Study of the Mechanical Properties and Microstructural Response with Laser Shock Peening on 40CrMo Steel

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Materials

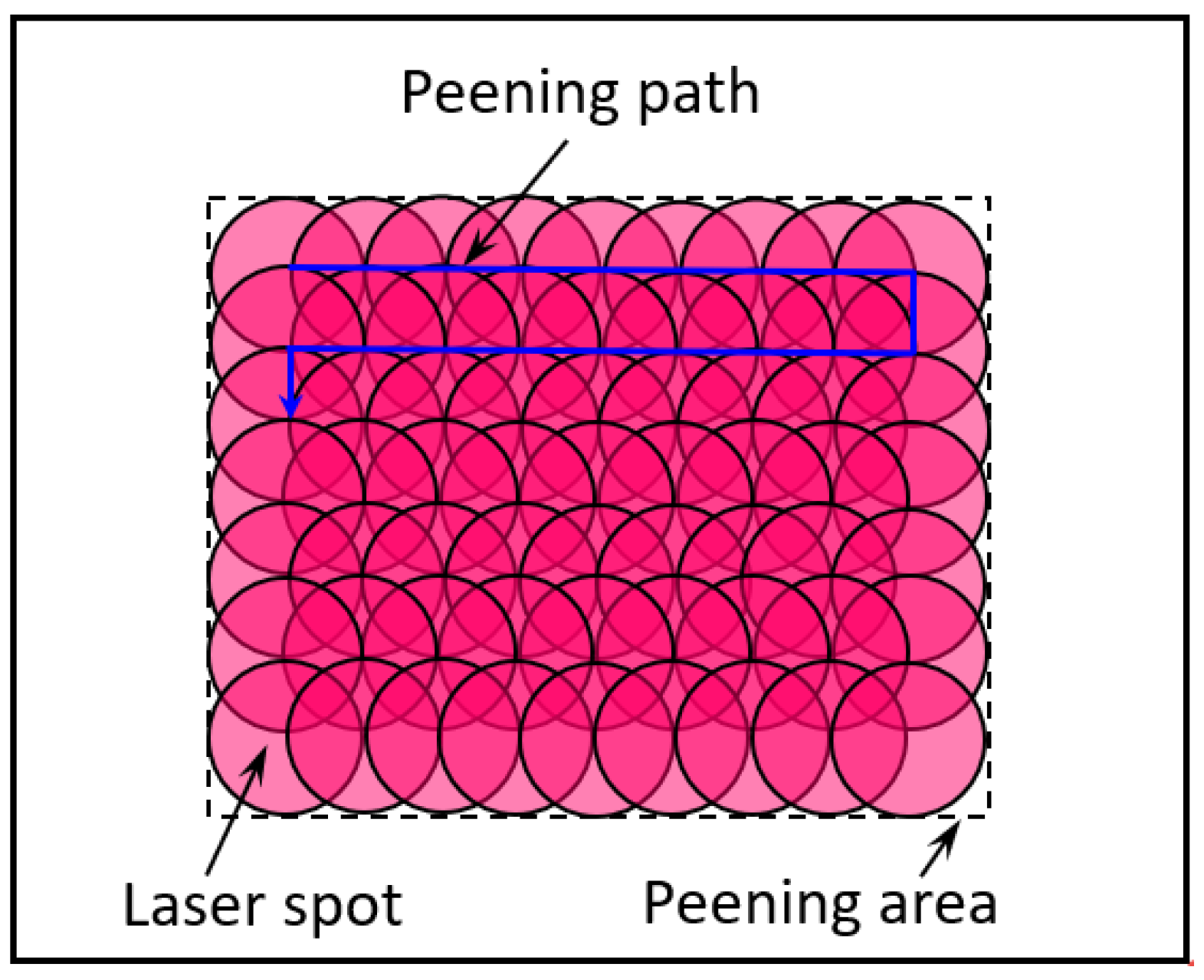

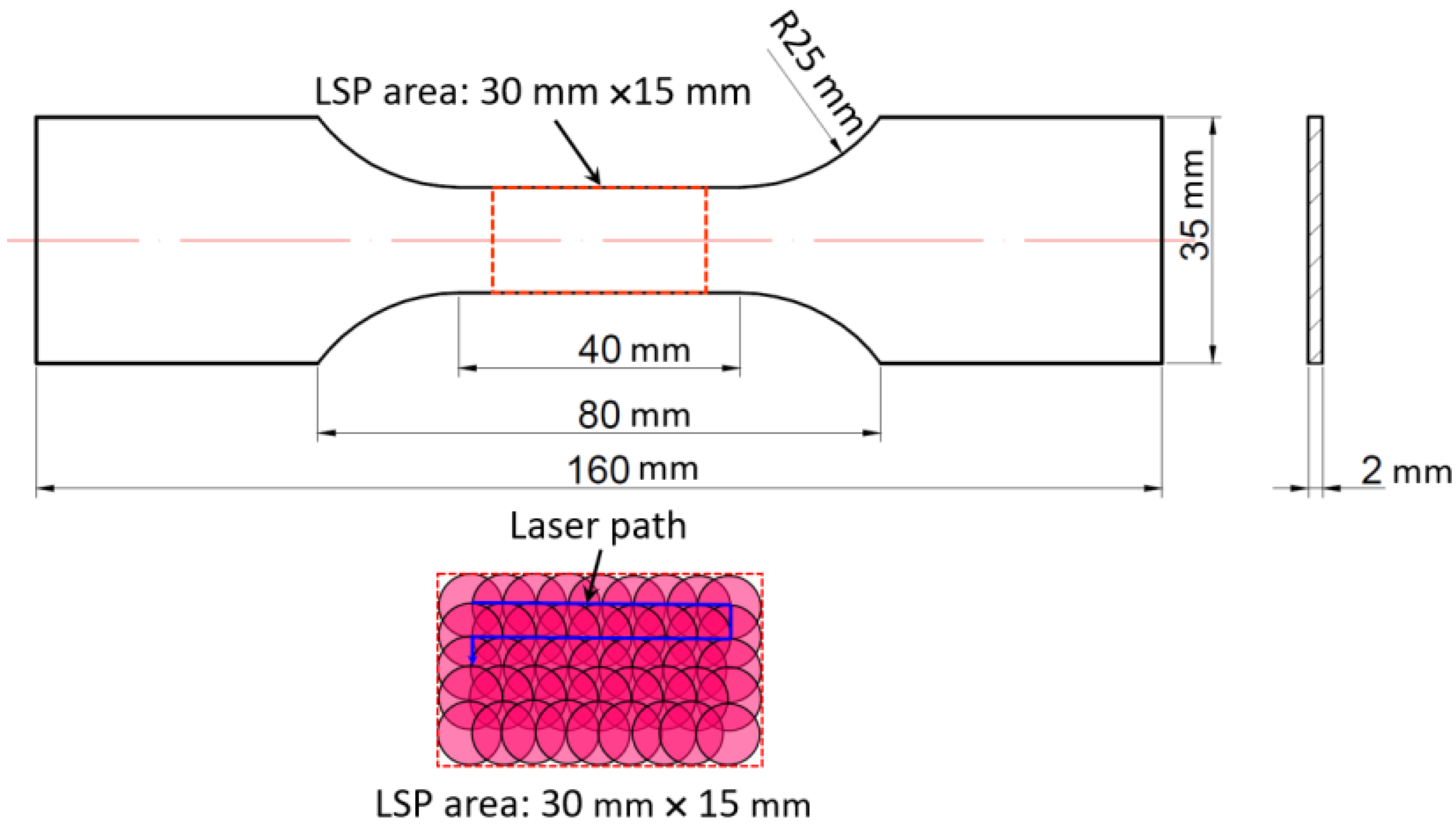

2.2. Laser Shock Peening Experiment

2.3. Microhardness Measurement

2.4. Tensile Properties Test

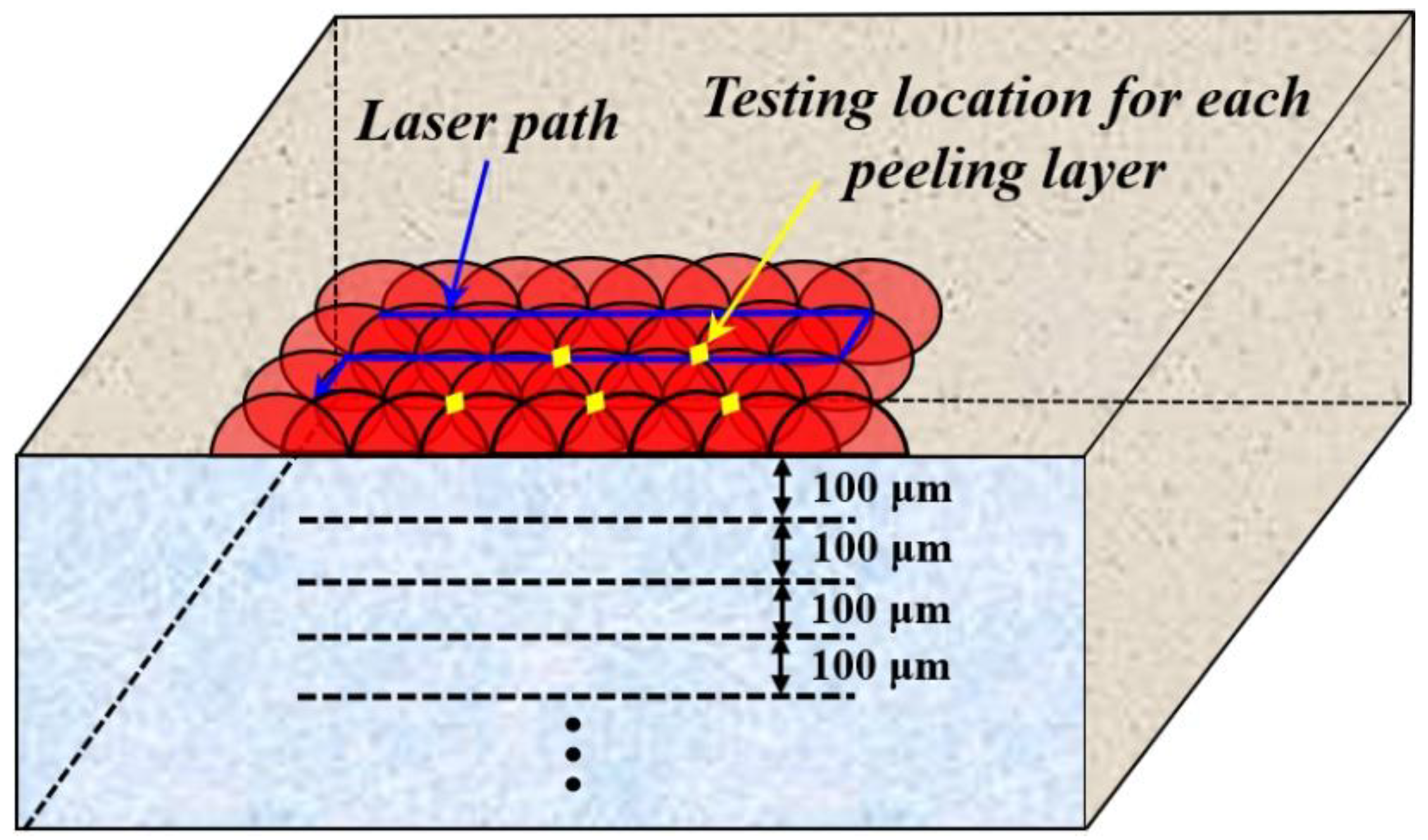

2.5. Residual Stress Test

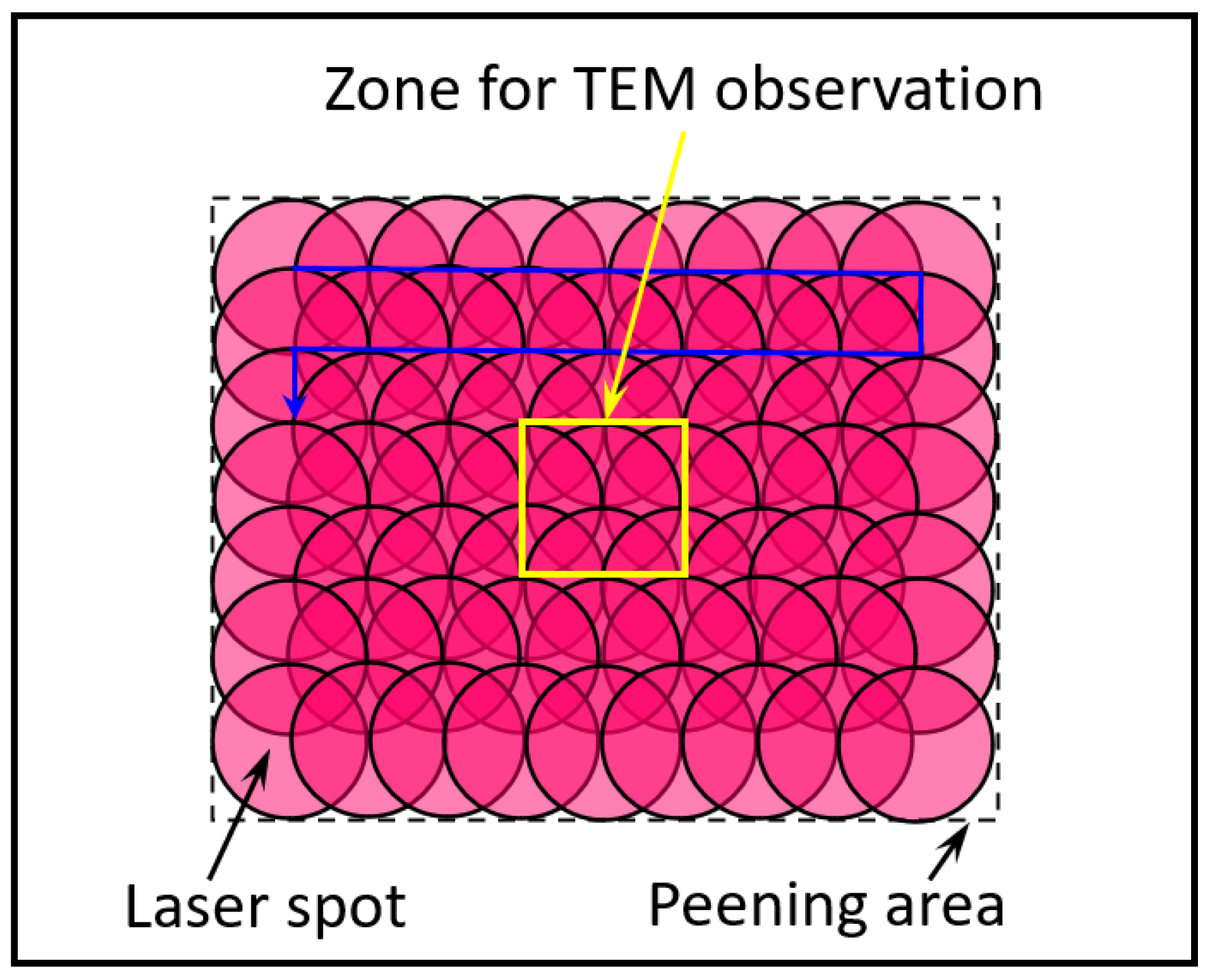

2.6. Microstructural Observation

2.7. Wear Test

3. Results and Discussion

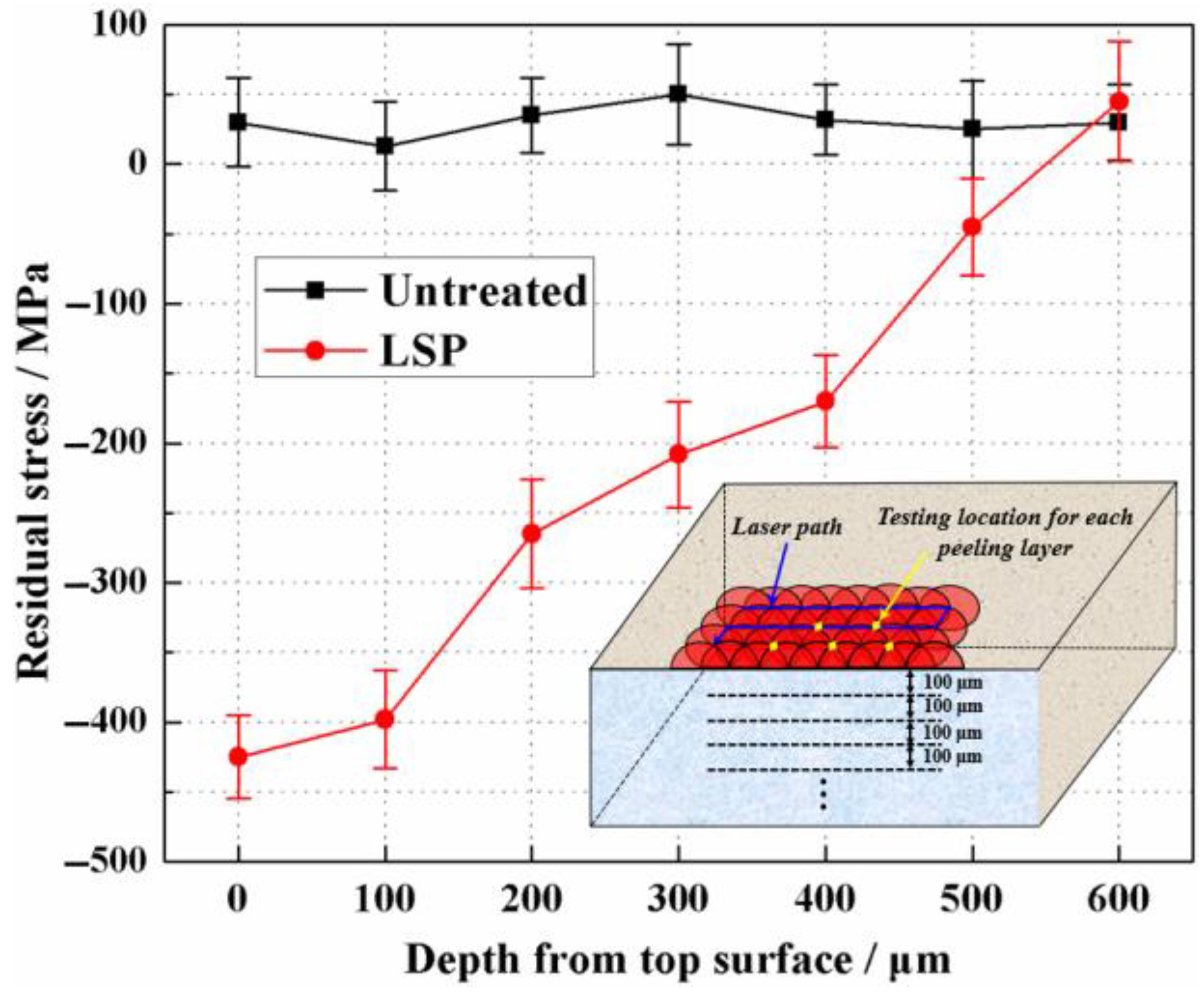

3.1. In-Depth Residual Stress

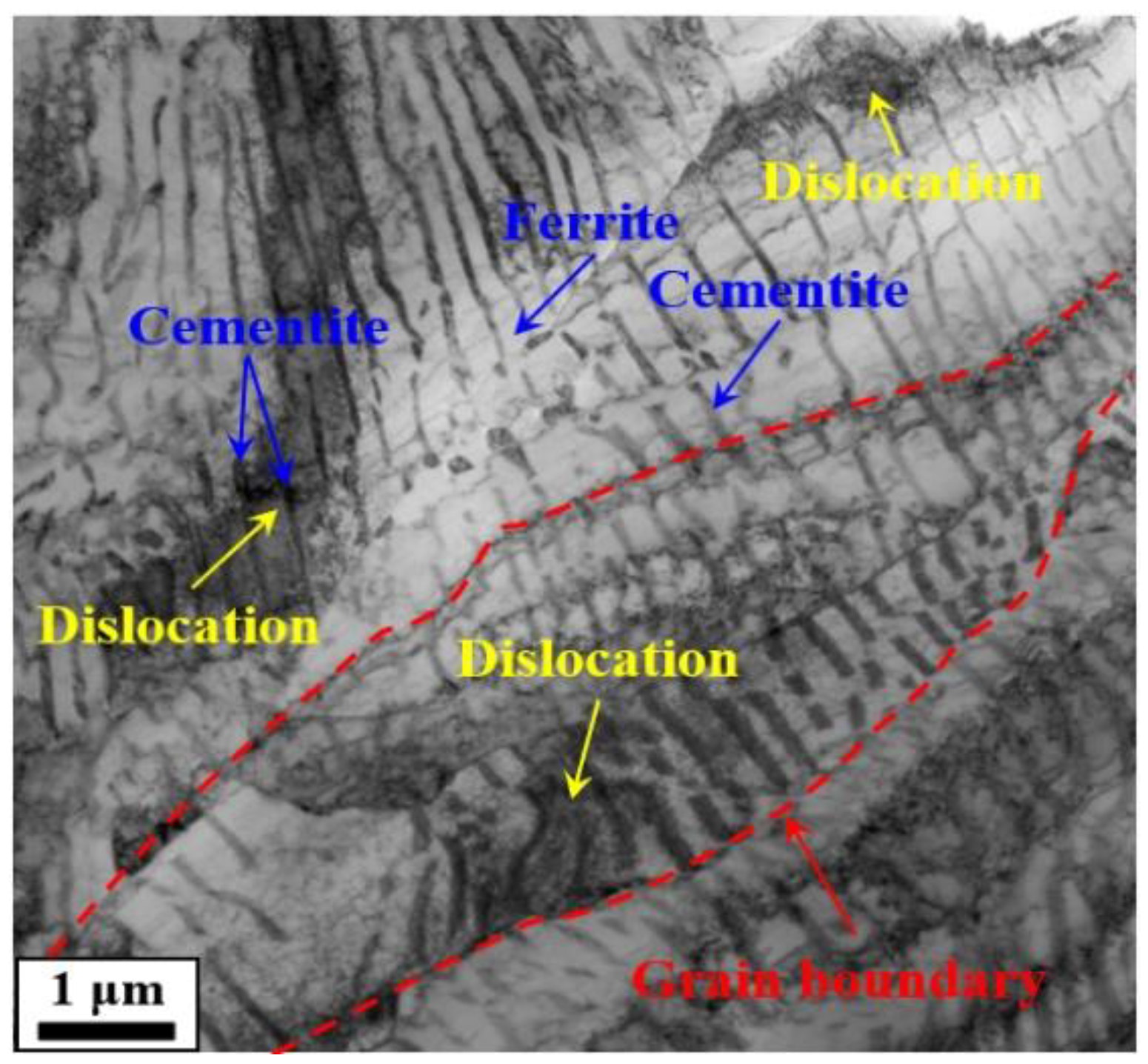

3.2. Microstructural Observation

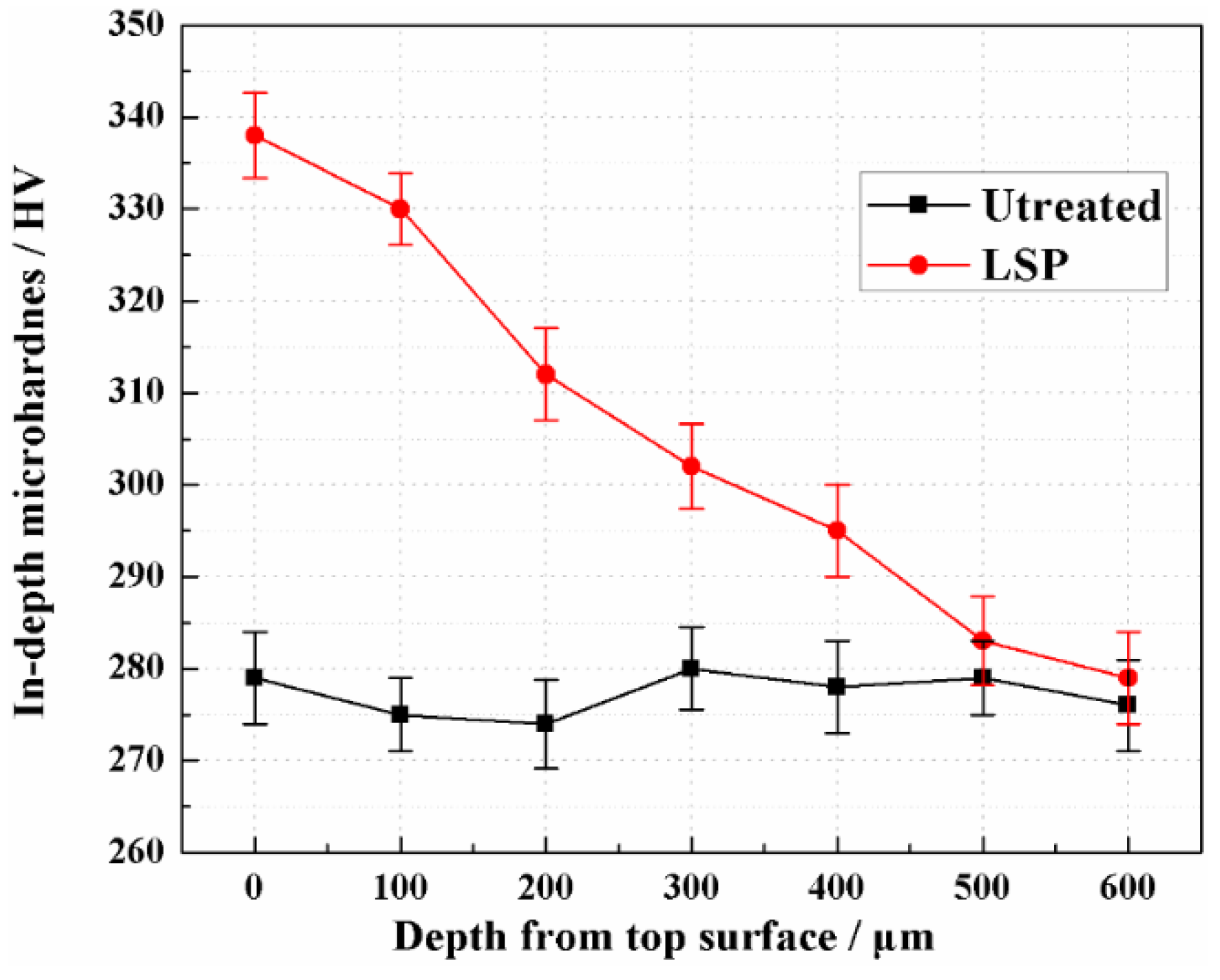

3.3. In-Depth Microhardness

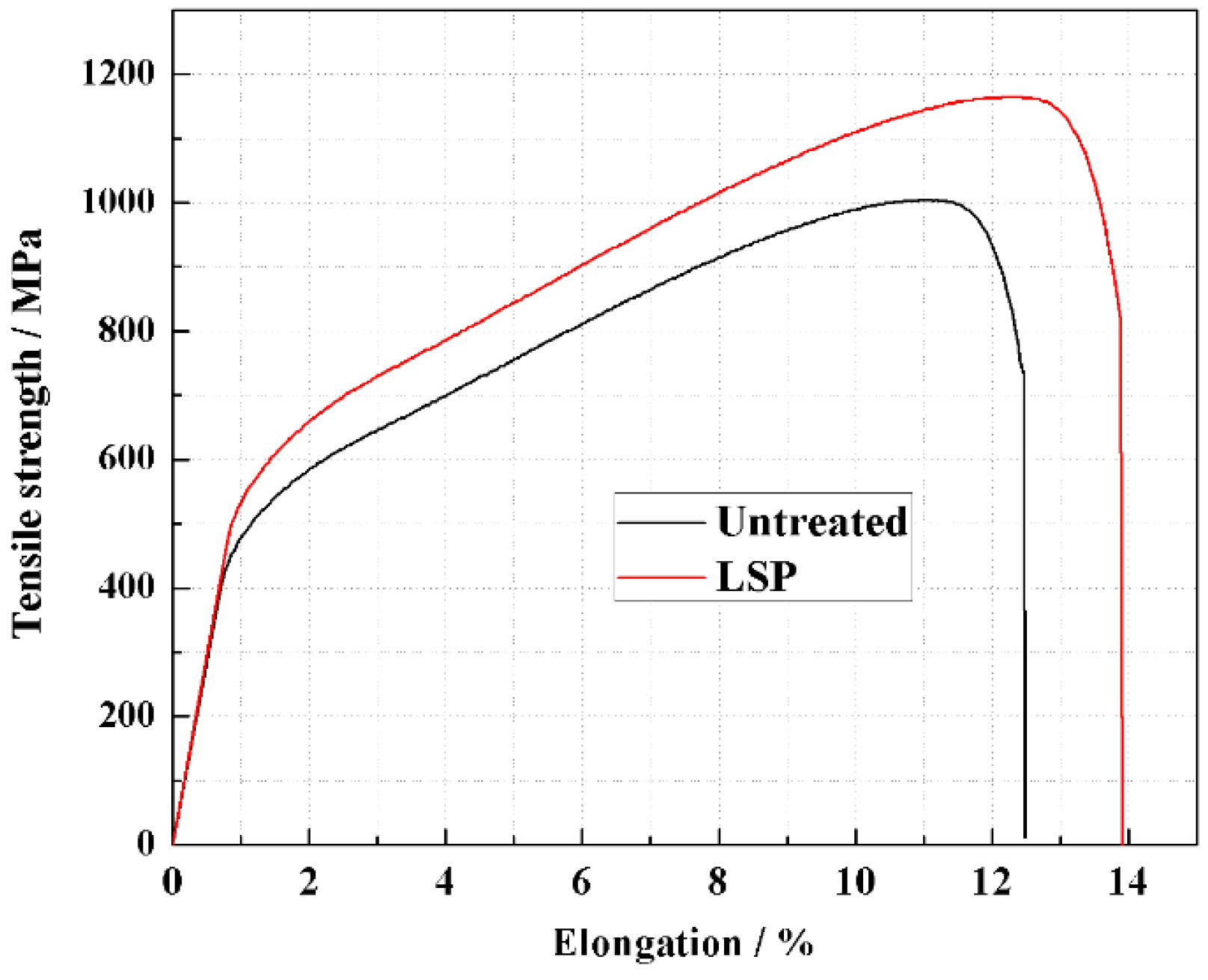

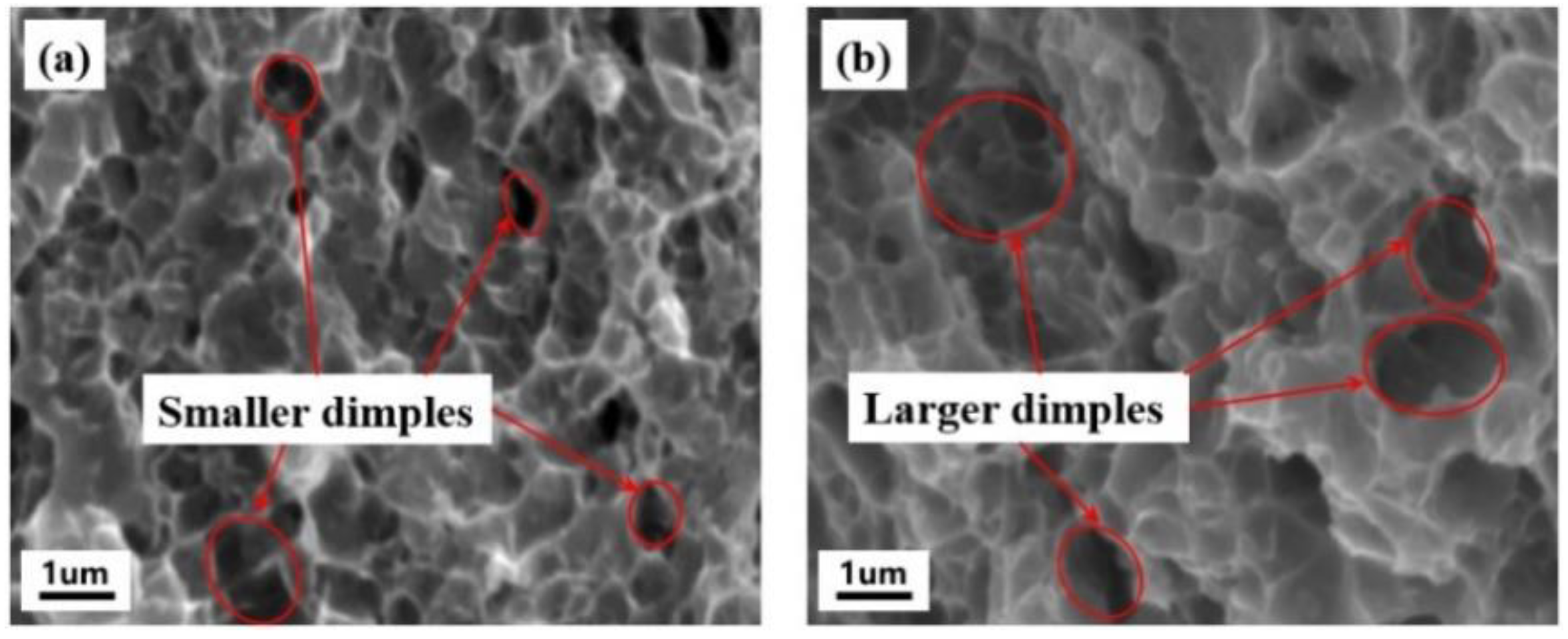

3.4. Tensile Strength and Elongation

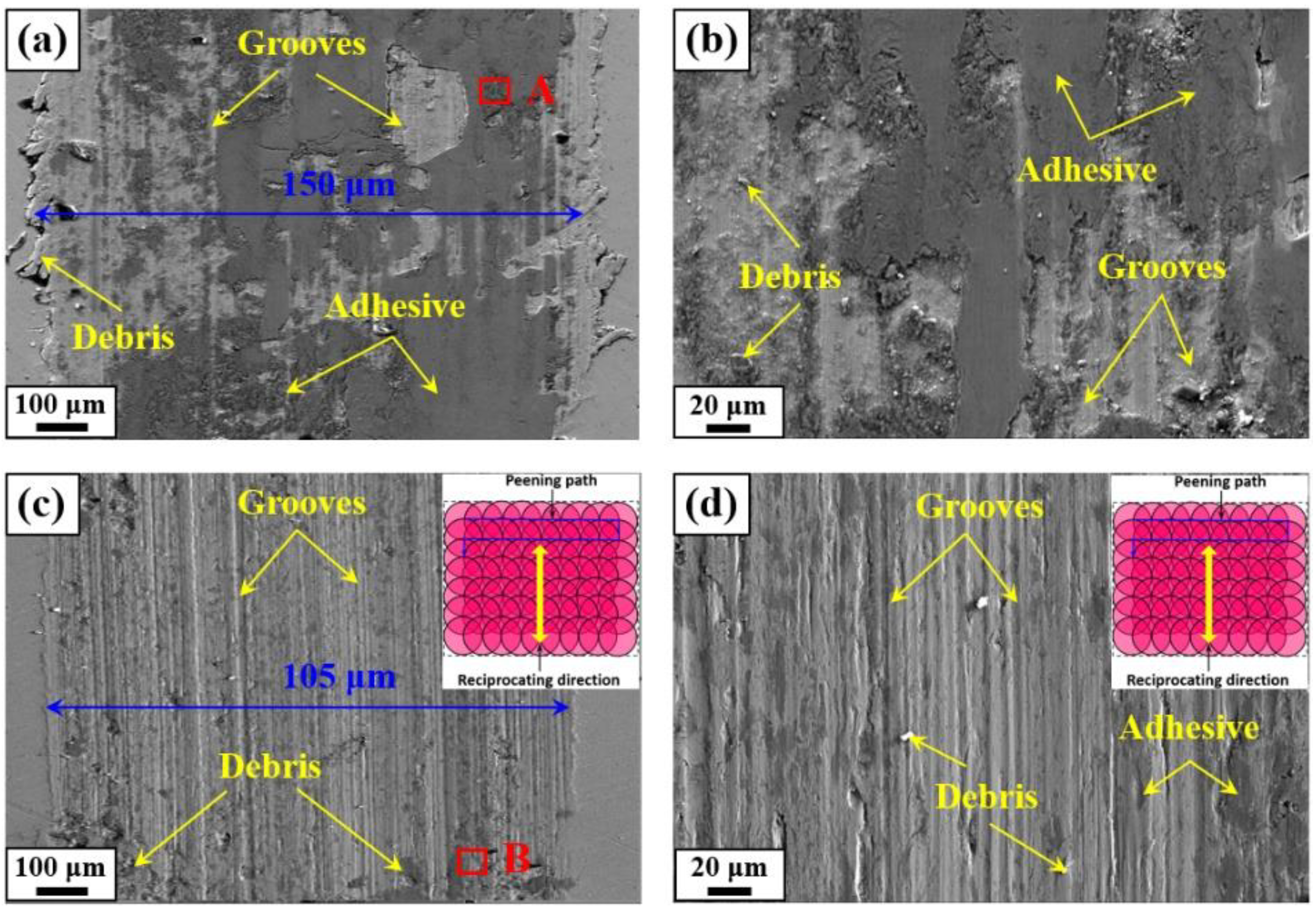

3.5. Wear Properties Analysis

3.6. Discussion

3.6.1. Microstructural Evolution Mechanism

3.6.2. Wear Mechanism

4. Conclusions

- (1)

- After laser shock peening, the surface state of the specimen changed from tensile stress to compressive stress, and the surface compressive residual stress measured parallel to the laser path reached −425 MPa. Meanwhile, the surface microhardness was 338 HV, which increased by 21.58% compared with the original sample. According to the test results of residual stress and microhardness in the depth direction, it was judged that the depth of the influence layer of LSP was about 600 μm.

- (2)

- Laser shock peening caused severe plastic deformation on the surface layer of the processed sample, which induced the proliferation of dislocations, the formation of deformation twins and the precipitation of carbide particles, and thus contributed to increasing the mechanical properties of treated 40CrMo steel.

- (3)

- After laser shock peening, the tensile strength increased by 15.9% and the elongation increased by 11.2%. The deformation twin boundaries induced by laser shock peening can both prevent the movement of dislocations and provide the paths for dislocation slip, which can contribute to the simultaneous enhancement of strength and plasticity.

- (4)

- Compared to the original specimen, the mass loss of the sample subjected to laser shock peening treatment reduced by 6.40%. Additionally, LSP changed the wear mechanism of 40CrMo steel from adhesive wear and severe abrasive wear to slight grooves-like abrasive wear. The high microhardness, beneficial microstructure and high magnitude of compressive residual stress induced by LSP were beneficial to provide the specimen with excellent wear resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thuong, L.V.; Trung, D.D.; Chau, H.V.; Thuan, H.M.; Ke, D.Q. Study on Plasma Nitriding Technology Imposed to Several Machine Parts Made of 40CrMo Steel; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Thuong, L.V.; Trung, D.D.; Chau, H.V.; Thuan, H.M.; Ke, D.Q. Optimizing plasma nitriding regime of 40CrMo steel on Eltropuls H045x080 device. Vietnam. Mech. Eng. Mag. 2012, 6, 62–69. [Google Scholar]

- Wang, X.; Chen, J.-G.; Su, G.-F.; Li, H.-Y.; Wang, C. Plastic damage evolution in structural steel and its non-destructive evaluation. J. Mater. Res. Technol. 2020, 9, 1189–1199. [Google Scholar] [CrossRef]

- Li, S.; Xie, X.; Cheng, C.; Tian, Q. A modified Coffin-Manson model for ultra-low cycle fatigue fracture of structural steels considering the effect of stress triaxiality. Eng. Fract. Mech. 2020, 237, 107223. [Google Scholar] [CrossRef]

- Yang, Y.; Cui, X.; Zhao, X.; Dong, M.; Zhou, J.; Jin, G. Surface nanocrystallized structural steel with enhanced tribological properties under different sliding conditions. Wear 2020, 460–461, 203429. [Google Scholar] [CrossRef]

- Sun, J.; Yang, C.; Guo, S.; Sun, X.; Ma, M.; Zhao, S.; Liu, Y. A novel process to obtain lamella structured low-carbon steel with bimodal grain size distribution for potentially improving mechanical property. Mater. Sci. Eng. A 2020, 785, 139339. [Google Scholar] [CrossRef]

- Tsuchiya, S.; Takahashi, K. Improving fatigue limit and rendering defects harmless through laser peening in additive-manufactured maraging steel. Metals 2022, 12, 49. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Z.; Shi, W.; Hua, G.; Qiu, M. Formation mechanism and weights analysis of residual stress holes in E690 high-strength steel by laser shock peening. Coatings 2022, 12, 285. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, Z.; Wan, Z.; Peng, P.; Zhang, H.; Sun, R.; Che, Z.; Guo, C.; Li, B.; Guo, W. Microstructure and mechanical properties of laser shock peened 38CrSi steel. Mater. Sci. Eng. A 2020, 788, 139486. [Google Scholar] [CrossRef]

- Wang, J.; Lu, Y.; Zhou, D.; Sun, L.; Xie, L.; Wang, J. Mechanical properties and microstructural response of 2A14 aluminum alloy subjected to multiple laser shock peening impacts. Vacuum 2019, 165, 193–198. [Google Scholar] [CrossRef]

- Liu, P.; Sun, S.; Xu, S.; Li, Y.; Ren, G. Microstructure and properties in the weld surface of friction stir welded 7050-T7451 aluminium alloys by laser shock peening. Vacuum 2018, 152, 25–29. [Google Scholar] [CrossRef]

- Lan, L.; Jin, X.; Gao, S.; He, B.; Rong, Y. Microstructural evolution and stress state related to mechanical properties of electron beam melted Ti-6Al-4V alloy modified by laser shock peening. J. Mater. Sci. Technol. 2020, 50, 153–161. [Google Scholar] [CrossRef]

- Wang, C.; Luo, K.; Bu, X.; Su, Y.; Cai, J.; Zhang, Q.; Lu, J. Laser shock peening-induced surface gradient stress distribution and extension mechanism in corrosion fatigue life of AISI 420 stainless steel. Corros. Sci. 2020, 177, 109027. [Google Scholar] [CrossRef]

- Pant, B.; Pavan, A.; Prakash, R.V.; Kamaraj, M. Effect of laser peening and shot peening on fatigue striations during FCGR study of Ti6Al4V. Int. J. Fatigue 2016, 93, 38–50. [Google Scholar] [CrossRef]

- Pavan, M.; Furfari, D.; Ahmad, B.; Gharghouri, M.; Fitzpatrick, M. Fatigue crack growth in a laser shock peened residual stress field. Int. J. Fatigue 2019, 123, 157–167. [Google Scholar] [CrossRef]

- Lu, H.; Wang, Z.; Cai, J.; Xu, X.; Luo, K.; Wu, L.; Lu, J. Effects of laser shock peening on the hot corrosion behaviour of the selective laser melted Ti6Al4V titanium alloy. Corros. Sci. 2021, 188, 109558. [Google Scholar] [CrossRef]

- Ye, C.; Suslov, S.; Lin, D.; Liao, Y.; Cheng, G.J. Cryogenic ultrahigh strain rate deformation induced hybrid nanotwinned microstructure for high strength and high ductility. J. Appl. Phys. 2014, 115, 213519. [Google Scholar] [CrossRef]

- Liu, L.; Chi, R. Effect of microstructure on high cycle fatigue behavior of brass processed by laser shock peening. Mater. Sci. Eng. A 2018, 740–741, 342–352. [Google Scholar] [CrossRef]

- Shi, X.; Feng, X.; Teng, J.; Zhang, K.; Zhou, L. Effect of laser shock peening on microstructure and fatigue properties of thin-wall welded Ti-6A1-4V alloy. Vacuum 2021, 184, 109986. [Google Scholar] [CrossRef]

- Liu, H.; Hu, Y.; Wang, X.; Shen, Z.; Li, P.; Gu, C.; Du, D.; Guo, C. Grain refinement progress of pure titanium during laser shock forming (LSF) and mechanical property characterizations with nanoindentation. Mater. Sci. Eng. A 2013, 564, 13–21. [Google Scholar] [CrossRef]

- Lu, J.; Luo, K.; Zhang, Y.; Sun, G.; Gu, Y.; Zhou, J.; Ren, X.; Zhang, X.; Zhang, L.; Chen, K.; et al. Grain refinement mechanism of multiple laser shock processing impacts on ANSI 304 stainless steel. Acta Mater. 2010, 58, 5354–5362. [Google Scholar] [CrossRef]

- Ye, C.; Suslov, S.; Kim, B.J.; Stach, E.A.; Cheng, G.J. Fatigue performance improvement in AISI 4140 steel by dynamicstrain aging and dynamic precipitation during warm laser shock peening. Acta Mater. 2011, 59, 1014–1025. [Google Scholar] [CrossRef]

- Gu, K.; Zhang, H.; Zhao, B.; Wang, J.; Zhou, Y.; Li, Z. Effect of cryogenic treatment and aging treatment on the tensile properties and microstructure of Ti–6Al–4V alloy. Mater. Sci. Eng. A 2013, 584, 170–176. [Google Scholar] [CrossRef]

- Li, G.; Cheng, J.; Wang, H.; Li, C. The influence of cryogenic-aging circular treatment on the microstructure and properties of aluminum matrix composites. J. Alloy. Compd. 2017, 695, 1930–1945. [Google Scholar] [CrossRef]

- Wang, H.; Kalchev, Y.; Wang, H.; Yan, K.; Gurevich, E.; Ostendorf, A. Surface modification of NiTi alloy by ultrashort pulsed laser shock peening. Surf. Coatings Technol. 2020, 394, 125899. [Google Scholar] [CrossRef]

- Lin, Y.; Cai, Z.-B.; Li, Z.-Y.; Yin, M.-G.; Wang, W.-J.; He, W.-F.; Zhou, Z.-R. Study on the abrasive wear behavior of laser shock peening Ti-6Al-4V titanium alloy under controlled cycling impact. Wear 2019, 426–427, 112–121. [Google Scholar] [CrossRef]

| Elements | Cr | Mo | Si | Mn | C | Impurity | Fe |

|---|---|---|---|---|---|---|---|

| (Wt%) | 1.35 | 0.25 | 0.25 | 0.55 | 0.38 | ≤0.07 | Bal. |

| Property | Value |

|---|---|

| Modulus of elasticity E (GPa) | 206 |

| Ultimate tensile strength σb (MPa) | 1005 |

| Tensile yield strength σ0.2 (MPa) | 425 |

| Elongation at break δ (%) | 12.5 |

| Poisson’s ratio | 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, X.; Gu, Z.; Qiu, H.; Feng, A.; Li, J. Study of the Mechanical Properties and Microstructural Response with Laser Shock Peening on 40CrMo Steel. Metals 2022, 12, 1034. https://doi.org/10.3390/met12061034

Pan X, Gu Z, Qiu H, Feng A, Li J. Study of the Mechanical Properties and Microstructural Response with Laser Shock Peening on 40CrMo Steel. Metals. 2022; 12(6):1034. https://doi.org/10.3390/met12061034

Chicago/Turabian StylePan, Xiaoming, Zhiyang Gu, Hui Qiu, Aixin Feng, and Jing Li. 2022. "Study of the Mechanical Properties and Microstructural Response with Laser Shock Peening on 40CrMo Steel" Metals 12, no. 6: 1034. https://doi.org/10.3390/met12061034

APA StylePan, X., Gu, Z., Qiu, H., Feng, A., & Li, J. (2022). Study of the Mechanical Properties and Microstructural Response with Laser Shock Peening on 40CrMo Steel. Metals, 12(6), 1034. https://doi.org/10.3390/met12061034