Correlation between Precipitation and Recrystallisation during Stress Relaxation in Titanium Microalloyed Steel

Abstract

1. Introduction

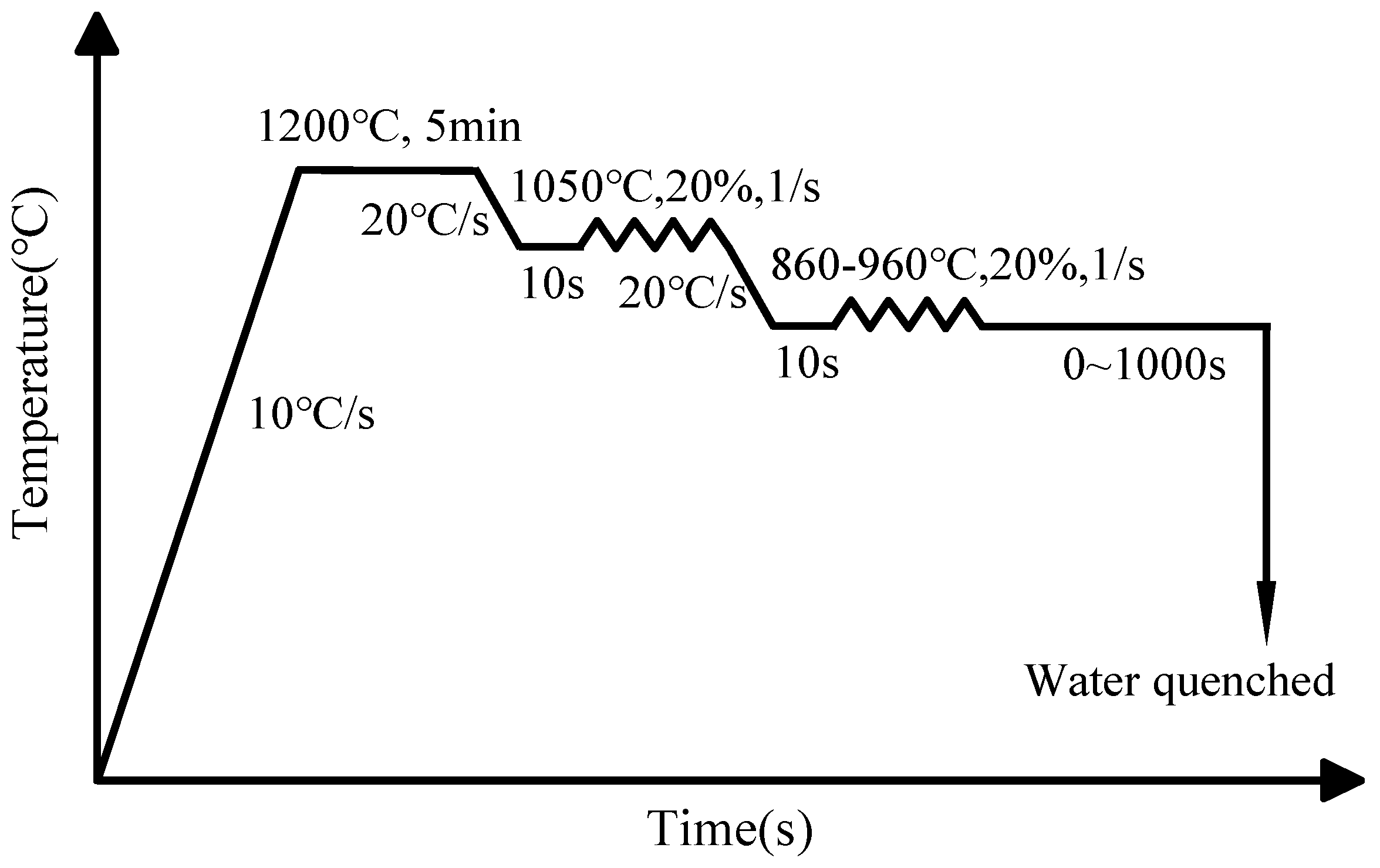

2. Materials and Methods

3. Results

3.1. Stress Relaxation Curves

3.2. PTT Curve

3.3. TEM Analysis of Precipitated Particles

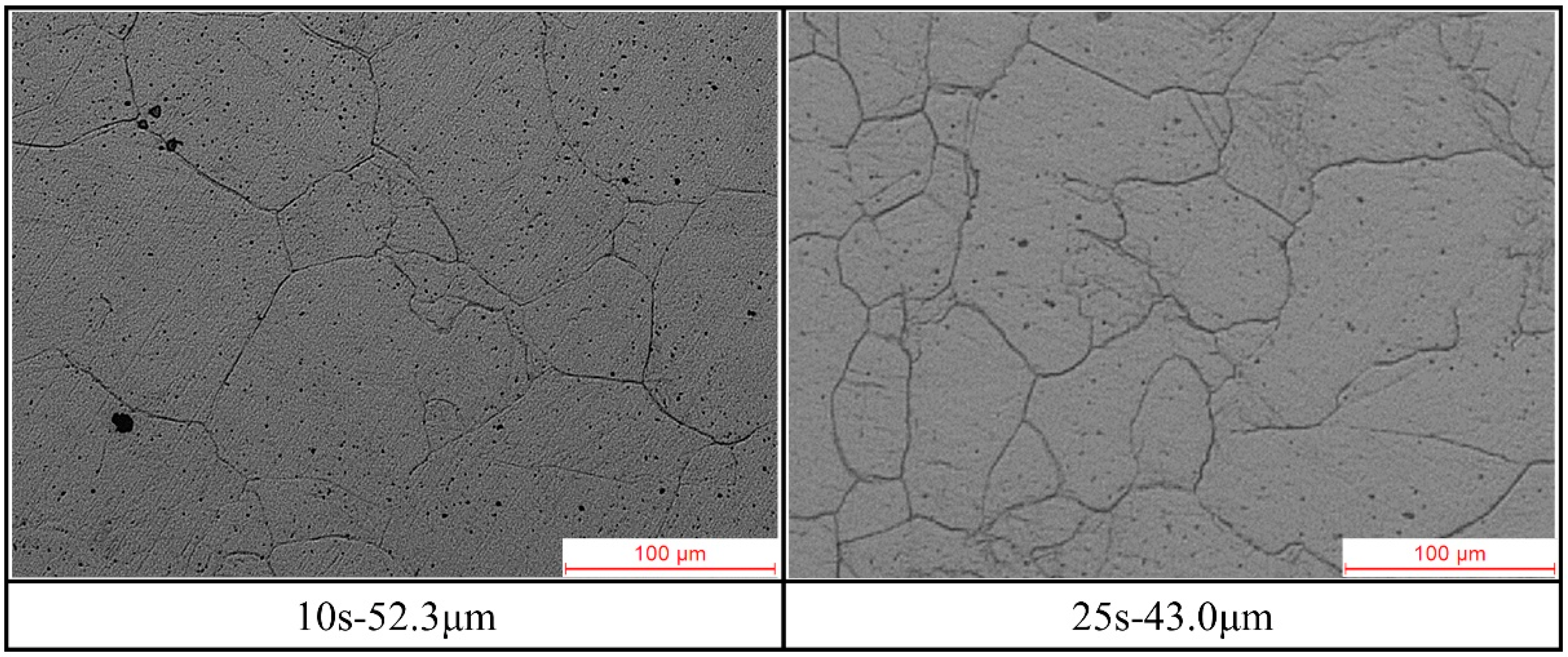

3.4. Evolution of Austenitic Microstructure

4. Discussion

4.1. Recrystallization-Precipitation-Time-Temperature Curve

4.2. Recrystallization driving Force FR and Precipitation Pinning Force FP

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Villalobos, J.C.; Del-Pozo, A.; Campillo, B.; Mayen, J.; Serna, S. Microalloyed Steels through History until 2018: Review of Chemical Composition, Processing and Hydrogen Service. Metals 2018, 8, 351. [Google Scholar] [CrossRef]

- Nasiri, Z.; Ghaemifar, S.; Naghizadeh, M.; Mirzadeh, H. Thermal Mechanisms of Grain Refinement in Steels: A Review. Met. Mater. Int. 2021, 27, 2078–2094. [Google Scholar] [CrossRef]

- Vervynckt, S.; Verbeken, K.; Lopez, B.; Jonas, J.J. Modern HSLA steels and role of non-recrystallisation temperature. Int. Mater. Rev. 2012, 57, 187–207. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, Z. Thermomechanical processing of advanced high strength steels. Prog. Mater. Sci. 2018, 94, 174–242. [Google Scholar]

- Kyzioł, K.; Kluska, S.; Januś, M.; Środa, M.; Jastrzębski, W.; Kaczmarek, L. Chemical composition and selected mechanical properties of Al–Zn alloy modified in plasma conditions by RF CVD. Appl. Surf. Sci. 2014, 311, 33–39. [Google Scholar] [CrossRef]

- Huo, X.; Xia, J.; Li, L.; Peng, Z.; Chen, S.; Peng, C. A review of research and development on titanium microalloyed high strength steels. Mater. Res. Express 2018, 5, 062002. [Google Scholar] [CrossRef]

- Xia, J.; Huo, X.; Li, L.; Peng, Z.; Chen, S. Development of Ti microalloyed high strength steel plate by controlling thermo-mechanical control process schedule. Mater. Res. Express 2017, 4, 126504. [Google Scholar] [CrossRef]

- Mao, X.; Huo, X.; Sun, X. Strengthening mechanisms of a new 700 MPa hot rolled Ti-microalloyed steel produced by compact strip production. J. Mater. Process. Technol. 2010, 210, 1660–1666. [Google Scholar] [CrossRef]

- Zhang, K.; Li, Z.; Sun, X.; Yong, Q.; Yang, J.; Li, Y.; Zhao, P. Development of Ti–V–Mo Complex Microalloyed Hot-Rolled 900-MPa-Grade High-Strength Steel. Acta Metall. Sin. 2015, 28, 641–648. [Google Scholar] [CrossRef]

- Larzabal, G.; Isasti, N.; Rodriguez-Ibabe, J.M.; Uranga, P. Evaluating Strengthening and Impact Toughness Mechanisms for Ferritic and Bainitic Microstructures in Nb, Nb-Mo and Ti-Mo Microalloyed Steels. Metals 2017, 7, 65. [Google Scholar] [CrossRef]

- Huo, X.; Li, L.; Peng, Z.; Chen, S. Effects of TMCP Schedule on Precipitation, Microstructure and Properties of Ti-microalloyed High Strength Steel. J. Iron. Steel Res. Int. 2016, 23, 593–601. [Google Scholar] [CrossRef]

- Zaitsev, A.; Arutyunyan, N. Low-Carbon Ti-Mo Microalloyed Hot Rolled Steels: Special Features of the Formation of the Structural State and Mechanical Properties. Metals 2021, 11, 1584. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, H.; Yang, Z.; Jiang, F. Decelerated Coarsening of (Ti, Mo)C Particles with a Core–Shell Structure in Austenite of a Ti-Mo-Bearing Steel. Metall. Mater. Trans. A 2018, 49, 1455–1459. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, X.; Yang, Z.; Yong, Q.; Zhang, C.; Li, Z.; Weng, Y. Carbide precipitation in austenite of a Ti–Mo-containing low-carbon steel during stress relaxation. Mater. Sci. Eng. A 2013, 573, 84–91. [Google Scholar] [CrossRef]

- Funakawa, Y.; Shiozaki, T.; Tomita, K.; Yamamoto, T.; Maeda, E. Development of High Strength Hot-rolled Sheet Steel Consisting of Ferrite and Nanometer-sized Carbides. ISIJ Int. 2004, 44, 1945–1951. [Google Scholar] [CrossRef]

- Andrade, H.L.; Akben, M.G.; Jonas, J.J. Effect of molybdenum, niobium, and vanadium on static recovery and recrystallization and on solute strengthening in microalloyed steels. Metall. Trans. A 1983, 14, 1967–1977. [Google Scholar] [CrossRef]

- Wang, Z.; Mao, X.; Yang, Z.; Sun, X.; Yong, Q.; Li, Z.; Weng, Y. Strain-induced precipitation in a Ti micro-alloyed HSLA steel. Mater. Sci. Eng. A 2011, 529, 459–467. [Google Scholar] [CrossRef]

- Liu, W.J.; Jonas, J.J. A stress relaxation method for following carbonitride precipitation in austenite at hot working temperatures. Metall. Trans. A 1988, 19, 1403–1413. [Google Scholar] [CrossRef]

- Chen, S.; Li, L.; Peng, Z.; Huo, X.; Gao, J. Strain-induced precipitation in Ti microalloyed steel by two-stage controlled rolling process. J. Mater. Res. Technol. 2020, 9, 15759–15770. [Google Scholar] [CrossRef]

- Huo, X.; Lv, Z.; Ao, C.; Li, L.; Xia, J.; Chen, S. Effect of strain-induced precipitation on microstructure and properties of titanium micro-alloyed steels. J. Iron Steel Res. Int. 2022, 29, 983–993. [Google Scholar] [CrossRef]

- Jung, J.-G.; Park, J.-S.; Kim, J.; Lee, Y.-K. Carbide precipitation kinetics in austenite of a Nb–Ti–V microalloyed steel. Mater. Sci. Eng. A 2011, 528, 5529–5535. [Google Scholar] [CrossRef]

- Liu, W.J. A Review of the Stress-Relaxation Method for Following the Kinetics of Precipitation, Recovery and Recrystallization. Mater. Sci. Forum 2012, 706–709, 2758–2763. Available online: www.scientific.net/MSF.706-709.2758 (accessed on 1 November 2022).

- Kwon, O.; DeArdo, A.J. Interactions between recrystallization and precipitation in hot-deformed microalloyed steels. Acta Metall. Mater. 1991, 39, 529–538. [Google Scholar] [CrossRef]

- Medina, S.F.; Quispe, A. Static Recrystallisation-Precipitation Interaction in Microalloyed Steels. Mater. Sci. Forum 2003, 426–432, 1139–1144. Available online: www.scientific.net/MSF.426-432.1139 (accessed on 1 November 2022).

- Jian, Z.; Kang, Y.; Mao, X.; Lin, Z.; Li, L. Effect of Ti on the mechanical properties of high strength weathering steel. J. Univ. Sci. Technol. B 2006, 28, 926–930. [Google Scholar]

- Yang, Z.; Enomoto, M. Calculation of the interfacial energy of B1-type carbides and nitrides with austenite. Metall. Mater. Trans. A 2001, 32, 267–274. [Google Scholar] [CrossRef]

- Fujiyama, N.; Nishibata, T.; Seki, A.; Hirata, H.; Kojima, K.; Ogawa, K. Austenite grain growth simulation considering the solute-drag effect and pinning effect. Sci. Technol. Adv. Mater. 2017, 18, 88–95. [Google Scholar] [CrossRef]

- Goins, P.E.; Frazier, W.E. A model of grain boundary complexion transitions and grain growth in Yttria-doped alumina. Acta Mater. 2020, 188, 79–91. [Google Scholar] [CrossRef]

- Gong, P.; Palmiere, E.J.; Rainforth, W.M. Characterisation of strain-induced precipitation behaviour in microalloyed steels during thermomechanical controlled processing. Mater. Charact. 2017, 124, 83–89. [Google Scholar] [CrossRef]

- Medina, S.; Quispe, A. Improved Model for Static Recrystallization Kinetics of Hot Deformed Austenite in Low Alloy and Nb/V Microalloyed Steels. ISIJ Int. 2001, 41, 774–781. [Google Scholar] [CrossRef]

- Gómez, M.; Rancel, L.; Fernández, B.J.; Medina, S.F. Evolution of austenite static recrystallization and grain size during hot rolling of a V-microalloyed steel. Mater. Sci. Eng. A 2009, 501, 188–196. [Google Scholar] [CrossRef]

- Beck, P.A.; Sperry, P.R.; Hu, H. The Orientation Dependence of the Rate of Grain Boundary Migration. J. Appl. Phys. 1950, 21, 420–425. [Google Scholar] [CrossRef]

- Gómez, M.; Medina, S.F.; Chaves, J.I. Static Recrystallization of Austenite in a Medium-Carbon Vanadium Microalloyed Steel and Inhibition by Strain-Induced Precipitates. Mater. Sci. Forum 2007, 550, 417–422. Available online: www.scientific.net/MSF.550.417 (accessed on 1 November 2022).

- Zener, C. Theory of Growth of Spherical Precipitates from Solid Solution. J. Appl. Phys. 1949, 20, 950–953. [Google Scholar] [CrossRef]

- Vervynckt, S.; Verbeken, K.; Thibaux, P.; Houbaert, Y. Recrystallization–precipitation interaction during austenite hot deformation of a Nb microalloyed steel. Mater. Sci. Eng. A 2011, 528, 5519–5528. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | S | P | N | Ti | dγ |

|---|---|---|---|---|---|---|---|---|

| Ti | 0.061 | 0.28 | 1.61 | 0.047 | 0.0030 | 0.0029 | 0.11 | 58 |

| Xr | 860 °C | 880 °C | 900 °C | 920 °C | 940 °C | 960 °C |

|---|---|---|---|---|---|---|

| 5% | 66.8 | 43.3 | 28.5 | 19.0 | 12.8 | 8.8 |

| 50% | 152.6 | 97.1 | 62.7 | 41.1 | 27.4 | 18.4 |

| 75% | 372.3 | 232.1 | 147.1 | 94.7 | 61.9 | 41.1 |

| Parameter | fe | C | q |

|---|---|---|---|

| Value | 0.0013 | 0.0070 | 1.3395 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Huo, X.; Li, L.; Chen, S.; Lu, C. Correlation between Precipitation and Recrystallisation during Stress Relaxation in Titanium Microalloyed Steel. Metals 2022, 12, 1920. https://doi.org/10.3390/met12111920

Zhang Q, Huo X, Li L, Chen S, Lu C. Correlation between Precipitation and Recrystallisation during Stress Relaxation in Titanium Microalloyed Steel. Metals. 2022; 12(11):1920. https://doi.org/10.3390/met12111920

Chicago/Turabian StyleZhang, Qifan, Xiangdong Huo, Liejun Li, Songjun Chen, and Chao Lu. 2022. "Correlation between Precipitation and Recrystallisation during Stress Relaxation in Titanium Microalloyed Steel" Metals 12, no. 11: 1920. https://doi.org/10.3390/met12111920

APA StyleZhang, Q., Huo, X., Li, L., Chen, S., & Lu, C. (2022). Correlation between Precipitation and Recrystallisation during Stress Relaxation in Titanium Microalloyed Steel. Metals, 12(11), 1920. https://doi.org/10.3390/met12111920