Microstructure and Deformation of Over-Aged Al-Zn-Mg-Cu Alloy with Fine Grains during Multiple Stress Relaxation Tests

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Investigated Materials

2.2. Microstructure Characterization

2.3. Mechanical Test

3. Results and Discussion

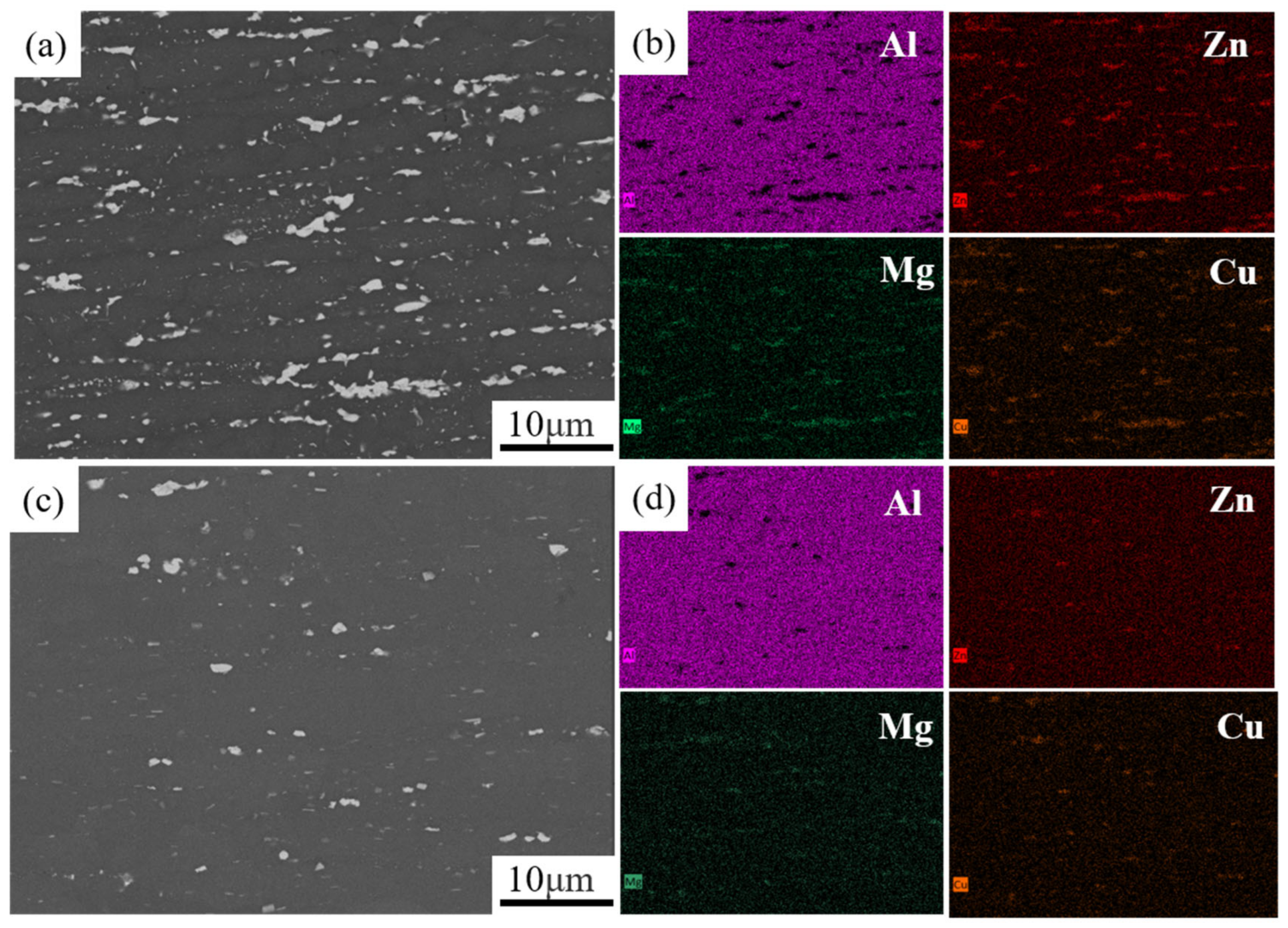

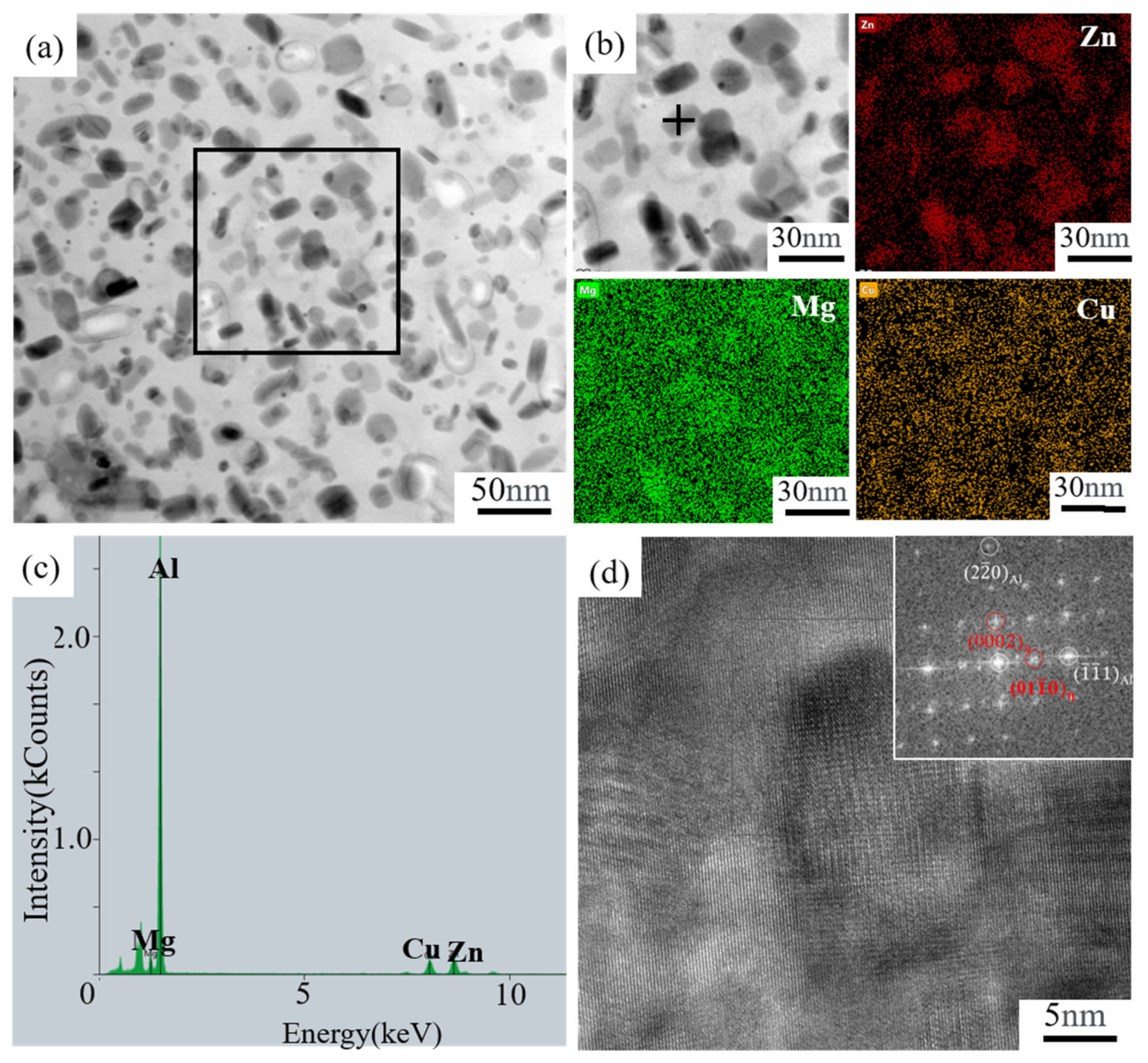

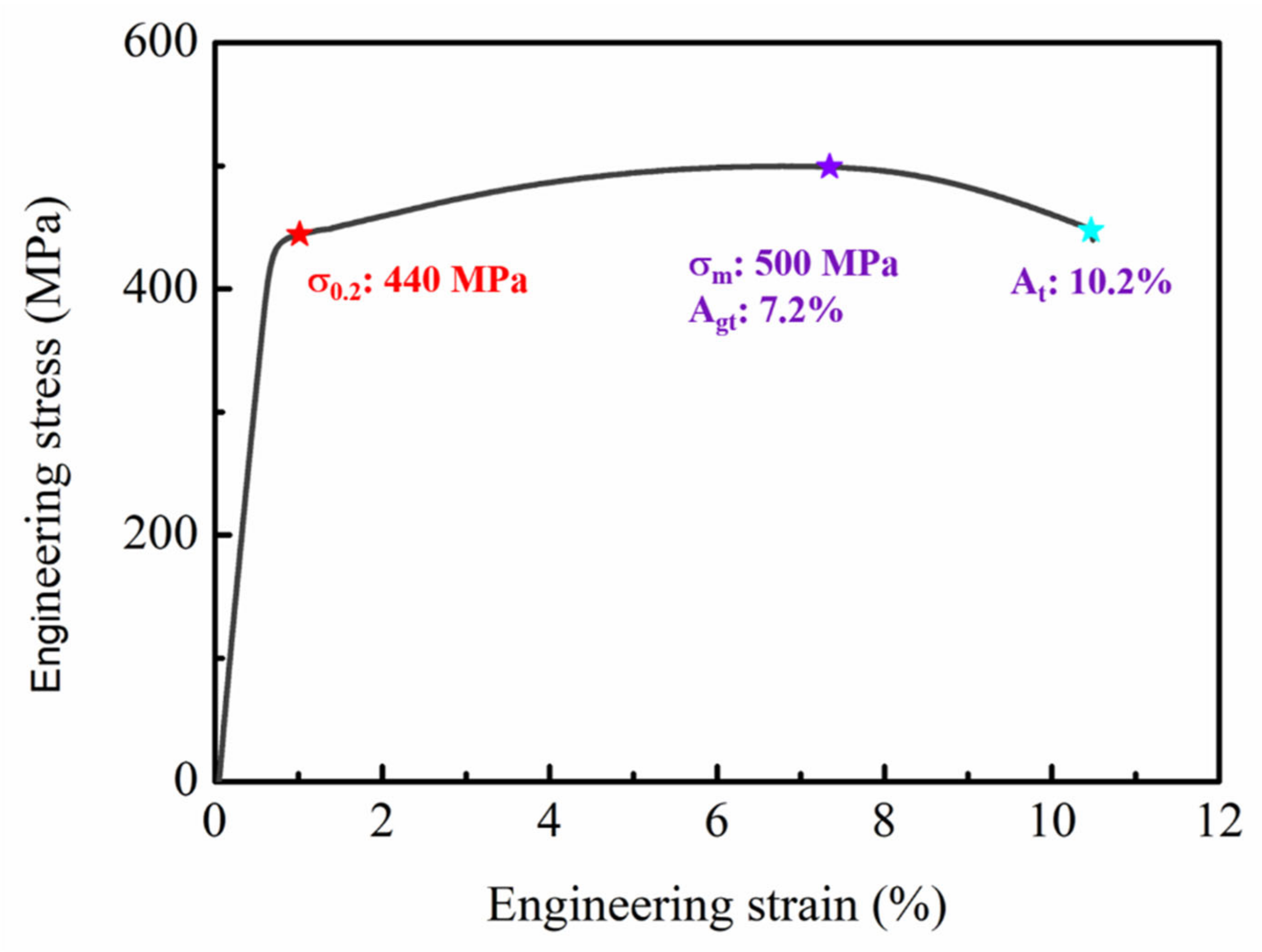

3.1. Microstructure and Mechanical Properties of the Al-Zn-Mg-Cu Alloy

3.2. Conventional Theory of Stress Relaxation Test

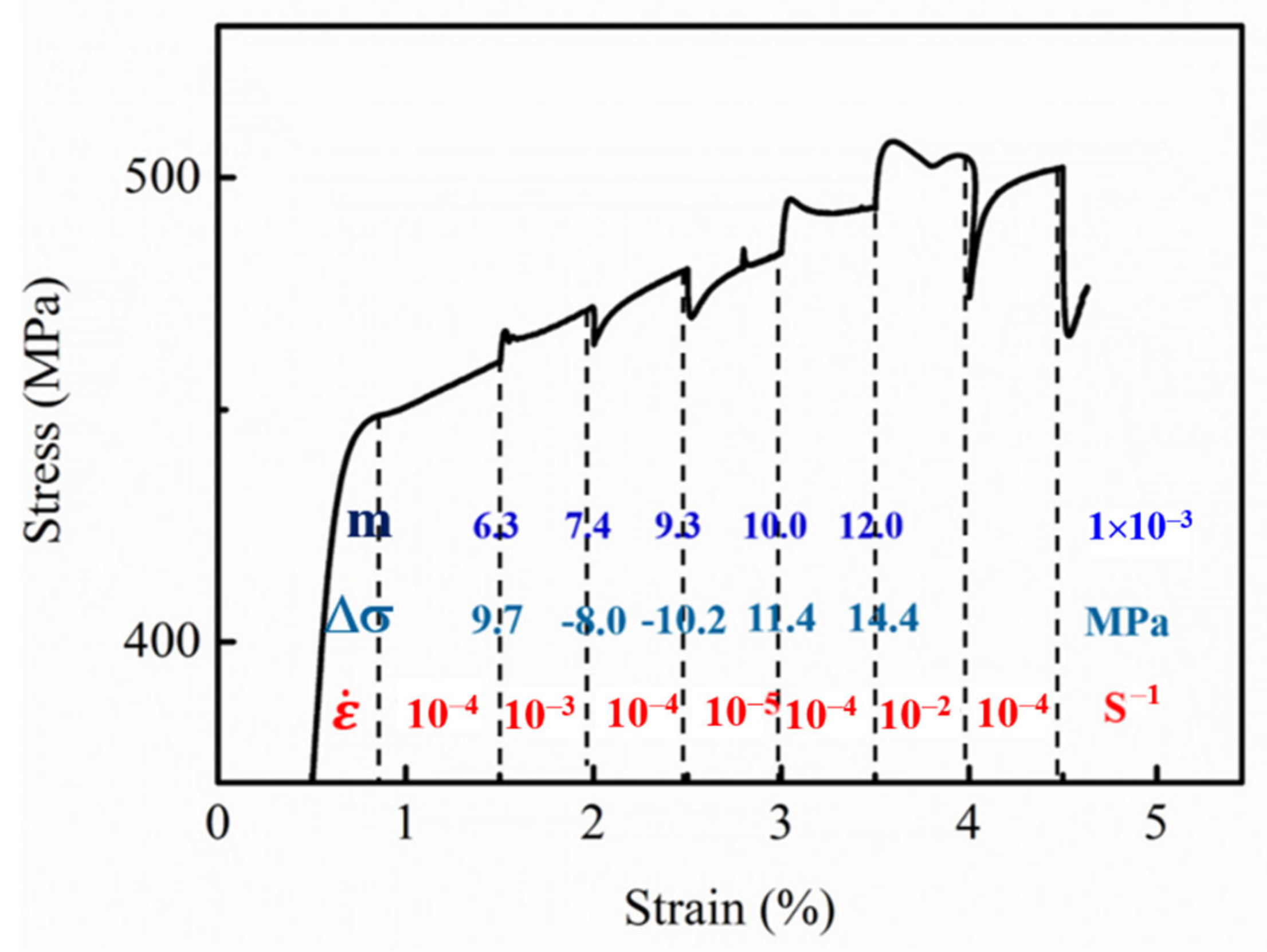

3.3. SRS Obtained by Strain Rate Jump Test

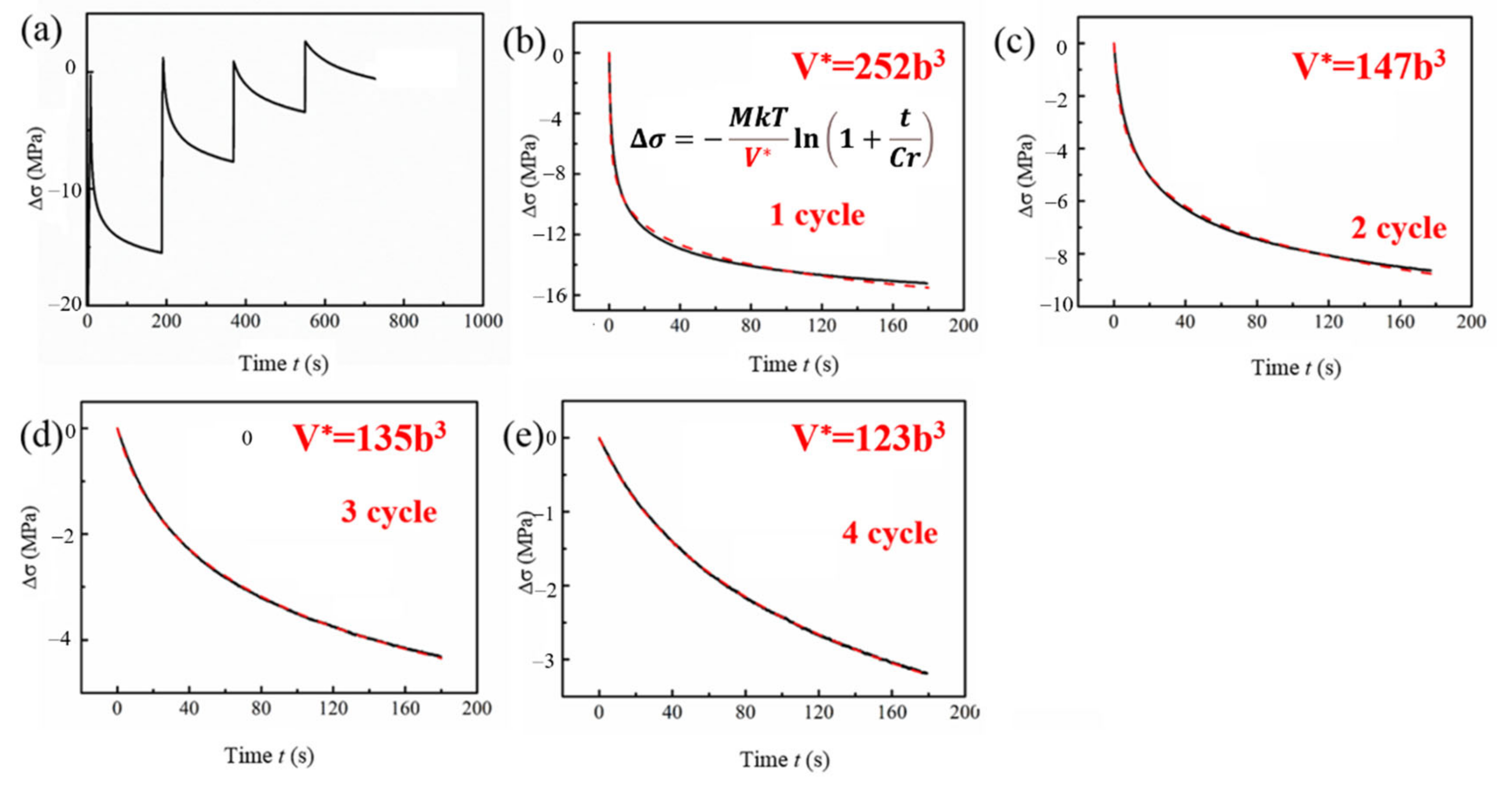

3.4. Strain-Rate-Dependent Activation Volume V* and SRS during Each Cycle

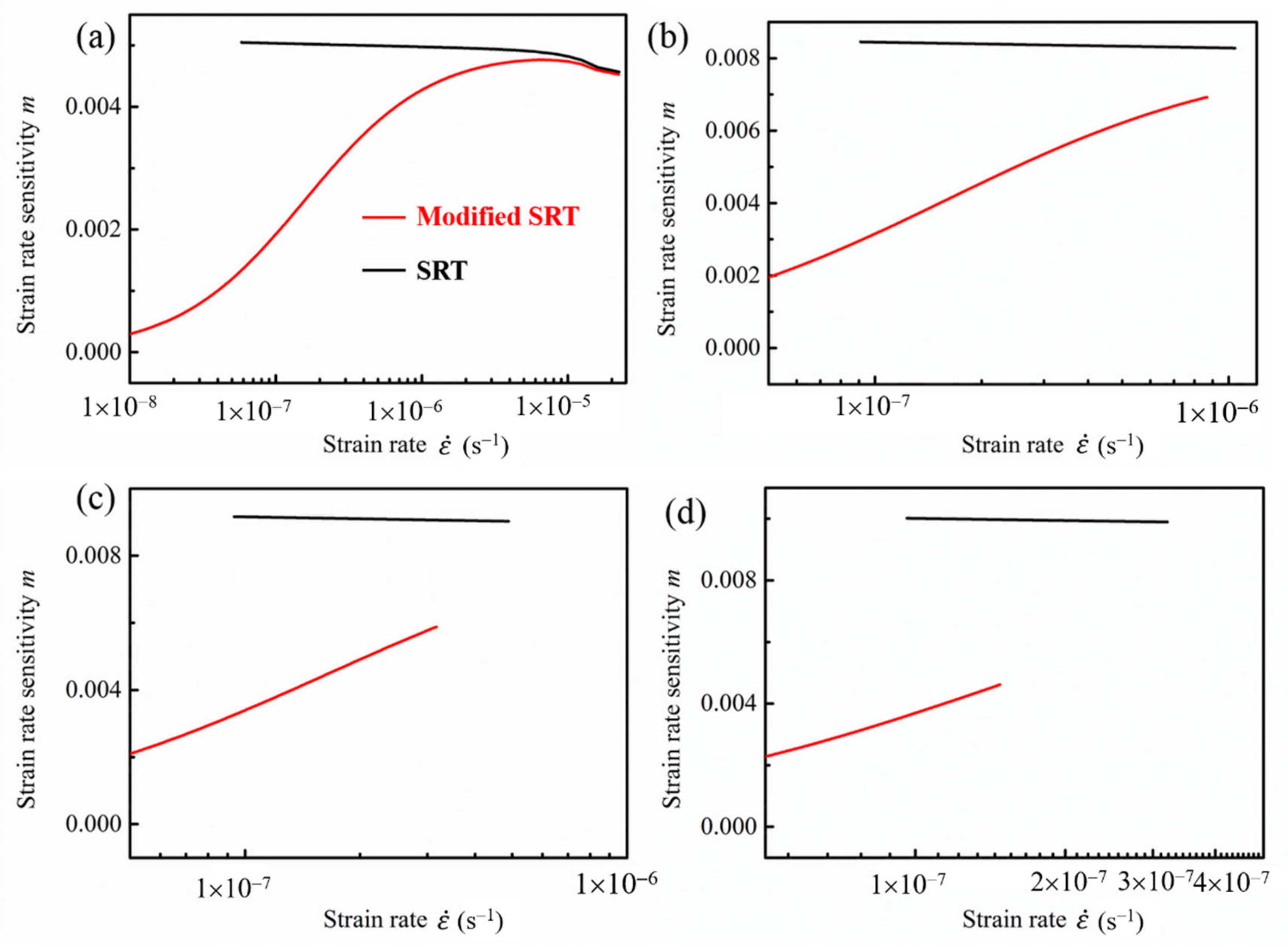

3.5. Modification

4. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Spigarelli, S.; Paoletti, C. A new model for the description of creep behaviour of aluminium-based composites reinforced with nanosized particles. Compos. Part A Appl. Sci. Manuf. 2018, 112, 346–355. [Google Scholar] [CrossRef]

- Pham, M.S.; Iadicola, M.; Creuziger, A.; Hu, L.; Rollett, A.D. Thermally-activated constitutive model including dislocation interactions, aging and recovery for strain path dependence of solid solution strengthened alloys: Application to AA5754-O. Int. J. Plast. 2015, 75, 226–243. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Salvado, F.C.; Teixeira-Dias, F.; Walley, S.M.; Lea, L.J.; Cardoso, J.B. A review on the strain rate dependency of the dynamic viscoplastic response of FCC metals. Prog. Mater. Sci. 2017, 88, 186–231. [Google Scholar] [CrossRef] [Green Version]

- Yin, F.; Hu, S.; Xu, R.; Han, X.; Qian, D.; Wei, W.; Hua, L.; Zhao, K. Strain rate sensitivity of the ultrastrong gradient nanocrystalline 316 L stainless steel and its rate-dependent modeling at nanoscale. Int. J. Plast. 2020, 129, 102696. [Google Scholar] [CrossRef]

- Zhang, H.; Li, P.; Gong, X.; Wang, T.; Li, L.; Liu, Y.; Wang, Q. Tensile properties, strain rate sensitivity and failure mechanism of single crystal superalloys CMSX-4. Mater. Sci. Eng. A 2020, 782, 139105. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.; Kurukuri, S.; Worswick, M.J.; Peng, Y.; Tang, D.; Li, D. Strain rate sensitivities of deformation mechanisms in magnesium alloys. Int. J. Plast. 2018, 107, 207–222. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Langdon, T.G. Deformation mechanisms in ultrafine-grained metals with an emphasis on the Hall-Petch relationship and strain rate sensitivity. J. Mater. Res. Technol. 2021, 14, 137–159. [Google Scholar] [CrossRef]

- Liang, Z.Y.; Wang, X.; Huang, W.; Huang, M.X. Strain rate sensitivity and evolution of dislocations and twins in a twinning-induced plasticity steel. Acta Mater. 2015, 88, 170–179. [Google Scholar] [CrossRef]

- Yasnikov, I.S.; Estrin, Y.; Vinogradov, A. What governs ductility of ultrafine-grained metals? A microstructure based approach to necking instability. Acta Mater. 2017, 141, 18–28. [Google Scholar] [CrossRef]

- Li, Z.; Voisin, T.; McKeown, J.T.; Ye, J.; Braun, T.; Kamath, C.; King, W.E.; Wang, Y.M. Tensile properties, strain rate sensitivity, and activation volume of additively manufactured 316 L stainless steels. Int. J. Plast. 2019, 120, 395–410. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, Z.; Li, D.; Kollo, L.; Luo, Z.; Zhang, W.; Prashanth, K.G. Selective laser melting of Cu–Ni–Sn: A comprehensive study on the microstructure, mechanical properties, and deformation behavior. Int. J. Plast. 2021, 138, 102926. [Google Scholar] [CrossRef]

- Wu, Z.; Gao, Y.; Bei, H. Thermal activation mechanisms and Labusch-type strengthening analysis for a family of high-entropy and equiatomic solid-solution alloys. Acta Mater. 2016, 120, 108–119. [Google Scholar] [CrossRef] [Green Version]

- Krishnaswamy, H.; Jain, J. Stress relaxation test: Issues in modelling and interpretation. Manuf. Lett. 2020, 26, 64–68. [Google Scholar] [CrossRef]

- Varma, A.; Krishnaswamy, H.; Jain, J.; Lee, M.-G.; Barlat, F. Advanced constitutive model for repeated stress relaxation accounting for transient mobile dislocation density and internal stress. Mech. Mater. 2019, 133, 138–153. [Google Scholar] [CrossRef]

- Gupta, S.; Beaudoin, A.J.; Chevy, J. Strain rate jump induced negative strain rate sensitivity (NSRS) in aluminum alloy 2024: Experiments and constitutive modeling. Mater. Sci. Eng. A 2017, 683, 143–152. [Google Scholar] [CrossRef]

- Ma, K.; Hu, T.; Yang, H.; Topping, T.; Yousefiani, A.; Lavernia, E.J.; Schoenung, J.M. Coupling of dislocations and precipitates: Impact on the mechanical behavior of ultrafine grained Al–Zn–Mg alloys. Acta Mater. 2015, 103, 153–164. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2013, 62, 141–155. [Google Scholar] [CrossRef]

- Lu, L.; Zhu, T.; Shen, Y.; Dao, M.; Lu, K.; Suresh, S. Stress relaxation and the structure size-dependence of plastic deformation in nanotwinned copper. Acta Mater. 2009, 57, 5165–5173. [Google Scholar] [CrossRef]

- Yang, X.S.; Wang, Y.J.; Wang, G.Y.; Zhai, H.R.; Dai, L.H.; Zhang, T.Y. Time, stress, and temperature-dependent deformation in nanostructured copper: Stress relaxation tests and simulations. Acta Mater. 2016, 108, 252–263. [Google Scholar] [CrossRef] [Green Version]

- Rizi, M.H.B.; Farahani, M.G.; Aghaahmadi, M.; Kim, J.H.; Karjalainen, L.P.; Sahu, P. Analysis of strain hardening behavior of a high-Mn TWIP steel using electron microscopy and cyclic stress relaxation. Acta Mater. 2022, 240, 118309. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Tan, Z.; Xiong, D.-B.; Guo, Q. Stress relaxation and the cellular structure-dependence of plastic deformation in additively manufactured AlSi10Mg alloys. Int. J. Plast. 2019, 127, 102640. [Google Scholar] [CrossRef]

- Lee, H.; Chae, H.; Kim, Y.S.; Song, M.J.; Lim, S.; Prasad, K.; Krishnaswamy, H.; Jain, J.; An, K.; Lee, S.Y. Viscoplastic lattice strain during repeated relaxation of age-hardened Al alloy. Mech. Mater. 2021, 158, 103899. [Google Scholar] [CrossRef]

- Guo, S.; Xie, Y.; Lei, J.; Han, S.; Liu, D.; He, Y. Coupled effect of specimen size and grain size on the stress relaxation of micron-sized copper wires. J. Mater. Sci. 2022, 57, 18655–18668. [Google Scholar] [CrossRef]

- Guo, S.; He, Y.; Liu, D.; Li, Z.; Lei, J.; Han, S. Geometrically necessary dislocations induced size effect in the torsional stress relaxation behavior of thin metallic wires. Scr. Mater. 2019, 173, 129–133. [Google Scholar] [CrossRef]

- Guo, S.; He, Y.; Li, Z.; Lei, J.; Liu, D. Size and stress dependences in the tensile stress relaxation of thin copper wires at room temperature. Int. J. Plast. 2019, 112, 278–296. [Google Scholar] [CrossRef]

- Jun, T.S.; Zhang, Z.; Sernicola, G.; Dunne, F.P.E.; Britton, T.B. Local strain rate sensitivity of single α phase within a dual-phase Ti alloy. Acta Mater. 2016, 107, 298–309. [Google Scholar] [CrossRef] [Green Version]

- Yang, Q.; Ma, Y.; Chen, Z.; Ji, G.; Wang, M.L.; Zhong, S.Y.; Wu, Y.; Ji, V.; Wang, H.W. A new powder metallurgy routine to fabricate TiB2/Al–Zn–Mg–Cu nanocomposites based on composite powders with pre-embedded nanoparticles. Materialia 2019, 8, 100458. [Google Scholar] [CrossRef]

- Yang, Q.; Shen, Y.; Liu, J.; Wang, L.; Chen, Z.; Wang, M.L.; Zhong, S.Y.; Wu, Y.; Wang, H.W. Microstructure and mechanical response of TiB2/Al–Zn–Mg–Cu composites with more addition of Zn. J. Alloys Compd. 2020, 816, 152584. [Google Scholar] [CrossRef]

- Kheradmand, A.B.; Tayebi, M.; Akbari, M.M.; Abbasian, A. Effect of quench-controlled precipitation hardening on microstructure and mechanical properties of Al-Zn-Mg-Cu-Zr alloys contain of Sc micro-alloying. J. Alloys Compd. 2022, 902, 163748. [Google Scholar] [CrossRef]

- Yang, Q.; Cheng, D.L.; Liu, J.; Wang, L.; Chen, Z.; Wang, M.L.; Zhong, S.Y.; Wu, Y.; Ji, G.; Wang, H.W. Microstructure evolution of the TiB2/Al composites fabricated by powder metallurgy during hot extrusion. Mater. Charact. 2019, 155, 109834. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, Y.T.; Liu, J.; Wang, L.; Chen, Z.; Wang, M.L.; Zhong, S.Y.; Wu, Y.; Wang, H.W. Microstructure evolution of the rapidly solidified alloy powders and composite powders. Mater. Des. 2019, 182, 108045. [Google Scholar] [CrossRef]

- Lv, B.-J.; Wang, S.; Xu, T.-W.; Guo, F. Effects of minor Nd and Er additions on the precipitation evolution and dynamic recrystallization behavior of Mg–6.0Zn–0.5Mn alloy. J. Magnes. Alloy. 2021, 9, 840–852. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, Z.; Yu, H.; Ning, Y. Microstructural origin and control mechanism of the mixed grain structure in Ni-based superalloys. J. Alloys Compd. 2022, 900, 163515. [Google Scholar] [CrossRef]

- Wang, S.C.; Starink, M.J.; Gao, N.; Qiao, X.G.; Xu, C.; Langdon, T.G. Texture evolution by shear on two planes during ECAP of a high-strength aluminum alloy. Acta Mater. 2008, 15, 3800–3809. [Google Scholar] [CrossRef] [Green Version]

- Mayama, T.; Noda, M.; Chiba, R.; Kuroda, M. Crystal plasticity analysis of texture development in magnesium alloy during extrusion. Int. J. Plast. 2011, 27, 1916–1935. [Google Scholar] [CrossRef] [Green Version]

- Chung, T.F.; Yang, Y.L.; Huang, B.M.; Shi, Z.; Lin, J.; Ohmura, T.; Yang, J.R. Transmission electron microscopy investigation of separated nucleation and in-situ nucleation in AA7050 aluminium alloy. Acta Mater. 2018, 149, 377–387. [Google Scholar] [CrossRef]

- Fang, X.; Song, M.; Li, K.; Du, Y.; Zhao, D.; Jiang, C.; Zhang, H. Effects of Cu and Al on the crystal structure and composition of η (MgZn2) phase in over-aged Al–Zn–Mg–Cu alloys. J. Mater. Sci. 2012, 47, 5419–5427. [Google Scholar] [CrossRef]

- Ou, Y.; Jiang, Y.; Wang, Y.; Liu, Z.; Lervik, A.; Holmestad, R. Vacancy and solute co-segregated η1 interface in over-aged Al-Zn-Mg alloys. Acta Mater. 2021, 218, 117082. [Google Scholar] [CrossRef]

- Mishra, S.; Yadava, M.; Kulkarni, K.N.; Gurao, N.P. Stress relaxation behavior of an aluminium magnesium silicon alloy in different temper condition. Mech. Mater. 2018, 125, 80–93. [Google Scholar] [CrossRef]

- Niewczas, M.; Jobba, M.; Mishra, R.K. Thermally activated flow of dislocations in Al–Mg binary alloys. Acta Mater. 2014, 83, 372–382. [Google Scholar] [CrossRef]

- Laplanche, G.; Bonneville, J.; Varvenne, C.; Curtin, W.A.; George, E.P. Thermal activation parameters of plastic flow reveal deformation mechanisms in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2018, 143, 257–264. [Google Scholar] [CrossRef]

- Mohebbi, M.S.; Akbarzadeh, A.; Kim, B.H.; Kim, S.K. Analysis of Strain Rate Sensitivity of Ultrafine-Grained AA1050 by Stress Relaxation Test. Met. Mater. Trans. A 2014, 45, 5442–5450. [Google Scholar] [CrossRef]

- Khan, A.S.; Liu, H. Variable strain rate sensitivity in an aluminum alloy: Response and constitutive modeling. Int. J. Plast. 2012, 36, 1–14. [Google Scholar] [CrossRef]

- George, E.P.; Curtin, W.A.; Tasan, C.C. High entropy alloys: A focused review of mechanical properties and deformation mechanisms. Acta Mater. 2020, 188, 435–474. [Google Scholar]

- Malyar, N.V.; Grabowski, B.; Dehm, G.; Kirchlechner, C. Dislocation slip transmission through a coherent Σ3{111} copper twin boundary: Strain rate sensitivity, activation volume and strength distribution function. Acta Mater. 2018, 161, 412–419. [Google Scholar] [CrossRef]

- Bach, J.; Stoiber, M.; Schindler, L.; Höppel, H.W.; Göken, M. Deformation mechanisms and strain rate sensitivity of bimodal and ultrafine-grained copper. Acta Mater. 2020, 186, 363–373. [Google Scholar] [CrossRef]

- Ruppert, M.; Schunk, C.; Hausmann, D.; Höppel, H.W.; Göken, M. Global and local strain rate sensitivity of bimodal Al-laminates produced by accumulative roll bonding. Acta Mater. 2016, 103, 643–650. [Google Scholar] [CrossRef]

- Wheeler, J.M.; Thilly, L.; Morel, A.; Taylor, A.A.; Montagne, A.; Ghisleni, R.; Michler, J. The plasticity of indium antimonide: Insights from variable temperature, strain rate jump micro-compression testing. Acta Mater. 2016, 106, 283–289. [Google Scholar] [CrossRef]

- Klepaczko, J. Strain rate history effetcs for polycrystalline aluminum and theory of interactions. J. Mech. Phys. Solids 1968, 16, 255–266. [Google Scholar] [CrossRef]

- Mohebbi, M.S.; Akbarzadeh, A. Development of equations for strain rate sensitivity of UFG aluminum as a function of strain rate. Int. J. Plast. 2017, 90, 167–176. [Google Scholar] [CrossRef]

- Ivanov, K.V.; Naydenkin, E.V. Grain boundary sliding in ultrafine grained aluminum under tension at room temperature. Scr. Mater. 2012, 66, 511–514. [Google Scholar] [CrossRef]

- Liu, F.C.; Ma, Z.Y. Contribution of grain boundary sliding in low-temperature superplasticity of ultrafine-grained aluminum alloys. Scr. Mater. 2010, 62, 125–128. [Google Scholar] [CrossRef]

- Tayebi, M.; Najafi, H.; Nategh, S.; Khodabandeh, A. Creep Behavior of ZK60 Alloy and ZK60/SiCw Composite After Extrusion and Precipitation Hardening. Met. Mater. Int. 2020, 27, 3905–3917. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Jia, C.; Tayebi, M.; Hamawandi, B. Microstructural Evolution during Accelerated Tensile Creep Test of ZK60/SiC(p) Composite after KoBo Extrusion. Materials 2022, 15, 6428. [Google Scholar] [CrossRef] [PubMed]

- Mirzadeh, H. High strain rate superplasticity via friction stir processing (FSP): A review. Mater. Sci. Eng. A 2021, 819, 141499. [Google Scholar] [CrossRef]

- Varma, A.; Gokhale, A.; Krishnaswamy, H.; Banerjee, D.K.; Jain, J. Grain boundary sliding and non-constancy strain during stress relaxation of pure Mg. Mater. Sci. Eng. A 2021, 817, 141349. [Google Scholar] [CrossRef]

- Wang, Y.M.; Ma, E. Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater. 2004, 52, 1699–1709. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rong, P.; Fang, X.; Xiao, Y.; Wang, Q.; Bian, Z.; Yang, Q.; Wang, H.; Chen, Z. Microstructure and Deformation of Over-Aged Al-Zn-Mg-Cu Alloy with Fine Grains during Multiple Stress Relaxation Tests. Metals 2022, 12, 2097. https://doi.org/10.3390/met12122097

Rong P, Fang X, Xiao Y, Wang Q, Bian Z, Yang Q, Wang H, Chen Z. Microstructure and Deformation of Over-Aged Al-Zn-Mg-Cu Alloy with Fine Grains during Multiple Stress Relaxation Tests. Metals. 2022; 12(12):2097. https://doi.org/10.3390/met12122097

Chicago/Turabian StyleRong, Peng, Xin Fang, Yakai Xiao, Qian Wang, Zeyu Bian, Qing Yang, Haowei Wang, and Zhe Chen. 2022. "Microstructure and Deformation of Over-Aged Al-Zn-Mg-Cu Alloy with Fine Grains during Multiple Stress Relaxation Tests" Metals 12, no. 12: 2097. https://doi.org/10.3390/met12122097

APA StyleRong, P., Fang, X., Xiao, Y., Wang, Q., Bian, Z., Yang, Q., Wang, H., & Chen, Z. (2022). Microstructure and Deformation of Over-Aged Al-Zn-Mg-Cu Alloy with Fine Grains during Multiple Stress Relaxation Tests. Metals, 12(12), 2097. https://doi.org/10.3390/met12122097