Simulation and Microstructure Prediction of Resistance Spot Welding of Stainless Steel to Carbon Steel

Abstract

1. Introduction

2. Materials and Methods

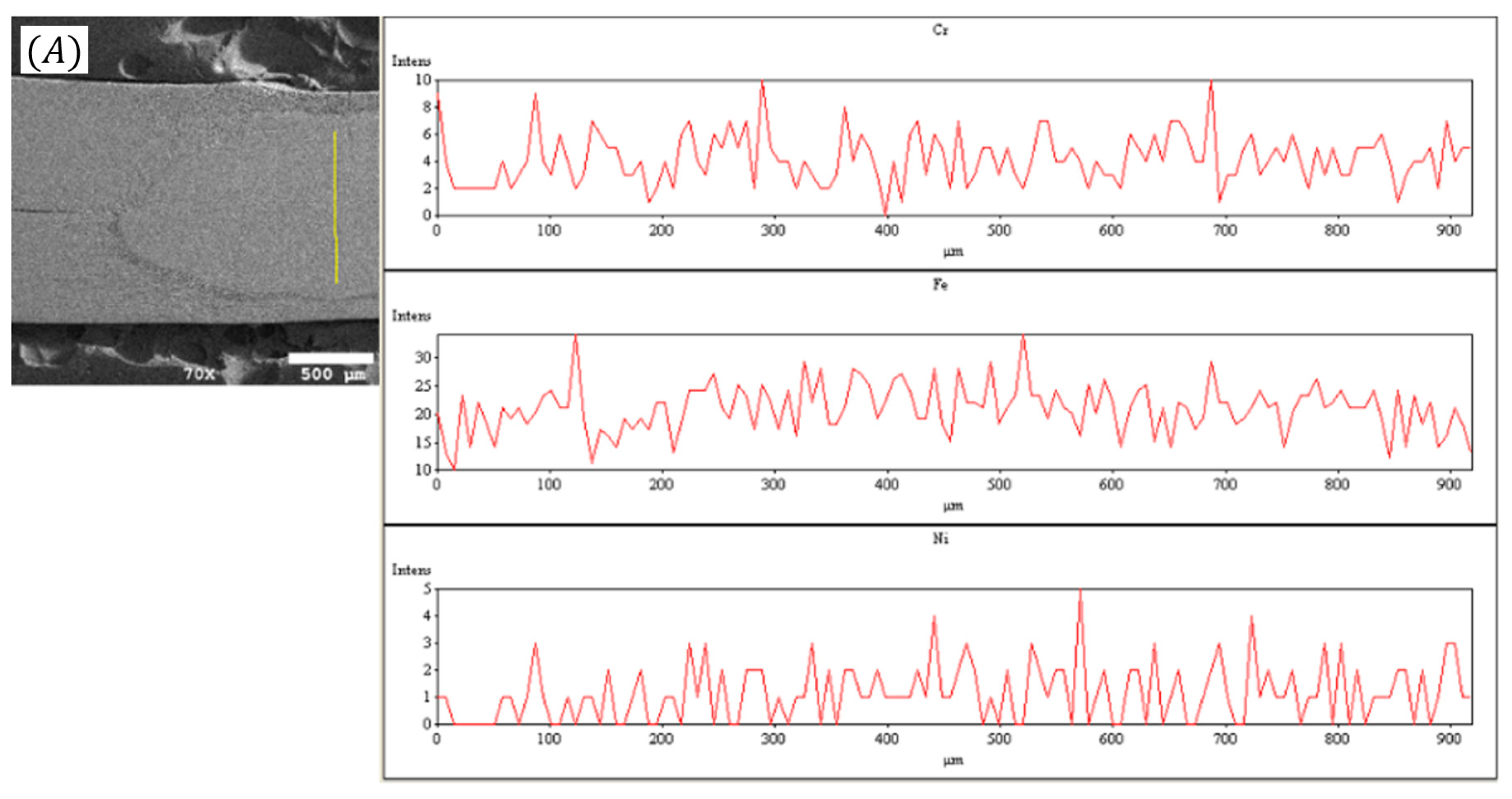

Microstructure and Mechanical Analysis

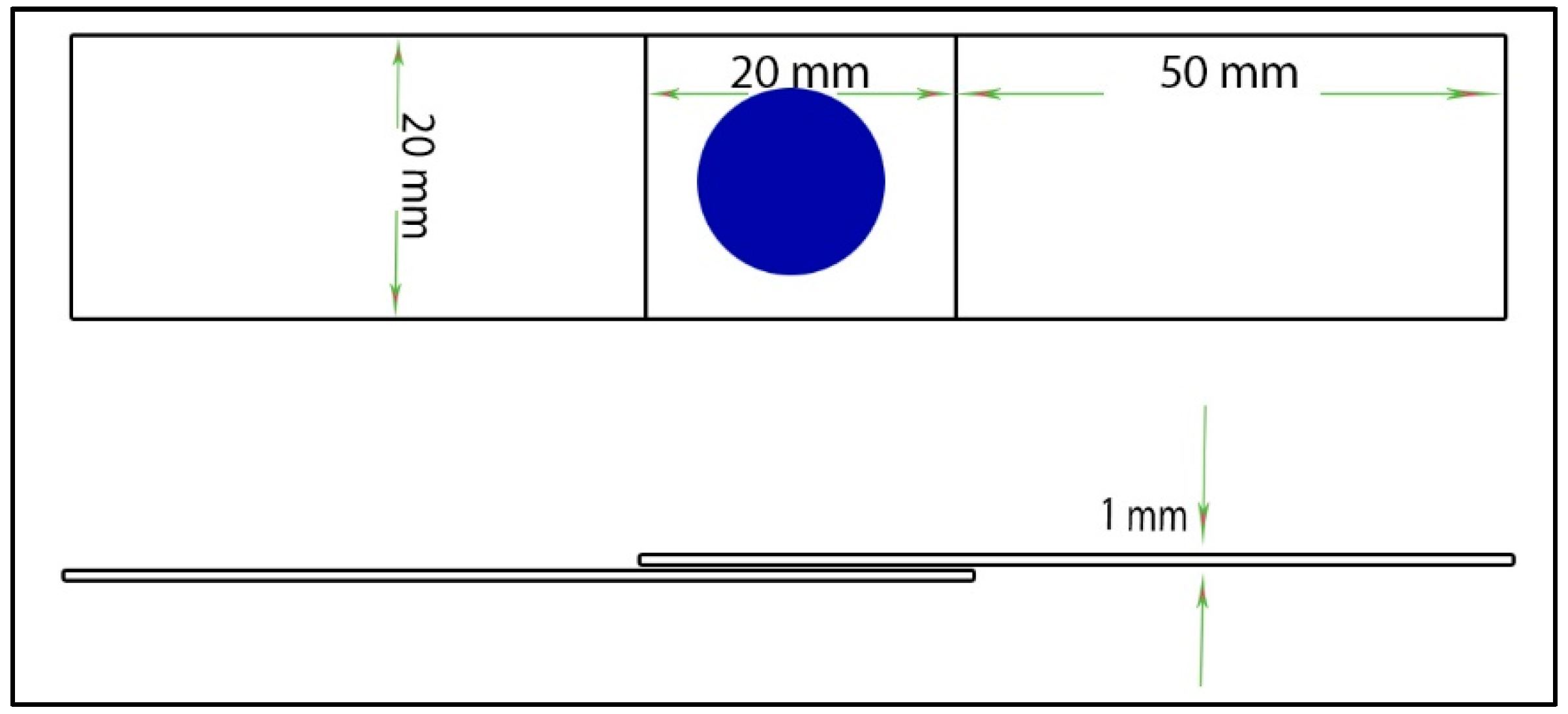

3. Model description

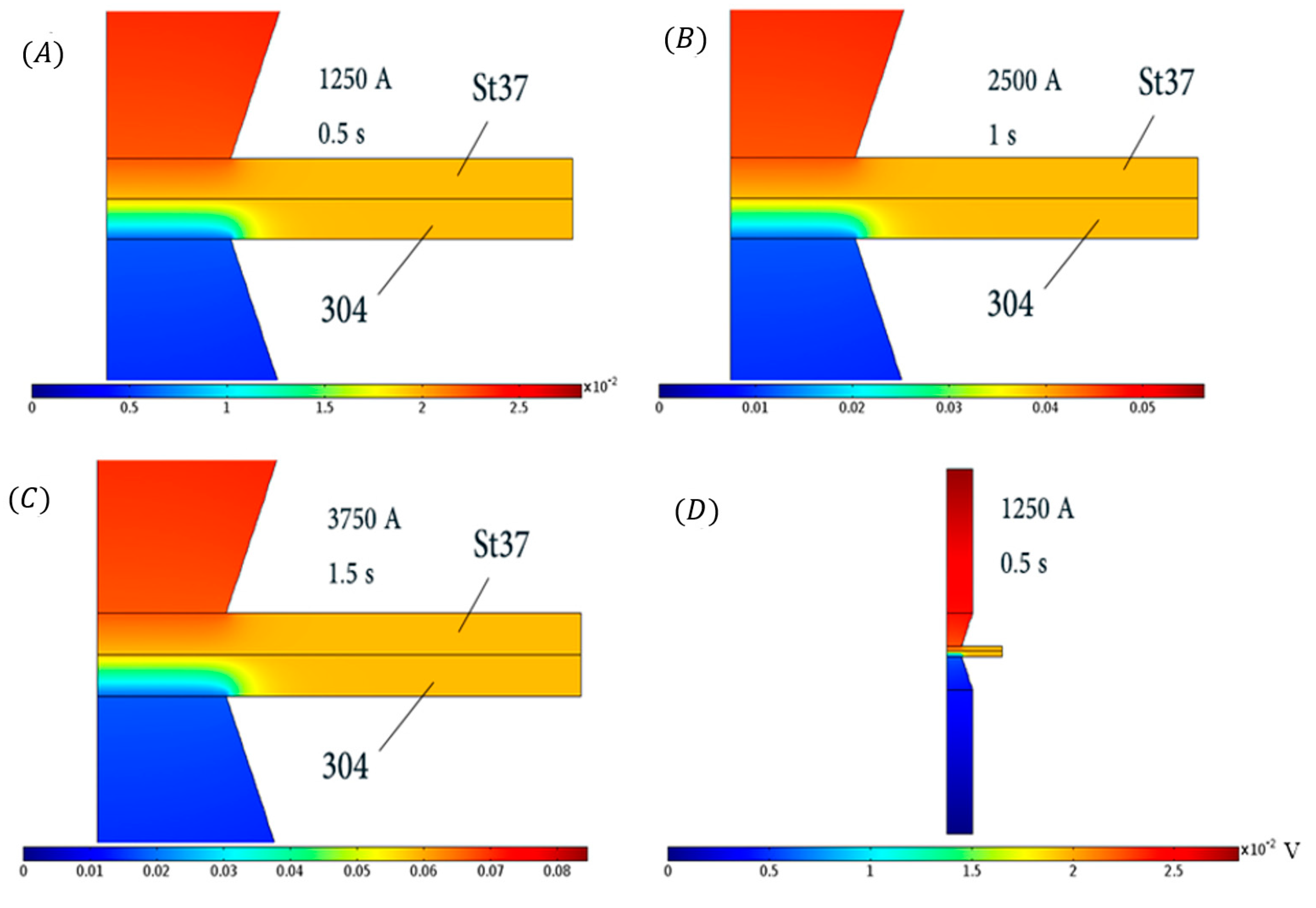

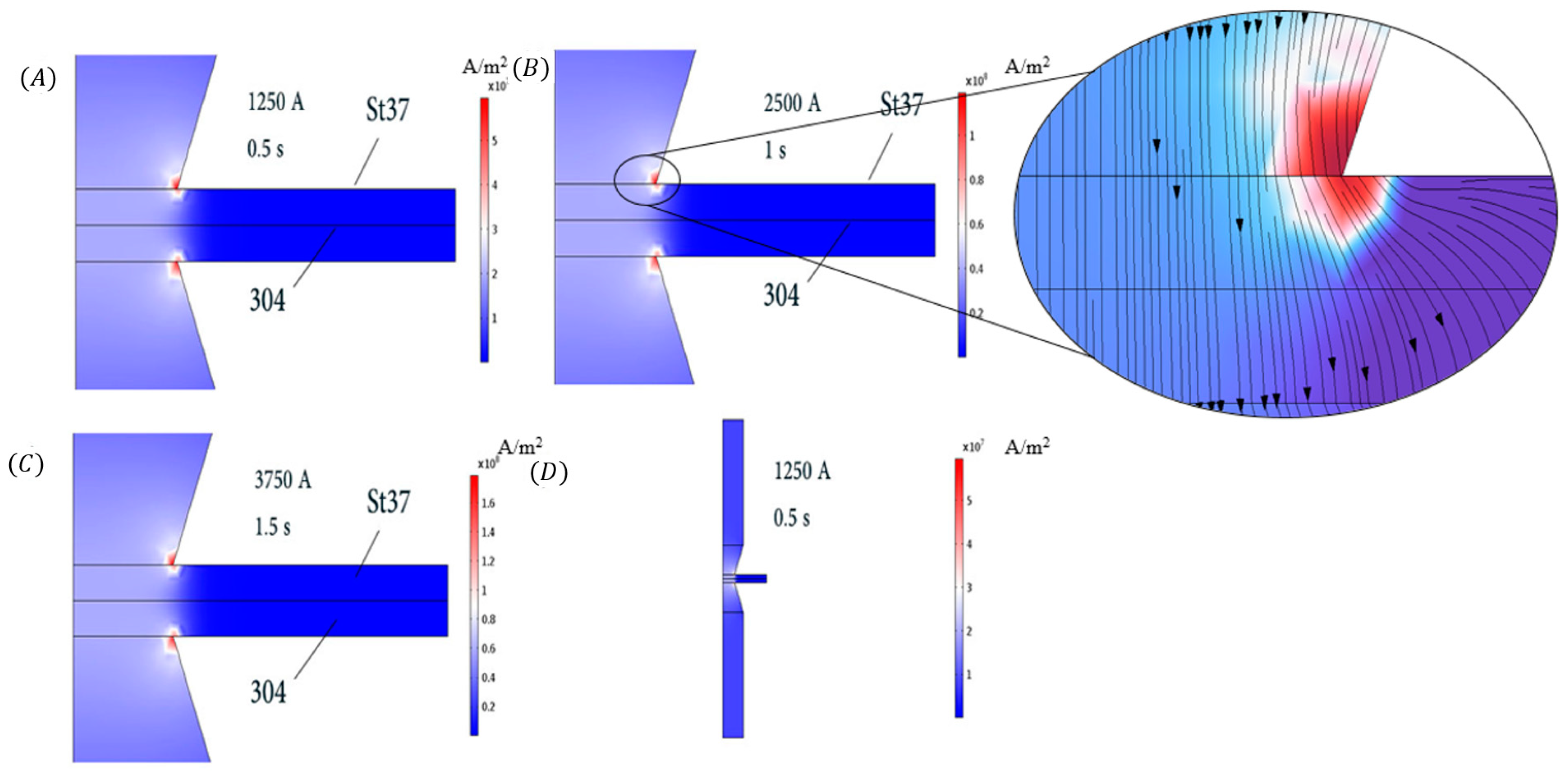

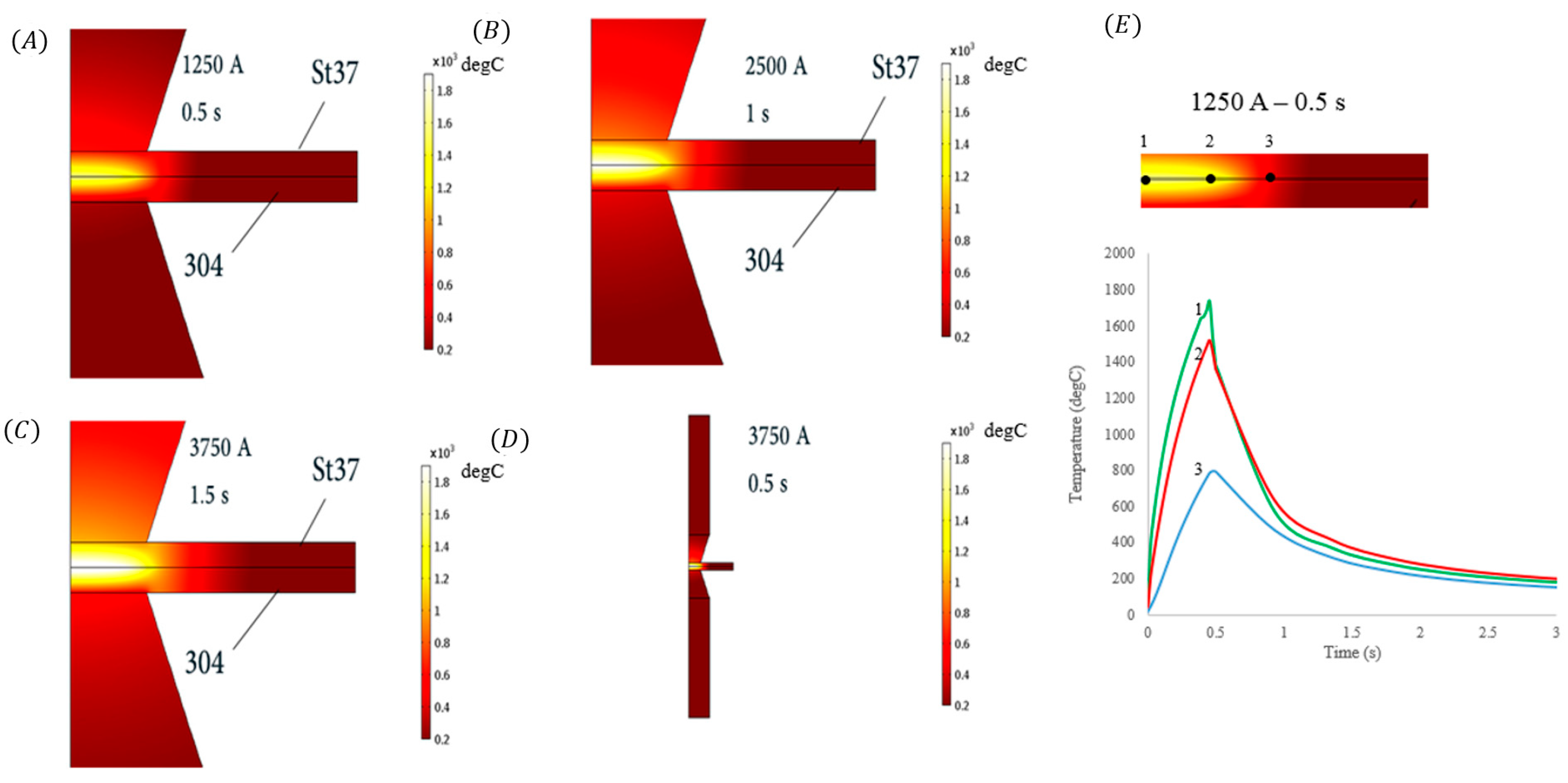

3.1. Electrical- Thermal and Mechanical Simulation

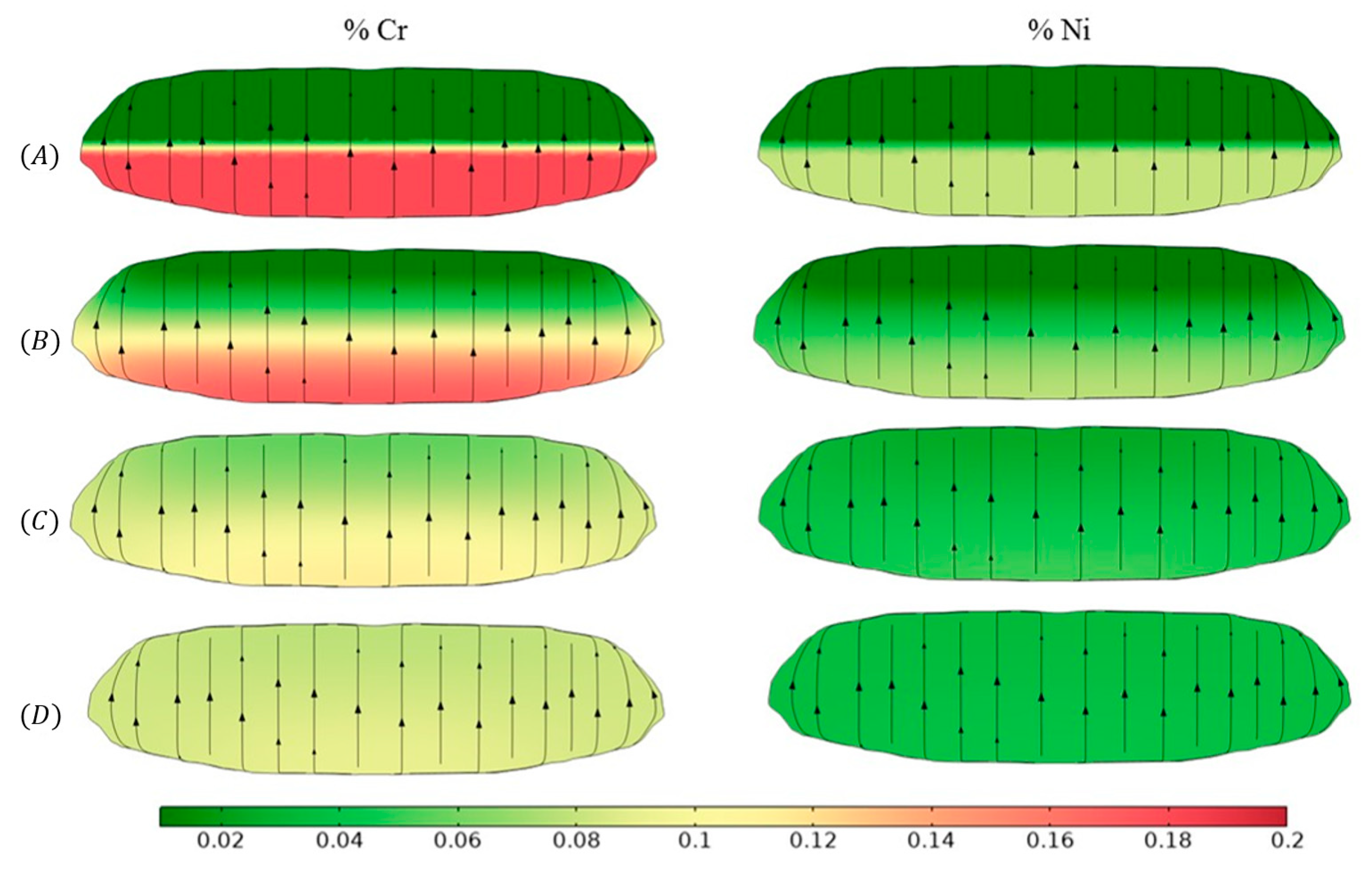

3.2. Solute Diffusion Simulation

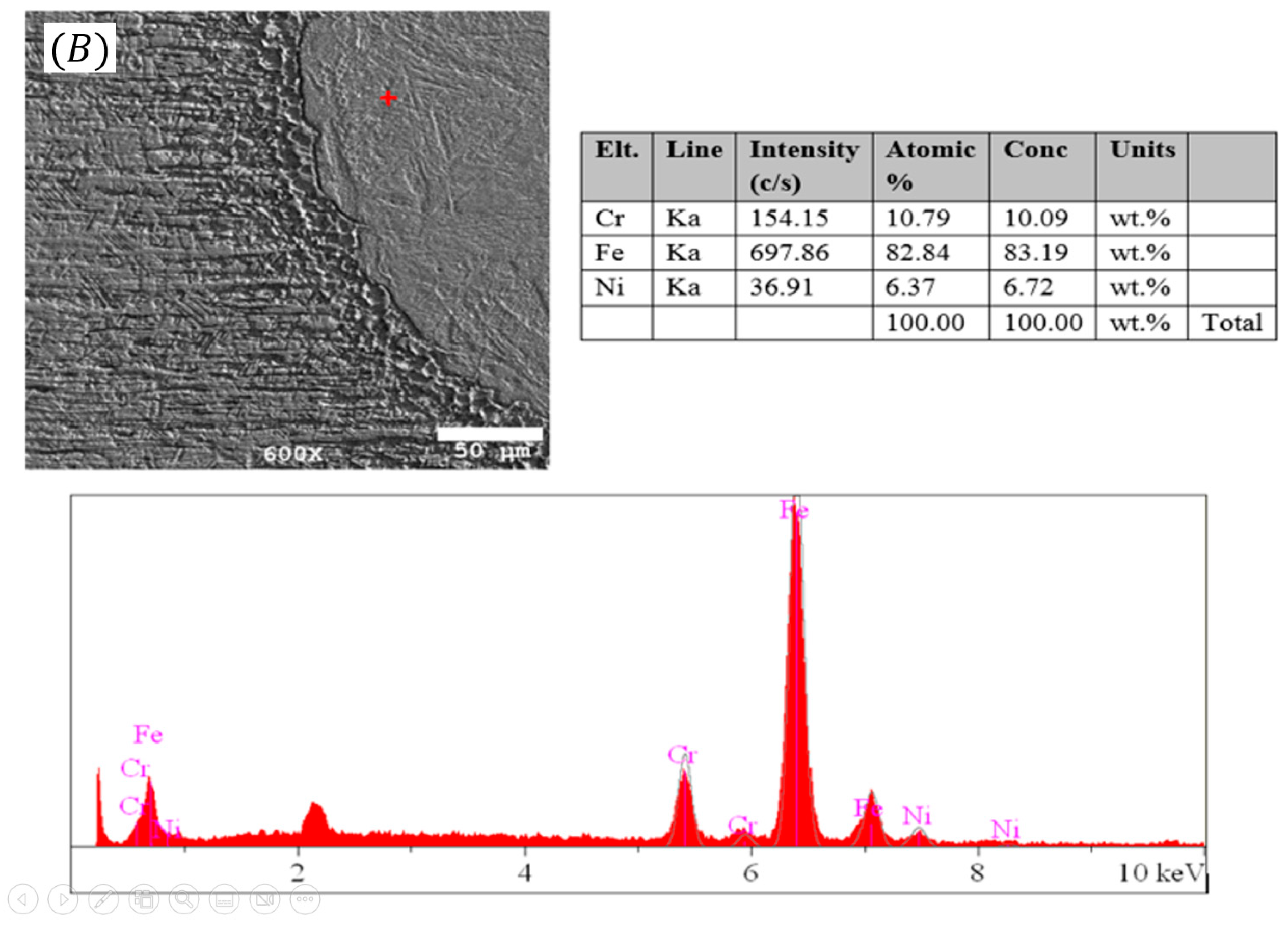

3.3. Microstructure Prediction

4. Result and Discussion

5. Conclusions

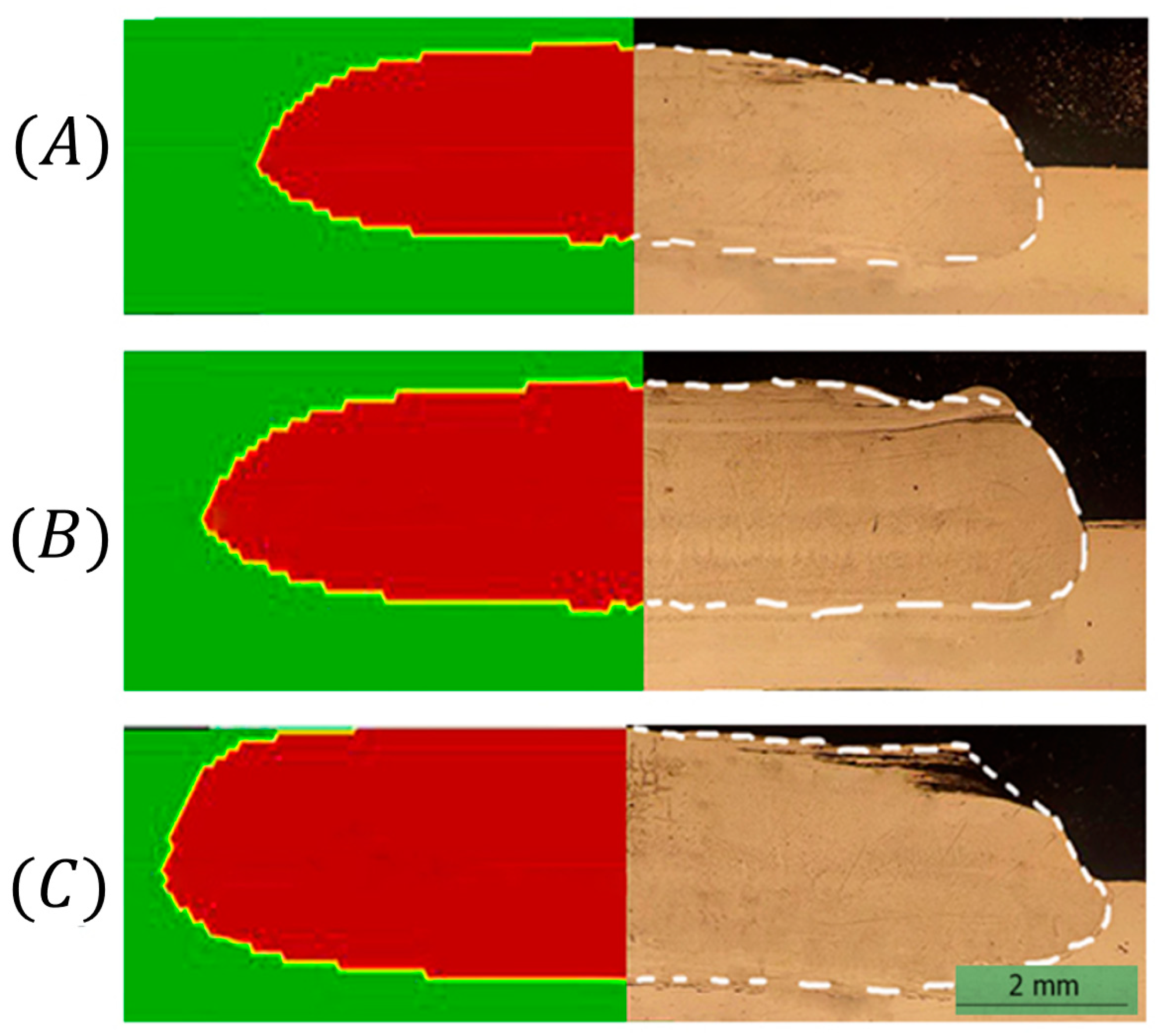

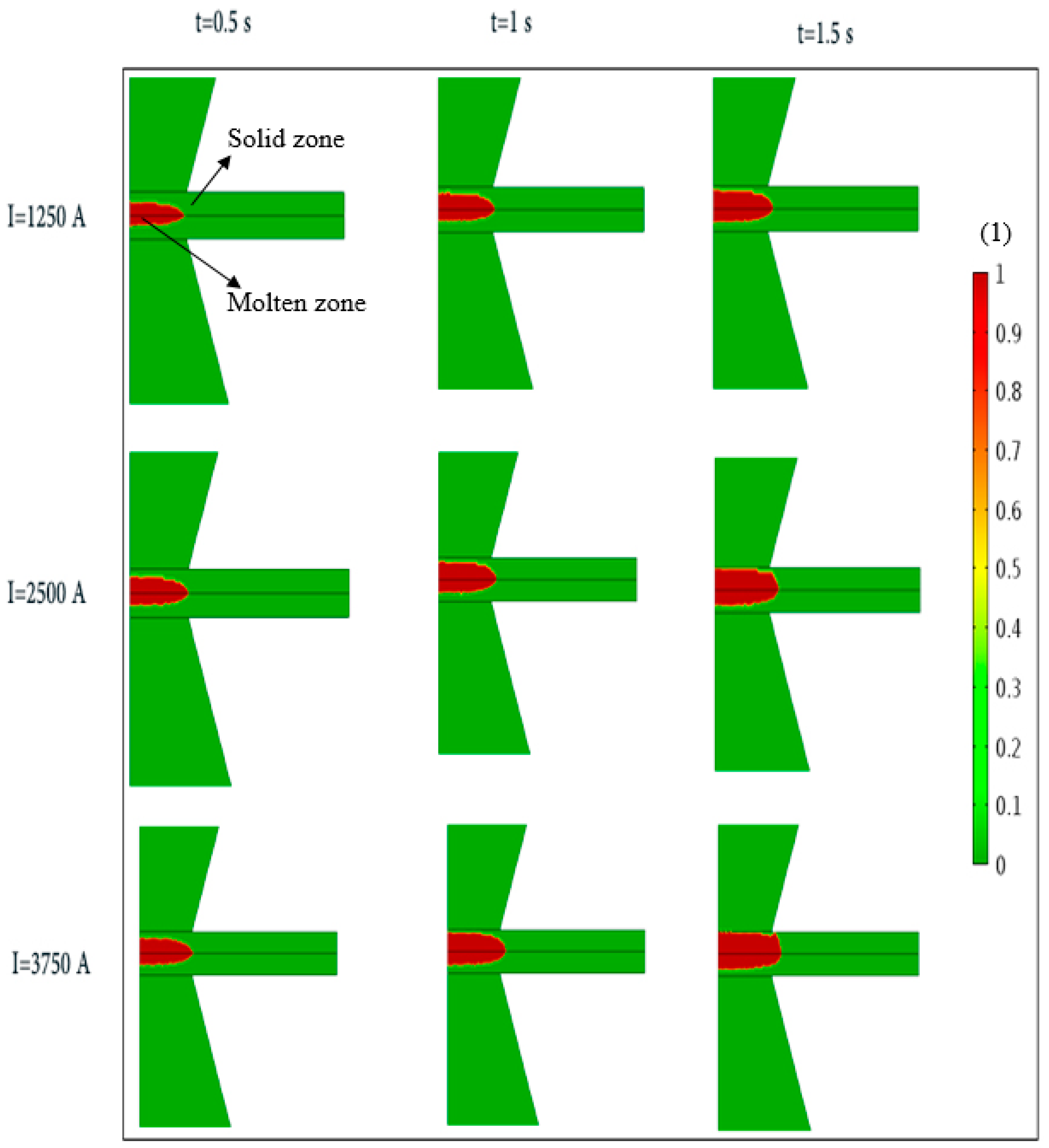

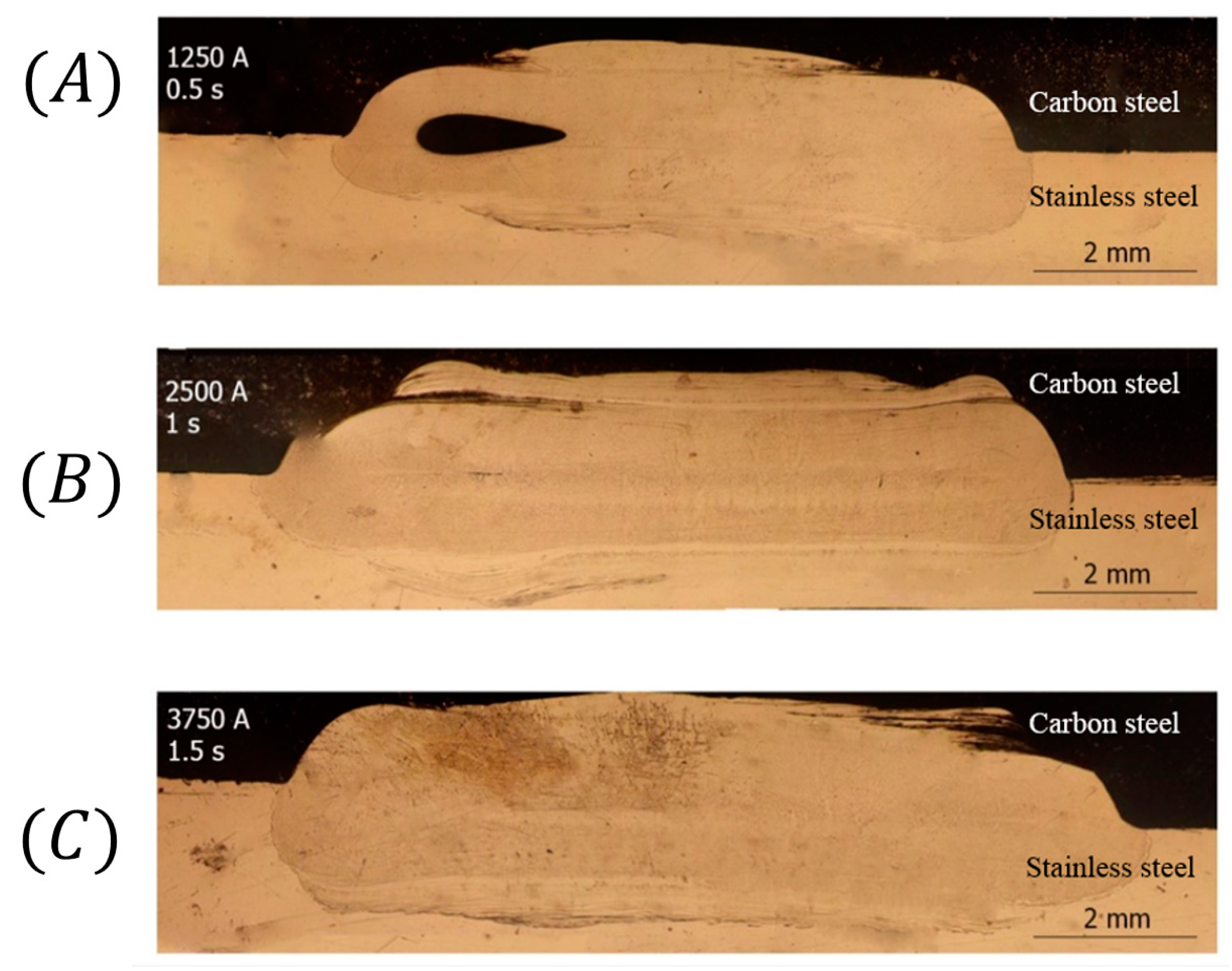

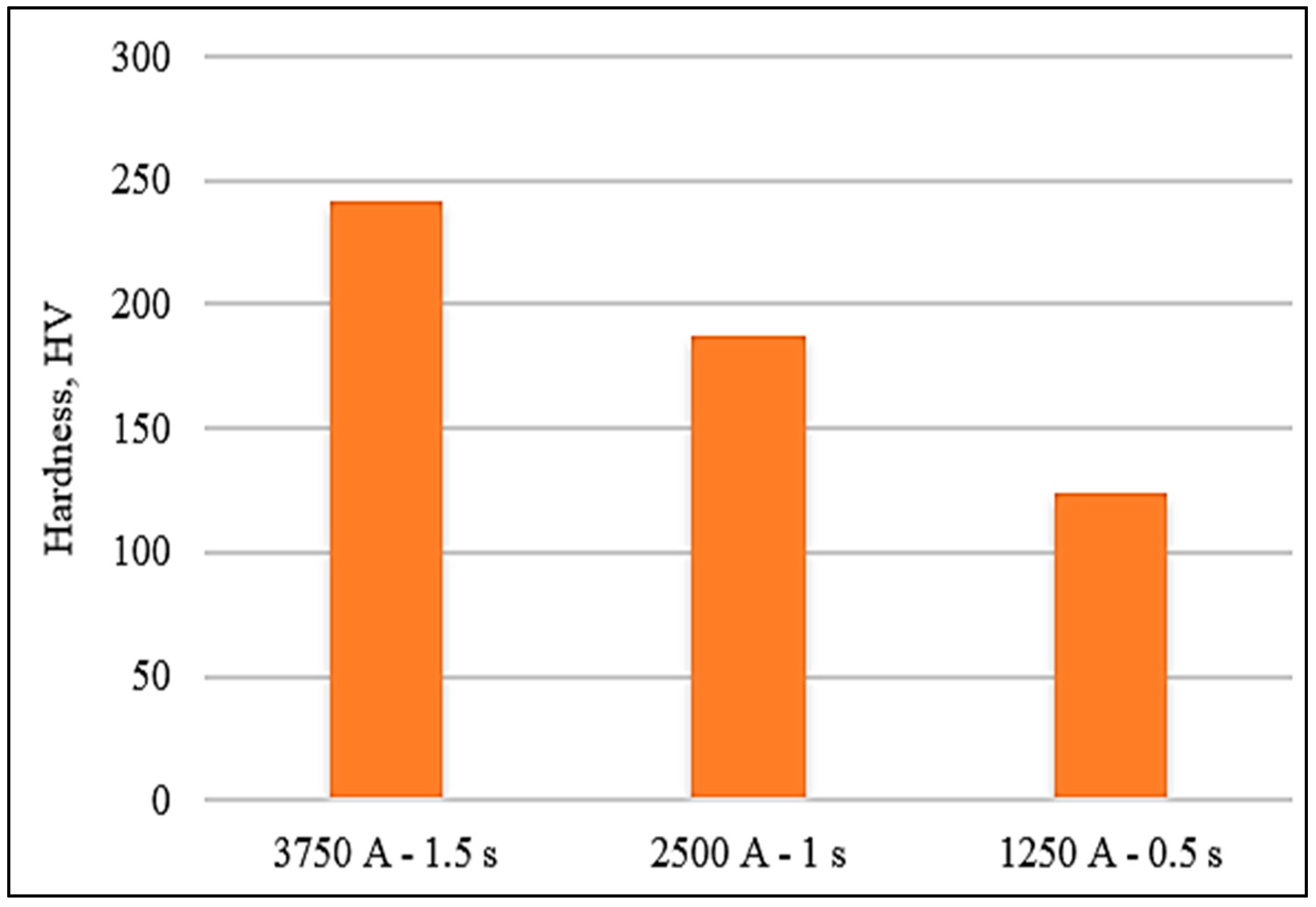

- Increasing the welding time (from 0.5 to 1.5 s) and current (from 1250 to 3750 degC) in the RSW process increases the heat input and consequently increases the diameter of the welding nugget.

- According to the proper agreement with negligible deviations of the experimental and simulation results, the FEM for solving the Laplace and Fourier equations is a suitable method for this process.

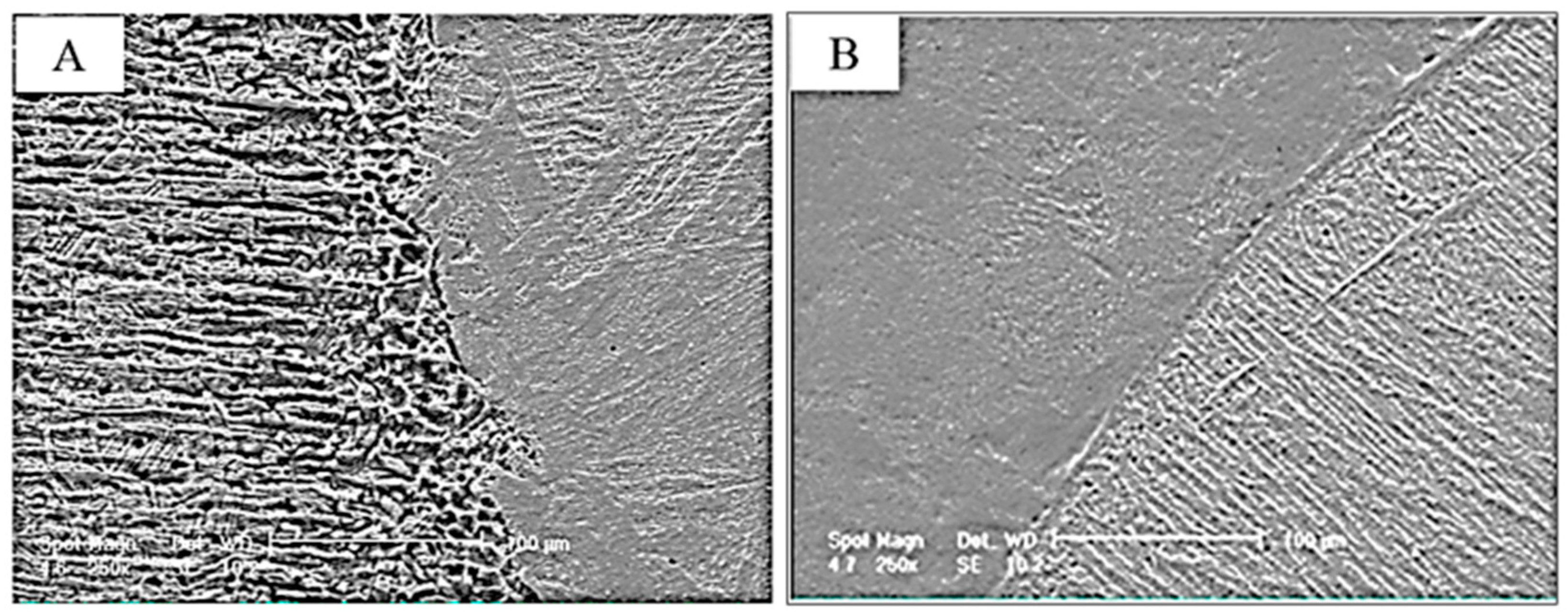

- Cr and Ni diffusion through the fusion zone, results in the formation of a kind of a stainless steel in the nugget zone. The simulated results was in consistence with experimental results.

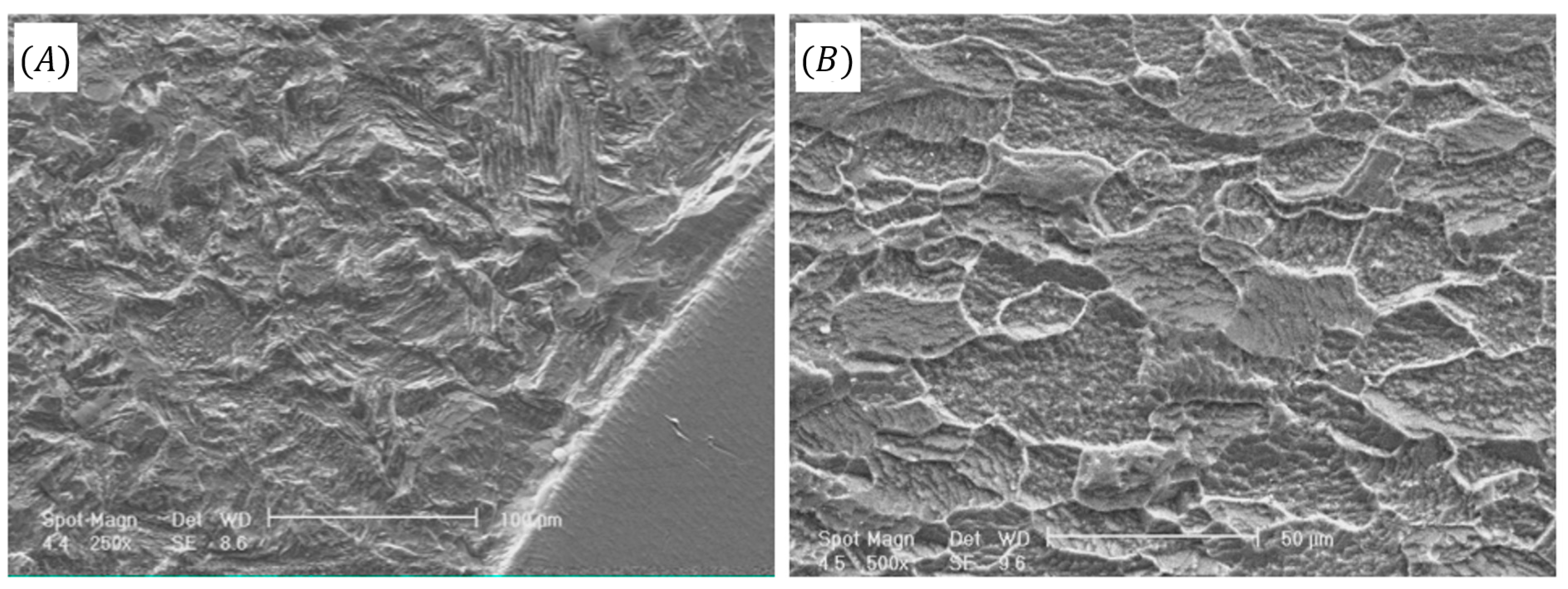

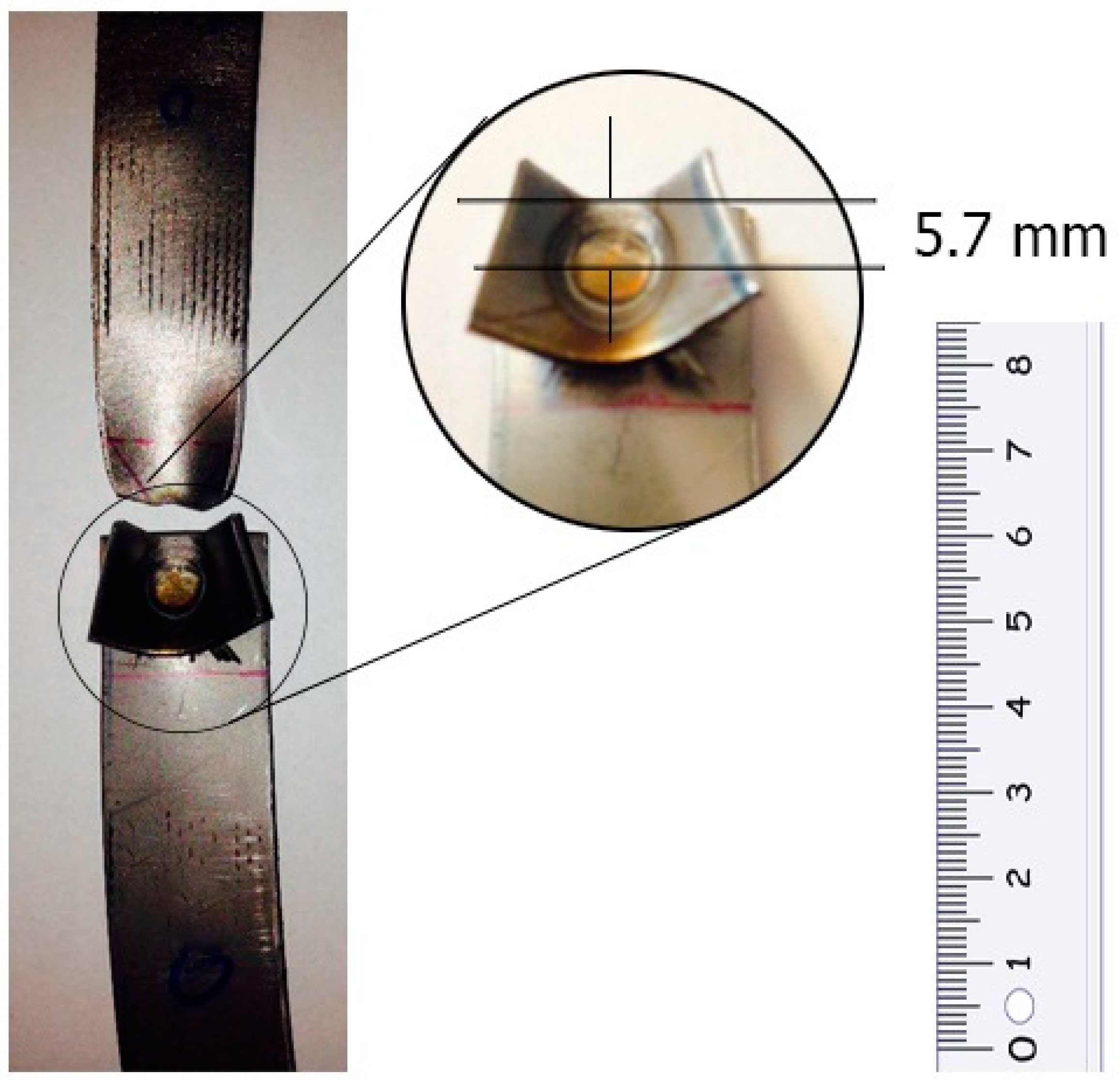

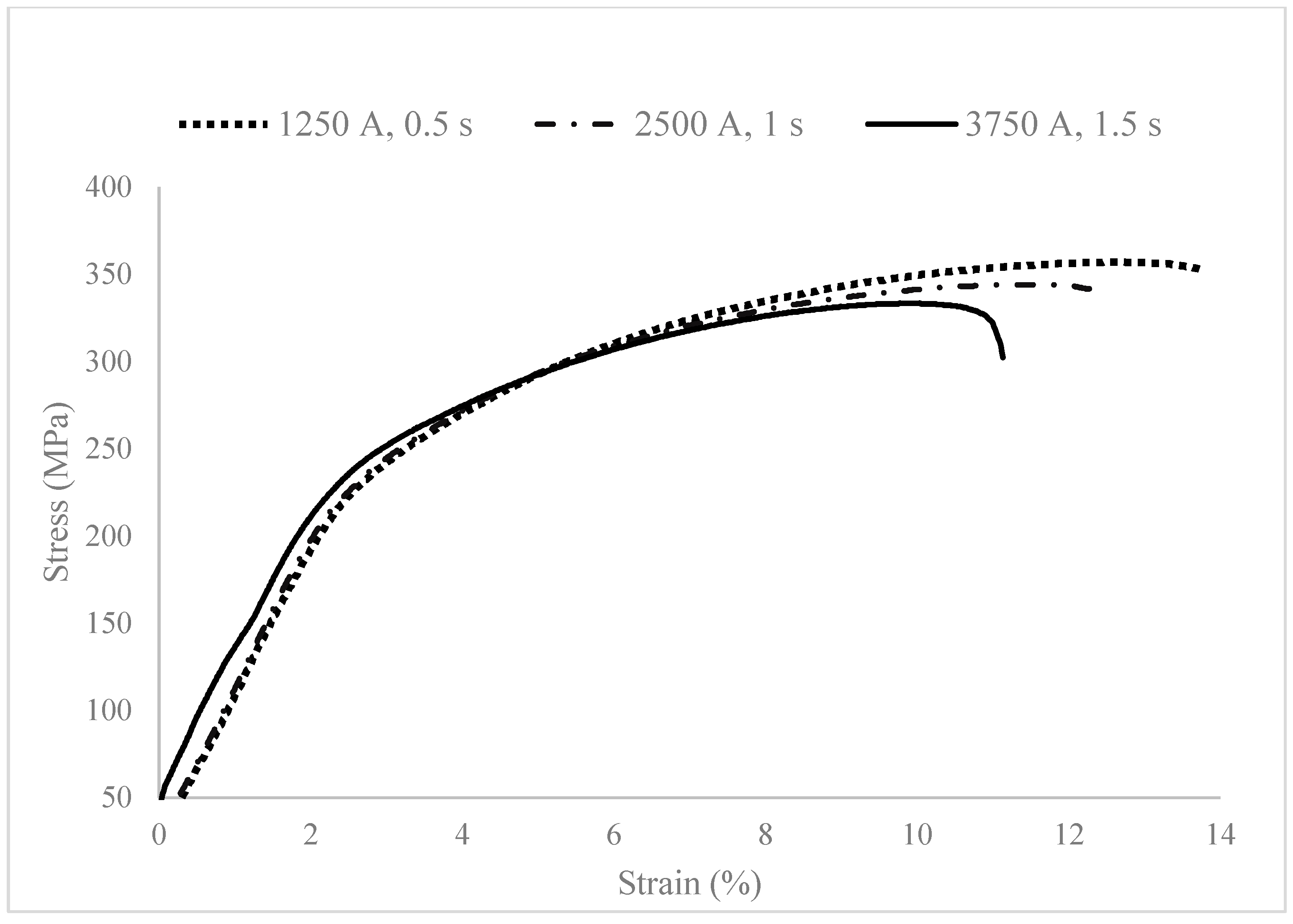

- The welding zone (weld nugget size) of stainless steel to carbon steel was so strong that all the specimens were broken from the carbon steel side in the tensile shear test. In fact, martensite formation in the HAZ results in more brittle region. This confirms the microstructure predictions.

- The results of microstructure prediction showed that increasing the heat input, including increasing the current and welding time, increases the percentage of martensite in the HAZ region and also widens the martensitic region, therefore, reduces the shear tensile strength.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ul-Hamid, A.; Tawancy, H.M.; Abbas, N.M. Failure of weld joints between carbon steel pipe and 304 stainless steel elbows. Eng. Fail. Anal. 2005, 12, 181–191. [Google Scholar] [CrossRef]

- Williams, N.; Parker, J. Review of resistance spot welding of steel sheets Part 1 Modelling and control of weld nugget formation. Int. Mater. Rev. 2004, 49, 45–75. [Google Scholar] [CrossRef]

- Bag, S.; DiGiovanni, C.; Han, X.; Zhou, N.Y. A phenomenological model of resistance spot welding on liquid metal embrittlement severity using dynamic resistance measurement. J. Manuf. Sci. Eng. 2020, 142, 031007. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, J.; Xu, H.; Xiong, C.; Liu, L. Regression modeling and process analysis of resistance spot welding on galvanized steel sheet. Mater. Des. 2009, 30, 2547–2555. [Google Scholar] [CrossRef]

- Muhammad, N.; Manurung, Y.H.P.; Jaafar, R.; Abas, S.K.; Tham, G.; Haruman, E. Model development for quality features of resistance spot welding using multi-objective Taguchi method and response surface methodology. J. Intell. Manuf. 2013, 24, 1175–1183. [Google Scholar] [CrossRef]

- Martín, Ó.; López, M.; Martín, F. Artificial neural networks for quality control by ultrasonic testing in resistance spot welding. J. Mater. Process. Technol. 2007, 183, 226–233. [Google Scholar] [CrossRef]

- Nied, H. The finite element modeling of the resistance spot welding process. Weld. J. 1984, 63, 123. [Google Scholar]

- Browne, D.J.; Chandler, H.W.; Evans, J.T.; Wen, J. Computer simulation of resistance spot welding in aluminum: Part I. Weld. J.-Incl. Weld. Res. Suppl. 1995, 74, 339s. [Google Scholar]

- Browne, D.J.; Chandler, H.W.; Evans, J.T.; James, P.S.; Wen, J.; Newton, C.J. Computer simulation of resistance spot welding in aluminum: Part II. Weld. J.-Incl. Weld. Res. Suppl. 1995, 74, 417s. [Google Scholar]

- Wei, P.; Ho, C. Axisymmetric nugget growth during resistance spot welding. J. Heat Transfer. 1990, 112, 309–316. [Google Scholar] [CrossRef]

- Gupta, O.; De, A. An improved numerical modeling for resistance spot welding process and its experimental verification. J. Manuf. Sci. Eng. 1998, 120, 246–251. [Google Scholar] [CrossRef]

- Feng, Z. An incrementally couples electrical-thermal-mechanical model for resistance spot welding, trends in welding research. In Proceedings of the 5th International Conference on Trends in Welding Research, Pine Mountain, GA, USA, 1–5 June 1998; ASM International: Almere, The Netherlands. [Google Scholar]

- Khan, J.; Xu, L.; Chao, Y.-J. Prediction of nugget development during resistance spot welding using coupled thermal–electrical–mechanical model. Sci. Technol. Weld. Join. 1999, 4, 201–207. [Google Scholar] [CrossRef]

- Andersson, O.; Melander, A. Prediction and verification of resistance spot welding results of ultra-high strength steels through FE simulations. Model. Numer. Simul. Mater. Sci. 2015, 5, 26. [Google Scholar] [CrossRef][Green Version]

- Eisazadeh, H.; Hamedi, M.; Halvaee, A. New parametric study of nugget size in resistance spot welding process using finite element method. Mater. Des. 2010, 31, 149–157. [Google Scholar] [CrossRef]

- Moshayedi, H.; Sattari-Far, I. Numerical and experimental study of nugget size growth in resistance spot welding of austenitic stainless steels. J. Mater. Process. Technol. 2012, 212, 347–354. [Google Scholar] [CrossRef]

- Eshraghi, M.; Tschopp, M.A.; Zaeem, M.A.; Felicelli, S.D. Effect of resistance spot welding parameters on weld pool properties in a DP600 dual-phase steel: A parametric study using thermomechanically-coupled finite element analysis. Mater. Des. 2014, 56, 387–397. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.-P.; Lu, F.; Carlson, B.E.; Sigler, D.R. Analysis of Al-steel resistance spot welding process by developing a fully coupled multi-physics simulation model. Int. J. Heat Mass Transf. 2015, 89, 1061–1072. [Google Scholar] [CrossRef]

- Dancette, S.; Huin, T.; Dupuy, T.; Fabrègue, D. Finite element modeling of deformation and fracture of advanced high strength steels dissimilar spot welds. Eng. Fract. Mech. 2021, 258, 108092. [Google Scholar] [CrossRef]

- Marashi, P.; Pouranvari, M.; Amirabdollahian, S.; Abedi, A.; Goodarzi, M. Microstructure and failure behavior of dissimilar resistance spot welds between low carbon galvanized and austenitic stainless steels. Mater. Sci. Eng. A 2008, 480, 175–180. [Google Scholar] [CrossRef]

- Charde, N.; Yusof, F.; Rajkumar, R. Material characterizations of mild steels, stainless steels, and both steel mixed joints under resistance spot welding (2-mm sheets). Int. J. Adv. Manuf. Technol. 2014, 75, 373–384. [Google Scholar] [CrossRef]

- Ishak, M.; Shah, L.H.; Aisha, I.S.R.; Hafizi, W.; Islam, M.R. Study of resistance spot welding between aisi 301 stainless steel and AISI 1020 carbon steel dissimilar alloys. J. Mech. Eng. Sci. 2014, 6, 793–806. [Google Scholar] [CrossRef]

- Sani, M.; Nazri, N.; Alawi, D. Vibration analysis of resistance spot welding joint for dissimilar plate structure (mild steel 1010 and stainless steel 304). Proceeding of the IOP Conference Series: Materials Science and Engineering, Birmingham, UK, 13–15 October 2017; IOP Publishing: Bristol, UK, 2017. [Google Scholar]

- Nandan, R.; Roy, G.G.; Lienert, T.J.; Debroy, T. Numerical modelling of 3D plastic flow and heat transfer during friction stir welding of stainless steel. Sci. Technol. Weld. Join. 2006, 11, 526–537. [Google Scholar] [CrossRef]

- Nandan, R.; Roy, G.; Lienert, T.; Debroy, T. Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Mater. 2007, 55, 883–895. [Google Scholar] [CrossRef]

- McKee, R. A generalization of the Nernst-Einstein equation for self-diffusion in high defect concentration solids. Solid State Ion. 1981, 5, 133–136. [Google Scholar] [CrossRef]

- Ono, Y.; Matsumoto, S. Diffusion of chromium, manganese, and nickel in molten iron. Trans. Jpn. Inst. Met. 1975, 16, 415–422. [Google Scholar] [CrossRef]

- Leblond, J.; Devaux, J. A new kinetic model for anisothermal metallurgical transformations in steels including effect of austenite grain size. Acta Metall. 1984, 32, 137–146. [Google Scholar] [CrossRef]

- Koistinen, D.P. A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon alloys and plain carbon steels. Acta Metall. 1959, 7, 59–60. [Google Scholar] [CrossRef]

- Leblond, J.-B.; Mottet, G.; Devaux, J.; Devaux, J.C. Mathematical models of anisothermal phase transformations in steels, and predicted plastic behaviour. Mater. Sci. Technol. 1985, 1, 815–822. [Google Scholar] [CrossRef]

- Lan, L.; Qiu, C.; Song, H.; Zhao, D. Correlation of martensite–austenite constituent and cleavage crack initiation in welding heat affected zone of low carbon bainitic steel. Mater. Lett. 2014, 125, 86–88. [Google Scholar] [CrossRef]

| Elements | C% | Si% | Mn% | Cr% | Ni% | P% | S% | Fe% |

|---|---|---|---|---|---|---|---|---|

| AISI304 | 0.03 | 0.35 | 2 | 18.02 | 8 | 0.01 | 0.003 | balanced |

| St37 | 0.17 | 0.55 | 1.2 | - | - | 0.01 | 0.02 | balanced |

| I(A) | 1250 | 2500 | 3750 | 1250 | 2500 | 3750 | 1250 | 2500 | 3750 |

| t(S) | 0.5 | 0.5 | 0.5 | 1 | 1 | 1 | 1.5 | 1.5 | 1.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadeghian, B.; Taherizadeh, A.; Salehi, T.; Sadeghi, B.; Cavaliere, P. Simulation and Microstructure Prediction of Resistance Spot Welding of Stainless Steel to Carbon Steel. Metals 2022, 12, 1898. https://doi.org/10.3390/met12111898

Sadeghian B, Taherizadeh A, Salehi T, Sadeghi B, Cavaliere P. Simulation and Microstructure Prediction of Resistance Spot Welding of Stainless Steel to Carbon Steel. Metals. 2022; 12(11):1898. https://doi.org/10.3390/met12111898

Chicago/Turabian StyleSadeghian, Behzad, Aboozar Taherizadeh, Talieh Salehi, Behzad Sadeghi, and Pasquale Cavaliere. 2022. "Simulation and Microstructure Prediction of Resistance Spot Welding of Stainless Steel to Carbon Steel" Metals 12, no. 11: 1898. https://doi.org/10.3390/met12111898

APA StyleSadeghian, B., Taherizadeh, A., Salehi, T., Sadeghi, B., & Cavaliere, P. (2022). Simulation and Microstructure Prediction of Resistance Spot Welding of Stainless Steel to Carbon Steel. Metals, 12(11), 1898. https://doi.org/10.3390/met12111898