Microstructure and Mechanical Properties of ZL205A Aluminum Alloy Produced by Squeeze Casting after Heat Treatment

Abstract

1. Introduction

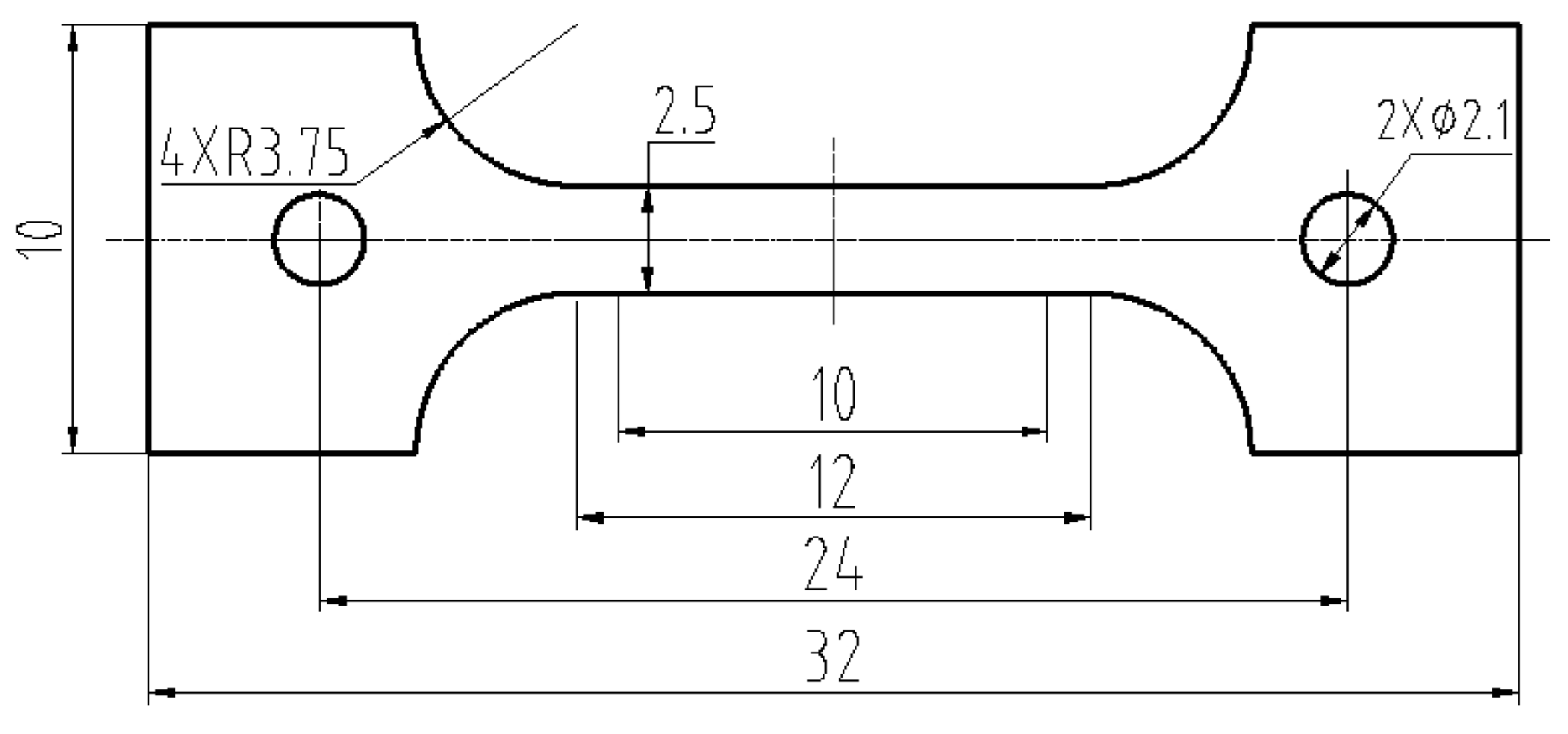

2. Materials and Methods

2.1. Materials

2.2. Heat Treatment and Characterization

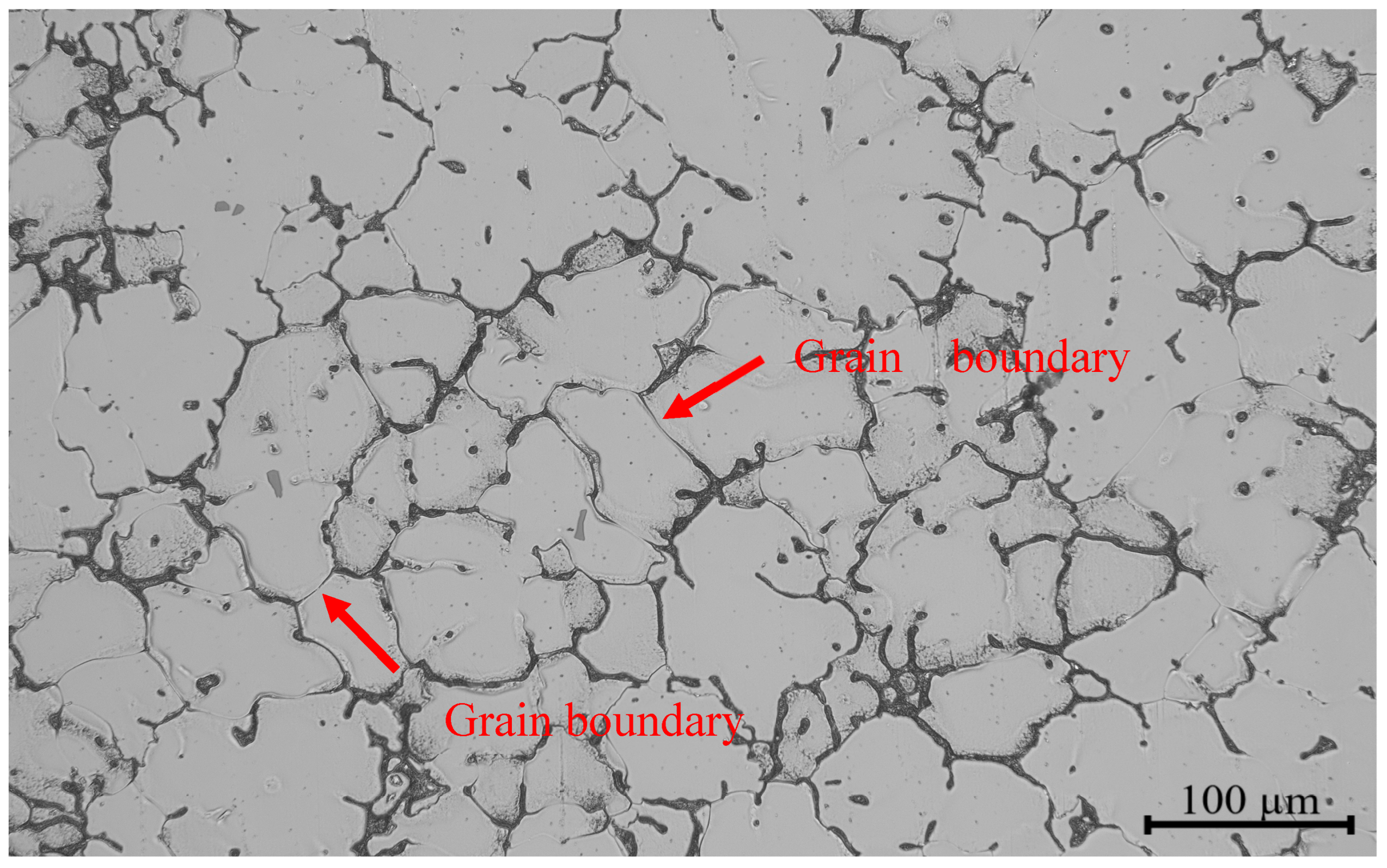

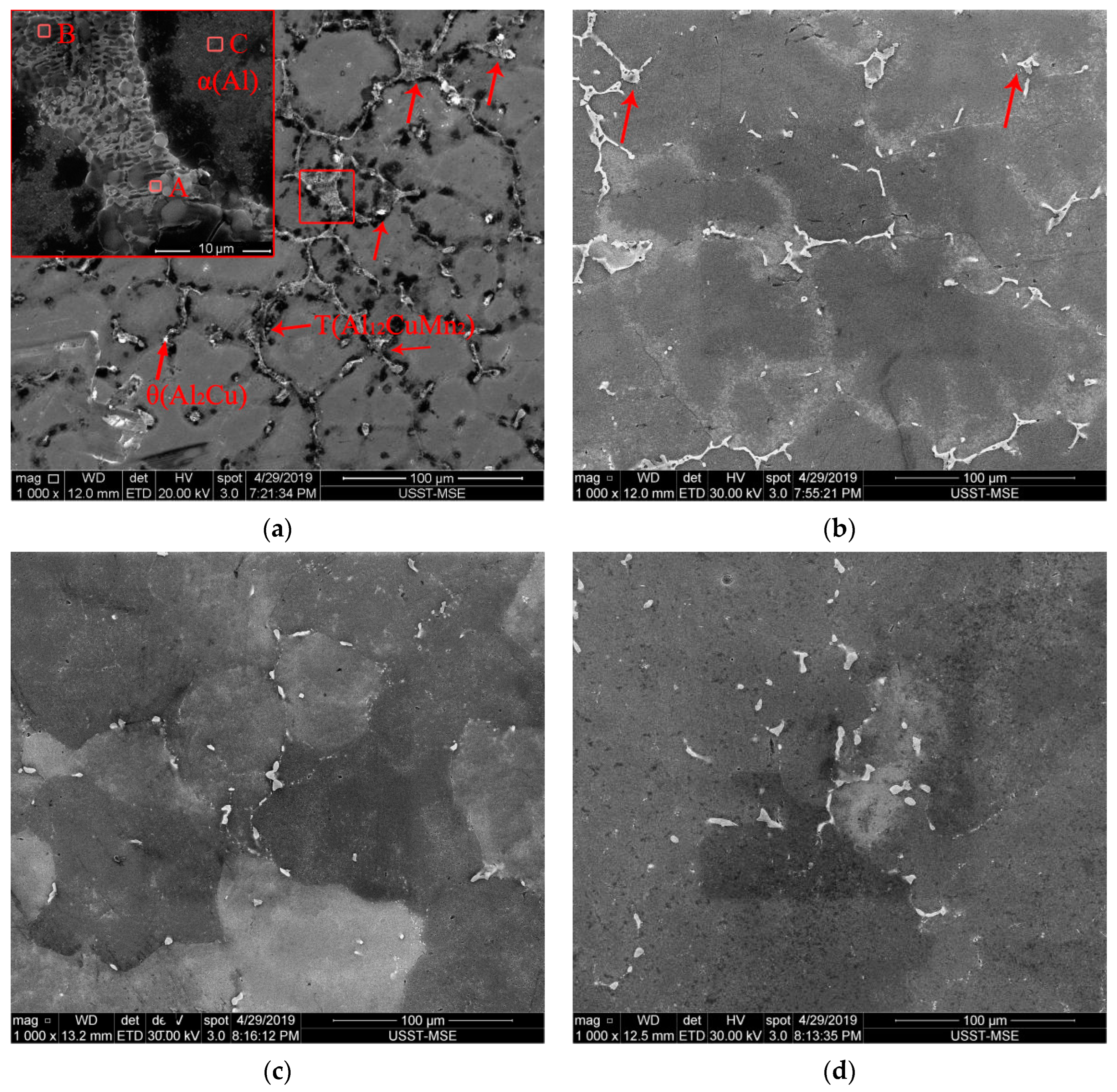

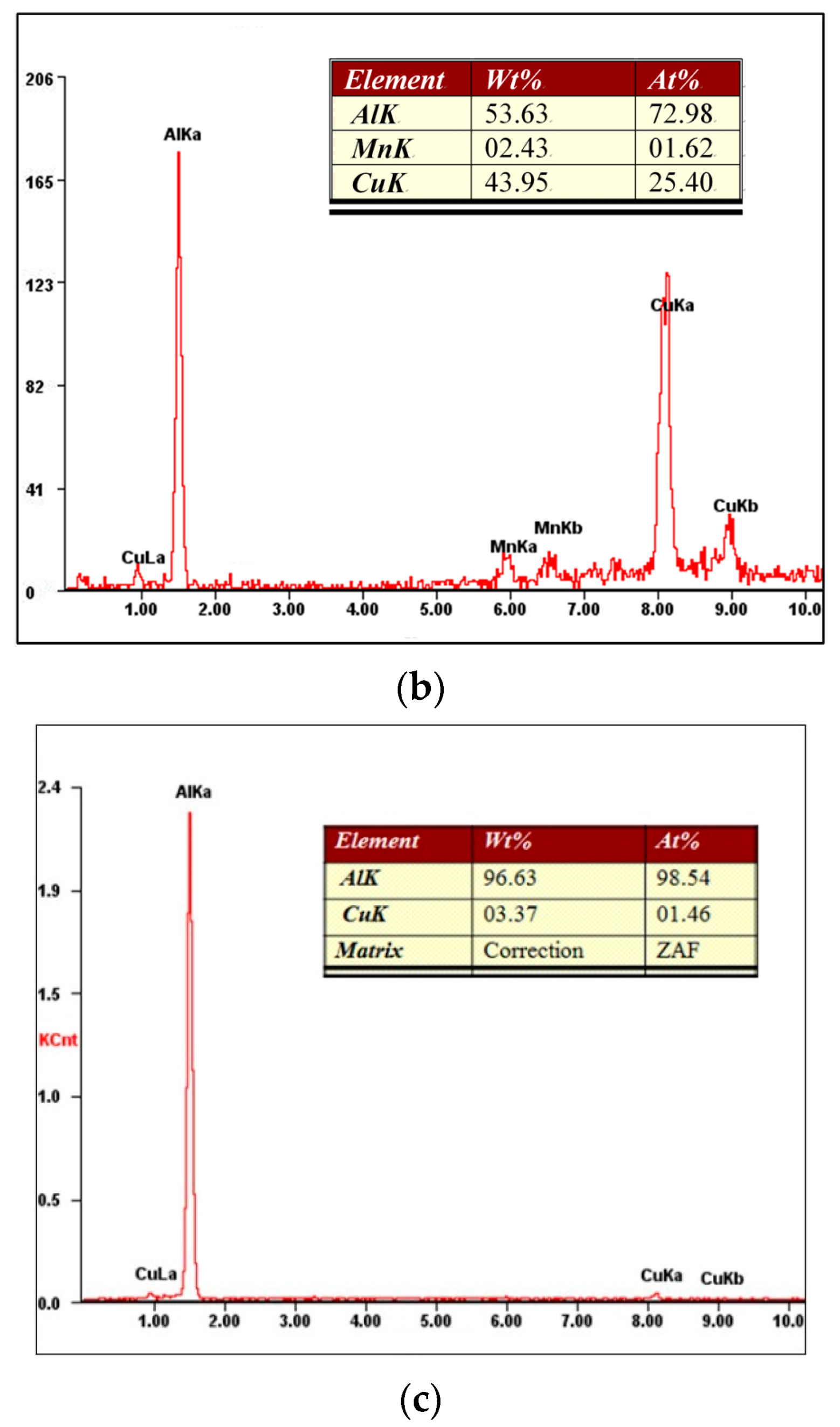

3. Results

4. Conclusions

- (1)

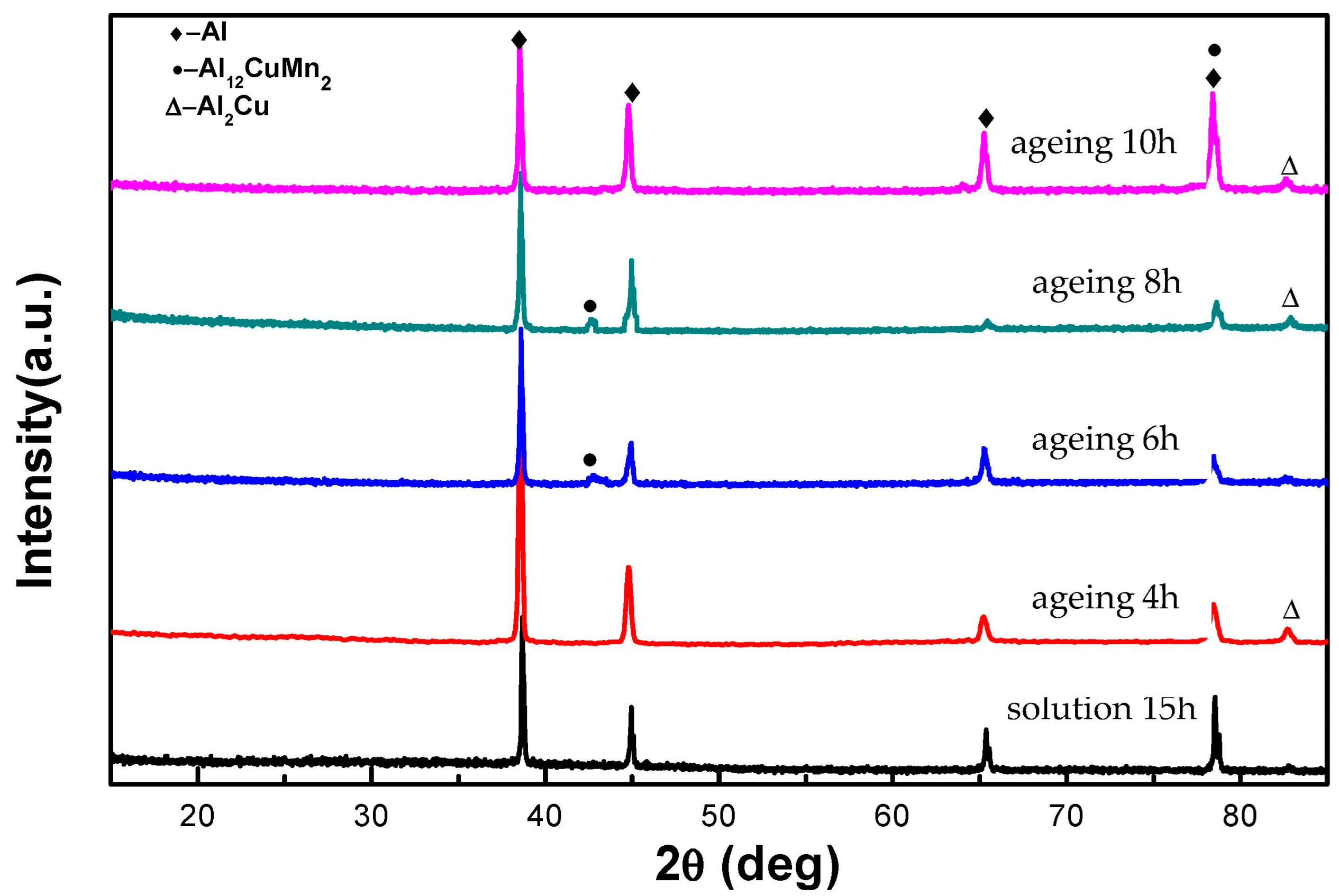

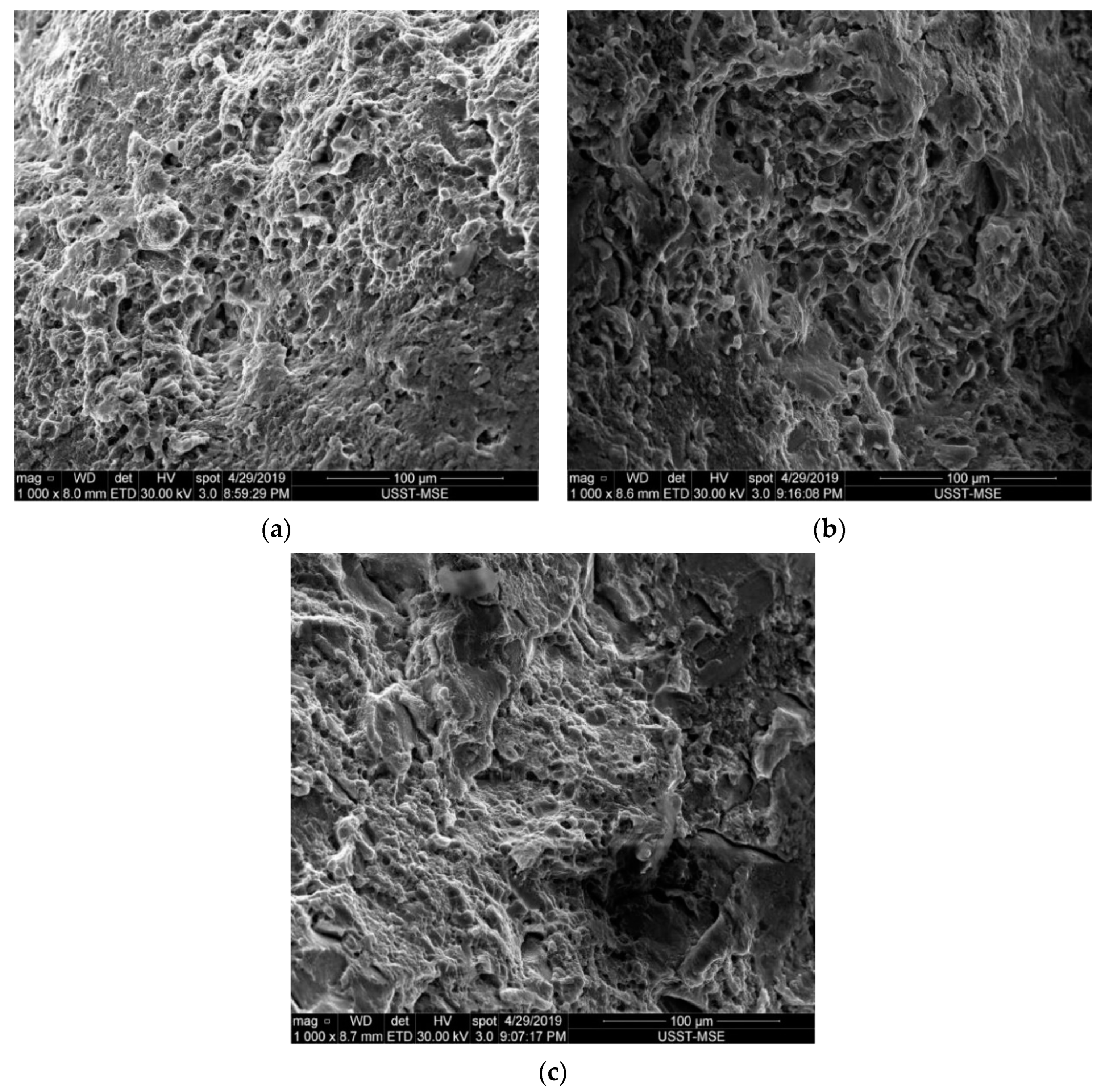

- Most of the θ(Al2Cu) and T(Al12CuMn2) phases dissolved in the α(Al) matrix after solution treatment for 15 h. When the ageing time increased to 8 h, the secondary T phase grew and the grain boundary presented a network of cleavage matrices, which was unfavorable to the plasticity of the specimen.

- (2)

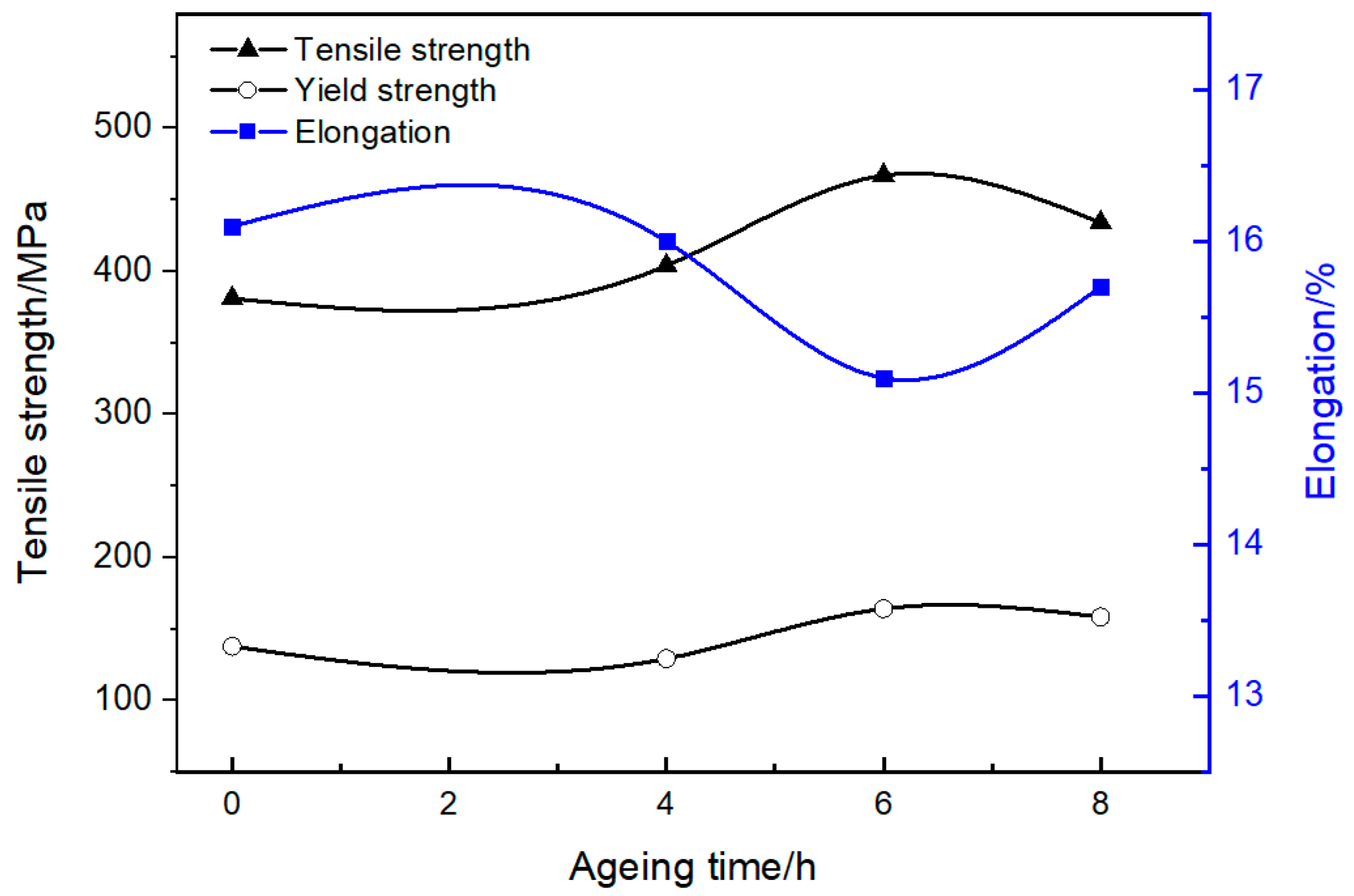

- After solution 15 h, the ultimate tensile strength reached the highest value of 381 MPa, and the elongation was 16.1%, which were much higher than those of as-cast. The tensile strength decreased with 17 h solution.

- (3)

- The specimen aged for 6 h showed good mechanical properties with the ultimate tensile strength of 467 MPa and the elongation of 15.1%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, M.; Zhang, W.-W.; Zhao, H.-D.; Zhang, D.-T.; Li, Y.-Y. Effect of pressure on microstructures and mechanical properties of Al-Cu-based alloy prepared by squeeze casting. Trans. Nonferrous Met. Soc. China 2007, 17, 496–501. [Google Scholar] [CrossRef]

- Lu, C.; Yan, M.F.; Wang, Y.X.; Zhang, C.S.; Zong, Y.Y.; Zhang, F.Y.; Fu, H.Y. Effect of the multiphase layer produced on surface of ZL205A aluminum alloy thin-wall barrel on quenching deformation. Surf. Coat. Technol. 2019, 372, 319–326. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, S.-P.; Xue, X.; Chen, R.-R.; Zhang, J.-B.; Xiao, W.-F. Formation mechanism and criterion of linear segregation in ZL205A alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 3632–3638. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, A.; Weng, Z.; Xiong, D.; Ye, B.; Qi, X. Porosity elimination and heat treatment of diode laser-clad homogeneous coating on cast aluminum-copper alloy. Surf. Coat. Technol. 2017, 321, 26–35. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.; Hu, W. Casting defects induced fatigue damage in aircraft frames of ZL205A aluminum alloy-A failure analysis. Mater. Des. 2011, 32, 2570–2582. [Google Scholar] [CrossRef]

- Lin, C.; Wu, S.; Lü, S.; An, P.; Wu, H. Effects of high pressure rheo-squeeze casting on Fe-containing intermetallic compounds and mechanical properties of Al-17Si-2Fe-(0, 0.8)V alloys. Mater. Sci. Eng. A 2018, 713, 105–111. [Google Scholar] [CrossRef]

- Nakai, M.; Eto, T. New aspect of development of high strength aluminum alloys for aerospace applications. Mater. Sci. Eng. A 2000, 285, 62–688. [Google Scholar] [CrossRef]

- Lin, B.; Xia, S.; Li, H.; Lou, Z.; Liu, K.; Zhang, W. Improved creep resistance of Al-Cu-Mn-Fe-Ni alloys through squeeze casting. Mater. Charact. 2019, 158, 109935. [Google Scholar] [CrossRef]

- Lumley, R.N.; Polmear, I.J. The effect of long term creep exposure on the microstructure and properties of an underaged Al-Cu-Mg-Ag alloy. Scr. Mater. 2004, 50, 1227–1231. [Google Scholar] [CrossRef]

- Wang, J.; Yi, D.; Su, X.; Yin, F. Influence of deformation ageing treatment on microstructure and properties of aluminum alloy 2618. Mater. Charact. 2008, 59, 965–968. [Google Scholar] [CrossRef]

- Park, J.K.; Ardell, A.J. Effect of retrogression and reaging treatments on the microstructure of Al-7075-T651. Metall. Trans. A 1984, 15, 1531–1543. [Google Scholar] [CrossRef]

- Eddahbi, M.; Jimenez, J.A.; Ruano, O.A. Microstructure and creep behaviour of an Osprey processed and extruded Al-Cu-Mg-TI-Ag alloy. J. Alloys Compd. 2007, 433, 97–107. [Google Scholar] [CrossRef][Green Version]

- Li, Y.X.; Ngai, T.; Zhao, H.D.; Zhang, W.W.; Li, Y.Y. Effect of solution treatment on microstructure and properties of squeeze cast Al-Cu alloy. Heat Treat. Met. 2017, 42, 66–69. [Google Scholar]

- Jang, J.-H.; Nam, D.-G.; Park, Y.-H.; Park, I.-M. Effect of solution treatment and artificial aging on microstructure and mechanical properties of Al-Cu alloy. Trans. Nonferrous Met. Soc. China 2013, 23, 631–635. [Google Scholar] [CrossRef]

- Ringer, S.P.; Hono, K. Microstructural Evolution and Age Hardening in Aluminium Alloys: Atom Probe Field-Ion Microscopy and Transmission Electron Microscopy Studies. Mater. Charact. 2000, 44, 101–131. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, G.; Wang, W.; Rong, Y. Effect of Precipitation During Quenching on the Prediction of the Mechanical Properties of Al-5 Pct Cu Alloy After T6 Treatment. Metall. Mater. Trans. A 2017, 48, 5667–5677. [Google Scholar] [CrossRef]

- Wang, W.; Wang, G.; Du, P.; Rong, Y. Investigation on Tensile Property and Constitutive Relationship for As-Quenched Al-5%Cu-0.4%Mn Alloy; Springer International Publishing: Cham, Switzerland, 2015; pp. 963–970. [Google Scholar]

- Xu, D.; Chen, K.; Chen, Y.; Chen, S. Evolution of the Second-Phase Particles and Their Effect on Tensile Fracture Behavior of 2219 Al-xCu Alloys. Metals 2020, 10, 197. [Google Scholar] [CrossRef]

| Cu | Mn | Ti | Fe | Al |

|---|---|---|---|---|

| 4.14 | 0.38 | 0.26 | 0.24 | Balance |

| Solution Treatment | Ageing Treatment | |

|---|---|---|

| T/°C | t/h | |

| 538 °C × 15 h | 155 °C | 4 h, 6 h, 8 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, H.; Zhang, L.; Zhao, B.; Sun, M.; He, M. Microstructure and Mechanical Properties of ZL205A Aluminum Alloy Produced by Squeeze Casting after Heat Treatment. Metals 2022, 12, 2037. https://doi.org/10.3390/met12122037

Jiang H, Zhang L, Zhao B, Sun M, He M. Microstructure and Mechanical Properties of ZL205A Aluminum Alloy Produced by Squeeze Casting after Heat Treatment. Metals. 2022; 12(12):2037. https://doi.org/10.3390/met12122037

Chicago/Turabian StyleJiang, Hong, Linfan Zhang, Biwei Zhao, Ming Sun, and Meifeng He. 2022. "Microstructure and Mechanical Properties of ZL205A Aluminum Alloy Produced by Squeeze Casting after Heat Treatment" Metals 12, no. 12: 2037. https://doi.org/10.3390/met12122037

APA StyleJiang, H., Zhang, L., Zhao, B., Sun, M., & He, M. (2022). Microstructure and Mechanical Properties of ZL205A Aluminum Alloy Produced by Squeeze Casting after Heat Treatment. Metals, 12(12), 2037. https://doi.org/10.3390/met12122037