Mechanical Properties Evolution of the 7B04-T74 Aluminum Alloy in the Marine Atmosphere

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials

2.2. Alternate Immersion Test

2.3. Surface Morphology Observation and Composition Identification

2.4. Mechanical Property Test

3. Results and Discussion

3.1. Surface Microstructure Analysis

3.2. Mechanical Property Test

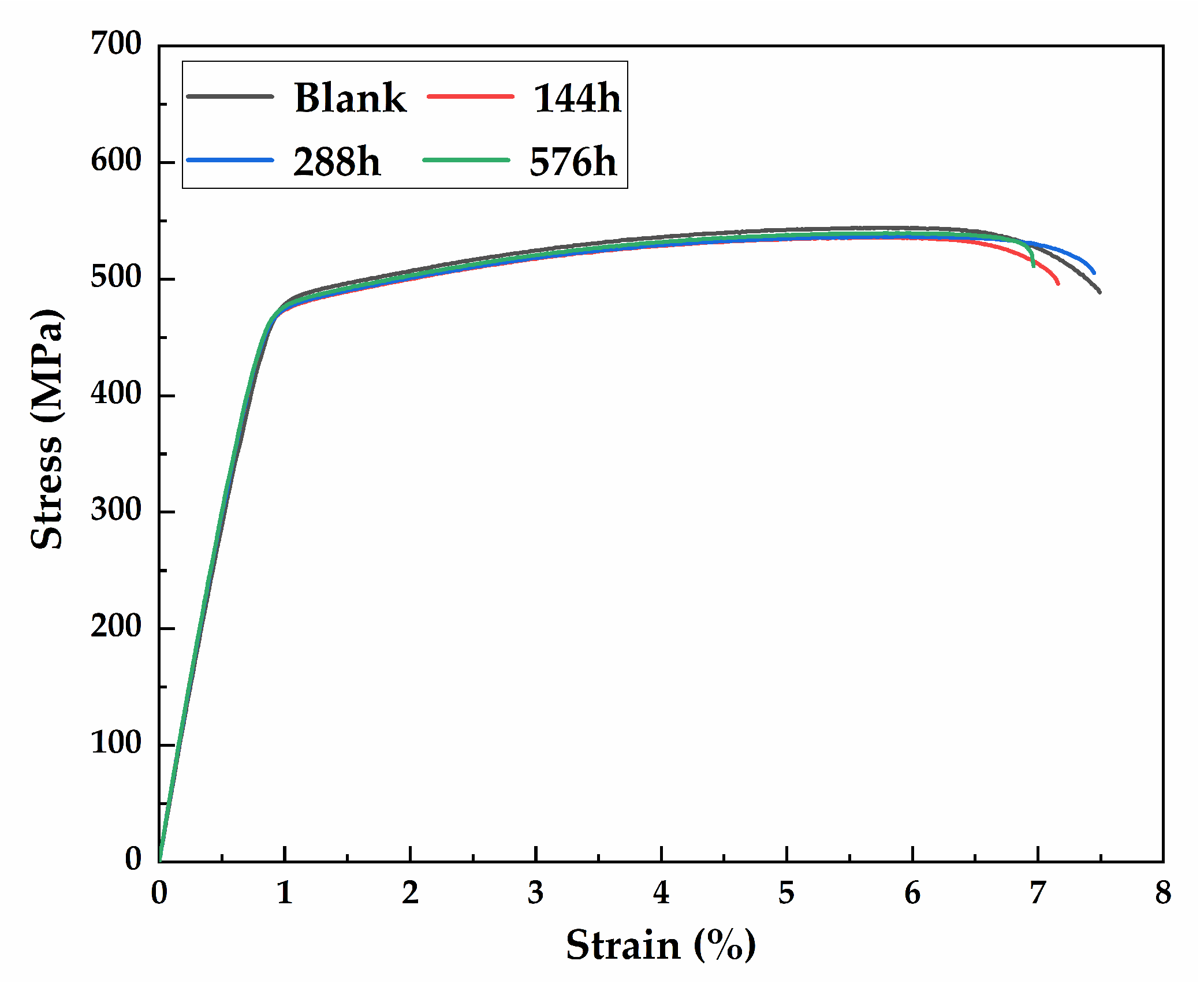

3.2.1. Tensile Test

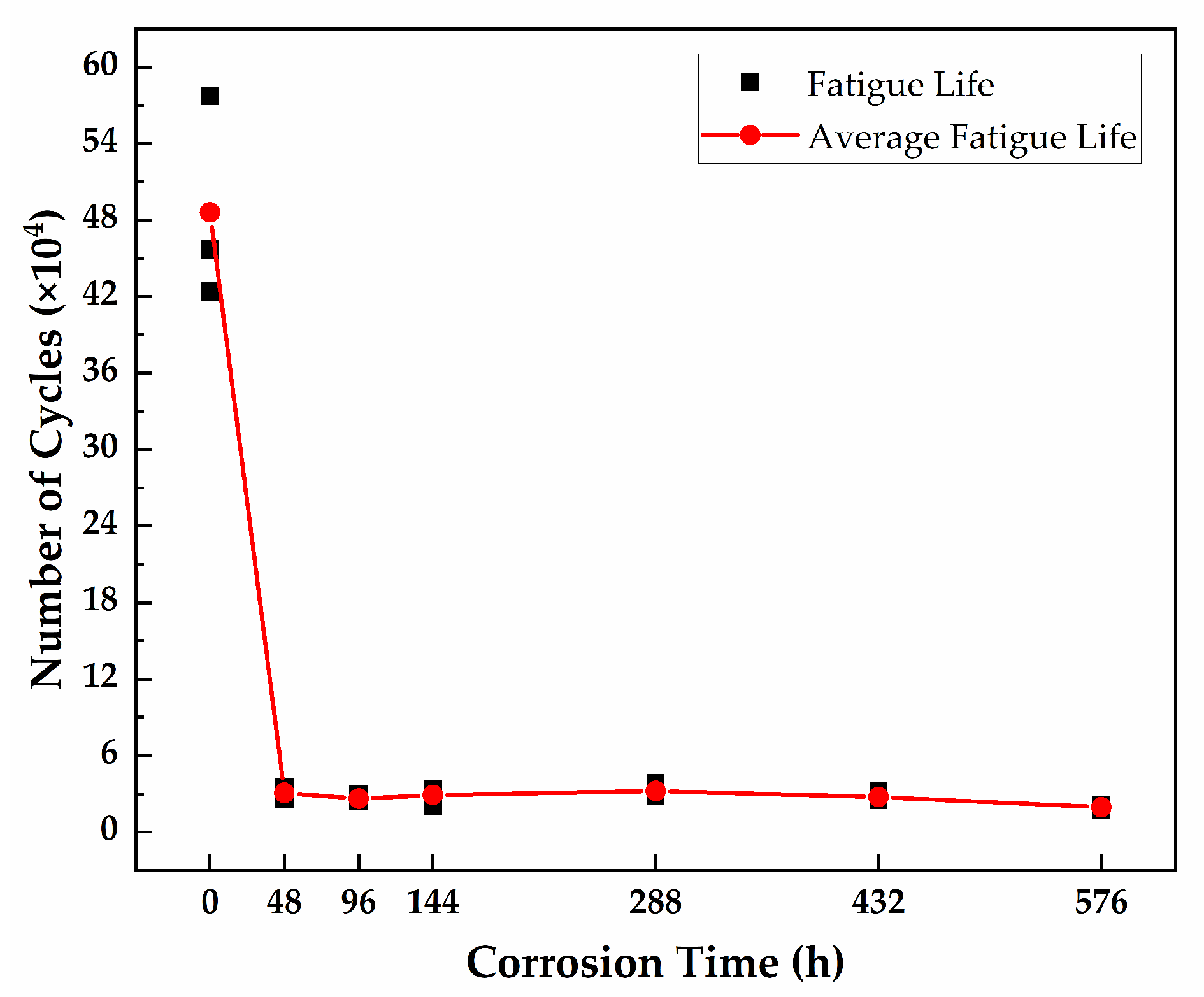

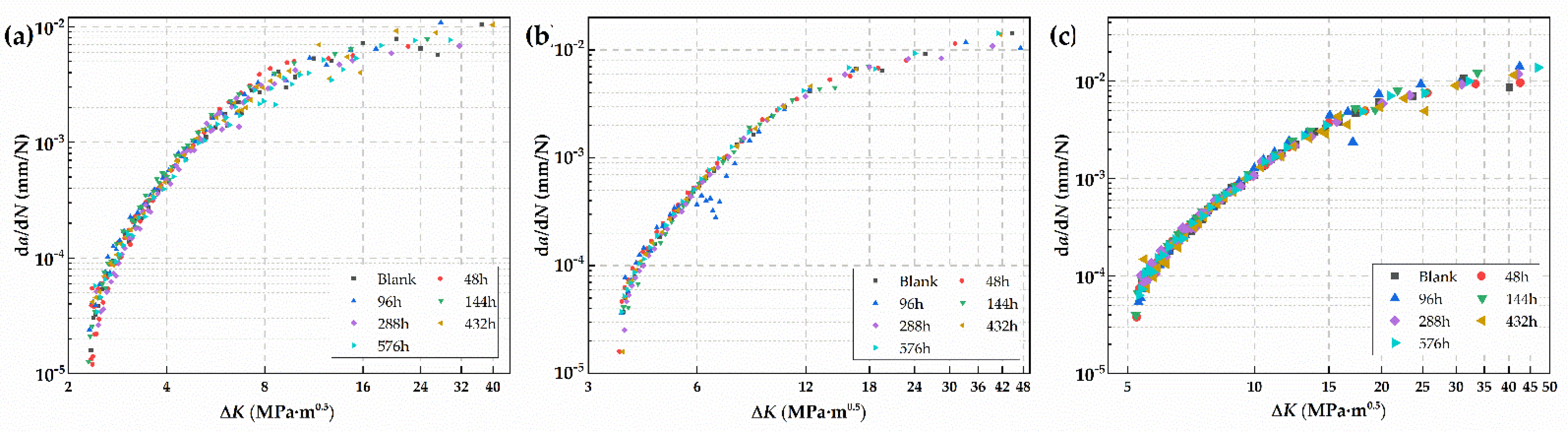

3.2.2. Fatigue Test

4. Conclusions

- The 7B04-T74 aluminum alloy is sensitive to the marine atmospheric environment. Pitting corrosion occurred rapidly on the surface of the specimen at the beginning of the alternate immersion test. However, the pitting corrosion of the specimen did not deteriorate further as the corrosion time lengthened, and the 7B04-T74 aluminum alloy showed no significant tendency to intergranular and exfoliation corrosion;

- After 576 h corrosion, the tensile properties of the 7B04-T74 aluminum alloy are fundamentally the same as in the non-corroded state, demonstrating that localized pitting corrosion cannot affect the tensile properties of the aluminum alloy;

- The fatigue properties of the 7B04-T74 aluminum alloy decreases seriously. The fatigue life of the specimens is reduced by at least 93% when pitting corrosion occurred, but this has little effect on the fatigue crack propagation rate of the specimens. The fatigue life of the specimen slowly decreases as the corrosion time increases after the pitting corrosion occurs. Pits occurring on the surface of the 7B04-T74 aluminum accelerate the crack initiation and reduce the crack initiation life of the aluminum alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, B.; Liu, B.; Zhang, S. The Advancement of 7XXX Series Aluminum Alloys for Aircraft Structures: A Review. Metals 2021, 11, 718. [Google Scholar] [CrossRef]

- Fuente, D. Corrosion of Aluminum, Aluminum Alloys, and Composites. Encycl. Mater. Met. Alloy. 2022, 1, 160–169. [Google Scholar]

- Koli, D.K.; Agnihotri, G.; Purohit, R. Advanced Aluminium Matrix Composites: The Critical Need of Automotive and Aerospace Engineering Fields. Mater. Today Proc. 2015, 2, 3032–3041. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Song, Y.H.; Zhang, T.F.; Fan, W.J.; Zhang, Y.; Yang, W.F.; Wang, A.D. Effect of the overlap ratio on surface properties of 7B04 aluminum alloy for aviation during laser derusting. J. Mater. Res. Technol. 2022, 20, 1495–1511. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.D.; Rong, H.S.; Wang, X.; Yang, J.; Ding, R.; Fan, W.J.; Zhang, Y. Role of Lysinibacillus sphaericus on aviation kerosene degradation and corrosion of 7B04 aluminum alloy. J. Mater. Res. Technol. 2022, 18, 2641–2653. [Google Scholar] [CrossRef]

- Gao, M.; Sun, Z.H.; Yan, W.; Tang, Z.H.; Zhang, Y.N. Influence of solid particles deposition on the initial atmospheric corrosion of 7B04 aluminum alloy. Mater. Today Commun. 2022, 31, 103562. [Google Scholar] [CrossRef]

- Hou, S.; Zhu, Y.L.; Cai, Z.H.; Wang, Y.L.; Ni, Y.H.; Du, X.K. Effect of hole cold expansion on fatigue performance of corroded 7B04-T6 aluminium alloy. Int. J. Fatigue 2019, 126, 210–220. [Google Scholar]

- Venugopal, A.; Mohammad, R.; Koslan, M.F.S.; Sayd Bakar, S.R.; Ali, A. The Effect of Tropical Environment on Fatigue Failure in Royal Malaysian Airforce (RMAF) Aircraft Structure and Operational Readiness. Materials 2021, 14, 2414. [Google Scholar] [CrossRef]

- Ganther, W.D.; Paterson, D.A.; Lewis, C.; Isaacs, P.; Galea, S.; Meunier, C.; Mangeon, G.; Cole, I.S. Monitoring Aircraft Microclimate and Corrosion. Procedia Eng. 2017, 188, 369–376. [Google Scholar] [CrossRef]

- Ren, K.L.; Gao, S.W.; Liu, P.P.; Dong, Y. Influence of environmental factors on corrosion damage of aircraft structure. Theor. Appl. Mech. Lett. 2011, 6, 18–21. [Google Scholar] [CrossRef] [Green Version]

- Wu, H.L.; Wu, G.; Xiang, L.; Tao, J.Q.; Zheng, Z.Y.; Sun, J.P.; Li, W.; Huang, C.Y.; Lan, X.L. Impact of Corrosion on the Degradation of the Mechanical Properties of 2195 and 2297 Al Alloys in the Marine Environment. Metals 2022, 12, 1371. [Google Scholar] [CrossRef]

- Zhang, W.F.; Jin, T.Z.; Lou, W.T.; Li, W.L.; Dai, W. Mechanical Properties and Corrosion Behavior of 5A06 Alloy in Seawater. IEEE Access 2018, 6, 24952–24961. [Google Scholar] [CrossRef]

- Crawford, B.R.; Loader, C.; Liu, Q.C.; Harrison, T.J.; Sharp, P.K. Can pitting corrosion change the location of fatigue failures in aircraft? Int. J. Fatigue 2014, 61, 304–314. [Google Scholar] [CrossRef]

- Dan, Z.H.; Takigawa, S.; Muto, I.; Hara, N. Applicability of constant dew point corrosion tests for evaluating atmospheric corrosion of aluminium alloys. Corros. Sci. 2011, 53, 2006–2014. [Google Scholar] [CrossRef]

- Dong, J.H.; Han, E.H.; Ke, W. Introduction to atmospheric corrosion research in China. Sci. Technol. Adv. Mater. 2007, 8, 559–565. [Google Scholar] [CrossRef] [Green Version]

- Cai, Y.K.; Xu, Y.M.; Zhao, Y.; Ma, X.B. Atmospheric corrosion prediction: A review. Corros. Rev. 2020, 38, 299–321. [Google Scholar] [CrossRef]

- Shi, L.X.; Xiang, L.; Tao, J.Q.; Liu, J.; Chen, Q.; Zhong, Y. Effects of Actual Marine Atmospheric Pre-Corrosion and Pre-Fatigue on the Fatigue Property of 7085 Aluminum Alloy. Metals 2022, 12, 81. [Google Scholar] [CrossRef]

- Shi, L.X.; Xiang, L.; Tao, J.Q.; Chen, Q.; Liu, J.; Zhong, Y. Actual Marine Atmospheric Pre-Corrosion Fatigue Performance of 7075-T73 Aluminum Alloy. Metals 2022, 12, 874. [Google Scholar] [CrossRef]

- Li, N.; Zhang, W.F.; Xu, H.; Cai, Y.K.; Yan, X.J. Corrosion Behavior and Mechanical Properties of 30CrMnSiA High-Strength Steel under an Indoor Accelerated Harsh Marine Atmospheric Environment. Materials 2022, 15, 629. [Google Scholar] [CrossRef]

- Blücher, D.B.; Svensson, J.E.; Johansson, L.G. The influence of CO2, AlCl3·6H2O, MgCl2·6H2O, Na2SO4 and NaCl on the atmospheric corrosion of aluminum. Corros. Sci. 2006, 48, 1848–1866. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Charalampidou, C.; Skarvelis, P.; Kourkoulis, S.K. Synergy of corrosion-induced micro-cracking and hydrogen embrittlement on the structural integrity of aluminium alloy (Al-Cu-Mg) 2024. Corros. Sci. 2017, 121, 32–42. [Google Scholar] [CrossRef]

- Ji, Z.G.; Ma, X.B.; Zhou, K.; Cai, Y.K. An Improved Atmospheric Corrosion Prediction Model Considering Various Environmental Factors. Corrosion 2021, 77, 1178–1191. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.K.; Zhao, Y.; Ma, X.B.; Zhou, K.; Chen, Y. Influence of environmental factors on atmospheric corrosion in dynamic environment. Corros. Sci. 2018, 137, 163–175. [Google Scholar] [CrossRef]

- Cai, Y.K.; Xu, Y.M.; Zhao, Y.; Zhou, K.; Ma, X.B. A spatial-temporal approach for corrosion prediction in time-varying marine environment. J. Loss. Prevent. Proc. 2020, 66, 104161. [Google Scholar] [CrossRef]

- Cai, Y.K.; Xu, Y.M.; Zhao, Y.; Ma, X.B. Extrapolating short-term corrosion test results to field exposures in different environments. Corros. Sci. 2021, 186, 109455. [Google Scholar] [CrossRef]

- Cao, M.; Liu, L.; Yu, Z.F.; Fan, L.; Li, Y.; Wang, F.H. Electrochemical corrosion behavior of 2A02 Al alloy under an accelerated simulation marine atmospheric environment. J. Mater. Sci. Technol. 2019, 35, 651–659. [Google Scholar] [CrossRef]

- Mishra, R.K. Study the effect of pre-corrosion on mechanical properties and fatigue life of aluminum alloy 8011. Mater. Today Proc. 2020, 25, 602–609. [Google Scholar] [CrossRef]

- Cavalcante, T.R.F.; Pereira, G.S.; Koga, G.Y.; Bolfarini, C.; Bose Filho, W.W.; Avila, J.A. Fatigue crack propagation of aeronautic AA7050-T7451 and AA2050-T84 aluminum alloys in air and saline environments. Int. J. Fatigue 2022, 15, 106519. [Google Scholar] [CrossRef]

- Yang, B.W.; Wang, Y.; Gao, M.Q.; Guan, R.G. The response of mechanical property to the microstructure variation of an Al–Mg alloy by adding tin element. Mat. Sci. Eng. A-Struct. 2021, 825, 141901. [Google Scholar] [CrossRef]

- Niverty, S.; Kale, C.; Solanki, K.N.; Chawla, N. Multiscale investigation of corrosion damage initiation and propagation in AA7075-T651 alloy using correlative microscopy. Corros. Sci. 2021, 185, 109429. [Google Scholar] [CrossRef]

- He, L.Z.; Jia, P.F.; Zhang, L.; Cui, J.Z. Evolution of secondary phases and properties of 7B04 aluminum alloy during DC homogenization. Trans. Nonferrous Met. Soc. China 2016, 26, 319–327. [Google Scholar] [CrossRef]

- Zhang, Y.G.; Chen, Y.L.; Bian, G.X.; Zhang, Y. Electrochemical behavior and corrosion mechanism of anodized 7B04 aluminum alloy in acid NaCl environments. J. Alloys Compd. 2021, 886, 161231. [Google Scholar] [CrossRef]

- Liang, M.X.; Melchers, R.; Chaves, I. Corrosion and pitting of 6060 series aluminium after 2 years exposure in seawater splash, tidal and immersion zones. Corros. Sci. 2018, 140, 286–296. [Google Scholar] [CrossRef]

- Birbilis, N.; Zhu, Y.M.; Kairy, S.K.; Glenn, M.A.; Nie, J.F.; Morton, A.J.; Gonzalez-Garcia, Y.; Terryn, H.; Mol, J.M.C.; Hughes, A.E. A closer look at constituent induced localised corrosion in Al-Cu-Mg alloys. Corros. Sci. 2016, 113, 160–171. [Google Scholar] [CrossRef]

- Ma, Y.; Zhou, X.; Huang, W.; Thompson, G.E.; Zhang, X.; Luo, C.; Sun, Z. Localized corrosion in AA2099-T83 aluminum–lithium alloy: The role of intermetallic particles. Mater. Chem. Phys. 2015, 161, 201–210. [Google Scholar] [CrossRef]

- Chen, Z.W.; Yan, K.; Ren, C.C.; Naseem, S. Precipitation sequence and hardening effect in 7A85 aluminum alloy. J. Alloys Compd. 2021, 875, 159950. [Google Scholar] [CrossRef]

- Li, Z.H.; Xiong, B.Q.; Zhang, Y.A.; Zhu, B.H.; Wang, F.; Liu, H.W. Effects of the two-step ageing treatment on the microstructure and properties of 7B04 alloy pre-stretched thick plates. Rare Met. 2007, 26, 193–199. [Google Scholar] [CrossRef]

- Chen, S.Y.; Chen, K.H.; Peng, G.S.; Jia, L.; Dong, P.X. Effect of heat treatment on strength, exfoliation corrosion and electrochemical behavior of 7085 aluminum alloy. Mater. Des. 2012, 35, 93–98. [Google Scholar] [CrossRef]

- Jones, K.; Hoeppner, D.W. Prior corrosion and fatigue of 2024-T3 aluminum alloy. Corros. Sci. 2006, 48, 3109–3122. [Google Scholar] [CrossRef]

- Liu, W.H.; Hu, Q.; Chen, Y.Q.; Tang, C.P.; Zhao, C.B.; Xiao, M.Y.; Song, Y.F. Investigation on fatigue crack propagation behaviors in the thickness direction of 2519A aluminum alloy thick plate. Int. J. Fatigue 2022, 163, 107099. [Google Scholar] [CrossRef]

| Element | Zn | Mg | Cu | Ni | Ti | Cr | Mn | Fe | Si | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| Composition (wt%) | 6.09 | 2.54 | 1.65 | <0.05 | 0.017 | 0.13 | 0.26 | 0.14 | 0.049 | Bal. |

| NaCl | MgCl2·6H2O | Na2SO4 | CaCl2 | KCl |

|---|---|---|---|---|

| 37.2 | 16.67 | 6.14 | 1.74 | 1.04 |

| Corrosion Time (h) | 0 | 144 | 288 | 576 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Yield Strength (MPa) | 443.9 | 476.9 | 486.8 | 478.7 | 478.9 | 482.5 | 479.7 | 474.6 | 476.2 | 481.8 | 477.1 | 479.4 |

| Average Yield Strength (MPa) | 469.2 | 480.1 | 476.8 | 479.4 | ||||||||

| Tensile Strength (MPa) | 501.5 | 533.7 | 544.1 | 536.0 | 536.2 | 538.3 | 536.0 | 530.1 | 532.4 | 539.5 | 534.4 | 535.9 |

| Average Tensile Strength (MPa) | 526.4 | 536.8 | 532.8 | 536.6 | ||||||||

| Maximum Tensile Stress (kN) | 22.57 | 24.01 | 24.49 | 24.12 | 24.13 | 24.22 | 24.12 | 23.85 | 23.96 | 24.28 | 24.05 | 24.11 |

| Average Maximum Tensile Stress (kN) | 23.69 | 24.16 | 23.98 | 24.15 | ||||||||

| Elongation at Break (%) | 8.41 | 6.86 | 7.49 | 7.16 | 7.97 | 7.37 | 7.45 | 8.14 | 7.34 | 6.97 | 8.83 | 7.48 |

| Average Elongation at Break (%) | 7.59 | 7.50 | 7.64 | 7.76 | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, N.; Yan, X.; Liu, X.; Han, L.; Zhang, W. Mechanical Properties Evolution of the 7B04-T74 Aluminum Alloy in the Marine Atmosphere. Metals 2022, 12, 2173. https://doi.org/10.3390/met12122173

Li N, Yan X, Liu X, Han L, Zhang W. Mechanical Properties Evolution of the 7B04-T74 Aluminum Alloy in the Marine Atmosphere. Metals. 2022; 12(12):2173. https://doi.org/10.3390/met12122173

Chicago/Turabian StyleLi, Ning, Xiaojun Yan, Xuerong Liu, Lu Han, and Weifang Zhang. 2022. "Mechanical Properties Evolution of the 7B04-T74 Aluminum Alloy in the Marine Atmosphere" Metals 12, no. 12: 2173. https://doi.org/10.3390/met12122173

APA StyleLi, N., Yan, X., Liu, X., Han, L., & Zhang, W. (2022). Mechanical Properties Evolution of the 7B04-T74 Aluminum Alloy in the Marine Atmosphere. Metals, 12(12), 2173. https://doi.org/10.3390/met12122173