Effect of Uniform and Non-Uniform Increasing Casting Flow Rate on Dispersion and Outflow Percentage of Tracers in Four Strand Tundishes under Strand Blockage Conditions

Abstract

:1. Introduction

2. Experimental Methods

2.1. Physical Modelling

2.2. CFD (Computational Fluid Dynamics) Modelling and Solution

2.2.1. Model Assumptions

- Both water and passive scalar were assumed to be in the liquid phase;

- In order to study the flow characteristics and outflow percentages, for simplicity, the thermal buoyancy is neglected, i.e., the liquid flow was assumed to be isothermal;

- For the same reason, chemical reaction in the tundish is not considered;

- The free surface is kept at a fixed level and the slag layer is not included in the tundish.

2.2.2. Governing Equations

2.2.3. Turbulence Model

2.2.4. Tracer Transport Model

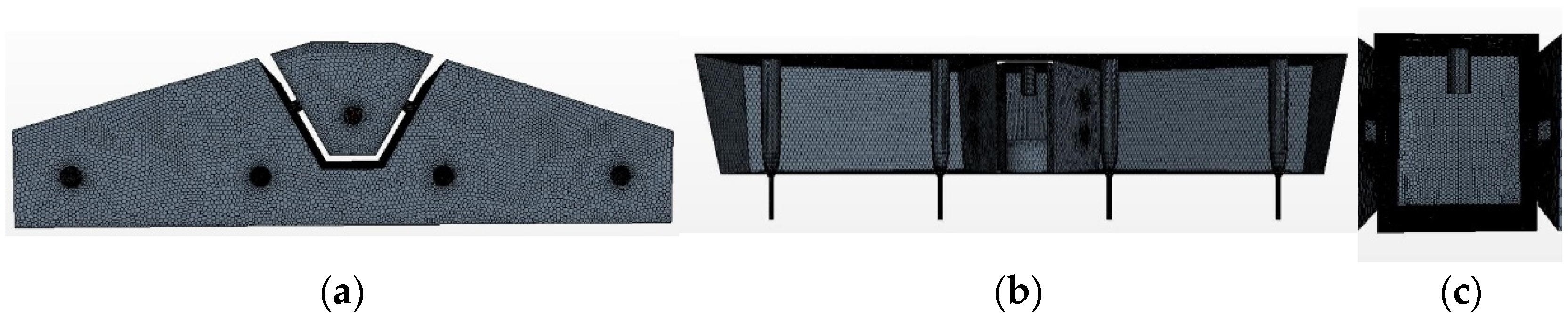

2.2.5. Mesh

2.2.6. Boundary Conditions

- No-slip conditions were applied at all solid surfaces for the liquid phase;

- A constant inlet velocity was used, and the inlet velocity was 0.58 m/s;

- At the tundish outlet, the outflow boundary with constant mass flow rate condition was applied;

- The outlet pressure was set to a constant value of one standard atmosphere;

- The roughness of turbulence inhibitor, inlet ladle shroud, stopper rod and raised part of the tundish bottom near the stopper rod were set as 1 × 10−5 m, Furthermore, the roughness in other solid walls was set as 2 × 10−6 m.

2.2.7. Initial Conditions

2.2.8. Solution Procedure

2.3. Analytical Method

3. Results and Discussion

3.1. Verification and Validation

3.1.1. Independent of Computational Mesh

3.1.2. Model Validation

- (1)

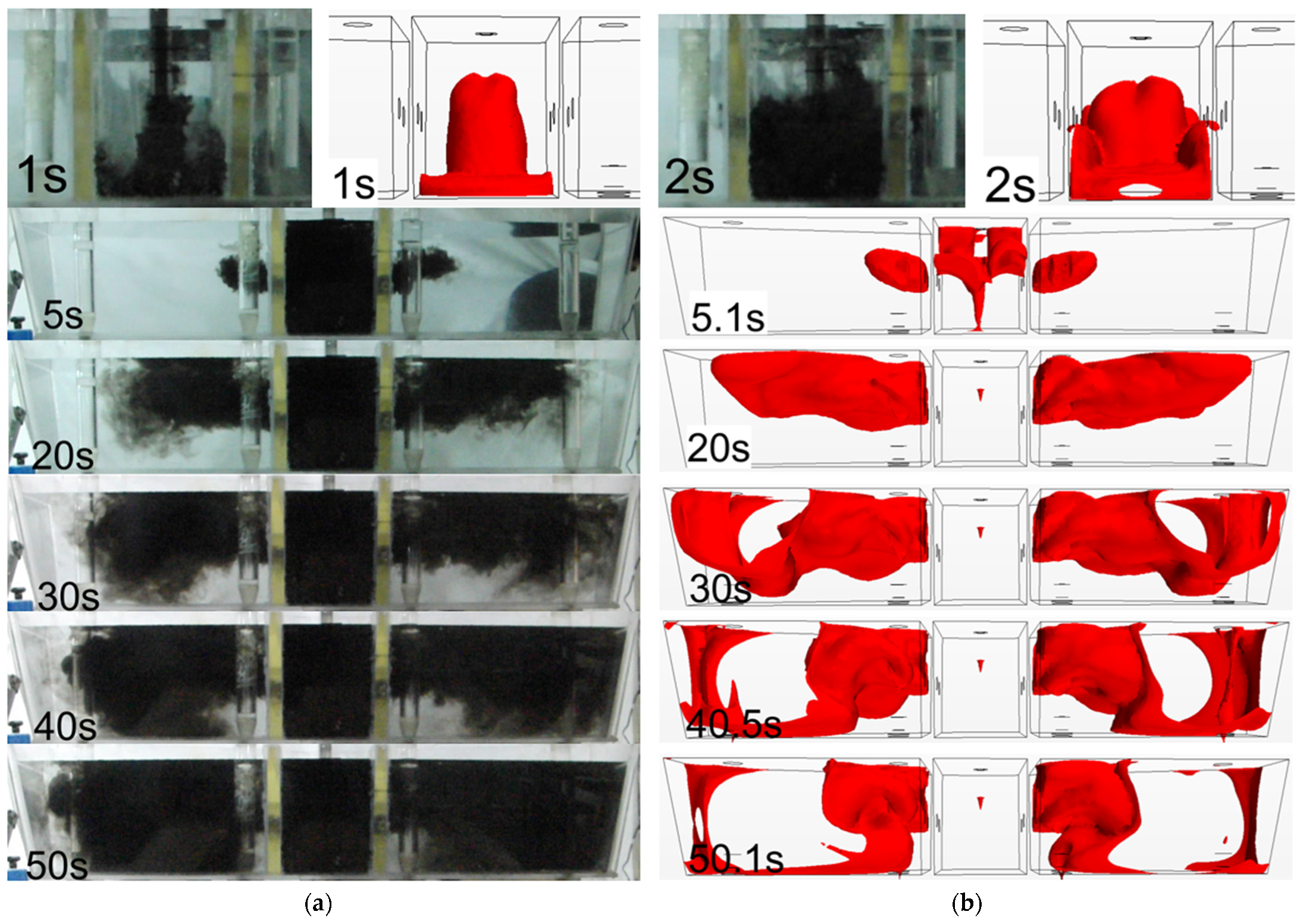

- Black ink dispersion validation

- (2)

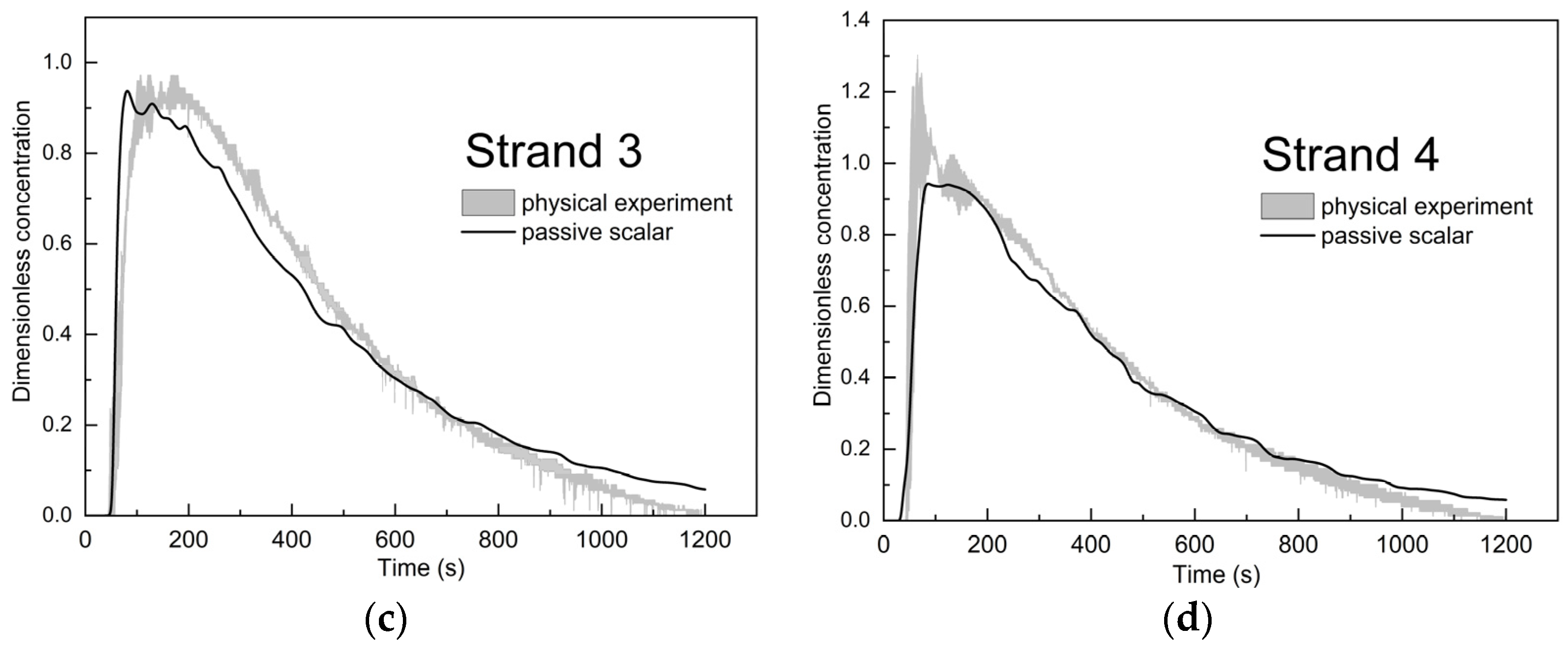

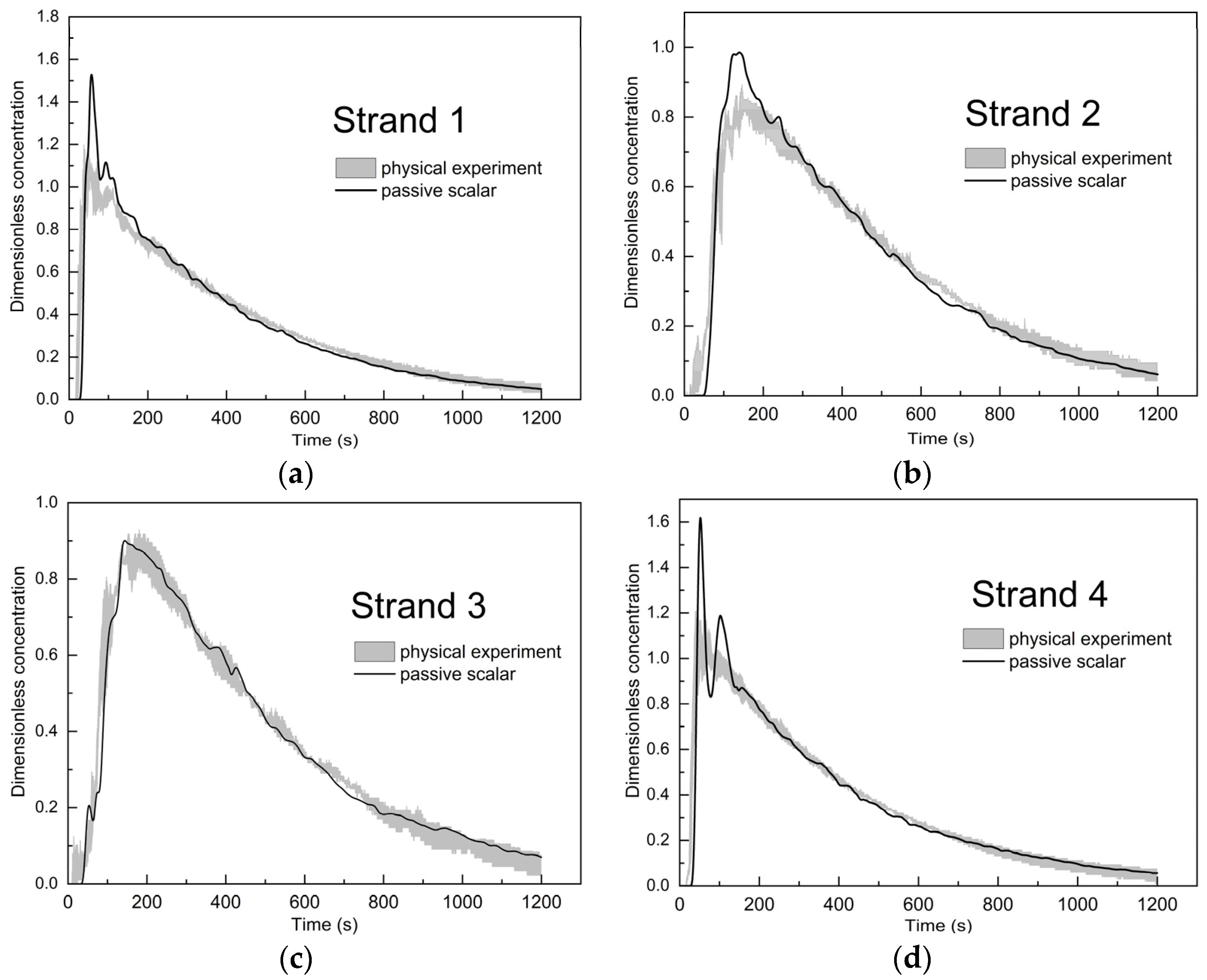

- RTD validation

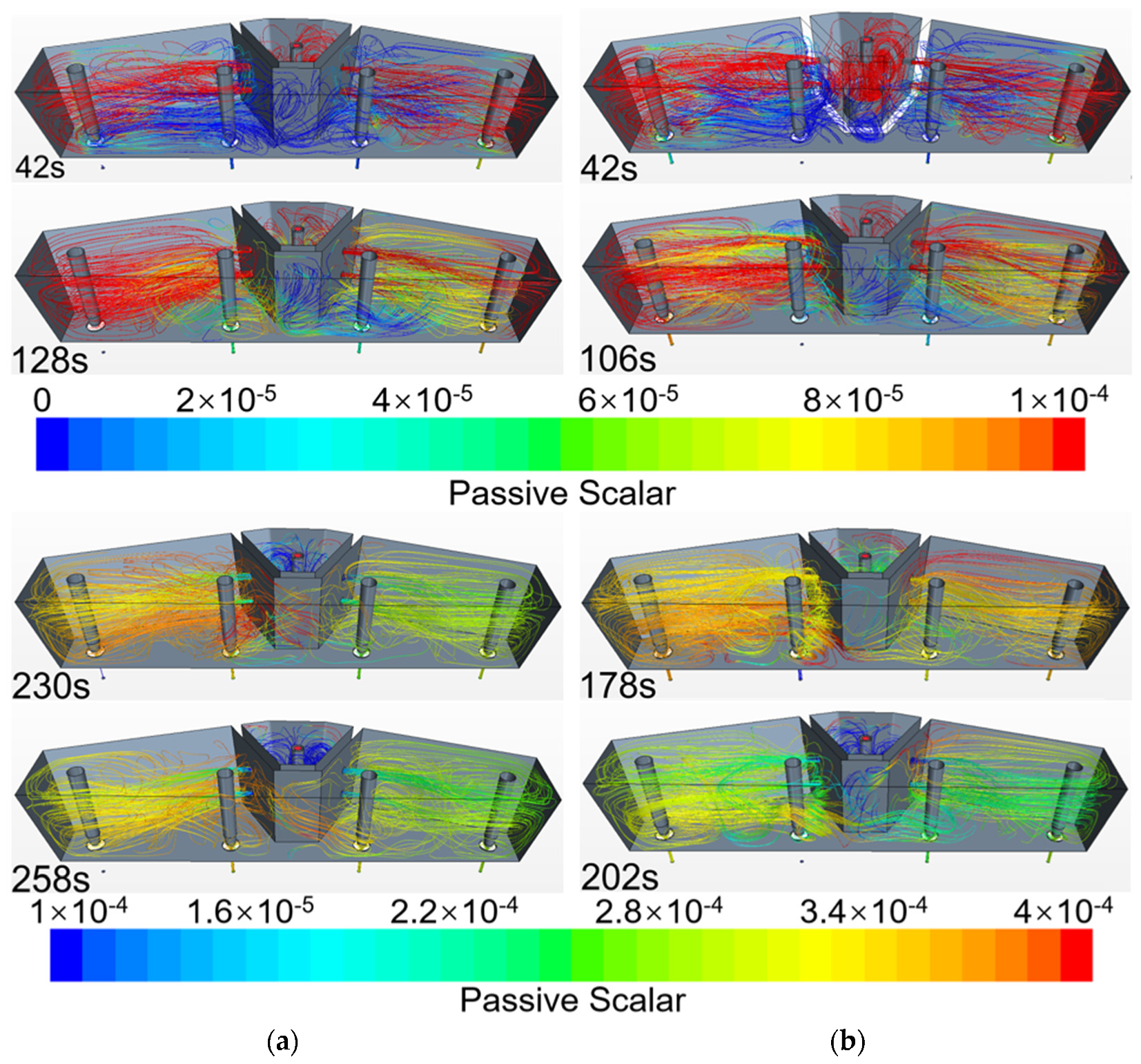

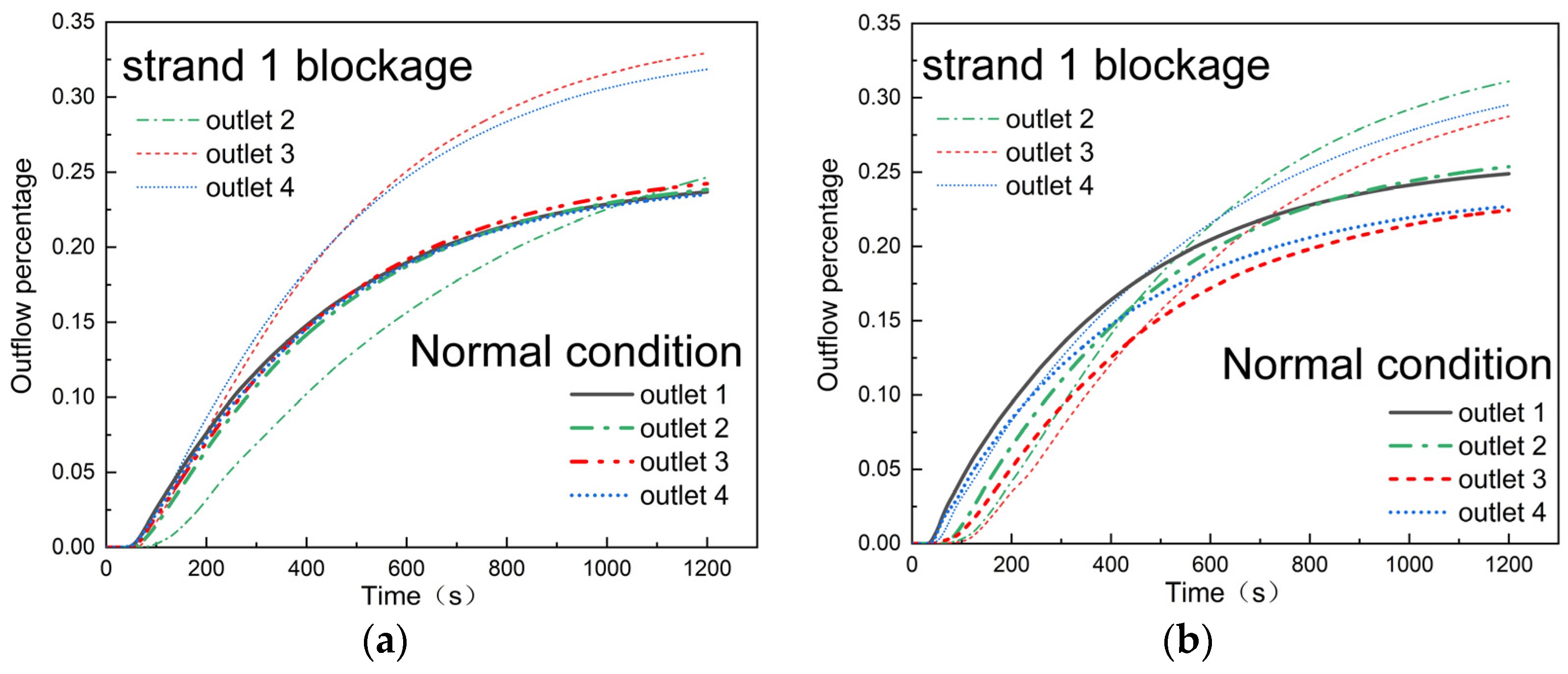

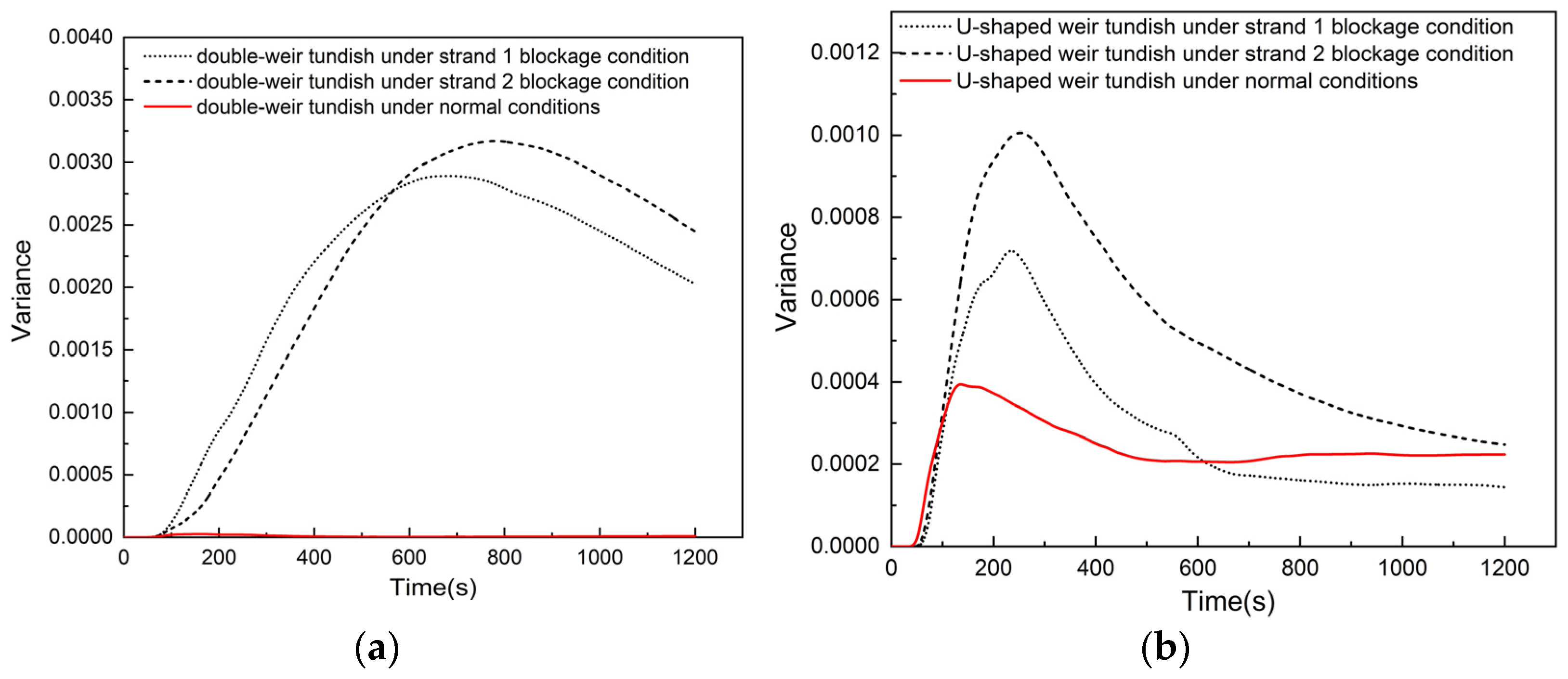

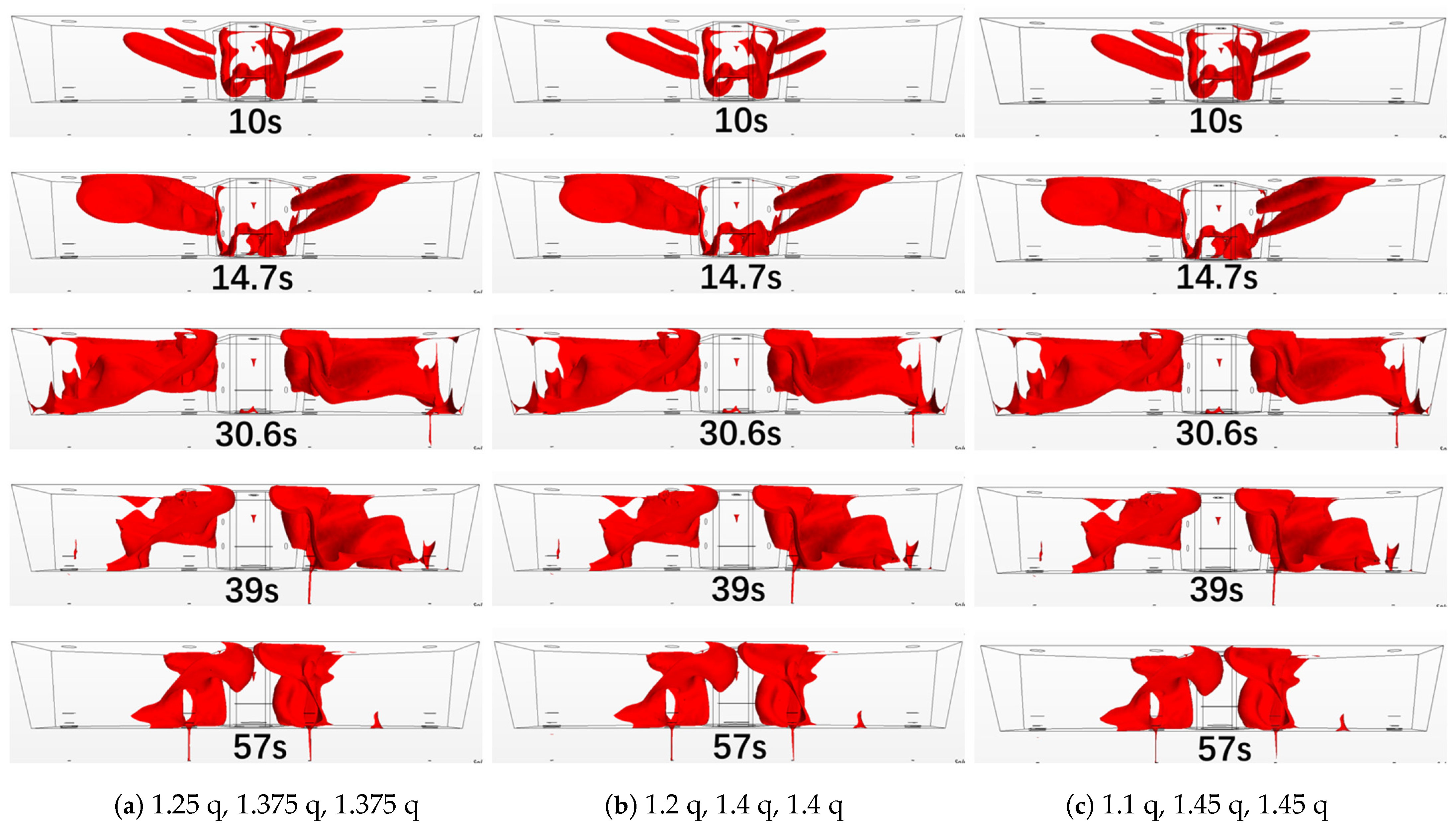

3.2. Fluid Flow and Tracer Dispersion in Tundishes under Single-Strand Blockage Conditions

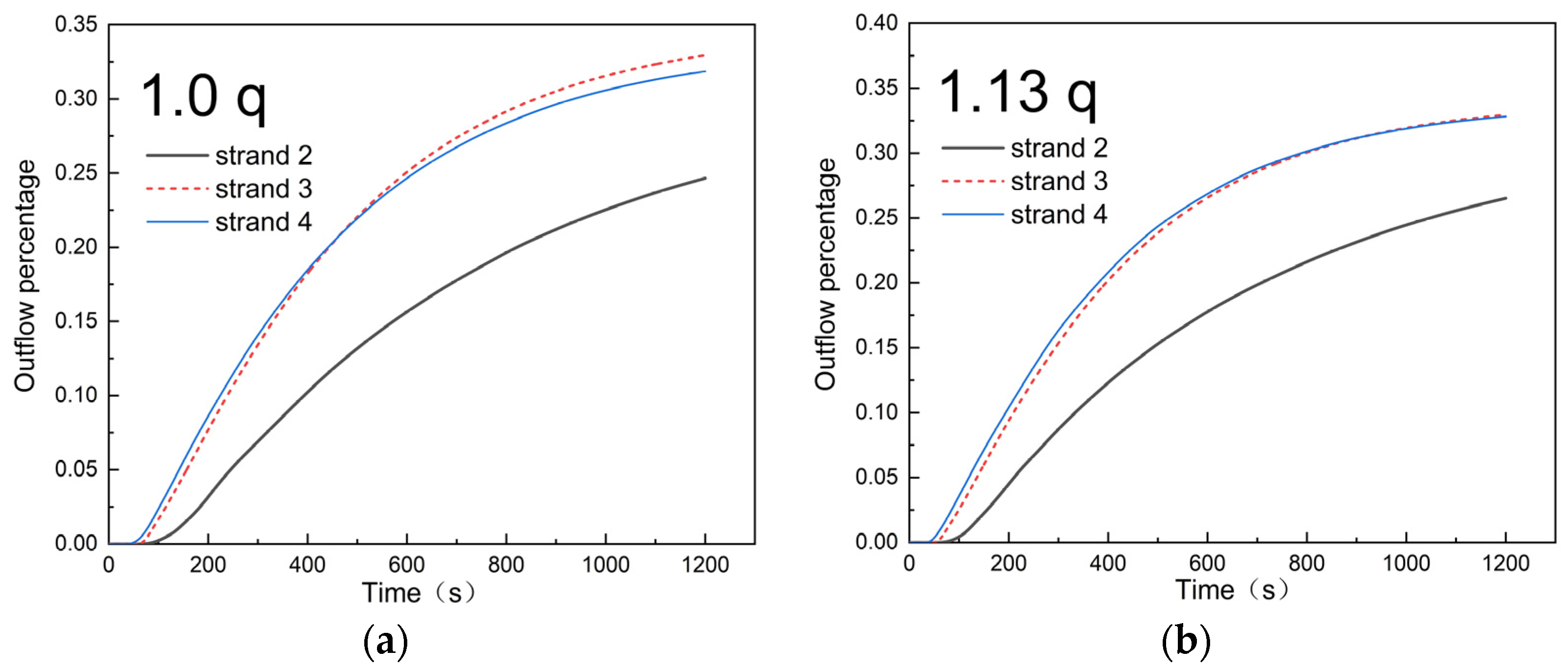

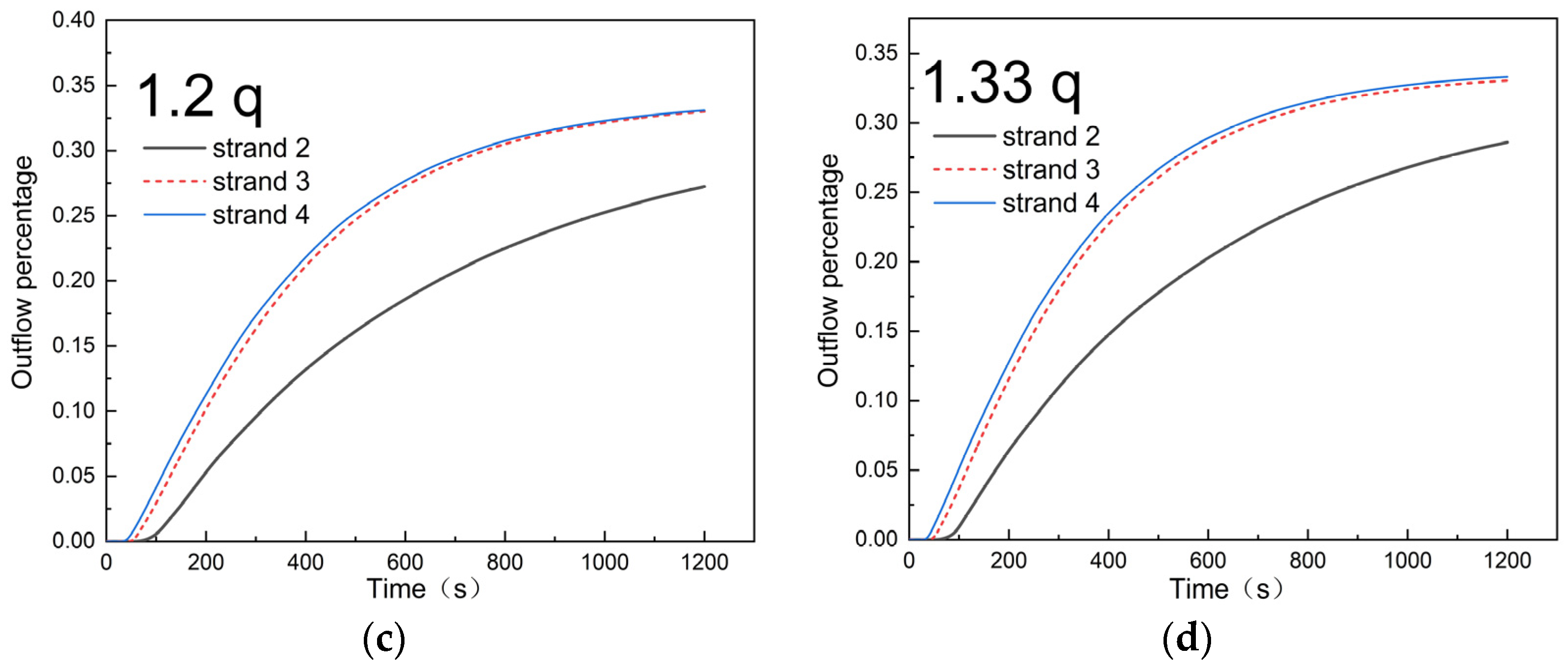

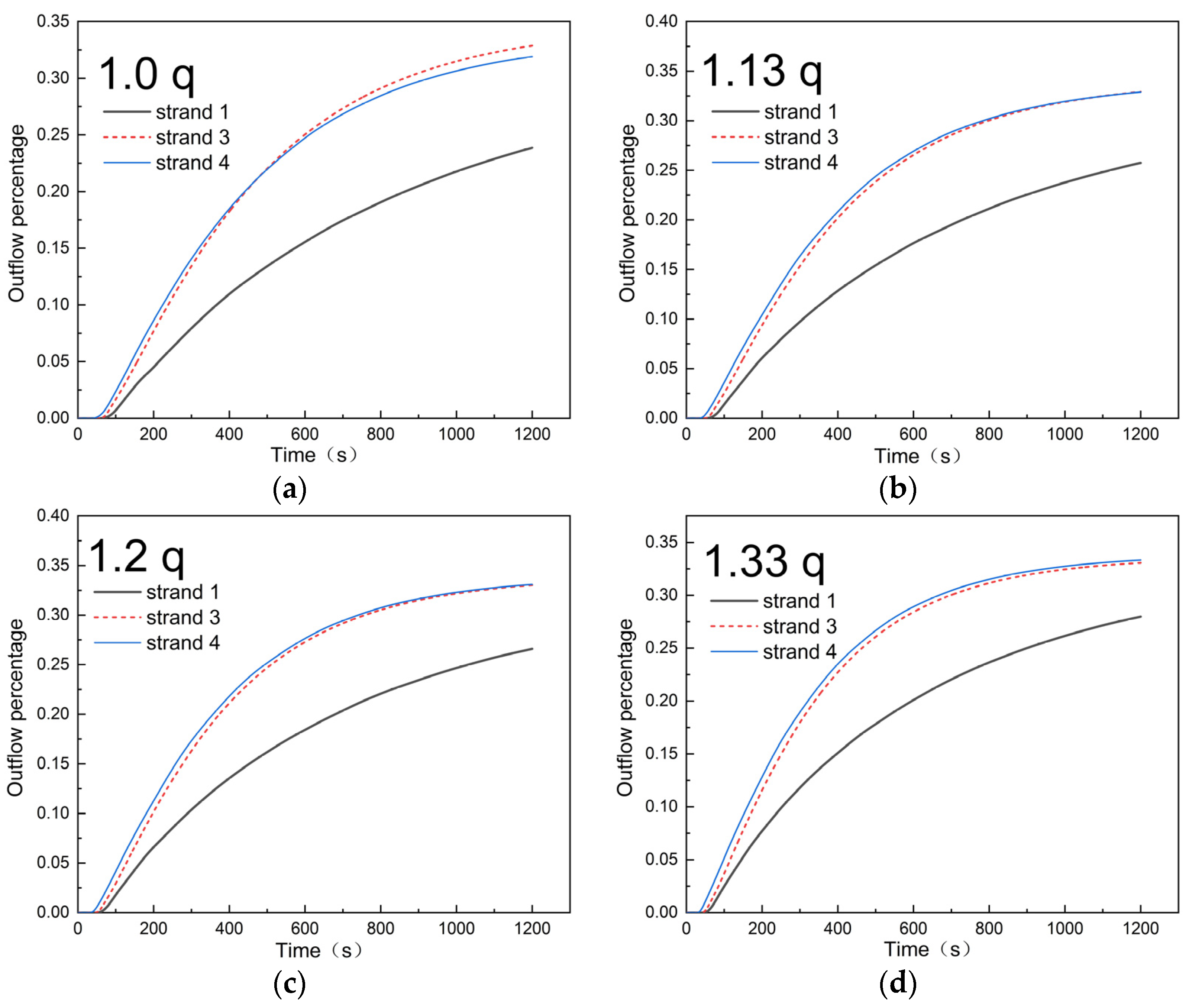

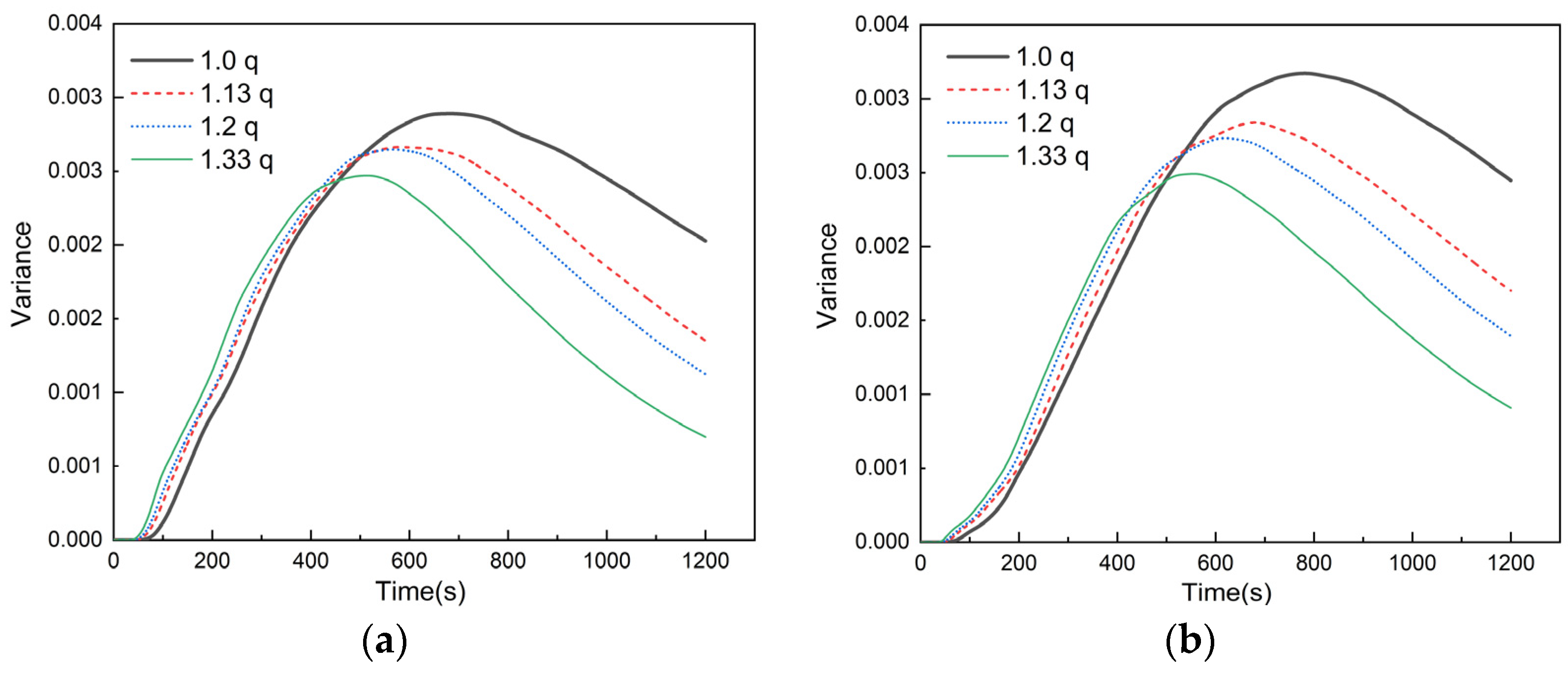

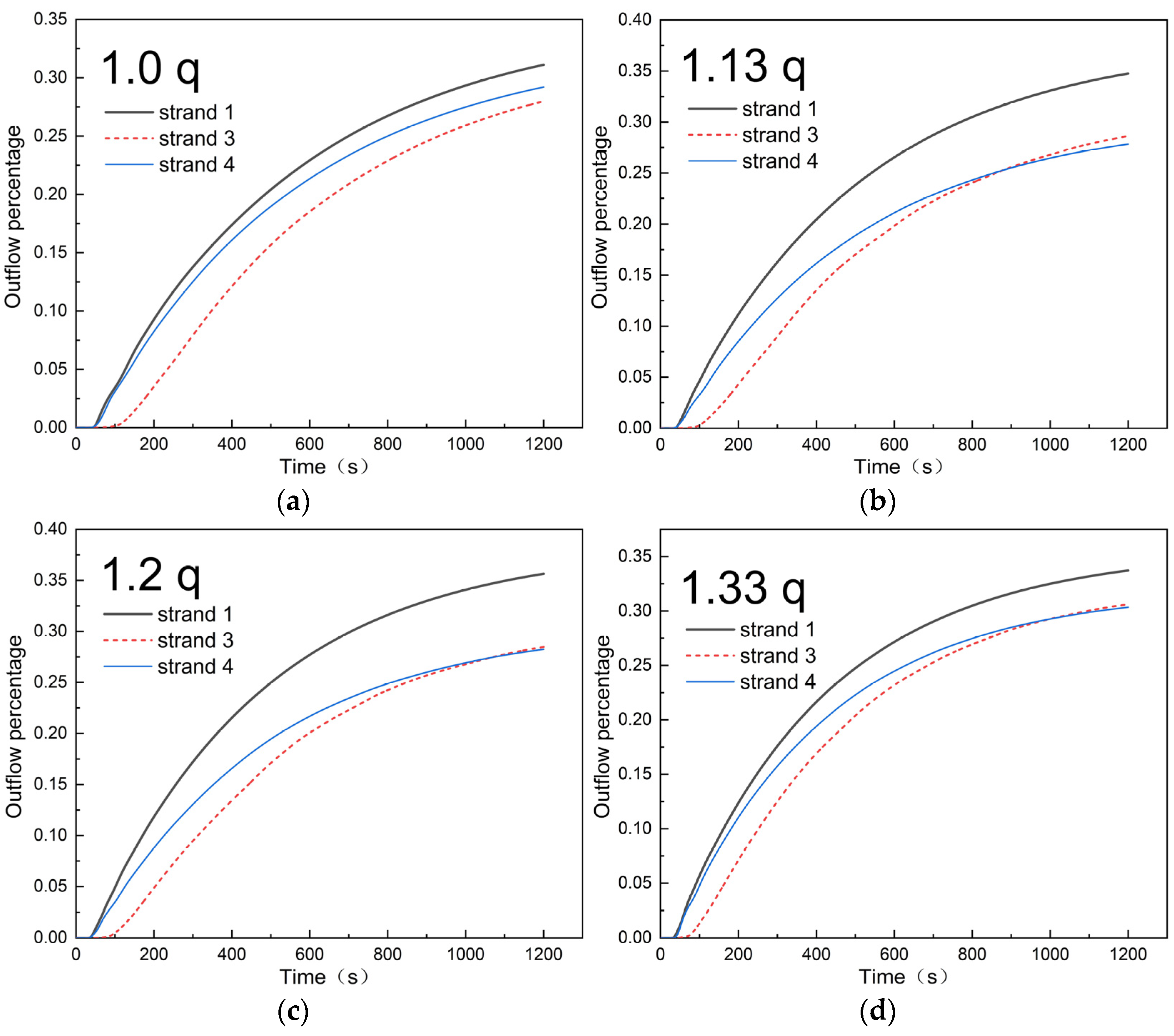

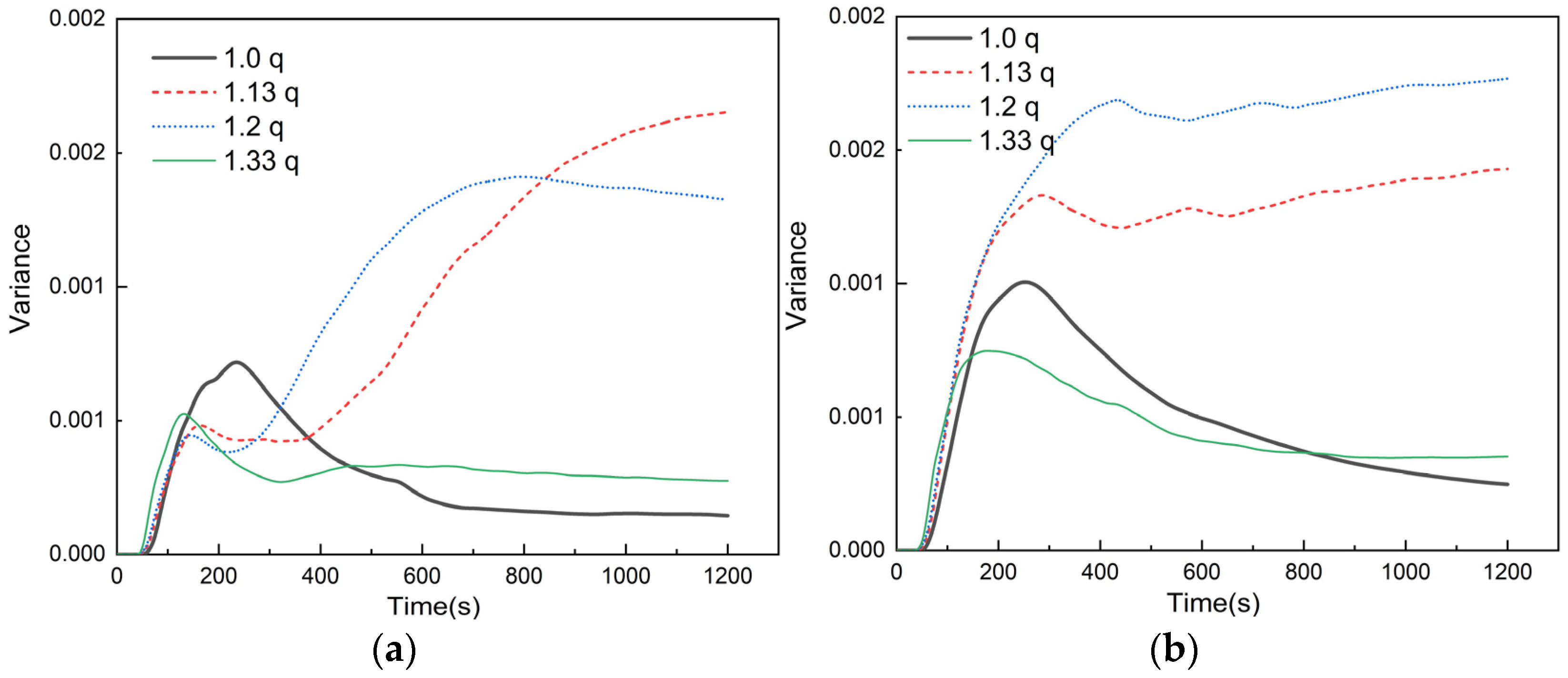

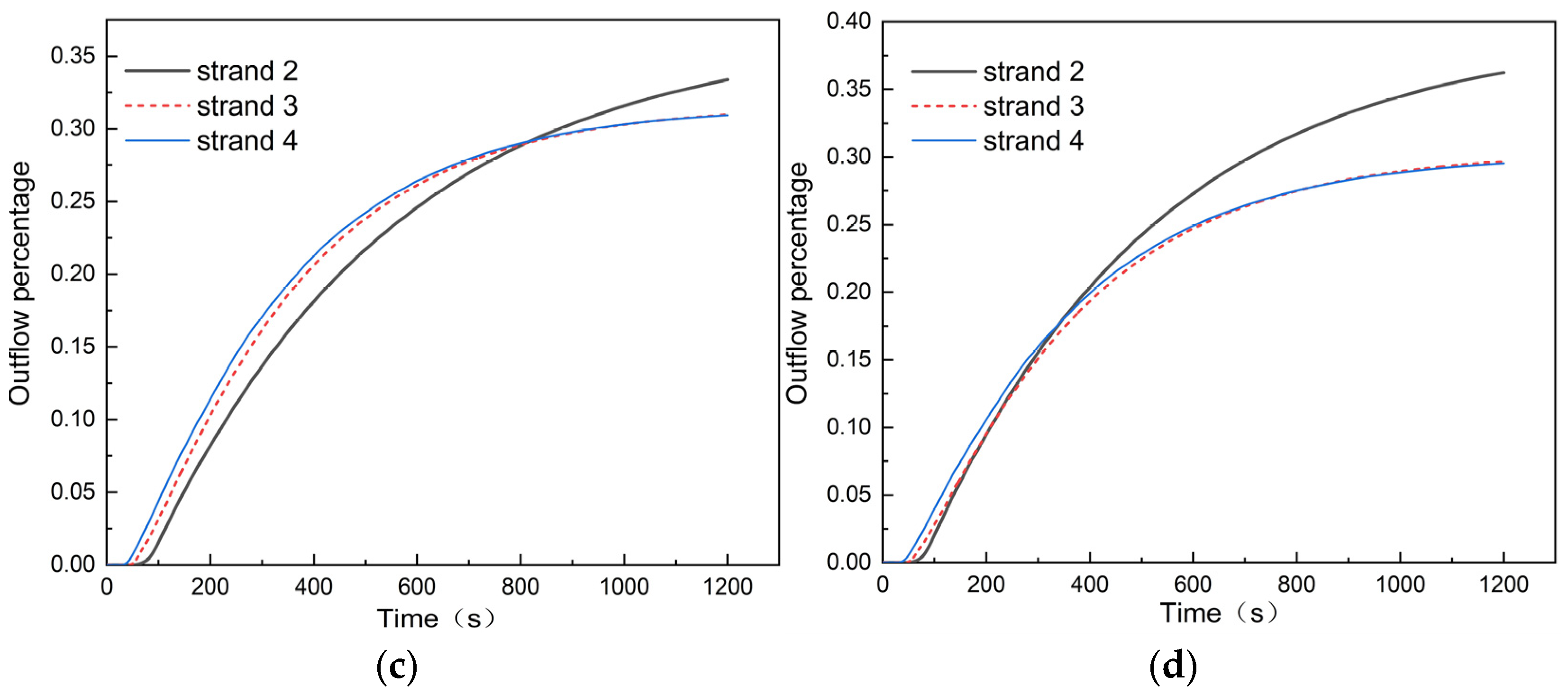

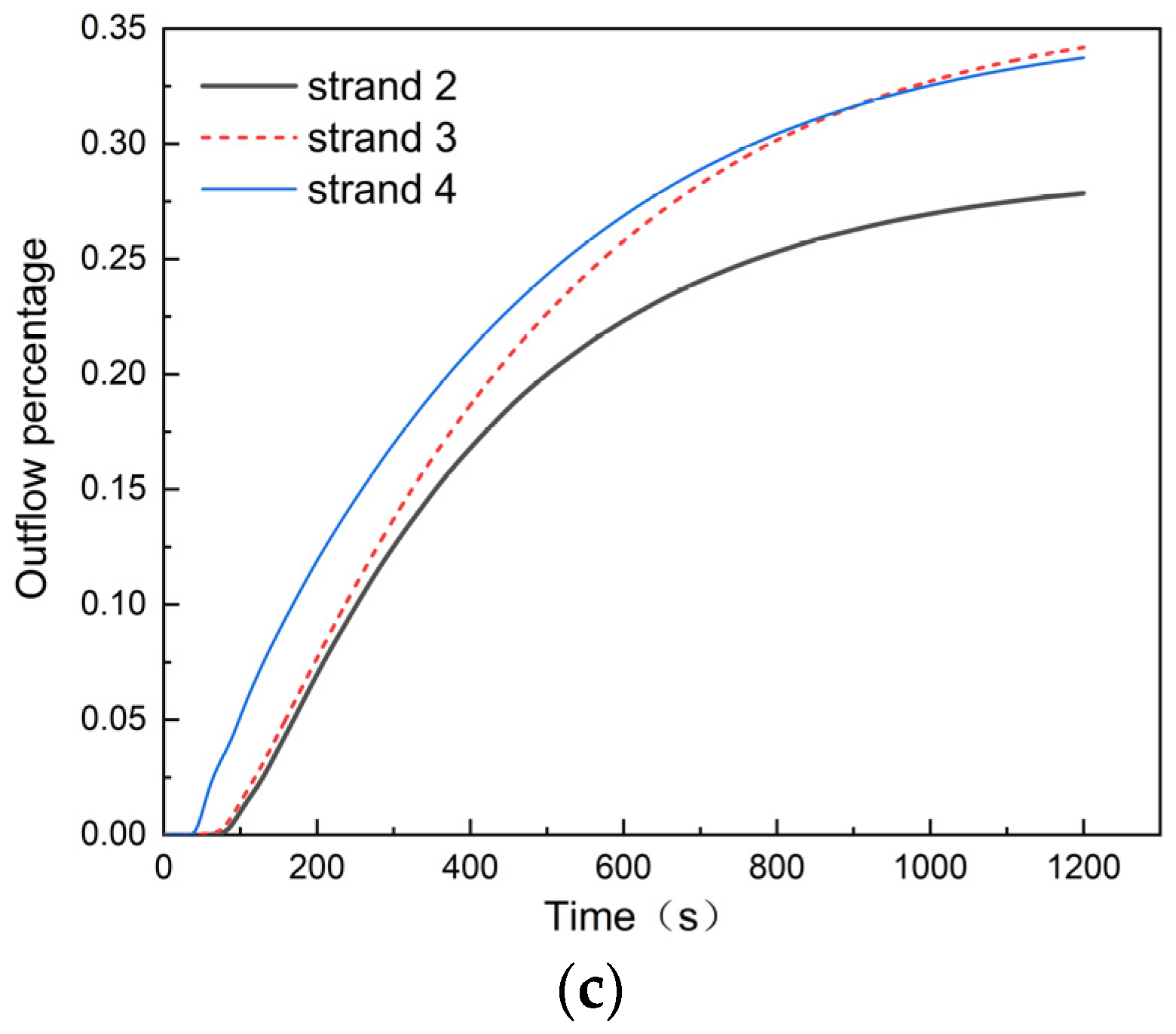

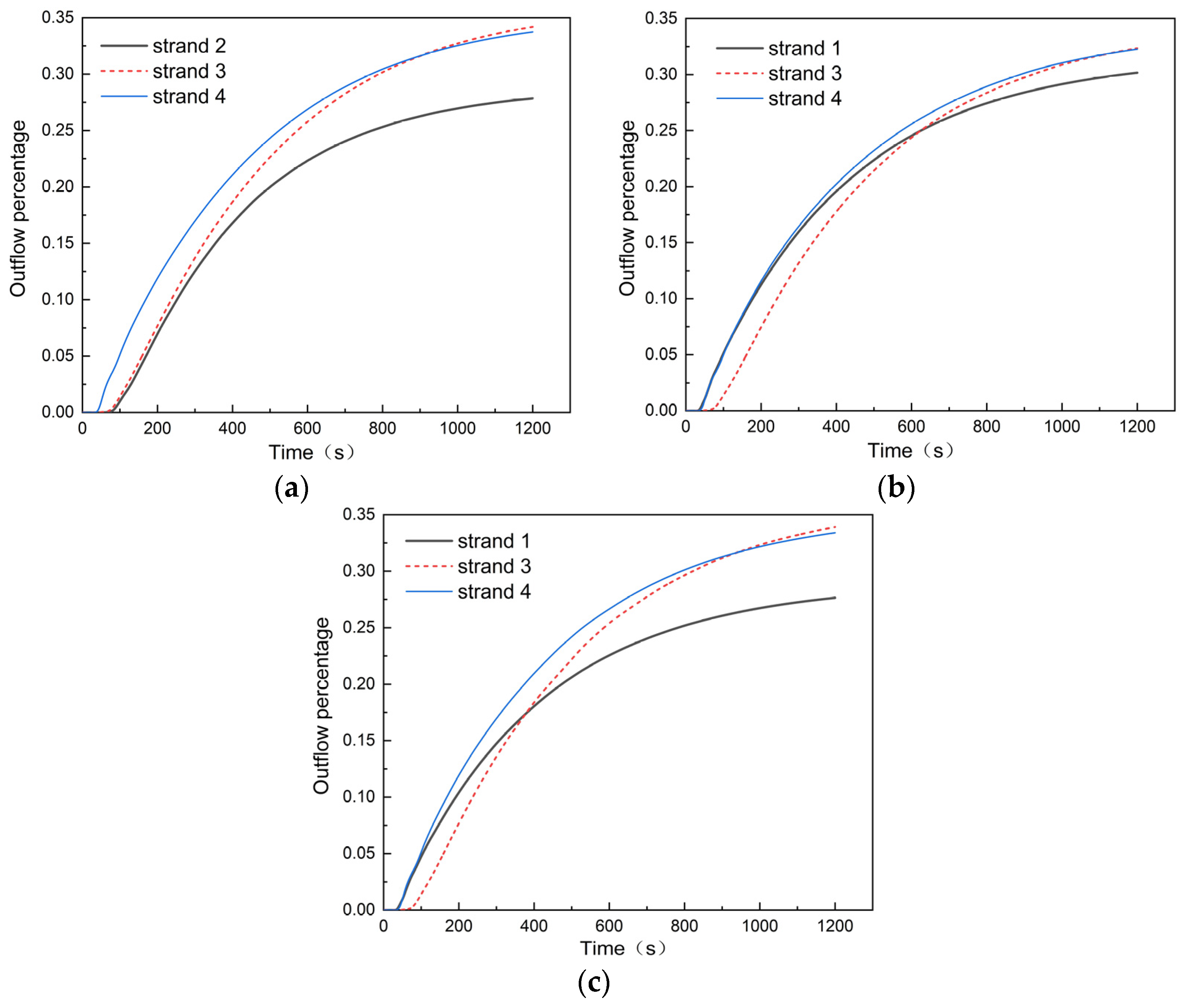

3.3. Dispersion and Outflow Percentage of Tracers under Single-Strand Blockage Conditions with Uniform Increasing Casting Flow Rate

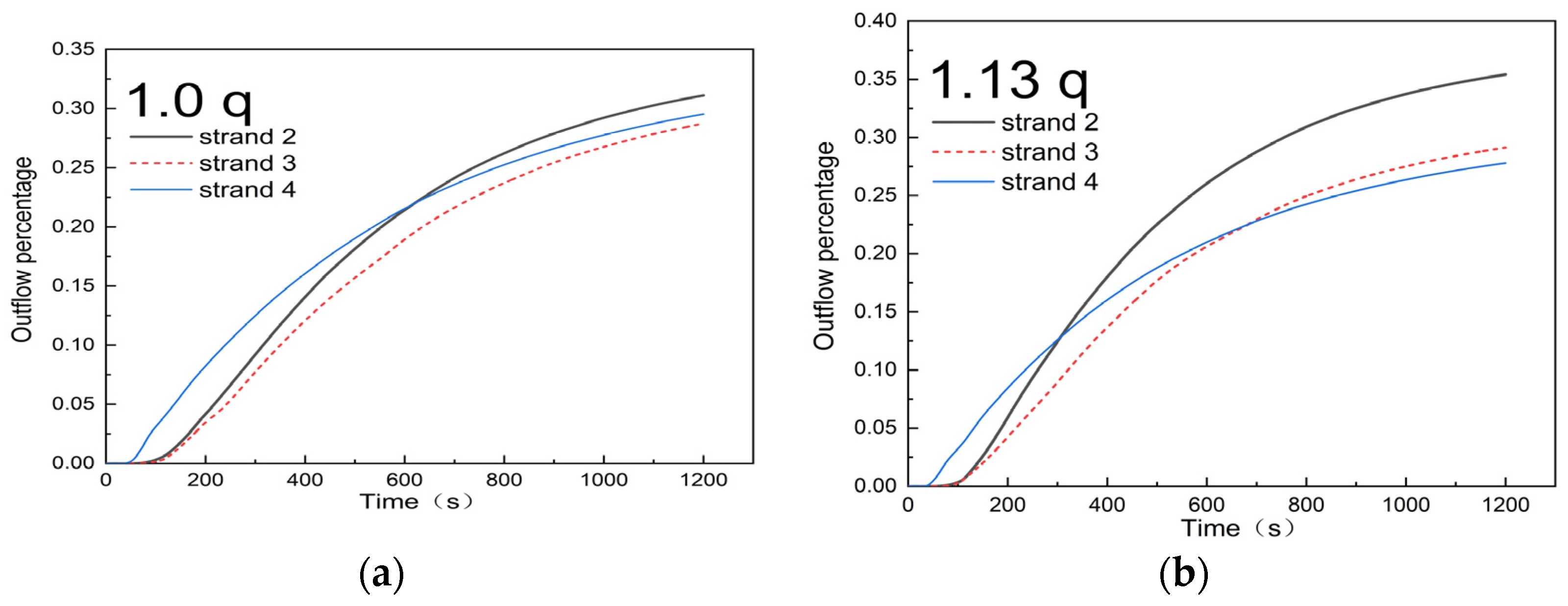

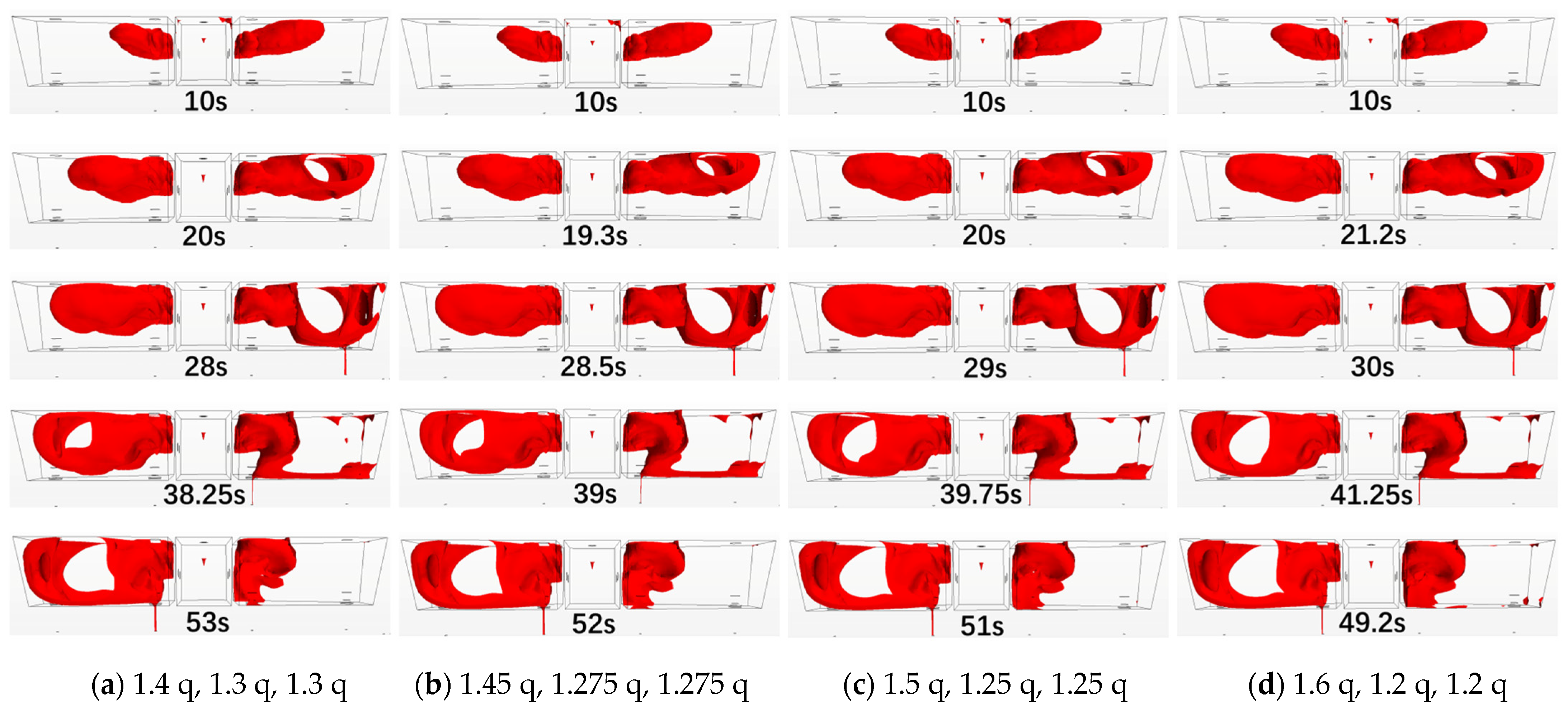

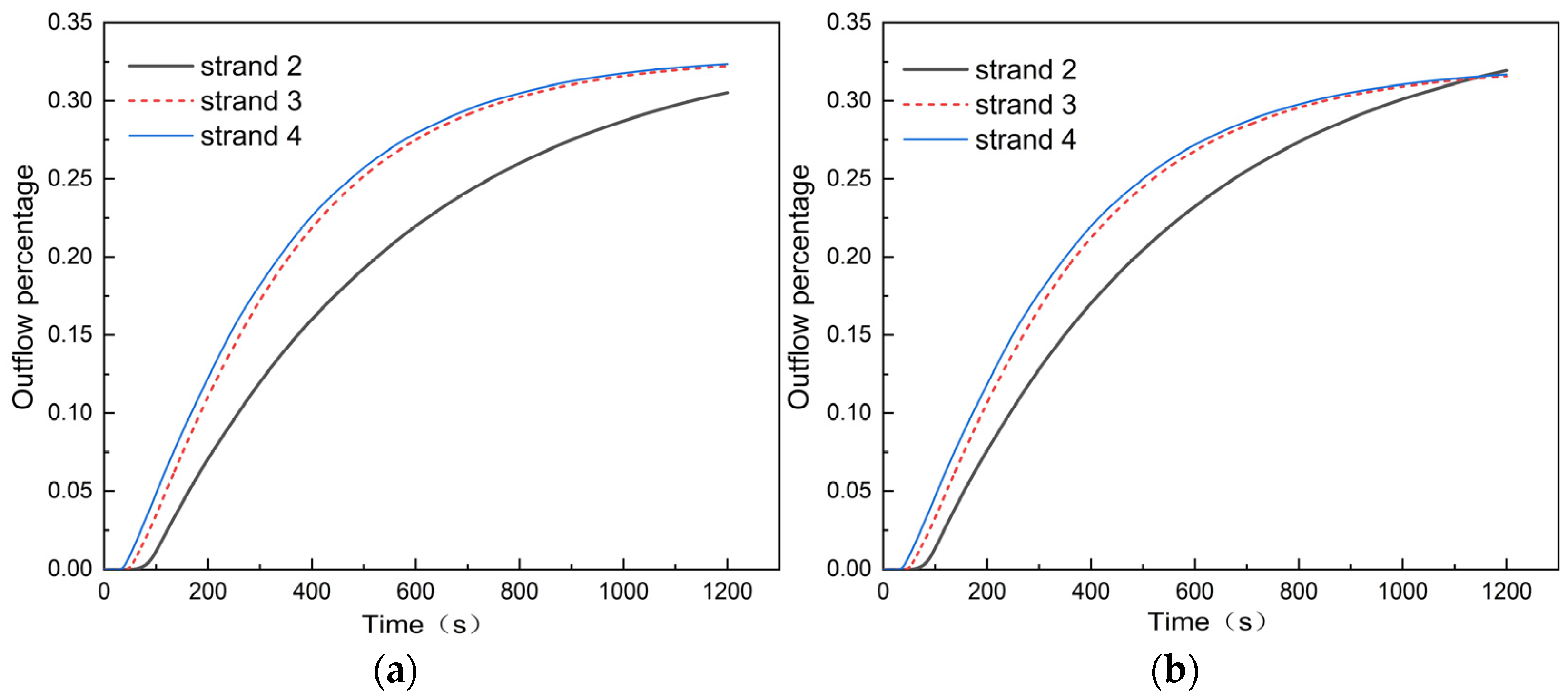

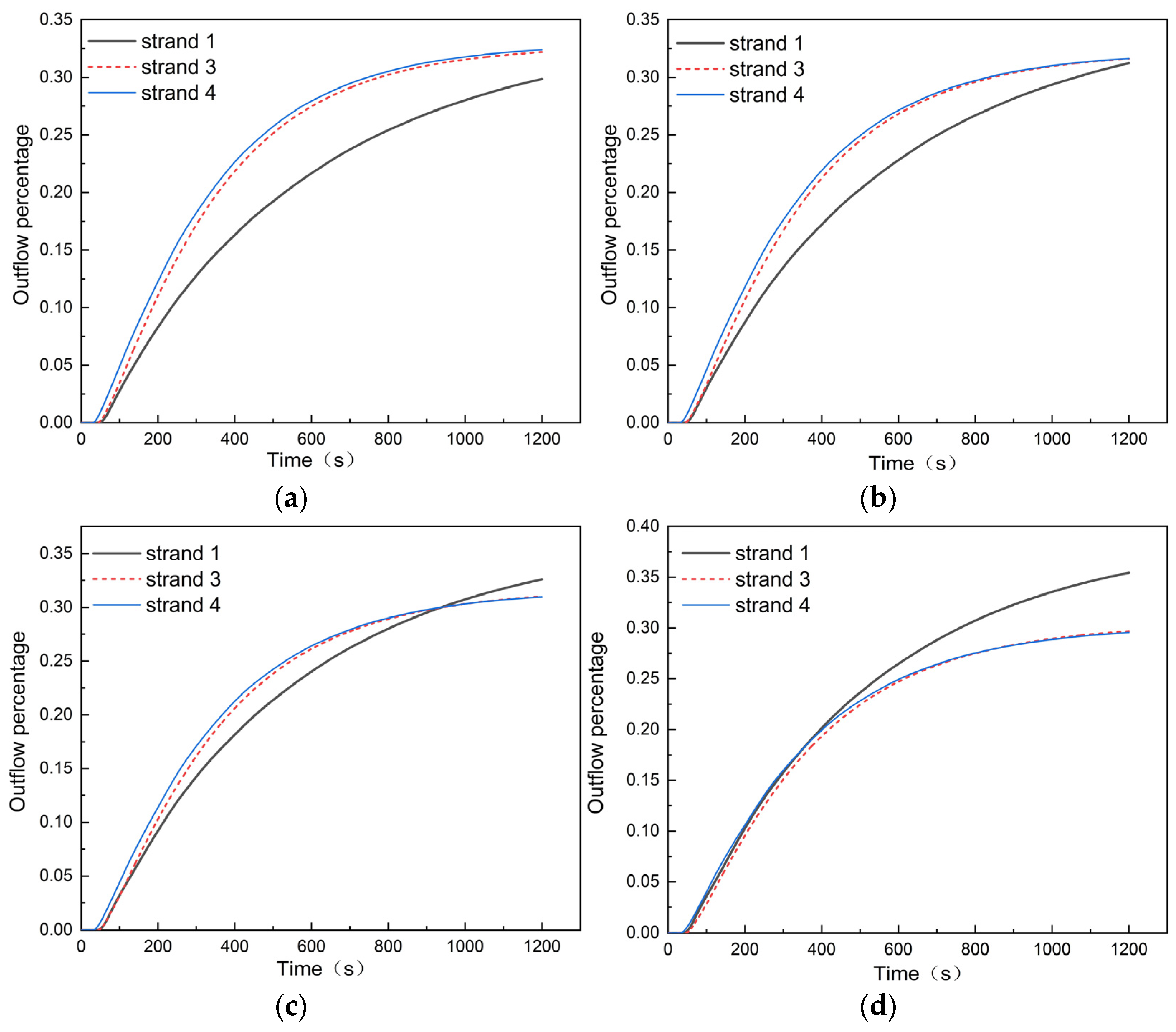

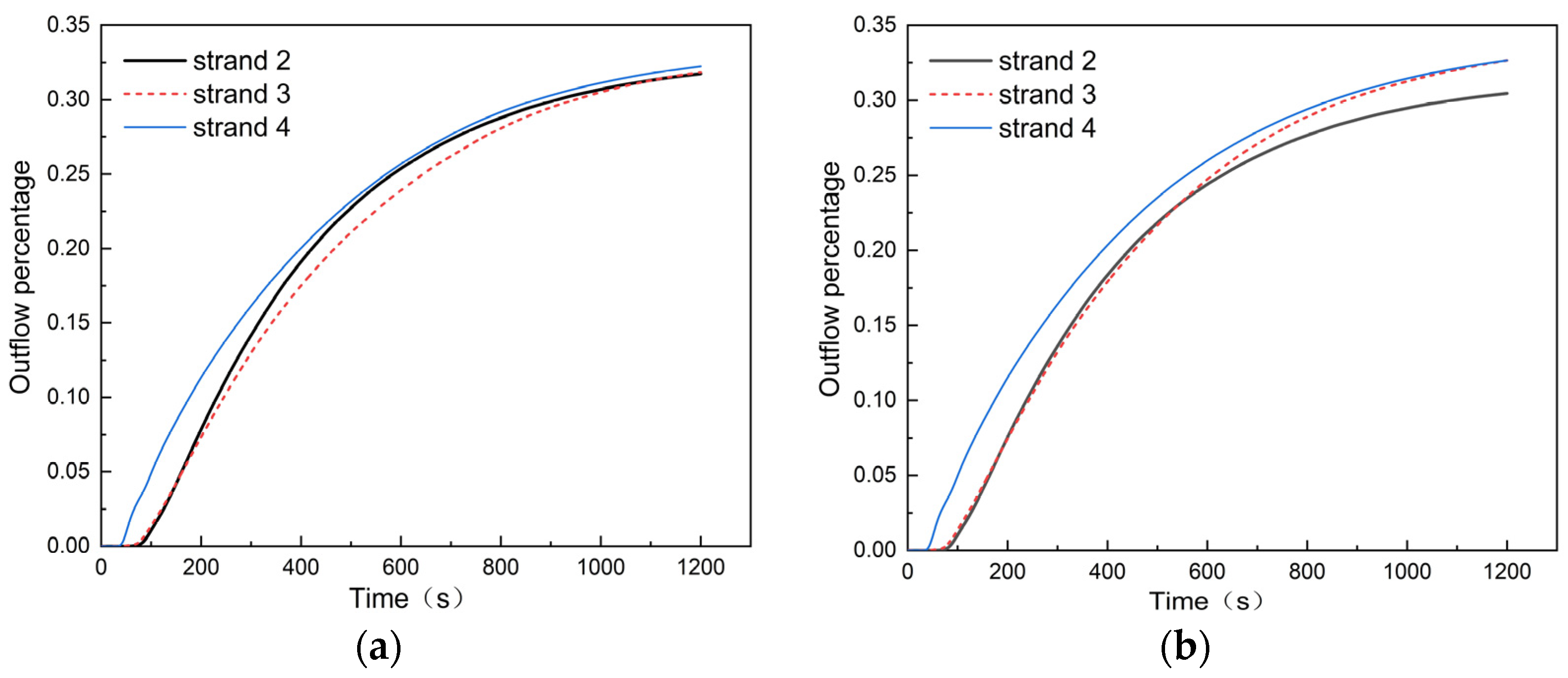

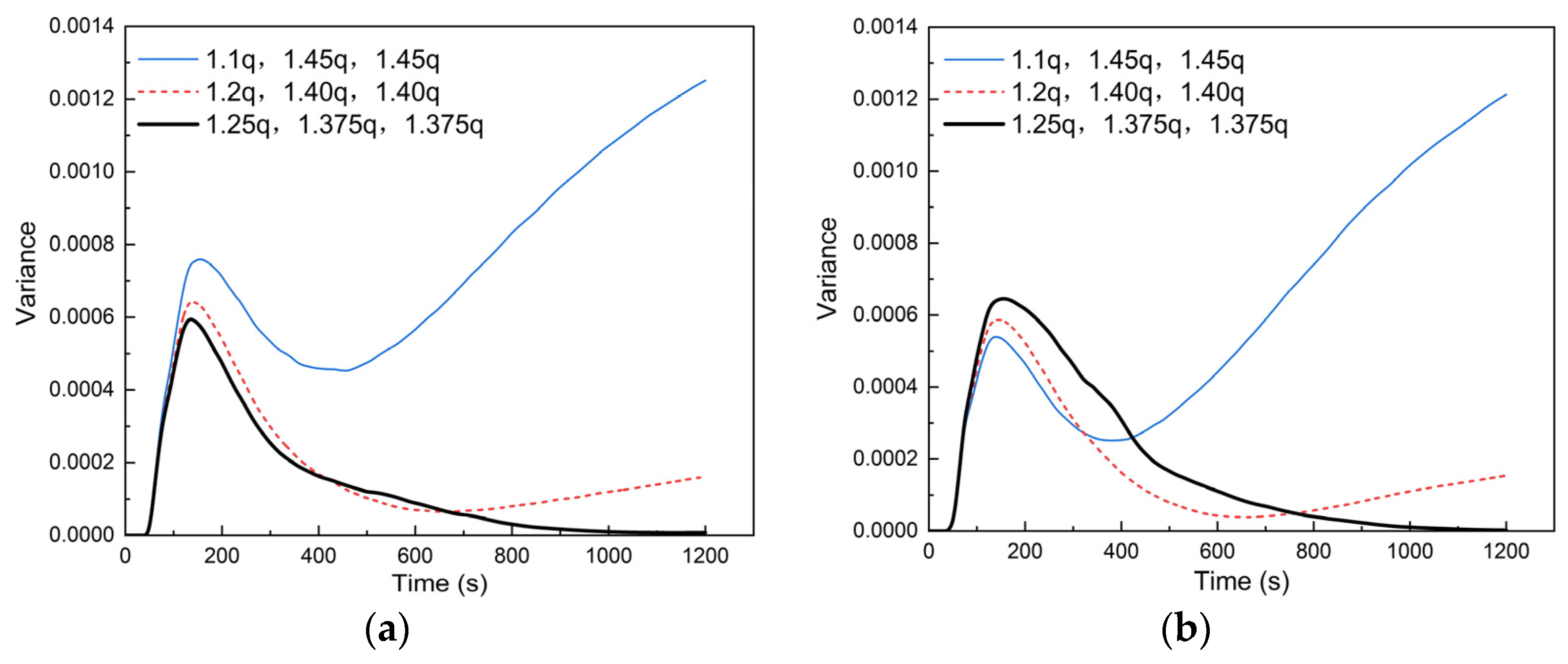

3.4. Dispersion and Outflow Percentage of Tracers under Single-Strand Blockage Conditions with Non-Uniform Increasing Casting Flow Rate

3.5. Discussion

4. Conclusions

- An analysis method of outflow percentage is proposed, and the consistency of the multi-strand tundish can be evaluated intuitively and quantitatively through the outflow percentage curve and time averaged variance;

- When a single-strand is blocked, the flow field in the tundish does not change significantly, but the consistency of each strand is significantly reduced. The consistency of each strand of the u-shaped weir tundish is better than that of the double-weir tundish;

- When a single-strand is blocked, uniformly increasing the casting flow rate of each strand has a limited effect on the flow field in the tundish. With the increase of the casting flow rate, the response time of each strand decreases and the outflow percentage increases. However, the uniformity of strands improved slightly in the double-weir tundish but decreased in the u-shaped tundish;

- For the double-weir tundish, by significantly increasing the casting flow rate of the strand located in the blocked part by a factor of 1.5 and slightly increasing the casting flow rate of the other strands by a factor of 1.25, the consistency of each strand is the best;

- For the u-shaped weir tundish, the consistency of each strand is improved by non-uniformly increasing the casting flow rate of the strands. The flow rates of the strand located in the blocked part and the other strands are increased by a factor of 1.25, and 1.375 or 1.2 and 1.4 are the optimized cases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chattopadhyay, K.; Isac, M.; Guthrie, R.I.L. Physical and mathematical modelling of steelmaking tundish operations: A review of the last decade (1999–2009). ISIJ Int. 2010, 50, 331–348. [Google Scholar] [CrossRef] [Green Version]

- Mazumdar, D. Review, analysis, and modeling of continuous casting tundish systems. Steel Res. Int. 2019, 90, 1800279. [Google Scholar] [CrossRef]

- Cwudziński, A. New Insight on Liquid Steel Microalloying by Pulse-Step Method in Two-Strand Slab Tundish by Numerical Simulations. Crystals 2021, 11, 448. [Google Scholar] [CrossRef]

- Zhao, M.; Wang, Y.; Yang, S.; Ye, M.; Li, J.; Liu, Y. Flow Field and Temperature Field in a Four-Strand Tundish Heated by Plasma. Metals 2021, 11, 722. [Google Scholar] [CrossRef]

- Ni, P.; Ersson, M.; Jonsson, L.T.I.; Zhang, T.-A.; Jönsson, P.G. Effect of Immersion Depth of a Swirling Flow Tundish SEN on Multiphase Flow and Heat Transfer in Mold. Metals 2018, 8, 910. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Liu, F.; Zhu, R.; Zhu, J. Effects of Multiple-Hole Baffle Arrangements on Flow Fields in a Five-Strand Asymmetric Tundish. Materials 2020, 13, 5129. [Google Scholar] [CrossRef] [PubMed]

- Sheng, D.-Y.; Yue, Q. Modeling of Fluid Flow and Residence-Time Distribution in a Five-Strand Tundish. Metals 2020, 10, 1084. [Google Scholar] [CrossRef]

- Bruch, C.; Valentin, P. Mathematical Modelling of Fluid Flow in a Continuous Casting Tundish with regard to Extraordinary Casting Conditions. Steel Res. Int. 2004, 75, 659–665. [Google Scholar] [CrossRef]

- Sengupta, A.; Mishra, P.; Singh, V.; Mishra, S.; Jha, P.K.; Ajmani, S.K.; Sharma, S.C. Physical Modelling Investigation of Influence of Strand Blockage on RTD Characteristics in a Multistrand Tundish. Ironmak. Steelmak. 2013, 40, 159–166. [Google Scholar] [CrossRef]

- Mishra, S.K.; Jha, P.K.; Sharma, S.C.; Ajmani, S.K. Effect of blockage of outlet nozzle on fluid flow and heat transfer in continuously cast multistrand billet caster tundish. Can. Metall. Q. 2012, 51, 170–183. [Google Scholar] [CrossRef]

- Merder, T. Numerical Investigation of The Hydrodynamic Conditions in a Multi-strand CC Tundish with Closed Outlets. Arch. Metall. Mater. 2014, 59, 891–896. [Google Scholar] [CrossRef]

- Zhang, L. Fluid Flow, Heat Transfer and Inclusion Motion in a Four-Strand Billet Continuous Casting Tundish. Steel Res. Int. 2005, 76, 784–796. [Google Scholar] [CrossRef]

- Hülstrung, J.; Zeimes, M.; Au, A.; Oppermann, W.; Radusch, G. Optimization of the Tundish Design to Increase the Product Quality by means of Numerical Fluid Dynamics. Steel Res. Int. 2005, 76, 59–63. [Google Scholar] [CrossRef]

- Zhong, L.; Wang, M.; Chen, B.; Wang, C.; Zhu, Y. Flow Control in Six-Strand Billet Continuous Casting Tundish with Different Configurations. J. Iron Steel Res. Int. 2010, 17, 7–12. [Google Scholar] [CrossRef]

- Yao, C.; Wang, M.; Pan, M.; Bao, Y. Optimization of large capacity six-strand tundish with flow channel for adapting situation of fewer strands casting. J. Iron Steel Res. Int. 2021, 28, 1114–1124. [Google Scholar] [CrossRef]

- Liu, Z.; Jin, Y.; Gan, F.; Lin, P.; Huang, J.; Li, J. Analysis of Optimization Weights for Flow Field of Internal Rotation Stabilizer Coupled with Porous Retaining Wall. Metals 2021, 11, 1208. [Google Scholar] [CrossRef]

- Sheng, D.-Y.; Chen, D. Comparison of Fluid Flow and Temperature Distribution in a Single-Strand Tundish with Different Flow Control Devices. Metals 2021, 11, 796. [Google Scholar] [CrossRef]

- Yang, B.; Lei, H.; Zhao, Y.; Xing, G.; Zhang, H. Quasi-Symmetric Transfer Behavior in an Asymmetric Two-Strand Tundish with Different Turbulence Inhibitor. Metals 2019, 9, 855. [Google Scholar] [CrossRef] [Green Version]

- Merder, T. Effect of casting flow rate on steel flow phenomena in tundish. Metalurgija 2013, 52, 161–164. [Google Scholar]

- Bul’ko, B.; Priesol, I.; Demeter, P.; Gašparovič, P.; Baricová, D.; Hrubovčáková, M. Geometric Modification of the Tundish Impact Point. Metals 2018, 8, 944. [Google Scholar] [CrossRef] [Green Version]

- Boonpen, K.; Kowitwarangkul, P.; Ninpetch, P.; Phophichit, N.; Chuchuay, P.; Threrujirapapong, T.; Otarawanna, S. Numerical study of influence of casting speed on fluid flow characteristics in the four strand tundish. Mater. Today 2021, 47, 3480–3486. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Cheng, C.; Lan, P.; Wu, W. Study on Parameter Optimization of Diversion Wall in an Eight-Strand Tundish during Continuous Casting of Billet with High Casting Speed. Processes 2022, 10, 555. [Google Scholar] [CrossRef]

- Raghavendra, K.; Sarkar, S.; Ajmani, S.K.; Denys, M.B.; Singh, M.K. Mathematical modelling of single and multi-strand tundish for inclusion analysis. Appl. Math. Model. 2013, 37, 6284–6300. [Google Scholar] [CrossRef]

- Wang, Q.; Tan, C.; Huang, A.; Yan, W.; Gu, H.; He, Z.; Li, G. Numerical simulation on refractory wear and inclusion formation in continuous casting tundish. Metall. Mater. Trans. B 2021, 52, 1344–1356. [Google Scholar] [CrossRef]

- Cwudzinski, A. Numerical Prediction of Hydrodynamic Conditions in One Strand Tundish. Influence of Thermal Conditions and Casting Speed. Arch. Metall. Mater. 2014, 59, 1249–1256. [Google Scholar] [CrossRef] [Green Version]

- He, F.; Wang, H.; Zhu, Z. Numerical Investigation of Effect of Casting Speed on Flow Characteristics of Molten Steel in Multistrand Tundish. ISIJ Int. 2019, 59, 1250–1258. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Jonsson, L.T.I.; Tilliander, A.; Cheng, G.; Jönsson, P.G. A mathematical modeling study of the influence of small amounts of KCl solution tracers on mixing in water and residence time distribution of tracers in a continuous flow reactor-metallurgical tundish. Chem. Eng. Sci. 2015, 137, 914–937. [Google Scholar] [CrossRef]

- Chen, C.; Jonsson, L.T.I.; Tilliander, A.; Cheng, G.; Jönsson, P.G. A mathematical modeling study of tracer mixing in a continuous casting tundish. Metall. Mater. Trans. B 2015, 46, 169–190. [Google Scholar] [CrossRef]

- Zheng, S.; Zhu, M. Criteria on the Similarity of Melt Flow among Strands in Multi-strand Continuous Casting Tundish. Chin. J. Eng. Des. 2006, 6, 522–526. [Google Scholar] [CrossRef]

- Tkadlečková, M.; Walek, J.; Michalek, K.; Huczala, T. Numerical Analysis of RTD Curves and Inclusions Removal in a Multi-Strand Asymmetric Tundish with Different Configuration of Impact Pad. Metals 2020, 10, 849. [Google Scholar] [CrossRef]

- Ai, X.; Han, D.; Li, S.; Zeng, H.; Li, H. Optimization of flow uniformity control device for six-stream continuous casting tundish. J. Iron Steel Res. Int. 2020, 27, 1035–1044. [Google Scholar] [CrossRef]

- Cui, H.; Liu, Y.; Li, D. Fluid Flow Characterization in Asymmetric Tundish. ISIJ Int. 2015, 55, 2604–2608. [Google Scholar] [CrossRef] [Green Version]

- Braga, B.M.; Tavages, R.P. Additional Information on “Fluid Flow Characterization in Asymmetric Tundish” by Cui, Liu and Li. ISIJ Int. 2018, 58, 1953–1955. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Cheng, G.G.; Yang, H.K.; Hou, Z.B. Physical modeling of fluid flow characteristics in a delta shaped, four-strand continuous casting tundish with different flow control devices. Adv. Mater. Res. 2011, 284, 1071–1079. [Google Scholar] [CrossRef]

- Shih, T.H.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A new k-ϵ eddy viscosity model for high reynolds number turbulent flows. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Rodi, W. Experience with two-layer models combining the k-epsilon model with a one-equation model near the wall. In Proceedings of the 29th Aerospace Sciences Meeting, Reno, NV, USA, 1–10 January 1991; ARC: Columbus, OH, USA, 1991; p. 216. [Google Scholar] [CrossRef]

- Wolfshtein, M. The velocity and temperature distribution in one-dimensional flow with turbulence augmentation and pressure gradient. Int. J. Heat Mass Transf. 1969, 12, 301–318. [Google Scholar] [CrossRef]

- Siemens. STAR-CCM+ Version 13.04 User Guide; Siemens PLM Software: Munich, Germany, 2019. [Google Scholar]

| Investigators | Year | Tundish Type | Research Focus |

|---|---|---|---|

| T. Merder [19] | 2013 | two-strand | dead volume and well mixed volume |

| K. Raghavendra. et al. [23] | 2013 | four-strand | inclusion separation efficiency |

| A. Cwudzinski [25] | 2014 | single-strand | temperatures difference |

| B. Bul’ko. et al. [20] | 2018 | two-strand | residence time |

| F. He. et al. [26] | 2019 | five-strand | flow characteristics |

| Q. Wang. et al. [24] | 2021 | single-strand | inclusion separation efficiency |

| Boonpen K. et al. [21] | 2021 | four-strand | response time |

| Liu Z. et al. [22] | 2022 | eight-strand | residence time and consistency |

| Parameters | Volumetric Flowrate per Nozzle (L/h) | Diameter of the Nozzle (mm) | Depth of Liquid (mm) | Distance between Two Nozzles (mm) | Depth of Shroud Penetration (mm) |

|---|---|---|---|---|---|

| Industrial tundish | 3105 | 30 | 800 | 1200 | 220 |

| Water model | 199 | 10 | 267 | 400 | 73 |

| Case | Double-Weir Tundish under Normal Conditions | u-Shaped Weir Tundish under Normal Conditions | Double-Weir Tundish under Single-Strand Blockage Conditions | u-Shaped Weir Tundish under Single-Strand Blockage Conditions | ||

|---|---|---|---|---|---|---|

| Strand 1 Blockage | Strand 2 Blockage | Strand 1 Blockage | Strand 2 Blockage | |||

| variance | 8.74 × 10−6 | 2.36 × 10−4 | 2.02 × 10−3 | 2.09 × 10−3 | 2.76 × 10−4 | 4.88 × 10−4 |

| Case | Double-Weir Tundish | u-Shaped Weir Tundish | ||||||

|---|---|---|---|---|---|---|---|---|

| Outlet flow rates | 1.0 q | 1.13 q | 1.2 q | 1.33 q | 1.0 q | 1.13 q | 1.2 q | 1.33 q |

| Strand 1 blockage | 2.02 × 10−3 | 1.81 × 10−3 | 1.73 × 10−3 | 1.51 × 10−3 | 2.76 × 10−4 | 9.29 × 10−4 | 9.92 × 10−4 | 3.04 × 10−4 |

| Strand 2 blockage | 2.09 × 10−3 | 1.85 × 10−3 | 1.76 × 10−3 | 1.52 × 10−3 | 4.88 × 10−4 | 1.18 × 10−3 | 1.46 × 10−3 | 4.42 × 10−4 |

| Strand Blockage | Double-Weir Tundish | u-Shaped Weir Tundish | ||||||

|---|---|---|---|---|---|---|---|---|

| Strand 1 | Strand 2 | Strand 3 | Strand 4 | Strand 1 | Strand 2 | Strand 3 | Strand 4 | |

| Strand 1 | 1.4 q | 1.3 q | 1.3 q | 1.1 q | 1.45 q | 1.45 q | ||

| 1.45 q | 1.275 q | 1.275 q | 1.2 q | 1.4 q | 1.4 q | |||

| 1.5 q | 1.25 q | 1.25 q | 1.25 q | 1.375 | 1.375 | |||

| 1.6 q | 1.2 q | 1.2 q | ||||||

| Strand 2 | 1.4 q | 1.3 q | 1.3 q | 1.1 q | 1.45 q | 1.45 q | ||

| 1.45 q | 1.275 q | 1.275 q | 1.2 q | 1.4 q | 1.4 q | |||

| 1.5 q | 1.25 q | 1.25 q | 1.25 q | 1.375 | 1.375 | |||

| 1.6 q | 1.2 q | 1.2 q | ||||||

| Case | Double-Weir Tundish | u-Shaped Weir Tundish | |||||

|---|---|---|---|---|---|---|---|

| outlet flow rates | 1.4 q, 1.3 q, 1.3 q | 1.45 q, 1.275 q, 1.275 q | 1.5 q, 1.25 q, 1.25 q | 1.6 q, 1.2 q, 1.2 q | 1.2 q, 1.4 q, 1.4 q | 1.1 q, 1.45 q, 1.45 q | 1.25 q, 1.375 q, 1.375 q |

| Strand 1 blockage | 6.94 × 10−4 | 3.15 × 10−4 | 1.33 × 10−4 | 4.39 × 10−4 | 1.84 × 10−4 | 7.14 × 10−4 | 1.37 × 10−4 |

| Strand 2 blockage | 7.00 × 10−4 | 3.08 × 10−4 | 1.05 × 10−4 | 2.91 × 10−4 | 1.69 × 10−4 | 5.93 × 10−4 | 1.87 × 10−4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, J.; Li, Y.; Chen, C.; Ouyang, X.; Wang, T.; Lin, W. Effect of Uniform and Non-Uniform Increasing Casting Flow Rate on Dispersion and Outflow Percentage of Tracers in Four Strand Tundishes under Strand Blockage Conditions. Metals 2022, 12, 1016. https://doi.org/10.3390/met12061016

Fan J, Li Y, Chen C, Ouyang X, Wang T, Lin W. Effect of Uniform and Non-Uniform Increasing Casting Flow Rate on Dispersion and Outflow Percentage of Tracers in Four Strand Tundishes under Strand Blockage Conditions. Metals. 2022; 12(6):1016. https://doi.org/10.3390/met12061016

Chicago/Turabian StyleFan, Jinping, Yuqian Li, Chao Chen, Xin Ouyang, Tianyang Wang, and Wanming Lin. 2022. "Effect of Uniform and Non-Uniform Increasing Casting Flow Rate on Dispersion and Outflow Percentage of Tracers in Four Strand Tundishes under Strand Blockage Conditions" Metals 12, no. 6: 1016. https://doi.org/10.3390/met12061016

APA StyleFan, J., Li, Y., Chen, C., Ouyang, X., Wang, T., & Lin, W. (2022). Effect of Uniform and Non-Uniform Increasing Casting Flow Rate on Dispersion and Outflow Percentage of Tracers in Four Strand Tundishes under Strand Blockage Conditions. Metals, 12(6), 1016. https://doi.org/10.3390/met12061016