Microscale Damage Evolution and Failure Behavior of Metal–Composite Friction Spot Joints: Modelling and Experimental Analyses

Abstract

:1. Introduction

2. Materials and Methods

2.1. Aluminum Alloy 2024-T3

2.2. Carbon-fiber-reinforced Polyphenylene Sulfide (CF-PPS)

2.3. Experimental Procedure

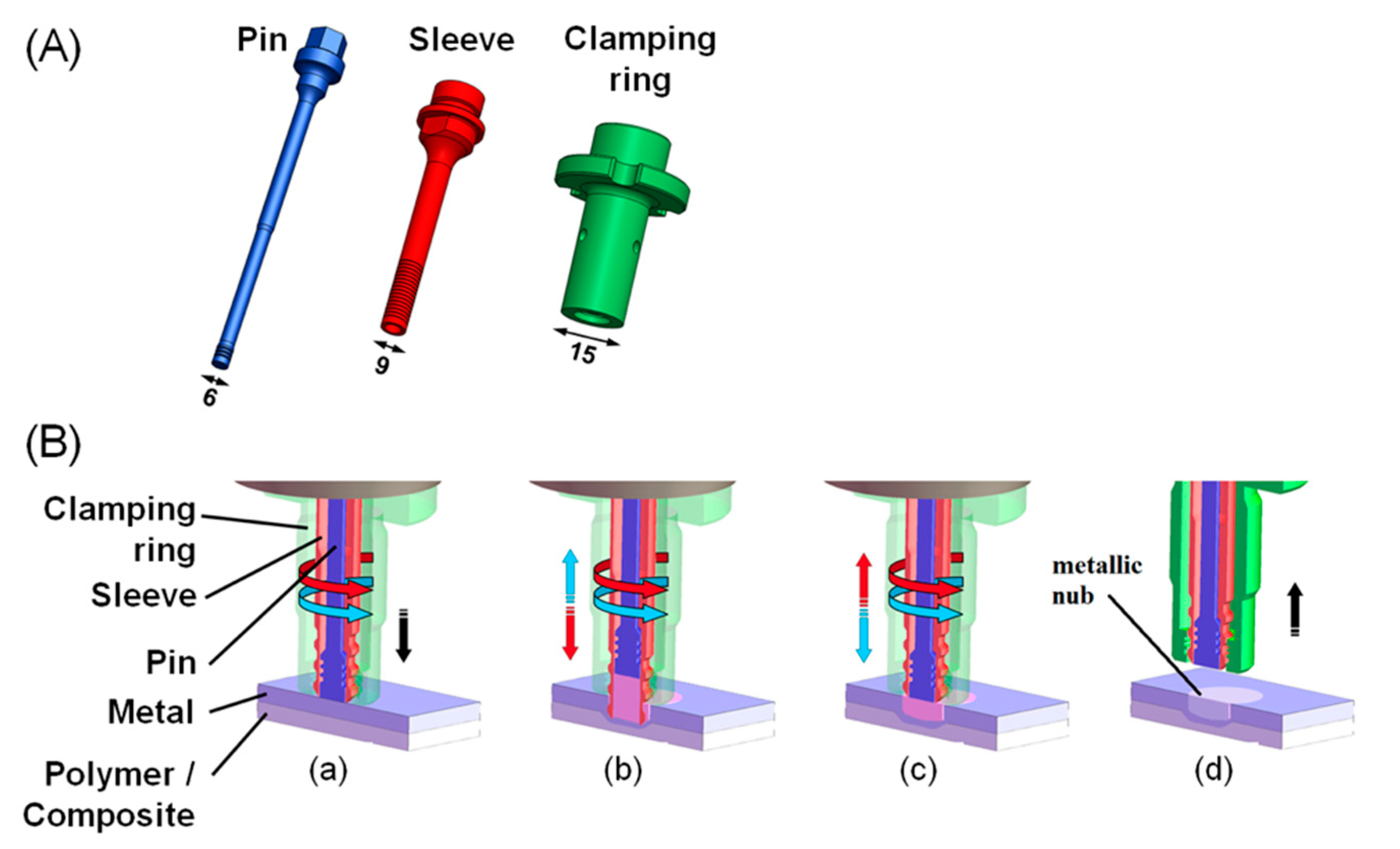

2.3.1. Production of the Joints

2.3.2. Lap Shear Test

2.3.3. Fracture Surface Analysis

2.4. Modelling Procedure

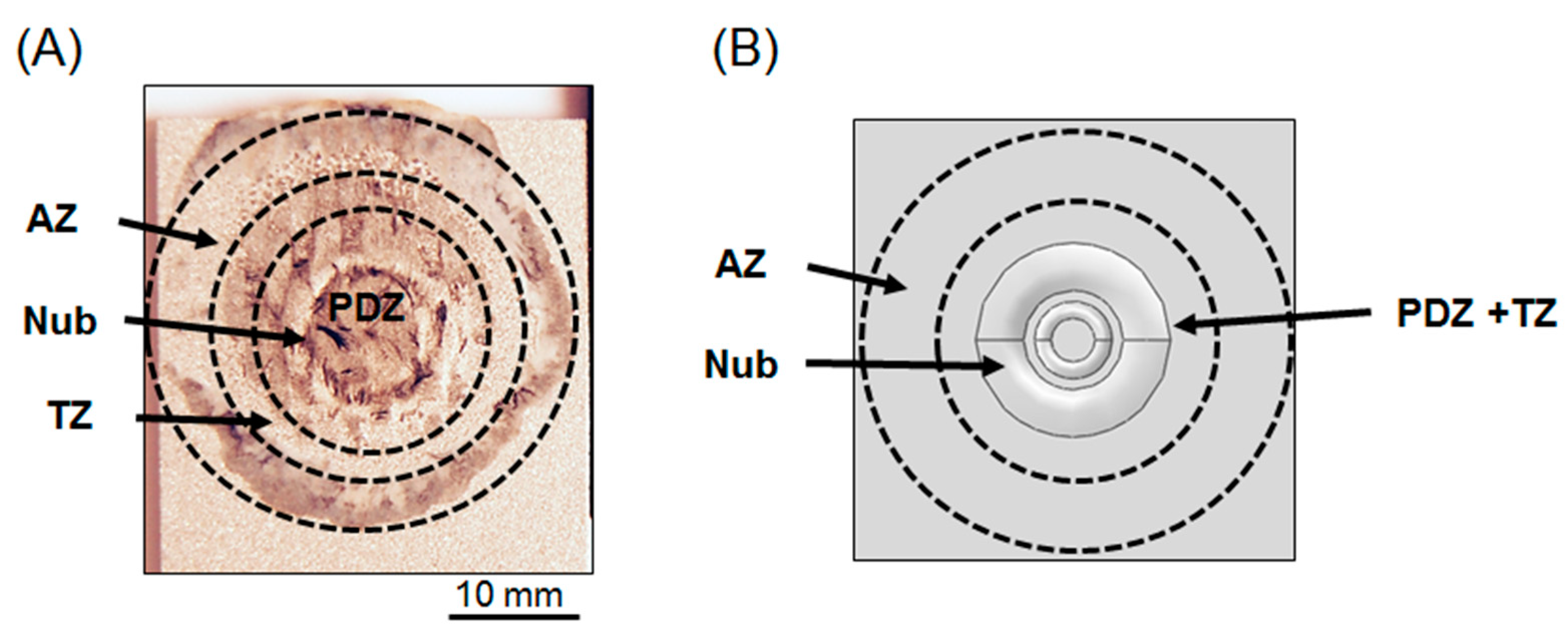

2.4.1. Discretization of the Interface

2.4.2. Interface Interaction

2.4.3. Damage Criteria

2.4.4. Boundary Conditions

2.4.5. Modelling of base Materials

3. Results and Discussion

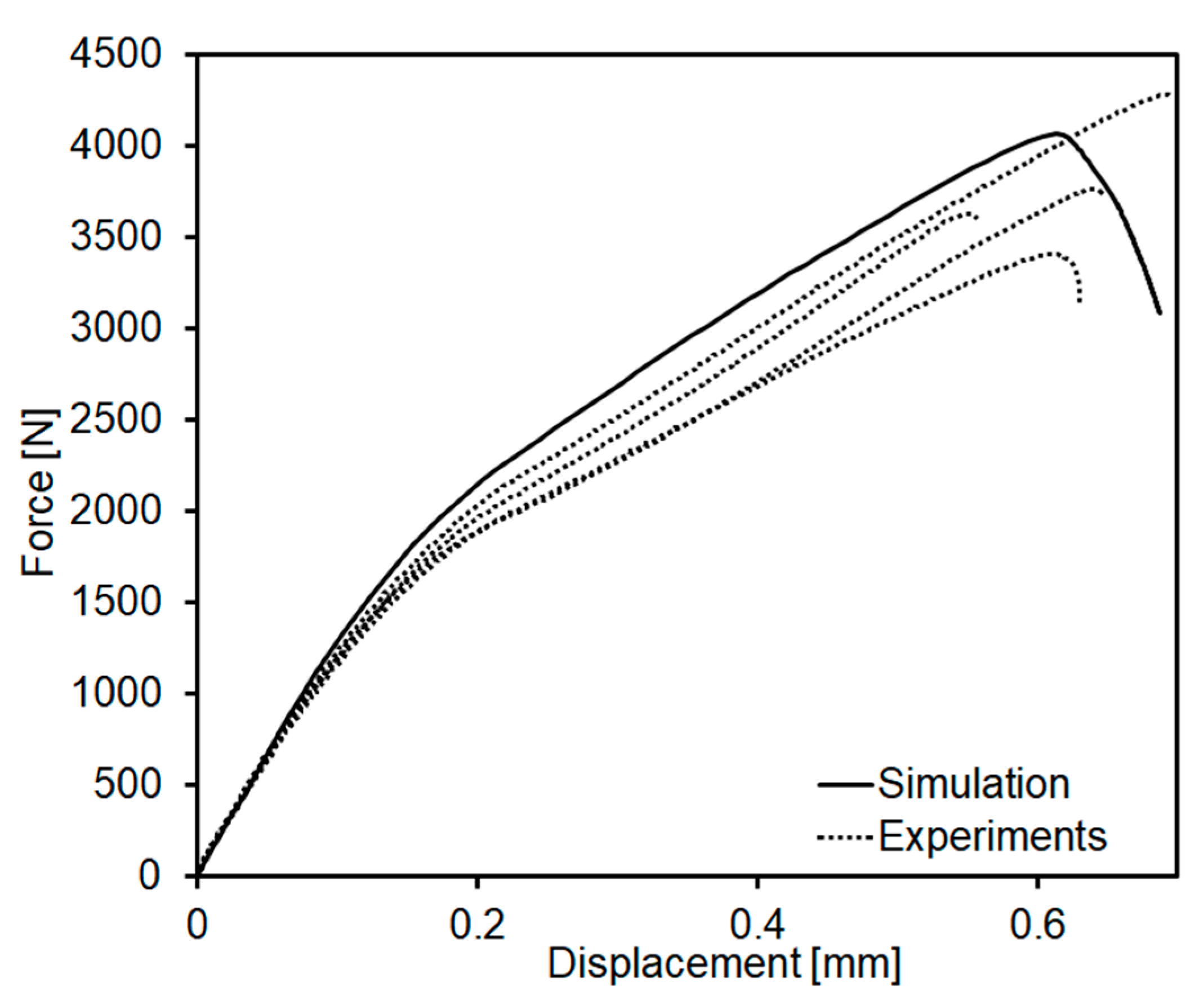

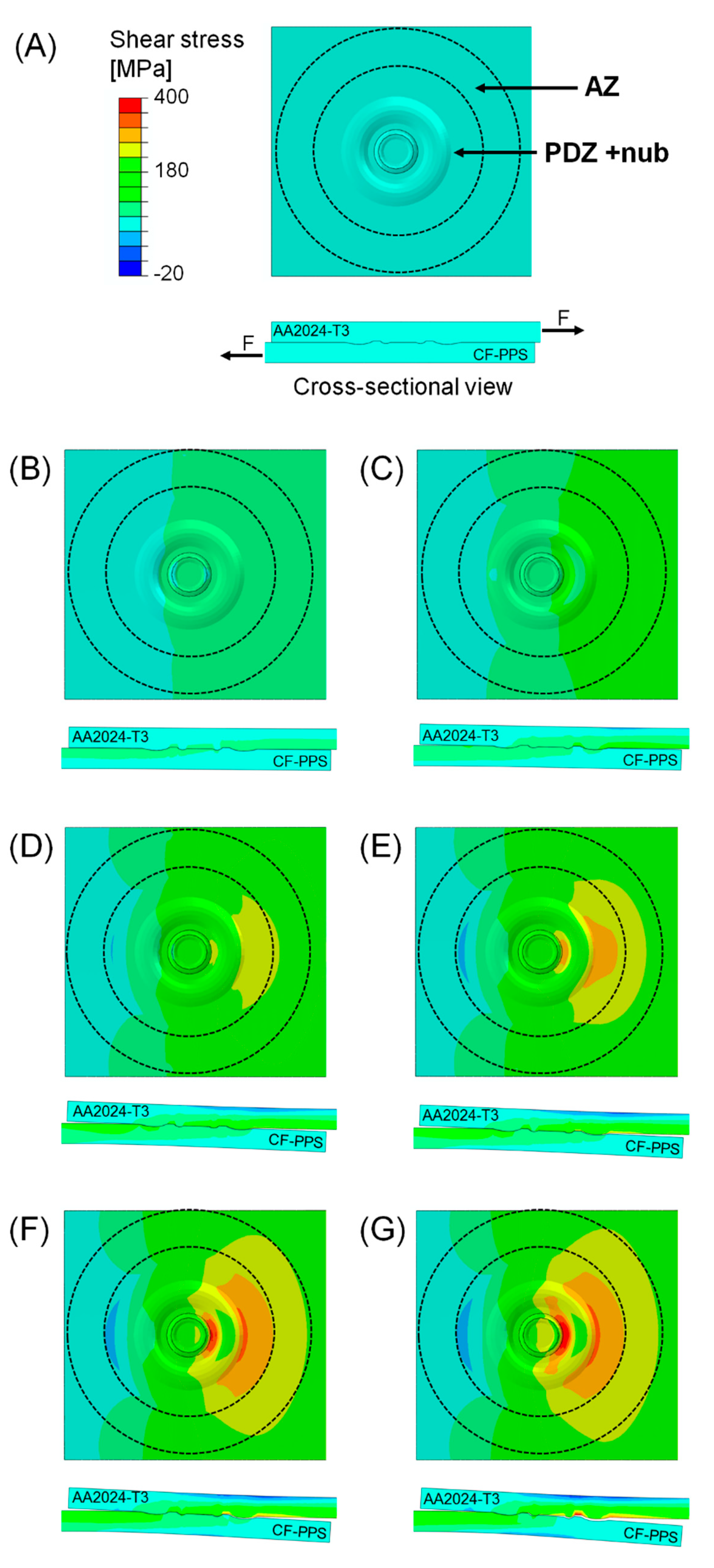

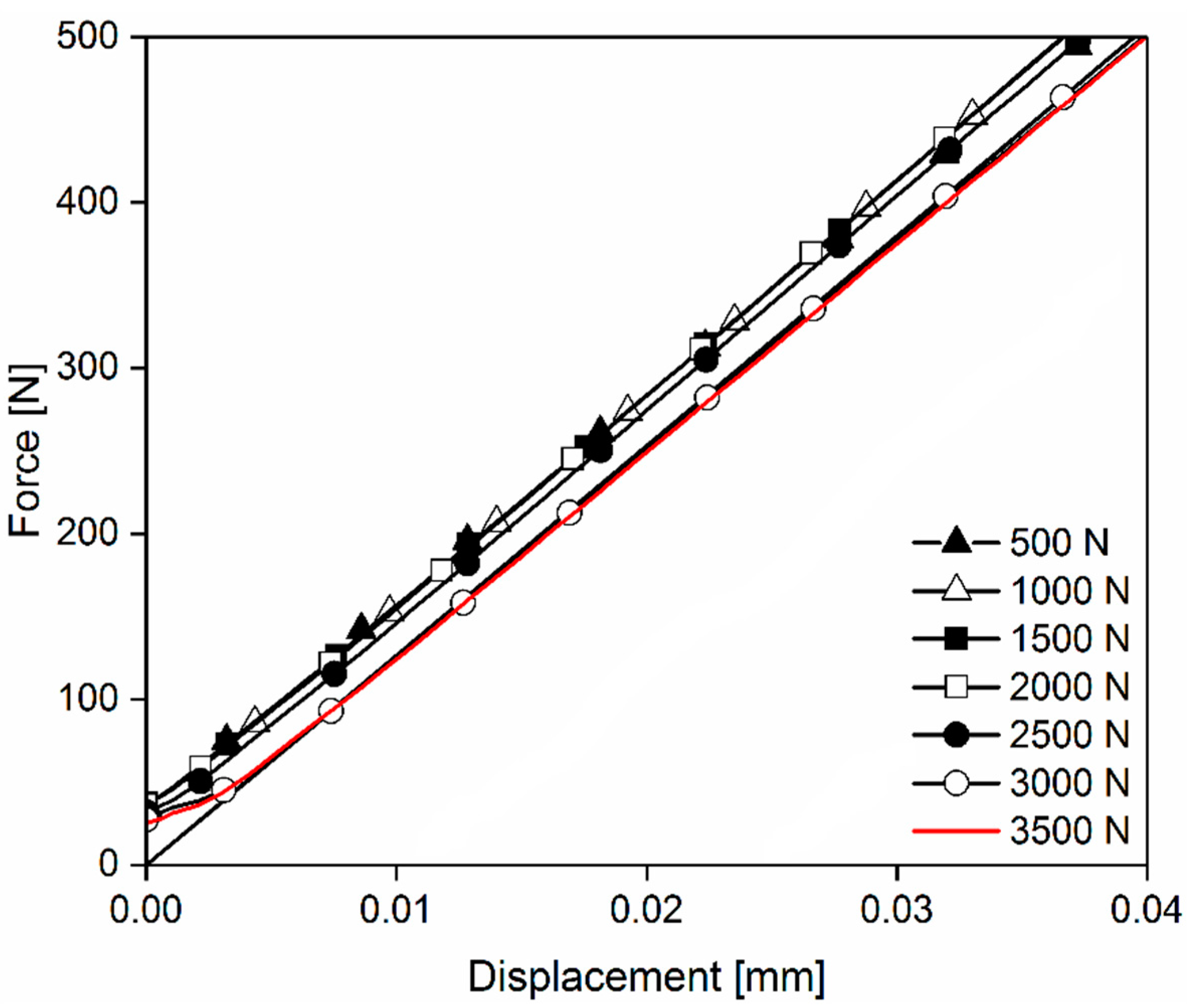

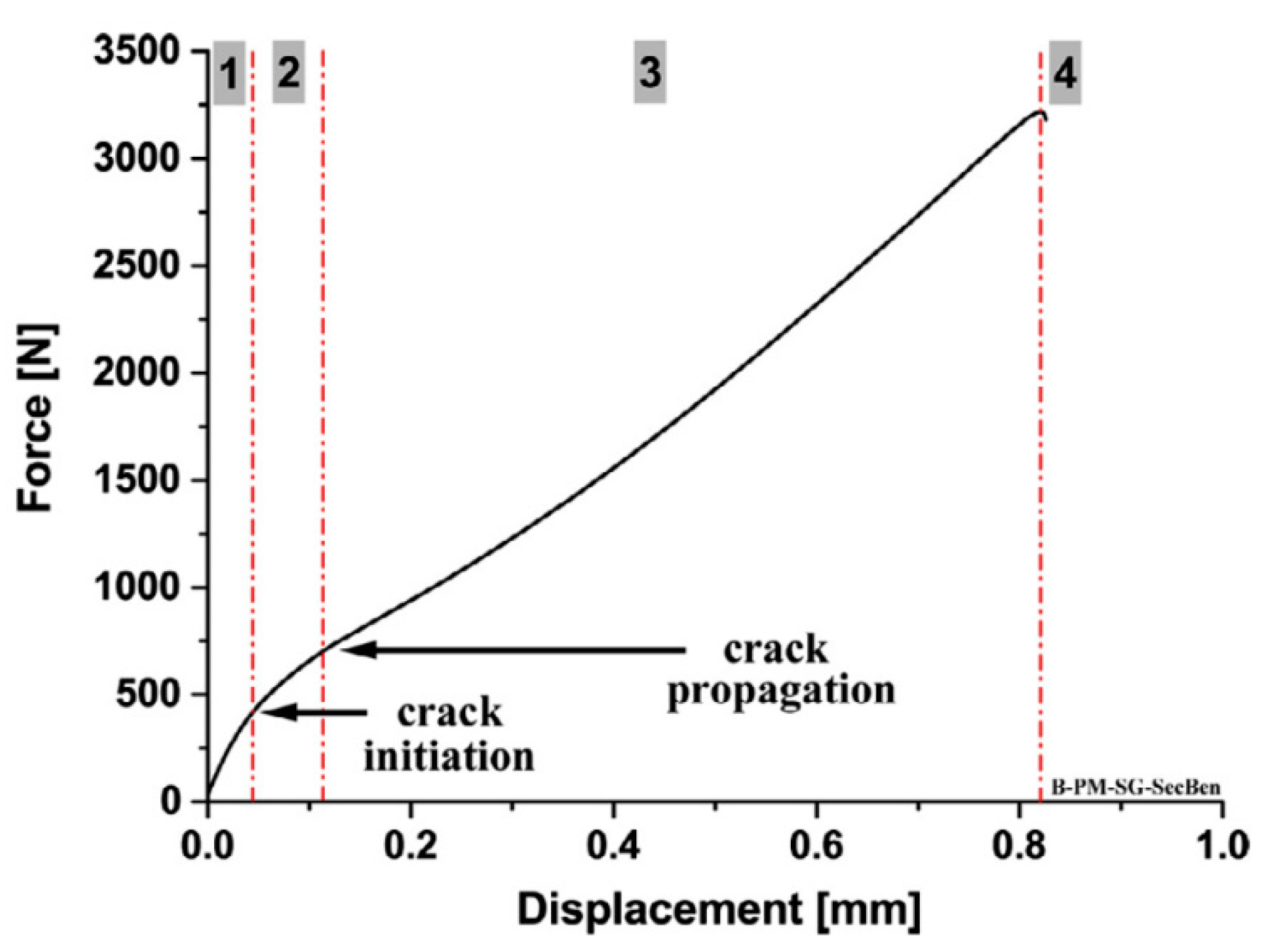

3.1. Prediction of Damage Evolution at the Interface of the Joint using Finite Element Method

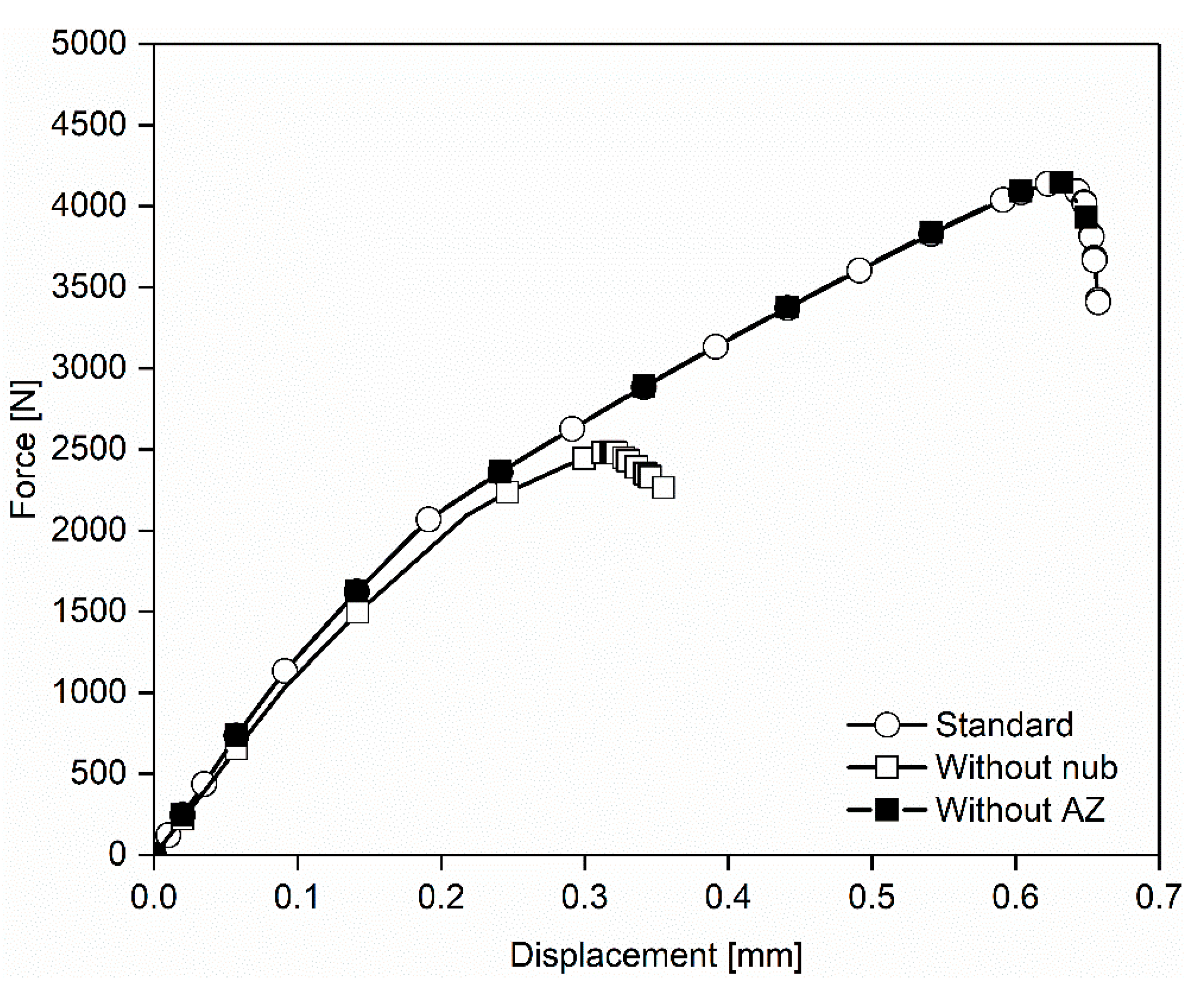

3.2. Influence of the Bonding Zones in the Mechanical Behavior of Friction Spot Joints

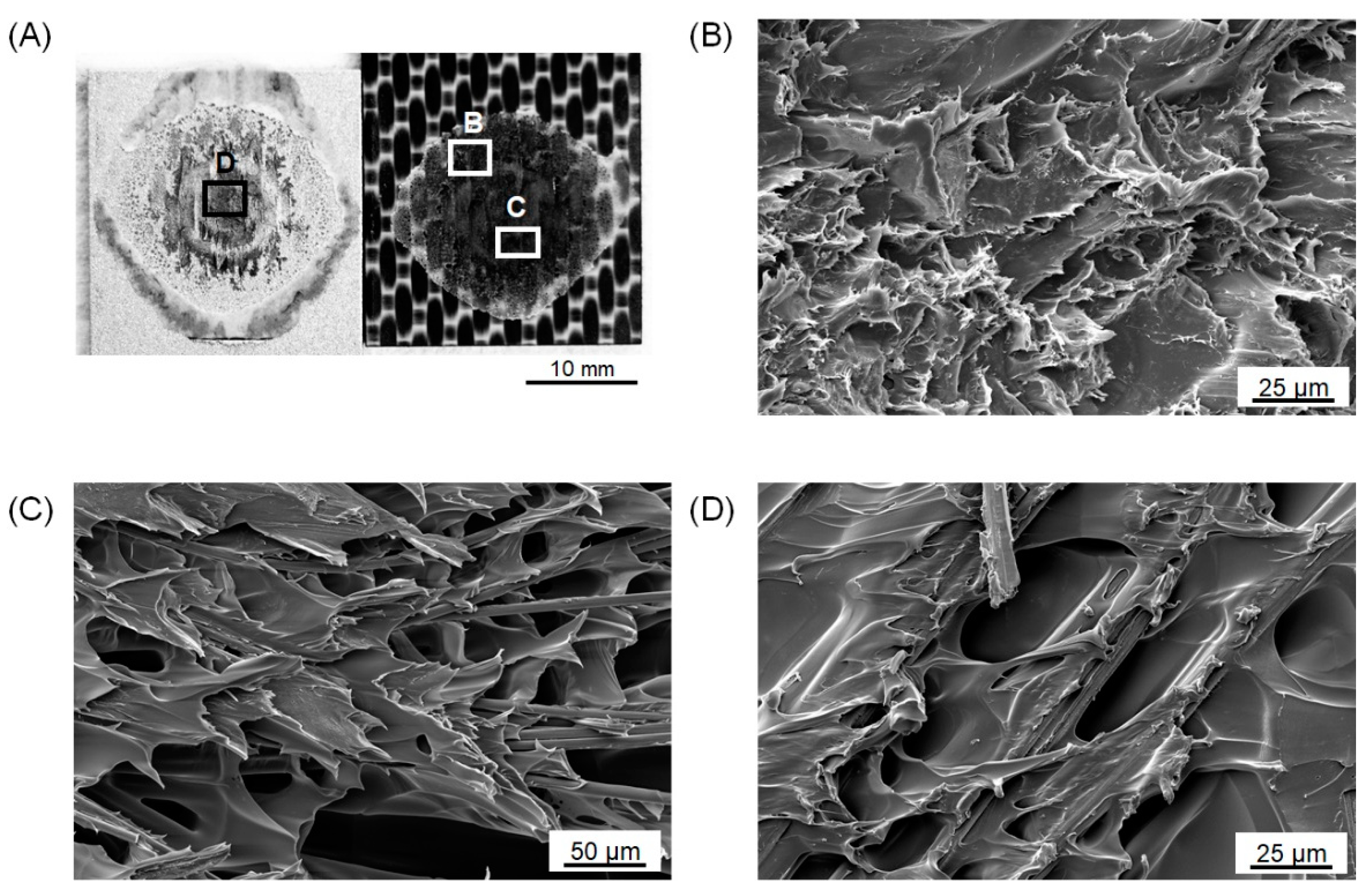

3.3. Damage Evolution and Its Mechanisms

3.4. Failure Theory for Friction Spot Joints: A Summary

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amancio-Filho, S.T.; Blaga, L.-A. Joining of Polymer-Metal Hybrid Structures: Principles and Applications; John Wiley & Sons Inc: Hoboken, NJ, USA, 2018; 416p. [Google Scholar]

- Lambiase, F.; Balle, F.; Blaga, L.-A.; Liu, F.; Amancio-Filho, S.T. Friction-based processes for hybrid multi-material joining. Comp. Struct. 2021, 266, 113828. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; dos Santos, J.F. European Patent 2329905B1, 30 May 2012.

- Amancio-Filho, S.T.; Bueno, C.; dos Santos, J.F.; Huber, N.; Hage, E. On the Feasibility of Friction Spot Joining in Magnesium/Fiber-Reinforced Polymer Composite Hybrid Structures. Mater. Sci. Eng. A 2011, 528, 3841–3848. [Google Scholar] [CrossRef] [Green Version]

- Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. Friction Spot Joining of Aluminum AA2024/Carbon-Fiber Reinforced Poly(Phenylene Sulfide) Composite Single Lap Joints: Microstructure and Mechanical Performance. Mater. Des. 2014, 54, 196–206. [Google Scholar] [CrossRef]

- Goushegir, S.M. Friction Spot Joining (FSpJ) of Aluminum-CFRP Hybrid Structures. Weld. World 2016, 60, 1073–1093. [Google Scholar] [CrossRef] [Green Version]

- André, N.M.; dos Santos, J.F.; Amancio-Filho, S.T. Evaluation of Joint Formation and Mechanical Performance of the AA7075-T6/CFRP Spot Joints Produced by Frictional Heat. Materials 2019, 12, 891. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- André, N.M.; Goushegir, S.M.; dos Santos, J.F.; Canto, L.B.; Amancio-Filho, S.T. Friction Spot Joining of Aluminum Alloy 2024-T3 and Carbon-Fiber-Reinforced Poly(Phenylene Sulfide) Laminate with Additional PPS Film Interlayer: Microstructure, Mechanical Strength and Failure Mechanisms. Compos. Part B Eng. 2016, 94, 197–208. [Google Scholar] [CrossRef]

- Esteves, J.V.; Goushegir, S.M.; dos Santos, J.F.; Canto, L.B.; Hage, E.; Amancio-Filho, S.T. Friction Spot Joining of Aluminum AA6181-T4 and Carbon Fiber-Reinforced Poly(Phenylene Sulfide): Effects of Process Parameters on the Microstructure and Mechanical Strength. Mater. Des. 2015, 66, 437–445. [Google Scholar] [CrossRef] [Green Version]

- Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. Failure and Fracture Micro-Mechanisms in Metal-Composite Single Lap Joints Produced by Welding-Based Joining Techniques. Compos. Part A Appl. Sci. Manuf. 2016, 81, 121–128. [Google Scholar] [CrossRef] [Green Version]

- Chaves, F.J.P.; da Silva, L.F.M.; de Moura, M.F.S.F.; Dillard, D.A.; Esteves, V.H.C. Fracture Mechanics Tests in Adhesively Bonded Joints: A Literature Review. J. Adhes. 2014, 90, 955–992. [Google Scholar] [CrossRef]

- Allix, O.; Corigliano, A. Modeling and Simulation of Crack Propagation in Mixed-Modes Interlaminar Fracture Specimens. Int. J. Fract. 1996, 77, 111–140. [Google Scholar] [CrossRef]

- de Moura, M.F.S.F.; Gonçalves, J.P.M. Cohesive Zone Model for High-Cycle Fatigue of Composite Bonded Joints under Mixed-Mode I+II Loading. Eng. Fract. Mech. 2015, 140, 31–42. [Google Scholar] [CrossRef]

- Chen, J. Predicting Progressive Delamination of Stiffened Fibre-Composite Panel and Repaired Sandwich Panel by Decohesion Models. J. Thermoplast. Compos. Mater. 2002, 15, 429–442. [Google Scholar] [CrossRef]

- Chandra, N.; Li, H.; Shet, C.; Ghonem, H. Some Issues in the Application of Cohesive Zone Models for Metal-Ceramic Interfaces. Int. J. Solids Struct. 2002, 39, 2827–2855. [Google Scholar] [CrossRef]

- Schellekens, J.C.J.; de Borst, R. A Non-Linear Finite Element Approach for the Analysis of Mode-I Free Edge Delamination in Composites. Int. J. Solids Struct. 1993, 30, 1239–1253. [Google Scholar] [CrossRef] [Green Version]

- de Moura, M.F.S.F.; Gonçalves, J.P.M.; Magalhães, A.G. A Straightforward Method to Obtain the Cohesive Laws of Bonded Joints under Mode i Loading. Int. J. Adhes. Adhes. 2012, 39, 54–59. [Google Scholar] [CrossRef] [Green Version]

- Sørensen, B.F. Cohesive Law and Notch Sensitivity of Adhesive Joints. Acta Mater. 2002, 50, 1053–1061. [Google Scholar] [CrossRef]

- Yang, Q.D.; Thouless, M.D.; Ward, S.M. Numerical Simulations of Adhesively-Bonded Beams Failing with Extensive Plastic Deformation. J. Mech. Phys. Solids 1999, 47, 1337–1353. [Google Scholar] [CrossRef]

- Xu, X.P.; Needleman, A. Numerical Simulations of Fast Crack Growth in Brittle Solids. J. Mech. Phys. Solids 1994, 42, 1397–1434. [Google Scholar] [CrossRef]

- Moura, M.F.S.F.D.; Gonçalves, J.P.M.; Marques, A.T.; Castro, P.M.S.T.D. Prediction of Compressive Strength of Carbon-Epoxy Laminates Containing Delamination by Using a Mixed-Mode Damage Model. Compos. Struct. 2000, 50, 151–157. [Google Scholar] [CrossRef]

- Turon, A.; Costa, J.; Camanho, P.P.; Dávila, C.G. Simulation of Delamination in Composites under High-Cycle Fatigue. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2270–2282. [Google Scholar] [CrossRef]

- Schellekens, J.C.J. Computational Strategies for Composite Structures. Ph.D. Thesis, TU Delft, Delft, The Netherlands, 1992. Available online: http://resolver.tudelft.nl/uuid:ecc16ece-34b5-4df3-90aa-83f8e8bc31a7 (accessed on 2 August 2022).

- Allix, O.; Ladevèze, P. Interlaminar Interface Modelling for the Prediction of Delamination. Compos. Struct. 1992, 22, 235–242. [Google Scholar] [CrossRef]

- Davis, J. Aluminum and Aluminum Alloys; ASM International: Materials Park, OH, USA, 1993. [Google Scholar]

- American Society for Metals Metals Handbook; American Society for Metals: Metals Park, OH, USA, 1981; Volume 2.

- Aluminium Alloy 2024-T3 Technical Datasheet; Constellium: Paris, France, 2012.

- Tencate Advanced Composites. CETEX® PPS Tech Datasheet and Guidelines. Available online: https://www.toraytac.com/media/221a4fcf-6a4d-49f3-837f-9d85c3c34f74/smphpw/TAC/Documents/Data_sheets/Thermoplastic/UD%20tapes,%20prepregs%20and%20laminates/Toray-Cetex-TC1100_PPS_PDS.pdf (accessed on 2 August 2022).

- André, N.M.; Goushegir, S.M.; Scharnagl, N.; dos Santos, J.F.; Canto, L.B.; Amancio-Filho, S.T. Composite Surface Pre-Treatments: Improvement on Adhesion Mechanisms and Mechanical Performance of Metal–Composite Friction Spot Joints with Additional Film Interlayer. J. Adhes. 2018, 94, 723–742. [Google Scholar] [CrossRef]

- Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. Influence of Aluminum Surface Pre-Treatments on the Bonding Mechanisms and Mechanical Performance of Metal-Composite Single-Lap Joints. Weld. World 2017, 61, 1099–1115. [Google Scholar] [CrossRef]

- Abaqus v. 6.14-1 software documentation, under License for Helmholtz-Zentrum Hereon (Formerly Helmholtz-Zentrum Geesthacht GmbH), Germany. Available online: http://130.149.89.49:2080/v6.14/ (accessed on 2 August 2022).

- Cui, W.; Wisnom, M.R. A Combined Stress-Based and Fracture-Mechanics-Based Model for Predicting Delamination in Composites. Composites 1993, 24, 467–474. [Google Scholar] [CrossRef]

- Needleman, A. A Continuum Model for Void Nucleation by Inclusion Debonding. J. Appl. Mech. 1987, 54, 525. [Google Scholar] [CrossRef]

- Chen, J.L.; Crisfield, M.; Kinloch, A.J.; Busso, E.P.; Matthews, F.L.; Qiu, Y. Predicting Progressive Delamination of Composite Material Specimens via Interface Elements. Mech. Compos. Mater. Struct. 1999, 6, 301–317. [Google Scholar] [CrossRef]

- Mi, Y.; Crisfield, M.A.; Davies, G.A.O.; Hellweg, H.B. Progressive Delamination Using Interface Elements. J. Compos. Mater. 1998, 32, 1246–1272. [Google Scholar] [CrossRef]

- Tvergaard, V.; Hutchinson, J.W. The Relation between Crack Growth Resistance and Fracture Process Parameters in Elastic-Plastic Solids. J. Mech. Phys. Solids 1992, 40, 1377–1397. [Google Scholar] [CrossRef]

- Barenblatt, G.I. The Mathematical Theory of Equilibrium Cracks in Brittle Fracture. Adv. App. Mech. 1962, 7, 55–129. [Google Scholar]

- McCarthy, C.T.; Gray, P.J. An Analytical Model for the Prediction of Load Distribution in Highly Torqued Multi-Bolt Composite Joints. Compos. Struct. 2011, 93, 287–298. [Google Scholar] [CrossRef]

- Ireman, T. Three-Dimensional Stress Analysis of Bolted Single-Lap Composite Joints. Compos. Struct. 1998, 43, 195–216. [Google Scholar] [CrossRef]

- McCarthy, M.A.; McCarthy, C.T.; Padhi, G.S. A Simple Method for Determining the Effects of Bolt-Hole Clearance on Load Distribution in Single-Column Multi-Bolt Composite Joints. Compos. Struct. 2006, 73, 78–87. [Google Scholar] [CrossRef]

- Egan, B.; McCarthy, C.T.; McCarthy, M.A.; Frizzell, R.M. Stress Analysis of Single-Bolt, Single-Lap, Countersunk Composite Joints with Variable Bolt-Hole Clearance. Compos. Struct. 2012, 94, 1038–1051. [Google Scholar] [CrossRef] [Green Version]

- Ekh, J.; Schön, J. Effect of Secondary Bending on Strength Prediction of Composite, Single Shear Lap Joints. Compos. Sci. Technol. 2005, 65, 953–965. [Google Scholar] [CrossRef]

- Yeh, H.-Y. Mixed Mode Fracture Analysis of the Lap Shear Specimen Test Per ASTM D1002. J. Reinf. Plast. Compos. 2005, 24, 839–853. [Google Scholar] [CrossRef]

- Lee, H.K.; Pyo, S.H.; Kim, B.R. On Joint Strengths, Peel Stresses and Failure Modes in Adhesively Bonded Double-Strap and Supported Single-Lap GFRP Joints. Compos. Struct. 2009, 87, 44–54. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; das Neves, P.J.C.; Adams, R.D.; Wang, A.; Spelt, J.K. Analytical Models of Adhesively Bonded Joints-Part II: Comparative Study. Int. J. Adhes. Adhes. 2009, 29, 331–341. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; das Neves, P.J.C.; Adams, R.D.; Spelt, J.K. Analytical Models of Adhesively Bonded Joints-Part I: Literature Survey. Int. J. Adhes. Adhes. 2009, 29, 319–330. [Google Scholar] [CrossRef]

- André, N.M.; Bouali, A.; Maawad, E.; Staron, P.; do Santos, J.F.; Zheludkevich, M.L.; Amancio-Filho, S.T. Corrosion Behavior of Metal–Composite Hybrid Joints: Influence of Precipitation State and Bonding Zones. Corros. Sci. 2019, 158, 108075. [Google Scholar] [CrossRef]

- Hiss, R.; Hobeika, S.; Lynn, C.; Strobl, G. Network Stretching, Slip Processes, and Fragmentation of Crystallites during Uniaxial Drawing of Polyethylene and Related Copolymers. A Comparative Study. Macromolecules 1999, 32, 4390–4403. [Google Scholar] [CrossRef]

- Maes, D.; Groeninckx, G.; Ravenstijn, J.; Aerts, L. A Molecular Model for Structural Changes during Shear Yielding and Crazing in Amorphous Polymers. Polym. Bull. 1986, 16, 363–370. [Google Scholar] [CrossRef]

- Haward, R.N. Strain Hardening of Thermoplastics. Macromolecules 1993, 26, 5860–5869. [Google Scholar] [CrossRef]

- Liu, A.F. Mechanics and Mechanisms of Fracture: An Introduction; ASM International: Materials Park, OH, USA, 2005. [Google Scholar]

- Canevarolo, S.V., Jr. Ciência Dos Polímeros. 2°. Edição; Artliber: São Paulo, Brazil, 2006. [Google Scholar]

- Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. Fatigue Performance of Metal–Composite Friction Spot Joints. Materials 2021, 14, 4516. [Google Scholar] [CrossRef] [PubMed]

| Element | Cu | Mg | Mn | Fe | Zn | Si | Ti | Cr | Al |

|---|---|---|---|---|---|---|---|---|---|

| Wt% | 4.55 | 1.49 | 0.45 | 0.17 | 0.16 | 0.10 | 0.02 | <0.01 | Bal. |

| Property | Value |

|---|---|

| Tensile Strength (TL direction) [MPa] | 437 |

| Yield Strength (TL direction) [MPa] | 299 |

| Tensile Modulus [GPa] | 73 |

| Shear Modulus [GPa] | 28 |

| Incipient Melting Temperature [°C] | 502 |

| Density [g·cm−3] | 2.78 |

| Poisson Ratio | 0.33 |

| Property | Value |

|---|---|

| Tensile Strength (warp/weft) [MPa] | 790/750 |

| In-Plane Shear Strength [MPa] | 119 |

| Tensile Modulus [GPa] | 53 |

| Flexural Modulus (warp/weft) | 60/45 |

| Glass Transition Temperature [°C] | 120 |

| Melting Temperature [°C] | 280 |

| Density [g·cm−3] | 1.35 |

| Poisson Ratio | 0.2 |

| Bonding Zone | Knn [N·m−1] | Kss [N·m−1] | Ktt [N·m−1] |

|---|---|---|---|

| AZ | 106 | 107 | 105 |

| PDZ | 3.6 × 1010 | 3.6 × 1011 | 3.6 × 109 |

| Bonding Zone | Initiation—δ nn, ss, tt [mm] | Complete Failure—δmax [mm] |

|---|---|---|

| AZ | 10−3 | 0.10 |

| PDZ | 0.08 | 0.62 |

| Bonding Zone | Damage Initiation [N] | Complete Failure [N] | Damage Evolution Rate [% N−1 of Applied Force] |

|---|---|---|---|

| AZ | 29 | 726 | 0.14 |

| PDZ | 1532 | 4061 | 0.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

André, N.M.; Alessio, R.P.; dos Santos, J.F.; Amancio-Filho, S.T. Microscale Damage Evolution and Failure Behavior of Metal–Composite Friction Spot Joints: Modelling and Experimental Analyses. Metals 2022, 12, 2080. https://doi.org/10.3390/met12122080

André NM, Alessio RP, dos Santos JF, Amancio-Filho ST. Microscale Damage Evolution and Failure Behavior of Metal–Composite Friction Spot Joints: Modelling and Experimental Analyses. Metals. 2022; 12(12):2080. https://doi.org/10.3390/met12122080

Chicago/Turabian StyleAndré, Natalia M., Renan Pereira Alessio, Jorge F. dos Santos, and Sergio T. Amancio-Filho. 2022. "Microscale Damage Evolution and Failure Behavior of Metal–Composite Friction Spot Joints: Modelling and Experimental Analyses" Metals 12, no. 12: 2080. https://doi.org/10.3390/met12122080

APA StyleAndré, N. M., Alessio, R. P., dos Santos, J. F., & Amancio-Filho, S. T. (2022). Microscale Damage Evolution and Failure Behavior of Metal–Composite Friction Spot Joints: Modelling and Experimental Analyses. Metals, 12(12), 2080. https://doi.org/10.3390/met12122080