3.2. Optimization through CCD model

As mentioned in

Table 2, a five-level design for four different variables was provided through the central composite design (CCD) illustrated in

Table 3. These tests were separately conducted for Se and Te, but

Table 3 is presented for both elements to summarize the contents. Accordingly, the experiments were randomly conducted to diminish the influence of uncontrolled variables [

41]. Different conditions for each experiment set (e.g., Se or Te) cementation were provided with sixteen cube points and eight axial points with six center points in one cube. The quadratic polynomial model was utilized based on the responses in

Table 3, through which the regression coefficients were achieved.

Based on the responses in

Table 3, a statistical model via the CCD model was achieved for both selenium and tellurium extraction. The coefficient of determination (R

2), adjusted R-square (adj. R

2), and the analysis of variance (ANOVA) tests were used to estimate the goodness-of-fit of the suggested model. As observed in

Table 4 and

Table 5, the determination coefficient for Se(IV) cementation is 0.910, and the determination coefficient for Te(IV) cementation is 0.917, demonstrating the appropriate efficiency of the suggested models. Moreover, the predicted R

2 for Te and Se is 0.7034 and 0.6418, respectively, and the differences between adjusted and predicted R

2 are less than 0.2 for Te and Se. In general, the higher level of F-Values in the model increases the unity of the model, and a proposed model becomes significant because of the higher F-values. In contradiction, a considerable amount of

p-values, or lack of fit, can make a model insignificant [

33]. As can be observed, the

p-values of models are negligible, whereas the criteria are insignificant for both Se and Te. Moreover, the lower pure error can make a convenient model to fit experimental outcomes. Therefore, the proposed Se and Te extraction model can be accepted as a feasible and practical tool.

Regarding inputs and the models provided via response surface methodology and CCD, a semi-empirical relation for Se extraction containing interactions between the existing parameters, is defined as Equation (5):

The semi-empirical equation for Te precipitation percentage is found as Equation (6):

Positive terms express a synergistic effect, whereas negative terms designate antagonism. Moreover, the interactions between some factors were not significant, so these interactions were eliminated in the suggested models.

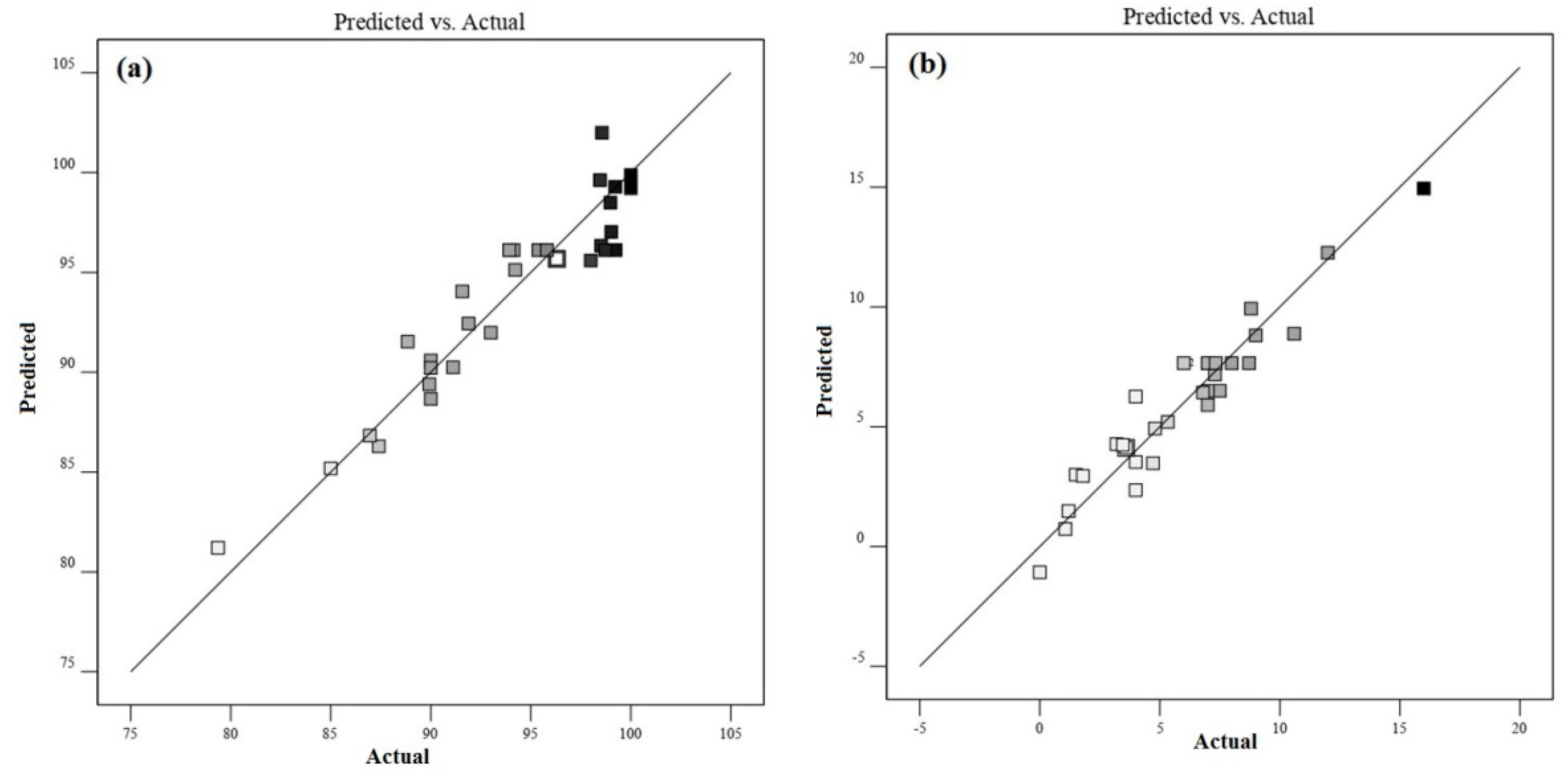

Figure 4a,b illustrate the validity of the suggested models for precipitation percentages of Se and Te alongside the experimental extraction percentages presented in

Table 3. As can be seen, the validity of the predicted models for both elements versus the actual outputs is acceptable. Moreover, the determination coefficients for Se and Te cementation are 0.912 and 0.92, respectively, which confirm the significant efficiency of the achieved models. These models (Equations (5) and (6)) can be used for the prediction of Se and Te precipitation in sulfuric acid media. Although the models may not always present the accurate rate of the process, but these models can undoubtedly be a helpful index to estimate Se or Te concentration in the Cu cementation process.

3.3. Three-Dimensional (3D) Response Surface Graphs

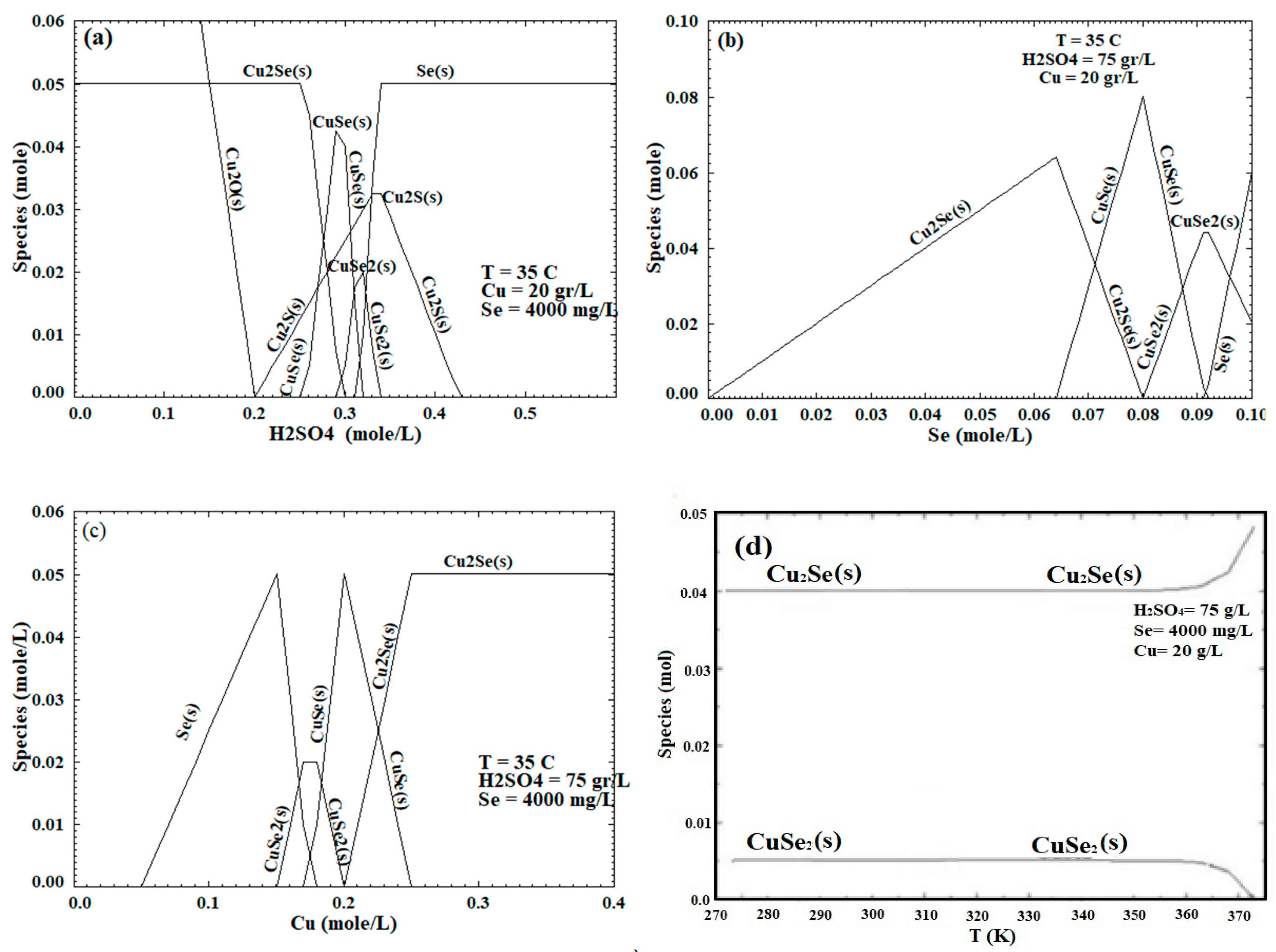

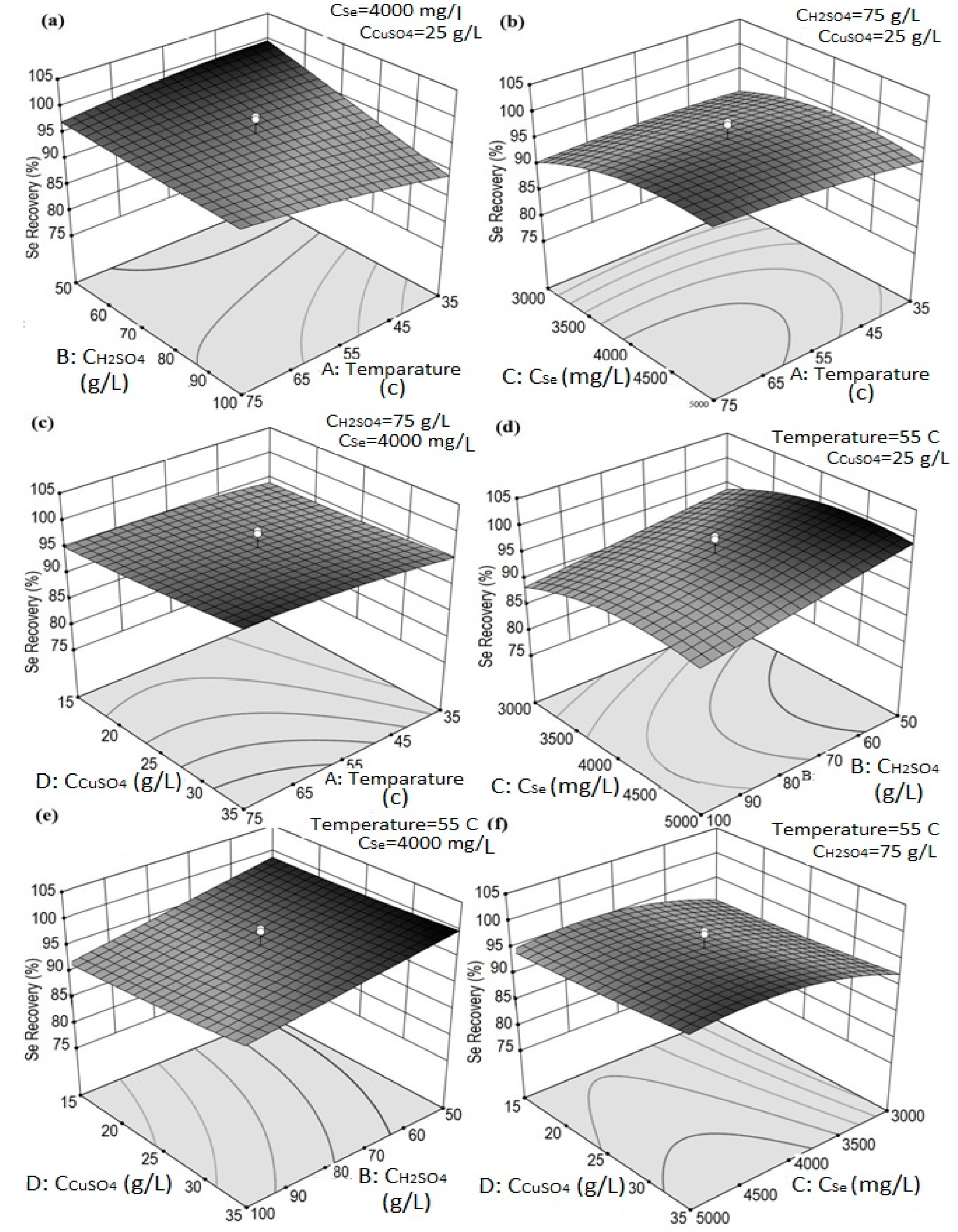

Three-dimensional surface plots of the parameters influencing the cementation of Se (IV) are illustrated in

Figure 5. The three-dimensional surface graph in

Figure 5a demonstrates the Se recovery as a function of temperature and initial H

2SO

4 concentration, which are both practical parameters in the separation process at a constant Se concentration (4000 mg/L) and initial Cu concentration of 25 g/L. As observed, the minor level of temperature and H

2SO

4 concentration led to the highest Se recovery value (99.4%). Nevertheless, rising temperature slightly reduces Se recovery at a minimum concentration of H

2SO

4, whereas the temperature escalates the criterion at a higher level of H

2SO

4 and reduces the negative influence of H

2SO

4. Additionally, the detrimental effect of H

2SO

4 at 75 °C is more conspicuous than at lower temperatures. According to thermodynamic analysis,

Figure 5, despite the temperature effect not changing the Se cementation, H

2SO

4 reduces Se solid phase stability.

Figure 5b illustrates the simultaneous effect of temperature and Se concentration on Se recovery at a constant level of Cu, 25 g/L, and H

2SO

4, 75 g/L. As the thermodynamic evaluation also confirms in

Figure 5b, Se recovery has enhanced with Se concentration at a constant temperature. In this way, the selenious acid (H

2SeO

3) can be reduced based on an electrochemical reaction expressed in Equation (7) [

40]:

According to the above reaction, Mokemeli [

40] expressed that Stewart et al. [

42] suggested a desirable effect of initial Se concentration for Se cementation by copper. Moreover, this behavior was confirmed in other studies [

40], as the Se concentration order in the kinetic equation was specified between 1 and 1.8. In addition,

Figure 5c shows the effects of temperature and Cu concentration on Se recovery. Temperature is a reluctant parameter in a lower Cu concentration, as shown in the thermodynamic survey, but enhancing Cu concentration promotes Cu

2Se phase formation.

Figure 5d exhibits the Se recovery as the function of sulfuric acid concentration and Se concentration at a certain temperature, 55 °C, and Cu concentration, 25 g/L. Based on

Figure 5a,b, the higher concentration of H

2SO

4 diminishes Cu

2Se, while the higher Se concentration extends Se cementation. H

2SO

4 increases the copper dissolution affinity, decreasing Cu

2Se stability and recovery. Nevertheless, Se concentration can escalate the Se cementation reaction, Equation (8), and extend the Cu

2Se precipitation rate.

Figure 5e shows the interaction between H

2SO

4 and Cu concentration that confirms a futile effect of Cu concentration on Se recovery because of Cu

2Se amount promotion, while H

2SO

4 diminishes Se recovery.

Moreover,

Figure 5f illustrates the effect of Se and Cu concentration on Se recovery. As can be seen, the concentration of Se definitely increases the Se recovery percentage. In contrast, Cu concentration has a limited effect on the Se cementation efficiency.

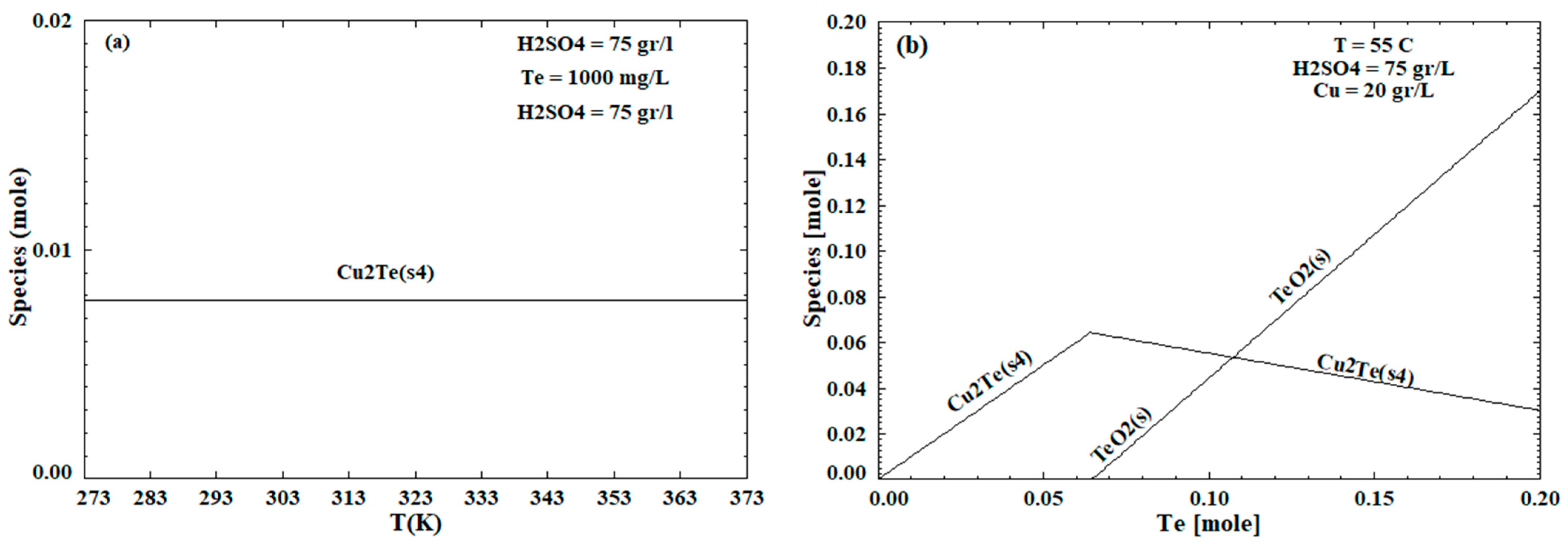

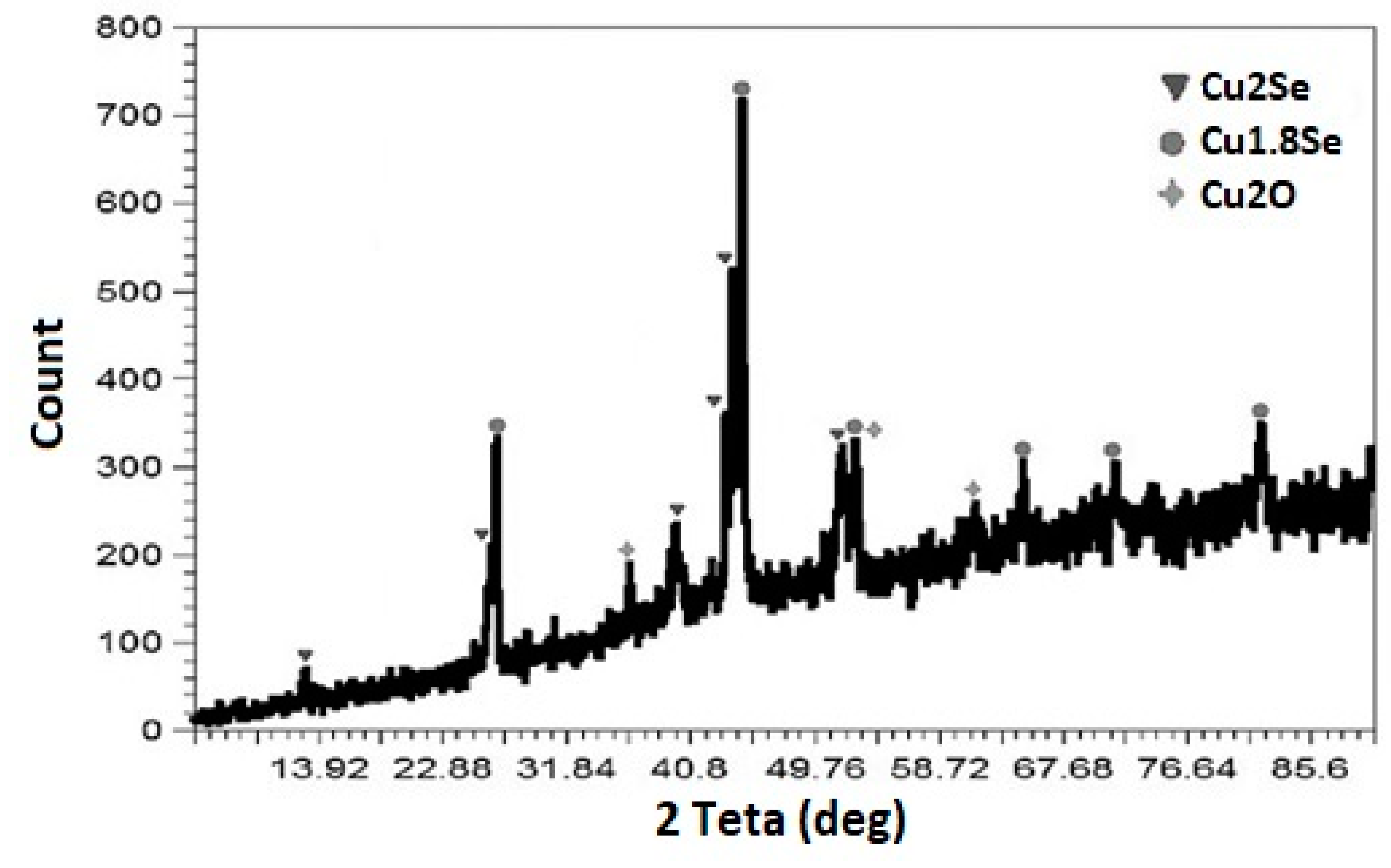

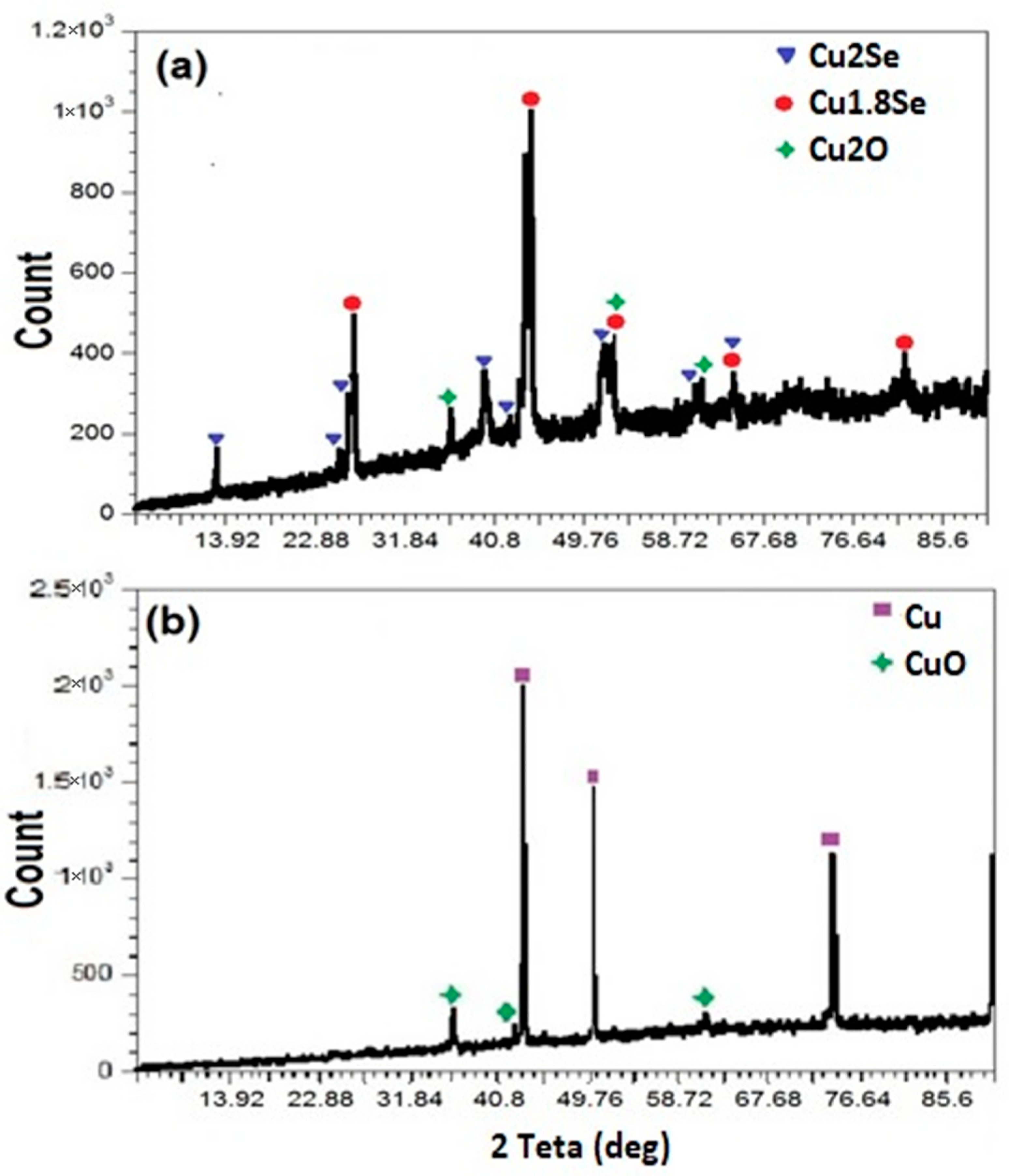

The prime purpose of the work is to determine the functional condition of the cementation process. As observed, adjusting the different parameters could lead to the desired Se cementation by copper. Nevertheless, as mentioned in previous reports [

12,

34], tellurium is able to be precipitated by the copper cementation method. However, our results exhibit that tellurium slightly precipitates in this temperature range, and the extraction percentage is low. The main reason for restricted tellurium cementation is the instability of Cu

+ at a temperature lower than 75 °C [

27], illustrated in the thermodynamic analysis. Nevertheless,

Figure 5 was brought to explore the interaction between some parameters, e.g., initial Cu concentration, H

2SO

4 concentration, and temperature, on the Te precipitation process.

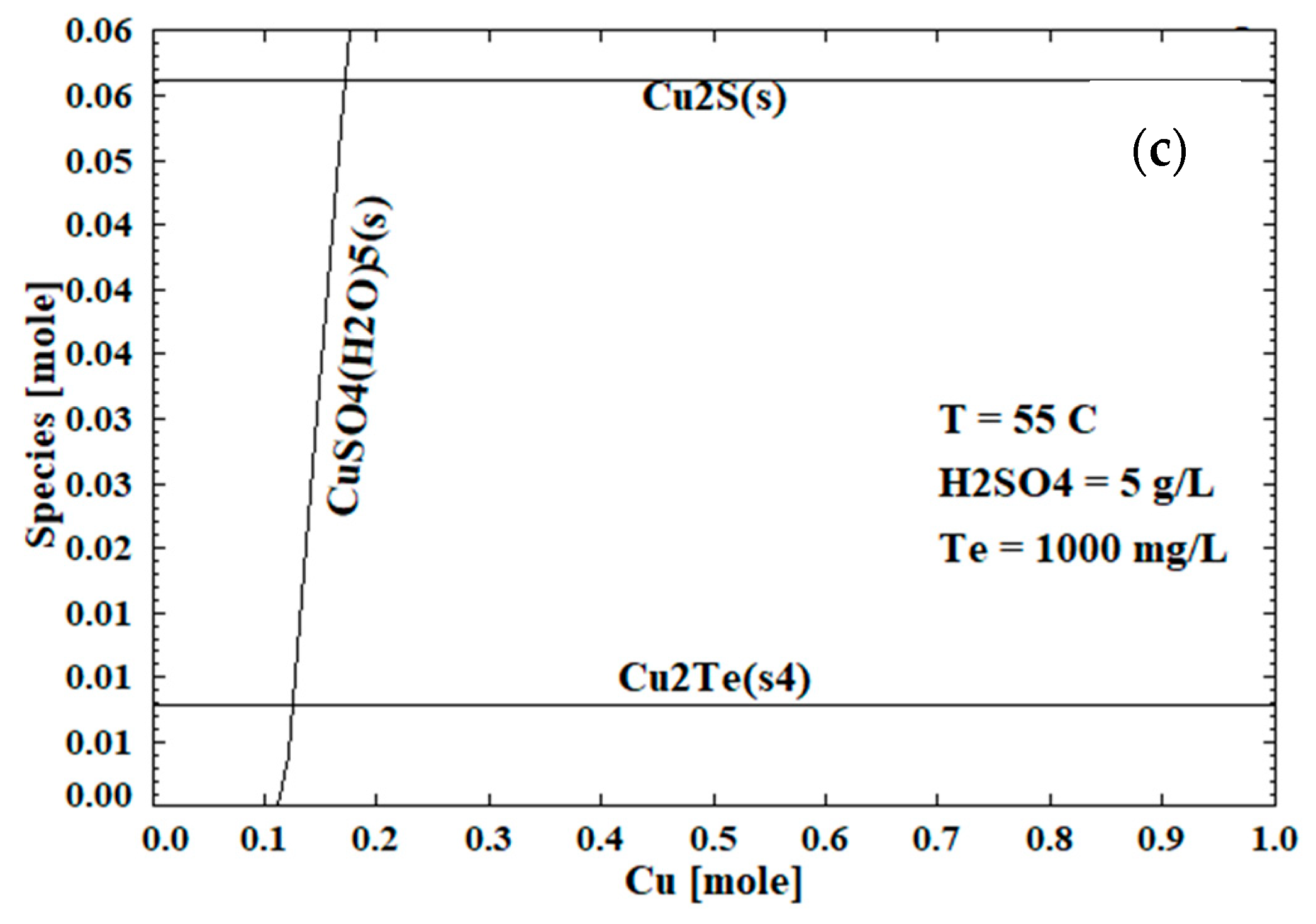

As seen in

Figure 6a, both temperature and sulfuric acid concentration slightly increase Te precipitation, indicating the synergism effect of both factors. Regarding thermodynamic analysis, rising temperature is favorable for the endothermic cementation reaction leading to higher recovery. Moreover, Jennings et al. [

12] expressed that the tellurium precipitation reaction happens at least 75 °C, and the process rate at a lower temperature is too slow. In another way, H

2SO

4 promotes Te cementation reaction to form Cu

2Te as follows:

As can be observed, sulfuric acid leads to higher Se recovery, as Cooper [

43] reported that at least 50 g/L of sulfuric acid is needed to accelerate the precipitation of tellurium.

Figure 6b presents the effect of Cu concentration and temperature on Te extraction percent at 1000 mg/L Te and 75 g/L H

2SO

4. These data indicate that the influence of temperature on Te recovery is not desirable, whereas raising the level of Cu concentration hurts Te recovery. In the Te cementation process, the cupric species can reach an equilibrium between cuprous and Cu

2Te, which is expressed as follows [

40]:

However, CuTe is an unstable component that can be disassociated from Cu2Te to Te and Cu, decreasing Te extraction efficiency. However, by adding more Te to the solution, the detrimental effect of cupric ions is declined in the model, which may confirm the occurrence of the Cu2Te dissociation. It should be noted that the interaction of other parameters is quite limited, so they were not discussed in the section to summarize the content.