Tempering Behavior of Novel Low-Alloy High-Strength Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

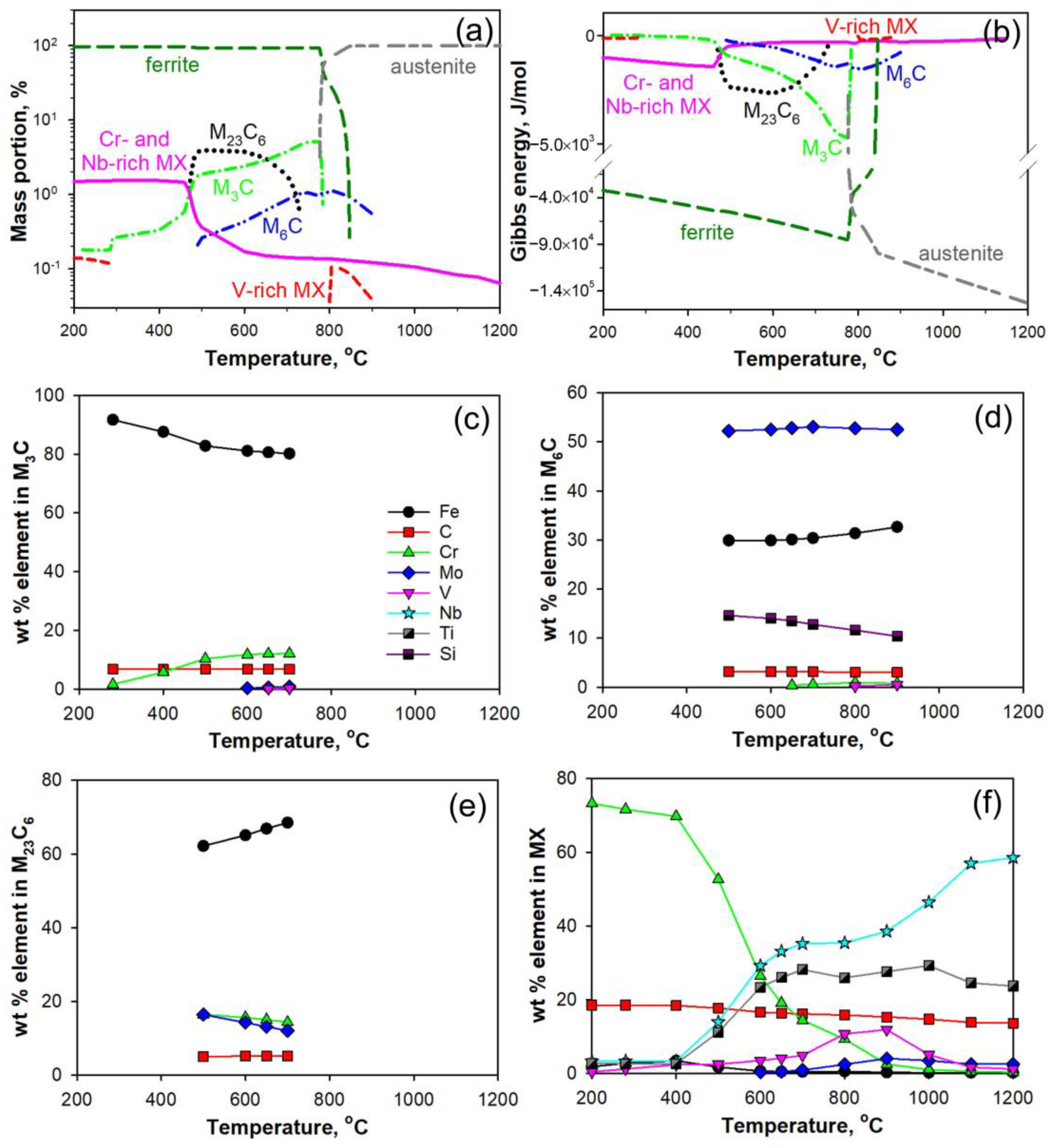

3.1. Thermodynamic Analysis

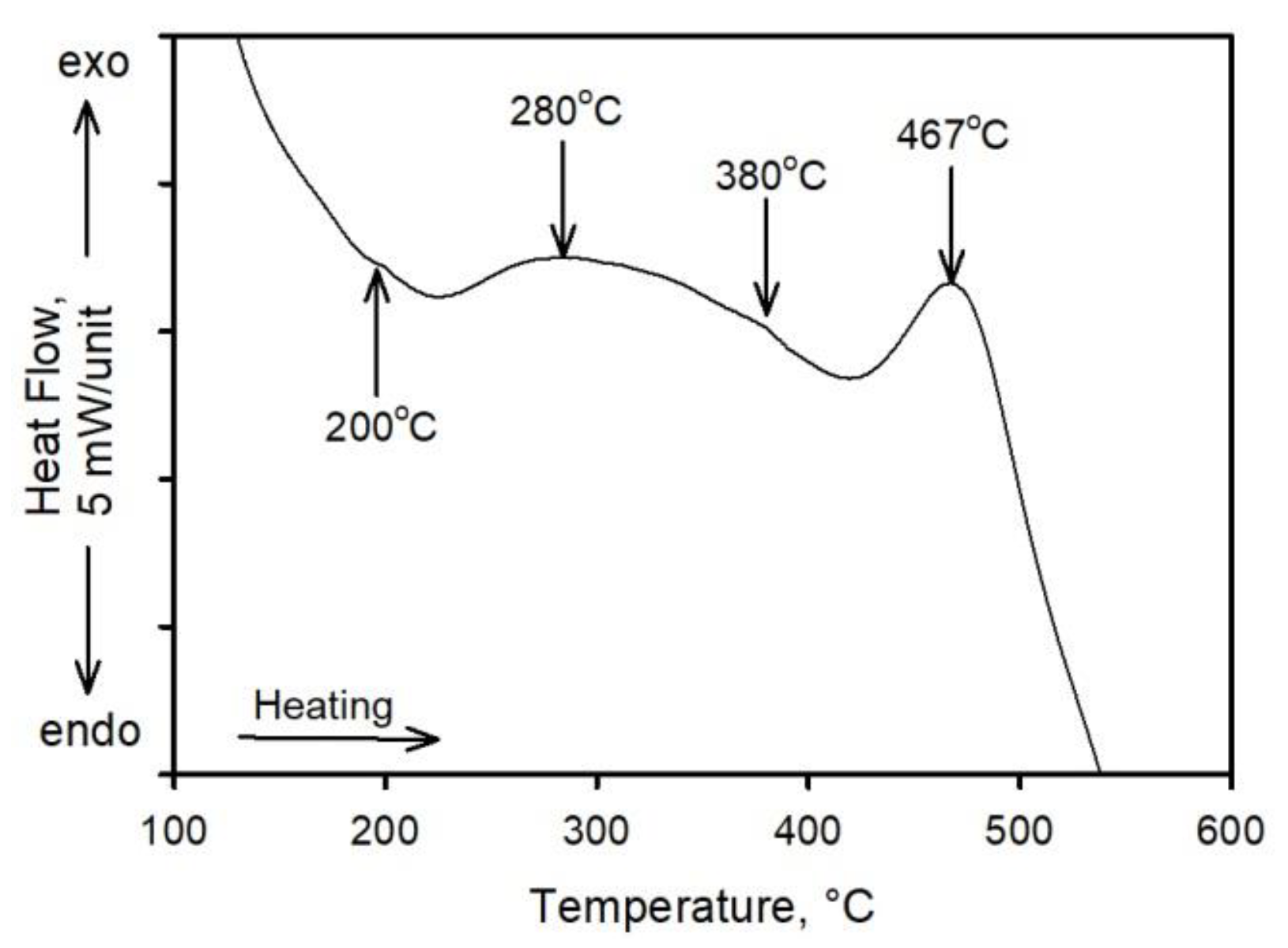

3.2. DSC Analysis

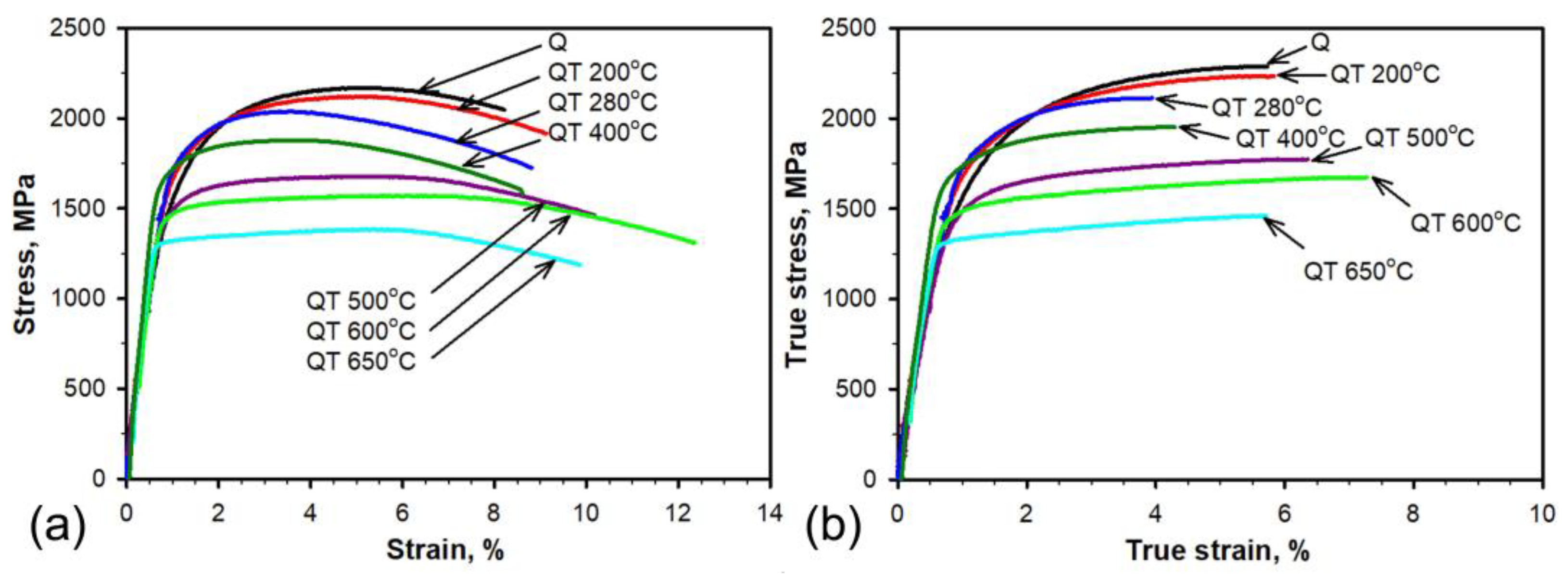

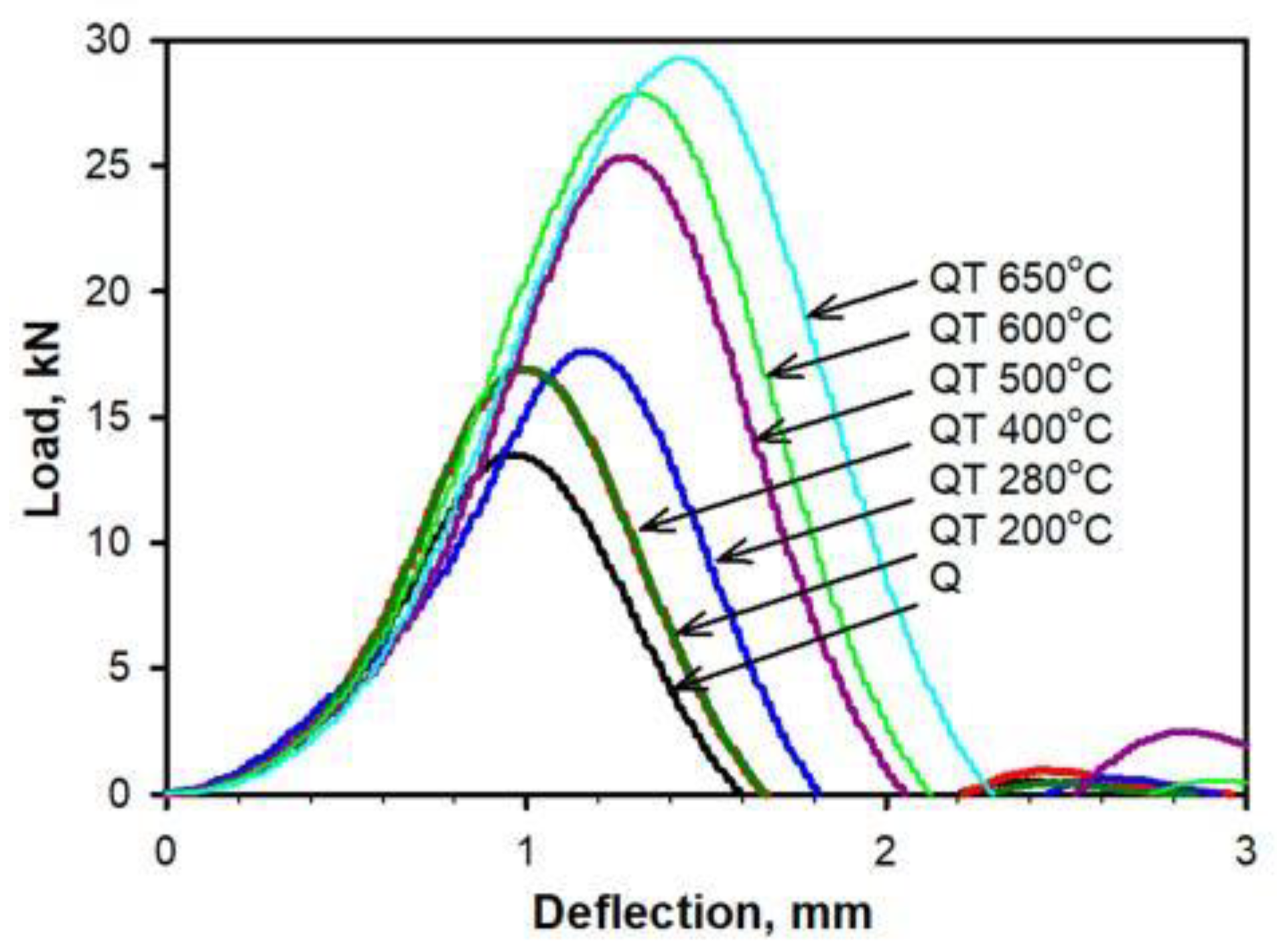

3.3. Mechanical Properties

3.4. Microstructure after Quenching

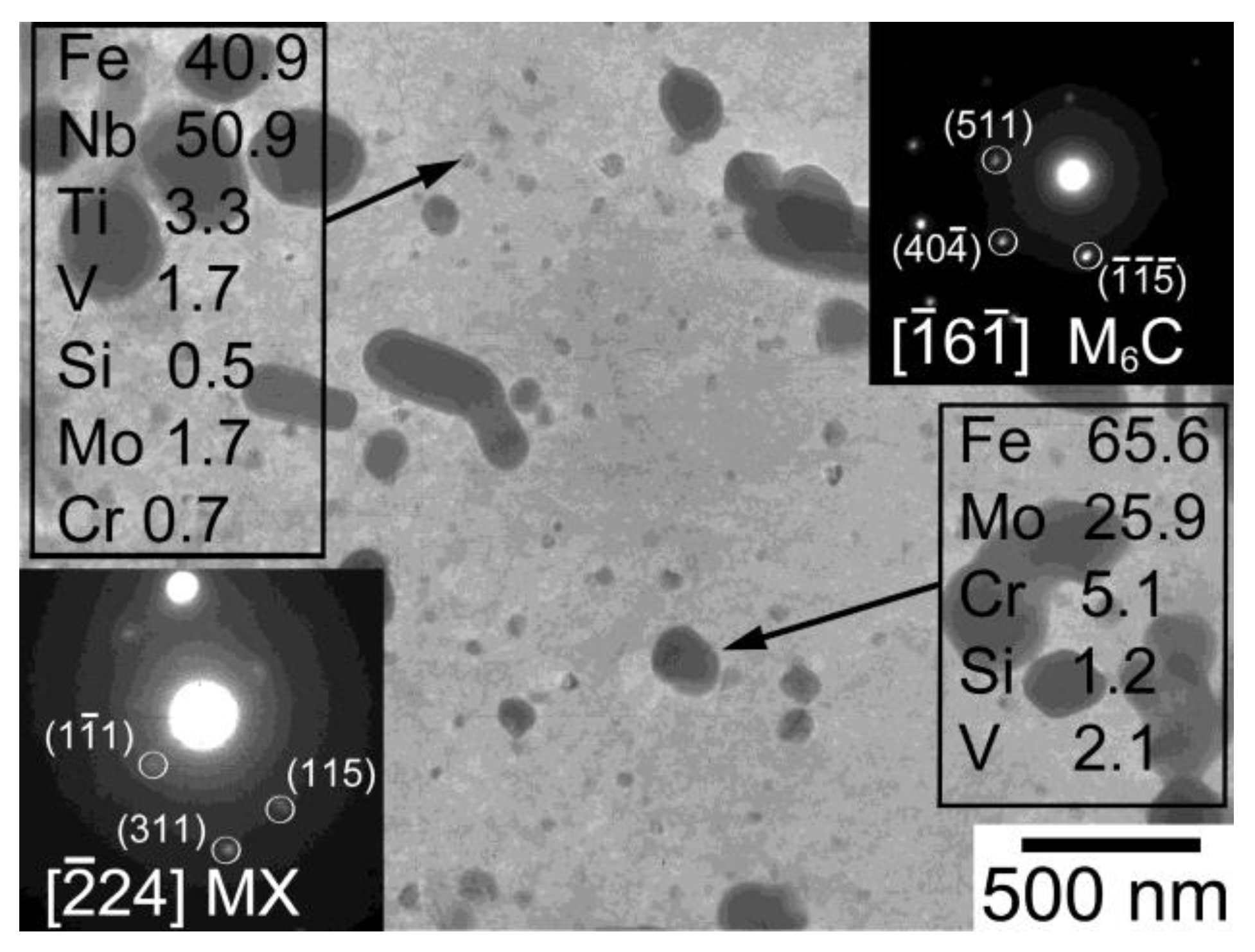

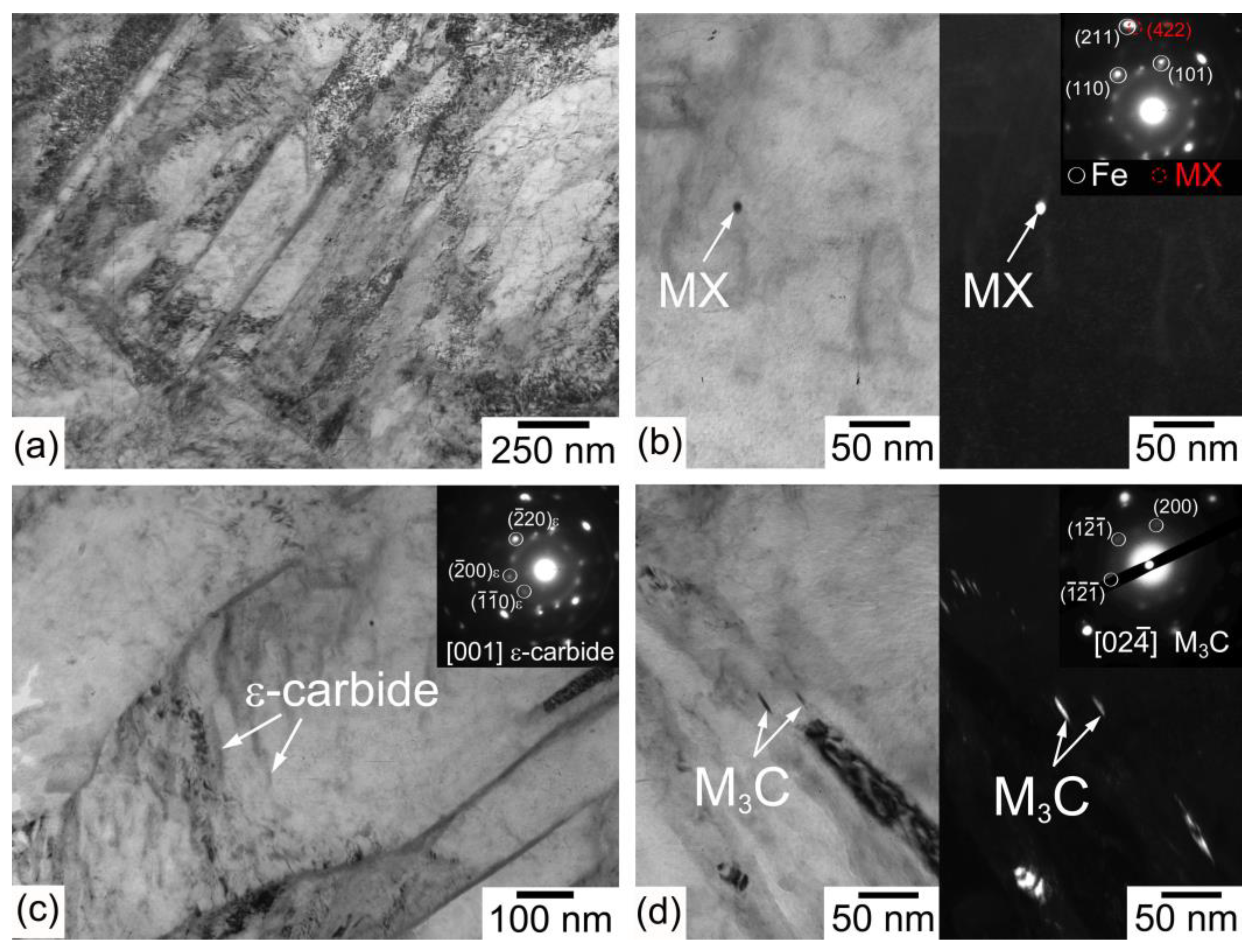

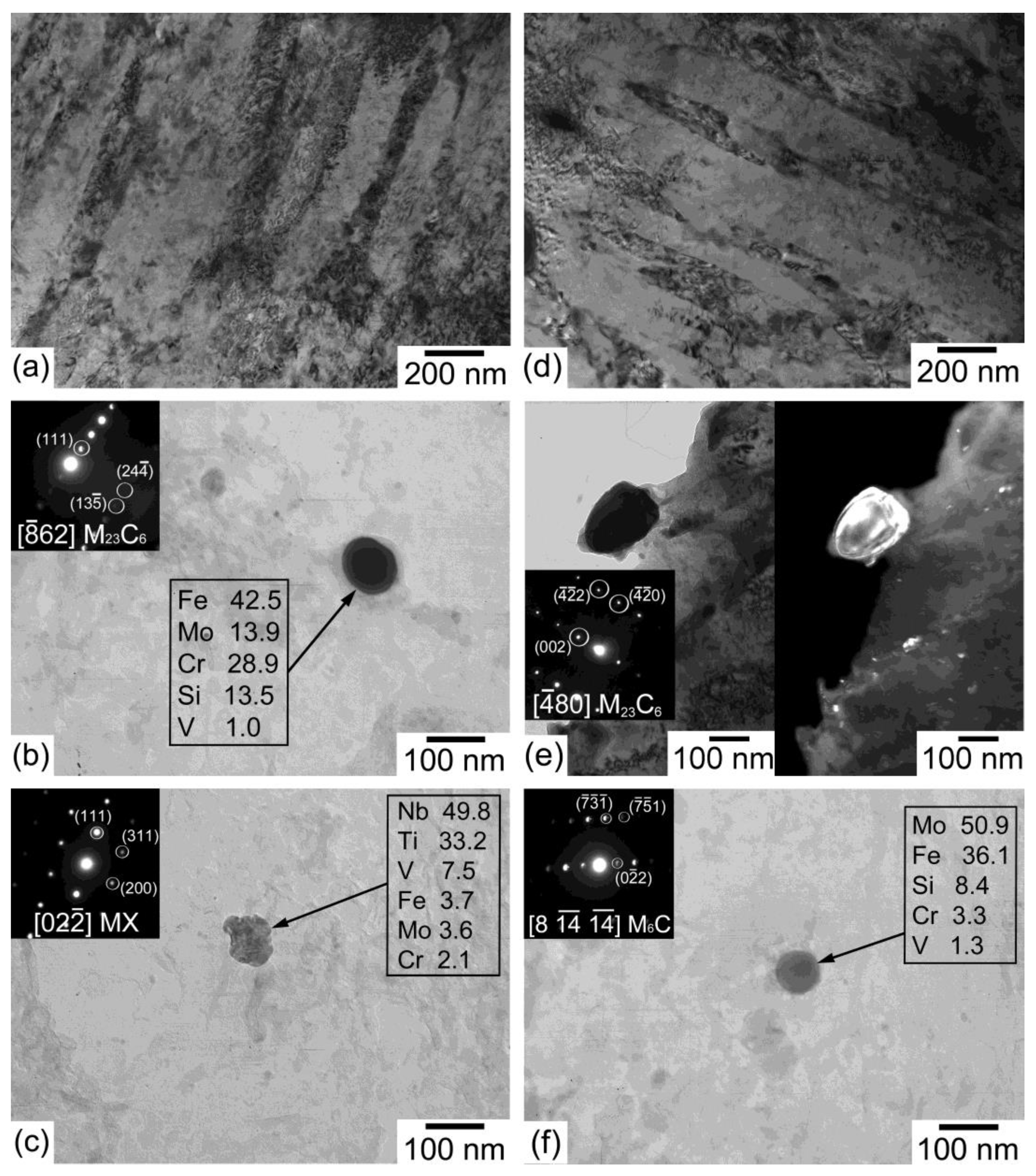

3.5. Microstructure after Tempering Treatments

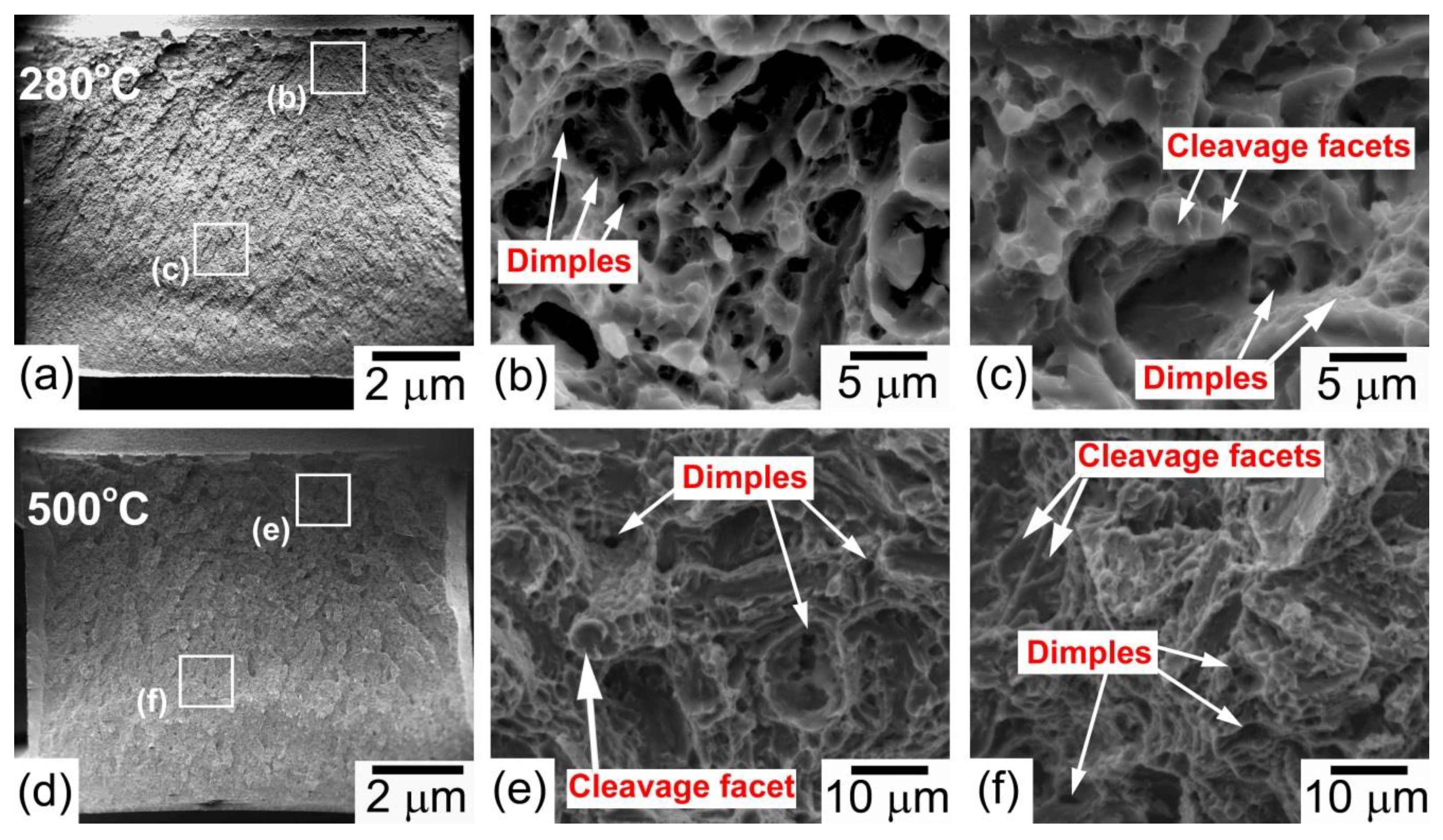

3.6. Fractography

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tomita, Y. Development of fracture toughness of ultrahigh strength, medium carbon, low alloy steels for aerospace applications. Int. Mater. Rev. 2000, 45, 27–37. [Google Scholar] [CrossRef]

- Youngblood, J.L.; Raghavan, M. Microstructure and Mechanical Properties of Quenched and Tempered 300M Steel; National Aeronautics and Space Administration, Scientific and Technical Information Office: Washington, DC, USA, 1978. [Google Scholar]

- Military Handbook—MIL-HDBK-5H: Metallic Materials and Elements for Aerospace Vehicle Structures; The Department of Defense: Washington, DC, USA, 2003.

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279–1288. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Pydrin, A.; Gaidar, S.; Kaibyshev, R.; Belyakov, A. Microstructure and Strengthening Mechanisms in an HSLA Steel Subjected to Tempforming. Metals 2021, 12, 48. [Google Scholar] [CrossRef]

- Xiong, Z.; Timokhina, I.; Pereloma, E. Clustering, nano-scale precipitation and strengthening of steels. Prog. Mater. Sci. 2020, 118, 100764. [Google Scholar] [CrossRef]

- Krauss, G. Steels: Processing Structure, and Performance, 2nd ed.; ASM International: Materials Park, OH, USA, 2005. [Google Scholar]

- Kim, B.; Celada, C.; Martín, D.S.; Sourmail, T.; Rivera-Díaz-Del-Castillo, P. The effect of silicon on the nanoprecipitation of cementite. Acta Mater. 2013, 61, 6983–6992. [Google Scholar] [CrossRef] [Green Version]

- Forsik, S.A.; Rivera-Diaz-Del-Castillo, P.E. Martensitic Steels: Epsilon Carbides in Tempered. In Encyclopedia of Iron, Steel, and Their Alloys; Taylor and Francis: New York, USA, 2016; pp. 2169–2181. [Google Scholar] [CrossRef]

- Fedoseeva, A.; Dudova, N.; Kaibyshev, R. Creep strength breakdown and microstructure evolution in a 3%Co modified P92 steel. Mater. Sci. Eng. A 2015, 654, 1–12. [Google Scholar] [CrossRef]

- Vervynckt, S.; Verbeken, K.; Lopez, B.; Jonas, J.J. Modern HSLA steels and role of non-recrystallisation temperature. Int. Mater. Rev. 2012, 57, 187–207. [Google Scholar] [CrossRef]

- Hidalgo, J.; Santofimia, M.J. Effect of Prior Austenite Grain Size Refinement by Thermal Cycling on the Microstructural Features of As-Quenched Lath Martensite. Met. Mater. Trans. A 2016, 47, 5288–5301. [Google Scholar] [CrossRef] [Green Version]

- Galindo-Nava, E.; Rivera-Díaz-Del-Castillo, P. A model for the microstructure behaviour and strength evolution in lath martensite. Acta Mater. 2015, 98, 81–93. [Google Scholar] [CrossRef]

- Dong, J.; Zhou, X.; Liu, Y.; Li, C.; Liu, C.; Guo, Q. Carbide precipitation in Nb-V-Ti microalloyed ultra-high strength steel during tempering. Mater. Sci. Eng. A 2016, 683, 215–226. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, K.; Eckert, J. Effect of tempering and deep cryogenic treatment on microstructure and mechanical properties of Cr–Mo–V–Ni steel. Mater. Sci. Eng. A 2020, 787, 139520. [Google Scholar] [CrossRef]

- Ren, J.; Li, C.; Han, Y.; Li, E.; Gao, C.; Qiu, C. Effect of initial martensite and tempered carbide on mechanical properties of 3Cr2MnNiMo mold steel. Mater. Sci. Eng. A 2021, 812, 141080. [Google Scholar] [CrossRef]

- ASTM E 23-12c; Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2013; pp. 1–25. [CrossRef]

- Gey, N.; Humbert, M. Characterization of the Variant Selection Occurring during the A→β→α Phase Transformations of a Cold Rolled Titanium Sheet. Acta Mater. 2002, 50, 277–287. [Google Scholar] [CrossRef]

- Hua, P.; Mironov, S.; Sato, Y.S.; Kokawa, H.; Park, S.H.C.; Hirano, S. Crystallography of Martensite in Friction-Stir-Welded 12Cr Heat-Resistant Steel. Met. Mater. Trans. A 2019, 50, 3158–3163. [Google Scholar] [CrossRef] [Green Version]

- Dudko, V.; Fedoseeva, A.; Kaibyshev, R. Ductile-brittle transition in a 9% Cr heat-resistant steel. Mater. Sci. Eng. A 2016, 682, 73–84. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Yanushkevich, Z.; Nikulin, S.; Belyakov, A.; Kaibyshev, R. Impact toughness of an S700MC-type steel: Tempforming vs ausforming. Mater. Sci. Eng. A 2018, 723, 259–268. [Google Scholar] [CrossRef] [Green Version]

- Horn, R.M.; Ritchie, R.O. Mechanisms of tempered martensite embrittlement in low alloy steels. Met. Mater. Trans. A 1978, 9, 1039–1053. [Google Scholar] [CrossRef]

- Antolovich, S.D.; Armstrong, R.W. Plastic strain localization in metals: Origins and consequences. Prog. Mater. Sci. 2014, 59, 1–160. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T. Mechanical Property of Ultrafine Elongated Grain Structure Steel Processed by Warm Tempforming and Its Application to Ultra-High-Strength Bolt. ISIJ Int. 2020, 60, 1108–1126. [Google Scholar] [CrossRef] [Green Version]

- Kimura, Y.; Inoue, T. Influence of Carbon Content on Toughening in Ultrafine Elongated Grain Structure Steels. ISIJ Int. 2015, 55, 1135–1144. [Google Scholar] [CrossRef] [Green Version]

- Server, W.L. General Yielding of Charpy V-Notch and Precracked Charpy Specimens. J. Eng. Mater. Technol. 1978, 100, 183–188. [Google Scholar] [CrossRef]

- Knott, J.F. Fundamentals of Fracture Mechanics; The Butterworth Group: London, UK, 1973. [Google Scholar]

- Chaouadi, R.; Fabry, A. On the Utilization of the Instrumented Charpy Impact Test for Characterizing the Flow and Fracture Behawiour of Reactor Pressure Vessel Steel. In From Charpy to Present Impact Testing; Franqois, D., Pineau, A., Eds.; Elsevier Science Ltd. and ESIS: Oxford, UK, 2002; pp. 103–117. ISBN 9780080528977. [Google Scholar]

- Porter, D.A.; Esterling, K.E.; Sherif, M. Phase Transformation in Metals and Alloys, 3rd ed.; CRS Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Kozeschnik, E.; Bhadeshia, H.K.D.H. Influence of silicon on cementite precipitation in steels. Mater. Sci. Technol. 2008, 24, 343–347. [Google Scholar] [CrossRef]

- Fedoseeva, A.; Dudova, N.; Glatzel, U.; Kaibyshev, R. Effect of W on tempering behaviour of a 3%Co modified P92 steel. J. Mater. Sci. 2016, 51, 9424–9439. [Google Scholar] [CrossRef]

- Fedorova, I.; Kostka, A.; Tkachev, E.; Belyakov, A.; Kaibyshev, R. Tempering behavior of a low nitrogen boron-added 9%Cr steel. Mater. Sci. Eng. A 2016, 662, 443–455. [Google Scholar] [CrossRef] [Green Version]

- Tkachev, E.; Belyakov, A.; Kaibyshev, R. Creep behavior and microstructural evolution of a 9%Cr steel with high B and low N contents. Mater. Sci. Eng. A 2018, 725, 228–241. [Google Scholar] [CrossRef]

| Tempering Temperature, °C | Sy, MPa | Su, MPa | Elu, % | Elt, % | HRC | CVN, J/cm2 |

|---|---|---|---|---|---|---|

| 20 | 1445 | 2170 | 4.9 | 7.2 | 55 | 10 |

| 200 | 1625 | 2120 | 4.7 | 8.2 | 54 | 12 |

| 280 | 1695 | 2040 | 3.4 | 8.0 | 54 | 14 |

| 400 | 1675 | 1880 | 3.6 | 8.0 | 53 | 12 |

| 500 | 1415 | 1680 | 5.0 | 10.2 | 50 | 21 |

| 600 | 1460 | 1580 | 6.5 | 11.5 | 48 | 26 |

| 650 | 1310 | 1390 | 5.0 | 9.2 | 44 | 33 |

| Tempering Temperature, °C | 20 | 200 | 280 | 400 | 500 | 600 | 650 |

|---|---|---|---|---|---|---|---|

| Pmax, kN | 13.5 | 16.9 | 17.7 | 16.8 | 25.3 | 27.8 | 29.5 |

| PGY, kN | 33.8 | 38.1 | 39.7 | 39.6 | 33.1 | 34.2 | 30.7 |

| Tempering Temperature, °C | 20 | 280 | 400 | 500 | 600 |

|---|---|---|---|---|---|

| PAG size, µm | 12.2 ± 0.7 | – | – | – | – |

| Distance between HAB, µm | 0.84 ± 0.03 | – | – | – | – |

| Lath size, nm | 137 ± 10 | 152 ± 31 | 203 ± 20 | 210 ± 14 | 200 ± 12 |

| Dislocation density, 1014 m−2 | 15 ± 2 | 8.6 ± 1.6 | 5.1 ± 1.1 | 5.8 ± 1.0 | 5.9 ± 1.3 |

| Cementite size, nm | – | 5/17 | 15/125 | – | – |

| ε-carbide size (width/length), nm | – | (6 ± 1)/(31 ± 10) | (7 ± 1)/(52 ± 10) | – | – |

| Carbonitrides size, nm | 40 ± 11 | 40 ± 10 | 41 ± 10 | 43 ± 11 | 46 ± 5 |

| M23C6, nm | – | – | – | 35 ± 9 | 49 ± 17 |

| M6C, nm | 209 ± 16 | 210 ± 16 | 207 ± 20 | 211 ± 12 | 208 ± 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dudko, V.; Yuzbekova, D.; Gaidar, S.; Vetrova, S.; Kaibyshev, R. Tempering Behavior of Novel Low-Alloy High-Strength Steel. Metals 2022, 12, 2177. https://doi.org/10.3390/met12122177

Dudko V, Yuzbekova D, Gaidar S, Vetrova S, Kaibyshev R. Tempering Behavior of Novel Low-Alloy High-Strength Steel. Metals. 2022; 12(12):2177. https://doi.org/10.3390/met12122177

Chicago/Turabian StyleDudko, Valeriy, Diana Yuzbekova, Sergey Gaidar, Sofia Vetrova, and Rustam Kaibyshev. 2022. "Tempering Behavior of Novel Low-Alloy High-Strength Steel" Metals 12, no. 12: 2177. https://doi.org/10.3390/met12122177

APA StyleDudko, V., Yuzbekova, D., Gaidar, S., Vetrova, S., & Kaibyshev, R. (2022). Tempering Behavior of Novel Low-Alloy High-Strength Steel. Metals, 12(12), 2177. https://doi.org/10.3390/met12122177