Abstract

Here, melt-extracted Ni- and Fe-based amorphous metallic fibers (AMFs) were annealed below their glass transition temperatures. The tensile behaviors and microstructures of the melt-extracted and the annealed AMF samples were studied. For melt-extracted Ni- and Fe-based samples, the difference of fracture angles can be attributed to their difference of parameter α in the unified tensile fracture criterion. The revolution in the microstructure and mechanical properties induced by annealing treatment has been interpreted in detail. Prolonging the annealing time or increasing the annealing temperature can lead to an increase in fracture stresses of both Ni- and Fe-based AMFs. It was demonstrated that the increase in the fracture stresses of annealed AMFs is caused by the free volume annihilation in annealing processing.

1. Introduction

Amorphous alloys are a kind of promising materials to meet the increasing demand of structure materials due to their unique mechanical properties, such as superior elastic limit and high fracture strength resulting from their disordered atomic arrangement [1,2,3,4,5]. Meanwhile, amorphous metallic fibers (AMFs) have triggered considerable interests and can exhibit broad application prospect, especially in small-sized components. In recent decades, tremendous efforts have been made by materials scientists to investigate the mechanical behaviors of AMFs. For instance, Zberg et al. [6] demonstrated that MgZnCa microwires have high yield strength at a low density, enabling them promising for lightweight applications. Wang et al. [7] found that cold-drawing obviously improved fracture strengths of Co-based microwires. All these previous studies are helpful for understanding the mechanical behaviors of AMFs. However, the mechanical properties of AMFs often change with the ambient environment, especially in high-temperature environments, when used as practical structural materials [8]. Therefore, it is of essence to study the mechanical properties of AMFs before and after heat treatment. For example, Wang et al. [9] found that, for Fe69Co10Si8B13 AMFs, the fracture stress significantly increases with prolonging the annealing time. Moreover, the mechanical properties of Gd53Al24Co20Zr3 AMFs were also found to be tuned through annealing treatments by Belliveau et al. [10]. In addition, for AMFs with different compositions, different annealing methods should be conducted to match their thermodynamic characteristics [11,12]. Understanding mechanical behaviors of different AMFs under different heat treatment conditions is useful to extend their industry applications [13].

In the present work, two different AMFs with nominal compositions of Ni61Nb19.2Ta19.8 and Fe61Zr10Co5Mo7W2B15 (in at. %) are selected as model materials. The purpose of this study is to investigate the effect of the annealing treatments on the microstructure and tensile deformation characteristics of different AMFs.

2. Experiments

Master ingots with the nominal compositions of Ni61Nb19.2Ta19.8 and Fe61Zr10Co5Mo7W2B15 were prepared by arc-melting in an argon atmosphere from a mixture of elements with purities higher than 99.5 wt.%. Each ingot was re-melted four times, accompanied by electromagnetic stirring. Then, the alloy melt was cast into a copper mold to obtain a cylindric sample with 8 mm in diameter. Finally, the continuous near-circular Ni-based and Fe-based fibers with diameters of ~40 μm were fabricated by a home-made melt-extracted equipment at Harbin Institute of Technology. The samples were isothermally annealed at different temperatures for various prolonging times (10, 20, and 30 min) in a vacuum furnace at a maximum pressure of 3 × 10−5 mbar to obtain samples with various states of structural relaxation. The samples were immediately removed from the furnace and allowed to cool to room temperature. For comparison, one sample in each composition was not annealed and will be, henceforth, denoted as the melt-extracted sample. The microstructures of the melt-extracted and annealed samples were characterized using X-ray diffractometer (XRD, D/max-rB, Rigaku, Japan) with Cu Ka radiation and a Talos F200X field emission high resolution transmission electron microscope (HRTEM, FEI, NY, USA). To quantitatively measure the atomic-scale structural ordering, which can be subsequently used as a basis for the quantitative comparison of the degree of local ordering between the melt-extracted and the annealed samples, the HRTEM images were transformed to their corresponding autocorrelation function (ACF) patterns by following the method well established in previous literature [14,15,16]. ACF image analysis was carried out using the software Digital Micrograph (Gatan695, Gatan, NY, USA). Scanning electron microscopy (SEM: HELIOS NanoLab 600i, FEI, Hillsboro, OR, USA) was used to examine the geometry and fractured surfaces of the extracted fibers. An STA449F3 differential scanning calorimetry (DSC, PerkinElmer, Waltham, UK) was used for thermal analysis under a pure argon atmosphere from room temperature to 900 °C with a heating rate of 20 °C/min. All tensile tests with a strain rate of 5 × 10−5 s−1 were conducted on an Instron D3379-75 micro-tensile setup with 10 N load cell at room temperature. A gauge length of 10 mm was used. In order to ensure the accuracy of the experimental results, at least nine samples were tested for each condition of fibers. An in situ video extensometer system (ZJU, Hangzhou, China) was used to monitor the strains in our work. Prior to tension, the tensile specimens were spray-painted to generate an artificial speckle suitable for the digital image correlation (DIC, ZJU, Hangzhou, China) measurement. Using pattern matching, the system follows a template drawn onto the fiber as the sample deforms. The distance between the templates in pixels on the charge-coupled device (CCD, ZJU, Moscow, Russia) array was then used to determine strain.

3. Results and Discussion

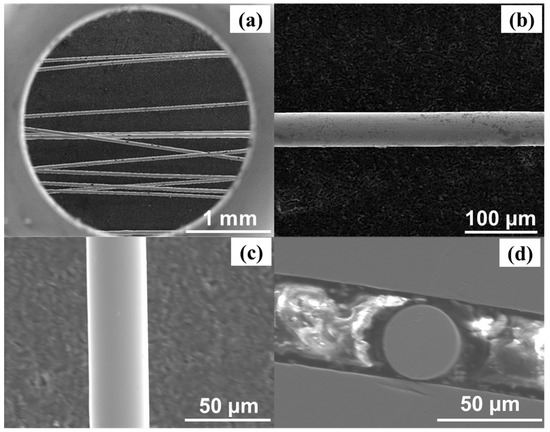

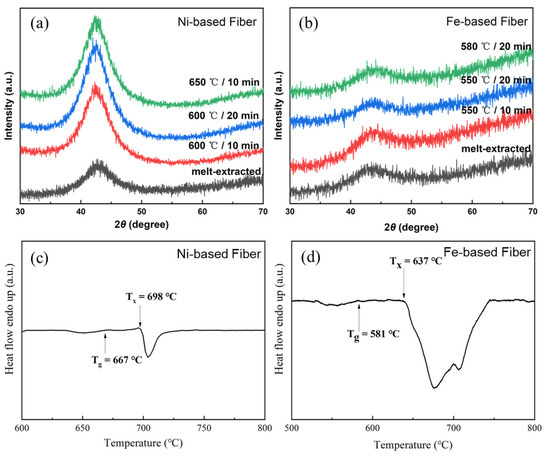

Figure 1a,b show the images of the melt-extracted Ni-based fibers. It can be seen that the melt-extracted AMFs are uniformly round and straight. The diameter of the fiber was measured to be about 40 µm. No obvious defects such as Rayleigh waves and grooves were observed in the sample surfaces. The melt-extracted Fe-based fibers (as shown in Figure 1c) also had a clean surface with a diameter of ~35 μm and showed an excellent roundness of cross section (as shown in Figure 1d). Figure 2a,b show the XRD patterns obtained from the melt-extracted Ni- and Fe-based samples, respectively. The XRD patterns exhibited typical halo peaks (Ni-based at ~43° and Fe-based at ~42°) of single amorphous structure, without any apparent crystalline Bragg peaks. The DSC curves of both the melt-extracted Ni-based and Fe-based AMFs exhibited an endothermic event characteristic of the glass transition and a supercooled liquid region, followed by exothermic events characteristic of crystallization processes as shown in Figure 2c,d. The glass transition temperature (Tg) and crystallization temperature (Tx) of Ni-based fibers were about 667 °C and 698 °C, which is consistent with the results in Ref. [17]. The Fe-based fibers had a glass transition temperature Tg of ~581 °C and crystallization temperature Tx of ~637 °C, similar to the results reported by Lu et al. [18]. High Tg values for both Ni-based and Fe-based AMFs suggest their high thermal stability and could be promising for high temperature applications. The supercooled liquid region of Fe-based AMFs (∆T ≈ 31 °C) was smaller than that of Ni-based AMFs (∆T ≈ 56 °C). Both the XRD and DSC results confirm the glass nature of both the melt-extracted Ni- and Fe-based AMFs.

Figure 1.

SEM images of AMFs. (a) Ni-based fibers. (b) The magnification of (a). (c) The magnification of Fe-based fiber and (d) cross-sectional image of Fe-based fiber.

Figure 2.

XRD and DSC patterns of melt-extracted AMFs, (a) XRD of Ni-based fibers, (b) XRD of Fe-based fibers, (c) DSC of Ni-based fibers, and (d) DSC of Fe-based fibers.

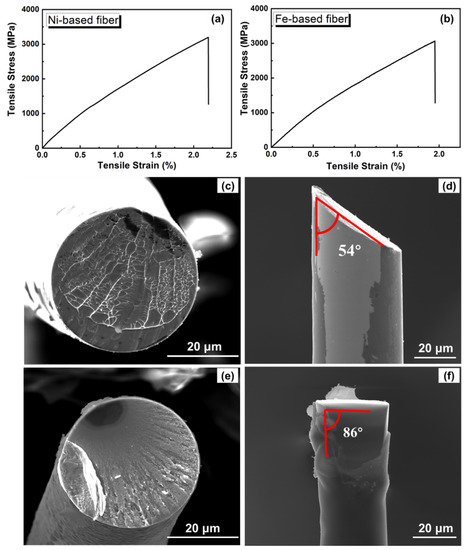

Figure 3a shows the tensile stress-strain curve of the melt-extracted Ni-based AMF, the fracture strength of which is the median value of the nine tested samples. The fiber had a large elastic strain value of about 2.3% and showed no apparent plastic deformation. The fracture stress of the melt-extracted Ni-based AMF was 3425 MPa, higher than that of bulk metallic glasses (BMGs) with a composition of Ni-Nb-Ta [19]. Figure 3b shows the tensile stress-strain curve of Fe-based fiber, the fracture strength of which is also the median value of the nine tested samples. Its fracture stress and elastic strain value were 3066 MPa and ~2.0%, respectively. No tensile plastic deformation was found in the Fe-based fiber either. These results suggest a deformation feature of brittle fracture for both Ni-based and Fe-based AMFs.

Figure 3.

Tensile stress-strain curves of melt-extracted AMFs. (a) Ni-based fiber. (b) Fe-based fiber, and SEM micrographs after fracture of melt-extracted AMFs. (c,d) Ni-based fiber. (e,f) Fe-based fiber.

Figure 3c shows the tensile fracture surface morphology of the melt-extracted Ni-based fiber. For amorphous metallic materials, the preferential and multiple shear banding preferentially generate in the regions where there are more free volume contents or defects, thereby causing the crack initiation. The fractured samples consisted of a mirror-like region of small area and a vein-like pattern region of large area. The mirror-like region was very smooth and featureless, where rapid fracture deformation eventually occurred. It was considered that these areas correspond to local nucleation sites of the crack because of the normal tensile stress on the fracture surface. The vein-like patterns formed in the fractured AMFs have been shown to be the result of the release of elastic energy, favoring adiabatic heating, re-melting, or a decrease in the viscosity of the shear plane. Contrarily, the fracture surface of Fe-based fibers was characterized by a radial pattern rather than a combination of mirror-like and vein-like regions, as shown in Figure 3d, indicating that the fracture mechanism was mainly characterized by typical cleavage fracture, and the cleavage plane rapidly intersected through the fiber during the final fracture moment. Meanwhile, the two kinds of fibers also exhibited different fracture angles. Figure 3e shows that the fracture angle of Ni-based fiber was about 54°, similar to that of BMGs [20,21]. Contrarily, Fe-based fiber failed along a plane perpendicular to the loading axis, i.e., about 86°, as shown in Figure 3f. This difference in fracture angle can be explained by the unified tensile fracture criterion [22], which can be expressed by:

where σ and σ0 represent the maximum and critical normal stress, respectively. τ and τ0 are, respectively, the maximum and critical shear stress. The τ0 and σ0 are two uncorrelated basic strengths, and their absolute and relative values determine the strength and brittleness of materials. The two strengths can be calculated by following equations:

where σT is the fracture stress measured by tensile tests. Then, α, i.e., the ratio of critical shear stress and critical normal stress, which is expressed by:

is considered to be associated with the fracture angles of different AMFs [23]. Since there are different fracture stresses of different AMFs, the α value should also be different. The α can also be calculated by fracture angle θT, which is expressed by:

when , the fracture angle ranges from 45° to 90°, which agrees well with the Mohr–Coulomb criterion (50°–65°). For , the main shear band propagates along the vertical direction with the tensile axis during fracture progress, meaning that the maximum normal stress criterion is also one of the special cases for the unified tensile fracture criterion [24,25,26].

In the current work, since the σT and θT of melt-extracted AMFs are known, substituting into the above equations, the α can be calculated. For Ni-based AMFs, one gets , and the fracture angle (54°) also exactly agrees with the Mohr–Coulomb criterion. For Fe-based AMFs, , indicating the fracture angle is close to 90°, which is in good agreement with the experimental result (86°). Based on the analysis above, the α value reflects the differences of various materials and in return, dominates the macroscale fracture behaviors of Ni- and Fe-based AMFs, thereby affecting their fracture angles.

The structure features of Ni- and Fe-based AMFs with the annealed states were also examined by XRD. The corresponding XRD patterns are shown in Figure 2. No Bragg peak corresponding to crystalline phase was observed from the XRD patterns for the annealed AMFs with different annealing times or annealing temperatures. Moreover, the position of the halo XRD peak for the fibers annealed for various time periods and temperatures remained almost unchanged, compared with the melt-extracted sample (as shown in Figure 2a,b). This indicates that, for both Ni- and Fe-based AMFs, the annealing treatment near Tg did not lead to crystallization.

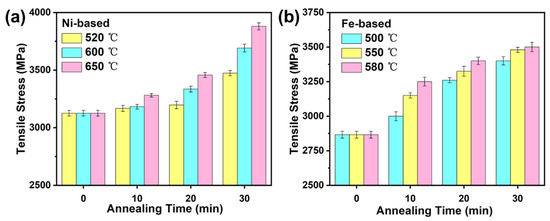

In order to study the effect of different annealing conditions on the mechanical properties of AMFs, the Ni- and Fe-based fibers of both melt-extracted and annealed states were subjected to tensile tests at room temperature. The corresponding average fracture stresses of each condition are plotted in Figure 4. For both fibers, the fracture stresses values increased with prolonging annealing time or increasing annealing temperature, compared with those of melt-extracted samples [27].

Figure 4.

Fracture stress variation of AMFs before and after annealing. (a) Ni-based fibers. (b) Fe-based fibers.

Accordingly, HRTEM observations were employed to further investigate the structure of the melt-extracted and annealed fibers, as shown in Figure 5a–h. For all the Ni- and Fe-based samples in melt-extracted and annealed states, their HRTEM images showed a mazy and homogeneous contrast. No crystallization was observed. The corresponding SAED patterns displayed no diffraction spots but an amorphous halo ring, typical of fully amorphous nature, consistent with the XRD results. These results further verified the glassy feature of all the melt-extracted and annealed AMFs. Then, the ACF technique was also performed to statistically determine the local order degree of the melt-extracted and annealed AMF samples. Firstly, areas of 16 nm × 16 nm were randomly selected from the HRTEM images. Then, the HRTEM images were divided into 64 sub-images, each of which corresponded to the small region with a dimension of 2 nm × 2 nm, close to the medium-range order atomic (MRO) cluster. Subsequently, the image in each cell was fast Fourier transformed into images, as shown in Figure 5a′–d′, in order to assess the local translational symmetry. All the sub-images whose atomic arrangements exhibited a crystal-like order are indicated by red rectangle. The increase of the ordered region marked by red squares in the AMFs can be clearly observed after annealing. For Ni-based fibers, the local order degrees in Figure 5a′–d′ were measured to be 3.1%, 4.7%, 6.3%, and 9.4%, respectively, for the melt-extracted sample, and the samples annealed at 600 °C for 10 min and 20 min, and annealed at 650 °C for 10 min. For Fe-based fibers, the order degrees of high-resolution images in Figure 5e′–h′ were measured to be 1.6%, 3.1%, 7.8%, and 12.5%, respectively, for the melt-extracted sample, and the samples annealed at 550 °C for 10 min and 20 min, and annealed at 580 °C for 20 min. That means that the local order degrees of annealed Ni- and Fe-based fibers were significantly higher than those of the melt-extracted samples.

Figure 5.

HRTEM images with inset showing the selected area electron diffraction patterns of Ni- and Fe-based samples. (a) melt-extracted Ni-based sample, and Ni-based samples annealed at (b) 600 °C for 10 min, (c) 600 °C for 20 min, (d) 650 °C for 10 min; (e) melt-extracted Fe-based sample, and Fe-based samples annealed at (f) 550 °C for 10 min, (g) 550 °C for 20 min, (h) 580 °C for 20 min, and the corresponding ACF images (a′–h′).

Generally, the free volume is the deformation unit of AMFs [28,29]. It is well documented that annealing treatment results in a reduction in the free volume content of amorphous materials [30,31,32]. A glass-forming liquid is composed of the liquid phase and some crystal-like phases [33,34]. Thermodynamically, the liquid phase with a disordered structure is metastable and transforms into more stable crystal-like phase of lower energy when applied more external energy, such as isothermal annealing [35,36]. When annealed at sufficiently high temperatures, the fibers with metastable equilibrium pass through a series of lower energy states. The relaxed fibers have a shorter atomic distance and a denser packing after annealing treatment, as shown in Figure 5, hindering local atomic movements. This means that structural relaxation could occur in annealed AMFs, leading to a reduction in free volume and thus an increase in density. For example, Nagel et al. [37] reported a ~0.1% increase in the density of Zr-based amorphous alloys after annealing. The reduction of free volume caused by annealing treatment increases the viscosity of amorphous alloys, thus reducing atomic mobility. More difficult viscoplastic flow improves the strength. Therefore, it can be inferred that the free volume annihilation caused by structural relaxation has a certain impact on the microstructures of AMFs, resulting in the improvement of tensile strength, as shown in Figure 4.

4. Summary

In this work, Ni- and Fe-based AMFs were successfully prepared through melt-extracted technique and their different structural states were obtained by annealing processes. The effect of annealing processes on mechanical properties of the two different fibers was investigated. The following conclusions can be drawn:

- (1)

- All the samples remained fully amorphous structure before and after annealing treatments. Both melt-extracted and annealed Ni/Fe-based AMFs exhibited brittle fracture characteristics.

- (2)

- The fracture angles of melt-extracted Ni- and Fe-based AMFs were different. This can be explained by the parameter α in the unified tensile fracture criterion, which reflects the differences of various materials and thereby affects their fracture angles.

- (3)

- Prolonging the annealing time or increasing the annealing temperature can lead to an increase in fracture stresses in both Ni- and Fe-based AMFs. The increasing of fracture stresses of annealed AMFs resulted from their lower free volume content compared with that of melt-extracted ones.

Author Contributions

Conceptualization, S.S. and Y.H.; data curation, S.S., J.Z., H.W. and Z.N.; formal analysis, S.S. and Y.H.; funding acquisition, Z.N. and J.S.; investigation, S.S., Y.H. and J.Z.; methodology, S.S.; project administration, J.S.; writing—original draft, S.S. and Y.H.; writing—review and editing, Y.H. and L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of China (NSFC, Nos. 52071118 and 52171154).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest that could have appeared to influence the work reported in this paper.

References

- Cui, J.; Luo, Q.; Di, S.; Zhang, Z.; Shen, B. Rejuvenation-to-Relaxation Transition Induced by Elastostatic Compression and Its Effect on Deformation Behavior in a Zr-Based Bulk Metallic Glass. Metals 2022, 12, 282. [Google Scholar] [CrossRef]

- Rösner, H.; Kübel, C.; Ostendorp, S.; Wilde, G. In Situ Generated Shear Bands in Metallic Glass Investigated by Atomic Force and Analytical Transmission Electron Microscopy. Metals 2022, 12, 111. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, T.; Li, L.; Yang, J.; Zhang, M.; Wang, C.; Zhang, Y. Fatigue Behavior of Zr58Cu15.46Ni12.74Al10.34Nb2.76Y0.5 Bulk Metallic Glass Fabricated by Industrial-Grade Zirconium Raw Material. Metals 2021, 11, 187. [Google Scholar] [CrossRef]

- Liu, J.; Pang, M.; Cao, G.; Qu, G.; Wang, X.; Zhang, Y.; Liu, R.; Shen, H. Comparative study of tensile properties and magnetic properties for Nb-doped Fe-based wires. J. Mater. Res. Technol. 2020, 9, 12907–12916. [Google Scholar] [CrossRef]

- Zhang, M.; Qu, G.; Liu, J.; Pang, M.; Wang, X.; Liu, R.; Cao, G.; Ma, G. Enhancement of Magnetic and Tensile Mechanical Performances in Fe-Based Metallic Microwires Induced by Trace Ni-Doping. Materials 2021, 14, 3589. [Google Scholar] [CrossRef]

- Zberg, B.; Arata, E.R.; Uggowitzer, P.J.; Löffler, J.F. Tensile properties of glassy MgZnCa wires and reliability analysis using Weibull statistics. Acta Mater. 2009, 57, 3223–3231. [Google Scholar] [CrossRef]

- Wang, H.; Qin, F.X.; Xing, D.W.; Cao, F.Y.; Wang, X.D.; Peng, H.X.; Sun, J.F. Relating residual stress and microstructure to mechanical and giant magneto-impedance properties in cold-drawn Co-based amorphous microwires. Acta Mater. 2012, 60, 5425–5436. [Google Scholar] [CrossRef]

- Shweta, A.J.; Sumanth, T.; Chandra, S.M.; Zhonglue, H.; Molla, H.; Golden, K. Review of Thermoplastic Drawing with Bulk Metallic Glasses. Metals 2022, 12, 518. [Google Scholar]

- Wang, C.D.; Zhang, Z.H.; Xie, J.X. Influence of annealing on the magnetic and mechanical properties of glass-coated Fe69Col0Si8B13 microwires. J. Funct. Mater. Devices 2010, 16, 22–28. [Google Scholar]

- Belliveau, H.; Yu, Y.; Luo, Y.; Qin, F.; Wang, H.; Shen, H.; Sun, J.; Yu, S.; Srikanth, H.; Phan, M. Improving mechanical and magnetocaloric responses of amorphous melt-extracted Gd-based microwires via nanocrystallization. J. Alloys Compd. 2017, 692, 658–664. [Google Scholar] [CrossRef] [Green Version]

- Sharma, A.; Zadorozhnyy, V. Review of the Recent Development in Metallic Glass and Its Composites. Metals 2021, 11, 1933. [Google Scholar] [CrossRef]

- Su, S.; Ning, Z.L.; Huang, Y.J.; Yang, T.; Wang, K.Y.; Jiang, M.Q.; Sun, J.F.; Jiang, S.D. Effect of strain rate on fracture reliability of Cu45Zr45Co10 amorphous alloy microwires by statistical analyses. J. Alloys Compd. 2022, 898, 162951. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.; Wang, Q.; Wu, M.; Nan, D.; Shen, H.; Peng, H. Enhanced Tensile Properties and Fracture Reliability of Cu-Based Amorphous Wires via Pr-Doping. Adv. Eng. Mater. 2018, 20, 1700935. [Google Scholar] [CrossRef]

- Huang, Y.; He, F.; Fan, H.; Shen, J. Ductile Ti-based metallic glass spheres. Scr. Mater. 2012, 67, 661–664. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, H.; Hui, X.; Chen, G.; Lu, Z. Effects of drawing on the tensile fracture strength and its reliability of small-sized metallic glasses. Acta Mater. 2010, 58, 2564–2576. [Google Scholar] [CrossRef]

- Huang, Y.J.; Ning, Z.L.; Shen, Z.; Liang, W.Z.; Sun, H.C.; Sun, J.F. Bending behavior of as-cast and annealed ZrCuNiAl bulk metallic glass. J. Mater. Sci. Technol. 2017, 33, 1153–1158. [Google Scholar] [CrossRef]

- Lee, M.; Kim, J.H.; Park, J.; Kim, J.; Kim, W.; Kim, D. Fabrication of Ni–Nb–Ta metallic glass reinforced Al-based alloy matrix composites by infiltration casting process. Scr. Mater. 2004, 50, 1367–1371. [Google Scholar] [CrossRef]

- Lu, Z.; Liu, C.; Porter, W. Role of yttrium in glass formation of Fe-based bulk metallic glasses. Appl. Phys. Lett. 2003, 83, 2581–2583. [Google Scholar] [CrossRef]

- He, M.; Chen, S.; Yu, P.; Xia, L. Enhanced mechanical properties of Ni62Nb38 bulk metallic glasses by Ta substitution. J. Non-Cryst. Solids 2017, 471, 452–455. [Google Scholar] [CrossRef]

- Ertugrul, O.; He, T.; Shahid, R.N.; Scudino, S. Effect of heat treatment on microstructure and mechanical properties of Al 2024 matrix composites reinforced with Ni60Nb40 metallic glass particles. J. Alloys Compd. 2019, 808, 151732. [Google Scholar] [CrossRef]

- Dong, K.; Kong, J.; Ruan, X.; Yang, Y.; Peng, Y.; Zhou, Q.; Wang, K. Thermoplastic brazing of TiAl-and Ni-based alloys utilizing a Ni-based bulk metallic glass as the filler metal. J. Mater. Sci. Eng. A 2021, 815, 141255. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Eckert, J. Unified tensile fracture criterion. Phys. Rev. Lett. 2005, 94, 094301. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Z.F.; Eckert, J.; Schultz, L. Difference in compressive and tensile fracture mechanisms of Zr59Cu20Al10Ni8Ti3 bulk metallic glass. Acta Mater. 2003, 51, 1167–1179. [Google Scholar] [CrossRef]

- Wang, W.H. The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog. Mater. Sci. 2012, 57, 487–656. [Google Scholar] [CrossRef]

- Lewandowski, J.; Wang, W.; Greer, A. Intrinsic plasticity or brittleness of metallic glasses. Philos. Mag. 2005, 85, 77–87. [Google Scholar] [CrossRef]

- Lu, Z.; Liu, C. Glass formation criterion for various glass-forming systems. Phys. Rev. Lett. 2003, 91, 115505. [Google Scholar] [CrossRef]

- Liu, J.; Cao, F.; Xing, D.; Zhang, L.; Qin, F.; Peng, H.; Xue, X.; Sun, J. Enhancing GMI properties of melt-extracted Co-based amorphous wires by twin-zone Joule annealing. J. Alloys Compd. 2012, 541, 215–221. [Google Scholar] [CrossRef]

- Spaepen, F. Homogeneous flow of metallic glasses: A free volume perspective. Scr. Mater. 2006, 54, 363–367. [Google Scholar] [CrossRef]

- Abrosimova, G.; Chirkova, V.; Pershina, E.; Volkov, N.; Sholin, I.; Aronin, A. The Effect of Free Volume on the Crystallization of Al87Ni8Gd5 Amorphous Alloy. Metals 2022, 12, 332. [Google Scholar] [CrossRef]

- Yue, G.; Zhang, Y.; Sun, Y.; Shen, B.; Dong, F.; Wang, Z.; Zhang, R.; Zheng, Y.; Kramer, M.; Wang, S. Local structure order in Pd78Cu6Si16 liquid. Sci. Rep. 2015, 5, 8277. [Google Scholar] [CrossRef] [Green Version]

- Dmowski, W.; Fan, C.; Morrison, M.; Liaw, P.; Egami, T. Structural changes in bulk metallic glass after annealing below the glass-transition temperature. Mater. Sci. Eng. A 2007, 471, 125–129. [Google Scholar] [CrossRef]

- Murali, P.; Ramamurty, U. Embrittlement of a bulk metallic glass due to sub-Tg annealing. Acta Mater. 2005, 53, 1467–1478. [Google Scholar] [CrossRef]

- Ramamurty, U.; Lee, M.; Basu, J.; Li, Y. Embrittlement of a bulk metallic glass due to low-temperature annealing. Scr. Mater. 2002, 47, 107–111. [Google Scholar] [CrossRef] [Green Version]

- Taub, A.; Spaepen, F. The kinetics of structural relaxation of a metallic glass. Acta Metall. 1980, 28, 1781–1788. [Google Scholar] [CrossRef]

- Wang, W.H.; Wang, R.J.; Yang, W.; Wei, B.; Wen, P.; Zhao, D.; Pan, M. Stability of ZrTiCuNiBe bulk metallic glass upon isothermal annealing near the glass transition temperature. J. Mater. Res. 2002, 17, 1385–1389. [Google Scholar] [CrossRef] [Green Version]

- Huo, L.; Zeng, J.; Wang, W.; Liu, C.T.; Yang, Y. The dependence of shear modulus on dynamic relaxation and evolution of local structural heterogeneity in a metallic glass. Acta Mater. 2013, 61, 4329–4338. [Google Scholar] [CrossRef]

- Nagel, C.; Rätzke, K.; Schmidtke, E.; Wolff, J.; Geyer, U.; Faupel, F. Free-volume changes in the bulk metallic glass Zr46.7Ti8.3Cu7.5Ni10Be27.5 and the undercooled liquid. Phys. Rev. B 1998, 57, 10224. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).