [Google Scholar] [CrossRef]

- Helmer, H.E.; Körner, C.; Singer, R.F. Additive manufacturing of nickel-based superalloy Inconel 718 by selective electron beam melting: Processing window and microstructure. J. Mater. Res. 2014, 29, 1987–1996. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer US: New York, NY, USA, 2010. [Google Scholar]

- Galati, M. Chapter 8-Electron beam melting process: A general overview. In Additive Manufacturing; Pou, J., Riveiro, A., Davim, J.P., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 277–301. [Google Scholar]

- Smith, C.J.; Tammas-Williams, S.; Hernández-Nava, E.; Todd, I. Tailoring the thermal conductivity of the powder bed in Electron Beam Melting (EBM) Additive Manufacturing. Sci. Rep. 2017, 7, 10514. [Google Scholar] [CrossRef] [PubMed]

- Hryha, E.; Shvab, R.; Gruber, H.; Leicht, A.; Nyborg, L. Surface oxide state on metal powder and its changes during additive manufacturing: An overview. Metall. Ital. 2018, 3, 34–39. [Google Scholar]

- Chiba, A.; Daino, Y.; Aoyagi, K.; Yamanaka, K. Smoke Suppression in Electron Beam Melting of Inconel 718 Alloy Powder Based on Insulator–Metal Transition of Surface Oxide Film by Mechanical Stimulation. Materials 2021, 14, 4662. [Google Scholar] [CrossRef]

- Yi, F.; Zhou, Q.; Wang, C.; Yan, Z.; Liu, B. Effect of powder reuse on powder characteristics and properties of Inconel 718 parts produced by selective laser melting. J. Mater. Res. Technol. 2021, 13, 524–533. [Google Scholar] [CrossRef]

- Cordova, L.; Campos, M.; Tinga, T. Revealing the Effects of Powder Reuse for Selective Laser Melting by Powder Characterization. JOM 2019, 71, 1062–1072. [Google Scholar] [CrossRef]

- Gruber, H.; Henriksson, M.; Hryha, E.; Nyborg, L. Effect of Powder Recycling in Electron Beam Melting on the Surface Chemistry of Alloy 718 Powder. Met. Mater. Trans. A 2019, 50, 4410–4422. [Google Scholar] [CrossRef]

- Raza, A.; Hryha, E. Characterization of Spatter and Sublimation in Alloy 718 during Electron Beam Melting. Materials 2021, 14, 5953. [Google Scholar] [CrossRef]

- Gruber, H.; Luchian, C.; Hryha, E.; Nyborg, L. Effect of Powder Recycling on Defect Formation in Electron Beam Melted Alloy 718. Met. Mater. Trans. A 2020, 51, 2430–2443. [Google Scholar] [CrossRef]

- Gruber, H.; Karimi, P.; Hryha, E.; Nyborg, L. Effect of Powder Recycling on the Fracture Behavior of Electron Beam Melted Alloy 718. Powder Met. Prog. 2018, 18, 40–48. [Google Scholar] [CrossRef][Green Version]

- Marchetti, L.; Hulme-Smith, C. Flowability of steel and tool steel powders: A comparison between testing methods. Powder Technol. 2021, 384, 402–413. [Google Scholar] [CrossRef]

- Lefebvre, L.; Whiting, J.; Nijikovsky, B.; Brika, S.; Fayazfar, H.; Lyckfeldt, O. Assessing the robustness of powder rheology and permeability measurements. Addit. Manuf. 2020, 35, 101203. [Google Scholar] [CrossRef]

- Vock, S.; Klöden, B.; Kirchner, A.; Weißgärber, T.; Kieback, B. Powders for powder bed fusion: A review. Prog. Addit. Manuf. 2019, 4, 383–397. [Google Scholar] [CrossRef]

- Mussatto, A.; Groarke, R.; O’Neill, A.; Obeidi, M.A.; Delaure, Y.; Brabazon, D. Influences of powder morphology and spreading parameters on the powder bed topography uniformity in powder bed fusion metal additive manufacturing. Addit. Manuf. 2020, 38, 101807. [Google Scholar] [CrossRef]

- Strondl, A.; Lyckfeldt, O.; Brodin, H.; Ackelid, U. Characterization and Control of Powder Properties for Additive Manufacturing. JOM 2015, 67, 549–554. [Google Scholar] [CrossRef]

- Cordova, L.; Bor, T.; de Smit, M.; Campos, M.; Tinga, T. Measuring the spreadability of pre-treated and moisturized powders for laser powder bed fusion. Addit. Manuf. 2020, 32, 101082. [Google Scholar] [CrossRef]

- Hulme-Smith, C.N.; Hari, V.; Mellin, P. Spreadability Testing of Powder for Additive Manufacturing. BHM Berg Hüttenmännische Mon. 2021, 166, 9–13. [Google Scholar] [CrossRef]

- Baer, D.R.; Engelhard, M.H.; Lea, A.S.; Nachimuthu, P.; Droubay, T.C.; Kim, J.; Lee, B.; Mathews, C.; Opila, R.L.; Saraf, L.V.; et al. Comparison of the sputter rates of oxide films relative to the sputter rate of SiO2. J. Vac. Sci. Technol. A Vac. Surf. Film. 2010, 28, 1060–1072. [Google Scholar] [CrossRef]

- Spierings, A.B.; Voegtlin, M.; Bauer, T.; Wegener, K. Powder flowability characterisation methodology for powder-bed-based metal additive manufacturing. Prog. Addit. Manuf. 2015, 1, 9–20. [Google Scholar] [CrossRef]

- Snow, Z.; Martukanitz, R.; Joshi, S. On the development of powder spreadability metrics and feedstock requirements for powder bed fusion additive manufacturing. Addit. Manuf. 2019, 28, 78–86. [Google Scholar] [CrossRef]

- Mellmann, J. The transverse motion of solids in rotating cylinders—Forms of motion and transition behavior. Powder Technol. 2001, 118, 251–270. [Google Scholar] [CrossRef]

- Montes, B.C.; Martínez-Alejo, J.; Lozano-Perez, H.; Gumy, J.; Zemlyanov, D.; Carvajal, M. A surface characterization platform approach to study Flowability of food powders. Powder Technol. 2019, 357, 269–280. [Google Scholar] [CrossRef]

- Goh, H.P.; Heng, P.W.S.; Liew, C.V. Comparative evaluation of powder flow parameters with reference to particle size and shape. Int. J. Pharm. 2018, 547, 133–141. [Google Scholar] [CrossRef]

- Trpělková, Ž.; Hurychová, H.; Kuentz, M.; Vraníková, B.; Šklubalová, Z. Introduction of the energy to break an avalanche as a promising parameter for powder flowability prediction. Powder Technol. 2020, 375, 33–41. [Google Scholar] [CrossRef]

- Galati, M.; Iuliano, L. A literature review of powder-based electron beam melting focusing on numerical simulations. Addit. Manuf. 2018, 19, 1–20. [Google Scholar] [CrossRef]

- Milberg, J.; Sigl, M. Electron beam sintering of metal powder. Prod. Eng. 2008, 2, 117–122. [Google Scholar] [CrossRef]

- Kahnert, M.; Lutzmann, S.; Zaeh, M.F. Layer Formations in Electron Beam Sintering. In Proceedings of the 18th Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2007; pp. 88–99. [Google Scholar]

- Fu, Z.; Körner, C. Actual state-of-the-art of electron beam powder bed fusion. Eur. J. Mater. 2022, 2, 54–117. [Google Scholar] [CrossRef]

- Chandrasekar, S.; Coble, J.B.; Yoder, S.; Nandwana, P.; Dehoff, R.R.; Paquit, V.C.; Babu, S.S. Investigating the effect of metal powder recycling in Electron beam Powder Bed Fusion using process log data. Addit. Manuf. 2019, 32, 100994. [Google Scholar] [CrossRef]

- Nandwana, P.; Peter, W.H.; Dehoff, R.; Lowe, L.E.; Kirka, M.M.; Medina, F.; Babu, S. Recyclability Study on Inconel 718 and Ti-6Al-4V Powders for Use in Electron Beam Melting. Met. Mater. Trans. A 2015, 47, 754–762. [Google Scholar] [CrossRef]

- Algardh, J.K.; Horn, T.; West, H.; Aman, R.; Snis, A.; Engqvist, H.; Lausmaa, J.; Harrysson, O. Thickness dependency of mechanical properties for thin-walled titanium parts manufactured by Electron Beam Melting (EBM)®. Addit. Manuf. 2016, 12, 45–50. [Google Scholar] [CrossRef]

- Cordero, Z.C.; Meyer, H.M.; Nandwana, P.; Dehoff, R.R. Powder bed charging during electron-beam additive manufacturing. Acta Mater. 2017, 124, 437–445. [Google Scholar] [CrossRef]

| Elements | Ni | Co | Cr | Mo | Ti | Mn | Nb | Ta | Al | Fe | Si | C |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 54.1 | 0.04 | 19.0 | 2.99 | 1.02 | 0.12 | 4.97 | <0.01 | 0.52 | 17.12 | 0.06 | 0.03 |

| at% | 53.38 | 0.04 | 21.16 | 1.80 | 1.23 | 0.13 | 3.10 | <0.01 | 1.12 | 17.75 | 0.12 | 0.14 |

| Material | O (%) | H2O (%) | D10 (µm) | D50 (µm) | D90 (µm) |

|---|---|---|---|---|---|

| virgin | 0.0153 | 0.0255 | 51.73 | 78.32 | 113.90 |

| reused | 0.0184 | 0.0229 | 47.30 | 71.45 | 108.98 |

| Material | Apparent Density (g/cm3) | Loose Volume Fraction (%) | Tap Density (g/cm3) | Packed Volume Fraction (%) |

|---|---|---|---|---|

| Virgin AR | 4.65 ± 0.03 | 56.69 ± 0.31 | 4.96 ± 0.05 | 60.50 ± 0.63 |

| Virgin D | 4.60 ± 0.02 | 56.08 ± 0.27 | 4.90 ± 0.07 | 59.73 ± 0.87 |

| Reused AR | 4.57 ± 0.02 | 55.71 ± 0.19 | 4.67 ± 0.02 | 57.02 ± 0.29 |

| Reused D | 4.55 ± 0.03 | 55.54 ± 0.42 | 4.82 ± 0.05 | 58.81 ± 0.63 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cordova, L.; Raza, A.; Hryha, E. Rheological Behavior of Inconel 718 Powder for Electron-Beam Melting. Metals 2022, 12, 1231. https://doi.org/10.3390/met12071231

Cordova L, Raza A, Hryha E. Rheological Behavior of Inconel 718 Powder for Electron-Beam Melting. Metals. 2022; 12(7):1231. https://doi.org/10.3390/met12071231

Chicago/Turabian StyleCordova, Laura, Ahmad Raza, and Eduard Hryha. 2022. "Rheological Behavior of Inconel 718 Powder for Electron-Beam Melting" Metals 12, no. 7: 1231. https://doi.org/10.3390/met12071231

APA StyleCordova, L., Raza, A., & Hryha, E. (2022). Rheological Behavior of Inconel 718 Powder for Electron-Beam Melting. Metals, 12(7), 1231. https://doi.org/10.3390/met12071231