Study on the Effects of Multiple Laser Shock Peening Treatments on the Electrochemical Corrosion Performance of Welded 316L Stainless Steel Joints

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experiment Material

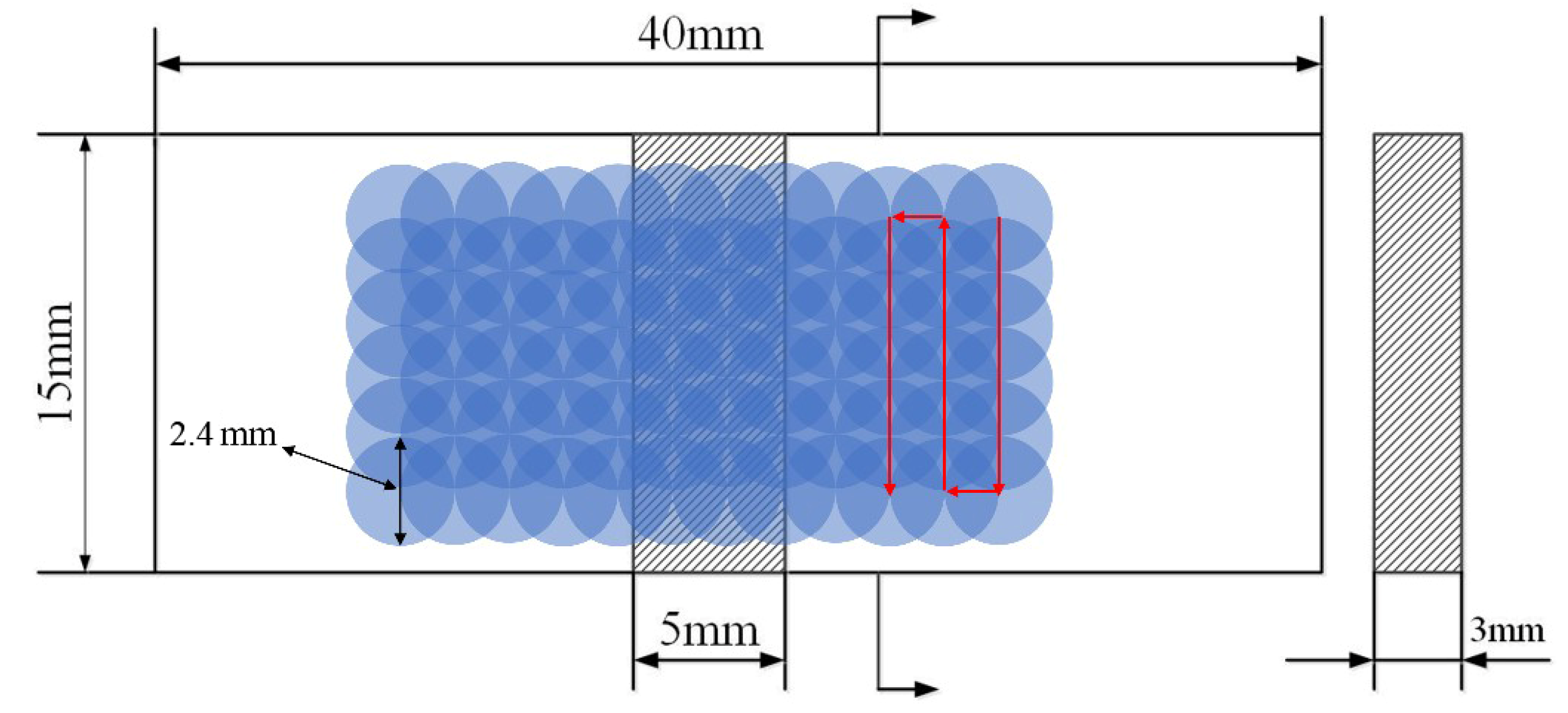

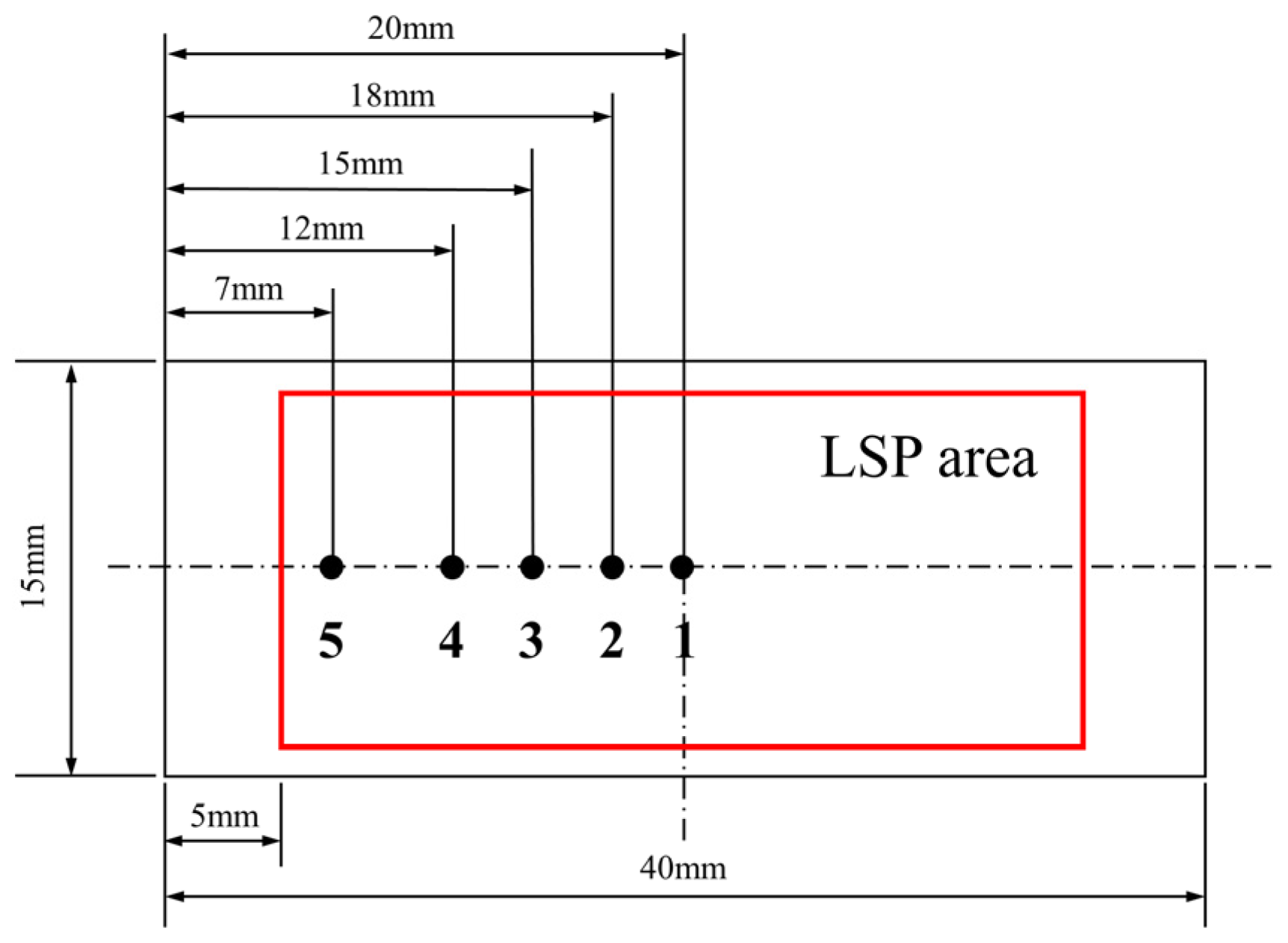

2.2. Laser Shock Peening Scheme

2.3. Performance Testing

3. Results

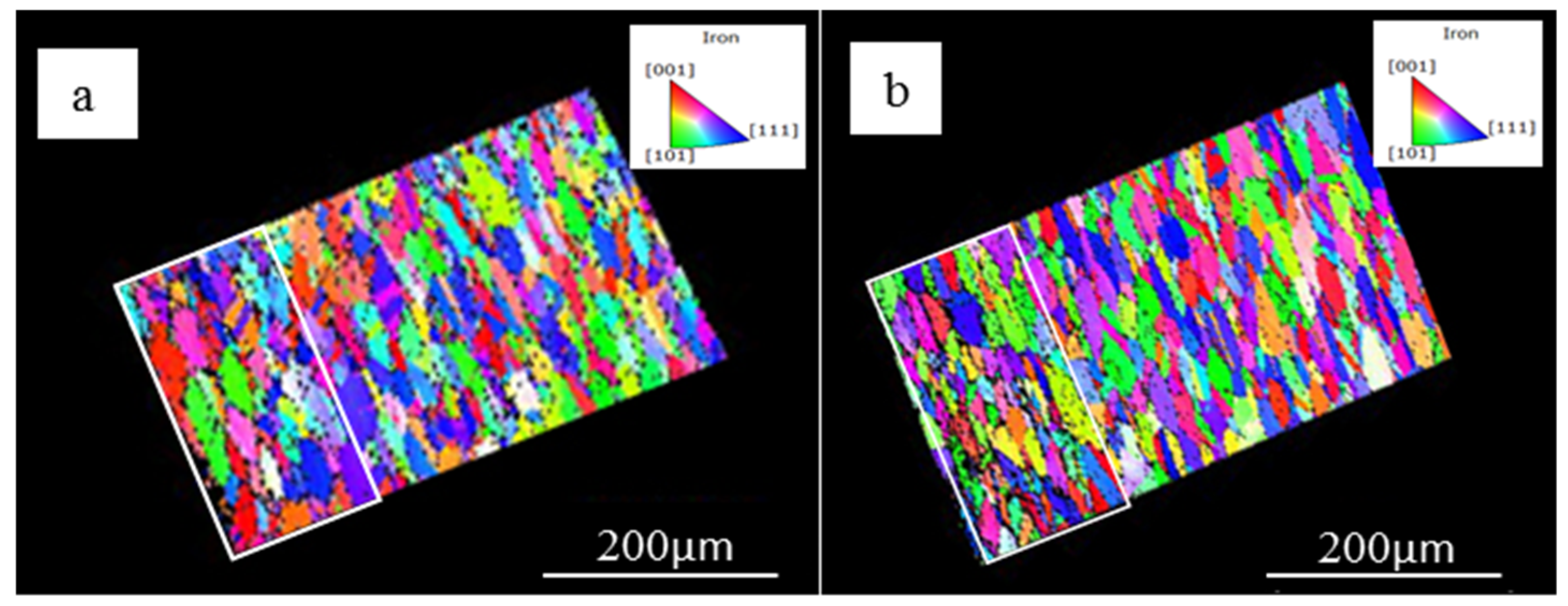

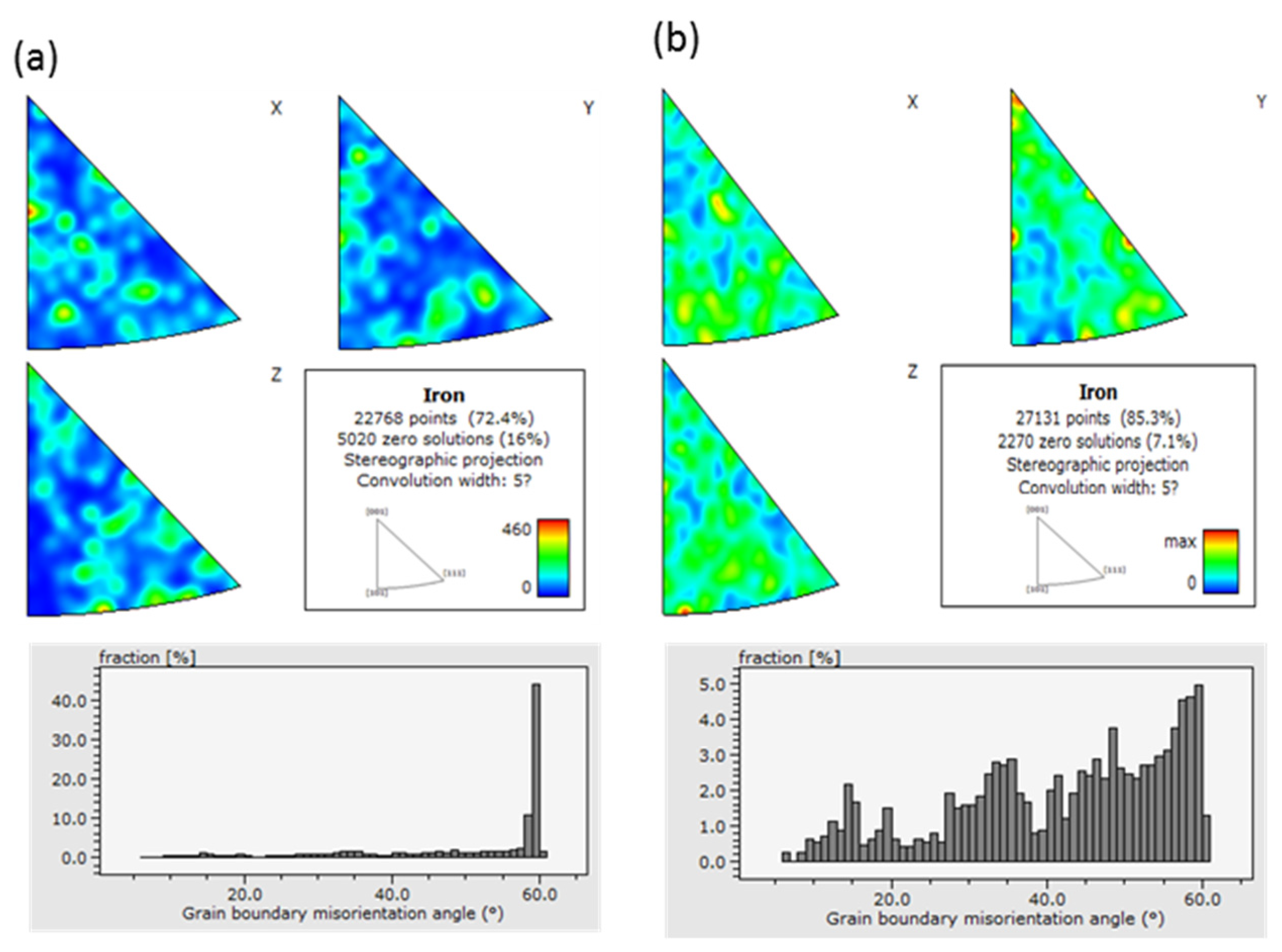

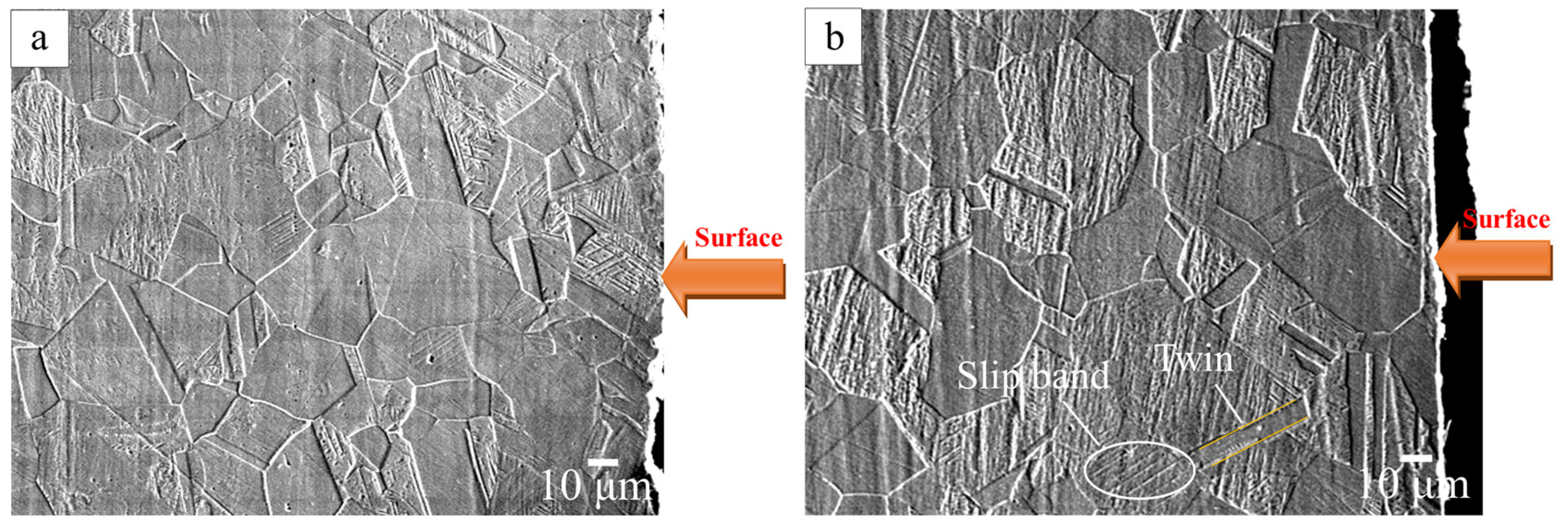

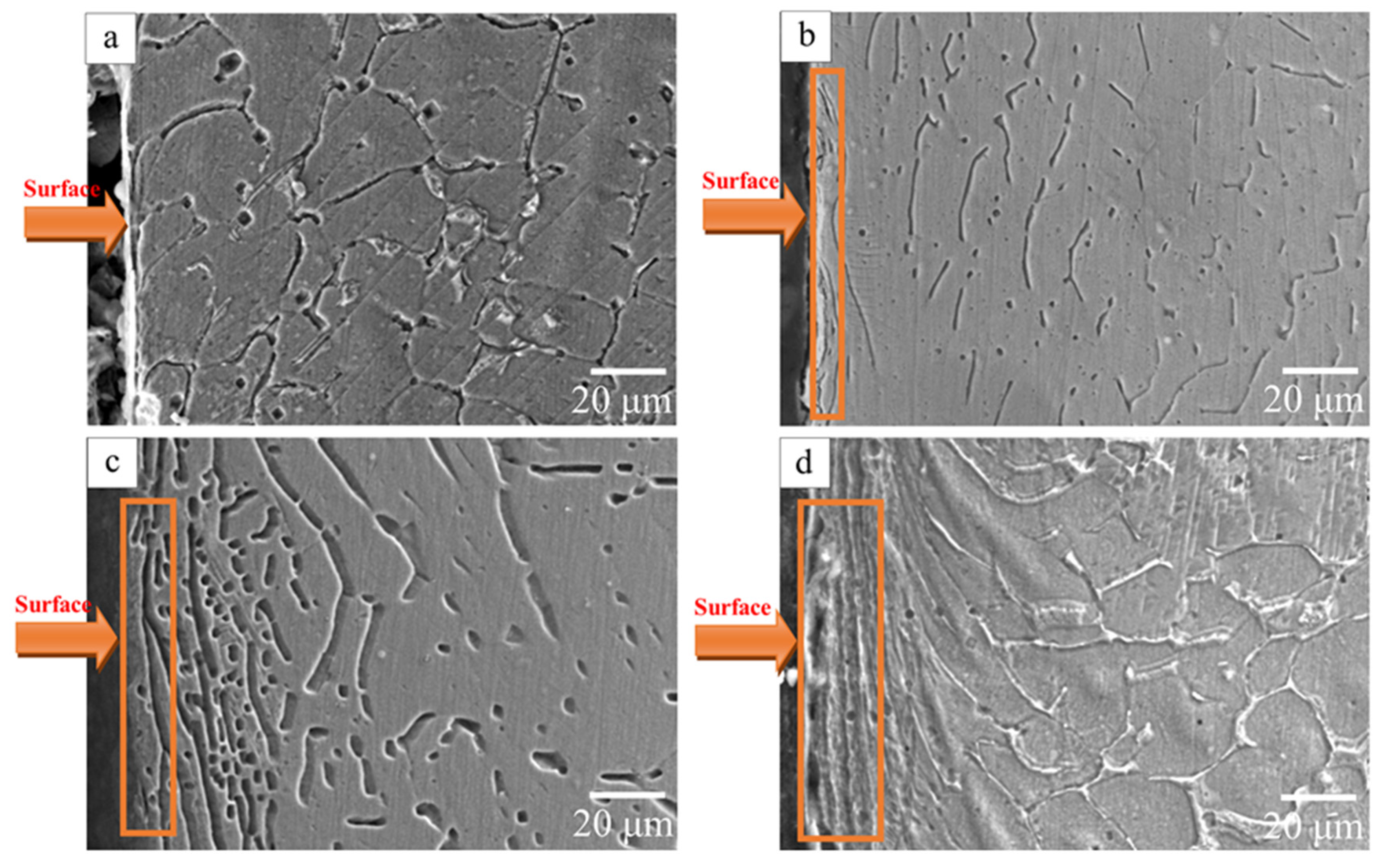

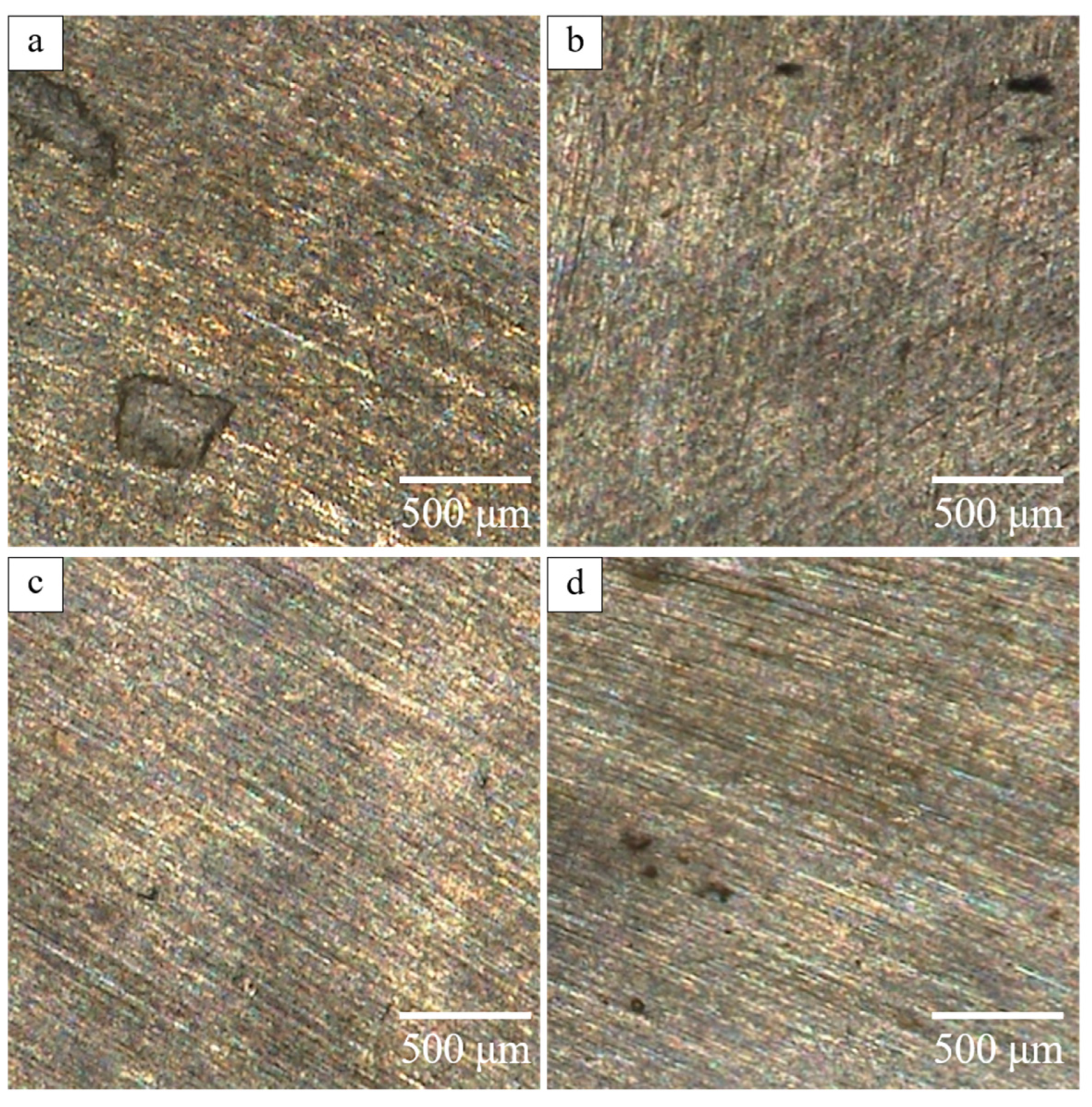

3.1. Effects of Different Laser Shock Treatments on the Microstructure of 316L

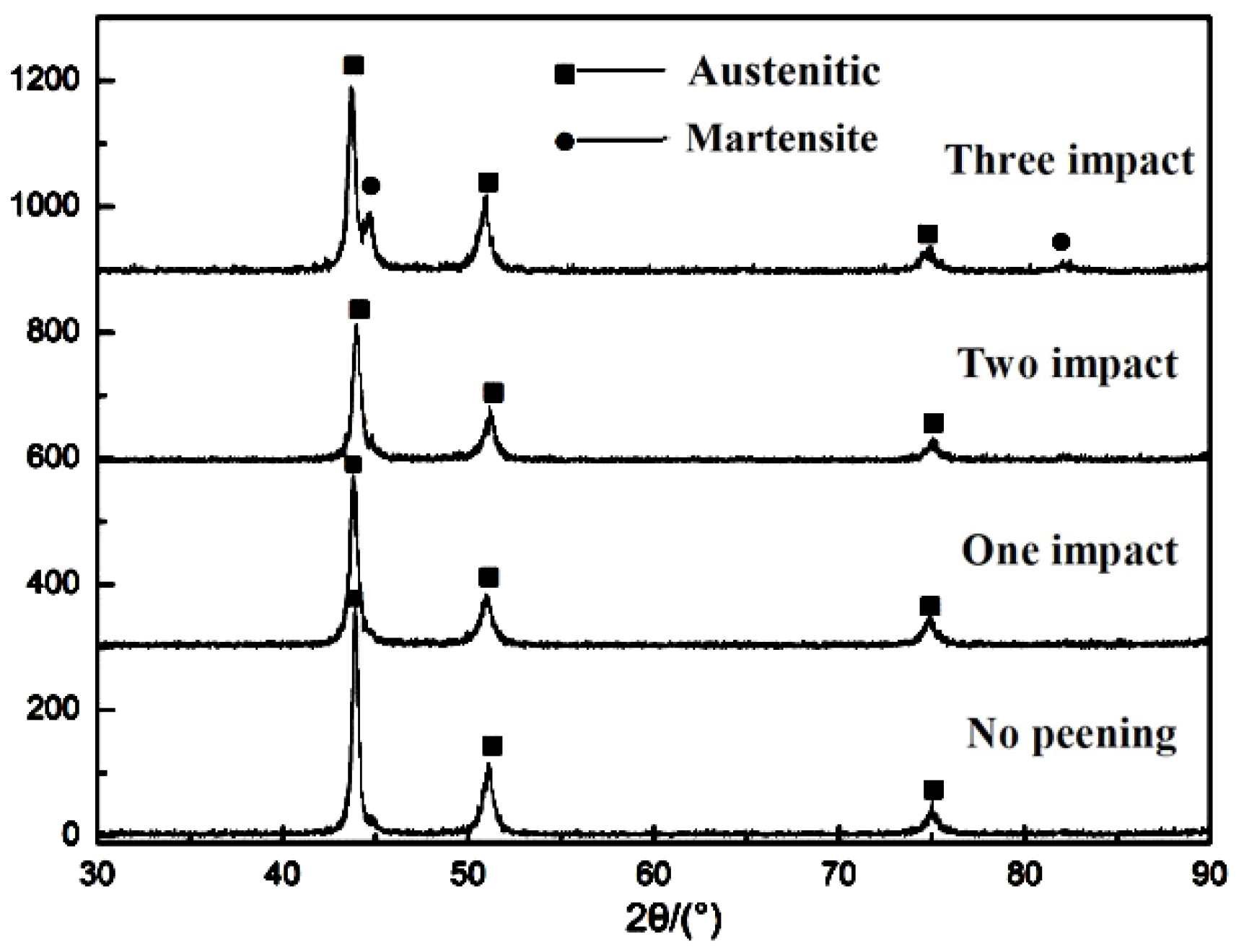

3.2. Phase Analysis of the Welded Area

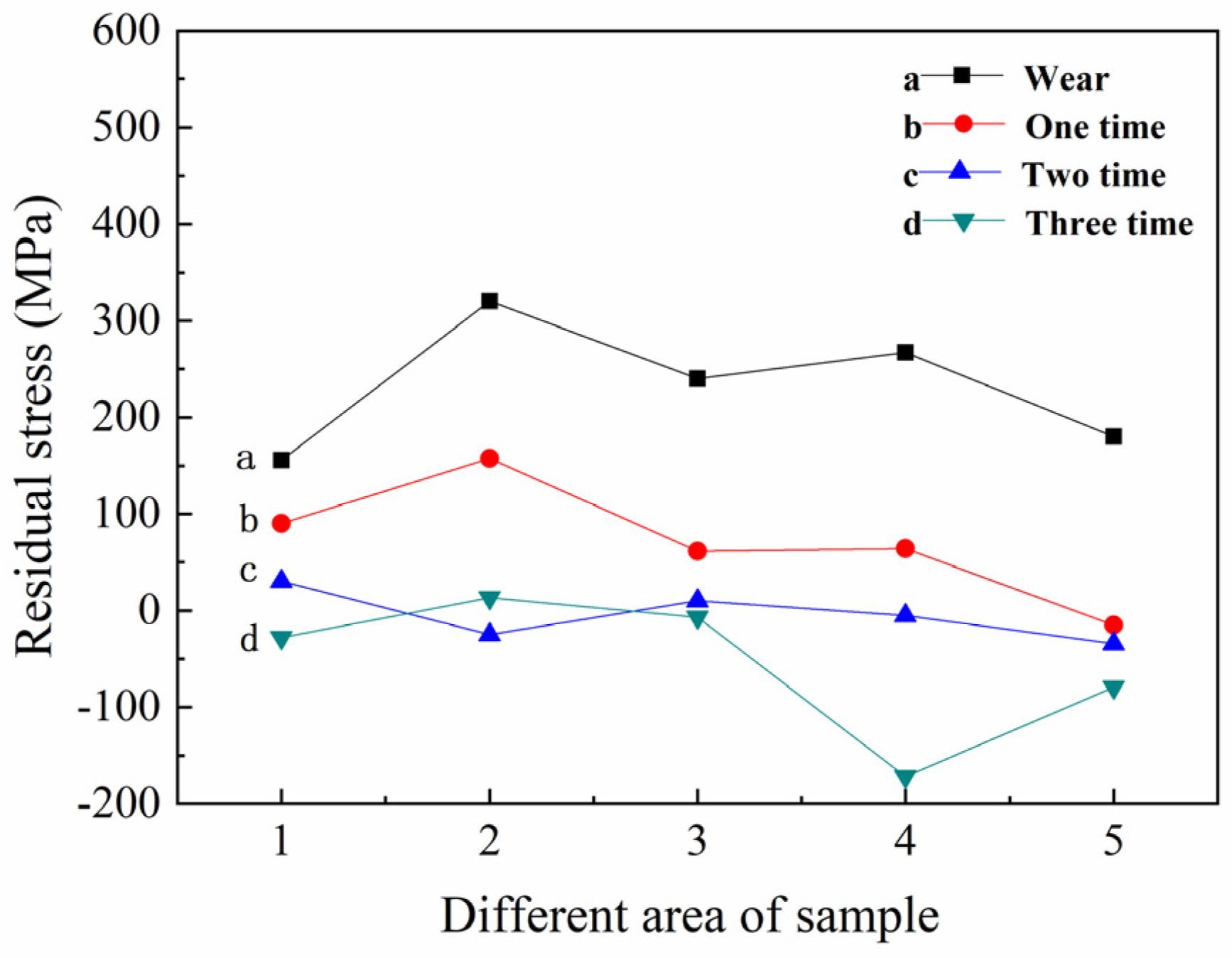

3.3. Effects of Laser Shock Peening on Welded 316L Stainless Steel Joints

3.4. Effects of Laser Shock on the Salt Spray Corrosion of Welded 316L Stainless Steel Joints

3.5. Effects of Laser Shock on the Electrochemical Corrosion of Welded 316L Stainless Steel Joints

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, J.-Z. Nuclear Structural Material; Chemical Industry Press: Beijing, China, 2007; pp. 202–203. [Google Scholar]

- Sánchez-Tovar, R.; Montaes, M.T.; García-Antón, J. Effect of the micro-plasma arc welding technique on the microstructure and pitting corrosion of AISI 316L stainless steels in heavy LiBr brines. Corros. Sci. 2011, 53, 2598–2610. [Google Scholar] [CrossRef]

- Lv, H.-W.; Dong, S.-G.; Wang, J.-J.; Li, N.; Lin, C.-J. Electrochemical Behaviors of the 316L Stainless Steel Welding Seam Corrosion. Sci. Technol. Rev. 2013, 31, 25–28. [Google Scholar]

- Lian, M.-Y. Study on Microstructure and Properties of 40CrNiMo Quenched and Tempered Steel CMT Surfacing HAZ for Gear; Zhengzhou University: Zhengzhou, China, 2020. [Google Scholar]

- Gao, H.-F. Seismic Performance of Fabricated Steel Lattice Columns with Lateral Force Resistance; Beijing University Of Civil Engineering and Architecture: Beijing, China, 2021. [Google Scholar]

- Wang, J.-H.; Lu, H. Some discussions on principle of causing and relieving welding residual stress. J. Weld. 2002, 23, 75–79. [Google Scholar]

- Zhao, R. Study of Welding Residual Stress’s Numerical Simulation and Reliving; Dalian University of Technology: Dalian, China, 2006. [Google Scholar]

- Luo, G.-L.; Zhang, L.-F.; Xiong, Y.; Zhang, B.-F.; Chen, X.-P. Effect of Laser Shock Peening on Microstructure and Properties of Ti-6Al-3Nb-2Zr-1Mo Titanium Alloy. Chin. J. Lasers 2022, 49, 215–226. [Google Scholar]

- Xu, S.; Su, B.-Y.; Hua, G.-R.; Wang, H.; Cao, Y.-P. Effect of Laser Shock Peening on the Interfacial Bonding Properties of TiN Coatings on TC4 Titanium Alloy. Surf. Technol. 2022, 51, 315–325. [Google Scholar]

- He, Z.-R.; Shen, Y.-Z.; Zhou, J.; Liu, W.-L.; Sun, R.-J. Microstructure evolution and performance enhancement of laser shock peening. Aeronaut. Manuf. Technol. 2021, 64, 48–58. [Google Scholar]

- Nie, X.-F.; Li, Y.-H.; He, W.-F.; Luo, S.-H.; Zhou, L.-C. Research Progress and Prospect of Laser Shock Peening Technology in Aero-engine Components. J. Mech. Eng. 2021, 57, 293–305. [Google Scholar]

- Jiao, Q.-Y.; Han, P.-P.; Lu, Y.; Zhao, D.; Qiao, H.-C.; Zhao, J.-B. Effect of laser shock peening on residual stress and mechanical properties of TA15 titanium alloy. J. Plast. Eng. 2021, 28, 146–152. [Google Scholar]

- Karthik, D.; Jiang, J.-C.; Hu, Y.-X.; Yao, Z. Effect of multiple laser shock peening on microstructure, crystallographic texture and pitting corrosion of Aluminum-Lithium alloy 2060-T8. Surf. Coat. Technol. 2021, 421, 127354. [Google Scholar] [CrossRef]

- Geng, Y.-X.; Xia, D.; Wang, K.-D.; Yan, X.; Duan, W.; Fan, Z.; Wang, W.; Mei, X. Effect of microstructure evolution and phase precipitations on hot corrosion behavior of IN718 alloy subjected to multiple laser shock peening. Surf. Coat. Technol. 2019, 370, 244–254. [Google Scholar] [CrossRef]

- Zhou, L.-C.; Li, Y.-H.; He, W.-F.; Chen, D. Effect of multiple laser shock processing on microstructure and mechanical properties of Ti-5Al-4Mo-4Cr- 2Sn-2Zr titanium alloy (English). Rare Metal. Mat. Eng. 2014, 43, 1067–1072. [Google Scholar]

- Wang, J.; Lu, Y.-L.; Zhou, D.-S.; Sun, L.; Xie, L.; Wang, J. Mechanical properties and microstructural response of 2A14 aluminum alloy subjected to multiple laser shock peening impacts. Vacuum 2019, 165, 193–198. [Google Scholar] [CrossRef]

- Duarte, T.; Meyer YAOsório, W.R. The Holes of Zn Phosphate and Hot Dip Galvanizing on Electrochemical Behaviors of Multicoatings on Steel Substrates. Metals 2022, 12, 863. [Google Scholar] [CrossRef]

- Osório, W.R.; Freitas, E.S.; Garcia, A. EIS and potentiodynamic polarization studies on immiscible monotectic Al–In alloys. Electrochim. Acta 2013, 102, 436–445. [Google Scholar] [CrossRef]

- Zhang, X.L.; Jiang, Z.H.; Yao, Z.P.; Song, Y.; Wu, Z.D. Effects of scan rate on the potentiodynamic polarization curve obtained to determine the Tafel slopes and corrosion current density. Corros. Sci. 2009, 51, 581–587. [Google Scholar] [CrossRef]

- McCafferty, E. Validation of corrosion rates measured by Tafel extrapolation method. Corros. Sci. 2005, 47, 3202–3215. [Google Scholar] [CrossRef]

- Li, Y.; Guan, L.; Wang, G.; Zhang, B.; Ke, W. Influence of mechanical stresses on pitting corrosion of stainless steel. J. Chin. Soc. Corros. Prot. 2019, 39, 215–226. [Google Scholar]

- Wang, Y.-J.; Wang, X.; Sha, A.-X.; Li, X. Simulation of residual stress and fatigue test in hole extrusion process for TiAlNb alloy. J. Aeronaut. Mater. 2021, 41, 66–74. [Google Scholar]

- Zhang, M.-Y.; Zhu, Y.; Guo, W.; Huang, S.; Hou, G. Effects of laser shock processing on fatigue properties of TC17 titanium alloy. Laser Technol. 2017, 41, 231–234. [Google Scholar]

- Lu, J.Z.; Luo, K.Y.; Zhang, Y.K.; Cui, C.Y.; Sun, G.F.; Zhou, J.Z.; Zhang, L.; You, J.; Chen, K.M.; Zhong, J.W. Grain refinement of LY2 aluminum alloy induced by ultra-high plastic strain during multiple laser shock processing impacts. Acta Mater. 2010, 58, 3984–3994. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, J.; Luo, K. Residual Stress Distribution and Microstructure at a Laser Spot of AISI 304 Stainless Steel Subjected to Different Laser Shock Peening Impacts. Metals 2016, 6, 6. [Google Scholar] [CrossRef] [Green Version]

- Lan, L.; Xin, R.; Jin, X.; Gao, S.; He, B.; Rong, Y.; Min, N. Effects of Laser Shock Peening on Microstructure and Properties of Ti–6Al–4V Titanium Alloy Fabricated via Selective Laser Melting. Materials 2020, 13, 3261. [Google Scholar] [CrossRef]

- Lu, Y.; Yang, Y.; Zhao, J.; Yang, Y.; Qiao, H.; Hu, X.; Wu, J.; Sun, B. Impact on Mechanical Properties and Microstructural Response of Nickel-Based Superalloy GH4169 Subjected to Warm Laser Shock Peening. Materials 2020, 13, 5172. [Google Scholar] [CrossRef]

- Sun, R.; He, G.; Bai, H.; Yan, J.; Guo, W. Laser Shock Peening of Ti6Al4V Alloy with Combined Nanosecond and Femtosecond Laser Pulses. Metals 2022, 12, 26. [Google Scholar] [CrossRef]

- Li, Y.-Q.; Meng, C.-J.; Wang, X.-D.; Luo, S.; Xu, W. Corrosion resistance property of 316L stainless steel welding joints treated by laser shock peening. Laser Optoelectron. Prog. 2017, 54, 165–169. [Google Scholar]

- Jiao, Y.; He, W.-F.; Luo, S.-H.; Zhou, L.-C.; Li, Y.-H. Study of micro-scale laser shock processing without coating improving the high cycle fatigue performance of K24 simulated blades. Chin. J. Lasers 2015, 42, 73–79. [Google Scholar]

- Liu, B.-J. Color Image Grading Evaluation of 316L Stainless Steel Passivation Film Damage and Its Application; Dalian University of Technology: Dalian, China, 2021. [Google Scholar]

- Guo, J.-G.; Chen, H.; Li, J.-R.; Tang, Z.-L.; Chen, Q.-M. Study on Corrosion Resistance Characteristics of 316L Stainless Steel Bipolar Plate Element Enrichment. Mater. Rep. 2021, 35, 391–394. [Google Scholar]

- Zhang, Y.; Wu, C.-H.; Fu, M.-J.; Li, Q.; Qin, Z.-W. Research Progress of Electrodeposited Corrosion Resistant Coatings on Surface of Stainless Steel. Mater. Prot. 2022, 55, 126–135. [Google Scholar]

- Wang, Z.; Feng, Z.; Zhang, L.; Lu, M.-X. Current application and development trend in electrochemical measurement methods for the corrosion study of stainless steels. Chin. J. Eng. 2020, 42, 549–556. [Google Scholar]

| Element | C | Cr | Ni | Mo | Mn | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.020 | 17.000 | 10.300 | 2.410 | 1.510 | 0.510 | 0.030 | 0.003 | bal |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Fan, J.; Wen, J.; Nie, X.; Zhou, L. Study on the Effects of Multiple Laser Shock Peening Treatments on the Electrochemical Corrosion Performance of Welded 316L Stainless Steel Joints. Metals 2022, 12, 1215. https://doi.org/10.3390/met12071215

Li Y, Fan J, Wen J, Nie X, Zhou L. Study on the Effects of Multiple Laser Shock Peening Treatments on the Electrochemical Corrosion Performance of Welded 316L Stainless Steel Joints. Metals. 2022; 12(7):1215. https://doi.org/10.3390/met12071215

Chicago/Turabian StyleLi, Yuqin, Jinyu Fan, Jianzhong Wen, Xiangfan Nie, and Liucheng Zhou. 2022. "Study on the Effects of Multiple Laser Shock Peening Treatments on the Electrochemical Corrosion Performance of Welded 316L Stainless Steel Joints" Metals 12, no. 7: 1215. https://doi.org/10.3390/met12071215

APA StyleLi, Y., Fan, J., Wen, J., Nie, X., & Zhou, L. (2022). Study on the Effects of Multiple Laser Shock Peening Treatments on the Electrochemical Corrosion Performance of Welded 316L Stainless Steel Joints. Metals, 12(7), 1215. https://doi.org/10.3390/met12071215