The Effect of Friction Stir Welding Parameters on the Weldability of Aluminum Alloys with Similar and Dissimilar Metals: Review

Abstract

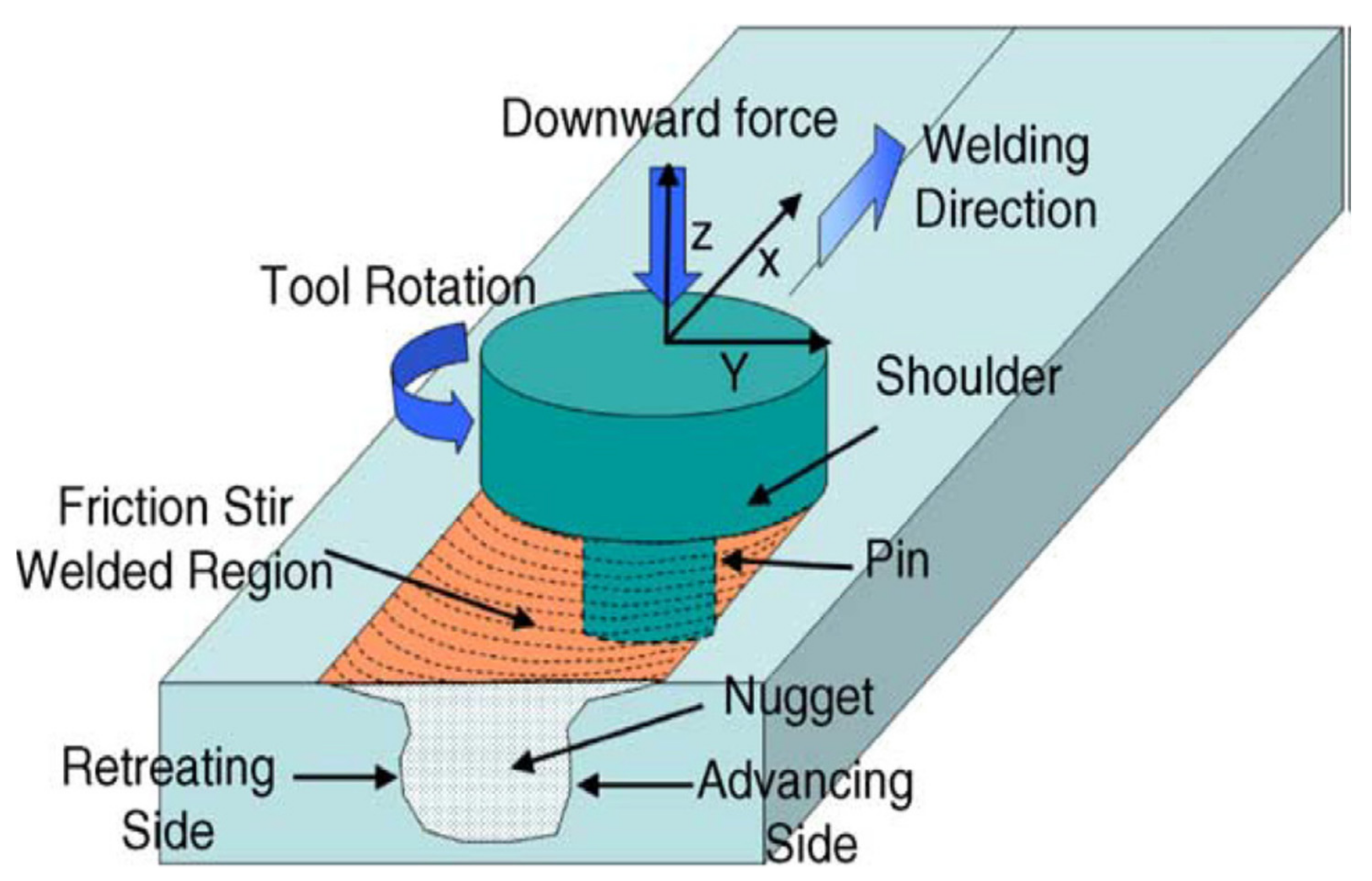

1. Introduction

2. FSW Machine Tool Parameters and Selection Criteria

- i

- Type of material to be welded by friction stir welding in line with the standard.

- ii

- Thickness of material.

- iii

- Friction stirs the welding position.

- iv

- Friction stirs welding quantity requirements.

- v

- Use the welded part.

- vi

- Mechanical properties are required for joint friction stir welding.

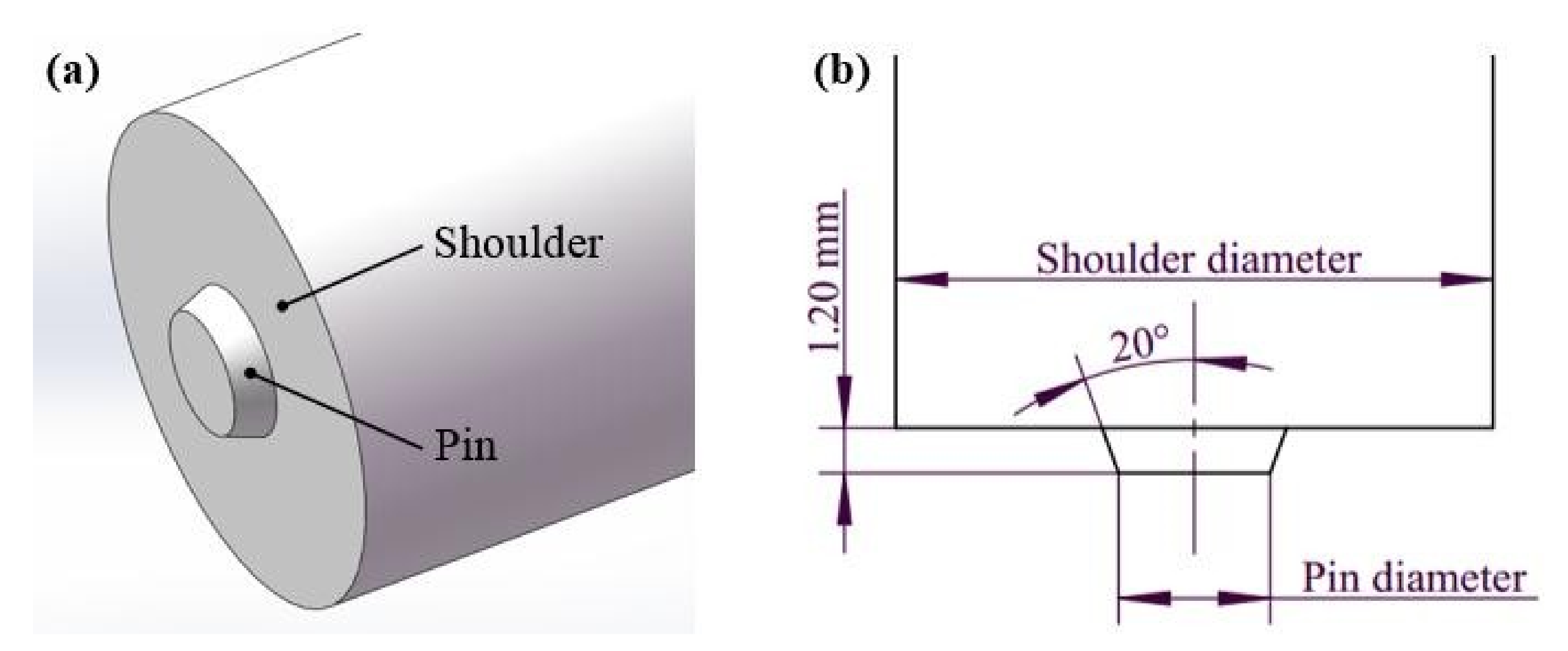

2.1. Geometry and Design of Tool

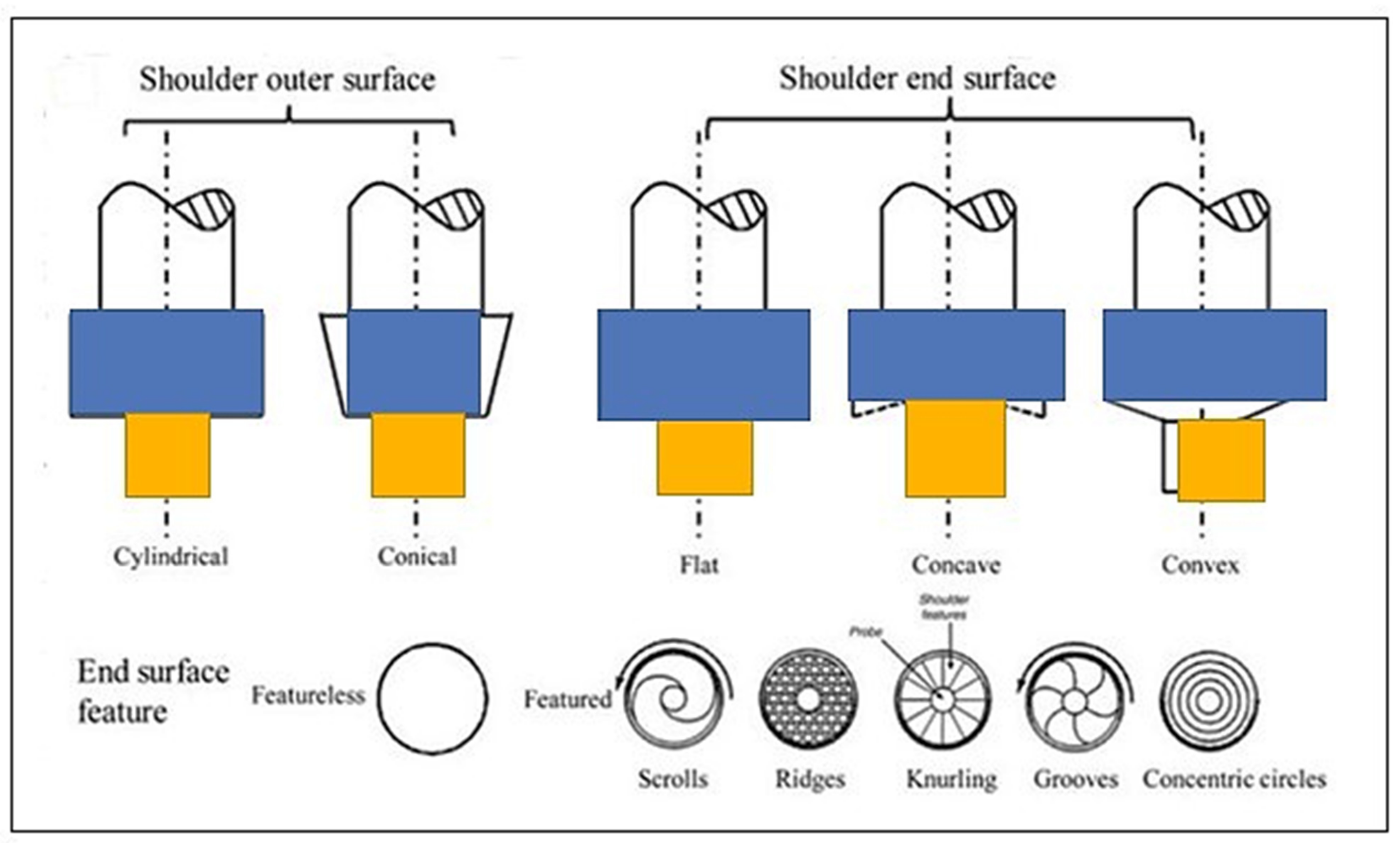

2.1.1. Shoulder Shapes

2.1.2. Probe Shapes

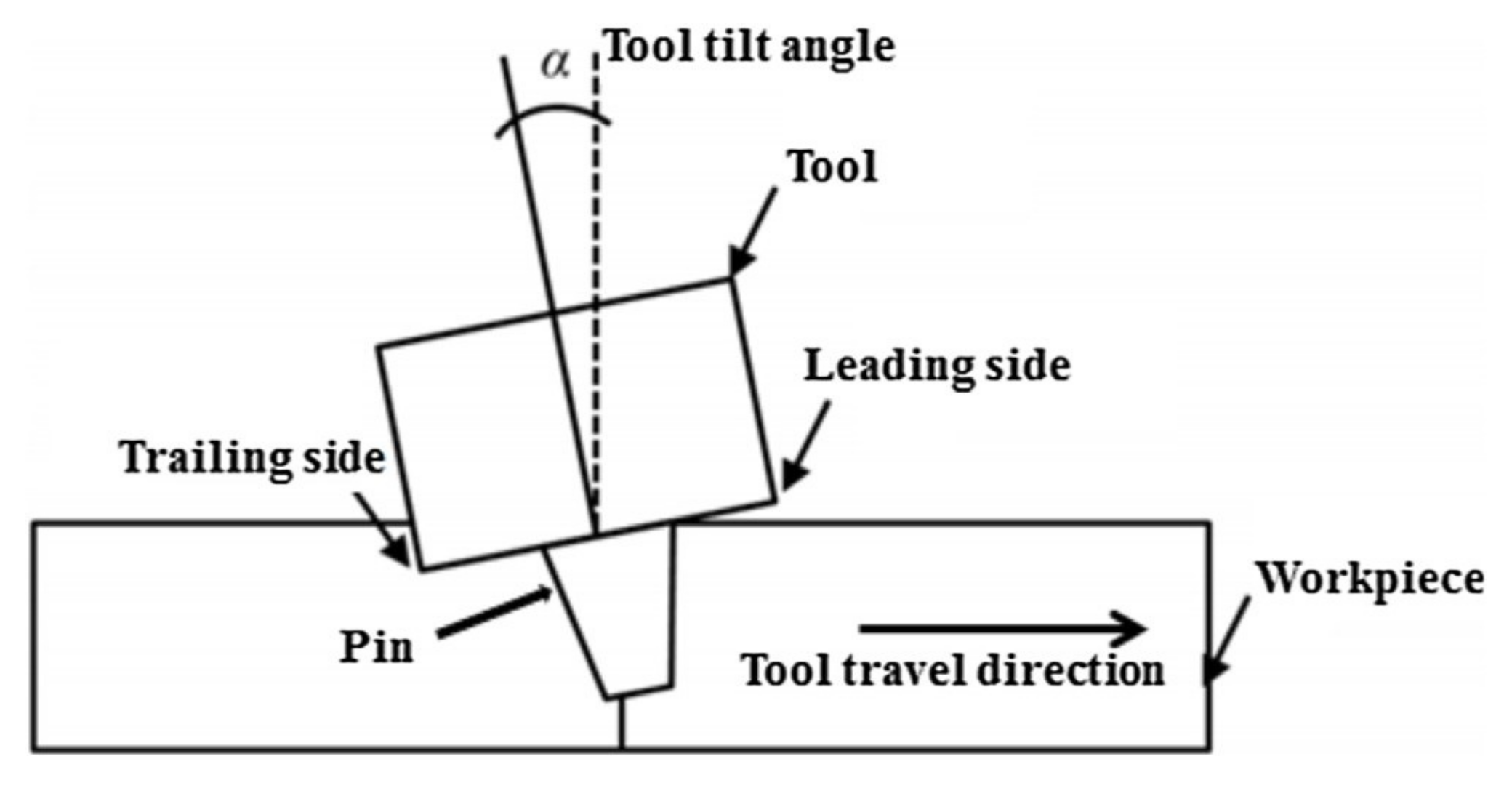

2.1.3. Tool Tilt

2.2. Tool Rotational Speed (N)

2.3. Tool Linear Speed (v)

2.4. Tool Indentation Time

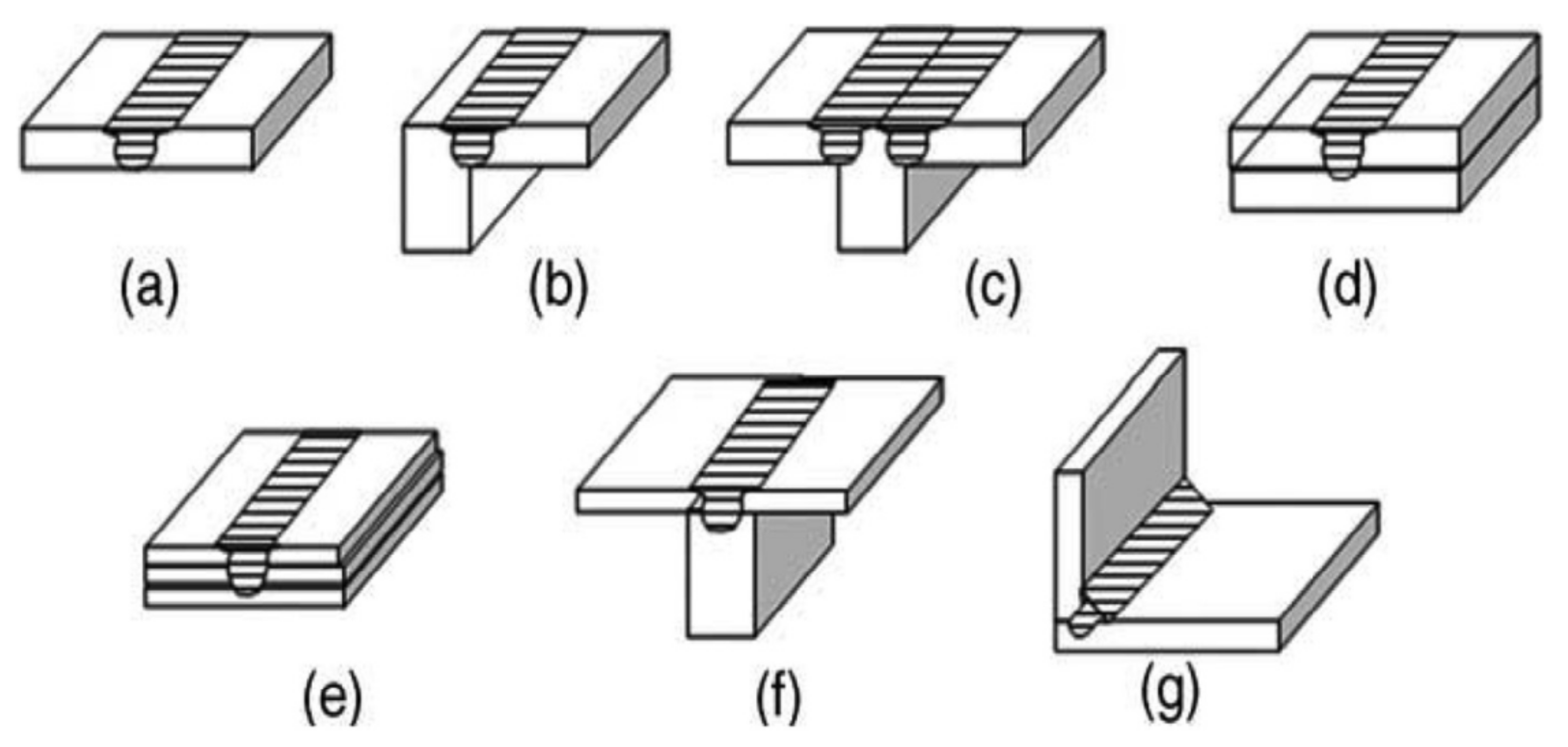

3. FSW Joint Design

4. Literature Review

4.1. FSW of Aluminum Alloys with Similar Metals

4.1.1. FSW of Aluminum Alloys AA6061-6T with AA5083

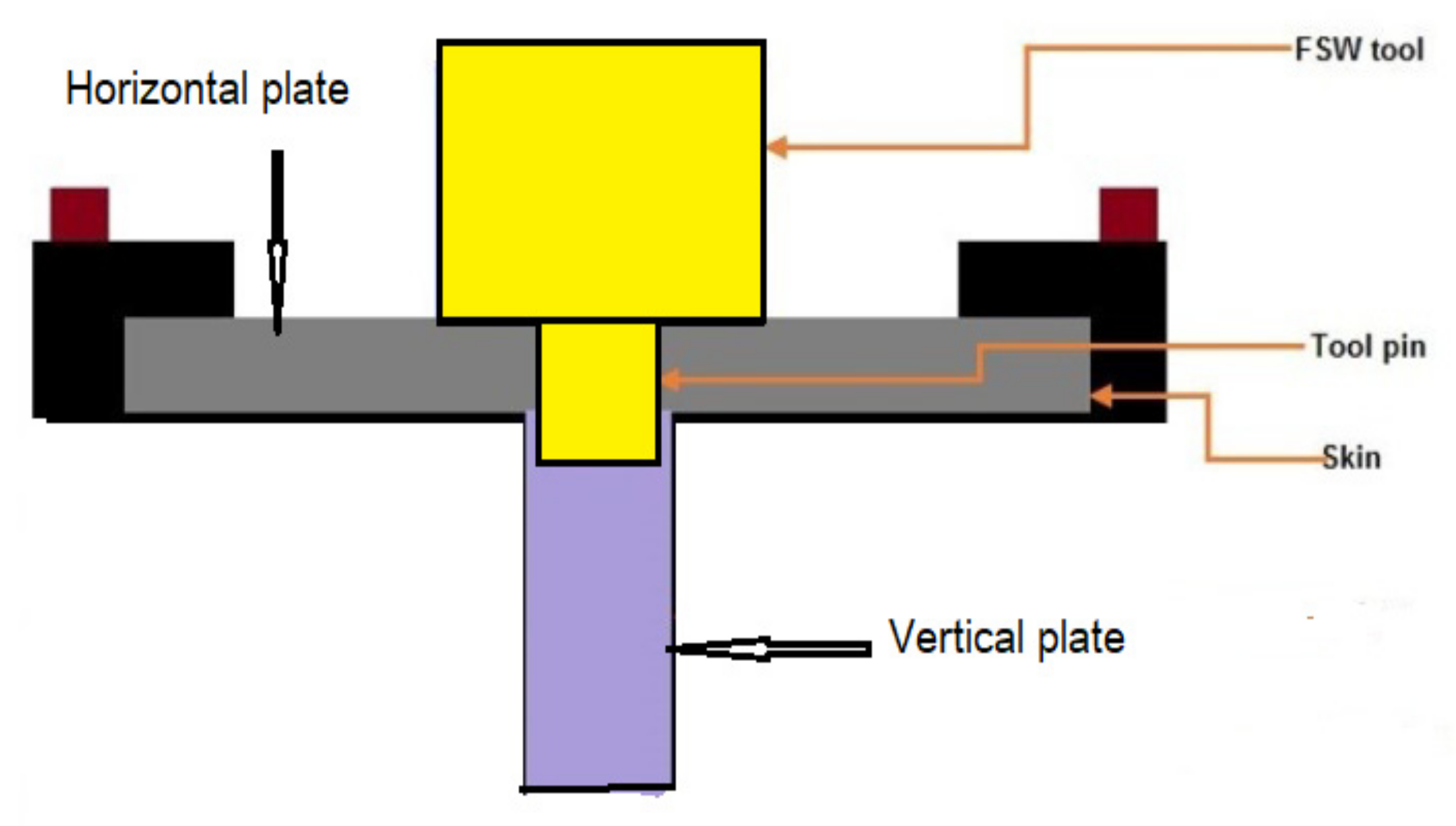

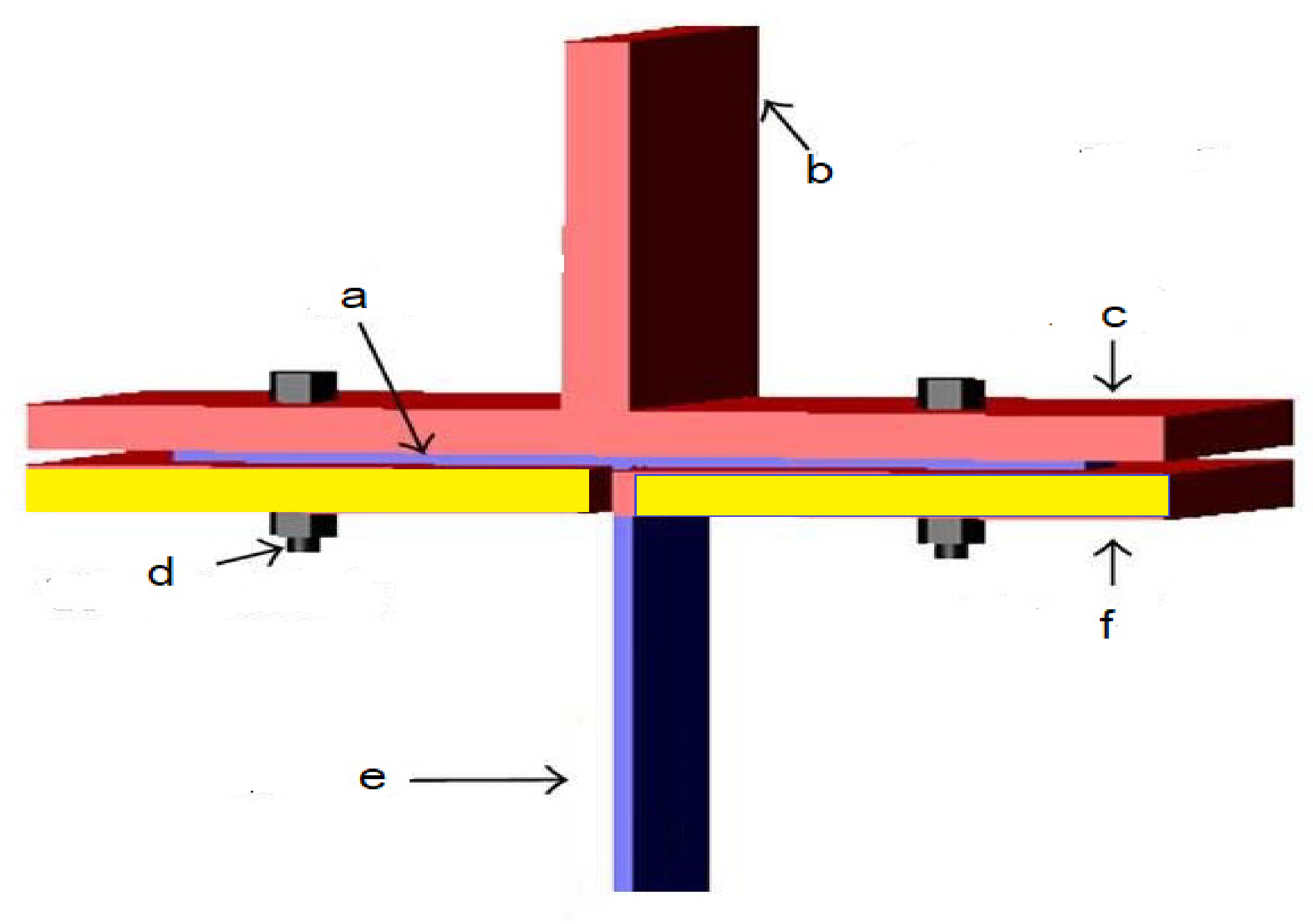

4.1.2. FSW of Aluminum Alloys AA6061 with AA5052 (T-Joint)

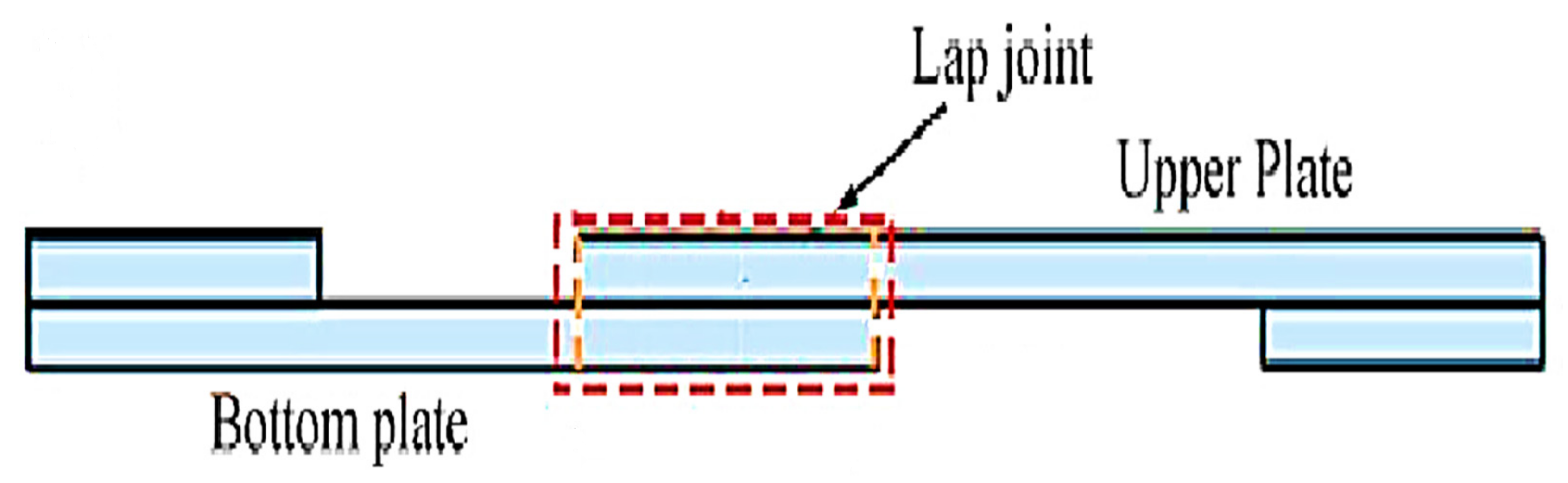

4.1.3. Friction Stirs Lap Welding (FSLW) of Aluminum Alloy (AA1100 with AA6061)

4.1.4. FSW of Aluminum Alloys AA6082-T6 with AA6082-T6

4.1.5. FSW of Aluminum Alloys AA2219 with AA5083

4.1.6. Friction Stir Lap Welding of Aluminum Alloys AA2198 with AA7075

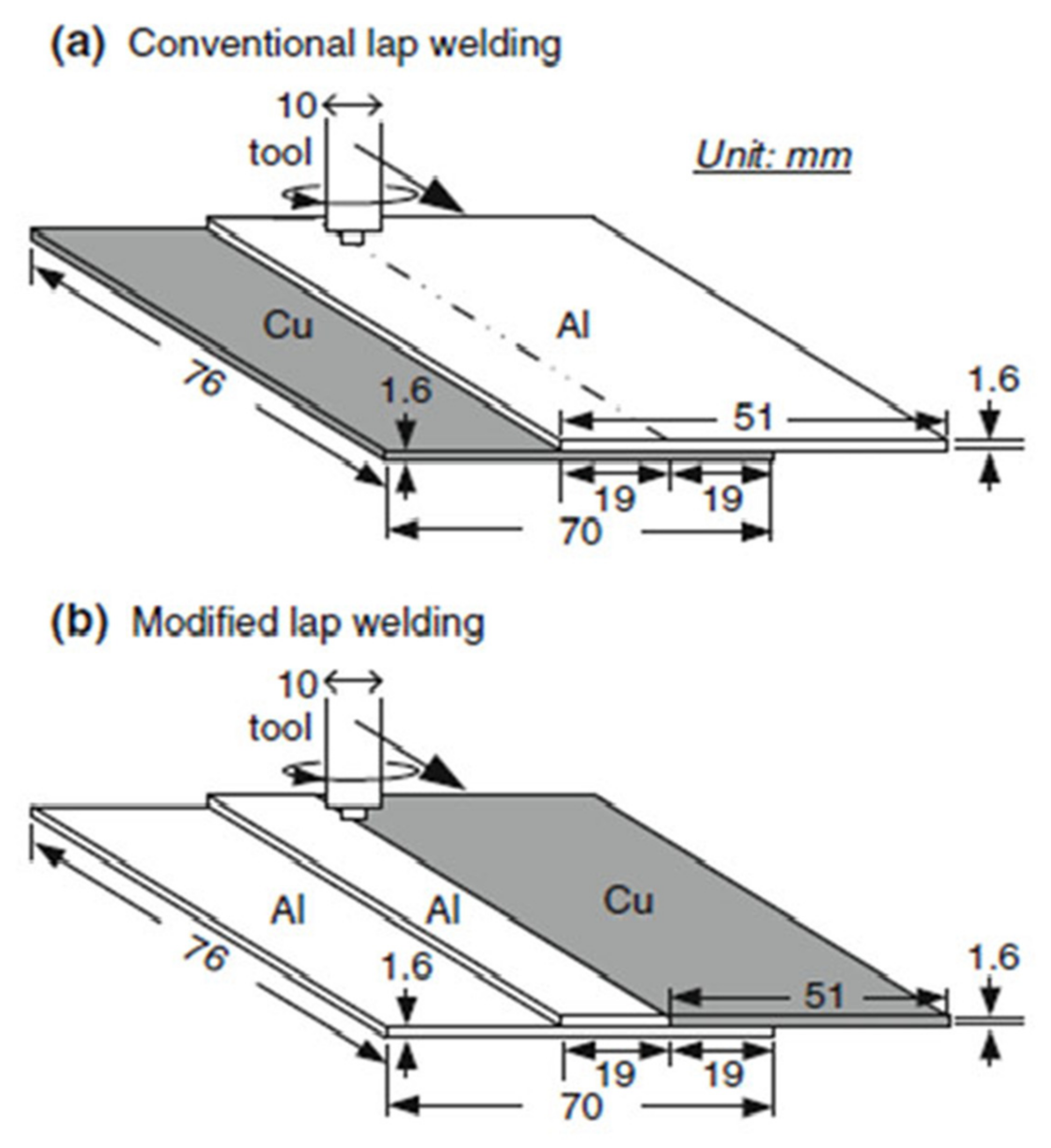

4.1.7. Friction Stir Lap Welding of Aluminum Alloys (AA5052-O) with Al-(AA2024-T4)

4.1.8. FSW of Aluminum Alloys AA2219 with AA2219

4.1.9. FSW of Aluminum Alloys AA 2024 T3 with AA2024

4.2. FSW of Aluminum Alloys with Dissimilar Metals

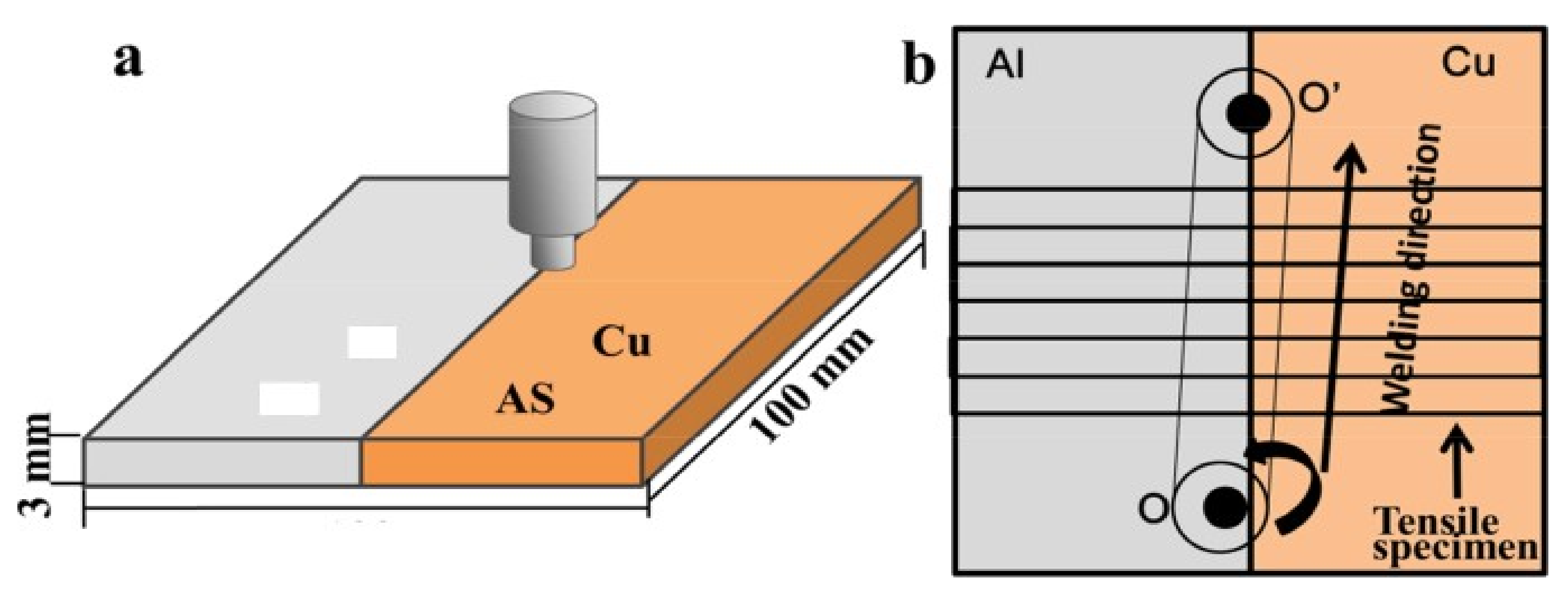

4.2.1. FSW of Aluminum Alloys with Copper

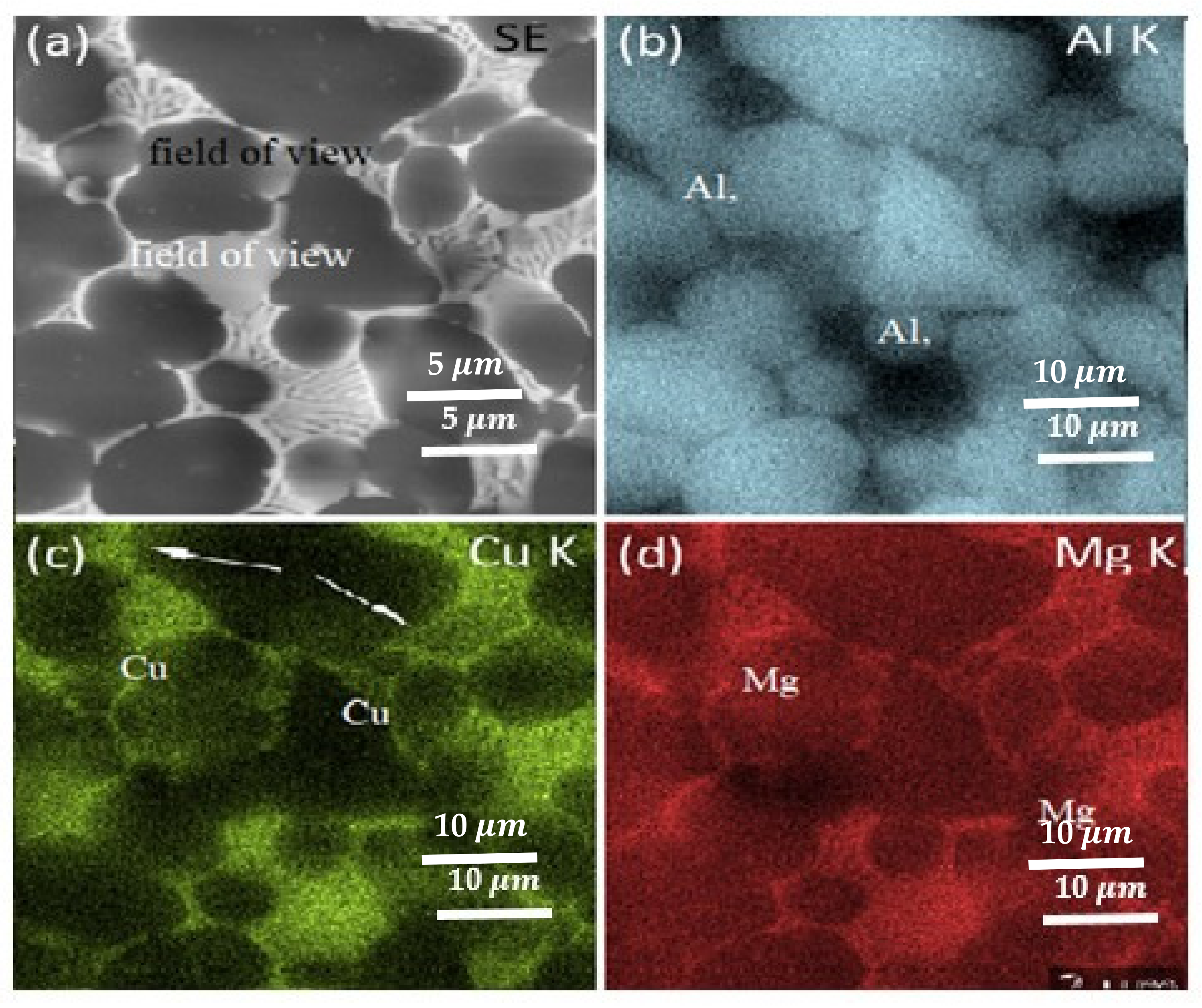

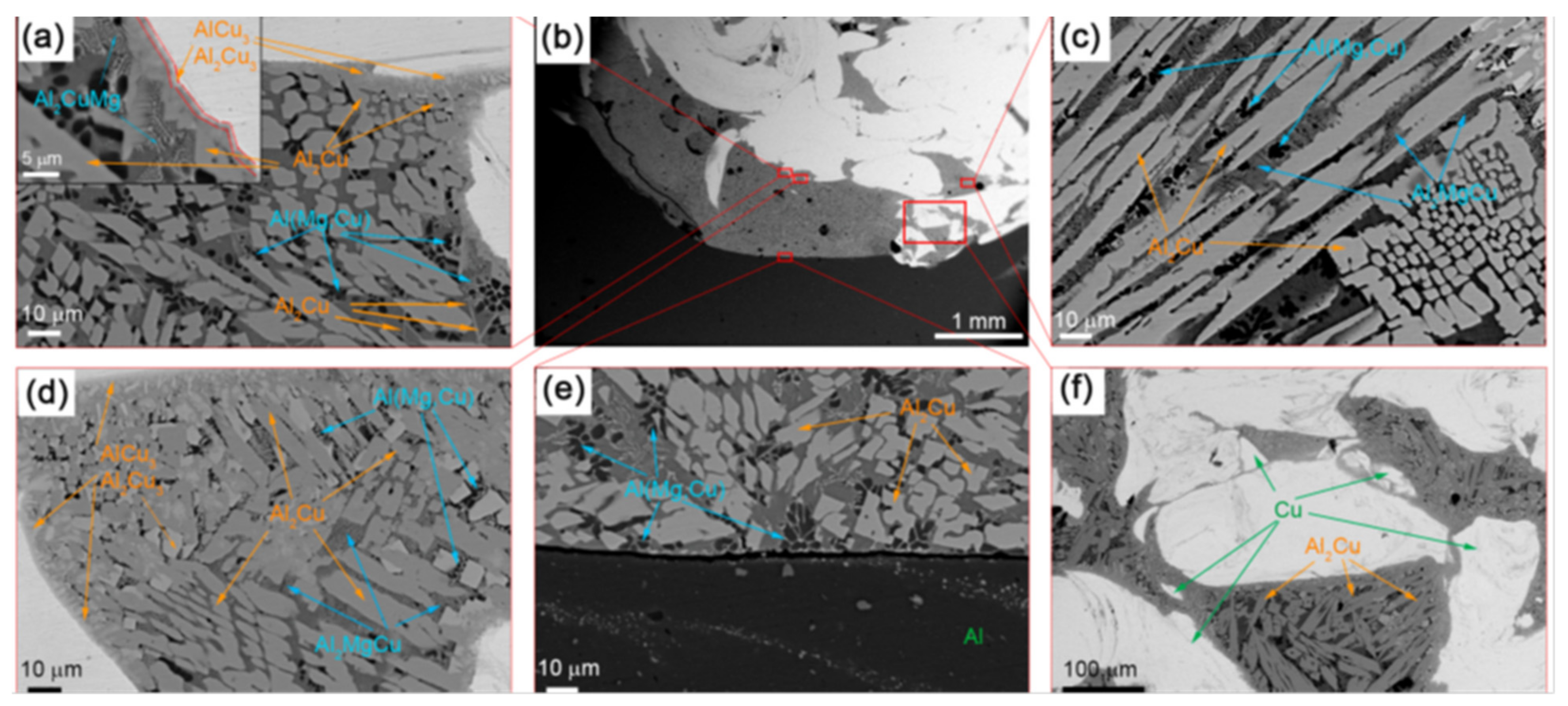

- The majority of the eutectic structures in the coupled and divorced forms of the a-Al-S eutectic are found in the Al/Cu weld. We can explain the eutectic melting by mass transfer caused by atomic diffusion, material flow, and plastic deformation in addition to the comparatively high-temperature exposure.

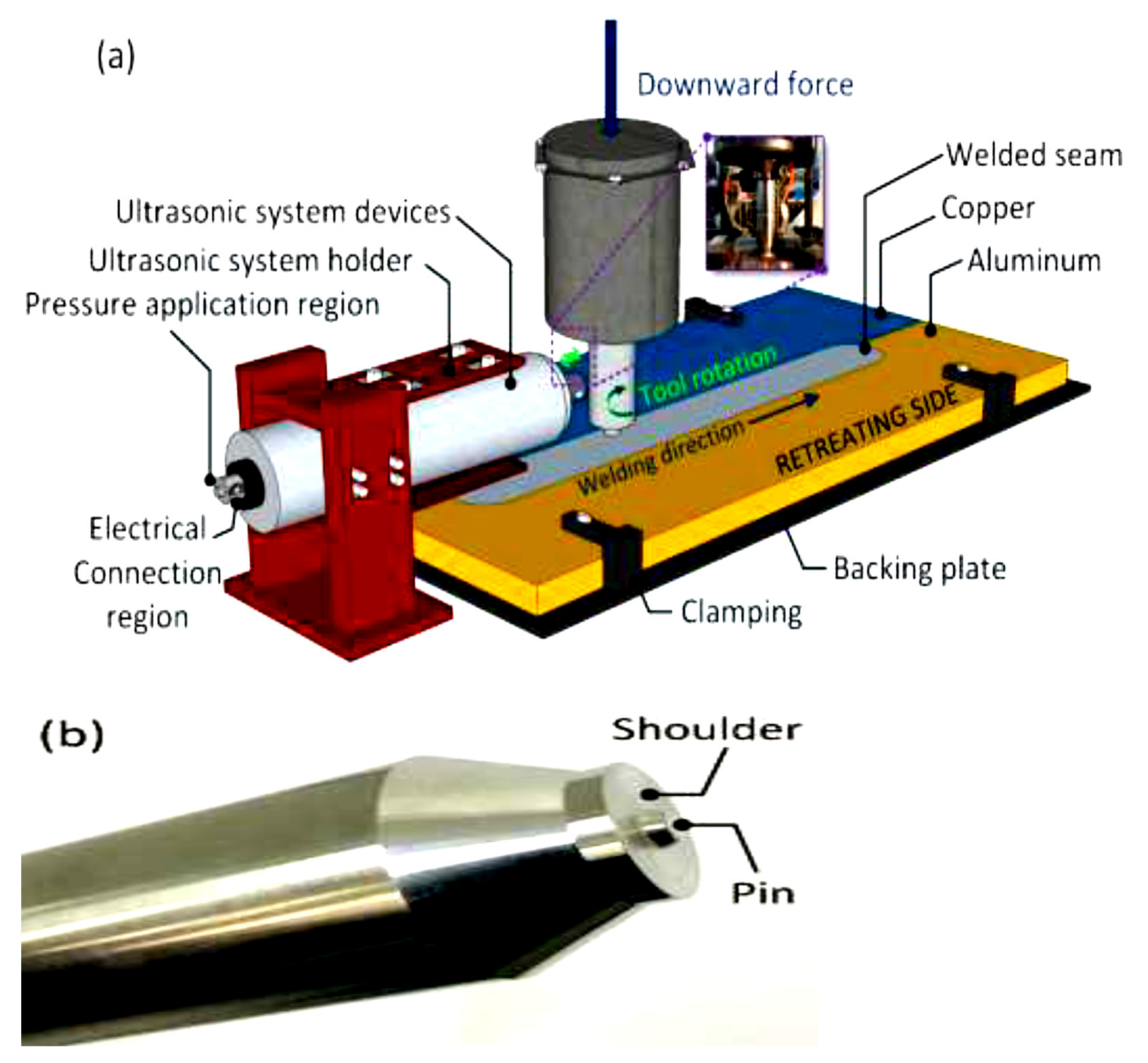

- The joint structure mechanism and mechanical properties were found to be improved by the innovative UVaFSW technique. Up to 600 rev/min it was discovered that the joint strength improved up to 600 rev/min. However, when the heat input improved, the joint strength reduced.

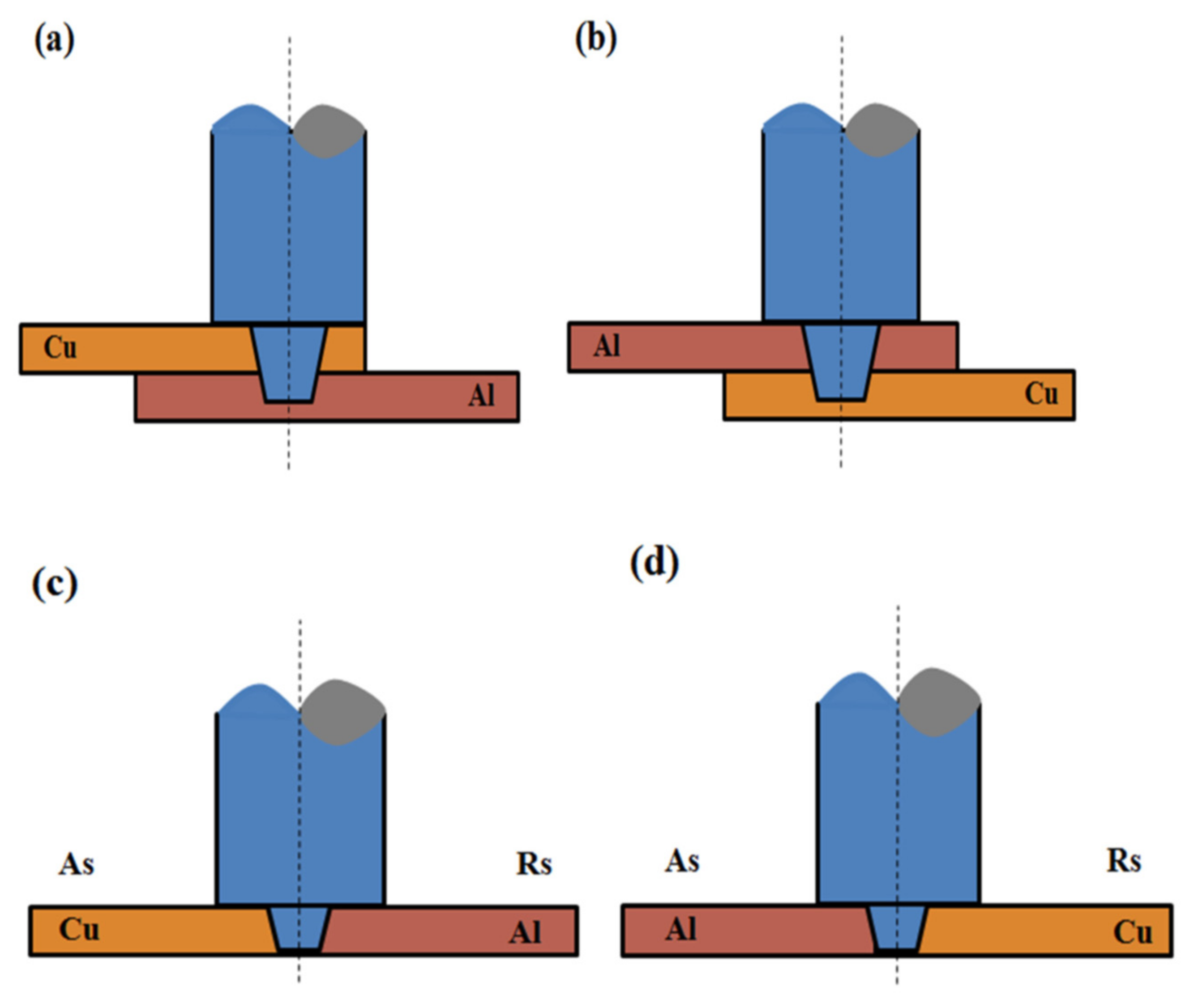

- According to various writers, it is challenging to obtain a high-quality weld and development in an Al/Cu FSW weld when Cu is placed at the RS. Despite this, copper was added to the AS (type I joints) and RS to create Al/Cu FSW and UVaFSW joints in the current investigation (type II joints).

- As a result of the aggregate-like composition and superior metallurgical connection created by FSW’s welding of AA5083 industrially pure Cu, the UTS reached 203 MPa, which represents a joint efficacy of 94.8 percent for the Al alloy. When an offset of 1.2 mm was employed, the highest UTS of 152 MPa was attained during friction stir butt welding by combining commercially pure and Al alloy 6061. The tool offset butt joining of commercially pure 6061 Al alloy determines the surface quality of the joins.

- Choosing the appropriate welding process parameters while employing the tool offset approach encourages the creation of a high-quality weld superficial even when ultrasonic vibration is present.

- Only when the tough Cu plate was attached on the moving side was a solid, defect-free junction possible. When the soft Al plate was mounted on the developing surface, a significant volume defect was seen. This is explained by the fact that during FSW, it was difficult to carry the hard Cu bulk material to the advancing side.

- There are still numerous issues with the FSW of Cu/Al dissimilar materials. Therefore, in future research, mathematical models of the FSW method for Cu/Al dissimilar fabrics have to be done using alternative software and finite element models. Moreover, the welded joint’s mechanical qualities are not very good. The subsequent stage is to constantly enhance the FSW welding method in order to attain the goal of increasing the mechanistic properties of the joint, to facilitate the FSW of Cu/Al dissimilar materials that can be employed more broadly across diverse industries.

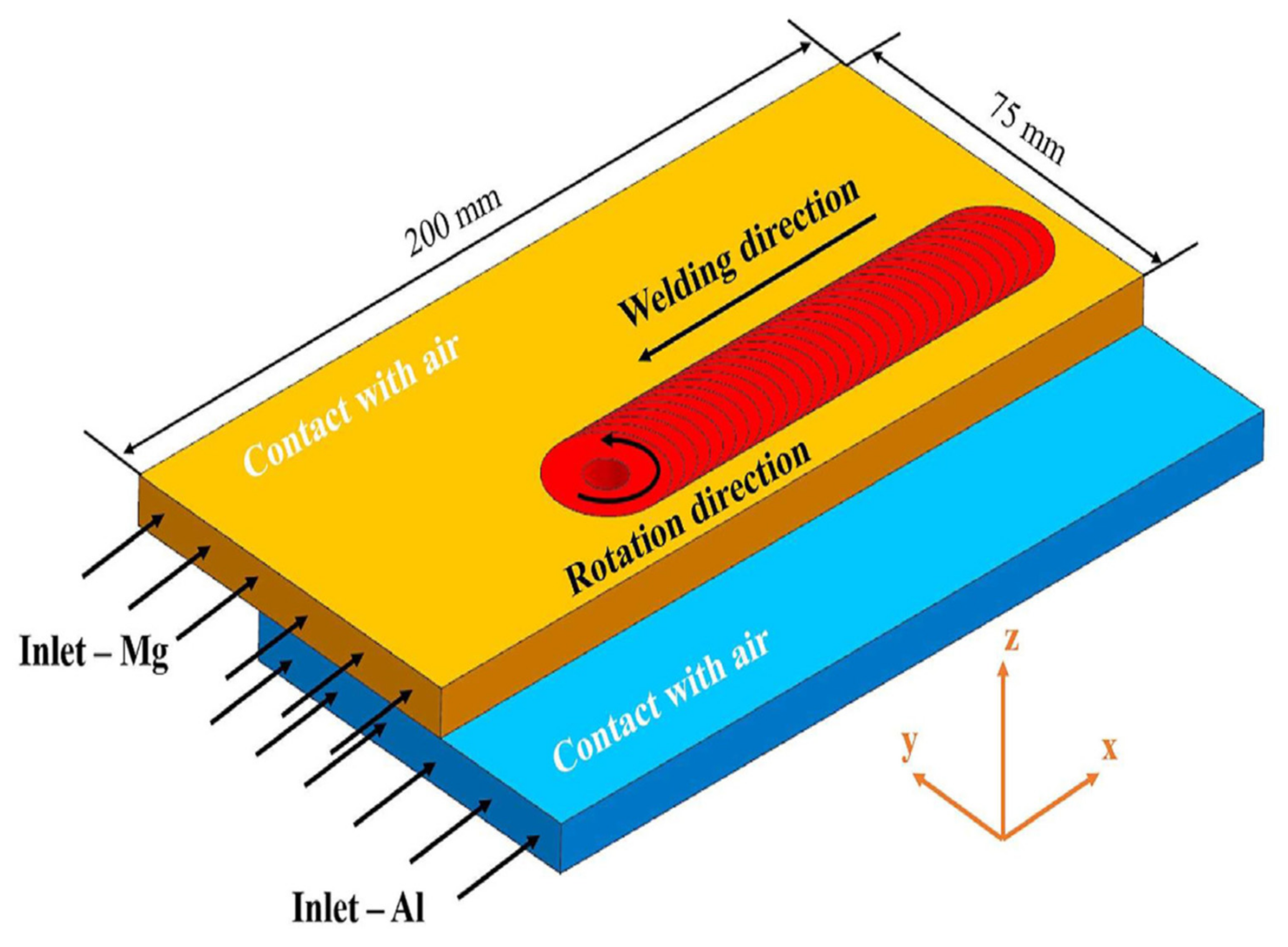

4.2.2. FSW of Aluminum Alloys with Magnesium

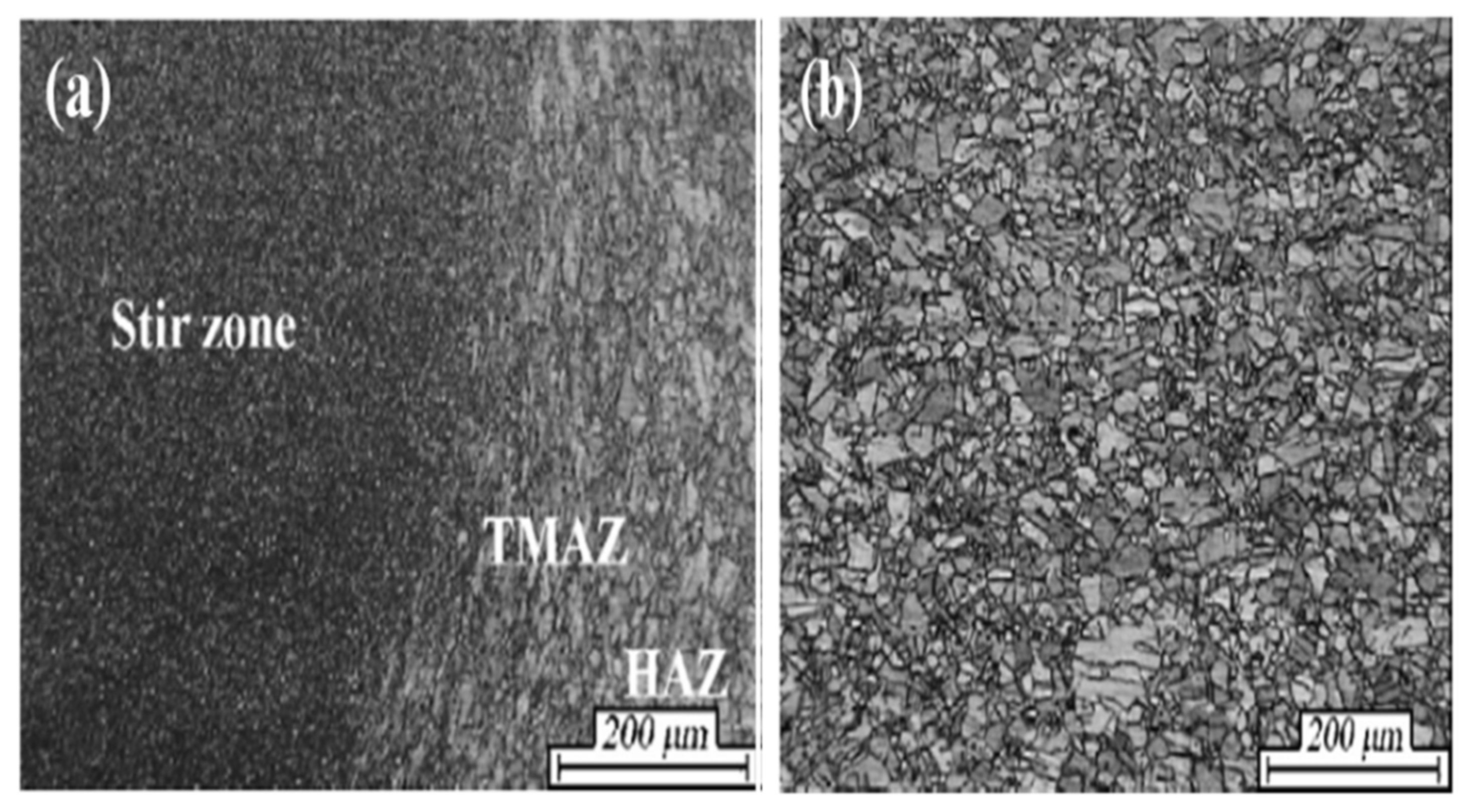

- The method by which grains recrystallize on the side of the Al alloy is not significantly impacted by ultrasonic vibration, but the structure of the grains on the side of the Mg alloy is.

- The primary component influencing the thermal-mechanical behavior in the welding process is accelerated vibration, which can facilitate the movement, accumulation, and destruction of displacements in agitated zones. As a result, the weld’s grain microstructure evolved in a variety of ways, and UVeFSW’s grain recrystallization degree increased.

- Three levels of pin lengths were used to numerically simulate the FSLW method in the Mg/Al structure. The peak temperature rises with increasing pin length, the high-heat zone surrounding the tool widens, and more materials are pushed to drift across it. As a result, the A/Mg blended zone grows, and IMCs are more prone to forming.

- When there are ultrasonic vibrations present, the FSW factor screen and solder ductile strength are both enhanced. The increase in ductile force is more visible at extremely low spin rates but less so at greater turning rates.

- Due to the inhibition of IMCs’ growth, the deterrence of extreme temperature input by using cooling systems has demonstrated a remarkable improvement in joint dependability. For upcoming work, various cooling-aided FSW techniques need to be encouraged.

- Although electrochemical rust assessment of the Al/Mg connection using FSW is a significant issue of attention and needs careful assessment, no thorough data is currently available.

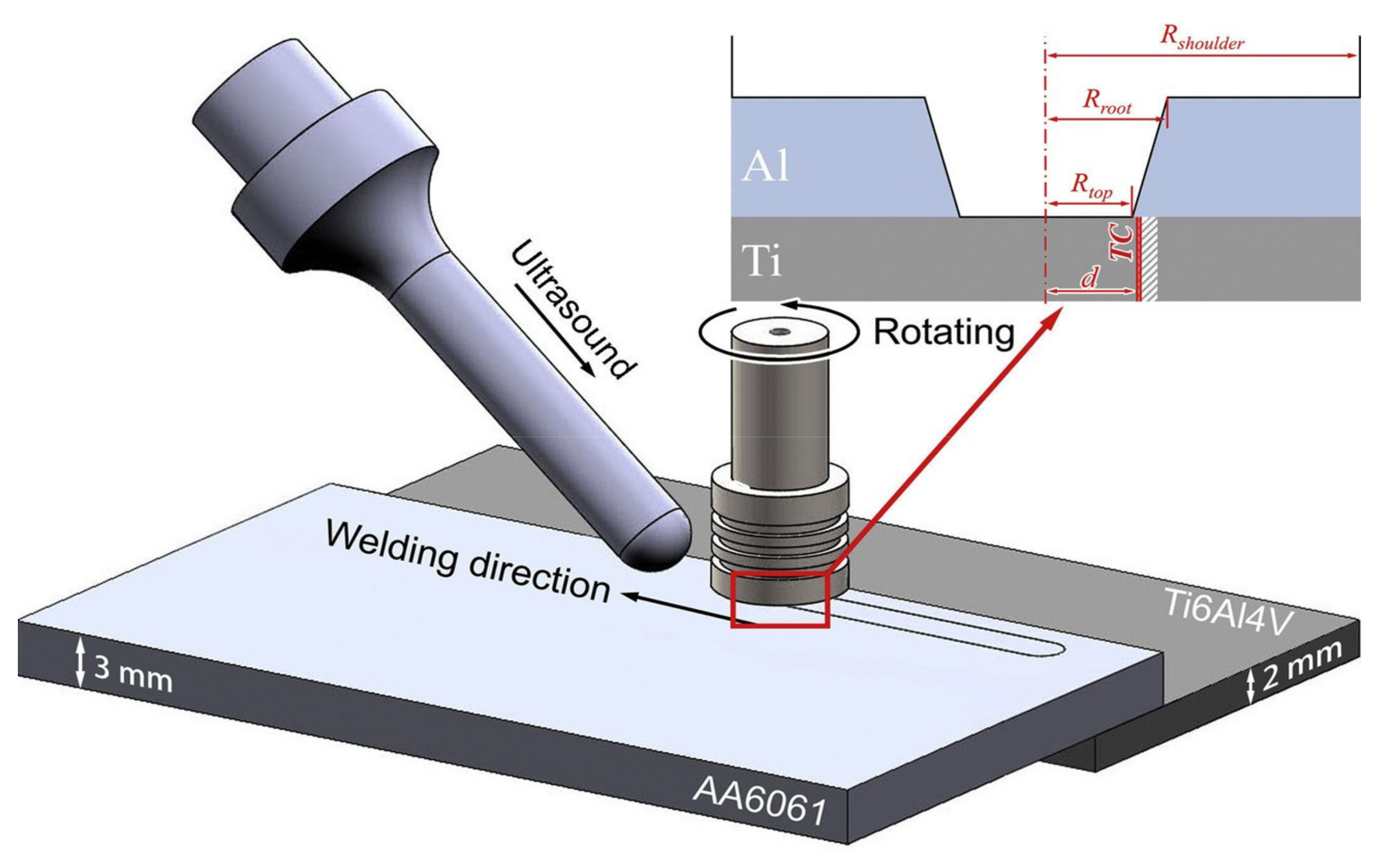

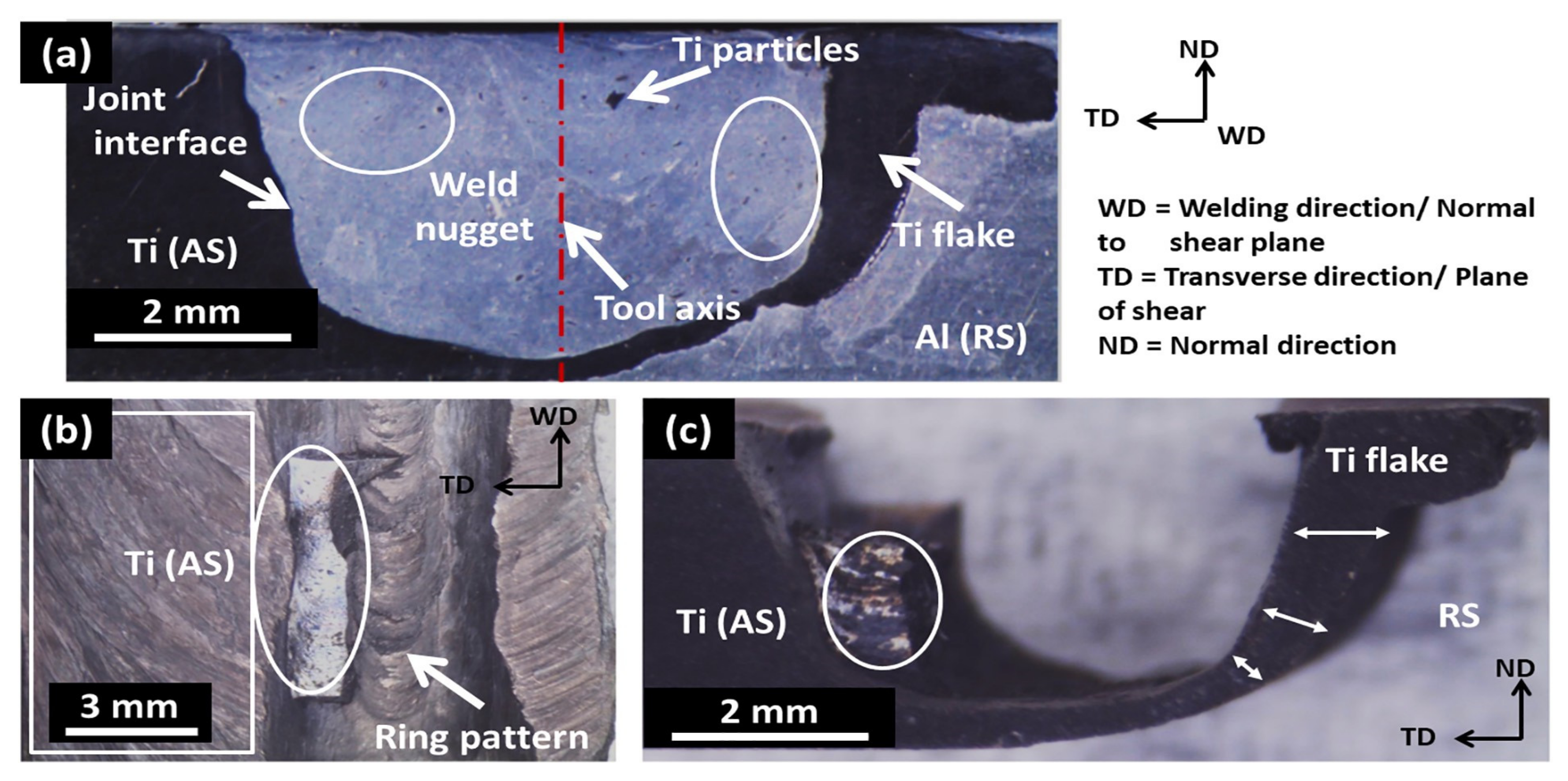

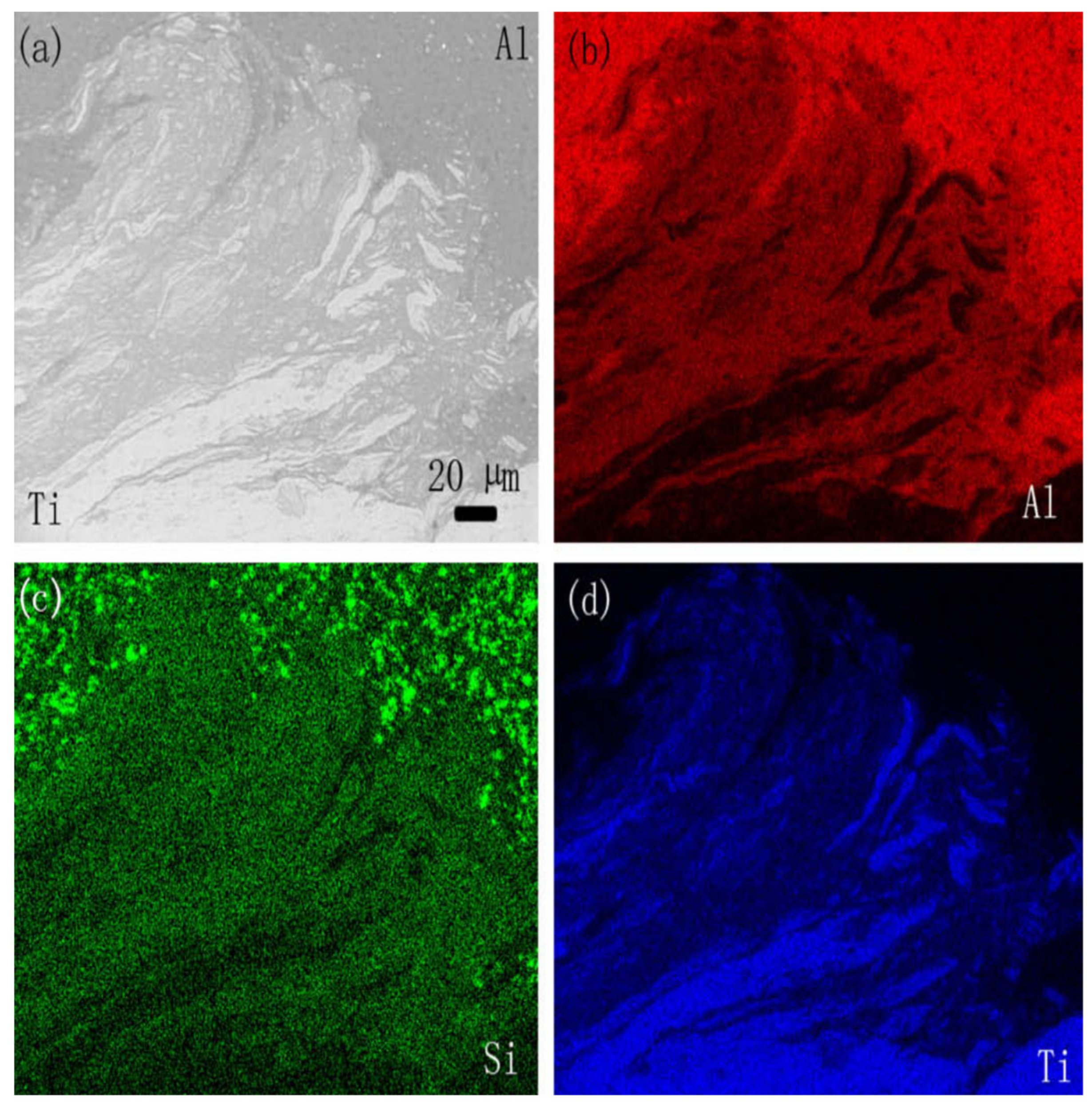

4.2.3. Friction Stirs Welding of Aluminum Alloys with Titanium

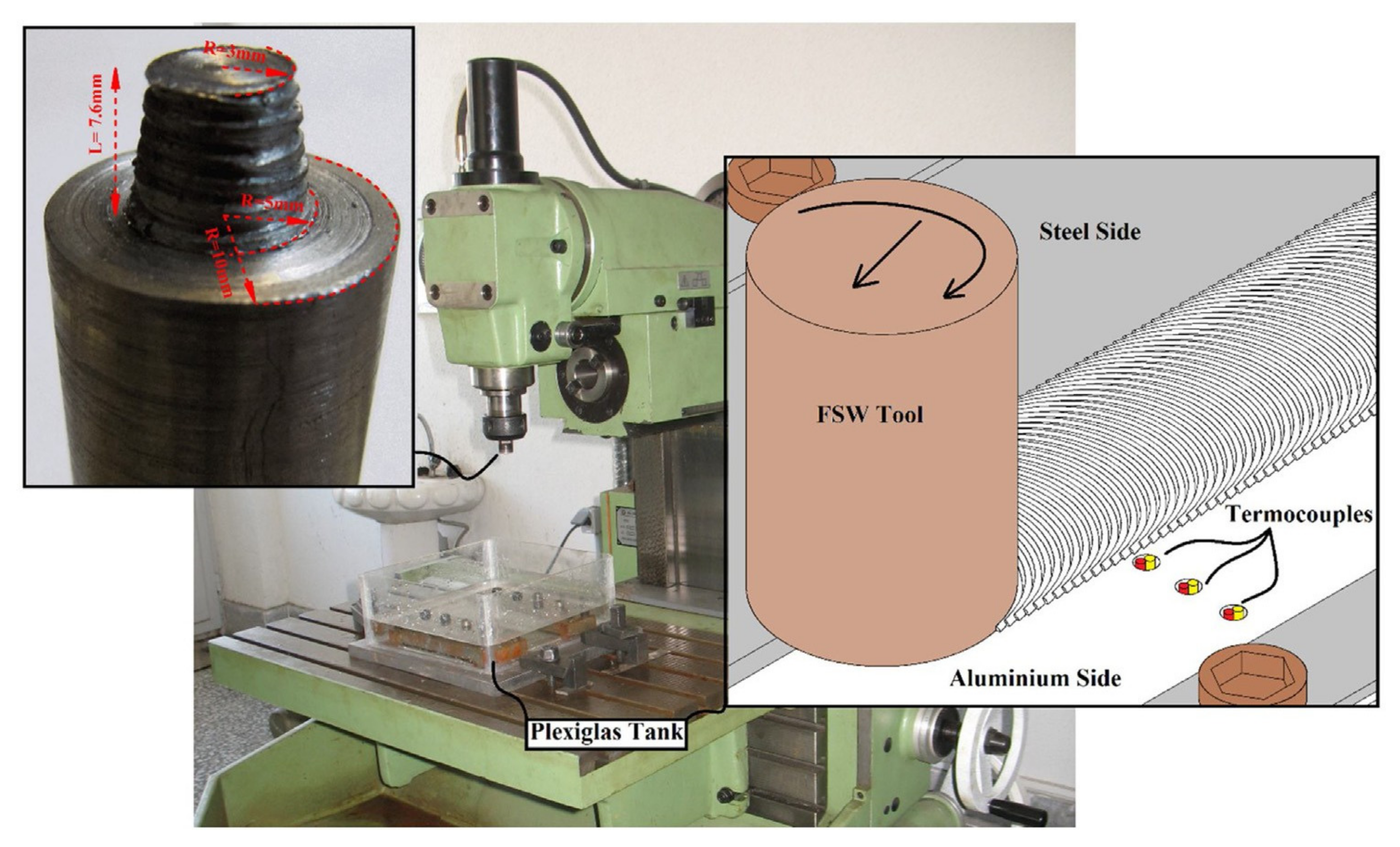

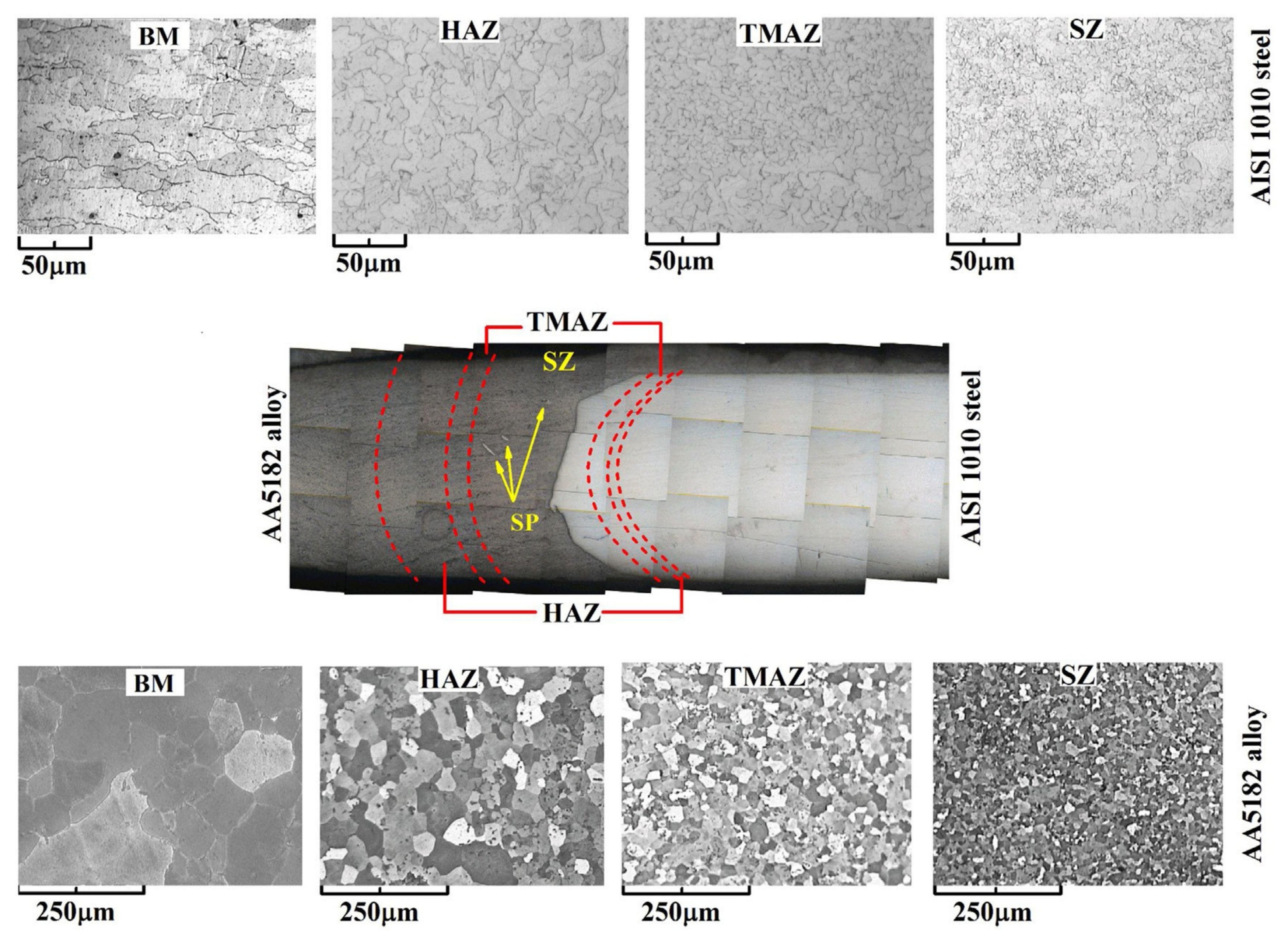

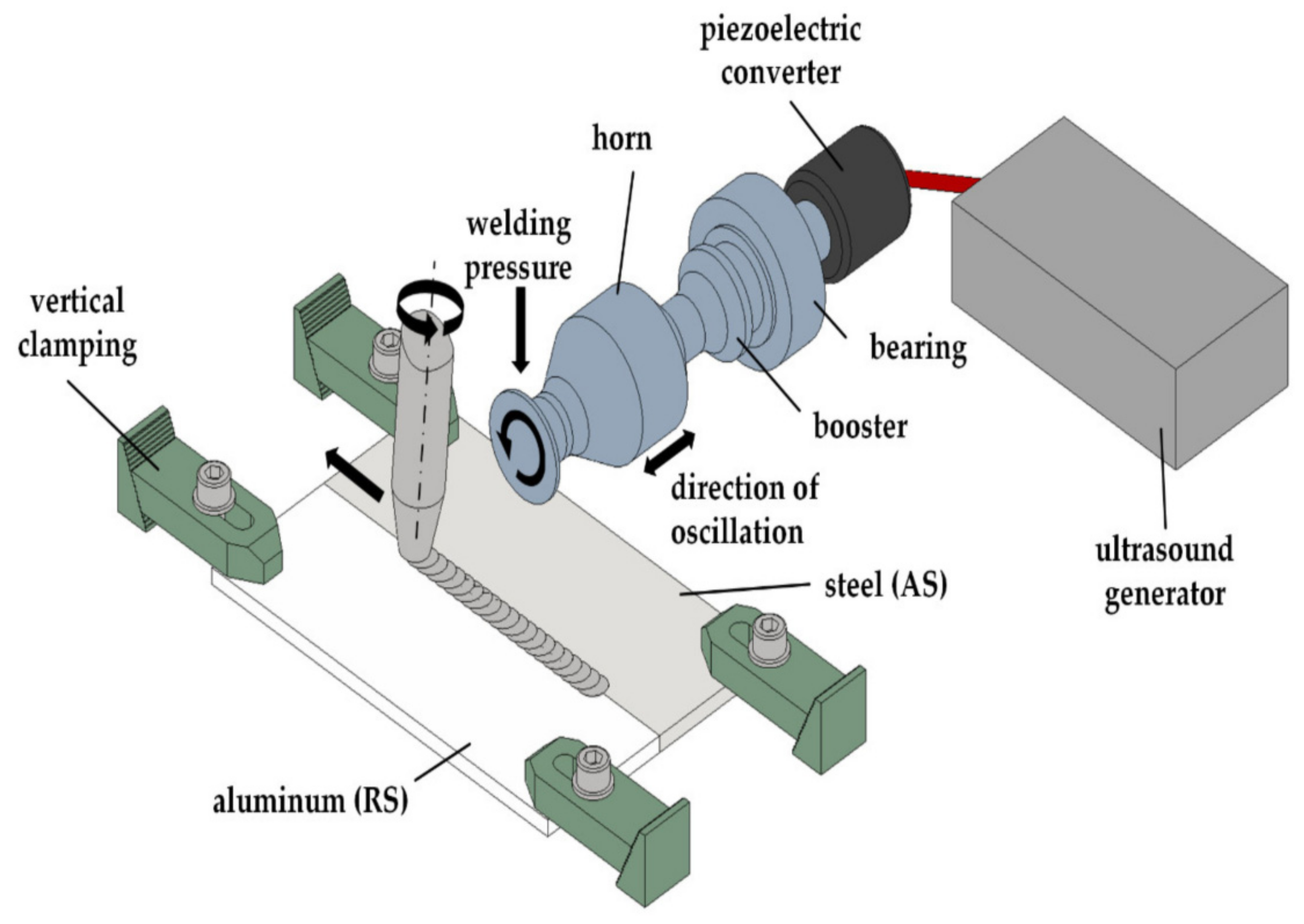

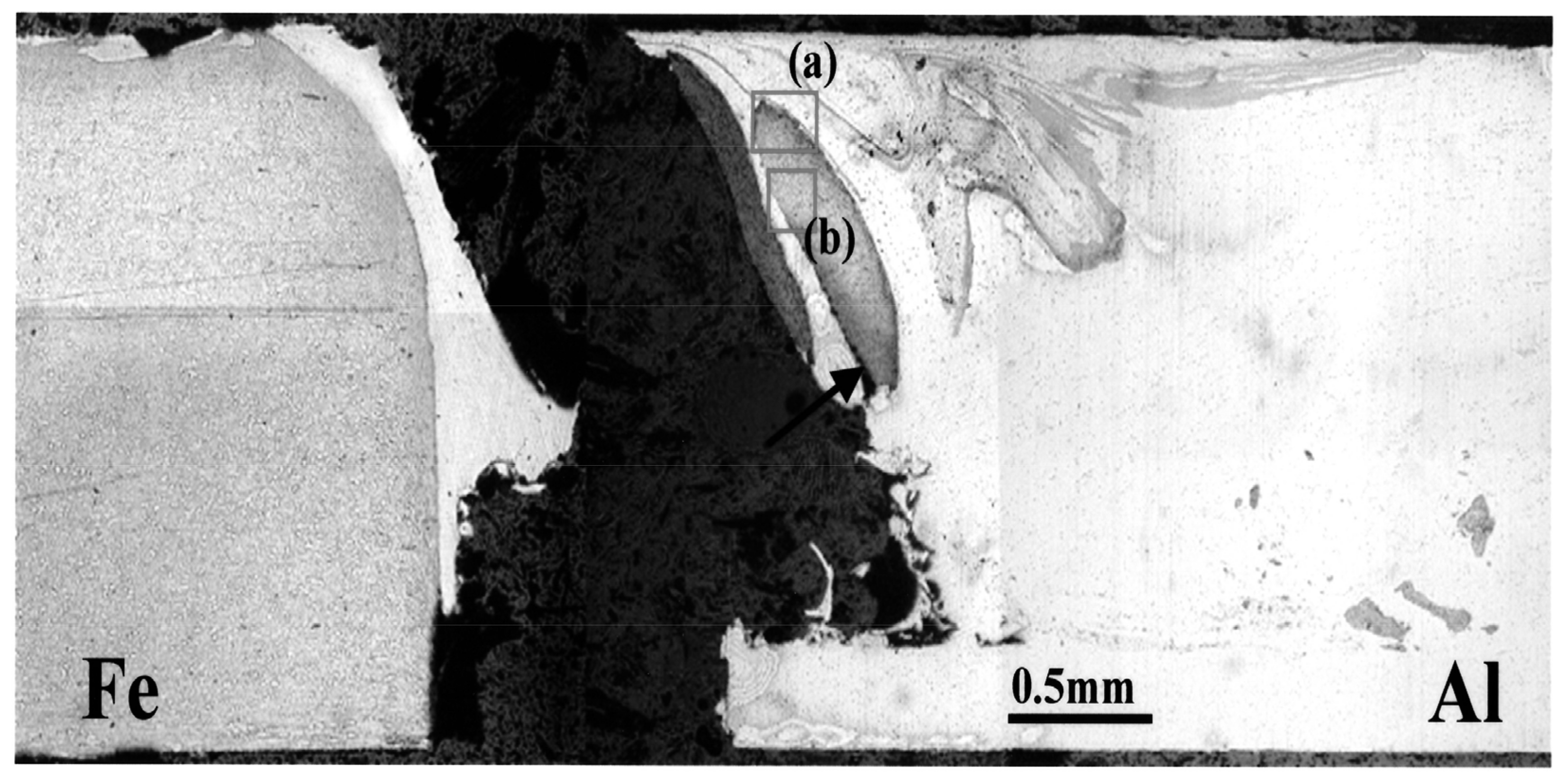

4.2.4. FSW of Aluminum Alloys with Steel

4.2.5. Friction Stir Welding Aluminum Alloys with Brass CuZn34

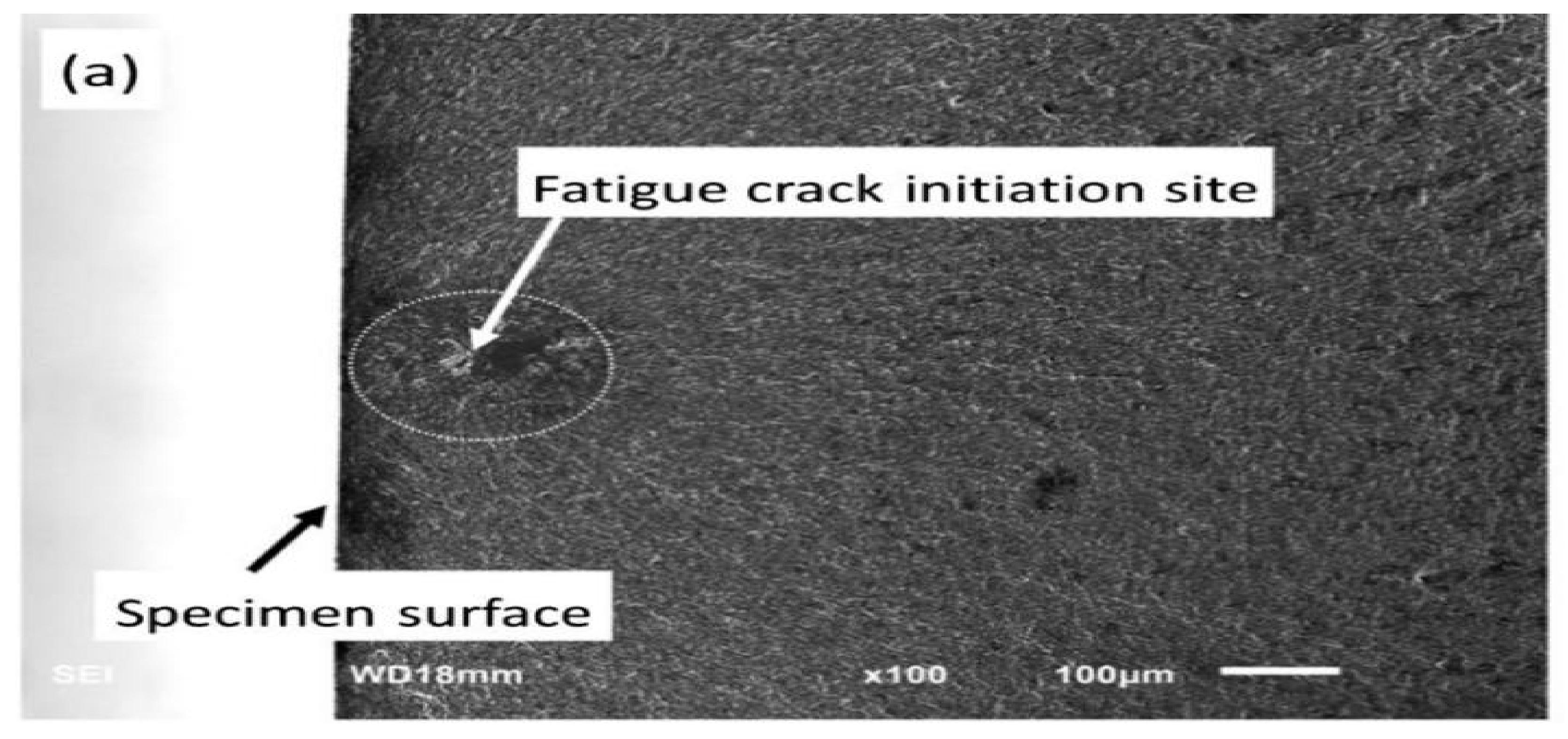

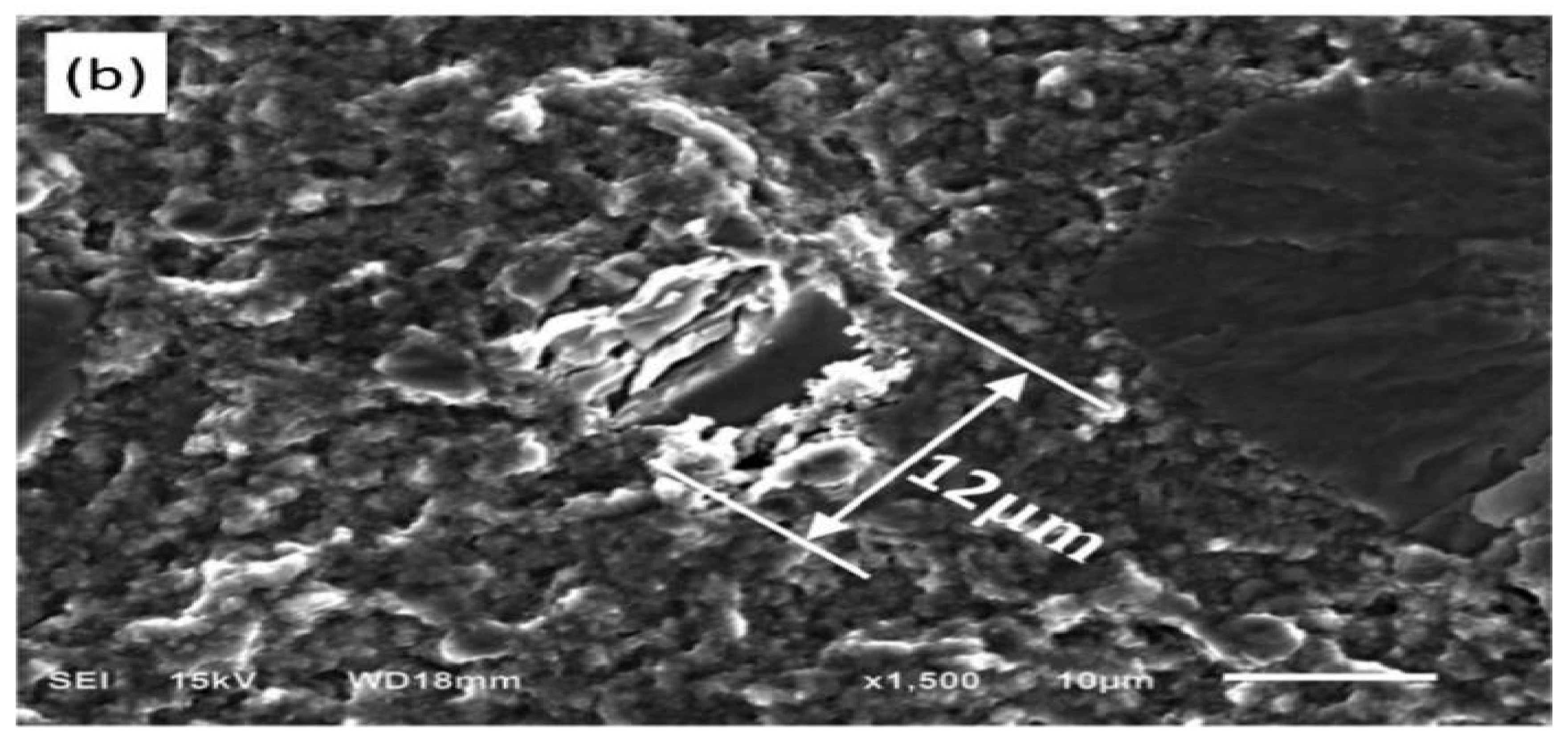

5. Fatigue Behavior of FSW Aluminum Alloys

5.1. Fatigue Behavior of FSW of Aluminum Alloys AA7150-AA2524

5.2. Fatigue Behavior of FSW of Aluminum Alloys AA5086-H32 with AA6061-T6

5.3. Fatigue Behavior of FSW of Aluminum Alloys 5052-H34 with 7075-T6

6. Gaps in Knowledge

7. Future Recommendations

- Aluminum is the second most used metal after steel for numerous industrial applications, and it has numerous positive aspects that suit it for such applications. However, with the continual growth of the industrial revolution, the new metals are recommended to join with Al (pure and or alloy based) through FSW and investigate its output parameters.

- There is a rich family of Al alloys consisting of a vast range of them. Therefore, it is recommended to investigate other Al alloys joined with each other and or with other metals through the FSW method.

- The selection of FSW process parameters is the most important and crucial part of research work in this field. Therefore, they must be properly selected so as to achieve optimum results for the research. Further, in this regard, the application of AI methods is encouraged to be used for finding and selecting the optimum FSW process parameters for research in this field.

- Most of the reviewed literature work in this review suggested the utilization of a milling machine set-up for producing FSW joints. Although the FSW machines have already been launched on the research/laboratory side, it is recommended to use proper FSW machines for research work in this field. The main benefit of using FSW machines is the degree of freedom for selecting optimum FSW process parameters.

- For future work, the literature suggests that these fine-grained alloys influence the strength and ductility of surface composites. Therefore, the study of mechanical and tribological properties like micro-hardness, tensile, fatigue, creep and plastic deformation, etc., at high processing temperatures is a new research scope and needs to be explored.

- Because the tool profile is such an important and effective parameter of friction stir welding, new designs must be developed in the future to be selected based on the type of metal to be welded, thickness, and welding position. The values of the variables tool of friction stir welding must be given in accordance with the principles and rules (Tool shoulder D, Tool pin diameter d, Tool pin length, tilt angle), as well as the tool material and tool pin profile (straight, square, cylindrical, cylindrical thread, hexagonal).

- A technological path (welding procedure specification) is required in which the variables of friction welding are determined depending on the product to be produced, like traditional methods of welding, which depend on the basic international standard.

- A new fatigue model for the materials using the regression approach and FSW parameters needs to be developed.

- The search for new parameters and the study of their effects on the mechanical properties of the welding line requires the friction stir welding produced, such as the time of the tool remaining in a rotational movement (Tool indentation time) to a linear velocity.

- In the future, specialized friction stir welding machines will be required to be manufactured to suit all positions of welding.

8. Conclusions

- i

- The input parameters of the system are found as “welding speed”, “rotational speed”, “plunge depth”, “spindle torque”, “shoulder design”, “base material”, “pin profile”, and “tool type”, etc. The output parameters are generally taken as “tensile strength”, “yield strength”, “elongation, hardness”, “wear rate”, “welding quality”, and “residual stress”, etc.

- ii

- It has been observed that with the latest advancements in AI approaches, selecting input parameters and predicting output parameters for FSW may be done more accurately.

- iii

- Several designs of joints can be used for friction stir welding of various types, such as “but joint”, “lap joint”, and “T joint”. In order to avoid any separation (de-welding) between the combined surfaces of two panels of almost the same thickness, it is necessary to fix these panels firmly to the “backing plate”.

- iv

- The research work on the fatigue behavior of Al welds is lacking in data and guidance for the assessment of structures welded through FSW. However, an effort has been made in this review work to highlight the little available data for fatigue behavior for FSW joints. Based on it, it has been observed that the measurement of key geometric and material parameters for which additional data collection would be beneficial for improving our understanding of the fatigue behavior of FSW joints.

- v

- The connection or joining of similar and dissimilar aluminum alloys by means of FSW has proven its success in many scientific research by obtaining high quality in the mechanical specifications of the welding joint, where the heat is generated as a result of friction between the tool and the metals to be welded. The generated heat is sufficient to form a plastic deformation to combine the pieces being welded. The selection of FSW needs to be correct and appropriate for the thickness and quality of the metal as well as the position of the weld.

- vi

- To limit the production of intermetallic compounds, the peak temperature and the thermal cycle can be controlled using an external cooling medium, such as water. Alternately, because FSW creates a robust and ductile joint, which can be trailed by a cold rolling process to lessen the extent of intermetallic compounds and the number of holes, enhancing the joint’s mechanical and electric qualities. The use of compatible transitional filler material, for instance, Zn, is a recent innovation in the connecting of dissimilar metals, including Al and Cu. By using a filler layer, brickle intermetallic compound production is prevented, resulting in joints with good mechanical and electrical properties.

- vii

- The influence of UV on the microstructure and mechanical properties of Al/Ti FSLW can be successfully achieved by FSW as well as URFW with different transmission sides.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Eren, B.; Guvenc, M.A.; Mistikoglu, S. Artificial intelligence applications for friction stir weldin. Met. Mater. Int. 2021, 27, 193–219. [Google Scholar] [CrossRef]

- Shrivastava, A.; Krones, M.; Pfefferkorn, F.E. Comparison of energy consumption and environmental impact of friction stir welding and gas metal arc welding for aluminum. CIRP J. Manuf. Sci. Technol. 2015, 9, 159–168. [Google Scholar] [CrossRef]

- Sezhian, M.V.; Ramadoss, R.; Giridharan, K.; Chakravarthi, G.; Stalin, B. Comparative study of friction stir welding process and its variables. Mater. Today Proc. 2020, 33, 4842–4847. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Çam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.P.; Robson, J.D.; et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater. Sci. 2021, 117, 100752. [Google Scholar]

- Patel, S.K.; Singh, V.P.; Roy, B.S.; Kuriachen, B. Recent research progresses in Al-7075 based in-situ surface composite fabrication through friction stir processing. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2020, 262, 114708. [Google Scholar] [CrossRef]

- Gite, R.A.; Loharkar, P.K.; Shimpi, R. Friction stir welding parameters and application: A review. Mater. Today Proc. 2019, 19, 361–365. [Google Scholar] [CrossRef]

- Avettand-Fènoël, M.N.; Simar, A. A review about friction stir welding of metal matrix composites. Mater. Charact. 2016, 120, 1–17. [Google Scholar] [CrossRef]

- Singh, K.; Singh, G.; Singh, H. Review on friction stir welding of magnesium alloys. J. Magnes. Alloys 2018, 6, 399–416. [Google Scholar] [CrossRef]

- Klag, O.; Gröbner, J.; Wagner, G.; Schmid-Fetzer, R.; Eifler, D. Microstructural and thermodynamic investigations on friction stir welded Mg/Al-joints. Int. J. Mater. Res. 2014, 105, 145–155. [Google Scholar] [CrossRef]

- Kwon, Y.J.; Shigematsu, I.; Saito, N. Dissimilar friction stir welding between magnesium and aluminum alloys. Mater. Lett. 2008, 62, 3827–3829. [Google Scholar] [CrossRef]

- Yan, J.; Xu, Z.; Li, Z.; Li, L.; Yang, S. Microstructure characteristics and performance of dissimilar welds between magnesium alloy and aluminum formed by friction stirring. Scr. Mater. 2005, 53, 585–589. [Google Scholar] [CrossRef]

- Singh, V.P.; Patel, S.K.; Ranjan, A.; Kuriachen, B. Recent research progress in solid state friction-stir welding of aluminium–magnesium alloys: A critical review. J. Mater. Res. Technol. 2020, 9, 6217–6256. [Google Scholar] [CrossRef]

- Nindekar, H.; Kapoor, D.P. A Review on Fracture Mechanics of AA2024 Aluminium Alloy Friction Stir Welding. Int. J. Res. Appl. Sci. Eng. Technol. 2020, 8, 993–1996. [Google Scholar] [CrossRef]

- Sidhu, M.S.; Chatha, S.S. Friction stir welding–process and its variables: A review. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 275–279. [Google Scholar]

- Ashish, B.I.S.T.; Saini, J.S.; Sharma, B. A review of tool wear prediction during friction stir welding of aluminium matrix composite. Trans. Nonferrous Met. Soc. China 2016, 26, 2003–2018. [Google Scholar] [CrossRef]

- Mohanty, H.K.; Mahapatra, M.M.; Kumar, P.; Biswas, P.; Mandal, N.R. Predicting the effects of tool geometries on friction stirred aluminium welds using artificial neural networks and fuzzy logic techniques. Int. J. Manuf. Res. 2013, 8, 296–312. [Google Scholar] [CrossRef]

- Dewan, M.W.; Huggett, D.J.; Liao, T.W.; Wahab, M.A.; Okeil, A.M. Prediction of tensile strength of friction stir weld joints with adaptive neuro-fuzzy inference system (ANFIS) and neural network. Mater. Des. 2016, 92, 288–299. [Google Scholar] [CrossRef]

- Prasanth, R.S.S.; Hans Raj, K. Determination of optimal process parameters of friction stir welding to join dissimilar aluminum alloys using artificial bee colony algorithm. Trans. Indian Inst. Met. 2018, 71, 453–462. [Google Scholar] [CrossRef]

- Teimouri, R.; Baseri, H. Forward and backward predictions of the friction stir welding parameters using fuzzy-artificial bee colony-imperialist competitive algorithm systems. J. Intell. Manuf. 2015, 26, 307–319. [Google Scholar] [CrossRef]

- Das, B.; Pal, S.; Bag, S. Weld quality prediction in friction stir welding using wavelet analysis. Int. J. Adv. Manuf. Technol. 2017, 89, 711–725. [Google Scholar] [CrossRef]

- Huggett, D.J.; Liao, T.W.; Wahab, M.A.; Okeil, A. Prediction of friction stir weld quality without and with signal features. Int. J. Adv. Manuf. Technol. 2018, 95, 1989–2003. [Google Scholar] [CrossRef]

- Zhang, H.R.; Zhang, Y.; Dai, D.B.; Cao, M.; Shen, W.F. Modelling and optimization of the superconducting transition temperature. Mater. Des. 2016, 92, 371–377. [Google Scholar] [CrossRef]

- D’Orazio, A.; Forcellese, A.; Simoncini, M. Prediction of the vertical force during FSW of AZ31 magnesium alloy sheets using an artificial neural network-based model. Neural Comput. Appl. 2019, 31, 7211–7226. [Google Scholar] [CrossRef]

- Dehabadi, V.M.; Ghorbanpour, S.; Azimi, G. Application of artificial neural network to predict Vickers microhardness of AA6061 friction stir welded sheets. J. Cent. South Univ. 2016, 23, 2146–2155. [Google Scholar] [CrossRef]

- Evans, W.T.; Gibson, B.T.; Reynolds, J.T.; Strauss, A.M.; Cook, G.E. Friction Stir Extrusion: A new process for joining dissimilar materials. Manuf. Lett. 2015, 5, 25–28. [Google Scholar] [CrossRef]

- Krishnan, M.M.; Maniraj, J.; Deepak, R.; Anganan, K. Prediction of optimum welding parameters for FSW of aluminium alloys AA6063 and A319 using RSM and ANN. Mater. Today Proc. 2018, 5, 716–723. [Google Scholar] [CrossRef]

- Wu, H.; Chen, Y.C.; Strong, D.; Prangnell, P. Stationary shoulder FSW for joining high strength aluminum alloys. J. Mater. Process. Technol. 2015, 221, 187–196. [Google Scholar] [CrossRef]

- Zhao, S.; Ni, J.; Wang, G.; Wang, Y.; Bi, Q.; Zhao, Y.; Liu, X. Effects of tool geometry on friction stir welding of AA6061 to TRIP steel. J. Mater. Process. Technol. 2018, 261, 39–49. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Cao, X.; Larose, S.; Wanjara, P. Review of tools for friction stir welding and processing. Can. Metall. Q. 2012, 51, 250–261. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mat. Sci. Eng. 2005, 2014, 9783319070. [Google Scholar] [CrossRef]

- Wahid, M.A.; Siddiquee, A.N. Review on underwater friction stir welding: A variant of friction stir welding with great potential of improving joint properties. Trans. Nonferrous Met. Soc. China 2018, 28, 193–219. [Google Scholar] [CrossRef]

- Fuse, K.; Badheka, V. Bobbin tool friction stir welding: A review. Sci. Technol. Weld. Join. 2019, 24, 277–304. [Google Scholar] [CrossRef]

- Mehta, K.P.; Badheka, V.J. A review on dissimilar friction stir welding of copper to aluminum: Process, properties, and variants. Mater. Manuf. Process. 2016, 31, 233–254. [Google Scholar] [CrossRef]

- Singh, R.P.; Dubey, S.; Singh, A.; Kumar, S. A review paper on friction stir welding process. Mater. Today Proc. 2021, 38, 5–10. [Google Scholar] [CrossRef]

- Salih, O.S.; Ou, H.; Sun, W.; McCartney, D.G. A review of friction stir welding of aluminium matrix composites. Mater. Des. 2015, 86, 61–71. [Google Scholar] [CrossRef]

- Zakaria, K.A.; Abdullah, S.; Ghazali, M.J. Comparative study of fatigue life behaviour of AA6061 and AA7075 alloys under spectrum loadings. Mater. Des. 2013, 49, 48–57. [Google Scholar] [CrossRef]

- Mohamadreza, N.; Abbas, S.M.; Spiro, Y. Taguchi optimization of process parameters in friction stir welding of 6061 aluminum alloy: A review and case study. Engineering 2011, 03, 144–155. [Google Scholar] [CrossRef]

- Mohan, D.G.; Gopi, S. Study on the mechanical behaviour of friction stir welded aluminium alloys 6061 with 5052. In Proceedings of the 2017 8th Annual Industrial Automation and Electromechanical Engineering Conference (IEMECON), Bangkok, Thailand, 16–18 August 2017. [Google Scholar] [CrossRef]

- Sahu, P.K.; Pal, S. Multi-response optimization of process parameters in friction stir welded AM20 magnesium alloy by Taguchi grey relational analysis. Mater. Today Proc. 2021, 37, 1172–1182. [Google Scholar] [CrossRef]

- Lombard, H.; Hattingh, D.G.; Steuwer, A.; James, M.N. Optimising FSW process parameters to minimise defects and maximise fatigue life in 5083-H321 aluminium alloy. Eng. Fract. Mech. 2008, 75, 341–354. [Google Scholar] [CrossRef]

- Feofanov, A.N.; Ovchinnikov, V.V.; Gubin, A.M. Mechanical Properties of Joints in Friction Stir Welding of Aluminum Alloys. Russ. Eng. Res. 2020, 40, 916–921. [Google Scholar] [CrossRef]

- Hirata, T.; Oguri, T.; Hagino, H.; Tanaka, T.; Chung, S.W.; Takigawa, Y.; Higashi, K. Influence of friction stir welding parameters on grain size and formability in 5083 aluminum alloy. Mater. Sci. Eng. A 2007, 456, 344–349. [Google Scholar] [CrossRef]

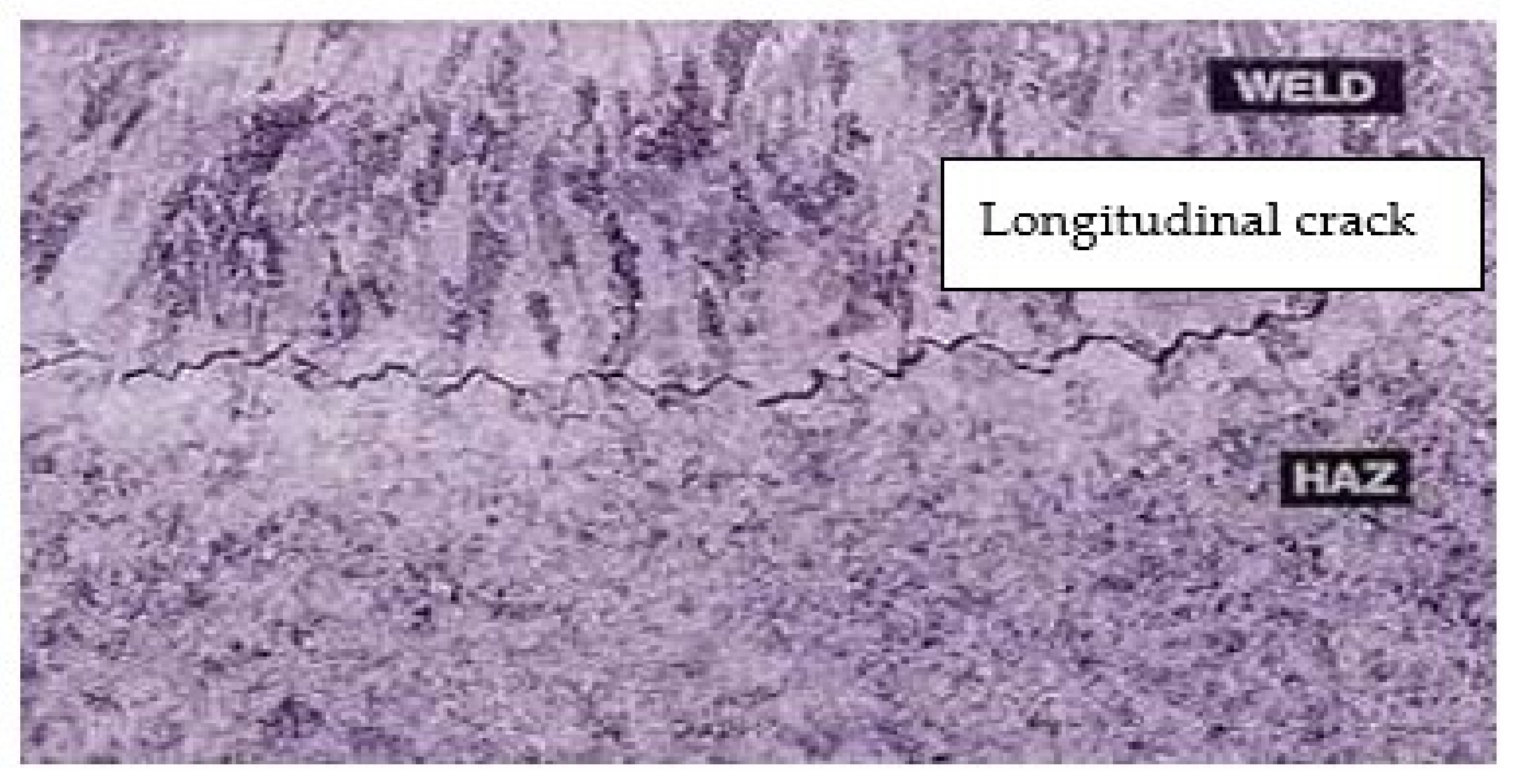

- Chen, H.B.; Yan, K.; Lin, T.; Chen, S.B.; Jiang, C.Y.; Zhao, Y. The investigation of typical welding defects for 5456 aluminum alloy friction stir welds. Mater. Sci. Eng. A 2006, 433, 64–69. [Google Scholar] [CrossRef]

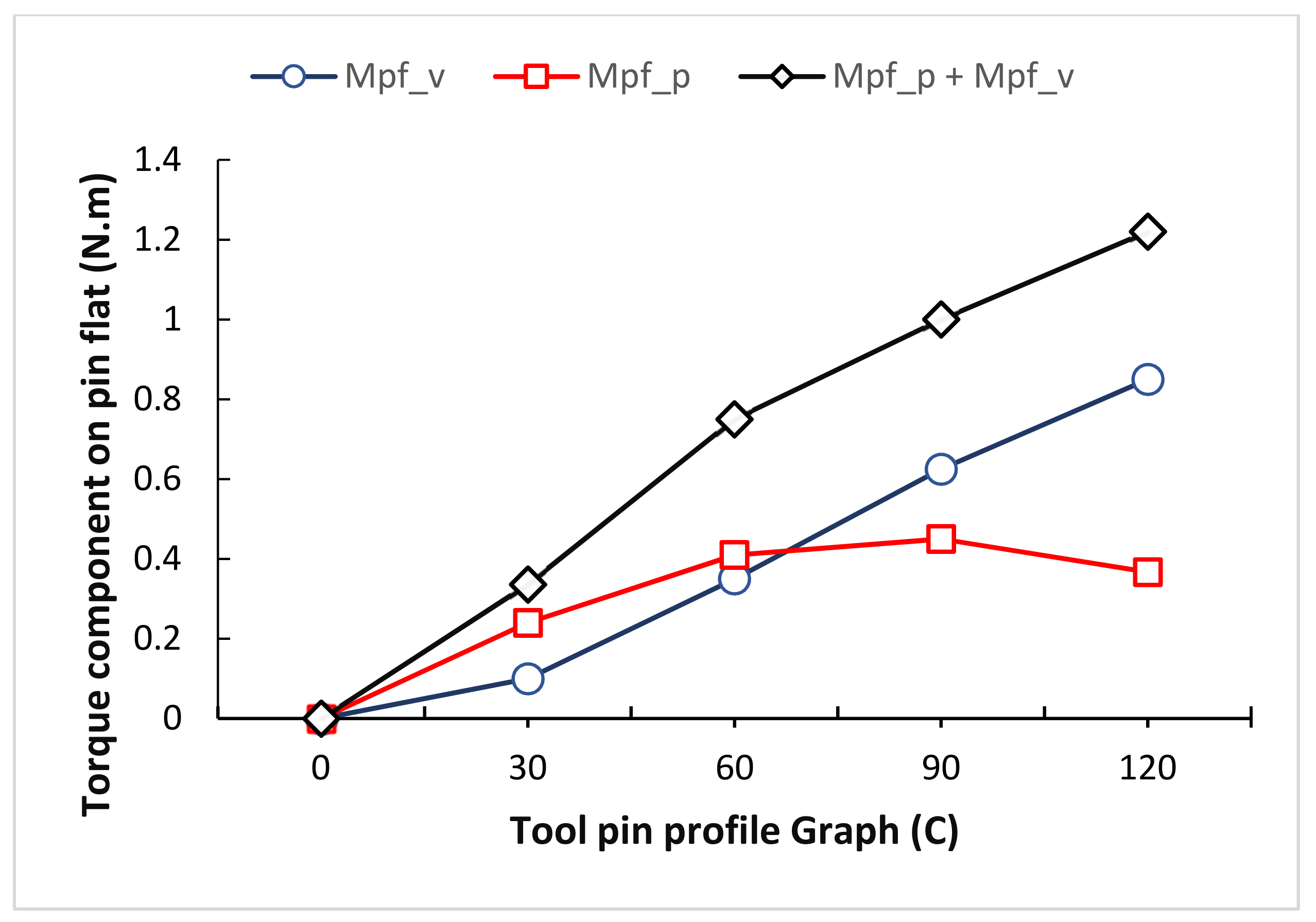

- Su, H.; Xue, L.; Wu, C. Optimizing the tool pin with three flats in friction stir welding of aluminum alloy. Int. J. Adv. Manuf. Technol. 2020, 108, 721–733. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Lin, S.B.; Wu, L.; Qu, F.X. The influence of pin geometry on bonding and mechanical properties in friction stir weld 2014 Al alloy. Mater. Lett. 2005, 59, 2948–2952. [Google Scholar] [CrossRef]

- Scialpi, A.; De Filippis, L.A.C.; Cavaliere, P. Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminium alloy. Mater. Des. 2007, 28, 1124–1129. [Google Scholar] [CrossRef]

- Lorrain, O.; Favier, V.; Zahrouni, H.; Lawrjaniec, D. Understanding the material flow path of friction stir welding process using unthreaded tools. J. Mater. Process. Technol. 2010, 210, 603–609. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of pin profile and rotational speed of the tool on the formation of friction stir processing zone in AA2219 aluminium alloy. Mater. Sci. Eng. A 2007, 459, 7–18. [Google Scholar] [CrossRef]

- Trimble, D.; O’Donnell, G.E.; Monaghan, J. Characterisation of tool shape and rotational speed for increased speed during friction stir welding of AA2024-T3. J. Manuf. Process. 2015, 17, 141–150. [Google Scholar] [CrossRef]

- Fujii, H.; Cui, L.; Maeda, M.; Nogi, K. Effect of tool shape on mechanical properties and microstructure of friction stir welded aluminum alloys. Mater. Sci. Eng. A 2006, 419, 25–31. [Google Scholar] [CrossRef]

- Dehghani, M.; Amadeh, A.; Mousavi, S.A. Investigations on the effects of friction stir welding parameters on intermetallic and defect formation in joining aluminum alloy to mild steel. Mater. Des. 2013, 49, 433–441. [Google Scholar]

- Ramachandran, K.K.; Murugan, N.; Kumar, S.S. Effect of tool axis offset and geometry of tool pin profile on the characteristics of friction stir welded dissimilar joints of aluminum alloy AA5052 and HSLA steel. Mater. Sci. Eng. A 2015, 639, 219–233. [Google Scholar] [CrossRef]

- Mehta, K.P.; Badheka, V.J. Influence of tool pin design on properties of dissimilar copper to aluminum friction stir welding. Trans. Nonferrous Met. Soc. China 2017, 27, 36–54. [Google Scholar] [CrossRef]

- Sathyabama University. Frontiers in Automobile and Mechanical Engineering International Conference Proceedings; Sathyabama University: Chennai, India, 2010. [Google Scholar]

- Abbass, M.K.; Raheef, K.M. Evaluation of the mechanical properties of friction stir lap welded joints for dissimilar aluminum alloys (AA1100 to AA6061). In Proceedings of the 2018 1st International Scientific Conference of Engineering Sciences-3rd Scientific Conference of Engineering Science (ISCES), Diyala, Iraq, 10–11 January 2018; pp. 192–197. [Google Scholar] [CrossRef]

- Anganan, K.; Murali, J.G.; Krishnan, M.M.; Marimuthu, K. Study of mechanical properties and experimental comparison of Mig and Friction stir welding processes for aa6082-t6 aluminium alloy. In Proceedings of the 2014 IEEE 8th International Conference on Intelligent Systems and Control (ISCO), Coimbatore, India, 10–11 January 2014; pp. 74–78. [Google Scholar] [CrossRef]

- Koilraj, M.; Sundareswaran, V.; Vijayan, S.; Rao, S.K. Friction stir welding of dissimilar aluminum alloys AA2219 to AA5083–Optimization of process parameters using Taguchi technique. Mater. Des. 2012, 42, 1–7. [Google Scholar] [CrossRef]

- Dilip, J.J.S.; Koilraj, M.; Sundareswaran, V.; Janaki Ram, G.D.; Koteswara Rao, S.R. Microstructural characterization of dissimilar friction stir welds between AA2219 and AA5083. Trans. Indian Inst. Met. 2010, 63, 757–764. [Google Scholar] [CrossRef]

- Astarita, A.; Tucci, F.; Silvestri, A.T.; Perrella, M.; Boccarusso, L.; Carlone, P. Dissimilar friction stir lap welding of AA2198 and AA7075 sheets: Forces, microstructure and mechanical properties. Int. J. Adv. Manuf. Technol. 2021, 117, 1045–1059. [Google Scholar] [CrossRef]

- Rafiei, R.; Shamanian, M.; Fathi, M.H.; Khodabakhshi, F. Dissimilar friction-stir lap-welding of aluminum-magnesium (AA5052) and aluminum-copper (AA2024) alloys: Microstructural evolution and mechanical properties. Int. J. Adv. Manuf. Technol. 2018, 94, 3713–3730. [Google Scholar] [CrossRef]

- Arora, K.S.; Pandey, S.; Schaper, M.; Kumar, R. Effect of process parameters on friction stir welding of aluminum alloy 2219-T87. Int. J. Adv. Manuf. Technol. 2010, 50, 941–952. [Google Scholar] [CrossRef]

- Viscusi, A.; Astarita, A.; Prisco, U. Mechanical properties optimization of friction stir welded lap joints in aluminium alloy. Advances in Materials Science and Engineering. Adv. Mater. Sci. Eng. 2019, 2019, 3832873. [Google Scholar] [CrossRef]

- Karrar, G.; Galloway, A.; Toumpis, A.; Li, H.; Al-Badour, F. Microstructural characterisation and mechanical properties of dissimilar AA5083-copper joints produced by friction stir welding. J. Mater. Res. Technol. 2020, 9, 11968–11979. [Google Scholar] [CrossRef]

- Mehta, K.P.; Badheka, V.J. Hybrid approaches of assisted heating and cooling for friction stir welding of copper to aluminum joints. J. Mater. Process. Technol. 2017, 239, 336–345. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Yang, F.; Xi, T.F.; Lai, C.; Ye, H.Q. Influence of heat treatment on interface of Cu/Al bimetal composite fabricated by cold rolling. Compos. Part B Eng. 2011, 42, 1468–1473. [Google Scholar] [CrossRef]

- Dalgaard, E.; Wanjara, P.; Trigo, G.; Jahazi, M.; Comeau, G.; Jonas, J.J. Linear friction welding of Al–Cu part 2–interfacial characteristics. Can. Metall. Q. 2011, 50, 360–370. [Google Scholar] [CrossRef]

- Tavassolimanesh, A.; Nia, A.A. Investigating the properties of bimetallic aluminum-clad copper tubes produced by friction stir welding. J. Alloys Compd. 2018, 751, 299–306. [Google Scholar] [CrossRef]

- Panaskar, N.; Terkar, R. A review on recent advances in friction stir lap welding of aluminium and copper. Mater. Today Proc. 2017, 4, 8387–8393. [Google Scholar] [CrossRef]

- Firouzdor, V.; Kou, S. Al-to-Cu friction stir lap welding. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2012, 43, 303–315. [Google Scholar] [CrossRef]

- Sharma, N.; Siddiquee, A.N. Friction stir welding of aluminum to copper—An overview. Trans. Nonferrous Met. Soc. China 2017, 27, 2113–2136. [Google Scholar] [CrossRef]

- Hou, W.; Shah, L.H.A.; Huang, G.; Shen, Y.; Gerlich, A. The role of tool offset on the microstructure and mechanical properties of Al/Cu friction stir welded joints. J. Alloys Compd. 2020, 825, 154045. [Google Scholar] [CrossRef]

- Li, M.; Zhang, C.; Wang, D.; Zhou, L.; Wellmann, D.; Tian, Y. Friction stir spot welding of aluminum and copper: A review. Materials 2020, 13, 156. [Google Scholar] [CrossRef]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.; De Smet, P.; Haszler, A.; Vieregge, A.J.M.S. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Sahlot, P.; Singh, A.K.; Badheka, V.J.; Arora, A. Friction stir welding of copper: Numerical modeling and validation. Trans. Indian Inst. Met. 2019, 72, 1339–1347. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Laleh, H.M.; Gerami, H.; Hosseinpour, P.; Shabestari, M.J.; Bahari, R. The origin of different microstructural and strengthening mechanisms of copper and brass in their dissimilar friction stir welded joint. Mater. Sci. Eng. A 2018, 735, 336–342. [Google Scholar] [CrossRef]

- Ouyang, J.; Yarrapareddy, E.; Kovacevic, R. Microstructural evolution in the friction stir welded 6061 aluminum alloy (T6-temper condition) to copper. J. Mater. Process. Technol. 2006, 172, 110–122. [Google Scholar] [CrossRef]

- Shen, Z.; Chen, Y.; Haghshenas, M.; Gerlich, A.P. Role of welding parameters on interfacial bonding in dissimilar steel/aluminum friction stir welds. Eng. Sci. Technol. Int. J. 2015, 18, 270–277. [Google Scholar] [CrossRef]

- Muhammad, N.A.; Wu, C.S. Ultrasonic vibration assisted friction stir welding of aluminium alloy and pure copper. J. Manufac. Proc. 2019, 39, 114–127. [Google Scholar] [CrossRef]

- Muhammad, N.A.; Wu, C.S. Evaluation of capabilities of ultrasonic vibration on the surface, electrical and mechanical behaviours of aluminium to copper dissimilar friction stir welds. Int. J. Mech. Sci. 2020, 183, 105784. [Google Scholar] [CrossRef]

- Sahu, P.K.; Pal, S.; Pal, S.K.; Jain, R. Influence of plate position, tool offset and tool rotational speed on mechanical properties and microstructures of dissimilar Al/Cu friction stir welding joints. J. Mater. Proc. Tech. 2016, 235, 55–67. [Google Scholar] [CrossRef]

- Muhammad, N.A.; Wu, C.S.; Su, H. Concurrent influences of tool offset and ultrasonic vibration on the joint quality and performance of dissimilar Al/Cu friction stir welds. J. Mater. Res. Technol. 2021, 14, 1035–1051. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Ni, D.R.; Ma, Z.Y. Enhanced mechanical properties of friction stir welded dissimilar Al–Cu joint by intermetallic compounds. Mater. Sci. Eng. 2010, 527, 5723–5727. [Google Scholar] [CrossRef]

- Xue, P.; Ni, D.R.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Effect of friction stir welding parameters on the microstructure and mechanical properties of the dissimilar Al–Cu joints. Mater. Sci. Eng. A 2011, 528, 4683–4689. [Google Scholar] [CrossRef]

- Karrar, G.; Sevvel, P.; Gurijala, C.; Kumar, B.Y. Biochar-assisted copper-steel dissimilar friction stir welding: Mechanical, fatigue, and microstructure properties. Biomass Convers. Biorefinery 2021. [Google Scholar] [CrossRef]

- Zykova, A.; Chumaevskii, A.; Gusarova, A.; Kalashnikova, T.; Fortuna, S.; Savchenko, N.; Kolubaev, E.; Tarasov, S. Microstructure of in-situ friction stir processed Al-Cu transition zone. Metals 2020, 10, 818. [Google Scholar] [CrossRef]

- Sun, Y.; Gong, W.; Feng, J.; Lu, G.; Zhu, R.; Li, Y. A Review of the Friction Stir Welding of Dissimilar Materials between Aluminum Alloys and Copper. Metals 2022, 12, 675. [Google Scholar] [CrossRef]

- Eslami, S.; Farahani, B.V.; Tavares, P.J.; Moreira, P.M.G.P. Fatigue behaviour evaluation of dissimilar polymer joints: Friction stir welded, single and double-rivets. Int. J. Fatigue 2018, 113, 351–358. [Google Scholar] [CrossRef]

- Thomas, W.M.; Staines, D.G.; Norris, I.M.; de Frias, R. Friction stir welding tools and developments. Weld. World 2003, 47, 10–17. [Google Scholar] [CrossRef]

- Hrishikesh, D.A.S.; Chakraborty, D.; Pal, T.K. High-cycle fatigue behavior of friction stir butt welded 6061 aluminium alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 648–656. [Google Scholar] [CrossRef]

- Besel, Y.; Besel, M.; Mercado, U.A.; Kakiuchi, T.; Hirata, T.; Uematsu, Y. Influence of local fatigue damage evolution on crack initiation behavior in a friction stir welded Al-Mg-Sc alloy. Int. J. Fatigue 2017, 99, 151–162. [Google Scholar] [CrossRef]

- He, C.; Liu, Y.; Dong, J.; Wang, Q.; Wagner, D.; Bathias, C. Fatigue crack initiation behaviors throughout friction stir welded joints in AA7075-T6 in ultrasonic fatigue. Int. J. Fatigue 2015, 81, 171–178. [Google Scholar] [CrossRef]

- Deng, C.; Gao, R.; Gong, B.; Yin, T.; Liu, Y. Correlation between micro-mechanical property and very high cycle fatigue (VHCF) crack initiation in friction stir welds of 7050 aluminum alloy. Int. J. Fatigue 2017, 104, 283–292. [Google Scholar] [CrossRef]

- Effertz, P.S.; Infante, V.; Quintino, L.; Suhuddin, U.; Hanke, S.; Dos Santos, J.F. Fatigue life assessment of friction spot welded 7050-T76 aluminium alloy using Weibull distribution. Int. J. Fatigue 2016, 87, 381–390. [Google Scholar] [CrossRef]

- Reshad Seighalani, K.; Besharati Givi, M.K.; Nasiri, A.M.; Bahemmat, P. Investigations on the effects of the tool material, geometry, and tilt angle on friction stir welding of pure titanium. J. Mater. Eng. Perform. 2010, 19, 955–962. [Google Scholar] [CrossRef]

- Shukla, S.; Komarasamy, M.; Mishra, R.S. Grain size dependence of fatigue properties of friction stir processed ultrafine-grained Al-5024 alloy. Int. J. Fatigue 2018, 109, 1–9. [Google Scholar] [CrossRef]

- Rambabu, G.; Naik, D.B.; Rao, C.V.; Rao, K.S.; Reddy, G.M. Optimization of friction stir welding parameters for improved corrosion resistance of AA2219 aluminum alloy joints. Def. Technol. 2015, 11, 330–337. [Google Scholar] [CrossRef]

- Wakchaure, K.N.; Thakur, A.G.; Gadakh, V.; Kumar, A. Multi-objective optimization of friction stir welding of aluminium alloy 6082-T6 Using hybrid Taguchi-Grey relation analysis-ANN method. Mater. Today Proc. 2018, 5, 7150–7159. [Google Scholar] [CrossRef]

- Forman, R.G.; Kearney, V.E.; Engle, R.M. Numerical analysis of crack propagation in cyclic-loaded structures. J. Fluids Eng. Trans. ASME 1967, 89, 459–463. [Google Scholar] [CrossRef]

- Klusák, J.; Profant, T.; Knésl, Z.; Kotoul, M. The influence of discontinuity and orthotropy of fracture toughness on conditions of fracture initiation in singular stress concentrators. Eng. Fract. Mech. 2013, 110, 438–447. [Google Scholar] [CrossRef]

- Lee, W.B.; Jung, S.B. Void free friction stir weld zone of the dissimilar 6061 aluminum and copper joint by shifting the tool insertion location. Mater. Res. Innov. 2004, 8, 93–96. [Google Scholar] [CrossRef]

- Venkateswaran, P.; Reynolds, A.P. Factors affecting the properties of Friction Stir Welds between aluminum and magnesium alloys. Mater. Sci. Eng. A 2012, 545, 26–37. [Google Scholar] [CrossRef]

- Jadav, H.H.; Badheka, V.; Sharma, D.K.; Upadhyay, G. Effect of pin diameter and different cooling media on friction stir welding of dissimilar Al-Mg alloys. Mater. Today Proc. 2020, 42, 362–369. [Google Scholar] [CrossRef]

- Zhai, M.; Wu, C.; Shi, L. Numerical simulation of friction stir lap welding of Al-to-Mg alloys under different lap configurations and pin lengths. J. Mater. Res. Technol. 2022, 20, 889–904. [Google Scholar] [CrossRef]

- Shen, J.; Suhuddin, U.F.; Cardillo, M.E.; dos Santos, J.F. Eutectic structures in friction spot welding joint of aluminum alloy to copper. App. Phys. Lett. 2014, 104, 191901. [Google Scholar] [CrossRef]

- Lv, X.; Wu, C.; Yang, C.; Padhy, G.K. Weld microstructure and mechanical properties in ultrasonic enhanced friction stir welding of Al alloy to Mg alloy. J. Mater. Process. Technol. 2018, 254, 145–157. [Google Scholar] [CrossRef]

- Jayaraj, R.K.; Malarvizhi, S.; Balasubramanian, V. Electrochemical corrosion behaviour of stir zone of friction stir welded dissimilar joints of AA6061 aluminium–AZ31B magnesium alloys. Transac. Nonfer. Metals Soc. China 2017, 27, 2181–2192. [Google Scholar] [CrossRef]

- Kar, A.; Suwas, S.; Kailas, S.V. Multi-length scale characterization of microstructure evolution and its consequence on mechanical properties in dissimilar friction stir welding of titanium to aluminum. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2019, 50, 5153–5173. [Google Scholar] [CrossRef]

- Kar, A.; Malopheyev, S.; Mironov, S.; Kaibyshev, R.; Suwas, S.; Kailas, S.V. A new method to elucidate fracture mechanism and microstructure evolution in titanium during dissimilar friction stir welding of aluminum and titanium. Mater. Charact. 2021, 171, 110791. [Google Scholar] [CrossRef]

- Pereira, V.F.; Fonseca, E.B.; Costa, A.M.; Bettini, J.; Lopes, E.S. Nanocrystalline structural layer acts as interfacial bond in Ti/Al dissimilar joints produced by friction stir welding in power control mode. Scr. Mater. 2020, 174, 80–86. [Google Scholar] [CrossRef]

- Yu, M.; Zhao, H.; Xu, F.; Chen, T.; Zhou, L.; Song, X.; Ma, N. Influence of ultrasonic vibrations on the microstructure and mechanical properties of Al/Ti friction stir lap welds. J. Mater. Process. Technol. 2020, 282, 116676. [Google Scholar] [CrossRef]

- Shehabeldeen, T.A.; Yin, Y.; Ji, X.; Shen, X.; Zhang, Z.; Zhou, J. Investigation of the microstructure, mechanical properties and fracture mechanisms of dissimilar friction stir welded aluminium/titanium joints. J. Mater. Res. Technol. 2021, 11, 507–518. [Google Scholar] [CrossRef]

- Chen, Y.C.; Nakata, K. Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Mater. Des. 2009, 30, 469–474. [Google Scholar] [CrossRef]

- Abd Elnabi, M.M.; Osman, T.A.; El Mokadem, A. Evaluation of the formation of intermetallic compounds at the intermixing lines and in the nugget of dissimilar steel/aluminum friction stir welds. J. Mater. Res. Technol. 2020, 9, 10209–10222. [Google Scholar] [CrossRef]

- Sadeesh, P.; Kannan, M.V.; Rajkumar, V.; Avinash, P.; Arivazhagan, N.; Ramkumar, K.D.; Narayanan, S. Studies on friction stir welding of AA 2024 and AA 6061 dissimilar metals. Procedia Eng. 2014, 75, 145–149. [Google Scholar] [CrossRef]

- Rao, T.S.; Reddy, G.M.; Rao, S.K. Microstructure and mechanical properties of friction stir welded AA7075–T651 aluminum alloy thick plates. Trans. Nonferrous Met. Soc. China 2015, 25, 1770–1778. [Google Scholar] [CrossRef]

- Dehghani, K.; Ghorbani, R.; Soltanipoor, A.R. Microstructural evolution and mechanical properties during the friction stir welding of 7075-O aluminum alloy. Int. J. Adv. Manuf. Technol. 2015, 77, 1671–1679. [Google Scholar] [CrossRef]

- Osman, T.A.; El Mokadem, A. Influence of friction stir welding parameters on metallurgical and mechanical properties of dissimilar AA5454–AA7075 aluminum alloys. J. Mater. Res. Technol. 2019, 8, 1684–1693. [Google Scholar] [CrossRef]

- Rodriguez, R.I.; Jordon, J.B.; Allison, P.G.; Rushing, T.; Garcia, L. Microstructure and mechanical properties of dissimilar friction stir welding of 6061-to-7050 aluminum alloys. Mater. Des. 2015, 83, 60–65. [Google Scholar] [CrossRef]

- Chen, C.M.; Kovacevic, R. Joining of Al 6061 alloy to AISI 1018 steel by combined effects of fusion and solid state welding. Int. J. Mach. Tools Manuf. 2004, 44, 1205–1214. [Google Scholar] [CrossRef]

- Darzi Naghibi, H.; Shakeri, M.; Hosseinzadeh, M. Neural network and genetic algorithm based modeling and optimization of tensile properties in FSW of AA 5052 to AISI 304 dissimilar joints. Trans. Indian Inst. Met. 2016, 69, 891–900. [Google Scholar] [CrossRef]

- Habibnia, M.; Shakeri, M.; Nourouzi, S.; Givi, M.K. Microstructural and mechanical properties of friction stir welded 5050 Al alloy and 304 stainless steel plates. Int. J. Adv. Manuf. Technol. 2014, 76, 819–829. [Google Scholar] [CrossRef]

- Çam, G. Friction stir welded structural materials: Beyond Al-alloys. Int. Mater. Rev. 2011, 56, 1–48. [Google Scholar] [CrossRef]

- Eyvazian, A.; Hamouda, A.; Tarlochan, F.; Derazkola, H.A.; Khodabakhshi, F. Simulation and experimental study of underwater dissimilar friction-stir welding between aluminium and steel. J. Mater. Res. Technol. 2020, 9, 3767–3781. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Gerlich, A.P.; Simchi, A.; Kokabi, A.H. Cryogenic friction-stir processing of ultrafine-grained Al–Mg–TiO2 nanocomposites. Mater. Sci. Eng. A 2015, 620, 471–482. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, Z.; Zhao, Y.; Yan, K.; Liu, C.; Zhang, H. The strengthening mechanism of spray forming Al-Zn-Mg-Cu alloy by underwater friction stir welding. Mater. Des. 2016, 102, 91–99. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, Z.; Zhao, Y.; Yan, K.; Zhang, H. The adjustment strategy of welding parameters for spray formed 7055 aluminum alloy underwater friction stir welding joint. Mater. Des. 2015, 88, 1366–1376. [Google Scholar] [CrossRef]

- Tan, Y.B.; Wang, X.M.; Ma, M.; Zhang, J.X.; Liu, W.C.; Fu, R.D.; Xiang, S. A study on microstructure and mechanical properties of AA 3003 aluminum alloy joints by underwater friction stir welding. Mater. Charact. 2017, 127, 41–52. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Nosko, M.; Gerlich, A.P. Effects of graphene nano-platelets (GNPs) on the microstructural characteristics and textural development of an Al-Mg alloy during friction-stir processing. Surf. Coat. Technol. 2018, 335, 288–305. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Nosko, M.; Gerlich, A.P. Dynamic restoration and crystallographic texture of a friction-stir processed Al–Mg–SiC surface nanocomposite. Mater. Sci. Technol. 2018, 34, 1773–1791. [Google Scholar] [CrossRef]

- McNelley, T.R.; Swaminathan, S.; Su, J.Q. Recrystallization mechanisms during friction stir welding/processing of aluminum alloys. Scr. Mater. 2008, 58, 349–354. [Google Scholar] [CrossRef]

- Kaushik, P.; Dwivedi, D.K. Effect of tool geometry in dissimilar Al-steel friction stir welding. J. Manuf. Process. 2021, 68, 198–208. [Google Scholar] [CrossRef]

- Thomä, M.; Gester, A.; Wagner, G.; Fritzsche, M. Analysis of the oscillation behavior of hybrid aluminum/steel joints realized by ultrasound enhanced friction stir welding. Metals 2020, 10, 1079. [Google Scholar] [CrossRef]

- Kimapong, K.; Watanabe, T. Friction stir welding of aluminum alloy to steel. Weld. J. 2004, 83, 277. [Google Scholar]

- Watanabe, T.; Takayama, H.; Yanagisawa, A. Joining of aluminum alloy to steel by friction stir welding. J. Mater. Proc. Technol. 2006, 178, 342–349. [Google Scholar] [CrossRef]

- Ramachandran, K.K.; Murugan, N.; Kumar, S.S. Friction stir welding of aluminum alloy AA5052 and HSLA steel. Weld. J. 2015, 94, 291–300. [Google Scholar]

- Murugan, B.; Thirunavukarasu, G.; Kundu, S.; Kailas, S.V.; Chatterjee, S. Interfacial microstructure and mechanical properties of friction stir welded joints of commercially pure aluminum and 304 stainless steel. J. Mater. Eng. Perf. 2018, 27, 2921–2931. [Google Scholar] [CrossRef]

- Seo, B.; Song, K.H.; Park, K. Corrosion properties of dissimilar friction stir welded 6061 aluminum and HT590 steel. Met. Mater. Int. 2018, 24, 1232–1240. [Google Scholar] [CrossRef]

- Esmaeili, A.; Rajani, H.Z.; Sharbati, M.; Givi, M.B.; Shamanian, M. The role of rotation speed on intermetallic compounds formation and mechanical behavior of friction stir welded brass/aluminum 1050 couple. Intermetallics 2011, 19, 1711–1719. [Google Scholar] [CrossRef]

- Akbari, M.; Abdi Behnagh, R. Dissimilar friction-stir lap joining of 5083 aluminum alloy to CuZn34 brass. Metall. Mater. Trans. 2012, 43, 1177–1186. [Google Scholar] [CrossRef]

- De Oliveira Miranda, A.C.; Gerlich, A.; Walbridge, S. Aluminum friction stir welds: Review of fatigue parameter data and probabilistic fracture mechanics analysis. Eng. Fract. Mech. 2015, 147, 243–260. [Google Scholar] [CrossRef]

- Li, H.; Gao, J.; Li, Q. Fatigue of friction stir welded aluminum alloy joints: A review. Appl. Sci. 2018, 8, 12. [Google Scholar] [CrossRef]

- Wahab, M.A.; Raghuram, V. Fatigue and Fracture Mechanics Analysis of Friction Stir Welded Joints of Aerospace Aluminum Alloys Al-2195. In International Mechanical Engineering Congress and Exposition, Proceedings of the ASME 2013 International Mechanical Engineering Congress and Exposition, San Diego, CA, USA, 15–21 November 2013; American Society of Mechanical Engineers: New York, NY, USA, 2013; Volume 4, p. 4. [Google Scholar] [CrossRef]

- Chen, A.; Zang, W.F.; Dong, D.K.; Gong, Y.Z. Fatigue behavior of friction stir welded lap joints for dissimilar AA7150-AA2524 aluminum alloy. IOP Conf. Ser. Mater. Sci. Eng. 2020, 751, 012086. [Google Scholar] [CrossRef]

- Dubourg, L.; Merati, A.; Jahazi, M. Process optimisation and mechanical properties of friction stir lap welds of 7075-T6 stringers on 2024-T3 skin. Mater. Des. 2010, 31, 3324–3330. [Google Scholar] [CrossRef]

- Chen, A.; Yang, J.; Chen, X.M.; Dong, D.K. Fatigue property of friction stir welded butt joints for 6156-T6 aluminum alloy. Mater. Sci. Forum 2019, 960, 45–50. [Google Scholar] [CrossRef]

- Matokhnyuk, L.E.; Byalonovich, A.V.; Gopkalo, E.E.; Vorob’ev, E.V.; Karaush, D.P.; Malyshko, V.I. Fatigue Resistance of 2219 Aluminum Alloy and its Welded Joints. Strength Mater. 2019, 51, 860–867. [Google Scholar] [CrossRef]

- Susmel, L.; Hattingh, D.G.; James, M.N.; Tovo, R. Multiaxial fatigue assessment of friction stir welded tubular joints of Al 6082-T6. Int. J. Fatigue 2017, 101, 282–296. [Google Scholar] [CrossRef]

- Sharma, S.R.; Ma, Z.Y.; Mishra, R.S. Effect of friction stir processing on fatigue behavior of A356 alloy. Scr. Mater. 2004, 51, 237–241. [Google Scholar] [CrossRef]

- Sun, Y.; Voyiadjis, G.Z.; Hu, W.; Shen, F.; Meng, Q. Fatigue and fretting fatigue life prediction of double-lap bolted joints using continuum damage mechanics-based approach. Int. J. Damage Mech. 2017, 26, 162–188. [Google Scholar] [CrossRef]

- Shen, Z.; Ding, Y.; Chen, J.; Gerlich, A.P. Comparison of fatigue behavior in Mg/Mg similar and Mg/steel dissimilar refill friction stir spot welds. Int. J. Fatigue 2016, 92, 78–86. [Google Scholar] [CrossRef]

- Plaine, A.H.; Suhuddin, U.F.H.; Alcântara, N.G.; Dos Santos, J.F. Fatigue behavior of friction spot welds in lap shear specimens of AA5754 and Ti6Al4V alloys. Int. J. Fatigue 2016, 91, 149–157. [Google Scholar] [CrossRef]

- Zainulabdeen, A.A.; Abbass, M.K.; Ataiwi, A.H.; Khanna, S.K.; Jashti, B.; Widener, C. Investigation of fatigue behavior and fractography of dissimilar friction stir welded joints of aluminum alloys 7075-T6 and 5052-H34. Int. J. Mater. Sci. Eng. 2014, 2, 115–121. [Google Scholar] [CrossRef]

- Mousa, A.B.; Abbass, M.K.; Hussein, S.K. Fatigue behavior and fractography in friction stir welding zones of dissimilar aluminum alloys (AA5086-H32 with AA6061-T6). IOP Conf. Ser. Mater. Sci. Eng. 2020, 881, 012059. [Google Scholar] [CrossRef]

- Zhou, C.; Yang, X.; Luan, G. Effect of root flaws on the fatigue property of friction stir welds in 2024-T3 aluminum alloys. Mater. Sci. Eng. A 2006, 418, 155–160. [Google Scholar] [CrossRef]

- Rao, H.M.; Ghaffari, B.; Yuan, W.; Jordon, J.B.; Badarinarayan, H. Effect of process parameters on microstructure and mechanical behaviors of friction stir linear welded aluminum to magnesium. Mater. Sci. Eng. A 2016, 651, 27–36. [Google Scholar] [CrossRef]

- Singh, A.; Sarkar, J.; Sahoo, R.R. Comparative analyses on a batch-type heat pump dryer using low GWP refrigerants. Food Bioprod. Process. 2019, 117, 1–13. [Google Scholar] [CrossRef]

- Shah, L.H.; Othman, N.H.; Gerlich, A. Review of research progress on aluminium–magnesium dissimilar friction stir welding. Sci. Technol. Weld. Join. 2018, 23, 256–270. [Google Scholar] [CrossRef]

- Zettler, R.; Vugrin, T.; Schmücker, M. Effects and defects of friction stir welds. In Friction Stir Welding: From Basics to Applications; Lohwasser, D., Chen, Z., Eds.; Woodhead Publishing Series in Welding and Other Joining Technologies; Woodhead Publishing: Cambridge, UK, 2010; pp. 245–276. [Google Scholar]

- Masoudian, A.; Tahaei, A.; Shakiba, A.; Sharifianjazi, F.; Mohandesi, J.A. Microstructure and mechanical properties of friction stir weld of dissimilar AZ31-O magnesium alloy to 6061-T6 aluminum alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 1317–1322. [Google Scholar] [CrossRef]

- Tan, S.; Zheng, F.; Chen, J.; Han, J.; Wu, Y.; Peng, L. Effects of process parameters on microstructure and mechanical properties of friction stir lap linear welded 6061 aluminum alloy to NZ30K magnesium alloy. J. Magnes. Alloys 2017, 5, 56–63. [Google Scholar] [CrossRef]

- Dialami, N.; Cervera, M.; Chiumenti, M. Effect of the tool tilt angle on the heat generation and the material flow in friction stir welding. Metals 2019, 9, 1. [Google Scholar] [CrossRef]

- Kumar, A.; Jadoun, R.S. Friction stir welding of dissimilar materials/alloys: A review. Int. J. Mech. Eng. Robot. Res. 2014, 1, 106–113. [Google Scholar]

- Imam, M.; Sun, Y.; Fujii, H.; Ma, N.; Tsutsumi, S.; Murakawa, H. Microstructural characteristics and mechanical properties of friction stir welded thick 5083 aluminum alloy. Metall. Mater. Trans. A 2017, 48, 208–229. [Google Scholar] [CrossRef]

- Arici, A.; Selale, S. Effects of tool tilt angle on tensile strength and fracture locations of friction stir welding of polyethylene. Sci. Technol. Weld. Join. 2007, 12, 536–539. [Google Scholar] [CrossRef]

- Mehta, K.P.; Badheka, V.J. Effects of tilt angle on the properties of dissimilar friction stir welding copper to aluminum. Mater. Manuf. Process. 2016, 31, 255–263. [Google Scholar] [CrossRef]

- Viswanadhapalli, B.; Raja, V.B. Experimental studies on formability of Butt-welded magnesium and aluminium alloy sheets by friction stir welding method. AIP Conf. Proc. 2020, 2311, 070024. [Google Scholar] [CrossRef]

- Liu, X.; Lan, S.; Ni, J. Analysis of process parameters effects on friction stir welding of dissimilar aluminum alloy to advanced high strength steel. Mater. Des. 2014, 59, 50–62. [Google Scholar] [CrossRef]

- Dehghani, M.; Mousavi, S.A.; Amadeh, A. Effects of welding parameters and tool geometry on properties of 3003-H18 aluminum alloy to mild steel friction stir weld. Trans. Nonferrous Met. Soc. China 2013, 23, 1957–1965. [Google Scholar] [CrossRef]

- Zadpoor, A.A.; Sinke, J.; Benedictus, R. Fracture mechanism of aluminium friction stir welded blanks. Int. J. Mater. Form. 2009, 2, 319–322. [Google Scholar] [CrossRef]

- Zhou, L.; Yu, M.; Liu, B.; Zhang, Z.; Liu, S.; Song, X.; Zhao, H. Microstructure and mechanical properties of Al/steel dissimilar welds fabricated by friction surfacing assisted friction stir lap welding. J. Mater. Res. Technol. 2020, 9, 212–221. [Google Scholar] [CrossRef]

- Huang, Y.; Huang, T.; Wan, L.; Meng, X.; Zhou, L. Material flow and mechanical properties of aluminum-to-steel self-riveting friction stir lap joints. J. Mater. Process. Technol. 2019, 263, 129–137. [Google Scholar] [CrossRef]

- Zhou, L.; Li, G.H.; Zhang, R.X.; Zhou, W.L.; He, W.X.; Huang, Y.X.; Song, X.G. Microstructure evolution and mechanical properties of friction stir spot welded dissimilar aluminum-copper joint. J. Alloys Compd. 2019, 775, 372–382. [Google Scholar] [CrossRef]

- Wang, X.; Pan, Y.; Lados, D.A. Friction stir welding of dissimilar Al/Al and Al/non-Al alloys: A review. Metall. Mater. Trans. B 2018, 49, 2097–2117. [Google Scholar] [CrossRef]

- Pourali, M.; Abdollah-Zadeh, A.; Saeid, T.; Kargar, F. Influence of welding parameters on intermetallic compounds formation in dissimilar steel/aluminum friction stir welds. J. Alloys Compd. 2017, 715, 1–8. [Google Scholar] [CrossRef]

- Lan, S.; Liu, X.; Ni, J. Microstructural evolution during friction stir welding of dissimilar aluminum alloy to advanced high-strength steel. Int. J. Adv. Manuf. Technol. 2016, 82, 2183–2193. [Google Scholar] [CrossRef]

- Zhao, J.; Wu, C.S.; Shi, L. Effect of ultrasonic field on microstructure evolution in friction stir welding of dissimilar Al/Mg alloys. J. Mater. Res. Technol. 2022, 17, 1–21. [Google Scholar] [CrossRef]

- Kar, A.; Suwas, S.; Kailas, S.V. Two-pass friction stir welding of aluminum alloy to titanium alloy: A simultaneous improvement in mechanical properties. Mater. Sci. Eng. A 2018, 733, 199–210. [Google Scholar] [CrossRef]

| S. No | Unit | Symbol | Levels | Parameters | ||

|---|---|---|---|---|---|---|

| −1 | +1 | 0 | ||||

| 1 | rpm | A | 800 | 1200 | 1000 | Rotational speed |

| 2 | mm/min | B | 30 | 90 | 60 | Translational speed |

| 3 | – | C | cy | H | Cy.th | Tool pin geometry |

| S/No | Welding Speed (mm/s) | Plunge Depth (mm) | Brinell Hardness | Tensile Strength (MPa) | Spindle Speed (rpm) |

|---|---|---|---|---|---|

| 1 | 1.4 | 0.1 | 75 | 233 | 1000 |

| 2 | 2 | 0 | 72 | 243 | 1000 |

| 3 | 0.8 | 0.1 | 78 | 251 | 1000 |

| 4 | 1.4 | 0 | 55 | 176 | 700 |

| 5 | 2 | 0.2 | 73 | 233 | 1000 |

| 6 | 1.4 | 0.2 | 67 | 219 | 1300 |

| 7 | 1.4 | 0.1 | 73 | 238 | 1000 |

| 8 | 1.4 | 0.2 | 52 | 178 | 700 |

| 9 | 1.4 | 0.1 | 71 | 239 | 1000 |

| 10 | 0.8 | 0.2 | 75 | 247 | 1000 |

| 11 | 0.8 | 0.1 | 66 | 220 | 1300 |

| 12 | 1.4 | 0.1 | 71 | 231 | 1000 |

| 13 | 2 | 0.1 | 57 | 165 | 700 |

| 14 | 1.4 | 0.1 | 74 | 235 | 1000 |

| 15 | 2 | 0.1 | 62 | 210 | 1300 |

| 16 | 1.4 | 0 | 65 | 200 | 1300 |

| 17 | 0.8 | 0.1 | 57 | 180 | 700 |

| Joint Symbol | Welding Speed mm/min | Tool Rotational Speed (rpm) | Pin Length mm | Max. Shear Force KN | Weld Strength σ Lap N/mm | Joint Efficiency % | Max. Hardness HV Instar Zone | Joint Sample |

|---|---|---|---|---|---|---|---|---|

| FSLW1 | 100 | 1250 | 5.4 | 3.5 | 175 | 66 | 94 | Similar AA6061 |

| FSLW2 | 100 | 1250 | 5.4 | 5.1 | 255 | 96.2 | 49 | Similar AA1100 |

| FSLW3 | 75 | 1600 | 5.4 | 2.54 | 127 | 47.9 | 96 | Dissimilar 3 |

| FSLW4 | 100 | 1250 | 5.7 | 3.93 | 169.5 | 74.1 | 98 | Dissimilar 4 |

| FSLW5 | 75 | 1250 | 2.8 | 4.93 | 246.5 | 93 | 80 | Dissimilar 5 |

| Material | Specimen Type | 0.2% Yield Strength | Elongation % | Ultimate Tensile Strength |

|---|---|---|---|---|

| AA6082-T6 | MIG Welded | 156 | 4 | 221 |

| AA6082-T6 | FS Welded | 158 | 5.5 | 241 |

| AA6082-T6 | Base Metal | 306 | 17 | 342 |

| No. | Aluminum Alloys | Thickness mm | Welding Positions | FSW Parameters | Mechanical Properties |

|---|---|---|---|---|---|

| 1 | AA6061-T6 & AA5083-H111 | 6 | Butt welding | r.p.m (800, 1000, 1200) mm/min (30, 60, 90) Tool (cy.cyth, H) | Max.Tensile strength 191 MPa in r.p.m 1000 Mm/min 60 cyth |

| 2 | AA6061 & AA5052 | 4/10 | T-joint | r.p.m (700–1300) mm/s (0.8–2) Tool D = 25, d = 8, L = 7 H | Max.Tensile strength 243 MPa BH 78 |

| 3 | AA1160 & AA6061 | 3 | Lap welding | r.p.m (1000–1600) mm/min (35–100) L pin(5.4–5.8) mm Cy-thread | High shear force 4.53 KN in 1250 r.p.m, 75 mm/min L pin 5.8 mm |

| 4 | AA2019 & AA5083 | - | Butt welding | 700 r.p.m 15 mm/min D/d = 3 Tubular thread | Efficacy of almost 90% alloys |

| 5 | AA2198 & AA7075 | 3 | Lap welding | r.p.m (1200, 1500, 1800) with 60 mm/min and Pich Rot/mm (20, 25, 30) and r.p.m (1200, 1500, 1800) with 120 mm/min, Rot/mm (15, 12.5, 10) | Internal defects were found for all of the welding produced using an advancing speed of 120 mm/min and for the samples processed adopting a tool rotational speed of 1800 rpm. |

| 6 | AA5052 & AA2024 | 2 | Lap welding | D = 15 mm, d = 6 mm, L = 3 w = 1000 rpm/v = 50 mm/min, e w = 1000 rpm/v = 100 mm/min, f w = 1000 rpm/v = 160 mm/min, w = 1250 rpm/v = 50 mm/min, h w = 1250 rpm/v = 100 mm/min, and i w = 1250 rpm/v = 160 mm/min | A complete and defect-free with exceptional interfacial bonding was attained by employing the FSW parameters of w = 1250 rpm and v = 160 mm/min |

| Materials | Density (g/cm3) | Melting Point (°C) | Coefficient of Liner Expansion (°C) | Crystal Structure | Resistivity (Ωm) | Thermal Conductivity (W/mK) |

|---|---|---|---|---|---|---|

| Al | 27 | 600 | 2.3 × 10−5 | FCC | 2.83 × 10−8 | 237 |

| Cu | 8.92 | 1083 | 1.7 × 10−5 | FCC | 1.75 × 10−8 | 401 |

| δmax (MPa) | Fatigue Life (Cycle) | β | N95/95 | DFR (MPa) |

|---|---|---|---|---|

| 192 | 367,113/218,166/ 368,258 221,223/267,024/ 310,275 | 310,218 | 98,811 | 191.54 |

| Alloy | Yield Stress, MPa | Tensile Stress, MPa | % Elongation |

|---|---|---|---|

| Al-5052 H34 | 193 | 228 | 12 |

| Al-7075 T6 | 503 | 572 | 11 |

| Al-5052-7075 Joint (combined) | 134 | 198 | 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khalafe, W.H.; Sheng, E.L.; Bin Isa, M.R.; Omran, A.B.; Shamsudin, S.B. The Effect of Friction Stir Welding Parameters on the Weldability of Aluminum Alloys with Similar and Dissimilar Metals: Review. Metals 2022, 12, 2099. https://doi.org/10.3390/met12122099

Khalafe WH, Sheng EL, Bin Isa MR, Omran AB, Shamsudin SB. The Effect of Friction Stir Welding Parameters on the Weldability of Aluminum Alloys with Similar and Dissimilar Metals: Review. Metals. 2022; 12(12):2099. https://doi.org/10.3390/met12122099

Chicago/Turabian StyleKhalafe, Wazir Hassan, Ewe Lay Sheng, Mohd Rashdan Bin Isa, Abdoulhadi Borhana Omran, and Shazarel Bin Shamsudin. 2022. "The Effect of Friction Stir Welding Parameters on the Weldability of Aluminum Alloys with Similar and Dissimilar Metals: Review" Metals 12, no. 12: 2099. https://doi.org/10.3390/met12122099

APA StyleKhalafe, W. H., Sheng, E. L., Bin Isa, M. R., Omran, A. B., & Shamsudin, S. B. (2022). The Effect of Friction Stir Welding Parameters on the Weldability of Aluminum Alloys with Similar and Dissimilar Metals: Review. Metals, 12(12), 2099. https://doi.org/10.3390/met12122099