4.1. Critical Buckling Force

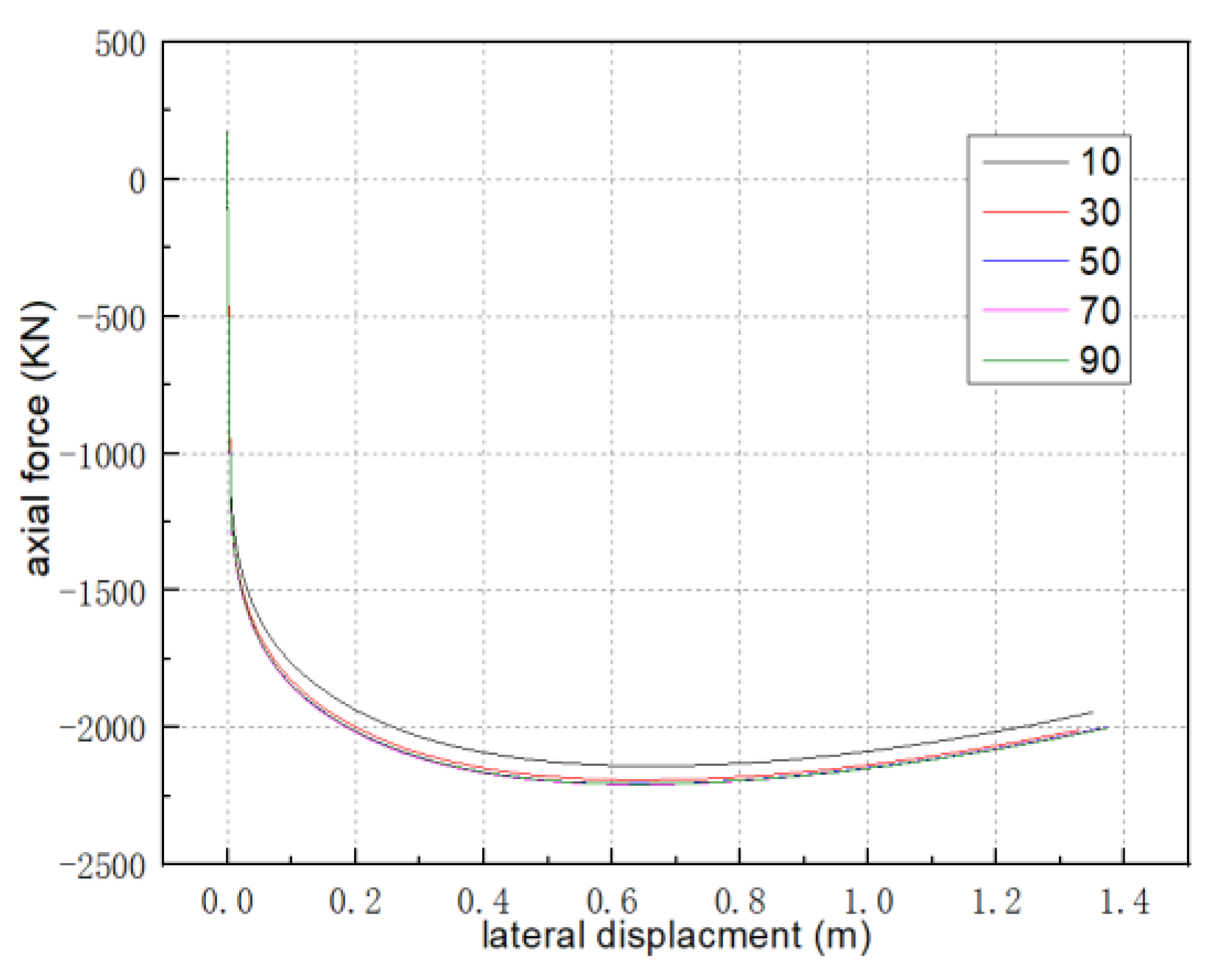

The main factors affecting the global buckling of a PIP system under the distributed buoyancy method include bending stiffness, buoyancy specific gravity, initial imperfection, pipe–sleeper friction coefficient, and stiffness ratio. Therefore, for an initial defect of a particular shape, the critical buckling axial force of the pipeline can be expressed as follows:

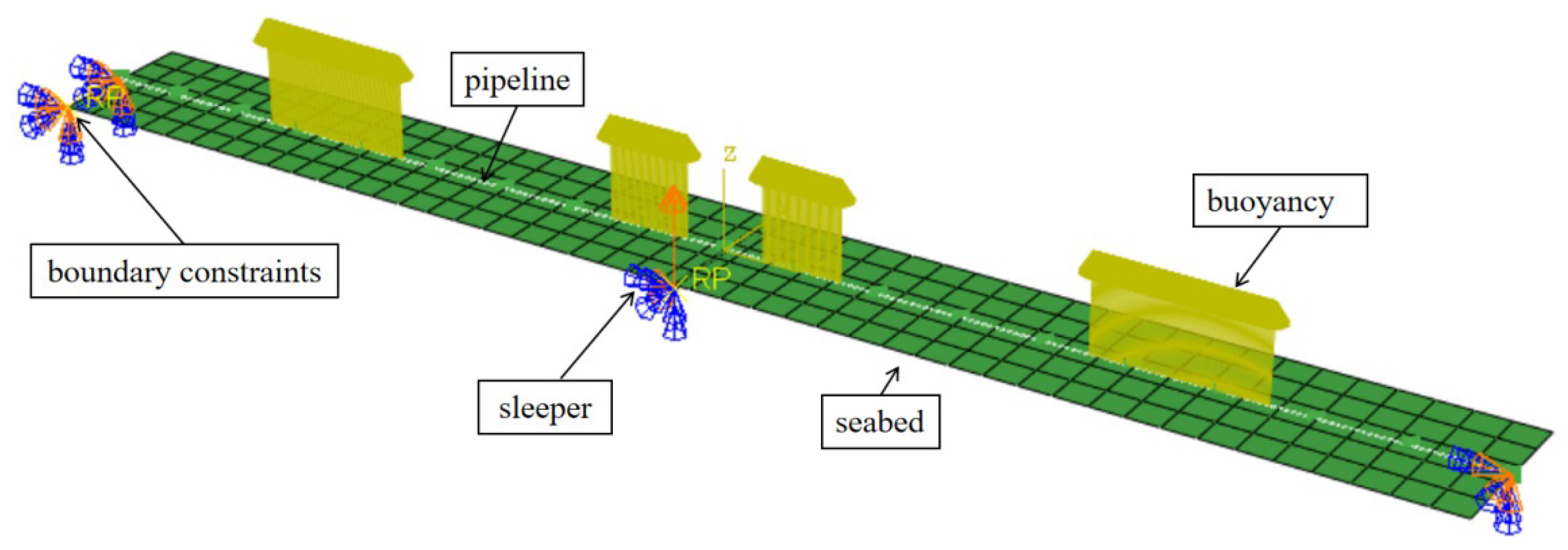

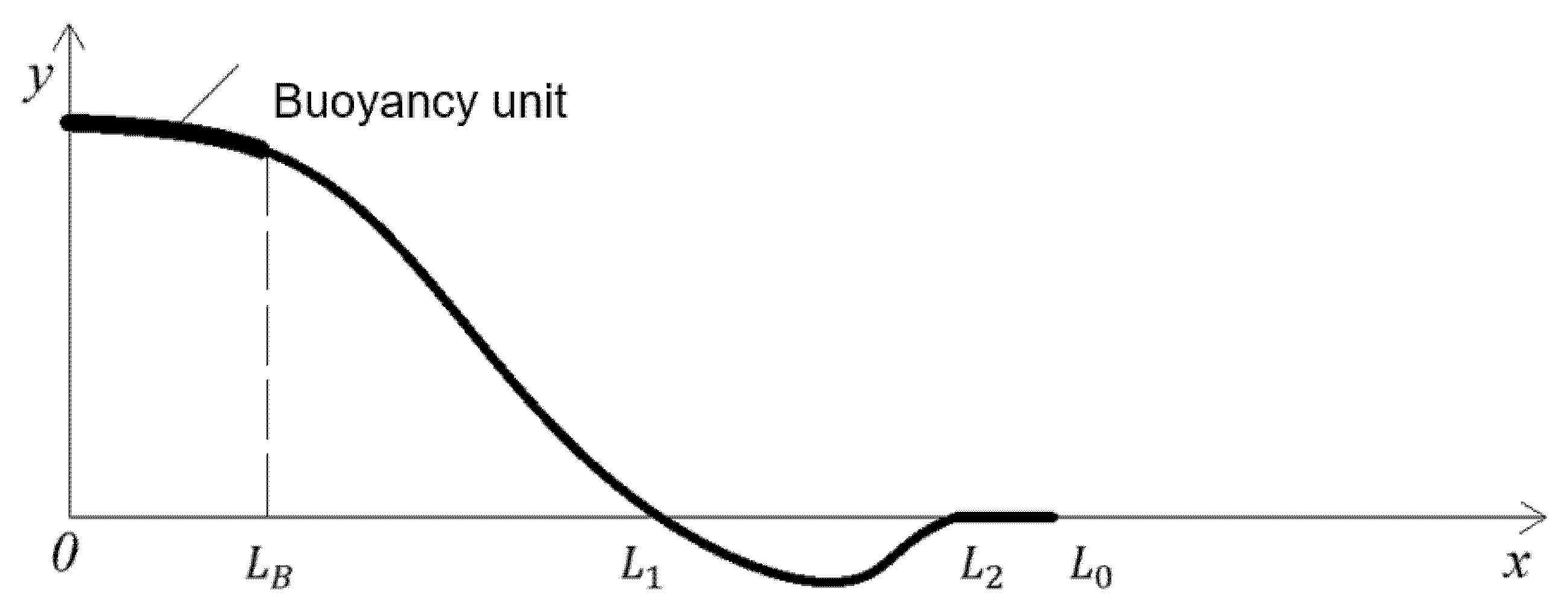

On the basis of symmetry, the lateral buckling mode of the PIP system under the distributed buoyancy method is selected and shown in

Figure 11. The X-0-Y coordinate is the projection surface of the pipeline on the seabed, in which the X direction is the axial direction of the pipeline, and the Y direction is the lateral direction of the pipeline. After buckling, the pipeline can be divided into three sections according to its deformation morphology and structural characteristics. The

section is the buoyancy unit installation section, where the pipeline buoyancy is defined as

and the ratio of buoyancy module section length to buckling section pipeline length is

, that is,

. The pipeline displacement and strain of the buoyancy unit section are marked as “B” below. The main buckling section of the pipeline is section

, in which

does not contain a buoyancy unit. The pipeline

is separated from the seabed surface due to the sleeper, thereby resulting in a suspension span. The displacement and strain of the pipeline are expressed by the following standard “1.” Section

is the secondary buckling section, and the displacement and strain of the pipeline are expressed as “2” below.

is the axial slip section, and the displacement and strain of the pipeline are marked as “3.” The virtual anchorage point is at

, and the floating weight of pipeline in

section is

.

According to the principle of virtual displacement, equilibrium equations can be established in different sections of the pipeline.

where

is the lateral displacement of the pipeline in the corresponding section,

is the axial displacement of the pipeline in the corresponding section,

is the axial friction coefficient of seabed and pipeline,

is the lateral friction coefficient of seabed and pipeline, and

is the friction coefficient of pipeline and sleeper. On the basis of the hypothesis of small deformation, the second derivative contribution of axial displacement is neglected. The satisfiable formula (9),

is fulfilled.

According to the mathematical forms of Equations (2)–(4), the general solution can be obtained as a lateral displacement function that satisfies the following forms:

where

Equation (8) is introduced into Equations (4)–(6) to obtain the axial and lateral displacements of buckling pipelines.

The axial displacement function of the pipeline in the slip section can be obtained by integrating Equation (7).

In the above formula, , , and are undetermined displacement coefficients. The axial and lateral displacements of the pipeline should satisfy the following boundary conditions and connection conditions at the boundary of the pipeline and at the junction of each section:

Lateral displacement

should be satisfied at

as follows:

Lateral displacements

and

satisfy the continuous boundary conditions at

as follows:

Lateral displacements

and

satisfy the following continuous boundary conditions at

:

Lateral displacement

satisfies the following continuous boundary conditions at

:

Axial displacement

should satisfy at

as follows:

Axial displacements

and

satisfy continuous boundary conditions at

as follows:

Axial displacements

and

satisfy the following continuous boundary conditions at

:

Axial displacements

and

satisfy the following continuous boundary conditions at

:

Axial displacement

satisfies the following continuous boundary conditions at

:

The lateral displacement functions (10)–(12) are introduced into the lateral displacement boundary conditions (18)–(24) and (25)–(30) to obtain the undetermined coefficients of the lateral displacement function.

The lateral displacement function

coefficient of buoyancy unit in lateral displacement buckling is

The displacement function

coefficient of the main buckling section without buoyancy is

The lateral displacement function

coefficient of the secondary buckling section is

Lateral displacement functions (10)–(12) are introduced into boundary conditions (24) and (38) to obtain the dimensionless parameters lambda

and lambda

, which must satisfy the following characteristic equations:

Formula (15) is integrated and introduced into boundary condition (34) to obtain the axial displacement function of the buoyancy section as follows:

Formula (16) is integrated from

to

X, and boundary condition (34) is introduced to obtain the axial displacement function of the main buckling section of the pipeline without buoyancy module as follows:

Formula (17) is integrated from

to

X and introduced into boundary condition (37) to obtain the axial displacement function of the secondary buckling section of the pipeline as follows:

The expressions of the axial displacement function can be obtained by introducing the slip section axial displacement function (18) into boundary conditions (40), (41) as follows:

The relationship between the axial load of the buckling section of the pipeline and the axial load of the virtual anchorage point can be obtained by introducing the upper formula to the boundary condition (41) as follows:

The lateral buckling equation can then be obtained as

where

.