Microstructure and Mechanical Properties of Medium-Carbon Si-Rich Steel Processed by Austempering after Intercritical Annealing

Abstract

:1. Introduction

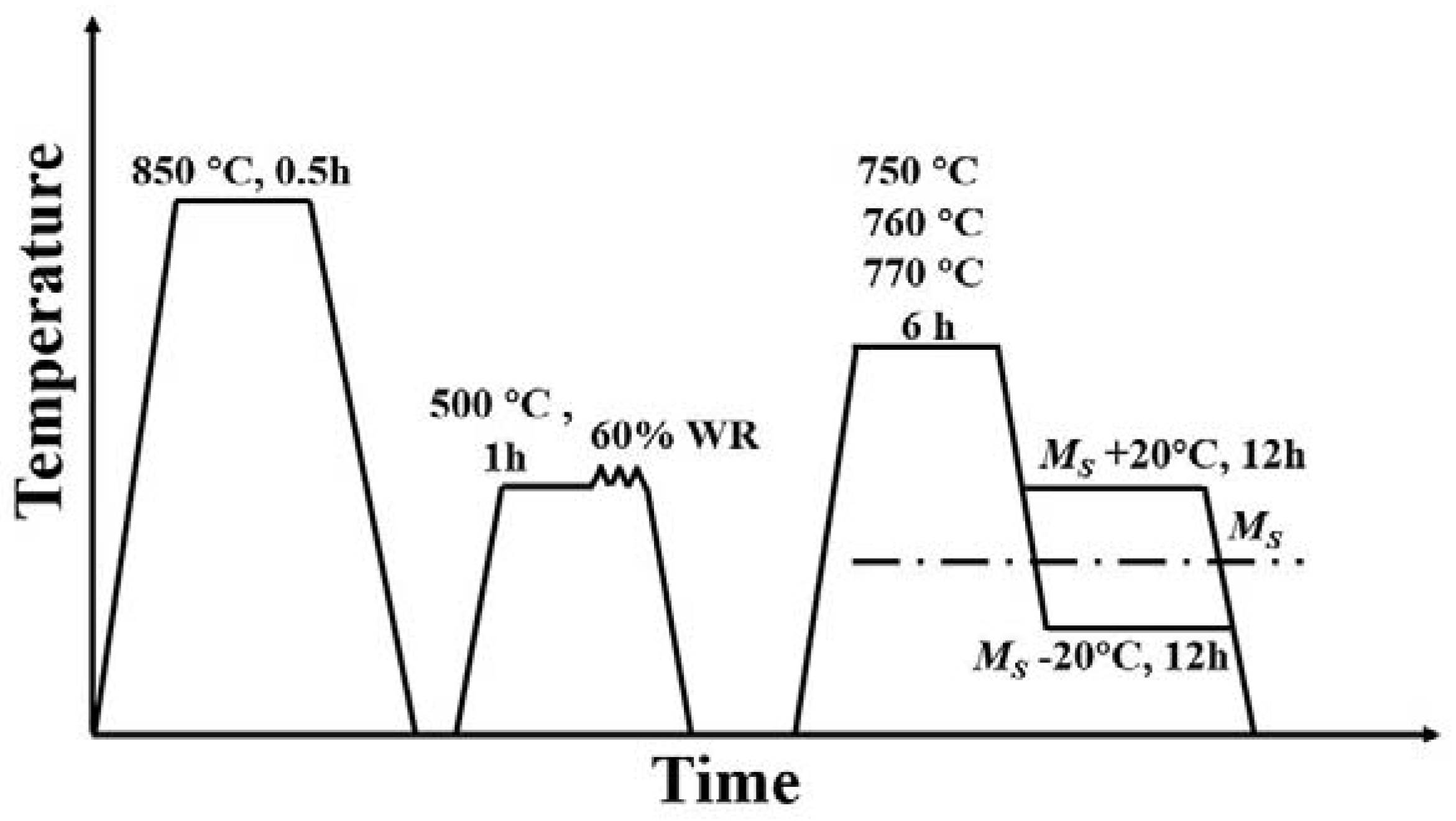

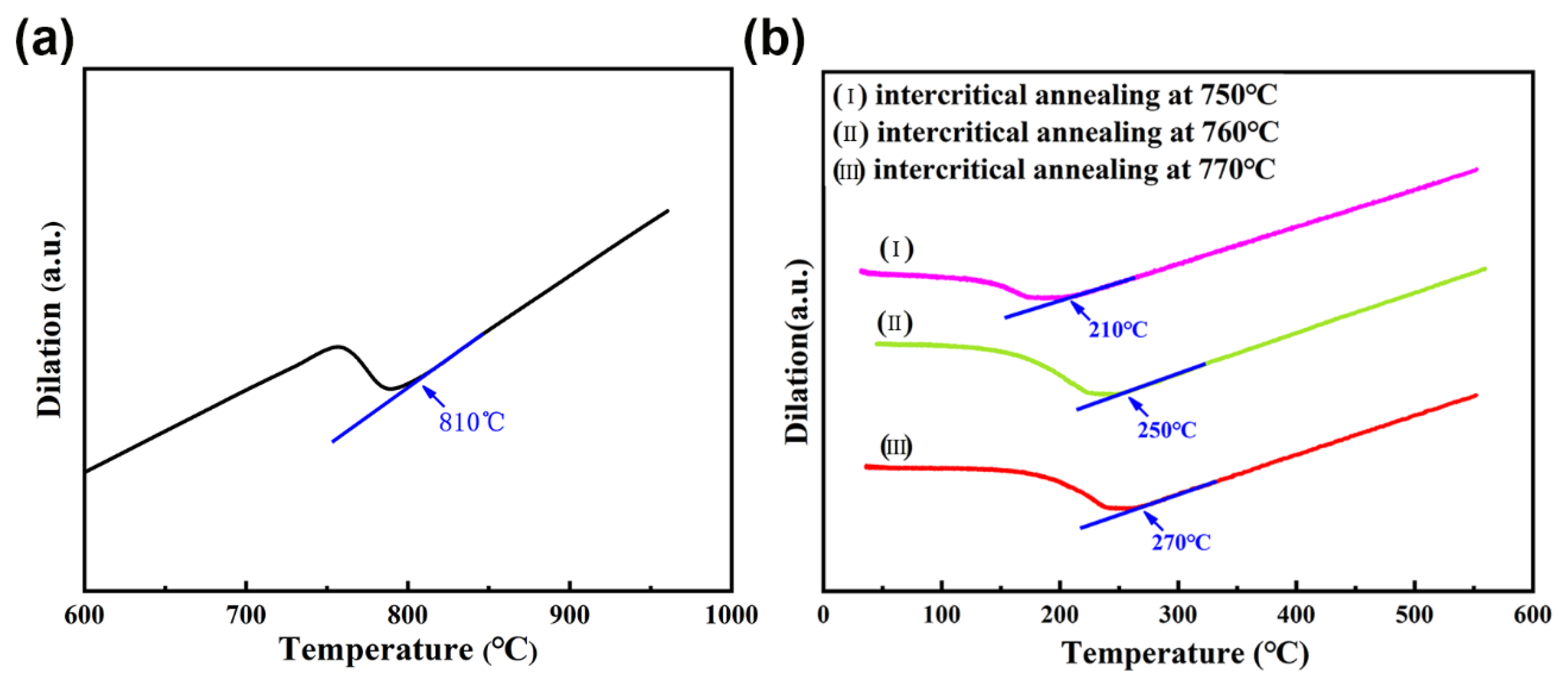

2. Materials and Experimental Methods

3. Results and Discussion

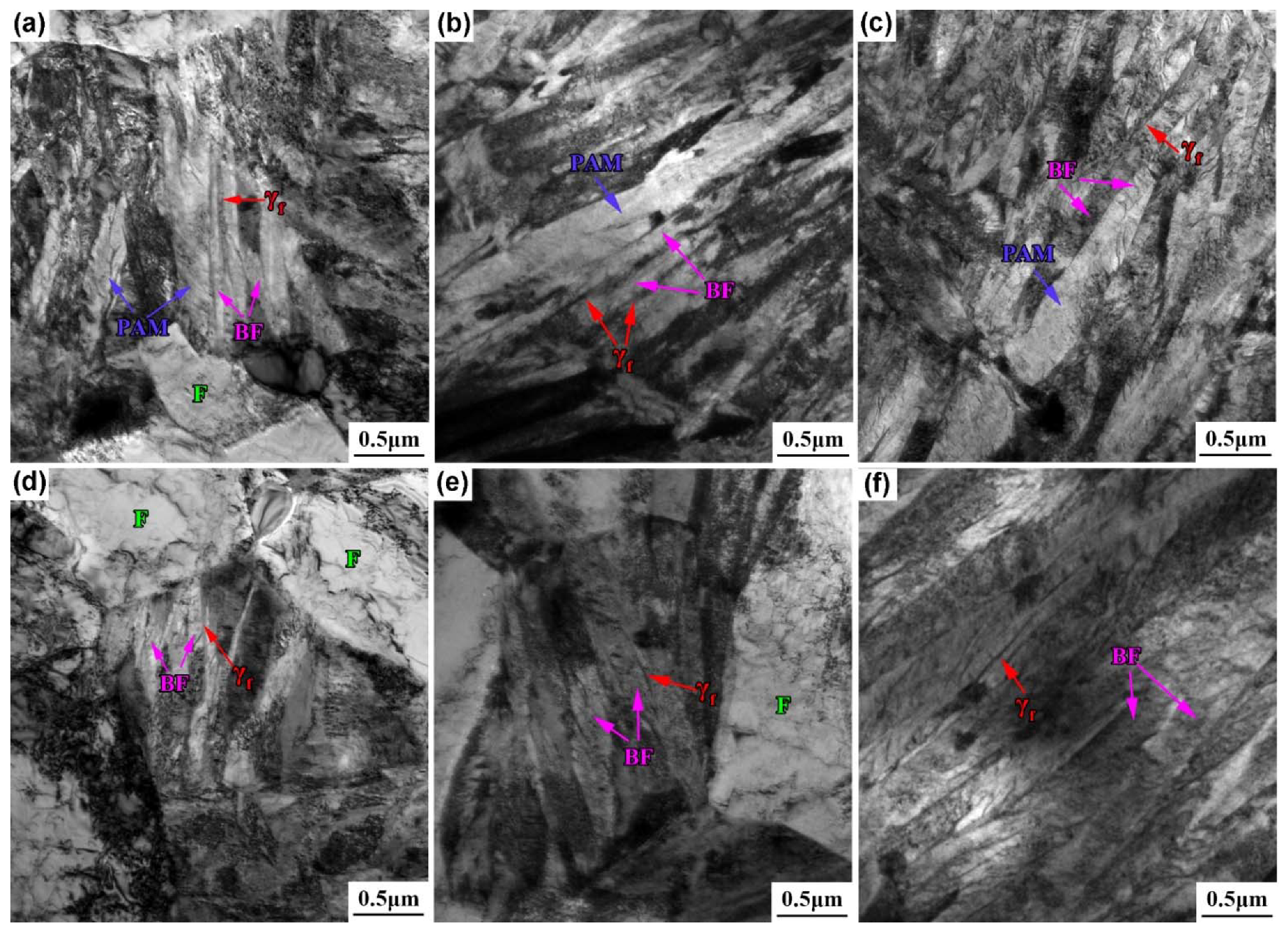

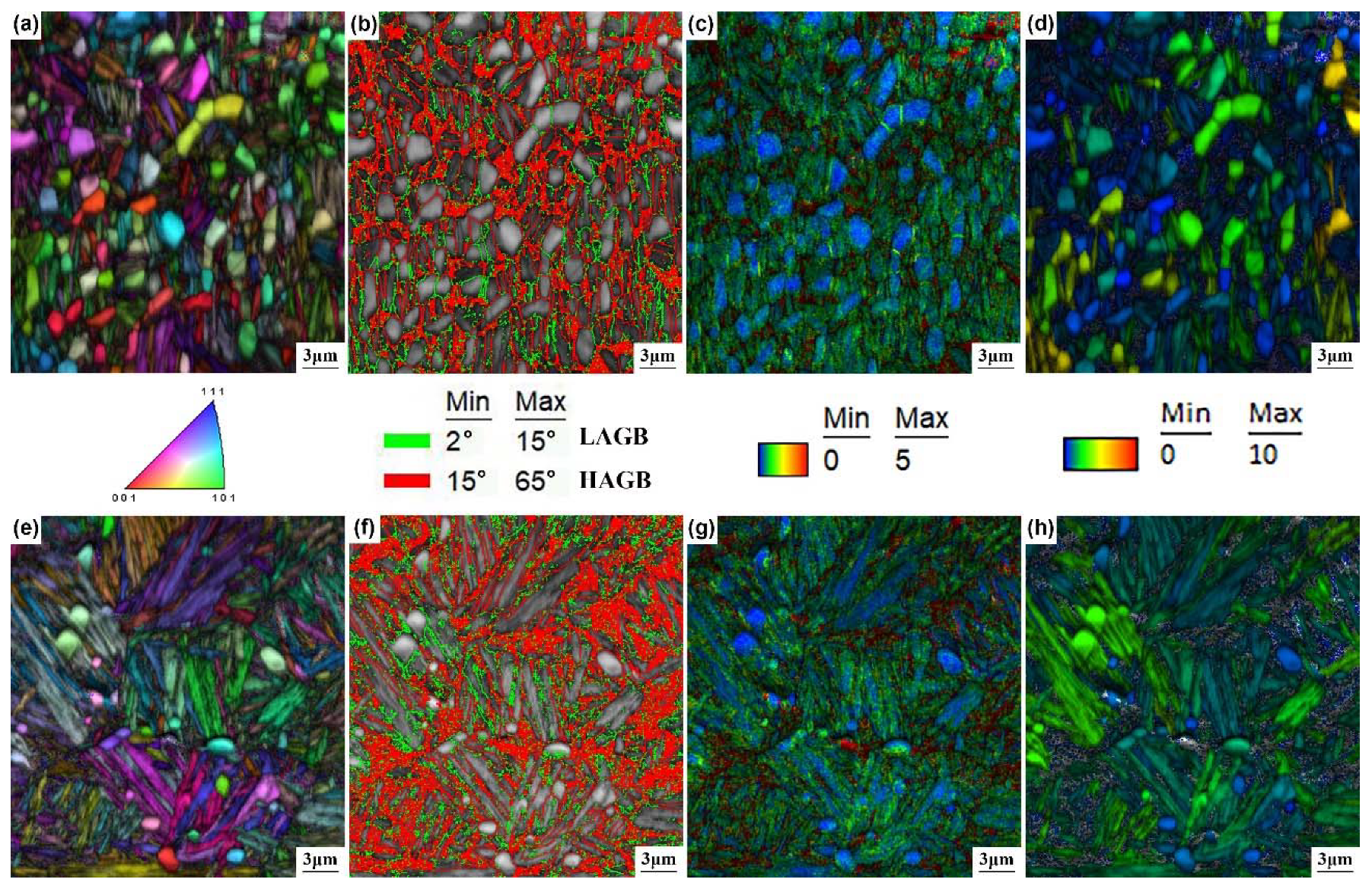

3.1. Microstructures

3.2. Mechanical Properties

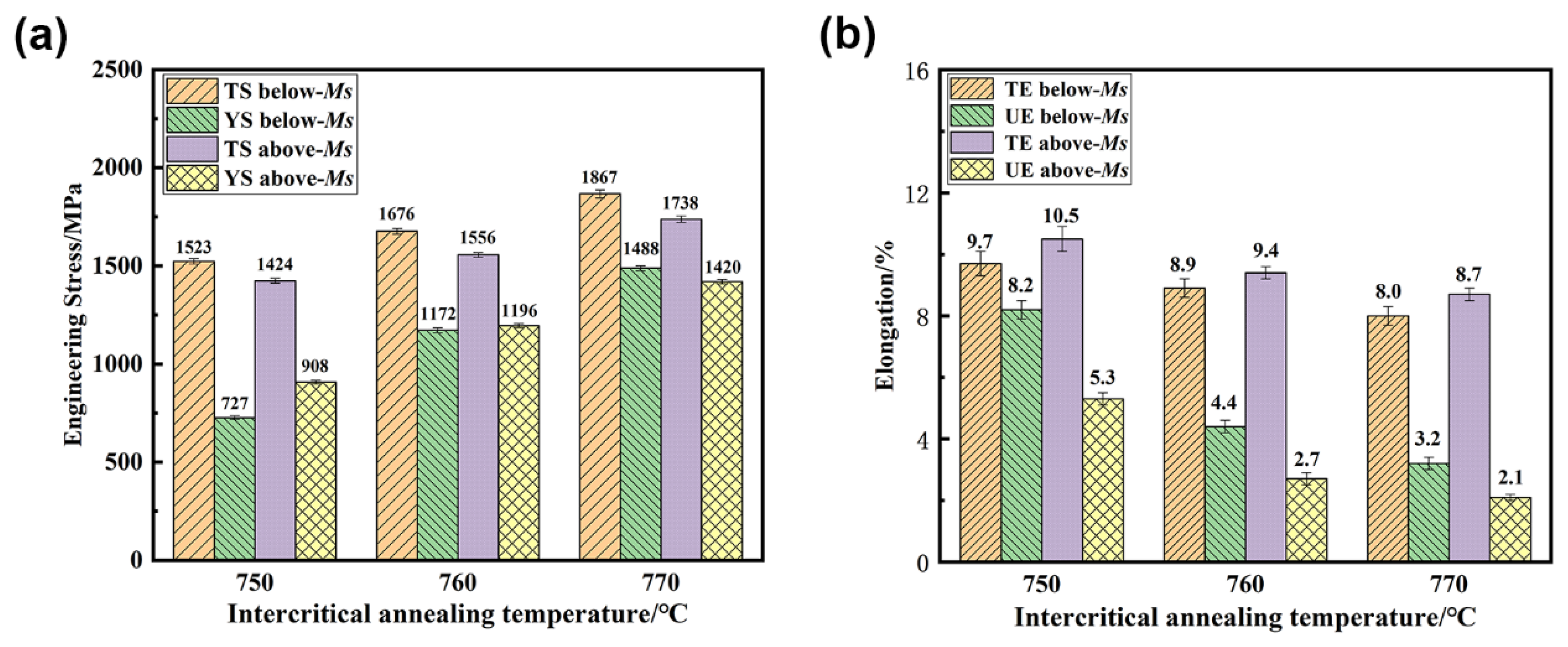

3.2.1. Tensile Properties

3.2.2. Impact Properties

4. Conclusions

- (1)

- After intercritical annealing at 750 °C, 760 °C and 770 °C, the volume fractions of ferrite of ~30%, ~15% and ~5% were obtained, respectively. At increasing intercritical annealing temperatures, the average ferrite grain size decreased slightly to ~1.6 μm, ~1.4 μm and ~1.2 μm at 750 °C, 760 °C and 770 °C, respectively. The bainite ferrite laths were obtained after austempering below and above Ms, and a certain amount of prior athermal martensite (PAM) was obtained after austempering below Ms, resulting in a finer bainite ferrite lath.

- (2)

- The interfaces in microstructures obtained by different processes were mainly HAGBs, while a few LAGBs existed at the ferrite grain boundaries and at the interfaces between ferrite and bainite ferrite. There were obvious strain concentrations at the interfaces between ferrite and bainite ferrite laths, and at the interfaces of bainite ferrite laths. In addition, the degree of recrystallization in ferrite grains was almost complete at increasing intercritical annealing temperature.

- (3)

- With increasing intercritical annealing temperature, the bainite content increased, resulting in the increase in yield strength and tensile strength, while the uniform elongation decreased significantly. This was due to the formation of the soft ferrite phase at lower intercritical annealing temperatures. The initiating time of strain transferring from soft to hard phase was delayed; thus, the uniform elongation improved. In addition, the tensile strength decreased slightly and the impact property improved after austempering above Ms at the same intercritical annealing temperature when compared to austempering below Ms.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, Z.H.; Guan, Z.Z.; Lian, J.S. Effects of microstructural variables on the deformation behavior of dual-phase steel. Mater. Sci. Eng. A 1995, 190, 55–64. [Google Scholar] [CrossRef]

- Sarwar, M.; Priestner, R. Influence of ferrite-martensite microstructural morphology on tensile properties of dual-phase steel. J. Mater. Sci. 1996, 31, 2091–2095. [Google Scholar] [CrossRef]

- Bouaziz, O.; Lung, T.; Kandel, M.; Lecomte, C. Physical modelling of microstructure and mechanical properties of dual-phase steel. J. Phys. IV 2001, 11, Pr4-223–Pr4-231. [Google Scholar] [CrossRef]

- Liedl, U.; Traint, S.; Werner, E.A. An unexpected feature of the stress–strain diagram of dual-phase steel. Comput. Mater. Sci. 2002, 25, 122–128. [Google Scholar] [CrossRef]

- Saeidi, N.; Ekrami, A. Comparison of mechanical properties of martensite/ferrite and bainite/ferrite dual phase 4340 steels. Mater. Sci. Eng. A 2009, 523, 125–129. [Google Scholar] [CrossRef]

- Bakhtiari, R.; Ekrami, A. The effect of bainite morphology on the mechanical properties of a high bainite dual phase (HBDP) steel. Mater. Sci. Eng. A 2009, 525, 159–165. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Development of hard bainite. ISIJ Int. 2003, 43, 1238–1243. [Google Scholar] [CrossRef] [Green Version]

- Caballero, F.G.; Bhadeshia, H.K.D.H. Very strong bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 251–257. [Google Scholar] [CrossRef] [Green Version]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Very strong low temperature bainite. Mater. Sci. Technol. 2002, 18, 279–284. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Mechanical Properties of Low-Temperature Bainite. Mater. Sci. Forum. 2005, 500–501, 495–502. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Acceleration of low-temperature bainite. ISIJ Int. 2003, 43, 285–288. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.L.; Lv, B.; Zhang, F.C.; Yang, Z.N.; Qian, L.H.; Chen, C.; Long, X.Y. Effects of austempering temperature on bainitic microstructure and mechanical properties of a high-C high-Si steel. Mater. Sci. Eng. A 2019, 742, 179–189. [Google Scholar] [CrossRef]

- Zhao, J.; Guo, K.; He, Y.M.; Wang, Y.F.; Wang, T.S. Extremely high strength achievement in medium-C nanobainite steel. Scr. Mater. 2018, 152, 20–23. [Google Scholar] [CrossRef]

- Tian, J.Y.; Xu, G.; Hu, H.J.; Wang, X.; Zurob, H. Transformation kinetics of carbide-free bainitic steels during isothermal holding above and below MS. J. Mater. Res. Technol. 2020, 9, 13594–13606. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Jahanara, A.H.; Sheikhi, M.; Kalashami, A.G. High strength-elongation balance in ultrafine grained ferrite-martensite dual phase steels developed by thermomechanical processing. Mater. Sci. Eng. A 2019, 761, 138021. [Google Scholar] [CrossRef]

- Jahanara, A.H.; Mazaheri, Y.; Sheikhi, M. Correlation of ferrite and martensite micromechanical behavior with mechanical properties of ultrafine grained dual phase steels. Mater. Sci. Eng. A 2019, 764, 138206. [Google Scholar] [CrossRef]

- Xiong, Z.P.; Saleh, A.A.; Kostryzhev, A.G.; Pereloma, E.V. Strain-induced ferrite formation and its effect on mechanical properties of a dual phase steel produced using laboratory simulated strip casting. J. Alloys Compd. 2017, 721, 291–306. [Google Scholar] [CrossRef] [Green Version]

- Zhao, T.; Jia, X.; Chen, C.; Zhang, F.C.; Wang, T.S. Simultaneously improved strength and impact toughness by introducing ultrafine ferrite in low-temperature bainitic steel. J. Mater. Res. Technol. 2021, 15, 5106–5113. [Google Scholar] [CrossRef]

- Jia, X.; Zhao, T.; Wang, L.; Sun, X.W.; Wang, Y.F.; Wang, T.S. Microstructure and Mechanical Properties of Low- and Medium-Carbon Si-Rich Low-Alloy Steels Processed by Austemping after Intercritical Annealing. Materials 2022, 15, 1178. [Google Scholar] [CrossRef]

- De, A.K.; Murdock, D.C.; Mataya, M.C.; Speer, J.G.; Matlock, D.K. Quantitative measurement of deformation-induced martensite in 304 stainless steel by X-ray diffraction. Scr. Mater. 2004, 50, 1445–1449. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Kermanpur, A.; Najafizadeh, A. A novel route for development of ultrahigh strength dual phase steels. Mater. Sci. Eng. A 2014, 619, 1–11. [Google Scholar] [CrossRef]

- Huang, J.; Poole, W.J.; Militzer, M. Austenite formation during intercritical annealing. Metall. Mater. Trans. A 2004, 35, 3363–3375. [Google Scholar] [CrossRef]

- Chang, L.C.; Bhadeshia, H.K.D.H. Austenite films in bainitic microstructures. Mater. Sci. Technol. 1995, 11, 874–882. [Google Scholar] [CrossRef]

- Zhao, L.J.; Qian, L.H.; Meng, J.Y.; Zhou, Q.; Zhang, F.C. Below-Ms austempering to obtain refined bainitic structure and enhanced mechanical properties in low-C high-Si/Al steels. Scr. Mater. 2016, 112, 96–100. [Google Scholar] [CrossRef]

- Qian, L.H.; Li, Z.; Wang, T.L.; Li, D.D.; Zhang, F.C.; Meng, J.Y. Roles of pre-formed martensite in below-Ms bainite formation, microstructure, strain partitioning and impact absorption energies of low-carbon bainitic steel. J. Mater. Sci. Technol. 2022, 96, 69–84. [Google Scholar] [CrossRef]

- Navarro-Lopez, A.; Hidalgo, J.; Sietsma, J.; Santofimia, M.J. Influence of the prior athermal martensite on the mechanical response of advanced bainitic steel. Mater. Sci. Eng. A 2018, 735, 343–353. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G. Ultra-high-strength bainitic steels. ISIJ Int. 2005, 45, 1736–1740. [Google Scholar] [CrossRef] [Green Version]

- Chiang, J.; Lawrence, B.; Boyd, J.D.; Pilkey, A.K. Effect of microstructure on retained austenite stability and work hardening of TRIP steels. Mater. Sci. Eng. A 2011, 528, 4516–4521. [Google Scholar] [CrossRef]

- Mark, A.F.; Wang, X.; Essadiqi, E.; Embury, J.D.; Boyd, J.D. Development and characterisation of model TRIP steel microstructures. Mater. Sci. Eng. A 2013, 576, 108–117. [Google Scholar] [CrossRef]

- Pierman, A.P.; Bouaziz, O.; Pardoen, T.; Jacques, P.J.; Brassart, L. The influence of microstructure and composition on the plastic behaviour of dual-phase steels. Acta Mater. 2014, 73, 298–311. [Google Scholar] [CrossRef]

- Wang, T.L.; Qian, L.H.; Li, K.F.; Zhang FC Meng, J.Y. Strain-hardening behavior and mechanisms of a lamellar-structured low-alloy TRIP steel. Mater. Sci. Eng. A 2021, 819, 141498. [Google Scholar] [CrossRef]

- Gurumurthy, B.M.; Sharma, S.S.; Kini, A.; Mansoor, S. Effect of preheat treatment structure on mechanical characterization of AISI 4340 ferrite bainite dual phase steel. Mater. Today Proc. 2018, 9, 84–89. [Google Scholar]

| Heat Treatment Processes | 750–190 | 750–230 | 760–230 | 760–270 | 770–250 | 770–290 |

|---|---|---|---|---|---|---|

| Thickness of bainite ferrite (BF) laths, nm | 74 ± 3 | 112 ± 8 | 108 ± 7 | 146 ± 18 | 123 ± 12 | 165 ± 23 |

| Volume fraction of retained austenite (RA), vol. % | 12.5 ± 0.3 | 15.3 ± 0.6 | 9.6 ± 0.3 | 13.1 ± 0.6 | 5.8 ± 0.4 | 8.6 ± 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, X.; Wang, Y.; Wang, L.; Sun, X.; Zhao, T.; Wang, T. Microstructure and Mechanical Properties of Medium-Carbon Si-Rich Steel Processed by Austempering after Intercritical Annealing. Metals 2022, 12, 441. https://doi.org/10.3390/met12030441

Jia X, Wang Y, Wang L, Sun X, Zhao T, Wang T. Microstructure and Mechanical Properties of Medium-Carbon Si-Rich Steel Processed by Austempering after Intercritical Annealing. Metals. 2022; 12(3):441. https://doi.org/10.3390/met12030441

Chicago/Turabian StyleJia, Xin, Yuefeng Wang, Lin Wang, Xiaowen Sun, Ting Zhao, and Tiansheng Wang. 2022. "Microstructure and Mechanical Properties of Medium-Carbon Si-Rich Steel Processed by Austempering after Intercritical Annealing" Metals 12, no. 3: 441. https://doi.org/10.3390/met12030441

APA StyleJia, X., Wang, Y., Wang, L., Sun, X., Zhao, T., & Wang, T. (2022). Microstructure and Mechanical Properties of Medium-Carbon Si-Rich Steel Processed by Austempering after Intercritical Annealing. Metals, 12(3), 441. https://doi.org/10.3390/met12030441