On the Prediction of Material Fracture for Thin-Walled Cast Alloys Using GISSMO

Abstract

1. Introduction

2. Materials and Methods

2.1. Studied Material

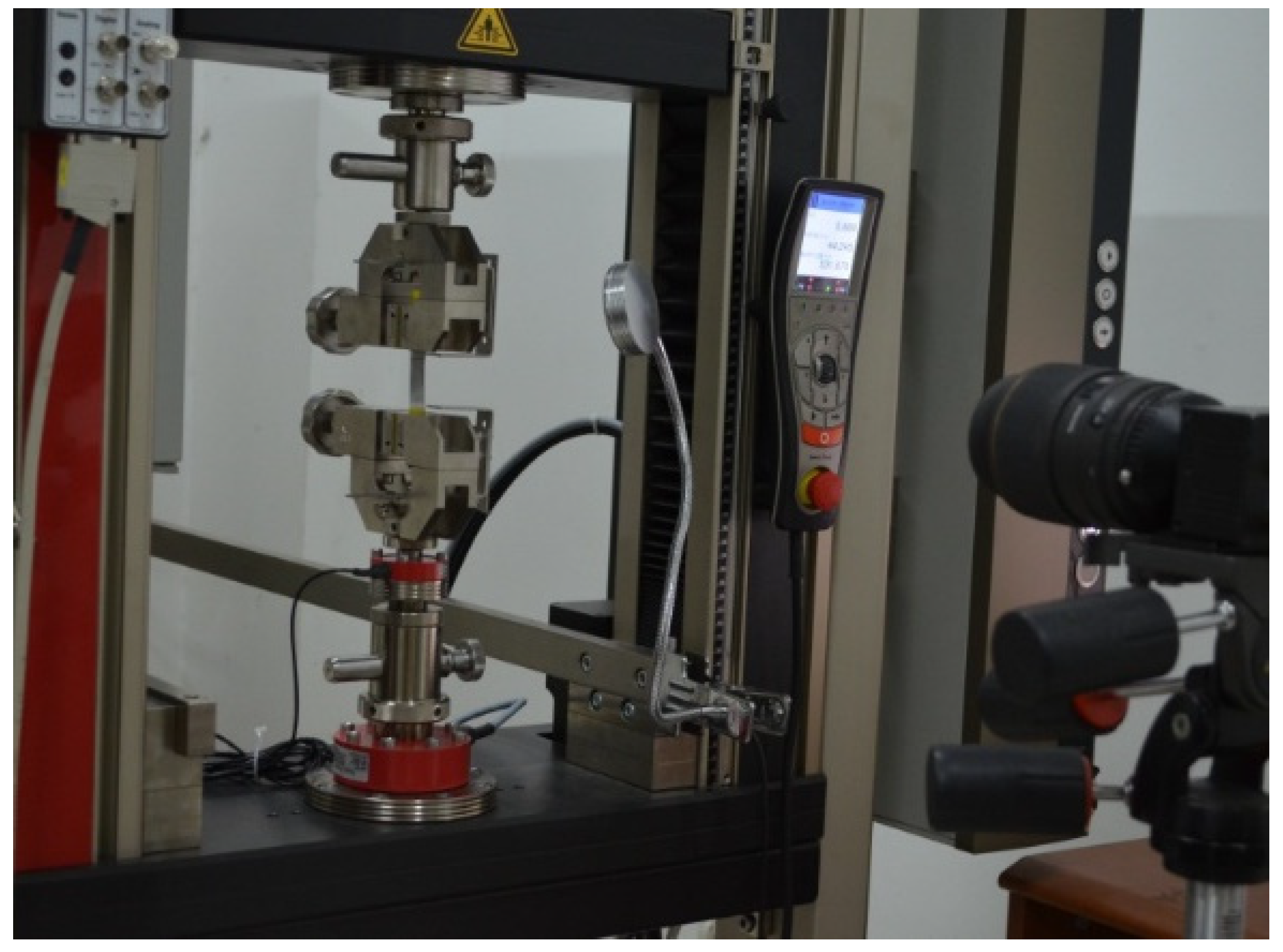

2.2. Experimental Methodology

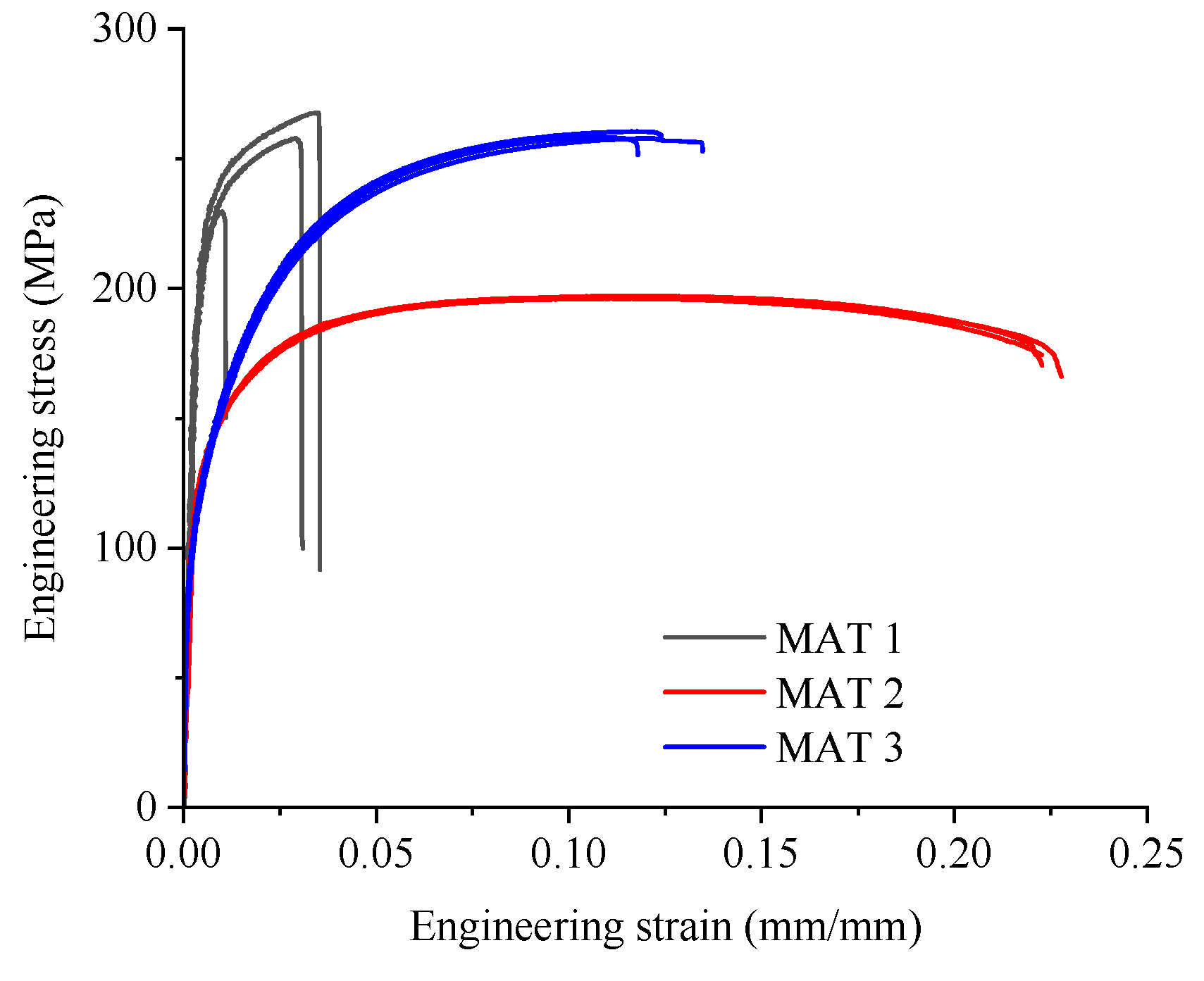

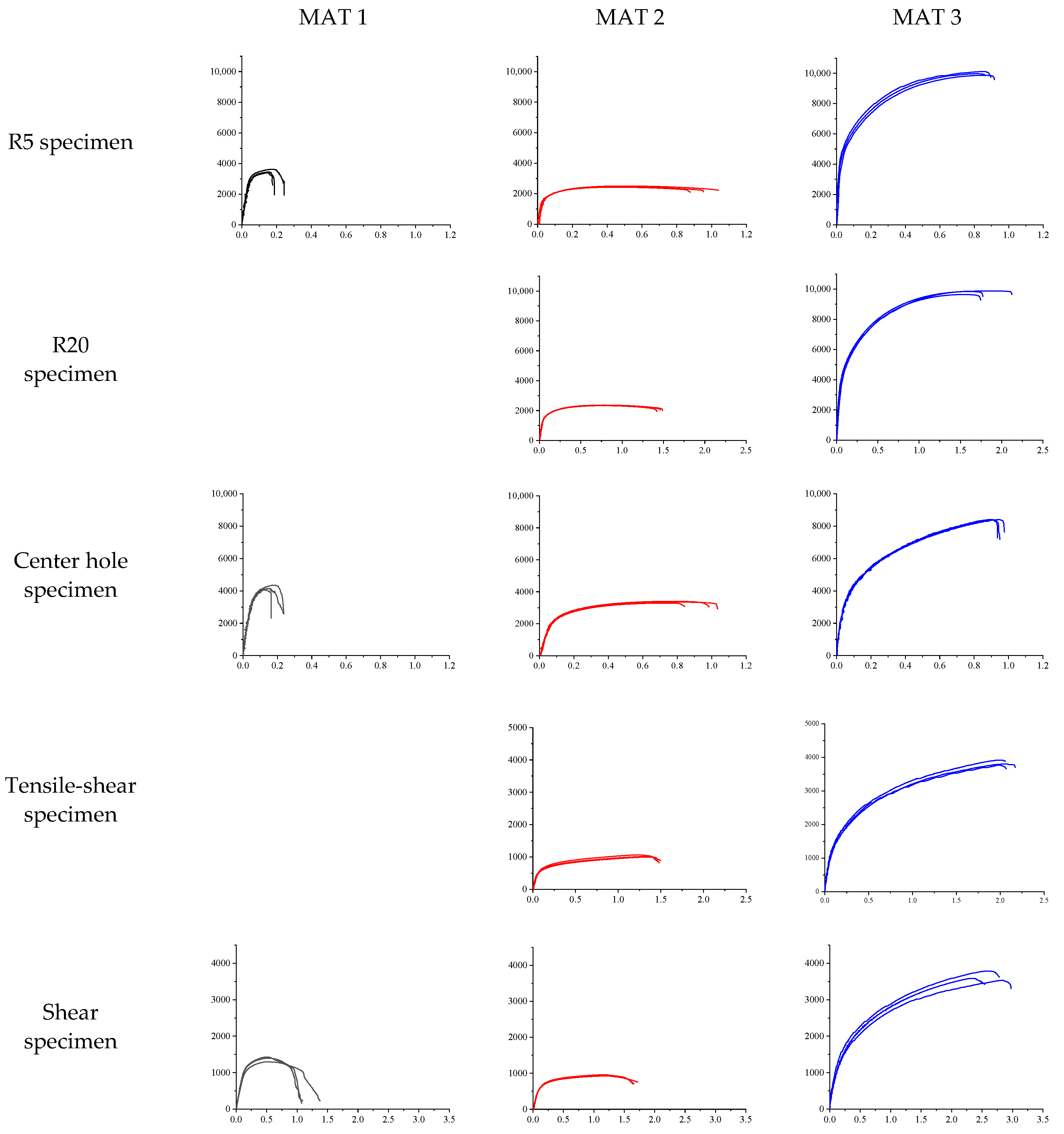

2.3. Experimental Results

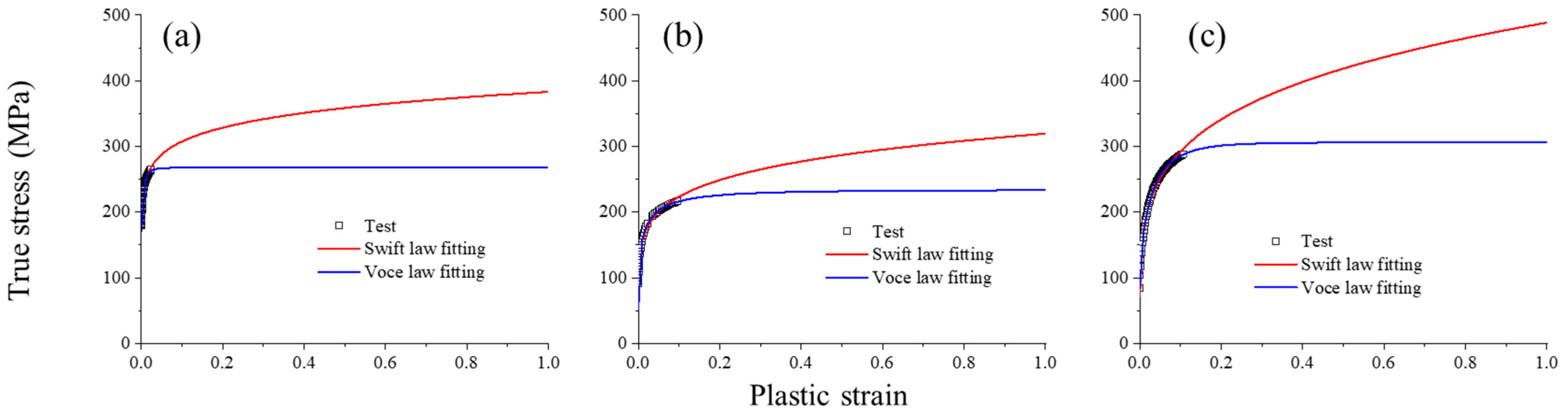

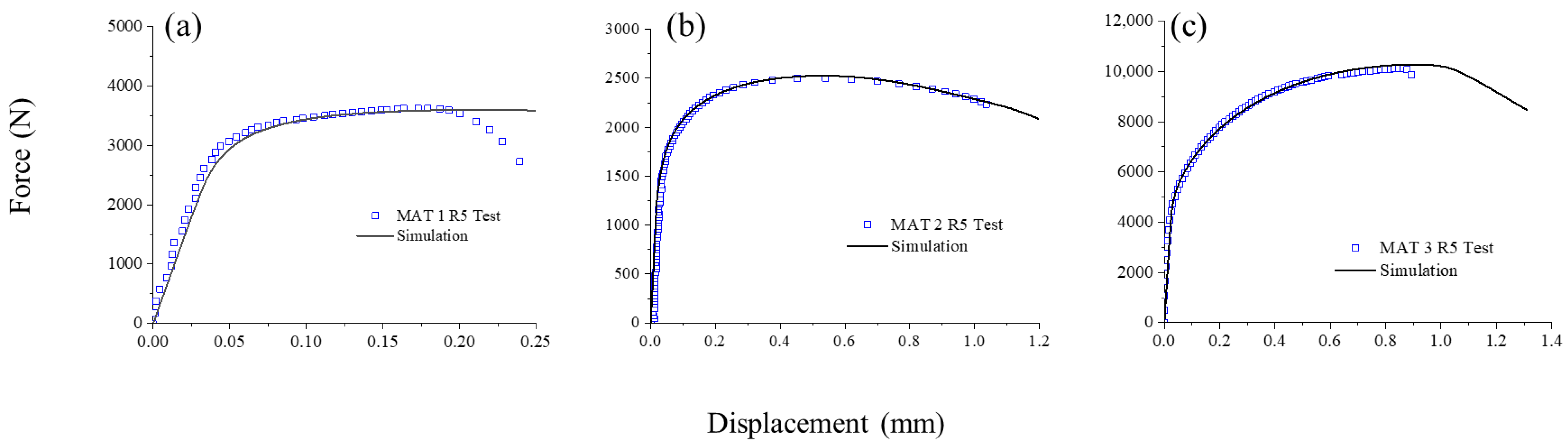

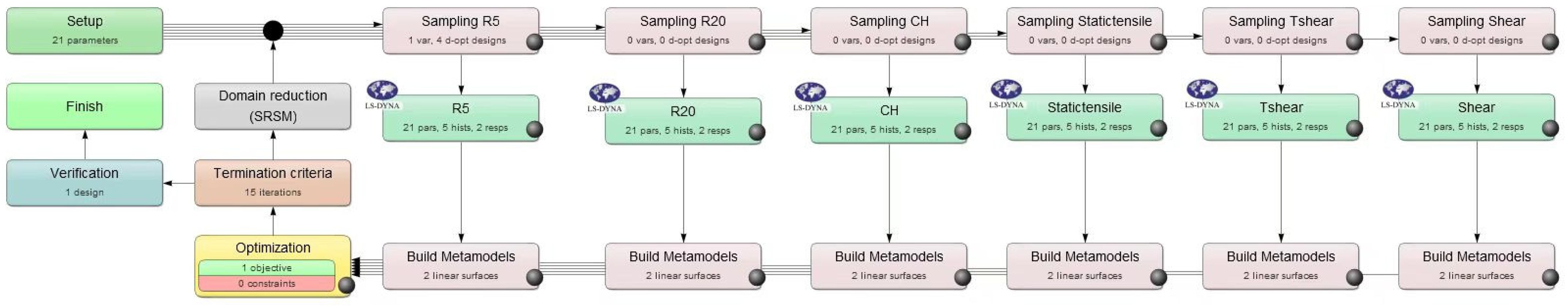

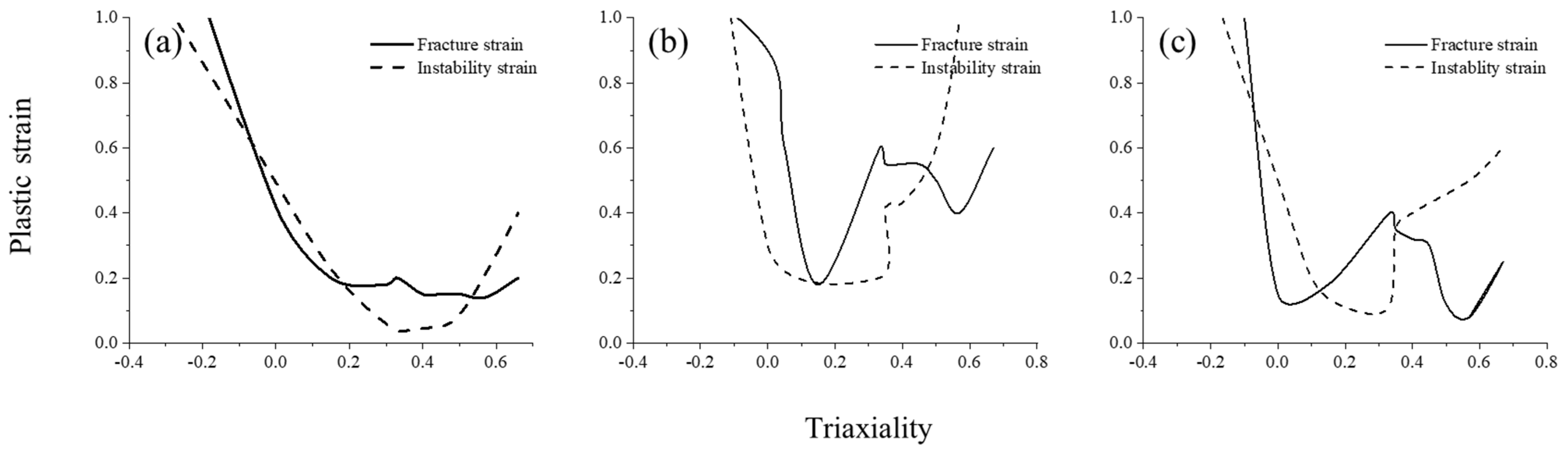

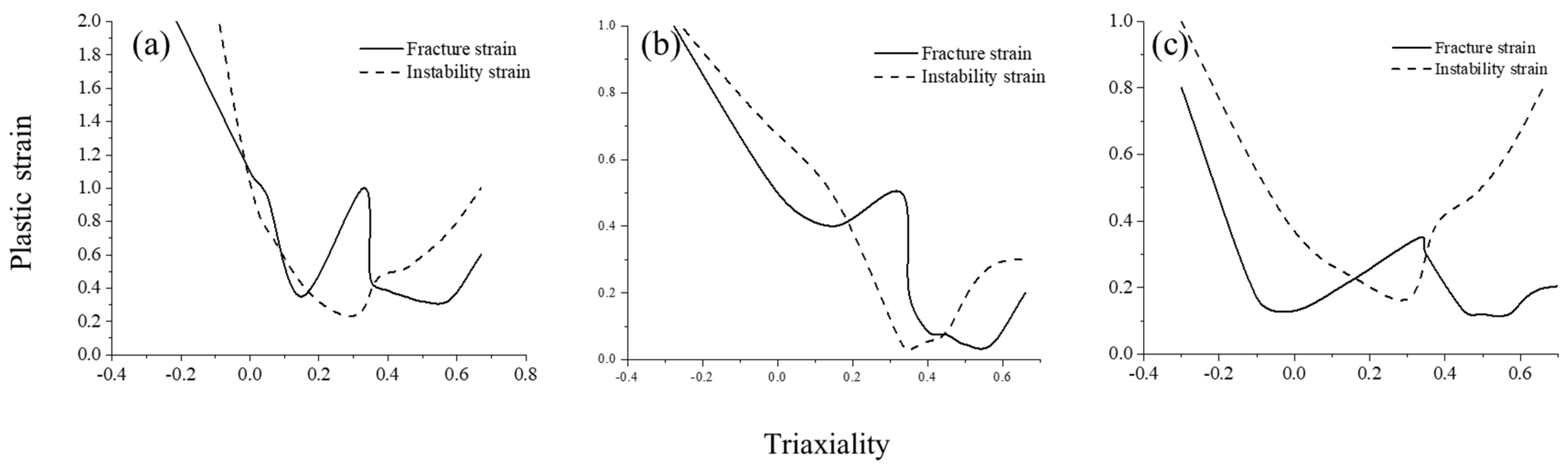

3. Characterization of Plasticity and Fracture Behaviors with GISSMO

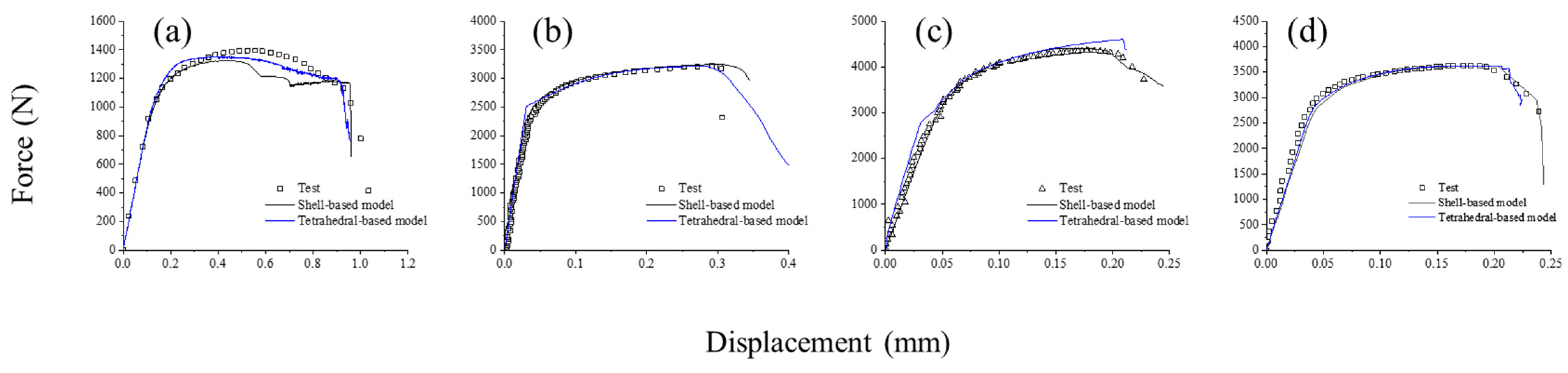

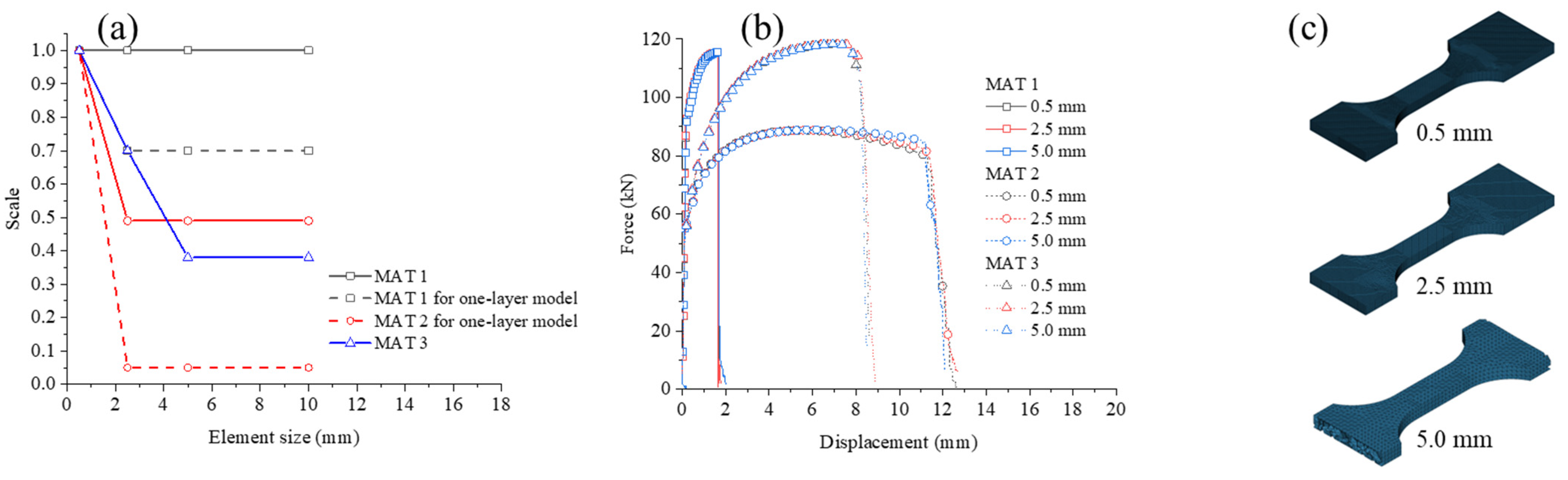

3.1. Shell-Based Model

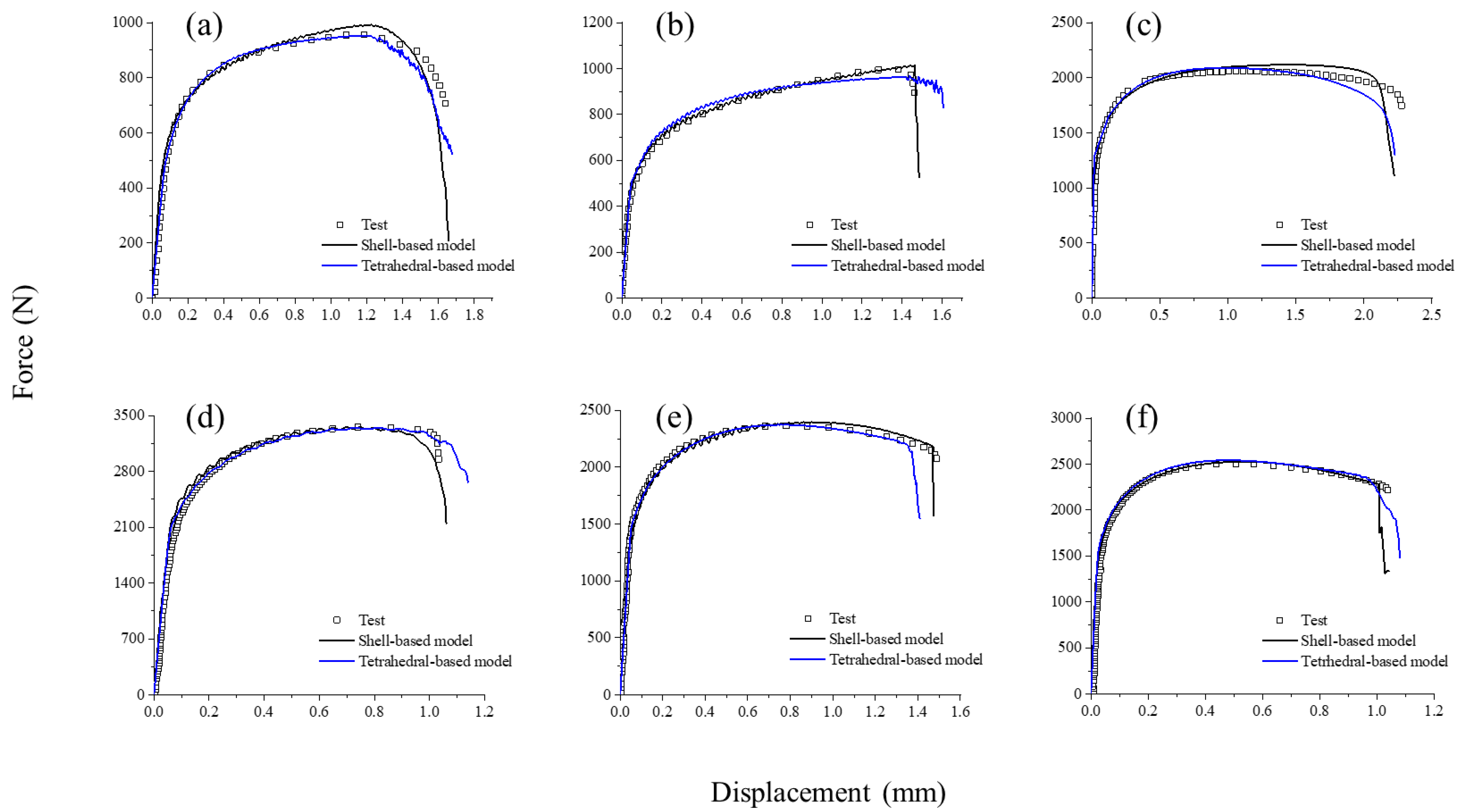

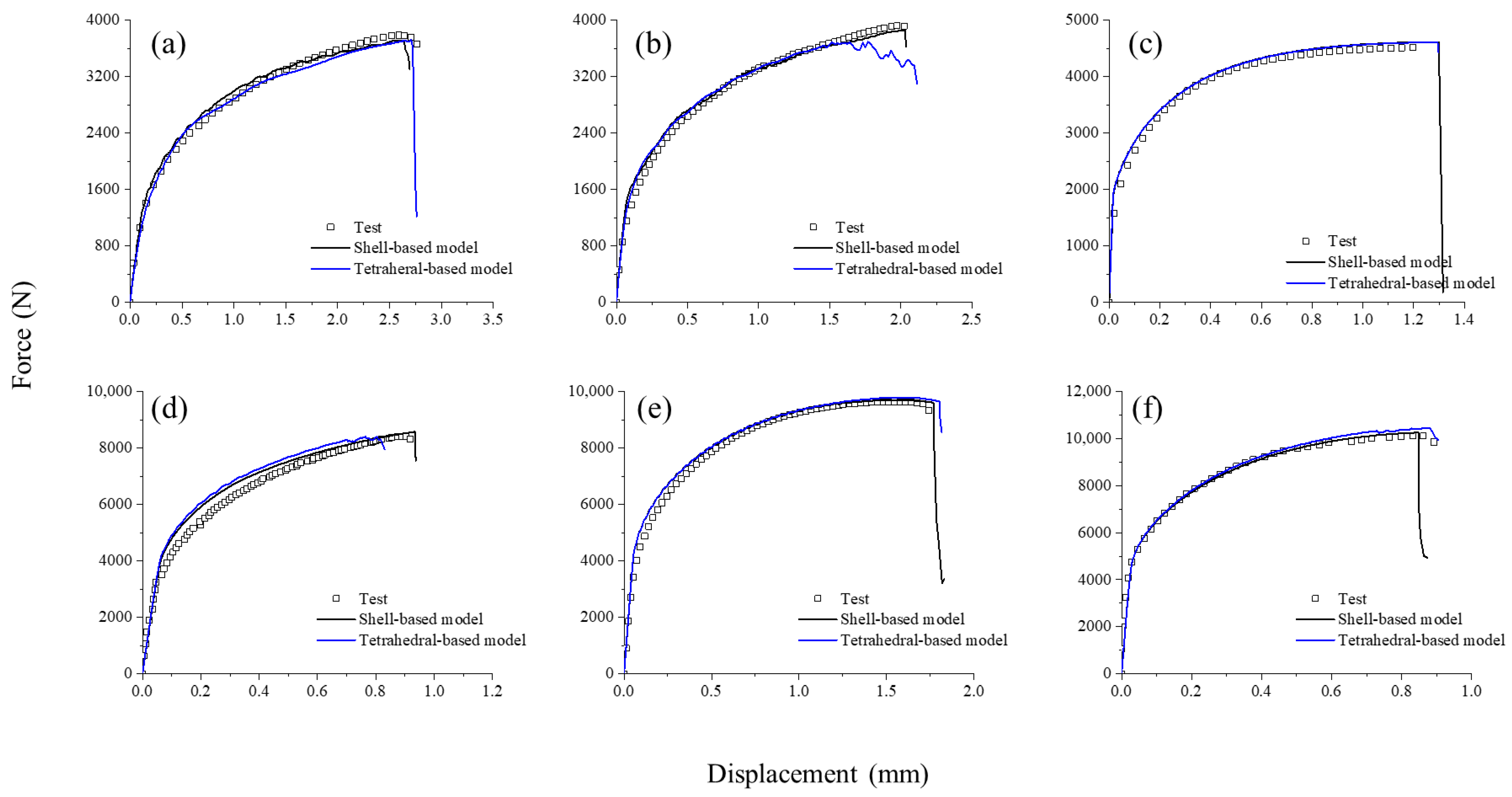

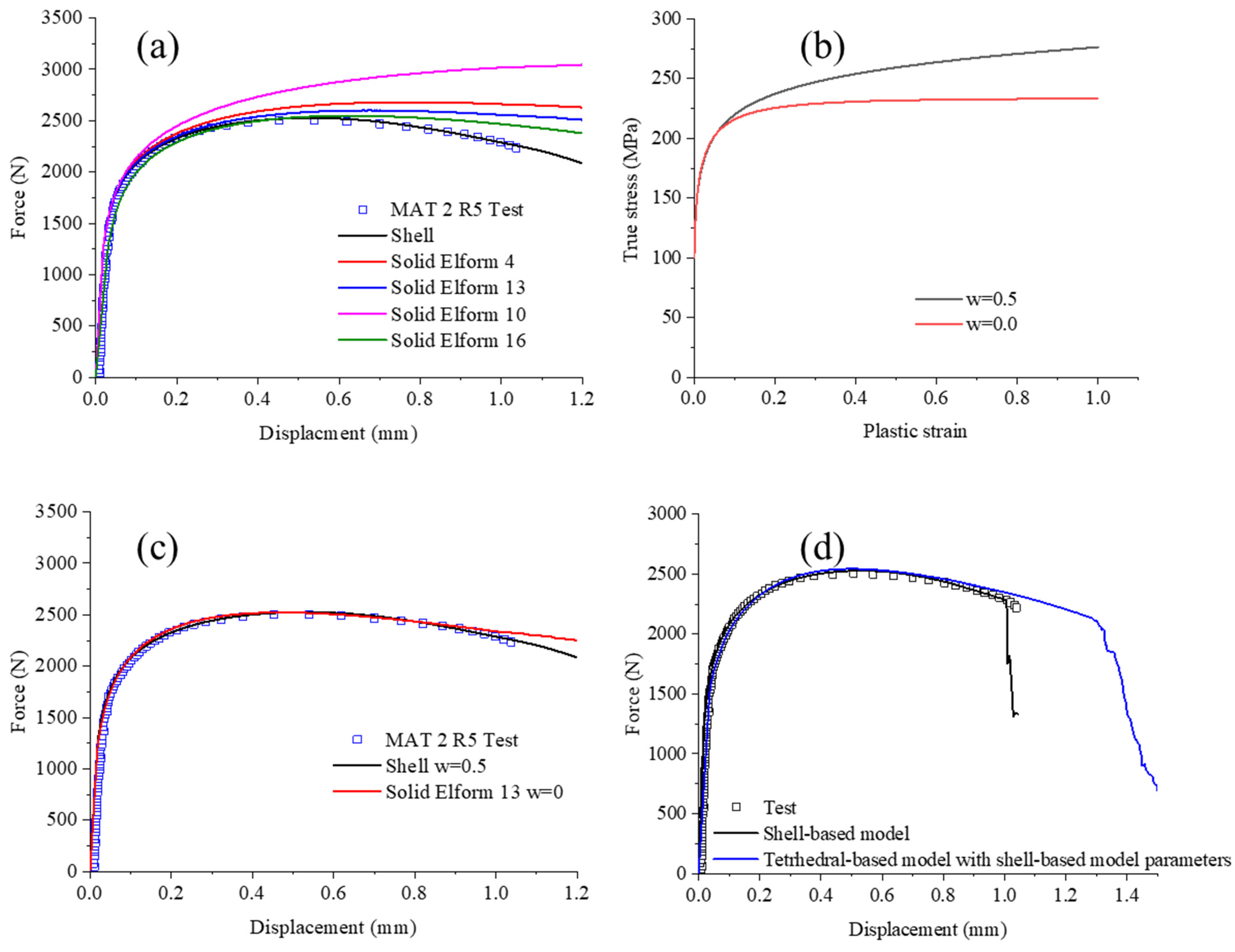

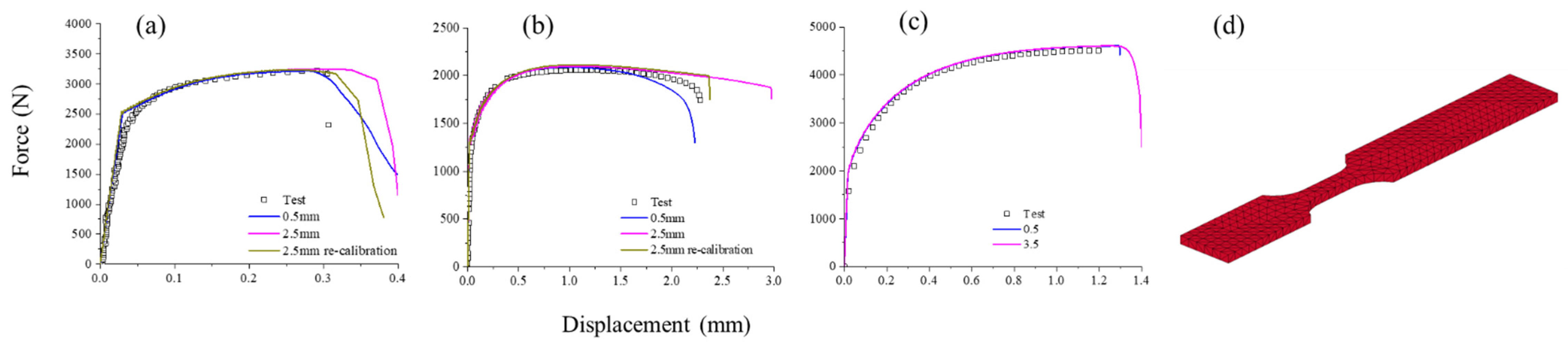

3.2. Tetrahedral-Based Models

4. Discussion

5. Conclusions

- With the well-calibrated parameters, GISSMO could reproduce the test results with good agreement for the multiple stress states.

- Optimization with LS-OPT was a feasible way to calibrate the parameters for GISSMO and avoid the requirement of practical skills.

- The part structures tests and simulations should be conducted in future work to evaluate whether the tetrahedral-based model with GISSMO is suitable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Corona, E.; Reedlunn, B. A Review of Macroscopic Ductile Failure Criteria; Sandia National Laboratories: Livermore, CA, USA, 2013. [Google Scholar]

- McClintock, F.A. A Criterion for Ductile Fracture by the Growth of Holes. J. Appl. Mech. 1968, 35, 363–371. [Google Scholar] [CrossRef]

- Rice, J.R.; Tracey, D.M. On the ductile enlargement of voids in triaxial stress fields. J. Mech. Phys. Solids 1969, 17, 201–217. [Google Scholar] [CrossRef]

- Gurson, A.L. Continuum Theory of Ductile Rupture by Void Nucleation and Growth: Part I—Yield Criteria and Flow Rules for Porous Ductile Media. J. Eng. Mater. Technol. 1977, 99, 2–15. [Google Scholar] [CrossRef]

- Bao, Y.; Wierzbicki, T. On fracture locus in the equivalent strain and stress triaxiality space. Int. J. Mech. Sci. 2004, 46, 81–98. [Google Scholar] [CrossRef]

- Mae, H.; Teng, X.; Bai, Y.; Wierzbicki, T. Calibration of ductile fracture properties of a cast aluminum alloy. Mater. Sci. Eng. A 2007, 459, 156–166. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. A new model of metal plasticity and fracture with pressure and Lode dependence. Int. J. Plast. 2008, 24, 1071–1096. [Google Scholar] [CrossRef]

- Luo, M.; Dunand, M.; Mohr, D. Experiments and modeling of anisotropic aluminum extrusions under multi-axial loading—Part II: Ductile fracture. Int. J. Plast. 2012, 32–33, 36–58. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.-J.; Park, H.; Bong, H.J.; Kim, D. Metal plasticity and ductile fracture modeling for cast aluminum alloy parts. J. Mater. Process. Technol. 2018, 255, 584–595. [Google Scholar] [CrossRef]

- Pack, K.; Mohr, D. Combined necking & fracture model to predict ductile failure with shell finite elements. Eng. Fract. Mech. 2017, 182, 32–51. [Google Scholar]

- Pack, K.; Roth, C.C. The second Sandia Fracture Challenge: Blind prediction of dynamic shear localization and full fracture characterization. Int. J. Fract. 2016, 198, 197–220. [Google Scholar] [CrossRef][Green Version]

- Mohr, D.; Marcadet, S.J. Micromechanically-motivated phenomenological Hosford–Coulomb model for predicting ductile fracture initiation at low stress triaxialities. Int. J. Solids Struct. 2015, 67–68, 40–55. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Steglich, D.; Lee, M.-G. Fracture prediction based on a two-surface plasticity law for the anisotropic magnesium alloys AZ31 and ZE10. Int. J. Plast. 2018, 105, 1–23. [Google Scholar] [CrossRef]

- Walters, C.L. Framework for adjusting for both stress triaxiality and mesh size effect for failure of metals in shell structures. Int. J. Crashworthiness 2014, 19, 1–12. [Google Scholar] [CrossRef]

- Hoque, S.E.; Scheiblhofer, S.; Ucsnik, S. A comparative study of the hexahedral elements in LS-DYNA for crashworthiness simulation. In Proceedings of the 12th European LS-DYNA Conference, Koblenz, Germany, 14–16 May 2019. [Google Scholar]

- Kim, D.-Y.; Han, Y.; Shin, S.; Yook, H. Numerical Fracture Analysis Considering Forming Effect and Element Size Regularization for Automotive Seat Structures. SAE Int. J. Engines 2017, 10, 287–295. [Google Scholar] [CrossRef]

- Eriksson, V. Numerical Simulation of Ductile Cast Iron Fracture: A parameterization of the material model *MAT_224 in the FE-code LS-DYNA. Master’s Thesis, Karlstad University, Karlstad, Sweden, 2013. [Google Scholar]

- Leost, Y.; Sonntag, A.; Haase, T. Modeling of a Cast Aluminum Wheel for Crash Application. In Proceedings of the 11th European LS-DYNA Conference, Salzburg, Austria, 9–11 May 2017. [Google Scholar]

- Sung, J.H.; Kim, J.H.; Wagoner, R.H. A plastic constitutive equation incorporating strain, strain-rate, and temperature. Int. J. Plast. 2010, 26, 1746–1771. [Google Scholar] [CrossRef]

- Johnsen, J.; Holmen, J.K.; Gruben, G.; Morin, D.; Langseth, M. Calibration and Application of GISSMO and* MAT_258 for Simulations Using Large Shell Elements. In Proceedings of the 16th International LS-DYNA User Conference, Online, 10–11 June 2020. [Google Scholar]

- Chen, X.; Chen, G.; Huang, L. Validation of GISSMO model for fracture prediction of a third-generation advanced high-strength steel. SAE Int. J. Mater. Manuf. 2018, 11, 293–302. [Google Scholar] [CrossRef]

- Gu, B.; Lim, J.; Hong, S. Determination and Verification of GISSMO Fracture Properties of Bolts Used in Radioactive Waste Transport Containers. Materials 2022, 15, 1893. [Google Scholar] [CrossRef] [PubMed]

- Ge, Y.-l.; Li, X.-X.; Lang, L.-H.; Ruan, S.-W. Optimized design of tube hydroforming loading path using multi-objective differential evolution. Int. J. Adv. Manuf. Technol. 2017, 88, 837–846. [Google Scholar] [CrossRef]

- Andrade, F.; Feucht, M.; Haufe, A. On the Prediction of Material Failure in LS-DYNA®: A Comparison between GISSMO and DIEM. In Proceedings of the 13th International LS-DYNA Users Conference, Detroit, MI, USA, 8 June 2014. [Google Scholar]

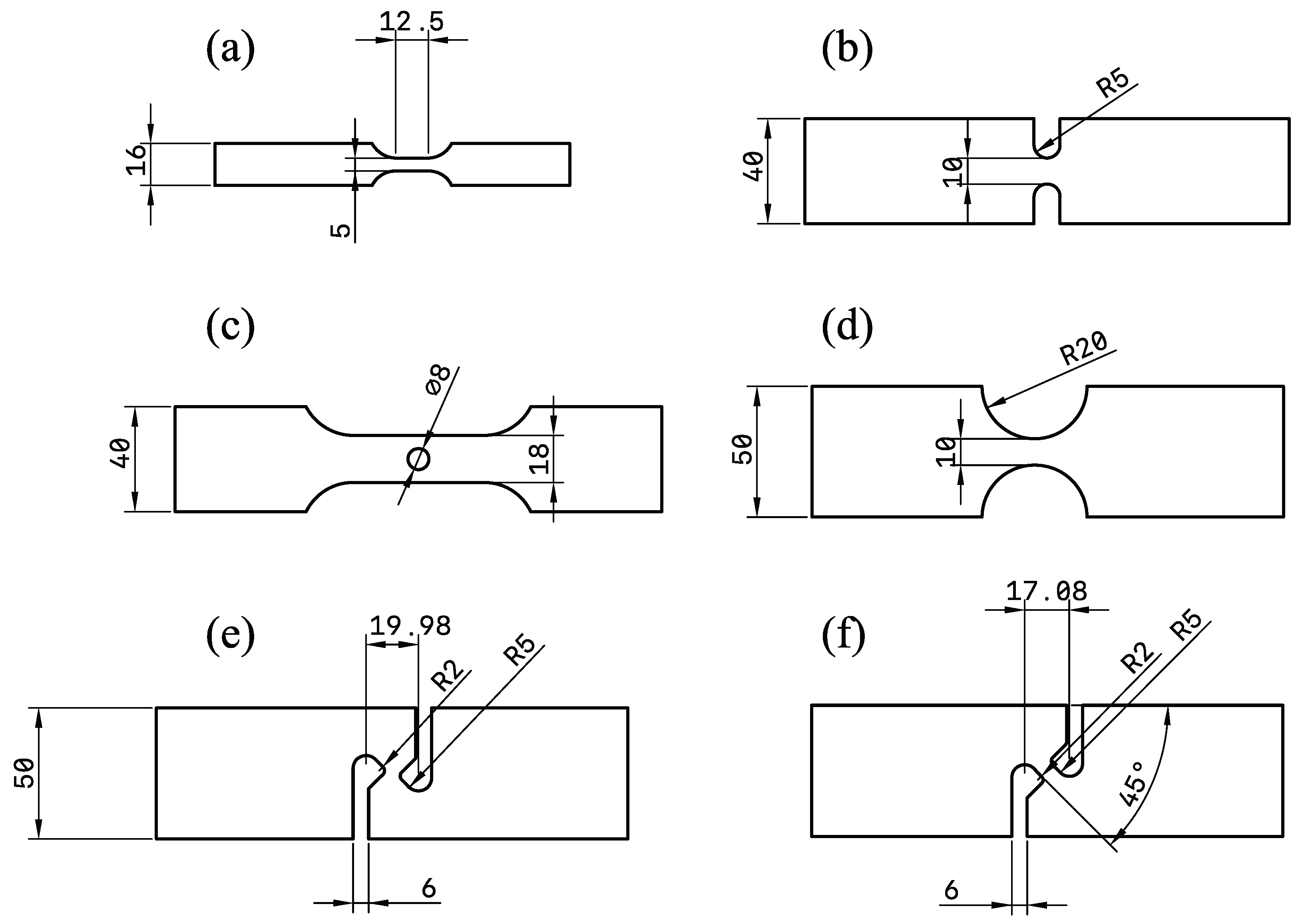

| Test # | Specimen | Desired | Desired |

|---|---|---|---|

| a | Tensile | 0.33 | 1 |

| b | R5 notched | 0.5 | 0.35 |

| c | Center hole | 0.38 | 0.85 |

| d | R20 notched | 0.40 | 0.80 |

| e | Tensile–shear | 0.10 | 0.25 |

| f | Shear | 0.0 | 0.0 |

| # | ||||||||

|---|---|---|---|---|---|---|---|---|

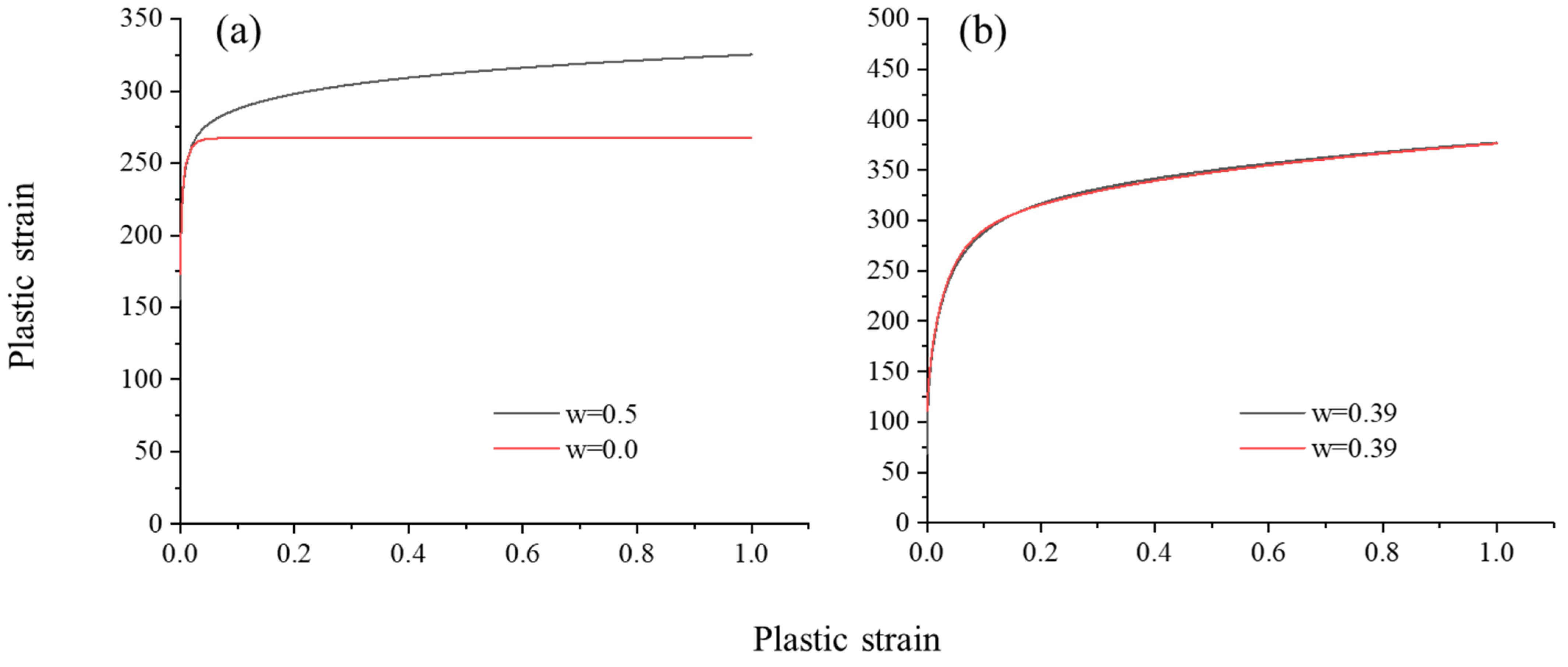

| MAT 1 | 383.143 | 0.09532 | 2.20 × 10−5 | 267.504 | 94.2477 | 40.0521 | 0.68908 | 0.5 |

| MAT 2 | 319.5 | 0.15532 | 1.2 × 10−5 | 267.504 | 186.023 | 6.12133 | 0.41562 | 0.5 |

| MAT 3 | 488.515 | 0.22313 | 1.9 × 10−5 | 306.092 | 221.370 | 11.5027 | 0.68509 | 0.39 |

| ELFORM 4 | ELFORM 10 | ELFORM 13 | ELFORM 16 |

|---|---|---|---|

| 149 s | 43 s | 49 s | 205 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, Y.; Dong, L.; Song, H.; Gao, L.; Xiao, R. On the Prediction of Material Fracture for Thin-Walled Cast Alloys Using GISSMO. Metals 2022, 12, 1850. https://doi.org/10.3390/met12111850

Ge Y, Dong L, Song H, Gao L, Xiao R. On the Prediction of Material Fracture for Thin-Walled Cast Alloys Using GISSMO. Metals. 2022; 12(11):1850. https://doi.org/10.3390/met12111850

Chicago/Turabian StyleGe, Yulong, Liping Dong, Huibin Song, Lechen Gao, and Rui Xiao. 2022. "On the Prediction of Material Fracture for Thin-Walled Cast Alloys Using GISSMO" Metals 12, no. 11: 1850. https://doi.org/10.3390/met12111850

APA StyleGe, Y., Dong, L., Song, H., Gao, L., & Xiao, R. (2022). On the Prediction of Material Fracture for Thin-Walled Cast Alloys Using GISSMO. Metals, 12(11), 1850. https://doi.org/10.3390/met12111850