Effects of Heat Treatment on the Microstructure and Properties of a Cast Nickel-Based High-Cr Superalloy

Abstract

1. Introduction

2. Materials and Methods

3. Results

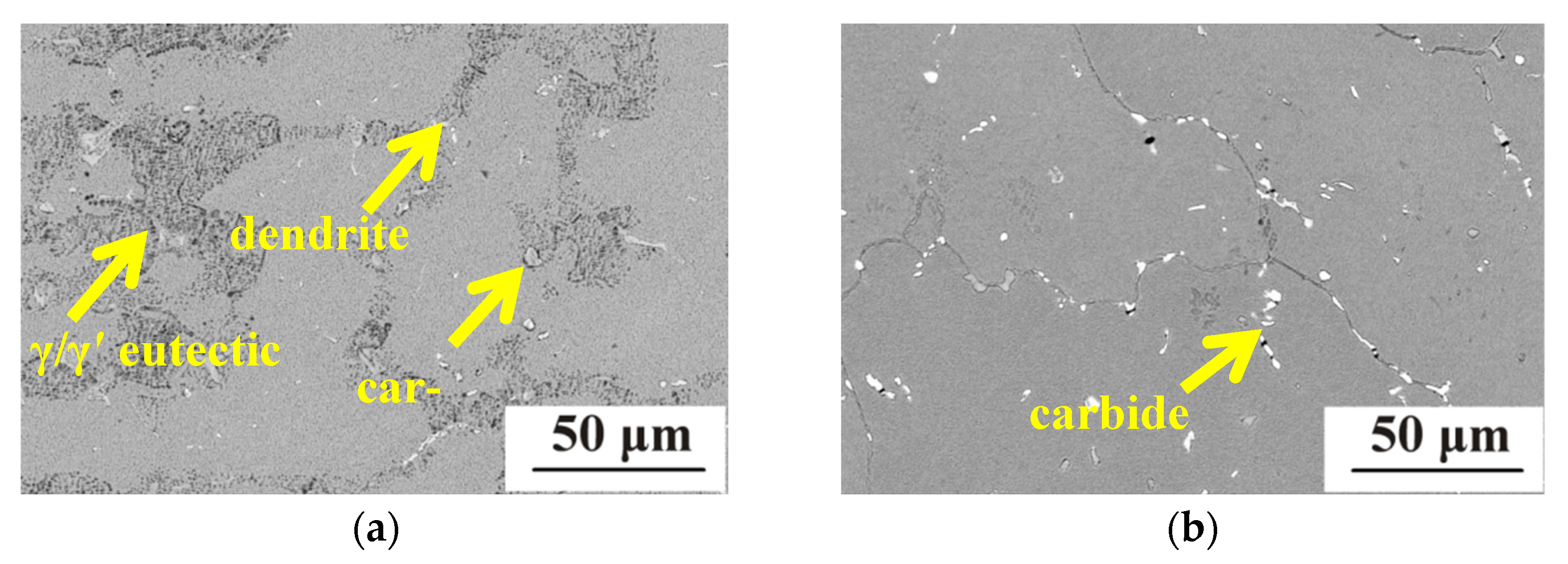

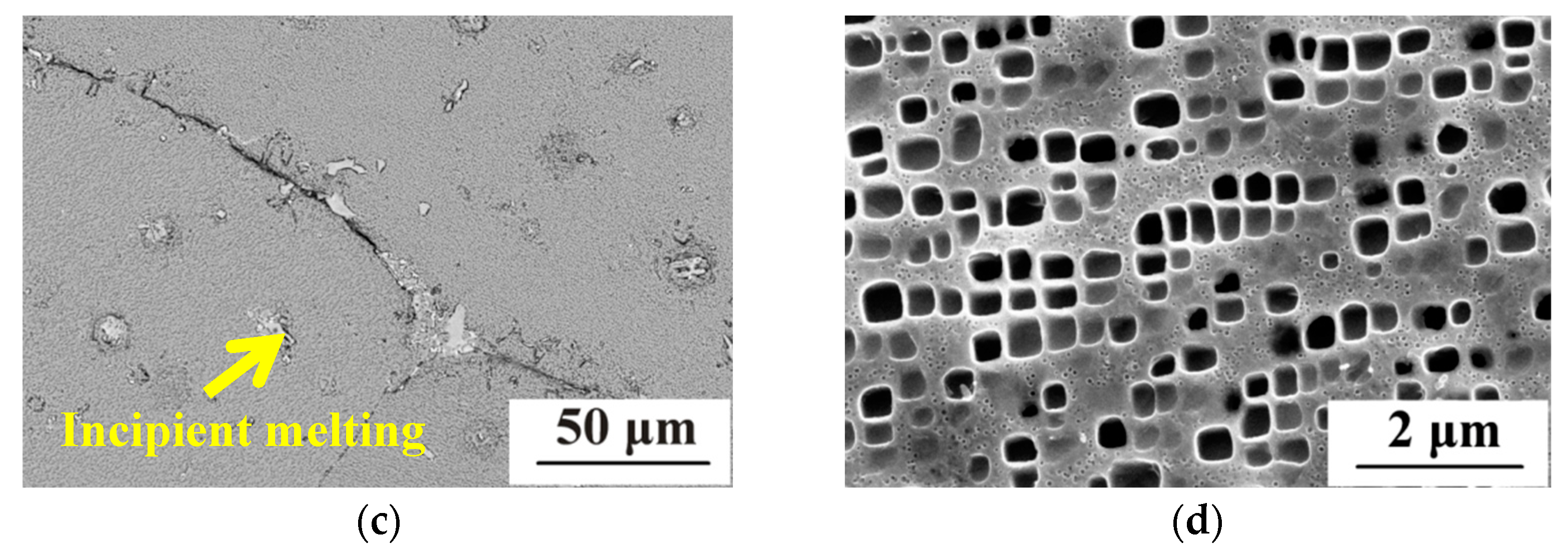

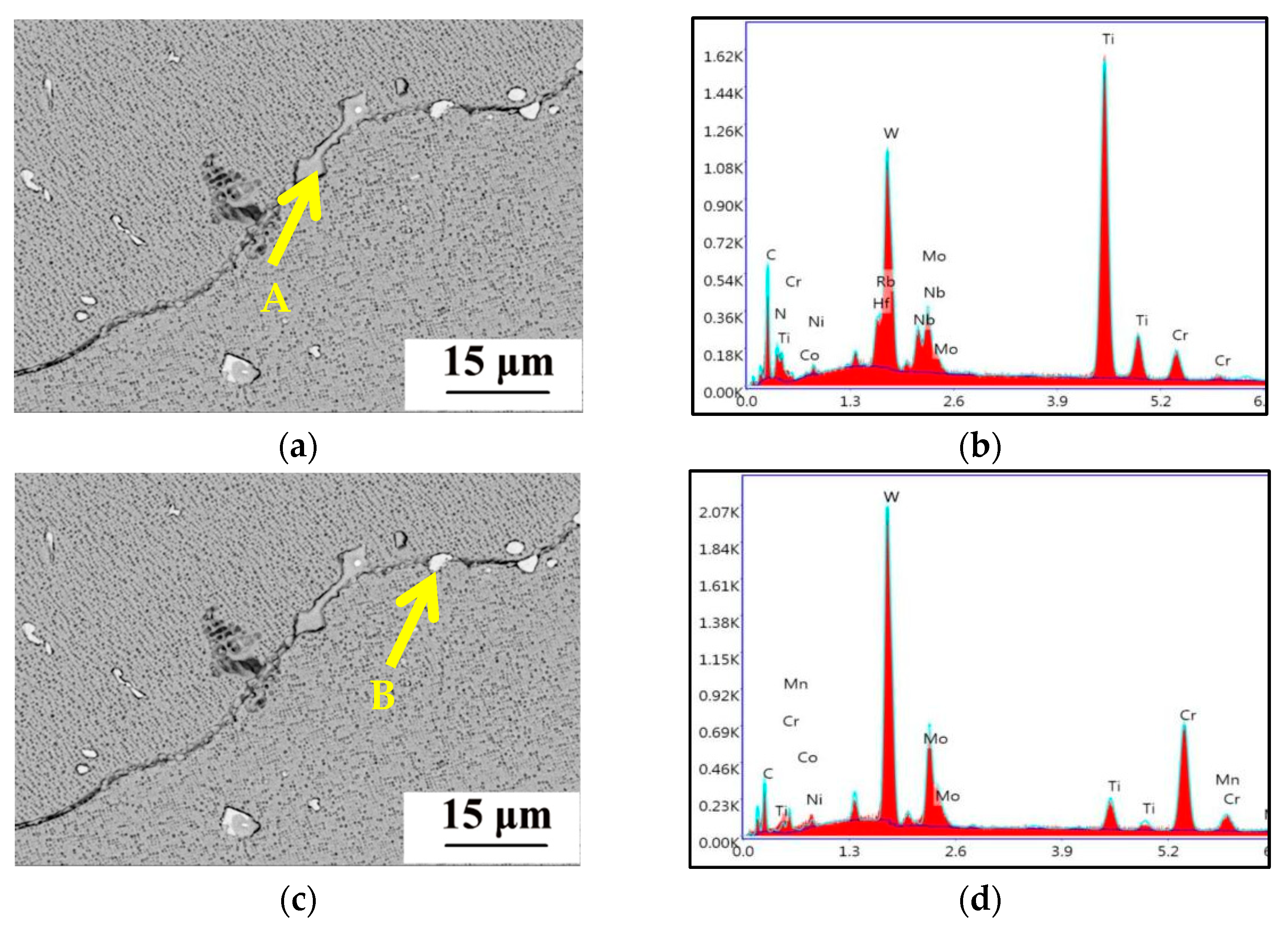

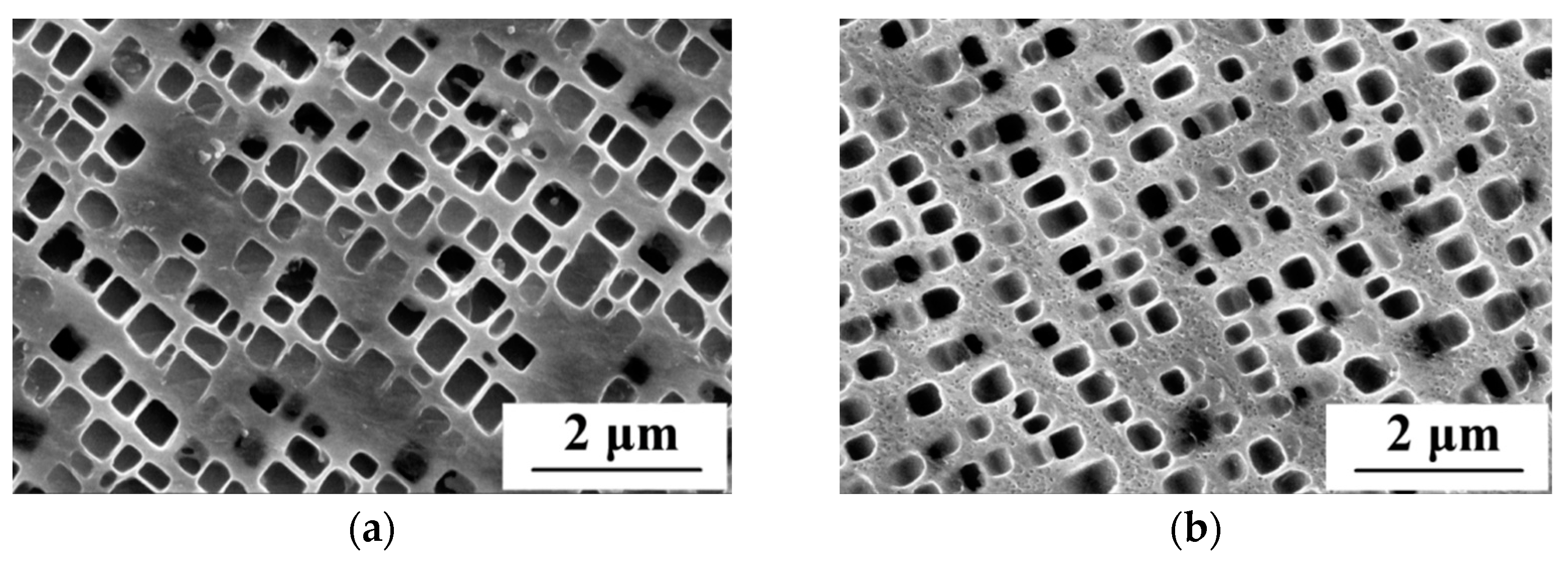

3.1. Microstructure after Heat Treatment

3.2. High-Temperature Tensile Properties

3.3. High-Temperature Rupture Properties

4. Discussion

4.1. Effect of Solution Temperature on Alloy Properties

4.2. Effect of Cooling Rate on Alloy Properties

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- China Superalloys Handbook; China Quality Inspection Press and China Standard Press: Beijing, China, 2012.

- Hou, J.S.; Guo, J.T.; Zhou, L.Z.; Yuan, C.; Ye, H.Q. Microstructure and mechanical properties of cast Ni-base superalloy K44. Mater. Sci. Eng. A 2004, 374, 327–334. [Google Scholar] [CrossRef]

- Yao, Z.H.; Dong, J.X.; Zhang, M.C.; Chen, H. Precipitation behaviors of γ′ phase in cast superalloy K480 and DD407 during heat treatment. Trans. Mater. Heat Treat. 2014, 35, 51–57. [Google Scholar]

- Hou, G.C.; Su, H.J.; Xie, J.; Xun, S.L.; Yu, J.J.; Sun, X.F.; Zhou, Y.Z. Effect of solid solution temperature on microstructure of Hf-containing K416B Ni-based superalloy with high W-content. J. Aeronaut. Mater. 2019, 39, 62–68. [Google Scholar]

- Yang, J.X.; Li, J.G.; Wang, M.; Wang, Y.H.; Jin, T.; Sun, X.F. Effects of heat treatment process on the microstructure and properties of a new cast nickel-based superalloy. Acta Metall. Sin. 2012, 48, 654–660. [Google Scholar] [CrossRef]

- Chen, H.; Dong, J.X.; Zhang, M.C. Effect of heat treatment process on microstructure of cast superalloy K480. Trans. Mater. Heat Treat. 2012, 33, 37–44. [Google Scholar]

- He, P.J.; Zhong, X.K.; Han, F.S. Effect of Aging Treatment on Microstructure and Properties of Novel Co-Ni Based Superalloy. Foundry Technol. 2021, 482, 816–819. [Google Scholar]

- Li, G.; Chen, B.; Du, Z.H.; Zhang, M.S.; Liu, R.C.; Liu, K. Investigation of solidification and segregation characteristics of cast Ni-base superalloy K417G. J. Mater. Sci. Technol. 2018, 34, 541–550. [Google Scholar]

- Zhang, Y.B.; Liu, L.; Huang, T.W.; Zhang, J.; Wang, H.F.; Jie, Z.Q.; Fu, H.Z. Incipient Melting and Solution Heat Treatment of a Boron-Bearing Third Generation Single Crystal Nickel Base Superalloy. Rare Met. Mater. Eng. 2017, 46, 3105–3110. [Google Scholar]

- Zhang, H.W.; Qin, X.Z.; Li, X.W.; Zhou, L.Z. Incipient Melting Behavior and Its Influences on the Mechanical Properties of a Directionally Solidified Ni-Based Superalloy with High Boron Content. Acta Metall. Sin. 2017, 53, 684–694. [Google Scholar]

- Zhang, W.G.; Liu, L.; Huang, T.W.; Zhao, X.B.; Yu, Z.H.; Fu, H.Z. Effect of Cooling Rate on γ′ Precipitate of DZ4125 Alloy Undey High Thermal Gradient Directional Solidification. Acta Metall. Sin. 2009, 45, 592–596. [Google Scholar]

- Zhou, X.; Li, Y.L.; Ma, T.F.; Zhang, Y.S.; Lai, Y.J.; Wang, K.X.; Liu, X.P.; Zhang, P.X. Precipitation Behavior of γ′ in Superalloy FGH97 During Continuous Cooling from Supersolvus Temperature. Rare Met. Mater. Eng. 2020, 49, 2147–2153. [Google Scholar]

- Shi, L.; Yu, J.J.; Cui, C.Y.; Sun, X.F. Temperature dependence of deformation behavior in a Co-Al-W-base single crystal superalloy. Mater. Sci. Eng. A 2014, 620, 36–43. [Google Scholar] [CrossRef]

- Cui, L.Q.; Su, H.H.; Yu, J.J.; Liu, J.L.; Jin, T.; Sun, X.F. Temperature dependence of tensile properties and deformation behaviors of nickel-base superalloy M951G. Mater. Sci. Eng. A 2017, 696, 323–330. [Google Scholar] [CrossRef]

- Yang, G.X.; Xu, Y.F.; Jiang, L.; Liang, S.H. High temperature tensile properties and fracture behavior of cast nickel-base K445 superalloy. Prog. Nat. Sci. Mater. Int. 2011, 21, 418–425. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, L.Z.; Qin, X.Z.; Sheng, L.Y.; Hou, J.S.; Guo, J.T. Primary MC decomposition and its effects on the rupture behaviors in hot-corrosion resistant Ni-based superalloy K444. Mater. Sci. Eng. A 2012, 553, 14–21. [Google Scholar] [CrossRef]

- Yuan, X.F.; Wu, J.T.; Li, J.T.; Yan, P. Microstructure and Typical Mechanical Properties of Overheated K424 Superalloy. Rare Met. Mater. Eng. 2018, 47, 1779–1785. [Google Scholar]

- Mao, P.L.; Xin, Y.; Han, K.; Jiang, W.G. Effects of heat treatment and Re-content on the TCP-phase in two Ni-Mo-Cr-Re superalloys. Acta Metall. Sin. (Engl. Lett.) 2009, 22, 365–372. [Google Scholar] [CrossRef]

- Qin, S.X.; Zhao, R.R.; Zhang, H.B.; Liu, J.; Lou, S.M. Influence of Long-Term Thermal Exposure on γ'-Phase of GH99 Alloy. Trans. Mater. Heat Treat. 2017, 38, 55–60. [Google Scholar]

- Qin, X.Z.; Guo, J.T.; Yuan, C.; Hou, J.S.; Zhou, L.Z.; Fu, H.Q. Evolutions of microstructures and mechanical properties of two cast Ni-based superalloys during long-term thermal exposure. Acta Metall. Sin. 2010, 46, 213–220. [Google Scholar] [CrossRef]

- Xie, J.; Yu, J.J.; Sun, X.F.; Jin, T.; Yang, Y.H. Influence of temperature on tensile behaviors of K416B Ni-based superalloy with high W content. Acta Metall. Sin. 2015, 51, 943–950. [Google Scholar]

- Yu, B.; Guo, Y.A.; Xiao, X.; Guo, J.T. Influence of heat treatment on γ' precipitates in thermal corrosion resistant superalloy K445. J. Shenyang Univ. Technol. 2008, 30, 543–546. [Google Scholar]

| C | Cr | Co | W | Mo | Al | Ti | Nb | Hf | B | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.06 | 15.8 | 10.7 | 5.16 | 2.0 | 3.1 | 4.5 | 0.2 | 0.3 | 0.06 | 0.2 | 57.92 |

| Sample Number | Solid Solution Treatment | Intermediate Treatment | Aging Treatment |

|---|---|---|---|

| S1 | 1160 °C + 4 h + AC | 1050 °C + 14 h + AC | 750 °C + 12 h + AC |

| S2 | 1180 °C + 4 h + AC | 1050 °C + 14 h + AC | |

| S3 | 1200 °C + 4 h + AC | 1050 °C + 14 h + AC | |

| S4 | 1220 °C + 4 h + AC | 1050 °C + 14 h + AC | |

| S5 | 1180 °C + 4 h + AC | 1050 °C + 14 h + FC | |

| S6 | 1180 °C + 4 h + AC | 1050 °C + 14 h + WC |

| Heat Treatment | Solution Temperature/°C | Tensile Strength, Rm/MPa | Yield Strength, Rp0.2/MPa | Elongation, A/% |

|---|---|---|---|---|

| S1 | 1160 °C | 630.8 | 530.5 | 15.62 |

| S2 | 1180 °C | 683.6 | 592.5 | 16.95 |

| S3 | 1200 °C | 651.7 | 578.8 | 2.23 |

| S4 | 1220 °C | 538.1 | 394.3 | 0.55 |

| Heat Treatment | Cooling Condition | Tensile Strength, Rm/MPa | Yield Strength, Rp0.2/MPa | Elongation, A/% |

|---|---|---|---|---|

| S5 | FC | 632.2 | 476.1 | 19.48 |

| S2 | AC | 683.6 | 592.5 | 16.95 |

| S6 | WC | 673.4 | 571.1 | 14.41 |

| Heat Treatment | Solution Temperature/°C | Rupture Time, t/h | Elongation, A/% | Reduction in Area, Z/% |

|---|---|---|---|---|

| S1 | 1160 °C | 142.06 | 8.55 | 3.97 |

| S2 | 1180 °C | 128.12 | 9.14 | 6.29 |

| S3 | 1200 °C | 36.29 | 2.83 | 5.52 |

| S4 | 1220 °C | 1.22 | 1.50 | 0.80 |

| Heat Treatment | Cooling Condition/°C | Rupture Time, t/h | Elongation, A/% | Reduction in Area, Z/% |

|---|---|---|---|---|

| S5 | FC | 123.61 | 9.03 | 5.14 |

| S2 | AC | 128.12 | 9.14 | 6.29 |

| S6 | WC | 123.62 | 7.03 | 7.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, H.; Yang, M.; Zhou, L.; Ma, Z.; Cui, B.; Yin, F.; Li, D. Effects of Heat Treatment on the Microstructure and Properties of a Cast Nickel-Based High-Cr Superalloy. Metals 2022, 12, 2176. https://doi.org/10.3390/met12122176

Lu H, Yang M, Zhou L, Ma Z, Cui B, Yin F, Li D. Effects of Heat Treatment on the Microstructure and Properties of a Cast Nickel-Based High-Cr Superalloy. Metals. 2022; 12(12):2176. https://doi.org/10.3390/met12122176

Chicago/Turabian StyleLu, Hongguo, Minghui Yang, Li Zhou, Zhonggang Ma, Bin Cui, Fengshi Yin, and Daoqian Li. 2022. "Effects of Heat Treatment on the Microstructure and Properties of a Cast Nickel-Based High-Cr Superalloy" Metals 12, no. 12: 2176. https://doi.org/10.3390/met12122176

APA StyleLu, H., Yang, M., Zhou, L., Ma, Z., Cui, B., Yin, F., & Li, D. (2022). Effects of Heat Treatment on the Microstructure and Properties of a Cast Nickel-Based High-Cr Superalloy. Metals, 12(12), 2176. https://doi.org/10.3390/met12122176