Impact of Cooling Rate during High-Pressure Gas Quenching on Fatigue Performance of Low Pressure Carburized Gears

Abstract

1. Introduction

2. Materials and Methods

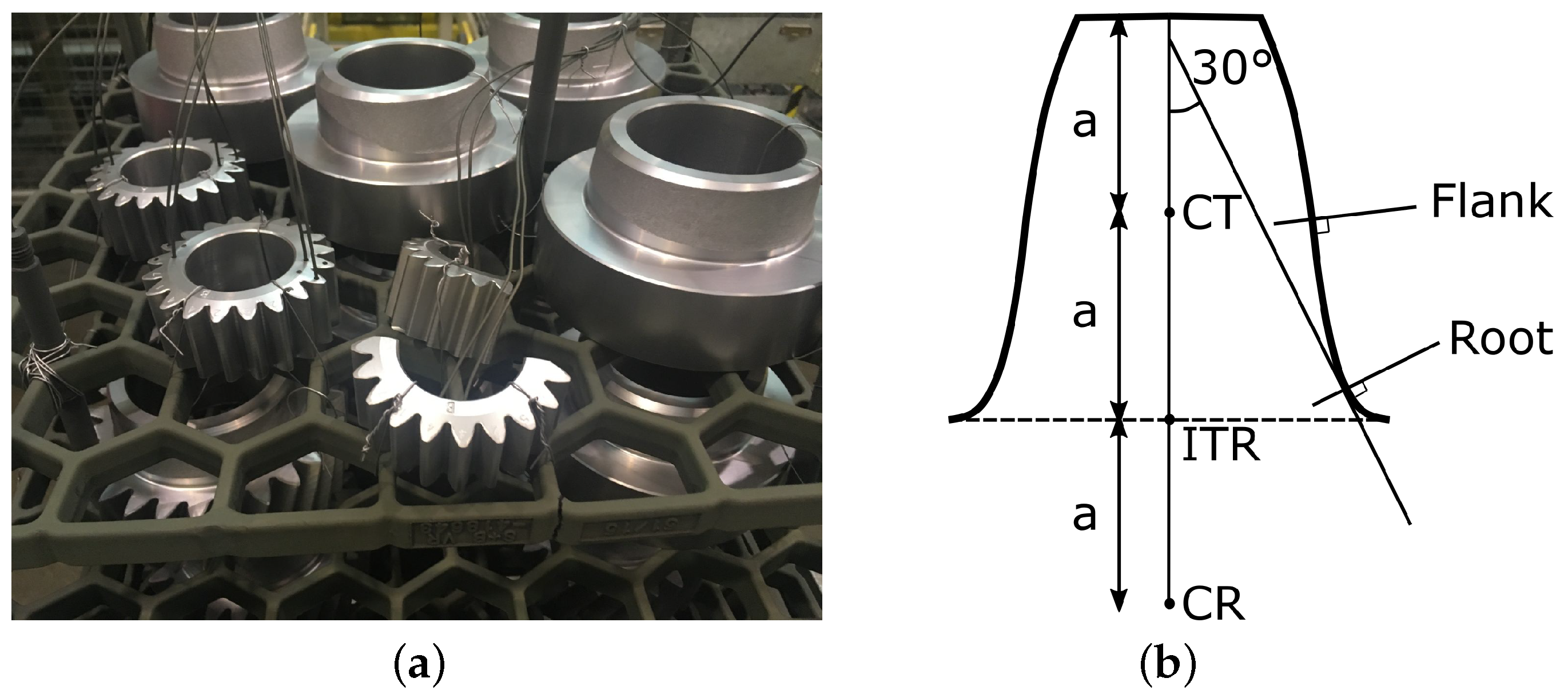

2.1. Heat Treatment and Quenching

2.2. Characterization

3. Results

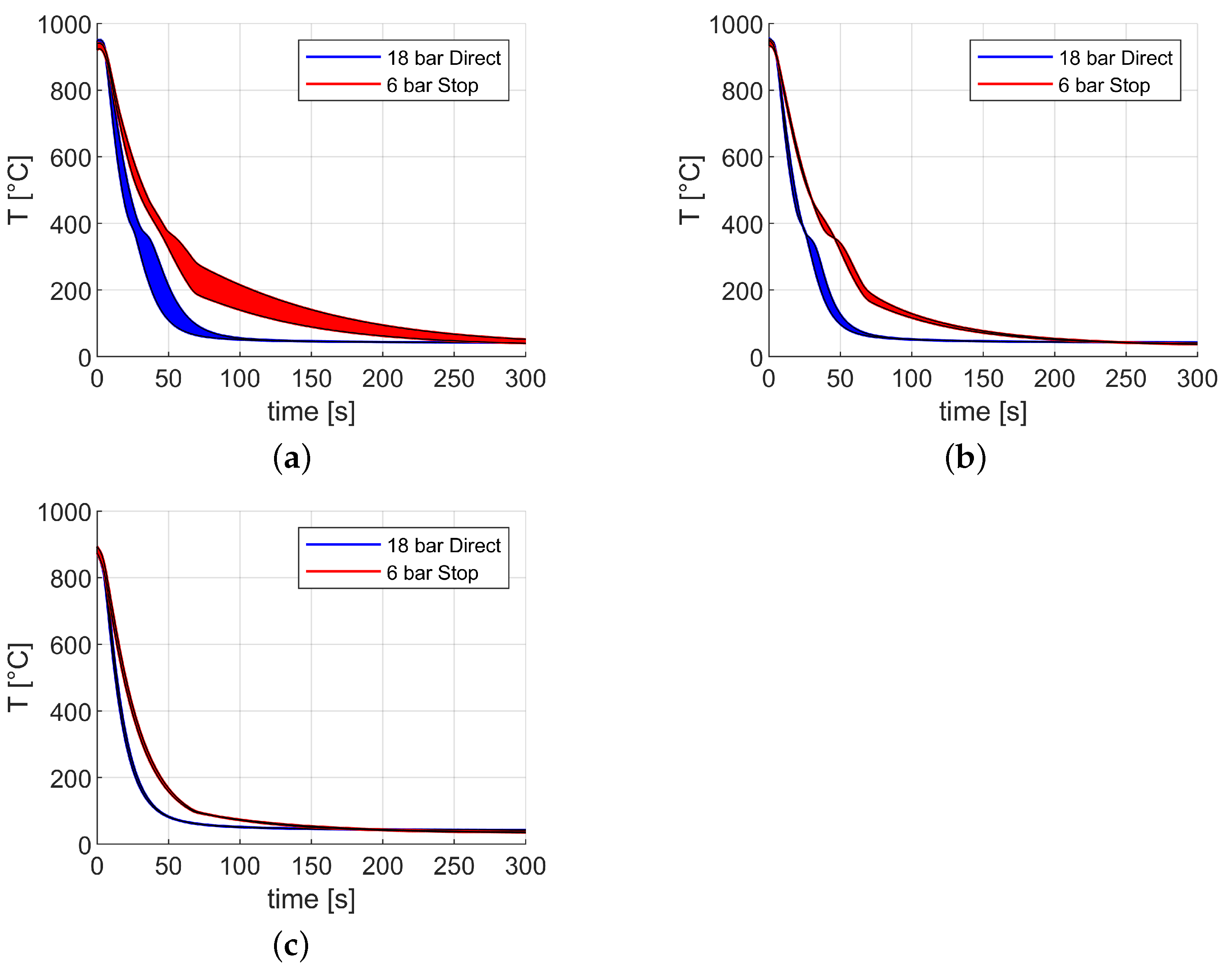

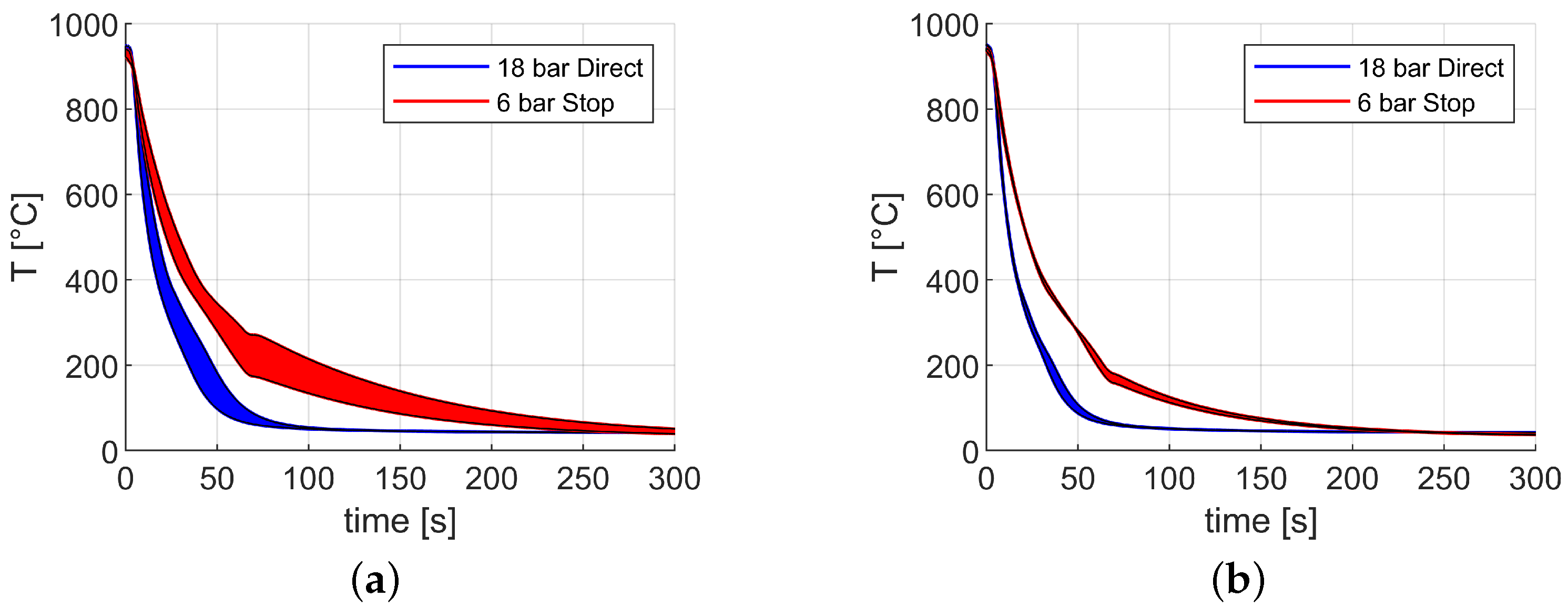

3.1. Quenching

3.2. Characterization

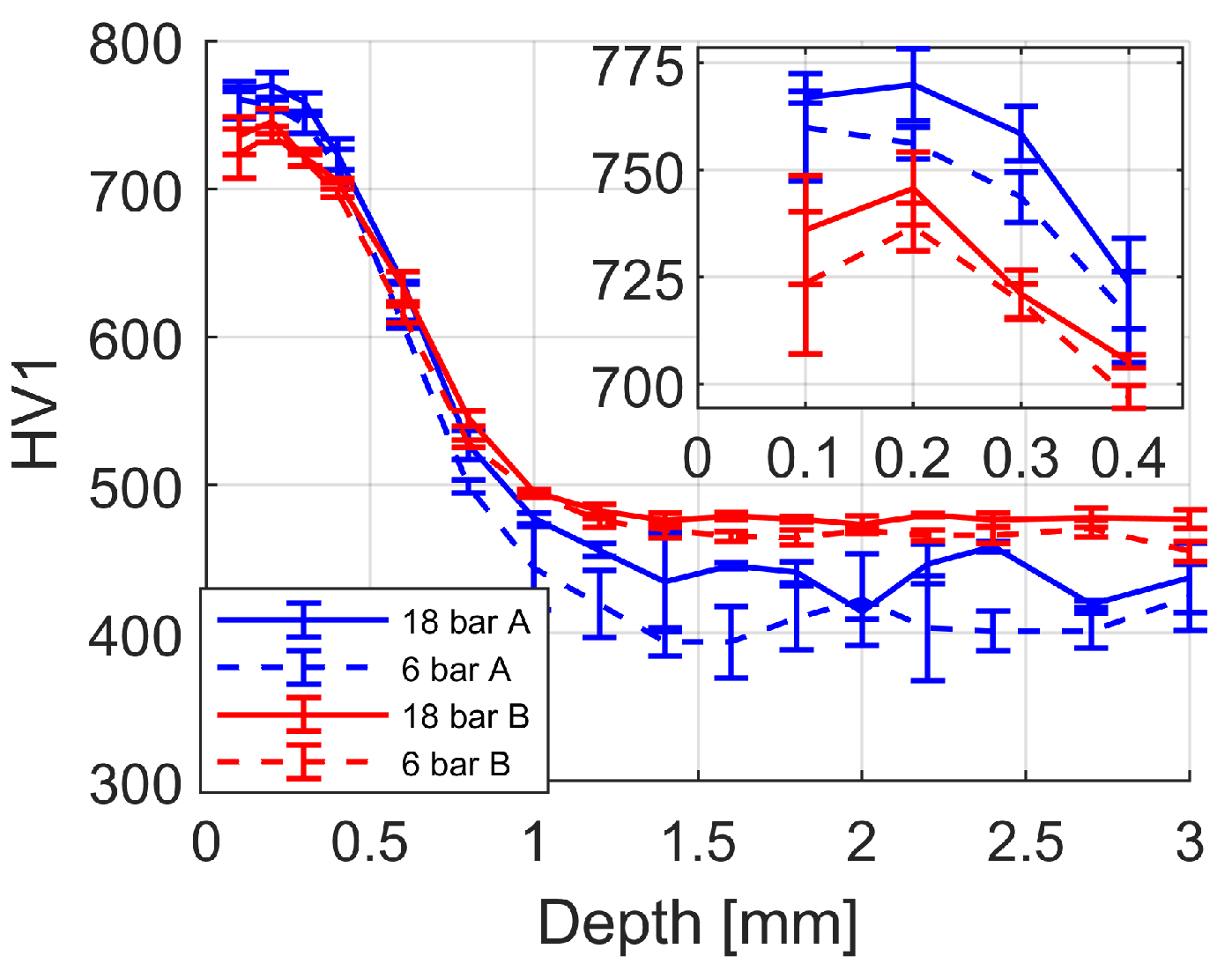

3.2.1. Hardness

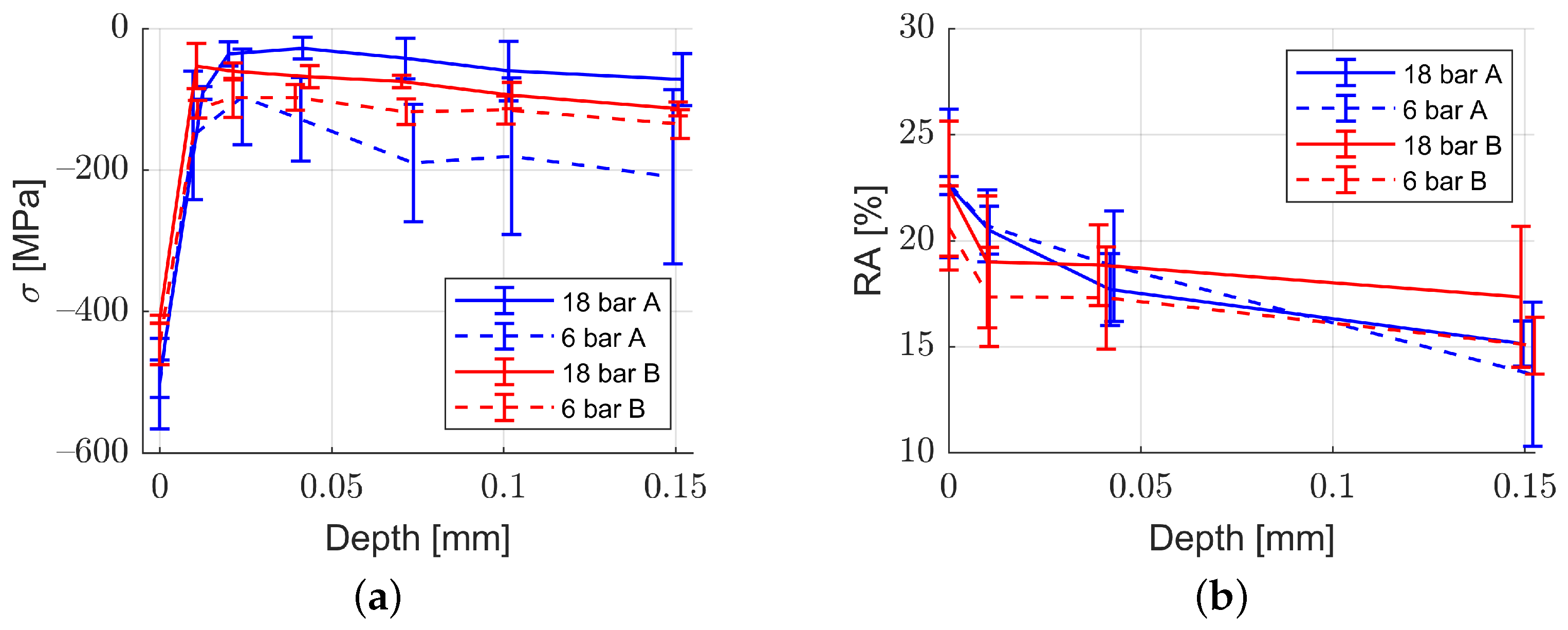

3.2.2. Residual Stress and Retained Austenite

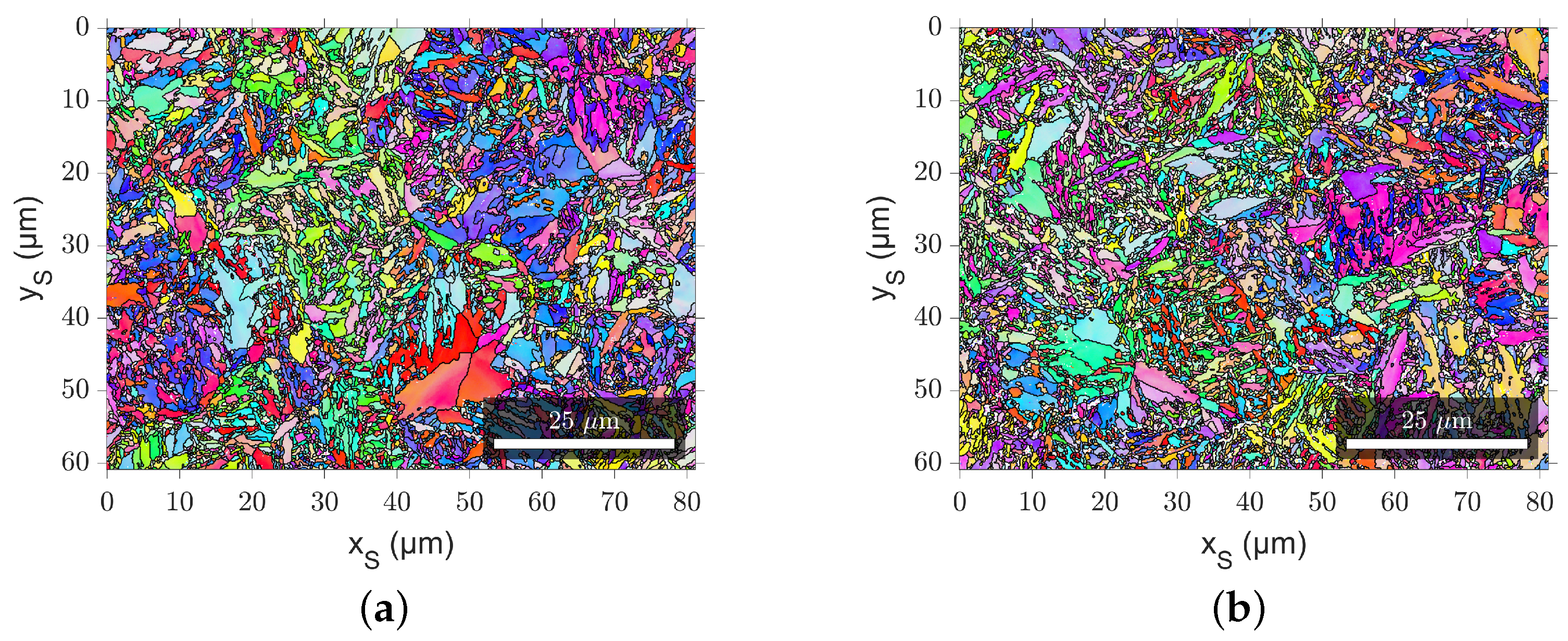

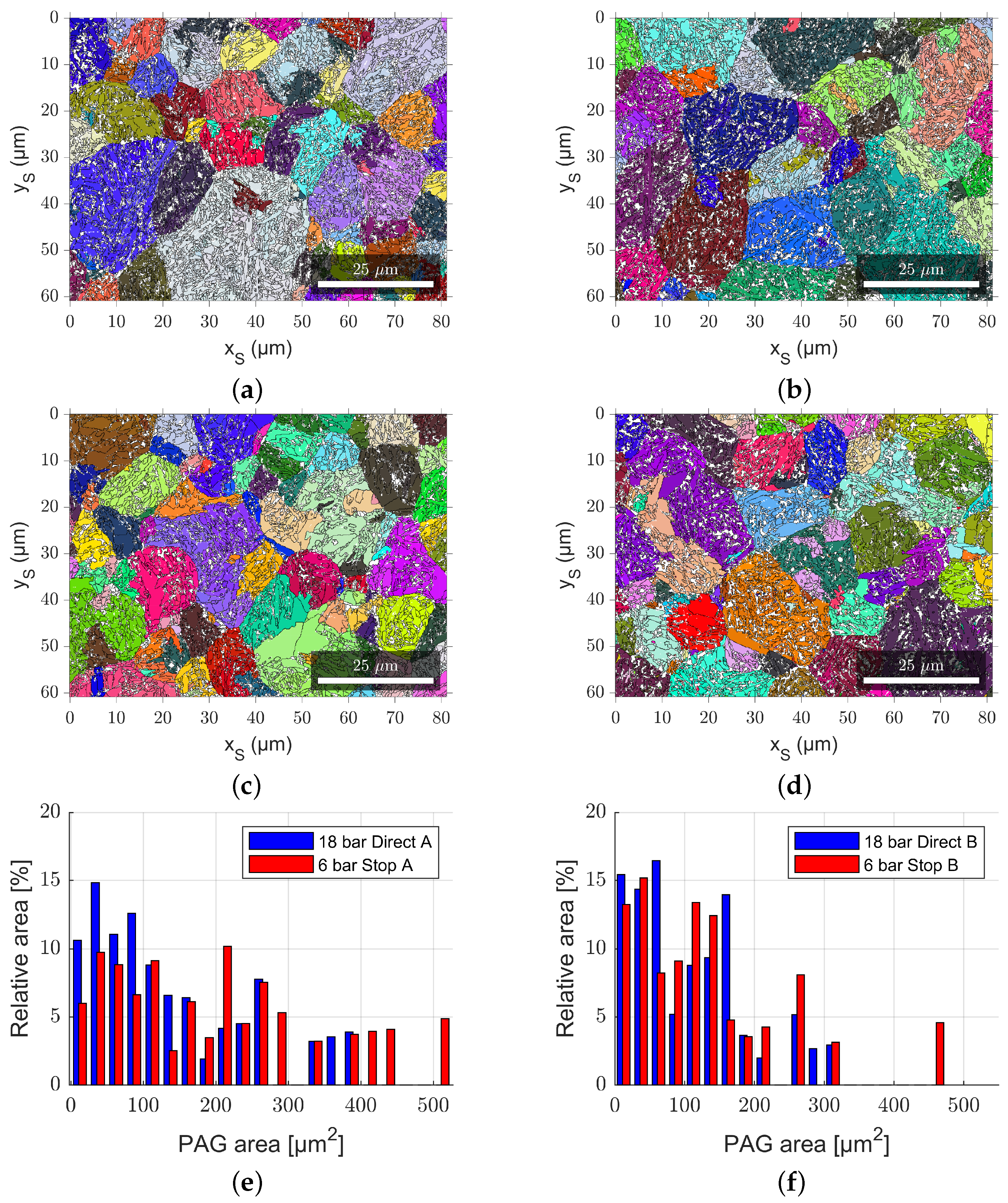

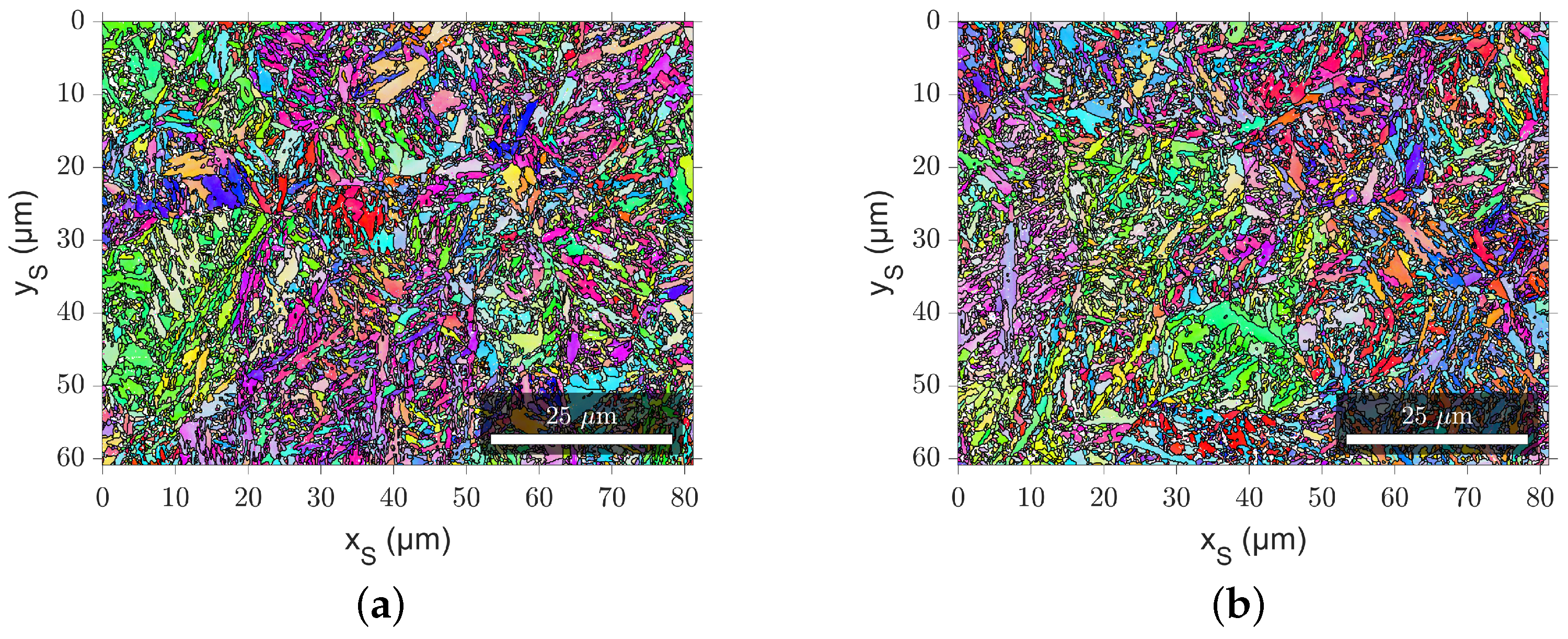

3.2.3. Microstructure

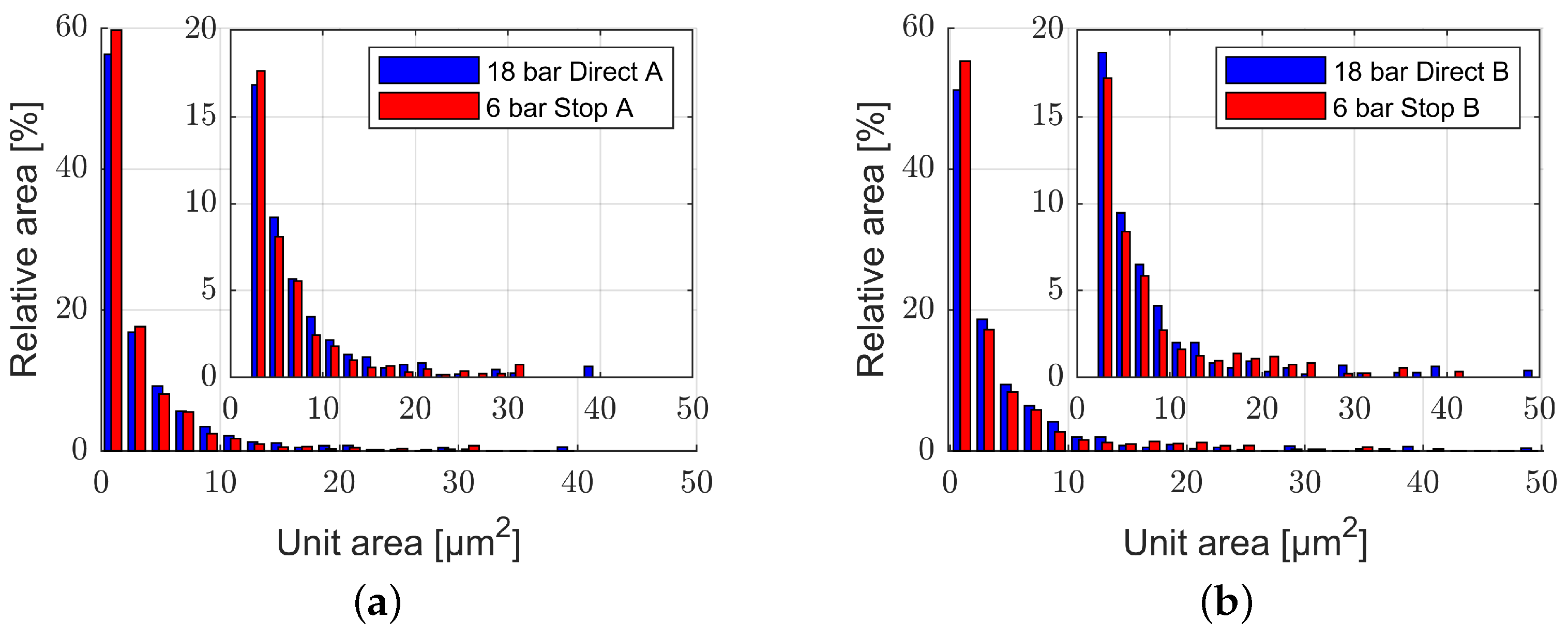

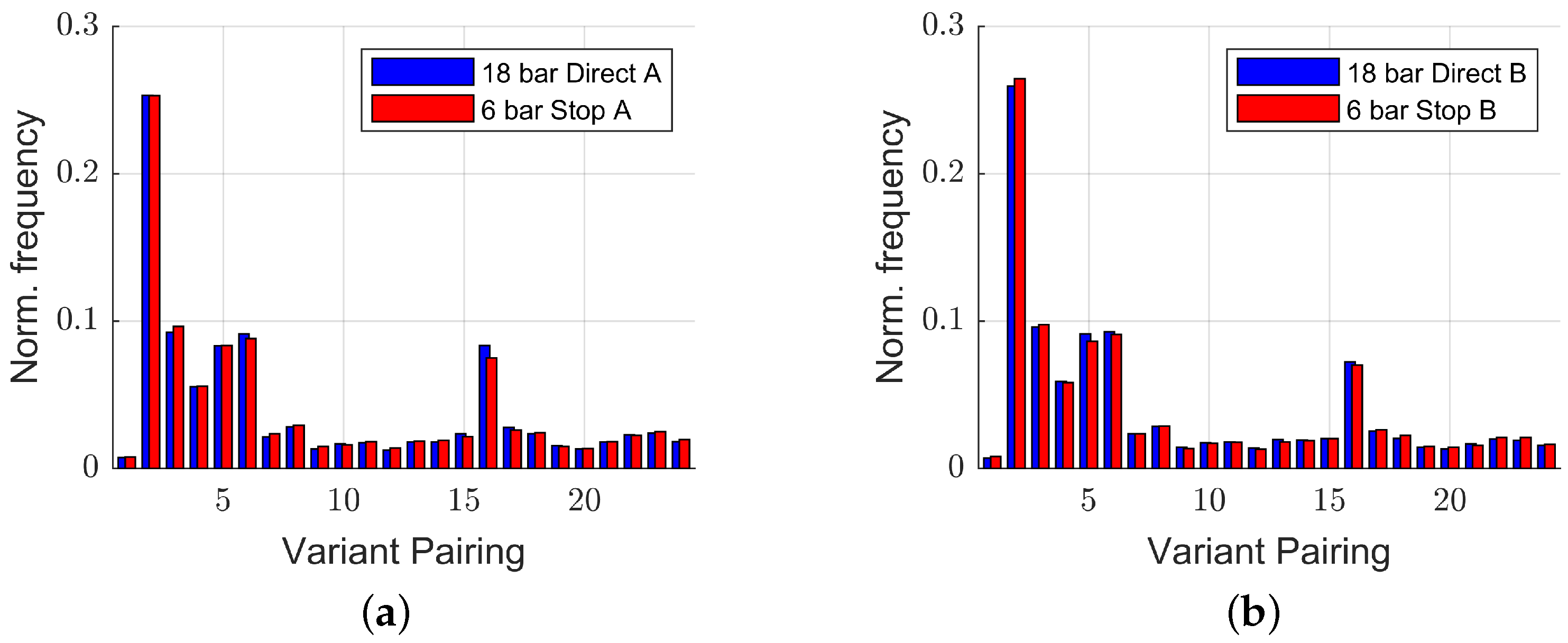

Statistical Analysis

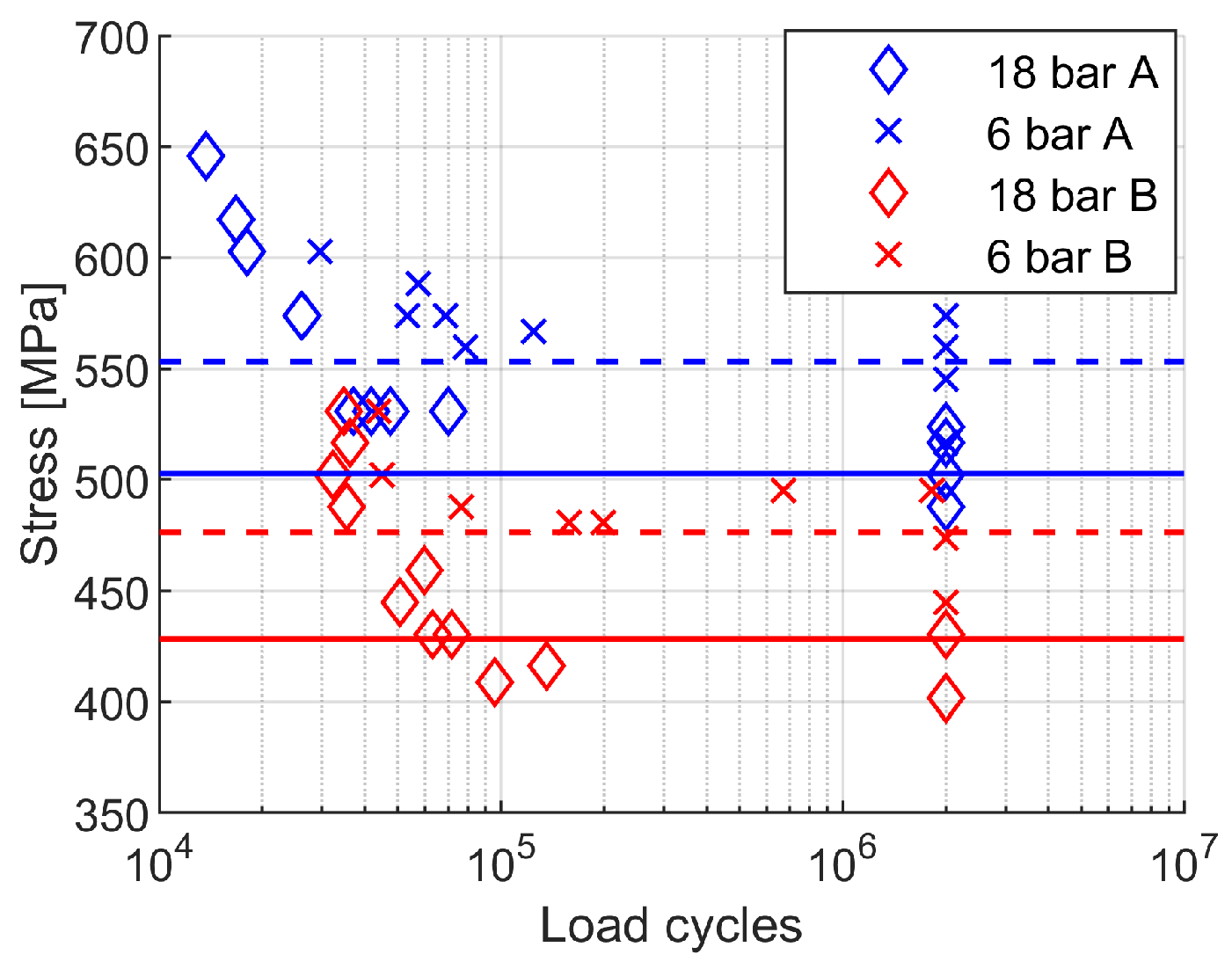

3.2.4. High-Cycle Fatigue

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Quenching

Appendix B. Microstructure

References

- Albertini, G.; Bruno, G.; Fiori, F.; Marcantoni, M.; Quadrini, E.; Turquier, F. Residual stresses in case hardened automotive steel gears. In Materials Science Forum; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2002; Volume 404, pp. 191–196. [Google Scholar]

- Lingamanaik, S.; Chen, B. The effects of carburising and quenching process on the formation of residual stresses in automotive gears. Comput. Mater. Sci. 2012, 62, 99–104. [Google Scholar] [CrossRef]

- Heuer, V.; Loeser, K.; Schmitt, G. Improved Materials and Enhanced Fatigue Resistance for Gear Components. In Proceedings of the Fall Technical Meeting, Detroit, MI, USA, 18–20 October 2015; American Gear Manufacturers Association: Alexandria, VA, USA, 2015. [Google Scholar]

- Stratton, P.; Bruce, S.; Cheetham, V. Low-pressure carburizing systems: A review of current technology. BHM Berg-Und Hüttenmänn. Monatshefte 2006, 151, 451–456. [Google Scholar] [CrossRef]

- Since, J.; Irretier, O. Vacuum heat treatment and high pressure gas quenching—Aspects in distortion control. Heat Process. 2010, 8, 1–10. [Google Scholar]

- Fahlkrans, J.; Melander, A.; Haglund, S. Gas quench rate ater low pressure carburizing and its inluence on fatigue properties of gears. HTM—J. Heat Treat. Mater. 2013, 68, 239–245. [Google Scholar] [CrossRef]

- Heuer, V.; Löser, K.; Faron, D.; Bolton, D. Low distortion heat treatment of transmission components. AGMA Tech. Pap. 2010, 3–16. [Google Scholar]

- Burkart, K.; Bomas, H.; Zoch, H.W. Fatigue of notched case-hardened specimens of steel SAE 5120 in the VHCF regime and application of the weakest-link concept. Int. J. Fatigue 2011, 33, 59–68. [Google Scholar] [CrossRef]

- Wei, P.; Zhou, H.; Liu, H.; Zhu, C.; Wang, W.; Deng, G. Modeling of contact fatigue damage behavior of a wind turbine carburized gear considering its mechanical properties and microstructure gradients. Int. J. Mech. Sci. 2019, 156, 283–296. [Google Scholar] [CrossRef]

- Wise, J.; Matlock, D. Bending fatigue of carburized steels: A statistical analysis of process and microstructural parameters. SAE Trans. 2000, 109, 182–191. [Google Scholar]

- Shaw, B.; Aylott, C.; O’hara, P.; Brimble, K. The role of residual stress on the fatigue strength of high performance gearing. Int. J. Fatigue 2003, 25, 1279–1283. [Google Scholar] [CrossRef]

- Li, Z.; Freborg, A.; Hansen, B.; Srivatsan, T. Modeling the effect of carburization and quenching on the development of residual stresses and bending fatigue resistance of steel gears. J. Mater. Eng. Perform. 2013, 22, 664–672. [Google Scholar] [CrossRef]

- Genel, K.; Demirkol, M. Effect of case depth on fatigue performance of AISI 8620 carburized steel. Int. J. Fatigue 1999, 21, 207–212. [Google Scholar] [CrossRef]

- Ramasamy, R.; Sivathanu, S.; Neelakandan, V.; Ganesan, T.; Rao, P. Influence of Retained Austenite on Fatigue Performance of Carburized Gears; Technical Report; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Da Silva, V.; Canale, L.; Spinelli, D.; Bose-Filho, W.; Crnkovic, O. Influence of retained austenite on short fatigue crack growth and wear resistance of case carburized steel. J. Mater. Eng. Perform. 1999, 8, 543–548. [Google Scholar] [CrossRef]

- Pacheco, J.; Krauss, G. Microstructure and high bending fatigue strength in carburized steel. J. Heat Treat. 1989, 7, 77–86. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Höhn, B.R.; Oster, P.; Tobie, T. Influence of shot peening on bending tooth fatigue limit of case hardened gears. Int. J. Fatigue 2002, 24, 1127–1136. [Google Scholar] [CrossRef]

- Krantz, T.; Alanou, M.; Evans, H.; Snidle, R. Surface fatigue lives of case-carburized gears with an improved surface finish. J. Trib. 2001, 123, 709–716. [Google Scholar] [CrossRef]

- Lin, H.; Fett, G.; Binoniemi, R.; Sanders, J.; Matlock, D.; Krauss, G. Investigation of SN test data scatter of carburized 4320 steel. SAE Trans. 2007, 116, 379–391. [Google Scholar]

- Kato, M.; Deng, G.; Inoue, K.; Takatsu, N. Evaluation of the strength of carburized spur gear teeth based on fracture mechanics. JSME Int. J. Ser. C Dyn. Control Robot. Des. Manuf. 1993, 36, 233–240. [Google Scholar] [CrossRef]

- Hyde, R.; Krauss, G.; Matlock, D. Phosphorus and carbon segregation: Effects on fatigue and fracture of gas-carburized modified 4320 steel. Metall. Mater. Trans. A 1994, 25, 1229–1240. [Google Scholar] [CrossRef]

- Brobst, R.; Krauss, G. The effect of austenite grain size on microcracking in martensite of an Fe-1.22 C alloy. Metall. Trans. 1974, 5, 457–462. [Google Scholar] [CrossRef]

- Apple, C.; Krauss, G. Microcracking and fatigue in a carburized steel. Metall. Trans. 1973, 4, 1195–1200. [Google Scholar] [CrossRef]

- EN 15305; Non-Destructive Testing—Test Method for Residual Stress Analysis by X-ray Diffraction. European Committee for Standardization: Brussels, Belgium, 2008.

- ASTM E975-13; Standard Practice for X-ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation. ASTM International: West Conshohocken, PA, USA, 2013.

- Bachmann, F.; Hielscher, R.; Schaeben, H. Grain detection from 2d and 3d EBSD data—Specification of the MTEX algorithm. Ultramicroscopy 2011, 111, 1720–1733. [Google Scholar] [CrossRef] [PubMed]

- Nyyssönen, T.; Isakov, M.; Peura, P.; Kuokkala, V. Iterative determination of the orientation relationship between austenite and martensite from a large amount of grain pair misorientations. Metall. Mater. Trans. A 2016, 47, 2587–2590. [Google Scholar] [CrossRef]

- Morito, S.; Tanaka, H.; Konishi, R.; Furuhara, T.; Maki, T. The morphology and crystallography of lath martensite in Fe-C alloys. Acta Mater. 2003, 51, 1789–1799. [Google Scholar] [CrossRef]

- Stormvinter, A.; Miyamoto, G.; Furuhara, T.; Hedström, P.; Borgenstam, A. Effect of carbon content on variant pairing of martensite in Fe–C alloys. Acta Mater. 2012, 60, 7265–7274. [Google Scholar] [CrossRef]

- Spindel, J.; Haibach, E. The method of maximum likelihood applied to the statistical analysis of fatigue data. Int. J. Fatigue 1979, 1, 81–88. [Google Scholar] [CrossRef]

- Grange, R. Estimating the hardenability of carbon steels. Metall. Trans. 1973, 4, 2231–2244. [Google Scholar] [CrossRef]

- Funatani, K. Residual Stress and Fatigue Strength of Carburized Steels and Gears; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2001. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Bocher, P.; Zhu, C.; Sun, Z. Effects of case hardening properties on the contact fatigue of a wind turbine gear pair. Int. J. Mech. Sci. 2018, 141, 520–527. [Google Scholar] [CrossRef]

- Bai, H.; Zhu, C.; Zhou, Y.; Chen, X.; Feng, H.; Ye, W. Study on tooth interior fatigue fracture failure of wind turbine gears. Metals 2020, 10, 1497. [Google Scholar] [CrossRef]

- Kohne, T.; Fahlkrans, J.; Stormvinter, A.; Maawad, E.; Winkelmann, A.; Hedström, P.; Borgenstam, A. Evolution of martensite tetragonality in high carbon steels revealed by in situ high energy X-ray diffraction. 2022; unpublished work. [Google Scholar]

- Sherman, D.; Cross, S.; Kim, S.; Grandjean, F.; Long, G.; Miller, M. Characterization of the carbon and retained austenite distributions in martensitic medium carbon, high silicon steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2007, 38, 1698–1711. [Google Scholar] [CrossRef]

- Clarke, A.; Klemm-Toole, J.; Clarke, K.; Coughlin, D.; Pierce, D.; Euser, V.; Poplawsky, J.; Clausen, B.; Brown, D.; Almer, J.; et al. Perspectives on quenching and tempering 4340 steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 4984–5005. [Google Scholar] [CrossRef]

- Kohne, T.; Dahlström, A.; Winkelmann, A.; Hedström, P.; Borgenstam, A. Correlation of Heterogeneous Local Martensite Tetragonality and Carbon Distribution in a High Carbon Steel. Materials 2022, 15, 6653. [Google Scholar] [CrossRef]

- Ohmori, Y.; Sugisawa, S. The precipitation of carbides during tempering of high carbon martensite. Trans. Jpn. Inst. Met. 1971, 12, 170–178. [Google Scholar] [CrossRef]

- Speich, G.; Leslie, W. Tempering of steel. Metall. Trans. 1972, 3, 1043–1054. [Google Scholar] [CrossRef]

- Waterschoot, T.; Verbeken, K.; De Cooman, D. Tempering kinetics of the martensitic phase in DP steel. ISIJ Int. 2006, 46, 138–146. [Google Scholar] [CrossRef]

- Van Bohemen, S.; Sietsma, J. Kinetics of martensite formation in plain carbon steels: Critical assessment of possible influence of austenite grain boundaries and autocatalysis. Mater. Sci. Technol. 2014, 30, 1024–1033. [Google Scholar] [CrossRef]

- Hou, Z.; Hedström, P.; Xu, Y.; Di, W.; Odqvist, J. Microstructure of martensite in Fe–C–Cr and its implications for modelling of carbide precipitation during tempering. ISIJ Int. 2014, 54, 2649–2656. [Google Scholar] [CrossRef]

- Morsdorf, L.; Tasan, C.; Ponge, D.; Raabe, D. 3D structural and atomic-scale analysis of lath martensite: Effect of the transformation sequence. Acta Mater. 2015, 95, 366–377. [Google Scholar] [CrossRef]

- Borgenstam, A.; Hillert, M. Driving force for fcc → bcc martensites in Fe-X alloys. Acta Mater. 1997, 45, 2079–2091. [Google Scholar] [CrossRef]

- Andersson, J.O.; Helander, T.; Höglund, L.; Shi, P.; Sundman, B. Thermo-Calc & DICTRA, computational tools for materials science. Calphad 2002, 26, 273–312. [Google Scholar]

- Stormvinter, A.; Borgenstam, A.; Ågren, J. Thermodynamically based prediction of the martensite start temperature for commercial steels. Metall. Mater. Trans. A 2012, 43, 3870–3879. [Google Scholar] [CrossRef]

- Huyan, F.; Hedström, P.; Höglund, L.; Borgenstam, A. A thermodynamic-based model to predict the fraction of martensite in steels. Metall. Mater. Trans. A 2016, 47, 4404–4410. [Google Scholar] [CrossRef]

| Composition [wt %] | C | Cr | Mn | Ni | Si | Al | Mo | Cu | S | P |

|---|---|---|---|---|---|---|---|---|---|---|

| 20MnCr5 (A) | 0.20 | 1.15 | 1.15 | 0.14 | 0.14 | 0.11 | 0.06 | 0.17 | 0.001 | 0.004 |

| 17NiCrMo6-4 (B) | 0.22 | 1.05 | 0.94 | 1.10 | 0.22 | - | 0.12 | 0.19 | 0.025 | 0.013 |

| 20MnCr5 (A) | 17NiCrMo6-4 (B) | |||

|---|---|---|---|---|

| 18 bar Direct | 6 bar Stop | 18 bar Direct | 6 bar Stop | |

| Fatigue limit [MPa] | ||||

| Core hardness CT [HV30] | ||||

| Core hardness ITR [HV30] | ||||

| Core hardness CR [HV30] | ||||

| Surface hardness root [HV1] | ||||

| CHD 550 HV1 [mm] | ||||

| Avg. residual stress between 75 and 150 m [MPa] | ||||

| Avg. martensite unit size [m] | 0.65 | 0.60 | 0.74 | 0.65 |

| Avg. martensite unit size m [m] | 8.75 | 8.41 | 9.08 | 9.28 |

| Amount PAGs m | 61 | 56 | 65 | 58 |

| Avg. PAGS m [m] | 125 | 157 | 112 | 124 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kohne, T.; Fahlkrans, J.; Haglund, S.; Stormvinter, A.; Troell, E.; Hedström, P.; Borgenstam, A. Impact of Cooling Rate during High-Pressure Gas Quenching on Fatigue Performance of Low Pressure Carburized Gears. Metals 2022, 12, 1917. https://doi.org/10.3390/met12111917

Kohne T, Fahlkrans J, Haglund S, Stormvinter A, Troell E, Hedström P, Borgenstam A. Impact of Cooling Rate during High-Pressure Gas Quenching on Fatigue Performance of Low Pressure Carburized Gears. Metals. 2022; 12(11):1917. https://doi.org/10.3390/met12111917

Chicago/Turabian StyleKohne, Thomas, Johan Fahlkrans, Sven Haglund, Albin Stormvinter, Eva Troell, Peter Hedström, and Annika Borgenstam. 2022. "Impact of Cooling Rate during High-Pressure Gas Quenching on Fatigue Performance of Low Pressure Carburized Gears" Metals 12, no. 11: 1917. https://doi.org/10.3390/met12111917

APA StyleKohne, T., Fahlkrans, J., Haglund, S., Stormvinter, A., Troell, E., Hedström, P., & Borgenstam, A. (2022). Impact of Cooling Rate during High-Pressure Gas Quenching on Fatigue Performance of Low Pressure Carburized Gears. Metals, 12(11), 1917. https://doi.org/10.3390/met12111917