Transferring A4 Paper to FeNi3/NiCx Coated Carbon Skeleton for Efficient Absorption of Multiband Microwave

Abstract

:1. Introduction

2. Experiments

2.1. Reagents

2.2. Preparation of C@(FeNi3/NiCx) Composites

2.3. Characterization

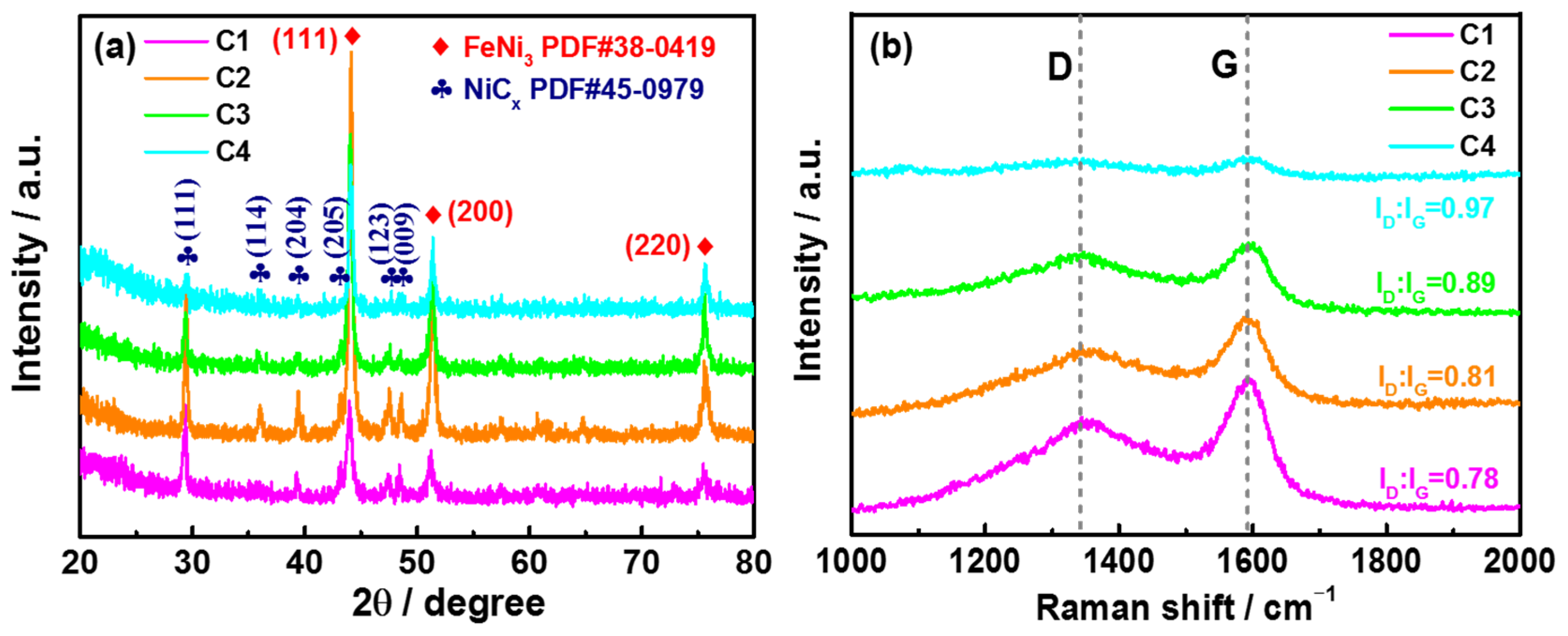

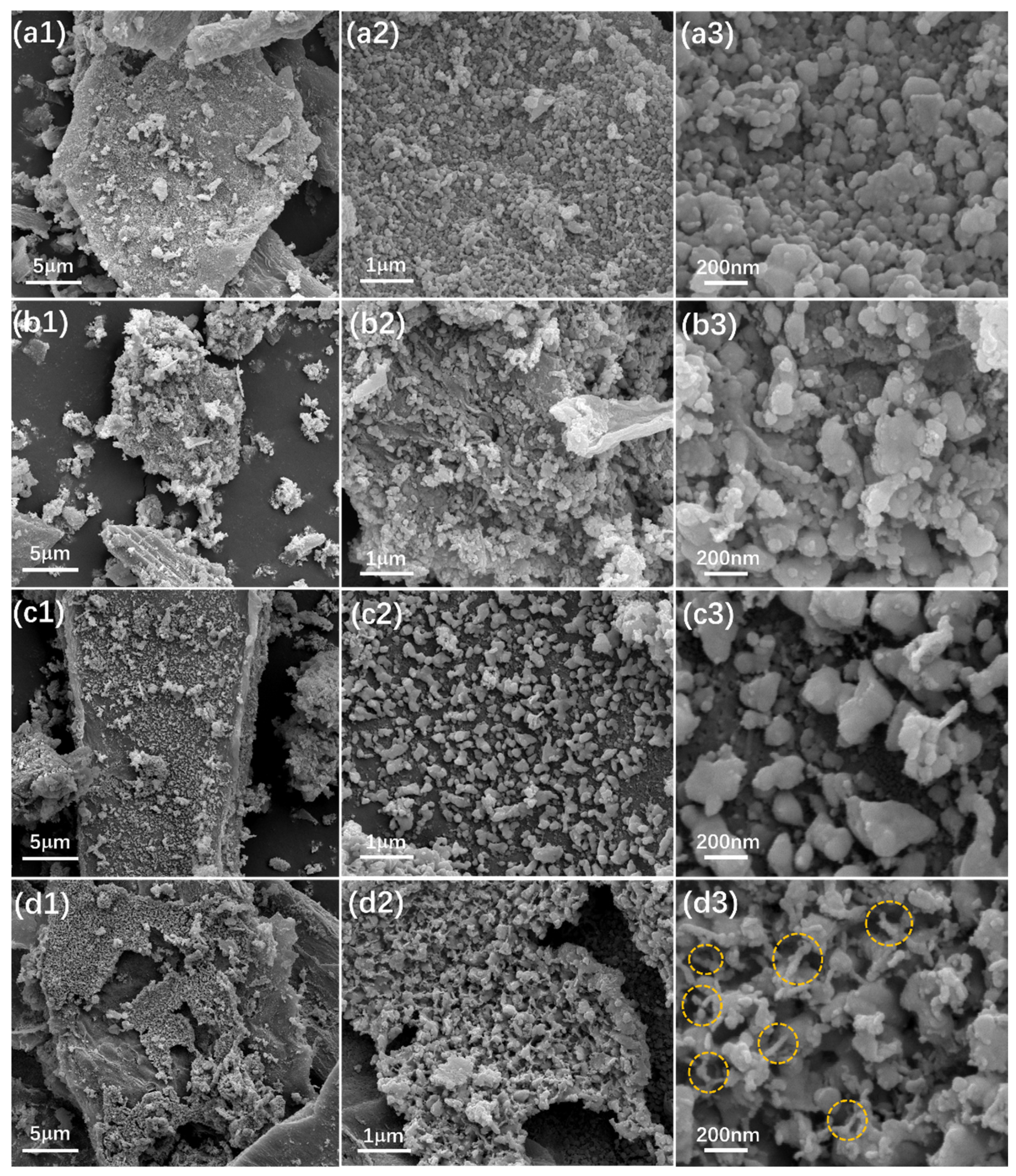

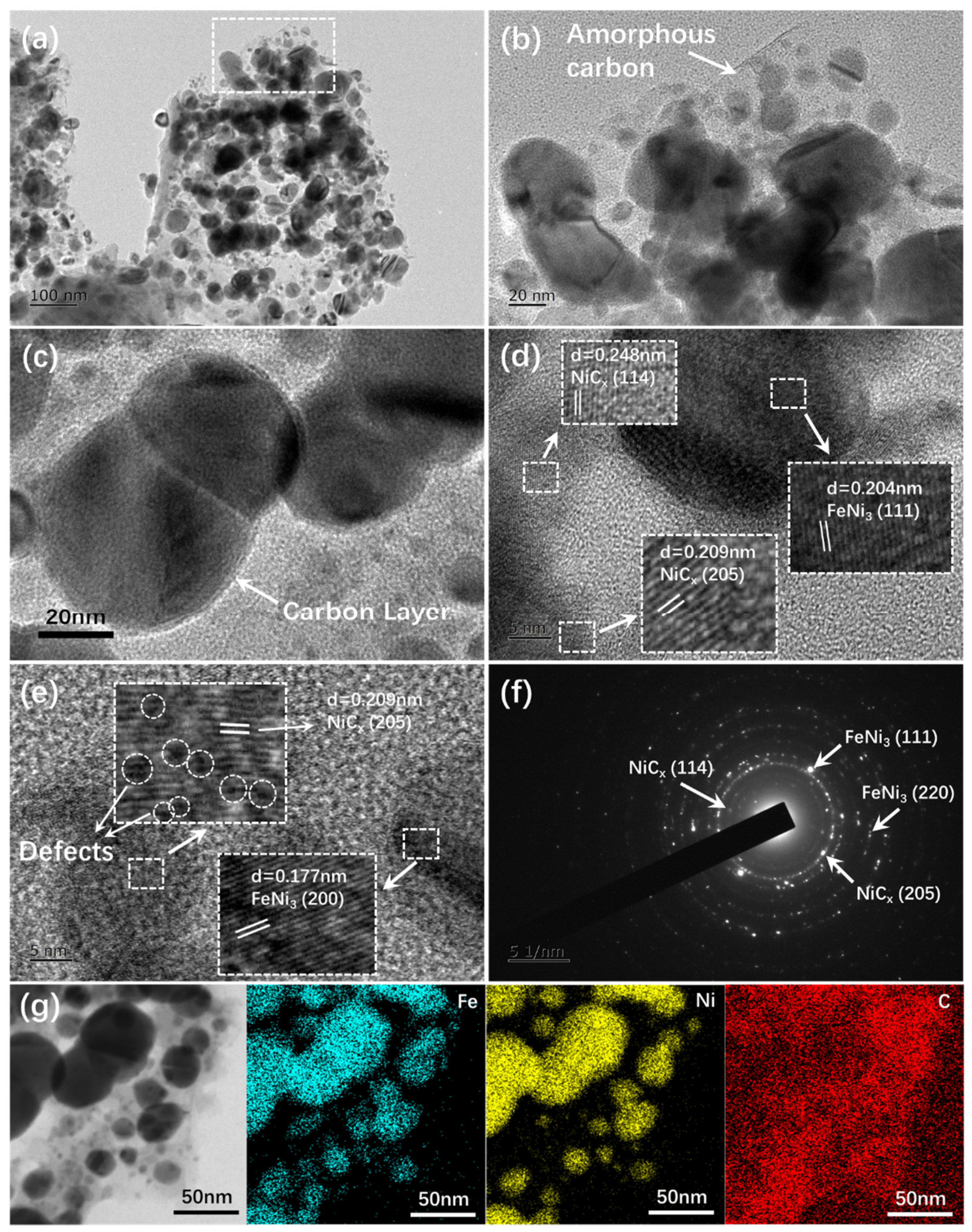

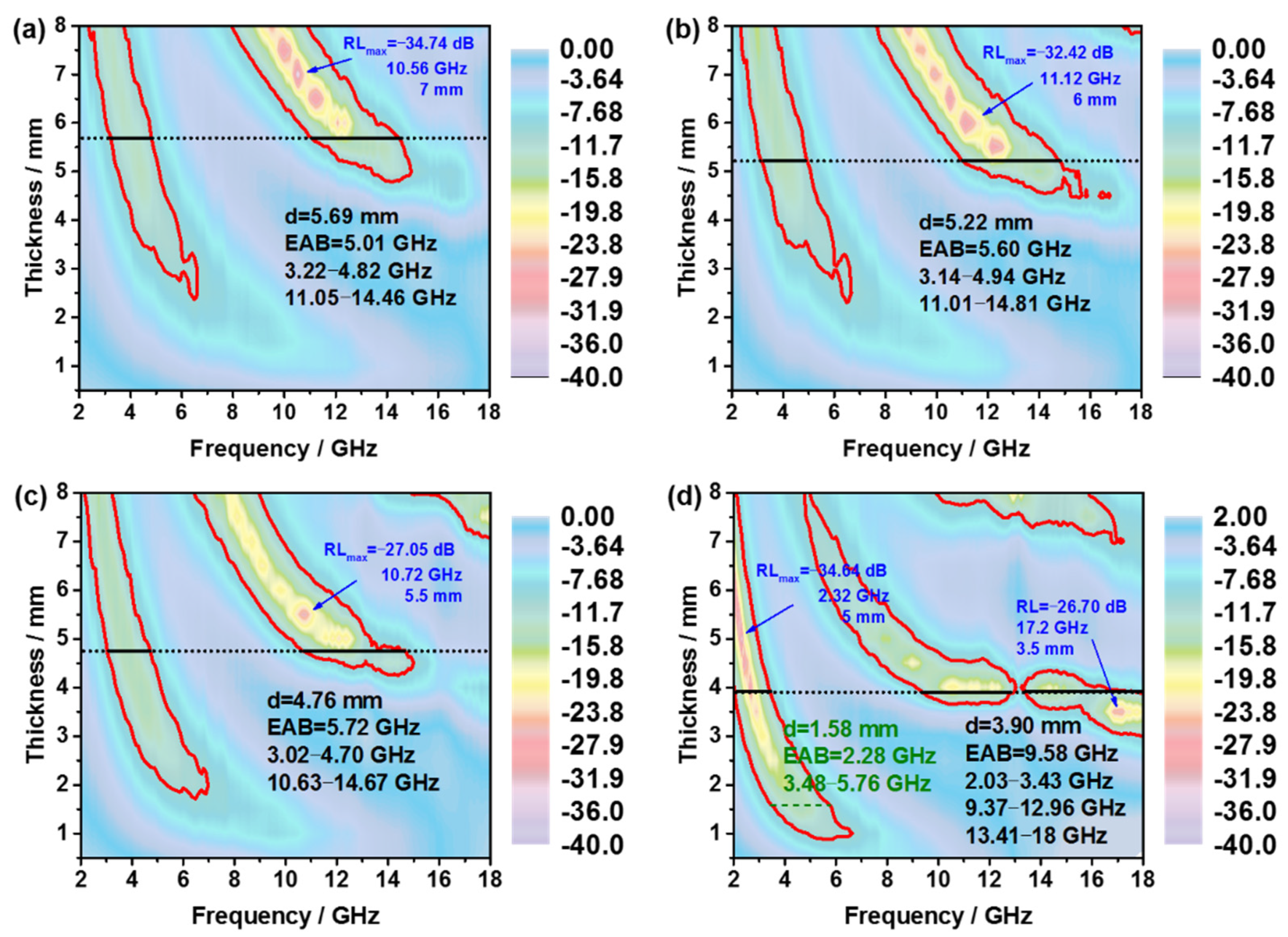

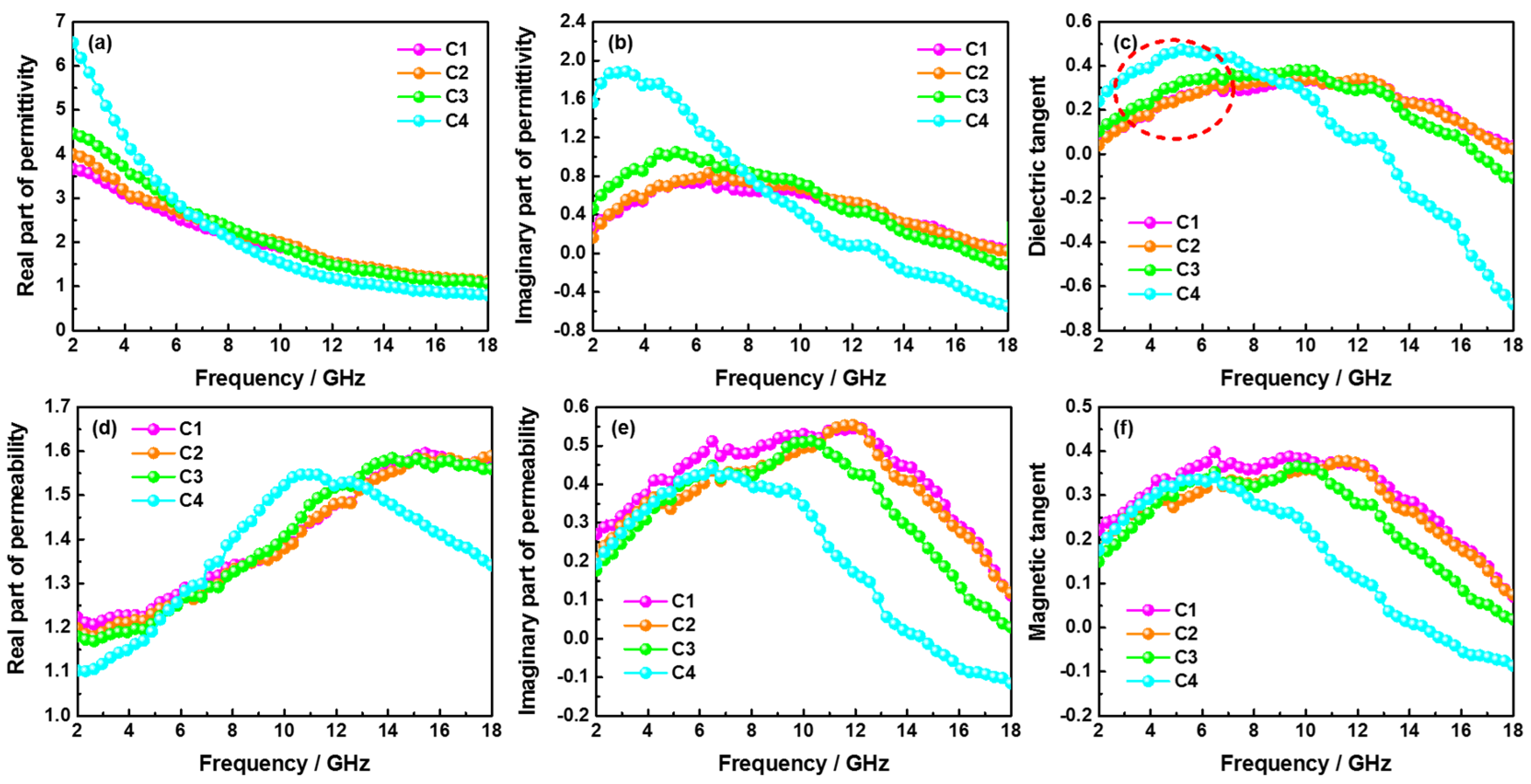

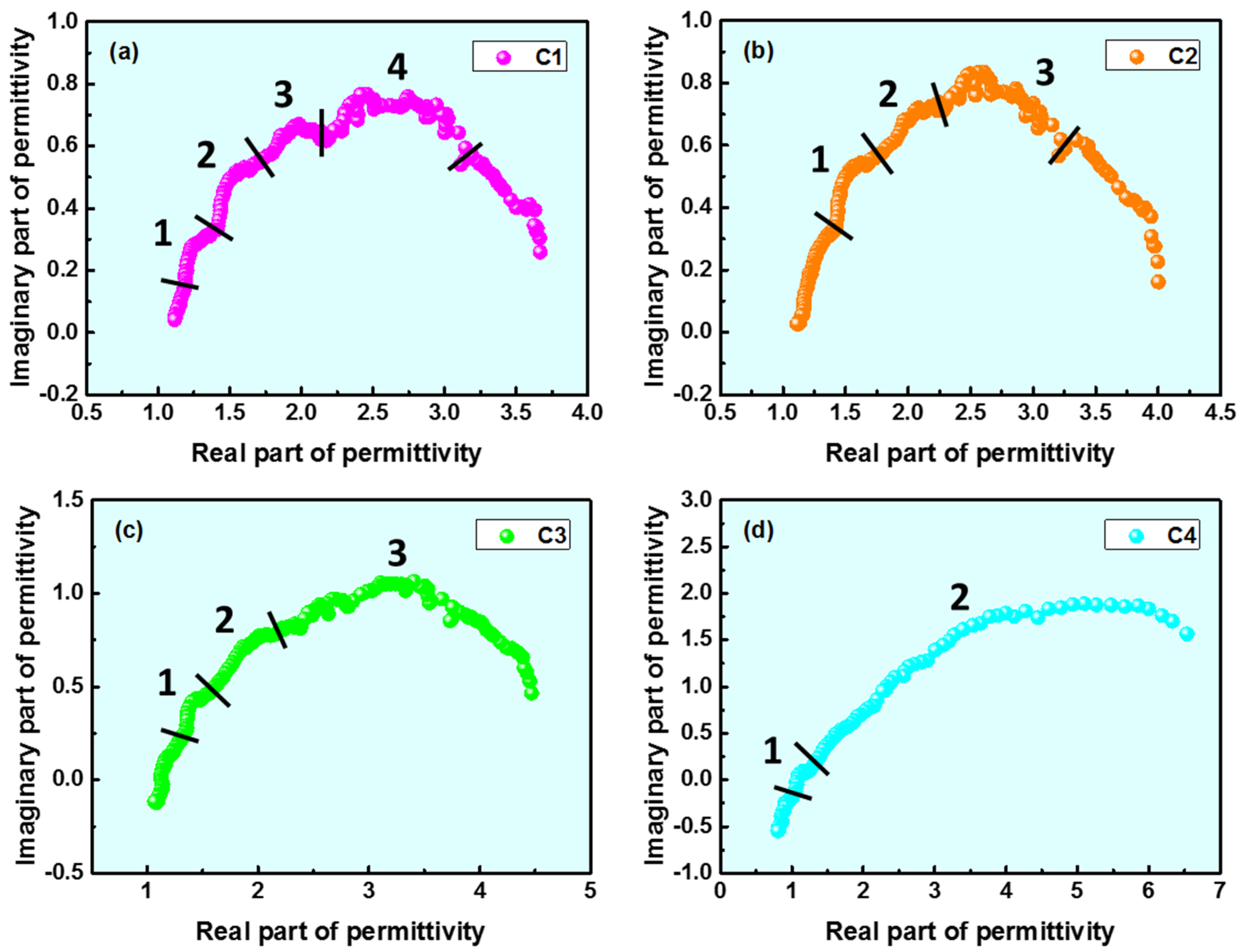

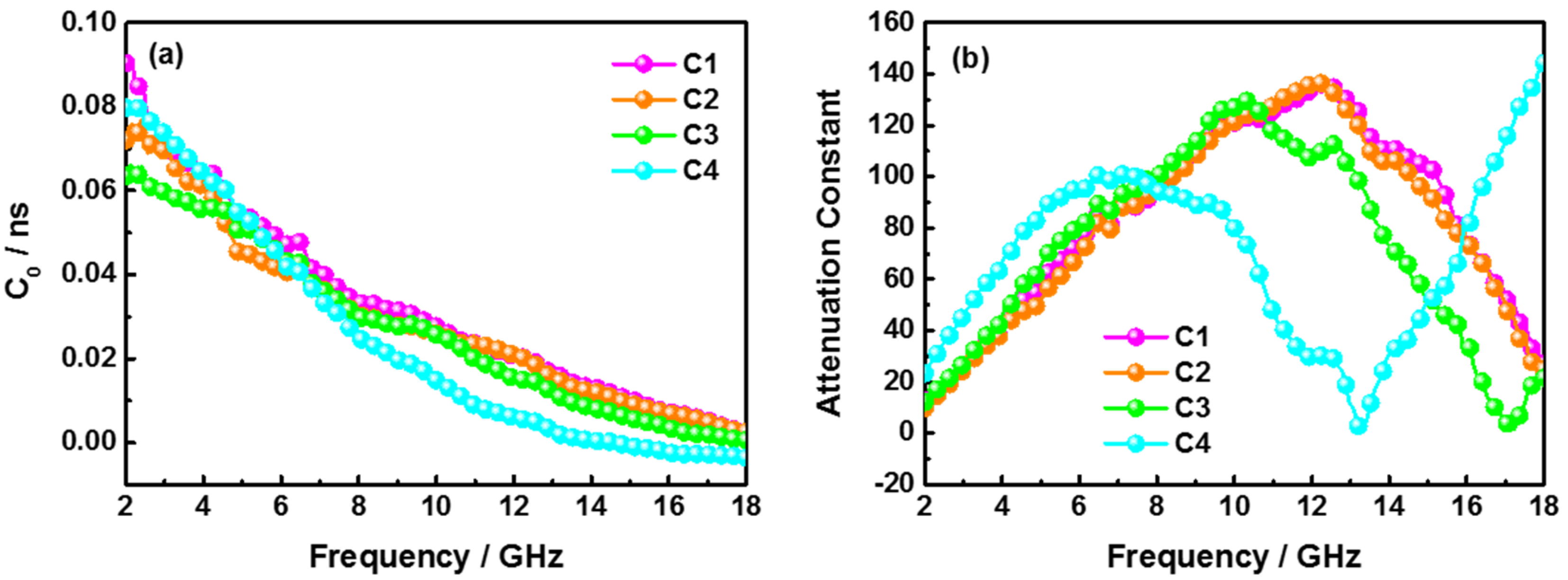

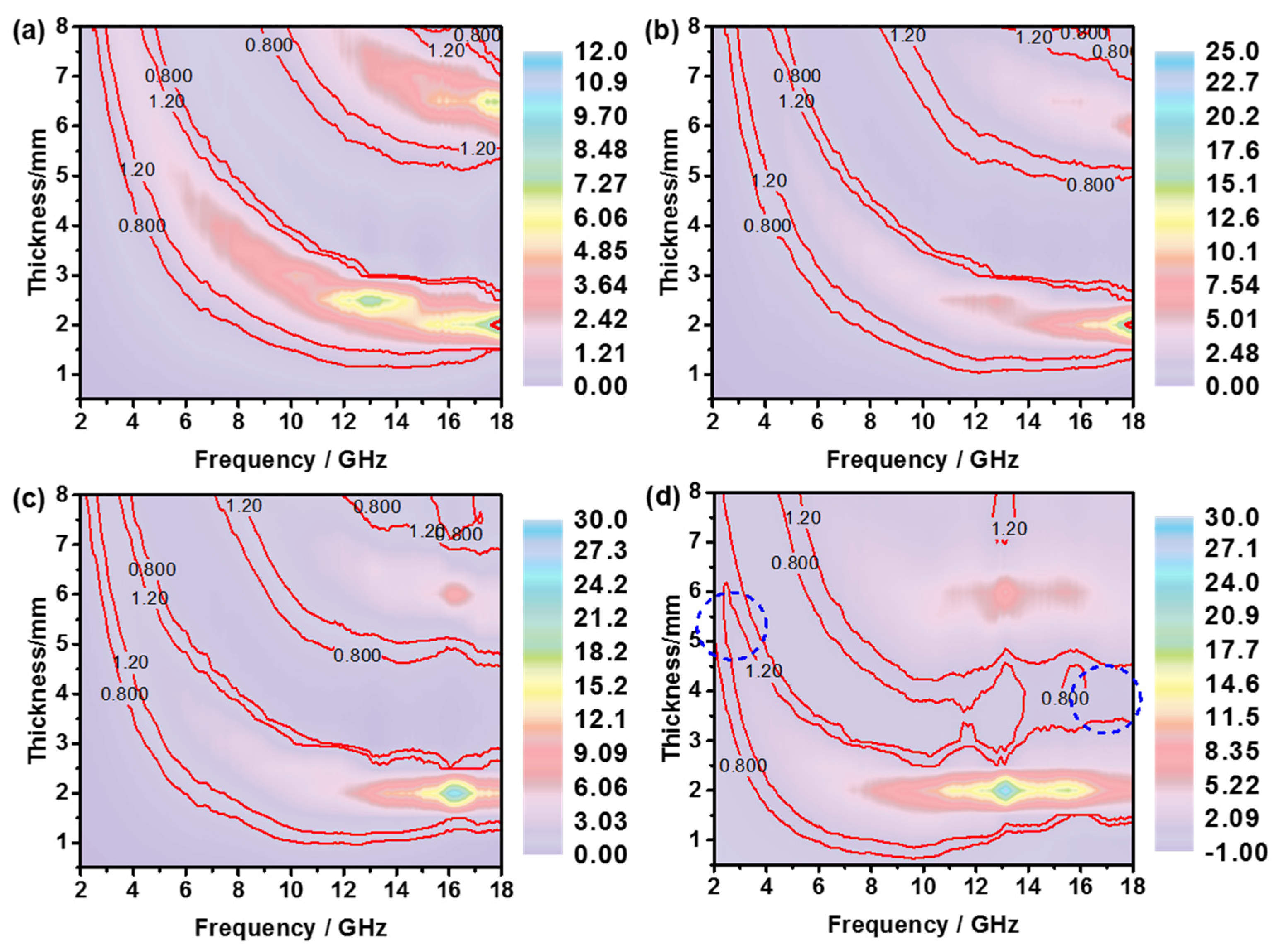

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

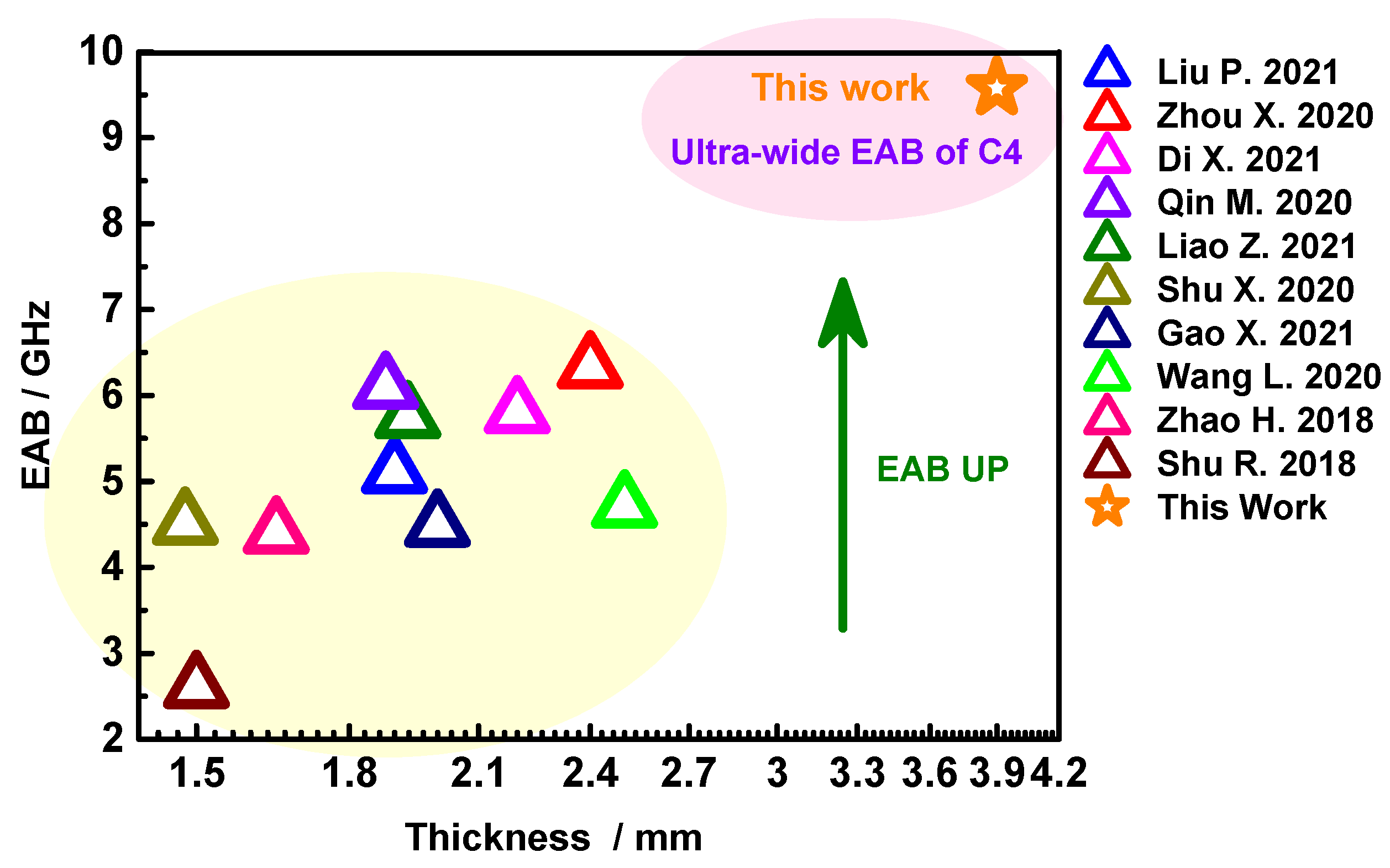

- Qin, M.; Lan, D.; Liu, J.; Liang, H.; Zhang, L.; Xing, H.; Xu, T.; Wu, H. Synthesis of single-component metal oxides with controllable multi-shelled structure and their morphology-related applications. Chem. Rec. 2020, 20, 102–119. [Google Scholar] [CrossRef] [PubMed]

- Gao, S.; Zhang, G.; Wang, Y.; Han, X.; Huang, Y.; Liu, P. MOFs derived magnetic porous carbon1 microspheres constructed by core-shell Ni@C with high-performance microwave absorption. J. Mater. Sci. Technol. 2021, 88, 56–65. [Google Scholar] [CrossRef]

- Wang, J.; Jia, Z.; Liu, X.; Dou, J.; Xu, B.; Wang, B.; Wu, G. Construction of 1D heterostructure NiCo@C/ZnO nanorod with enhanced microwave absorption. Micro-Nano Lett. 2021, 13, 175. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Lan, D.; Zhang, L.; Wu, H. Simultaneous manipulation of interfacial and defects polarization toward Zn/Co phase and ion hybrids for electromagnetic wave absorption. Adv. Funct. Mater. 2021, 31, 2106677. [Google Scholar] [CrossRef]

- Liu, P.; Gao, S.; Zhang, G.; Huang, Y.; You, W.; Che, R. Hollow engineering to Co@N-doped carbon nanocages via synergistic protecting-etching strategy for ultrahigh microwave absorption. Adv. Funct. Mater. 2021, 31, 2102812. [Google Scholar] [CrossRef]

- Zhou, X.; Jia, Z.; Feng, A.; Qu, S.; Wang, X.; Liu, X.; Wang, B.; Wu, G. Synthesis of porous carbon embedded with NiCo/CoNiO2 hybrids composites for excellent electromagnetic wave absorption performance. J. Collold. Interf. Sci. 2020, 575, 130–139. [Google Scholar] [CrossRef]

- Qin, M.; Zhang, L.; Zhao, X.; Wu, H. Lightweight Ni foam-based ultra-broadband electromagnetic wave absorber. Adv. Funct. Mater. 2021, 31, 2103436. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, M.; Shu, X.; Ma, J.; Ren, H.; Wang, Y.; Liu, Y.; Shu, R.; Oh, W.C.; Kong, L.B. Facile synthesis of La-doped cobalt ferrite@glucose-based carbon composite as effective multiband microwave absorber. J. Am. Ceram. Soc. 2021, 104, 2191–2200. [Google Scholar] [CrossRef]

- Di, X.; Wang, Y.; Lu, Z.; Cheng, R.; Yang, L.; Wu, X. Heterostructure design of Ni/C/porous carbon nanosheet composite for enhancing the electromagnetic wave absorption. Carbon 2021, 179, 566–578. [Google Scholar] [CrossRef]

- Qin, M.; Liang, H.; Zhao, X.; Wu, H. Filter paper templated one-dimensional NiO/NiCo2O4 microrod with wideband electromagnetic wave absorption capacity. J. Colloid Inter. Sci. 2020, 566, 347–356. [Google Scholar] [CrossRef]

- Liao, Z.; Ma, M.; Tong, Z.; Wang, R.; Bi, Y.; Chen, Y.; Chung, K.L.; Ma, Y. Fabrication of ZnFe2O4/C@PPy composites with efficient electromagnetic wave absorption properties. J. Colloid Interf. Sci. 2021, 602, 602–611. [Google Scholar] [CrossRef] [PubMed]

- Shu, X.; Ren, H.; Jiang, Y.; Zhou, J.; Wang, Y.; Wang, Y.; Liu, Y.; Oh, W.C. Enhanced electromagnetic wave absorption performance of silane coupling agent KH550@Fe3O4 hollow nanospheres/graphene composites. J. Mater. Chem. C 2020, 8, 2913–2926. [Google Scholar] [CrossRef]

- Gao, X.; Jia, Z.; Wang, B.; Wu, X.; Sun, T.; Liu, X.; Chi, Q.; Wu, G. Synthesis of NiCo-LDH/MXene hybrids with abundant heterojunction surfaces as a lightweight electromagnetic wave absorber. Chem. Eng. J. 2021, 419, 130019. [Google Scholar] [CrossRef]

- Yin, P.; Zhang, L.; Tang, Y.; Liu, J. Earthworm-like (Co/CoO)@C composite derived from MOF for solving the problem of low-frequency microwave radiation. J. Alloy. Compd. 2021, 881, 160556. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, L.; Zang, D.; Wu, H. A competitive reaction strategy toward binary metal sulfides for tailoring electromagnetic wave absorption. Adv. Funct. Mater. 2021, 31, 2105018. [Google Scholar] [CrossRef]

- Huang, X.; Liu, X.; Jia, Z.; Wang, B.; Wu, X.; Wu, G. Synthesis of 3D cerium oxide/porous carbon for enhanced electromagnetic wave absorption performance. Adv. Compos. Hybrid Mater. 2021, 4, 1398–1412. [Google Scholar] [CrossRef]

- Di, X.; Wang, Y.; Fu, Y.; Wu, X.; Wang, P. Controllable heterogeneous interfaces of cobalt/carbon nanosheets/rGO composite derived from metal-organic frameworks for high-efficiency microwave attenuation. Carbon 2022, 187, 404–414. [Google Scholar]

- Yin, P.; Zhang, L.; Sun, P.; Wang, J.; Feng, X.; Zhang, Y.; Dai, J.; Tang, Y. Apium-derived biochar loaded with MnFe2O4@C for excellent low frequency electromagnetic wave absorption. Ceram. Int. 2020, 46, 13641–13650. [Google Scholar] [CrossRef]

- Zhao, B.; Zhao, W.; Shao, G.; Fan, B.; Zhang, R. Morphology-control synthesis of a core-shell structured NiCu alloy with tunable electromagnetic-wave absorption capabilities. ACS Appl. Mater. Interf. 2015, 7, 12951–12960. [Google Scholar] [CrossRef]

- Wu, H.; Liu, J.; Liang, H.; Zang, D. Sandwich-like Fe3O4/Fe3S4 composites for electromagnetic wave absorption. Chem. Eng. J. 2020, 393, 124743. [Google Scholar] [CrossRef]

- Xie, X.; Pang, Y.; Kikuchi, H.; Liu, T. The synergistic effects of the carbon coating and micropore structure on the microwave absorption properties of the Co/CoO nanoparticles. Phys. Chem. Chem. Phys. 2016, 18, 30507–30514. [Google Scholar] [CrossRef] [PubMed]

- Hekmatara, H.; Seifi, M.; Forooraghi, K. Microwave absorption property of aligned MWCNT/Fe3O4. J. Magn. Magn. Mater. 2013, 346, 186–191. [Google Scholar] [CrossRef]

- Xiao, X.; Zhu, W.; Tan, Z.; Tian, W.; Guo, Y.; Wang, H.; Fu, J.; Jian, X. Ultra-small Co/CNTs nanohybrid from metal organic framework with highly efficient microwave absorption. Compos. Part B 2018, 152, 316–323. [Google Scholar] [CrossRef]

- Zhou, X.; Jia, Z.; Zhang, X.; Wang, B.; Wu, W.; Liu, X.; Xu, B.; Wu, G. Controllable synthesis of Ni/NiO@porous carbon hybrid composites towards remarkable electromagnetic wave absorption and wide absorption bandwidth. J. Mater. Sci. Technol. 2021, 87, 120–132. [Google Scholar] [CrossRef]

- Hou, T.; Jia, Z.; Feng, A.; Zhou, Z.; Liu, X.; Lv, H.; Wu, G. Hierarchical composite of biomass derived magnetic carbon framework and phytic acid doped polyanilne with prominent electromagnetic wave absorption capacity. J. Mater. Sci. Technol. 2021, 68, 61–69. [Google Scholar] [CrossRef]

- Wang, L.; Huang, M.; Yu, X.; You, W.; Zhang, J.; Liu, X.; Wang, M.; Che, R. MOF-derived Ni1−xCox@carbon with tunable nano-microstructure as lightweight and highly efficient electromagnetic wave absorber. Nano-Micro Lett. 2020, 12, 150. [Google Scholar] [CrossRef]

- Zhang, F.; Jia, Z.; Wang, Z.; Zhang, C.; Wang, B.; Xu, B.; Liu, X.; Wu, G. Tailoring nanoparticles composites derived from metal-organic framework as electromagnetic wave absorber. Mater. Today Phys. 2021, 20, 100475. [Google Scholar] [CrossRef]

- Sun, C.; Jia, Z.; Xu, S.; Hu, D.; Zhang, C.; Wu, G. Synergistic regulation of dielectric-magnetic dual-loss and triple heterointerface polarization via magnetic MXene for high-performance electromagnetic wave absorption. J. Mater. Sci. Technol. 2022, 113, 128–137. [Google Scholar] [CrossRef]

- Ma, M.; Liao, Z.; Su, X.; Zheng, Q.; Liu, Y.; Wang, Y.; Ma, Y.; Wan, F. Magnetic CoNi alloy particles embedded N-doped carbon fibers with polypyrrole for excellent electromagnetic wave absorption. J. Colloid Inter. Sci. 2022, 608, 2203–2212. [Google Scholar] [CrossRef]

- Cheng, R.; Wang, Y.; Di, X.; Lu, Z.; Wang, P.; Ma, M.; Ye, J. Construction of MOF-derived plum-like NiCo@C composite with enhanced multi-polarization for high-efficiency microwave absorption. J. Colloid Inter. Sci. 2022, 609, 224–234. [Google Scholar] [CrossRef]

- Dai, B.; Zhao, B.; Xie, X.; Su, T.; Fan, B.; Zhang, R.; Yang, R. A novel two-dimensional Ti3C2Tx MXenes/nano-carbon spheres hybrids for high-performance microwave absorption. J. Mater. Chem. C 2018, 6, 5690–5697. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, L.; Wu, H. Electromagnetic wave-absorbing performance of carbons, carbides, oxides, ferrites and sulfides: Review and perspective. J. Phys. D Appl. Phys. 2021, 54, 203001. [Google Scholar] [CrossRef]

- Cao, X.; Jia, Z.; Hu, D.; Wu, G. Synergistic construction of three-dimensional conductive network and double heterointerface polarization via magnetic FeNi for broadband microwave absorption. Adv. Compos. Hybrid Mater. 2022, 1–4. [Google Scholar] [CrossRef]

- Lan, D.; Qin, M.; Yang, R.; Chen, S.; Wu, H.; Fan, Y.; Fu, Q.; Zhang, F. Facile synthesis of hierarchical chrysanthemum-like copper cobaltate-copper oxide composites for enhanced microwave absorption performance. J. Colloid Inter. Sci. 2019, 533, 481–491. [Google Scholar] [CrossRef]

- Yin, P.; Zhang, L.; Wang, J.; Feng, X.; Zhang, Y.; Dai, J.; Liu, J. Tailoring microstructures in (Ni/NiO)@C composites via facile route for broadband microwave absorption. Ceram. Int. 2022, 48, 12979–12987. [Google Scholar] [CrossRef]

- Hou, T.; Jia, Z.; Dong, Y.; Liu, X.; Wu, G. Layered 3D structure derived from MXene/magnetic carbon nanotubes for ultra-broadband electromagnetic wave absorption. Chem. Eng. J. 2022, 431, 133919. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, L.; Wu, H.; Zang, D. Boosted electromagnetic wave absorption performance from vacancies, defects and interfaces engineering in Co(OH)F/Zn0.76Co0.24S/Co3S4 composite. Chem. Eng. J. 2021, 411, 128601. [Google Scholar] [CrossRef]

- Hou, T.; Jia, Z.; Wang, B.; Li, H.; Liu, X.; Chi, Q.; Wu, G. Metal-organic framework derived NiSe2-CoSe2@C/Ti3C2Tx composites as electromagnetic wave absorbers. Chem. Eng. J. 2021, 422, 130079. [Google Scholar] [CrossRef]

- Liao, Z.; Ma, M.; Tong, Z.; Bi, Y.; Chung, K.L.; Qiao, M.; Ma, Y.; Ma, A.; Wu, G.; Li, Z.; et al. Fabrication of one-dimensional ZnFe2O4@carbon@MoS2/FeS2 composites as electromagnetic wave absorber. J. Colloid Interf. Sci. 2021, 599, 262–270. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, X.; E, X.; Wang, B.; Jia, Z.; Chi, Q.; Wu, G. Synthesis of MnxOy@C hybrid composites for optimal electromagnetic wave absorption capacity and wideband absorption. J. Mater. Sci. Technol. 2022, 103, 157–164. [Google Scholar] [CrossRef]

- Xie, P.; Zhang, Z.; Wang, Z.; Sun, K.; Fan, R. Targeted double negative properties in silver/silica random metamaterials by precise control of microstructures. Research 2019, 2019, 1021368. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, Z.; Kou, K.; Zhang, L.; Wu, H. Optimal particle distribution induced interfacial polarization in bouquet-like hierarchical composites for electromagnetic wave absorption. Carbon 2021, 186, 323–332. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, L.; Luo, B.; Wu, H. Optimal control of the compositions, interfaces, and defects of hollow sulfide for electromagnetic wave absorption. J. Colloid Interf. Sci. 2021, 607, 24–33. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Xu, B.; Ma, M.; Feng, A.; Zhang, Y.; Liu, X.; Jia, Z.; Wu, G. Electrostatic self-assembly synthesis of ZnFe2O4 quantum dots (ZnFe2O4@C) and electromagnetic microwave absorption. Compos. Part B 2019, 179, 107417. [Google Scholar] [CrossRef]

- Zhang, X.; Jia, Z.; Zhang, F.; Xia, Z.; Zou, J.; Gu, Z.; Wu, G. MOF-derived NiFe2S4/porous carbon composites as electromagnetic wave absorber. J. Colloid Inter. Sci. 2022, 610, 610–620. [Google Scholar] [CrossRef]

- Wang, C.; Jia, Z.; He, S.; Zhou, J.; Zhang, S.; Tian, M.; Wang, B.; Wu, G. Metal-organic framework-derived CoSn/NC nanocubes as absorbers for electromagnetic wave attenuation. J. Mater. Sci. Technol. 2022, 108, 236–243. [Google Scholar] [CrossRef]

- Qin, M.; Zhang, L.; Wu, H. Dual-template hydrothermal synthesis of multi-channel porous NiCo2O4 hollow spheres as high-performance electromagnetic wave absorber. Appl. Surf. Sci. 2020, 515, 146132. [Google Scholar] [CrossRef]

- Wu, L.; Wu, F.; Sun, Q.; Shi, J.; Xie, A.; Zhu, X.; Dong, W. A TTF–TCNQ complex: An organic charge-transfer system with extraordinary electromagnetic response behavior. J. Mater. Chem. C 2021, 9, 3316–3323. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, K.; Shi, J.; Wu, F.; Zhu, X.; Dong, W.; Xie, A. Metal/nitrogen co-doped hollow carbon nanorods derived from self-assembly organic nanostructure for wide bandwidth electromagnetic wave absorption. Compos. Part B 2022, 228, 109424. [Google Scholar] [CrossRef]

- Lan, D.; Zhao, Z.; Gao, Z.; Kou, K.; Wu, H. Novel magnetic silicate composite for lightweight and efficient electromagnetic wave absorption. J. Mater. Sci. Technol. 2021, 92, 51–59. [Google Scholar] [CrossRef]

- Zhao, H.; Cheng, Y.; Ma, J.; Zhang, Y.; Jia, G.; Du, Y. A sustainable route from biomass cotton to construct lightweight and high-performance microwave absorber. Chem. Eng. J. 2018, 339, 432–441. [Google Scholar] [CrossRef]

- Shu, R.; Li, W.; Zhou, X.; Tian, D.; Zhang, G.; Gan, Y.; Shi, J.; He, J. Facile preparation and microwave absorption properties of RGO/MWCNTs/ZnFe2O4 hybrid nanocomposites. J. Alloy. Compd. 2018, 743, 163–174. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Yin, P.; Liu, J.; Zhang, T.; Wang, S.; Liu, L. Transferring A4 Paper to FeNi3/NiCx Coated Carbon Skeleton for Efficient Absorption of Multiband Microwave. Metals 2022, 12, 848. https://doi.org/10.3390/met12050848

Wang J, Yin P, Liu J, Zhang T, Wang S, Liu L. Transferring A4 Paper to FeNi3/NiCx Coated Carbon Skeleton for Efficient Absorption of Multiband Microwave. Metals. 2022; 12(5):848. https://doi.org/10.3390/met12050848

Chicago/Turabian StyleWang, Jian, Pengfei Yin, Junchi Liu, Tao Zhang, Shusheng Wang, and Lei Liu. 2022. "Transferring A4 Paper to FeNi3/NiCx Coated Carbon Skeleton for Efficient Absorption of Multiband Microwave" Metals 12, no. 5: 848. https://doi.org/10.3390/met12050848

APA StyleWang, J., Yin, P., Liu, J., Zhang, T., Wang, S., & Liu, L. (2022). Transferring A4 Paper to FeNi3/NiCx Coated Carbon Skeleton for Efficient Absorption of Multiband Microwave. Metals, 12(5), 848. https://doi.org/10.3390/met12050848