Formation Mechanism and Control of Solidification Cracking in Laser-Welded Joints of Steel/Copper Dissimilar Metals

Abstract

:1. Introduction

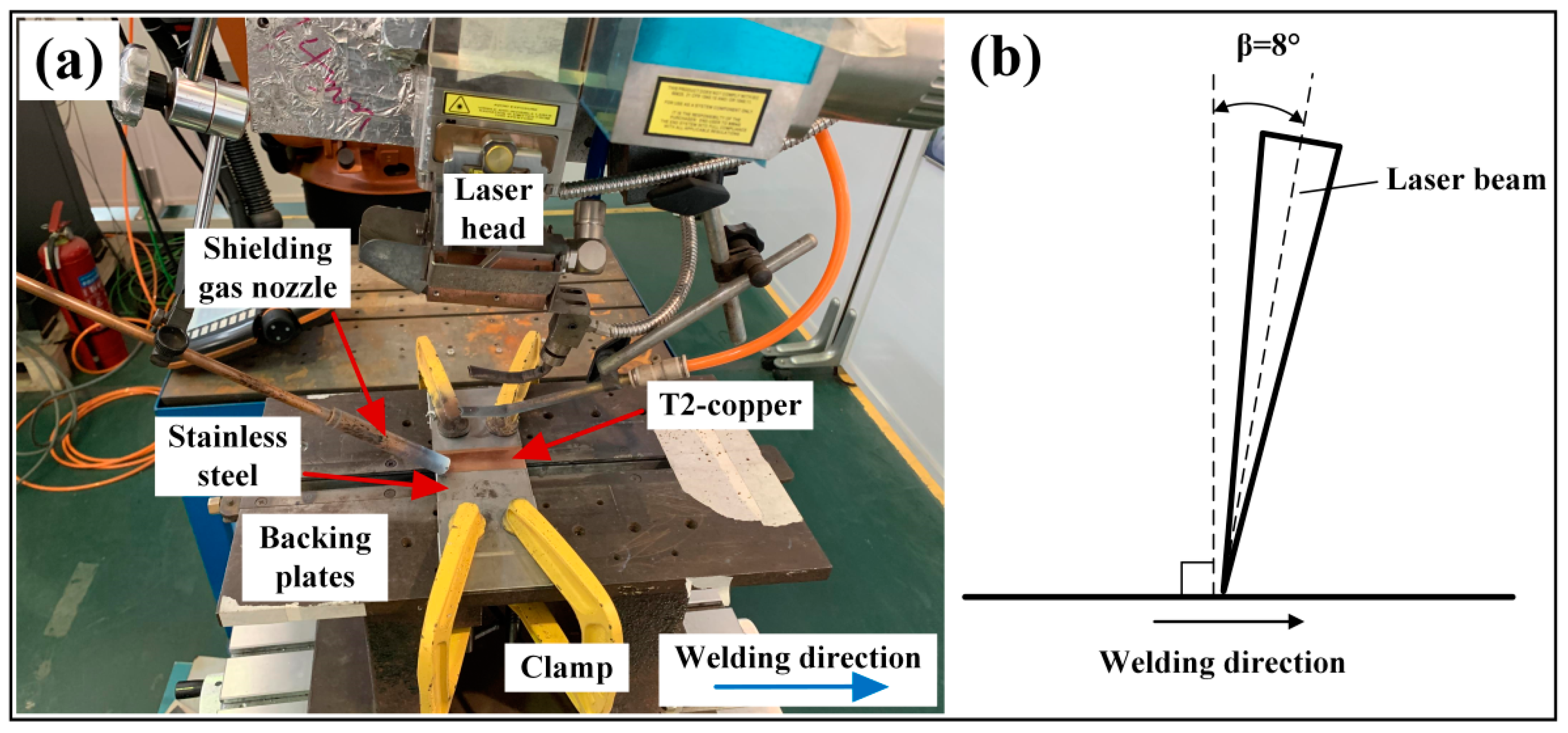

2. Materials and Methods

3. Results and Discussion

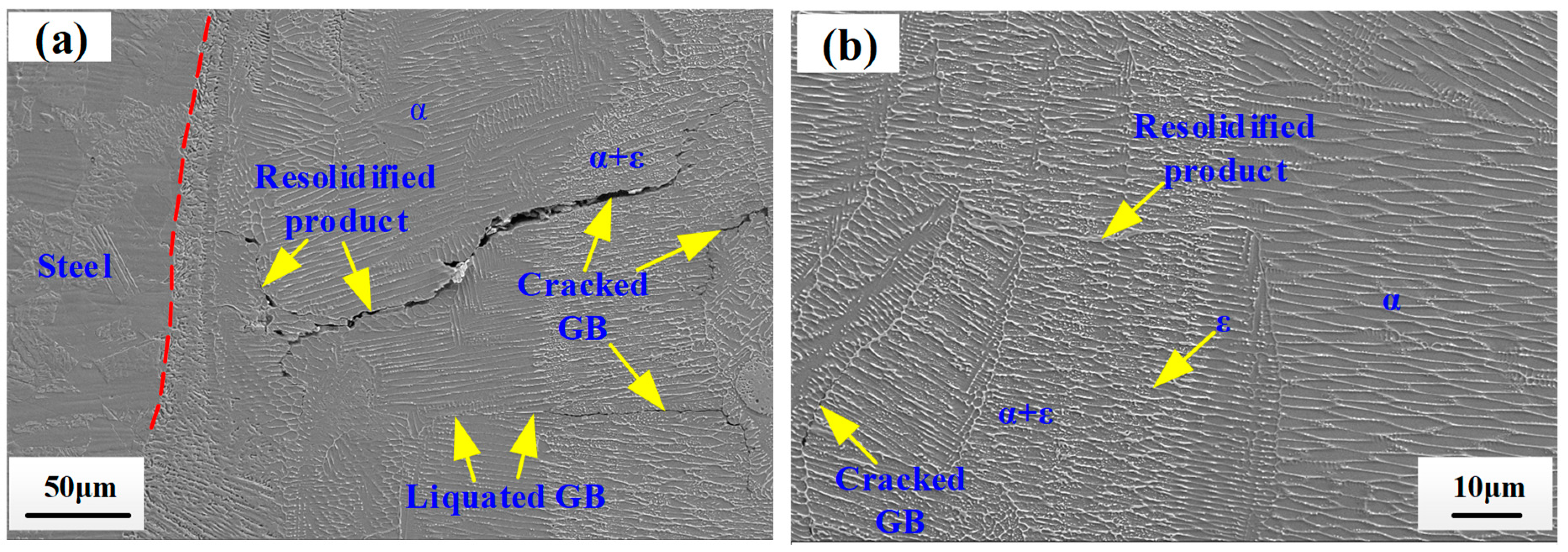

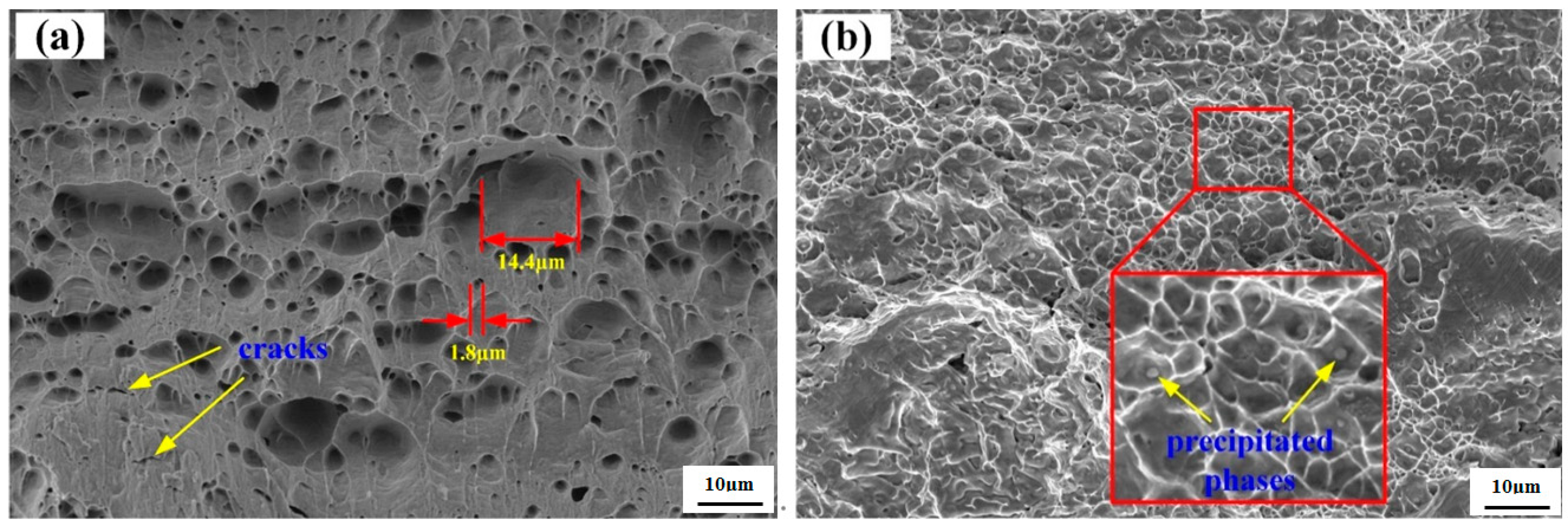

3.1. The Defects of Welded Joints

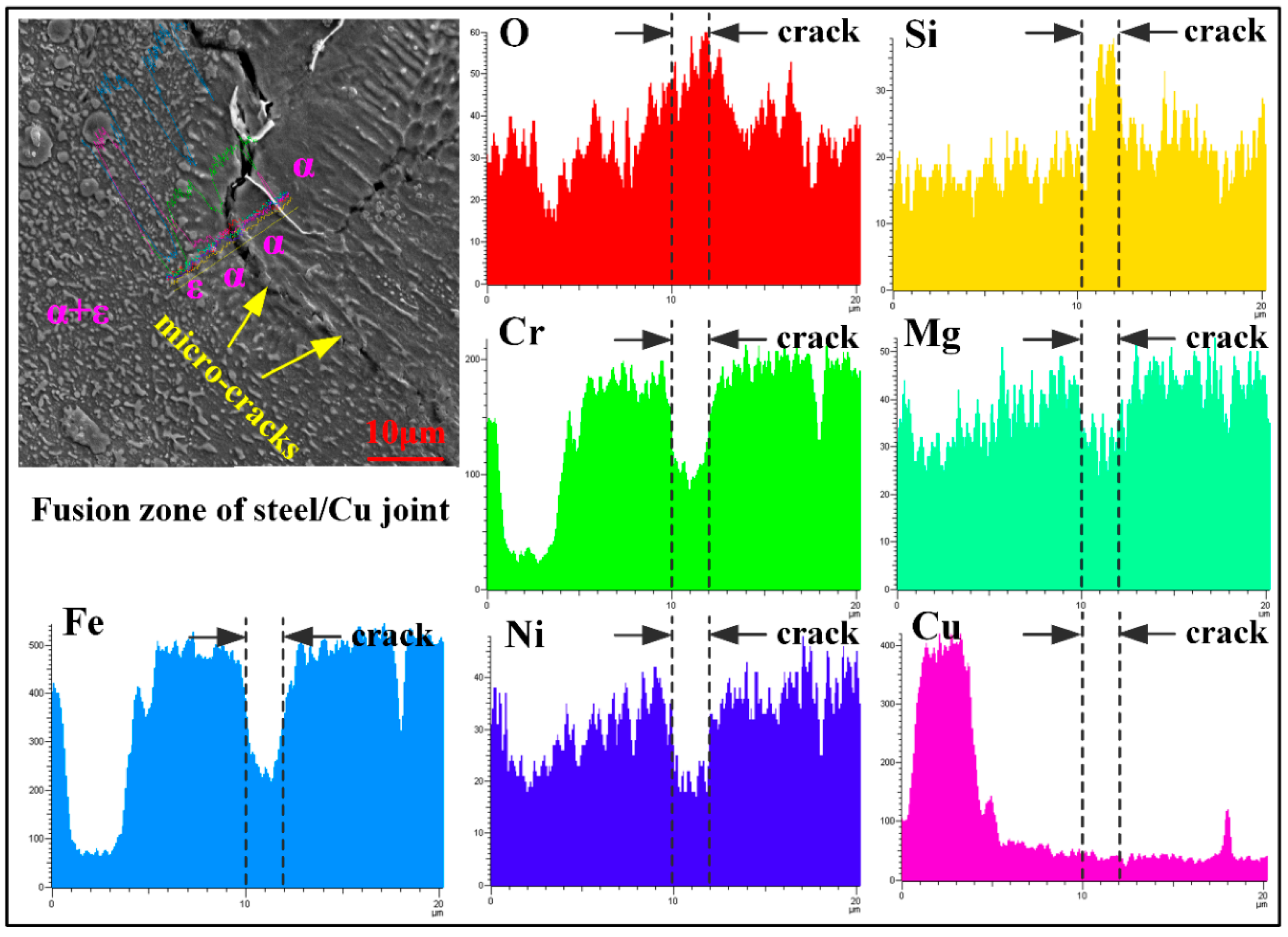

3.2. Element Distribution Near the Interface

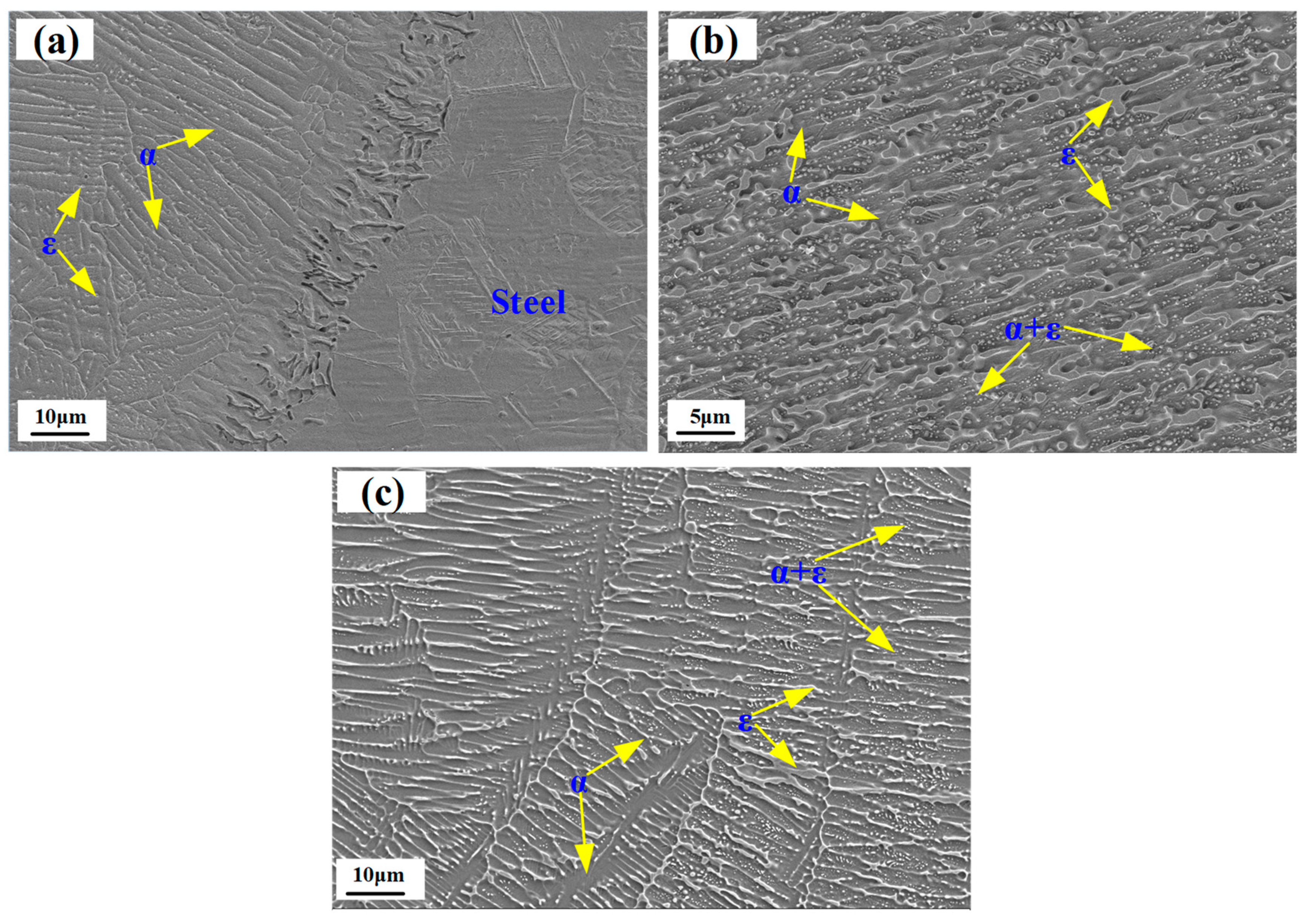

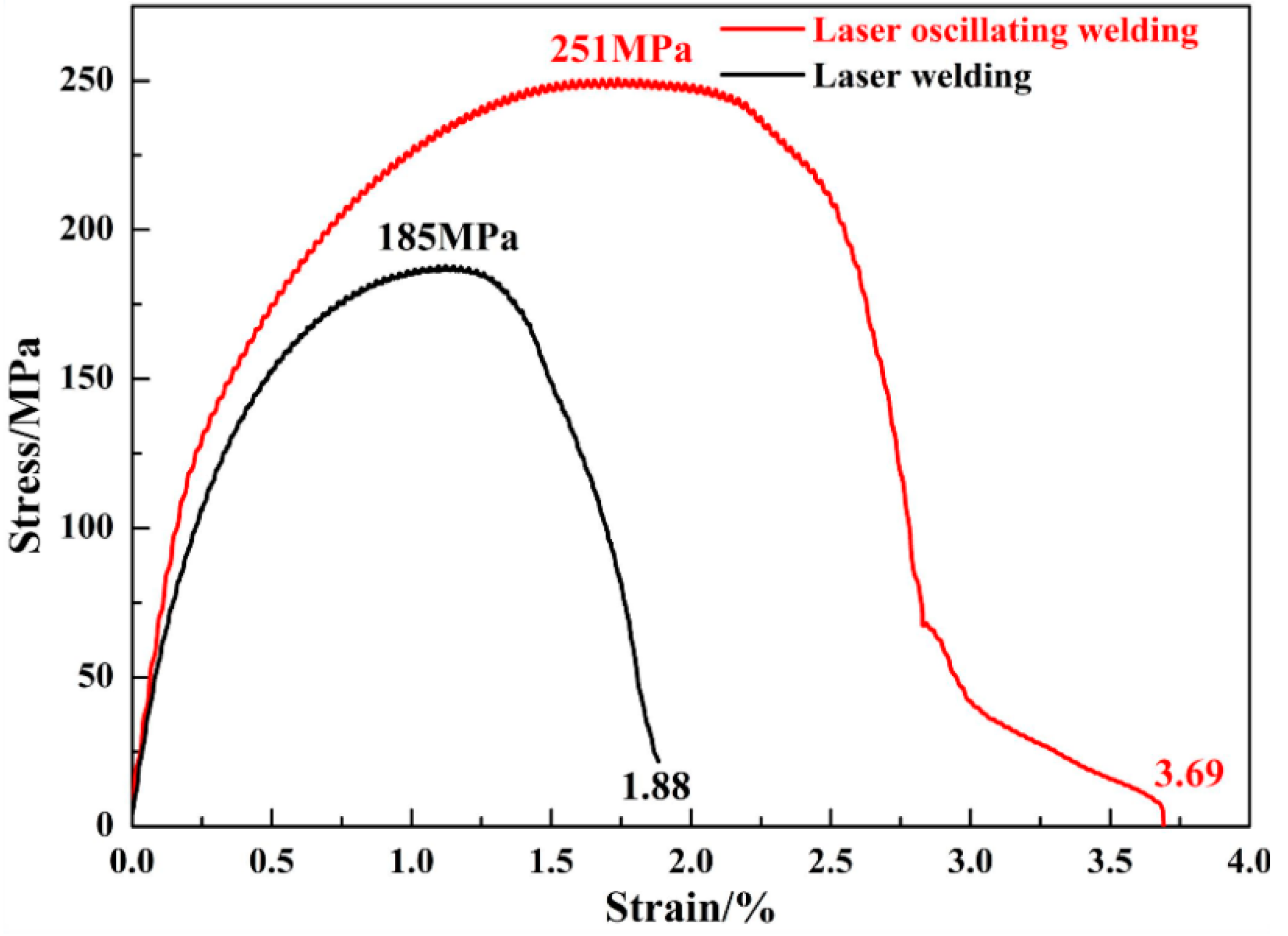

3.3. An Effective Solution for Inhibiting Solidification Cracking

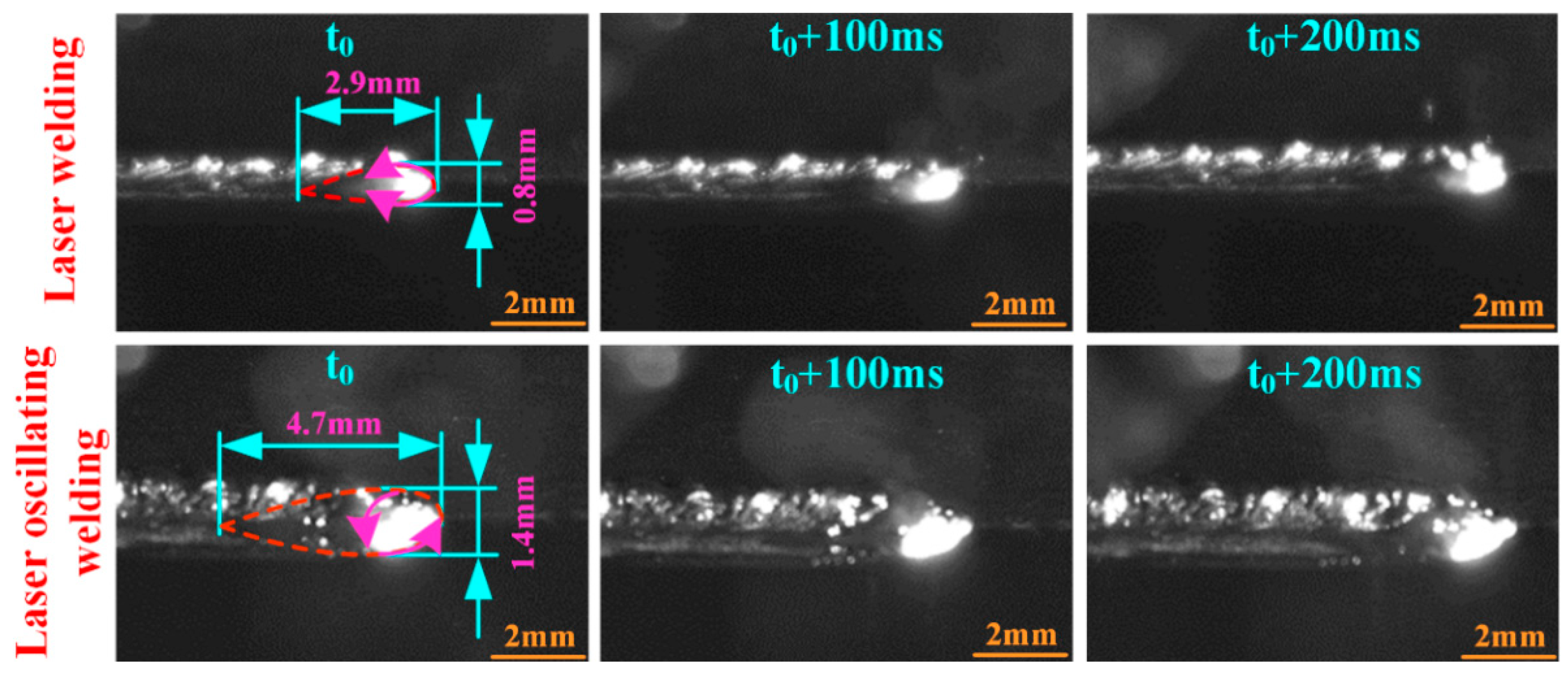

3.4. Inhibition Mechanism for Solidification Cracking

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rodrigues, T.A.; Bairrão, N.; Farias, F.W.C.; Shamsolhodaei, A.; Shen, J.; Zhou, N.; Maawad, E.; Schell, N.; Santos, T.G.; Oliveira, J.P. Steel-copper functionally graded material produced by twin-wire and arc additive manufacturing (T-WAAM). Mater. Des. 2022, 213, 110270. [Google Scholar] [CrossRef]

- Sadeghian, A.; Iqbal, N. A review on dissimilar laser welding of steel-copper, steel-aluminum, aluminum-copper, and steel-nickel for electric vehicle battery manufacturing. Opt. Laser Technol. 2022, 146, 107595. [Google Scholar] [CrossRef]

- Zhang, X.; Pan, T.; Flood, A.; Chen, Y.; Zhang, Y.; Liou, F. Investigation of copper/stainless steel multi-metallic materials fabricated by laser metal deposition. Mat. Sci. Eng. A 2021, 811, 141071. [Google Scholar] [CrossRef]

- Mai, T.A.; Spowage, A.C. Characterisation of dissimilar joints in laser welding of steel–kovar, copper–steel and copper–aluminium. Mat. Sci. Eng. A 2004, 374, 224–233. [Google Scholar] [CrossRef]

- Velu, M.; Bhat, S. Metallurgical and mechanical examinations of steel–copper joints arc welded using bronze and nickel-base superalloy filler materials. Mater. Des. 2013, 47, 793–809. [Google Scholar] [CrossRef]

- Li, J.; Cai, Y.; Yan, F.; Wang, C.; Zhu, Z.; Hu, C. Porosity and liquation cracking of dissimilar Nd: YAG laser welding of SUS304 stainless steel to T2 copper. Opt. Laser Technol. 2020, 122, 105881. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Rolfe, B.; Gibson, I. Additive manufacturing a powerful tool for the aerospace industry. Rapid Prototyp. J. 2022, 28, 87–100. [Google Scholar] [CrossRef]

- Sukhov, D.I.; Bogachev, I.A.; Hodyrev, N.A.; Filonova, E.V. Multiple recycling of nickel alloy powder for selective laser melting process: Influence on properties of the powder and printed material. Rapid Prototyp. J. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Sezer, H.; Tang, J.; Ahsan, A.N.; Kaul, S. Modeling residual thermal stresses in layer-by-layer formation of direct metal laser sintering process for different scanning patterns for 316L stainless steel. Rapid Prototyp. J. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Ullah, A.; Ur Rehman, A.; Salamci, M.U.; Pıtır, F.; Liu, T. The influence of laser power and scanning speed on the microstructure and surface morphology of Cu2O parts in SLM. Rapid Prototyp. J. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Mohan, D.G.; Tomków, J.; Karganroudi, S.S. Laser welding of UNS S33207 hyper-duplex stainless steel to 6061 aluminum alloy using high entropy alloy as a filler material. Appl. Sci. 2022, 12, 2849. [Google Scholar] [CrossRef]

- Rinne, J.; Nothdurft, S.; Hermsdorf, J.; Kaierle, S.; Overmeyer, L. Investigations on laser welding of dissimilar joints of stainless steel and copper for hot crack prevention. J. Laser Appl. 2021, 33, 042042. [Google Scholar] [CrossRef]

- Joshi, G.R.; Badheka, V.J. Processing of bimetallic steel-copper joint by laser beam welding. Mater. Manuf. Process 2019, 34, 1232–1242. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhang, D.Q.; Sing, S.L.; Chua, C.K.; Loh, L.E. Interfacial characterization of SLM parts in multi-material processing: Metallurgical diffusion between 316L stainless steel and C18400 copper alloy. Mater. Charact. 2014, 94, 116–125. [Google Scholar] [CrossRef]

- Tan, C.L.; Zhou, K.S.; Ma, W.Y.; Min, L. Interfacial characteristic and mechanical performance of maraging steel-copper functional bimetal produced by selective laser melting based hybrid manufacture. Mater. Des. 2018, 155, 77–85. [Google Scholar] [CrossRef]

- Imran, M.K.; Masood, S.H.; Brandt, M.; Bhattacharya, S.; Mazumder, J. Direct metal deposition (DMD) of H13 tool steel on copper alloy substrate: Evaluation of mechanical properties. Mater. Sci. Eng. A 2011, 528, 3342–3349. [Google Scholar] [CrossRef]

- Chen, S.; Huang, J.; Xia, J.; Zhang, H.; Zhao, X. Microstructural characteristics of a stainless steel/copper dissimilar joint made by laser welding. Metall. Mater. Trans. A 2013, 44, 3690–3696. [Google Scholar] [CrossRef]

- Weigl, M.; Schmidt, M. Influence of the feed rate and the lateral beam displacement on the joining quality of laser-welded copper-stainless steel connections. Phys. Procedia 2010, 5, 53–59. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, Q.; Azadkhou, A.; Akbari, M.; Panjehpour, A.; Karimipour, A. Experimental investigation of temperature field and fusion zone microstructure in dissimilar pulsed laser welding of austenitic stainless steel and copper. J. Manuf. Processes 2020, 56, 206–215. [Google Scholar] [CrossRef]

- Kuryntsev, S.V.; Morushkin, A.E.; Gilmutdinov, A.K. Fiber laser welding of austenitic steel and commercially pure copper butt joint. Opt. Lasers Eng. 2017, 90, 101–109. [Google Scholar] [CrossRef]

- Ramachandran, S.; Lakshminarayanan, A.K. An insight into microstructural heterogeneities formation between weld subregions of laser welded copper to stainless steel joints. Trans. Nonferrous Met. Soc. China 2020, 30, 727–745. [Google Scholar] [CrossRef]

- Moharana, B.R.; Sahu, S.K.; Maiti, A.; Sahoo, S.K.; Moharana, T.K. An experimental study on joining of AISI 304 SS to Cu by Nd-YAG laser welding process. Mater. Today Proc. 2020, 33, 5262–5268. [Google Scholar] [CrossRef]

- Shen, H.; Gupta, M.C. Nd: Yttritium–aluminum–garnet laser welding of copper to stainless steel. J. Laser Appl. 2004, 16, 2–8. [Google Scholar] [CrossRef]

- Sahul, M.; Tomčíková, E.; Sahul, M.; Pašák, M.; Ludrovcová, B.; Hodúlová, E. Effect of disk laser beam offset on the microstructure and mechanical properties of copper—AISI 304 stainless steel dissimilar metals joints. Metals 2020, 10, 1294. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Yang, C.; Gao, M. Study of porosity suppression in oscillating laser-MIG hybrid welding of AA6082 aluminum alloy. J. Mater. Process Tech. 2021, 292, 117053. [Google Scholar] [CrossRef]

- Wang, L.; Gao, M.; Hao, Z. A pathway to mitigate macrosegregation of laser-arc hybrid Al-Si welds through beam oscillation. Int. J. Heat Mass Tran. 2020, 151, 119467. [Google Scholar] [CrossRef]

- Yan, F.; Qin, Y.; Tang, B.; Zhou, Y.; Gao, Z.; Hu, Y.; Hu, C.; Xiao, Z.; Xiao, Z.; Wang, C. Effects of beam oscillation on microstructural characteristics and mechanical properties in laser welded steel-copper joints. Opt. Laser Technol. 2022, 148, 107739. [Google Scholar] [CrossRef]

- Chen, S.; Huang, J.; Xia, J.; Zhao, X.; Lin, S. Influence of processing parameters on the characteristics of stainless steel/copper laser welding. J. Mater. Process. Tech. 2015, 222, 43–51. [Google Scholar] [CrossRef]

- Pfaendtner, J.A.; Mcmahon, C.J., Jr. Oxygen-induced intergranular cracking of a Ni-base alloy at elevated temperatures—An example of dynamic embrittlement. Acta Mater. 2001, 49, 3369–3377. [Google Scholar] [CrossRef]

- Hippsley, C.A.; Knott, J.F.; Edwards, B.C. A study of stress relief cracking in 214 Cr 1 Mo steel—II. The effects of multi-component segregation. Acta Metall. 1982, 30, 641–654. [Google Scholar] [CrossRef]

- Karabela, A.; Zhao, L.G.; Lin, B.; Tong, J.; Hardy, M.C. Oxygen diffusion and crack growth for a nickel-based superalloy under fatigue-oxidation conditions. Mat. Sci. Eng. A 2013, 567, 46–57. [Google Scholar] [CrossRef] [Green Version]

- Hasselman, D.P.H.; Youngblood, G.E. Enhanced thermal stress resistance of structural ceramics with thermal conductivity gradient. J. Am. Ceram. Soc. 1978, 61, 49–52. [Google Scholar] [CrossRef]

| T2 | Cu + Ag | Sn | Pb | Fe | Sb | S | O | As |

| ≥99.90 | ≤0.002 | ≤0.005 | ≤0.005 | ≤0.002 | ≤0.005 | ≤0.06 | ≤0.002 | |

| 304 | C | Si | Mn | P | S | Cr | Ni | Fe |

| ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.5 | 8.6 | Balance |

| Variables | Units | Levels |

|---|---|---|

| welding speed | m/min | 1.8, 2.4, 3.0, 3.6 |

| laser power | kW | 3.0 |

| defocusing amount | mm | 0 |

| flow rate of Ar gas | L/min | 16.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Yang, Y.; Wang, L.; Zhou, B.; Yan, F. Formation Mechanism and Control of Solidification Cracking in Laser-Welded Joints of Steel/Copper Dissimilar Metals. Metals 2022, 12, 1147. https://doi.org/10.3390/met12071147

Gao Z, Yang Y, Wang L, Zhou B, Yan F. Formation Mechanism and Control of Solidification Cracking in Laser-Welded Joints of Steel/Copper Dissimilar Metals. Metals. 2022; 12(7):1147. https://doi.org/10.3390/met12071147

Chicago/Turabian StyleGao, Zhongmei, Yuye Yang, Lei Wang, Bin Zhou, and Fei Yan. 2022. "Formation Mechanism and Control of Solidification Cracking in Laser-Welded Joints of Steel/Copper Dissimilar Metals" Metals 12, no. 7: 1147. https://doi.org/10.3390/met12071147

APA StyleGao, Z., Yang, Y., Wang, L., Zhou, B., & Yan, F. (2022). Formation Mechanism and Control of Solidification Cracking in Laser-Welded Joints of Steel/Copper Dissimilar Metals. Metals, 12(7), 1147. https://doi.org/10.3390/met12071147