Effect of Thermo-Mechanically Activated Precipitation on the Hot Deformation Behavior of High Strength Aluminum Alloy AA7075

Abstract

1. Introduction

2. Materials and Methods

2.1. Investigated Material

2.2. Heat Treatment and Hot Deformation Experiments

2.3. Property Characterization and Microstructure Investigation

3. Results

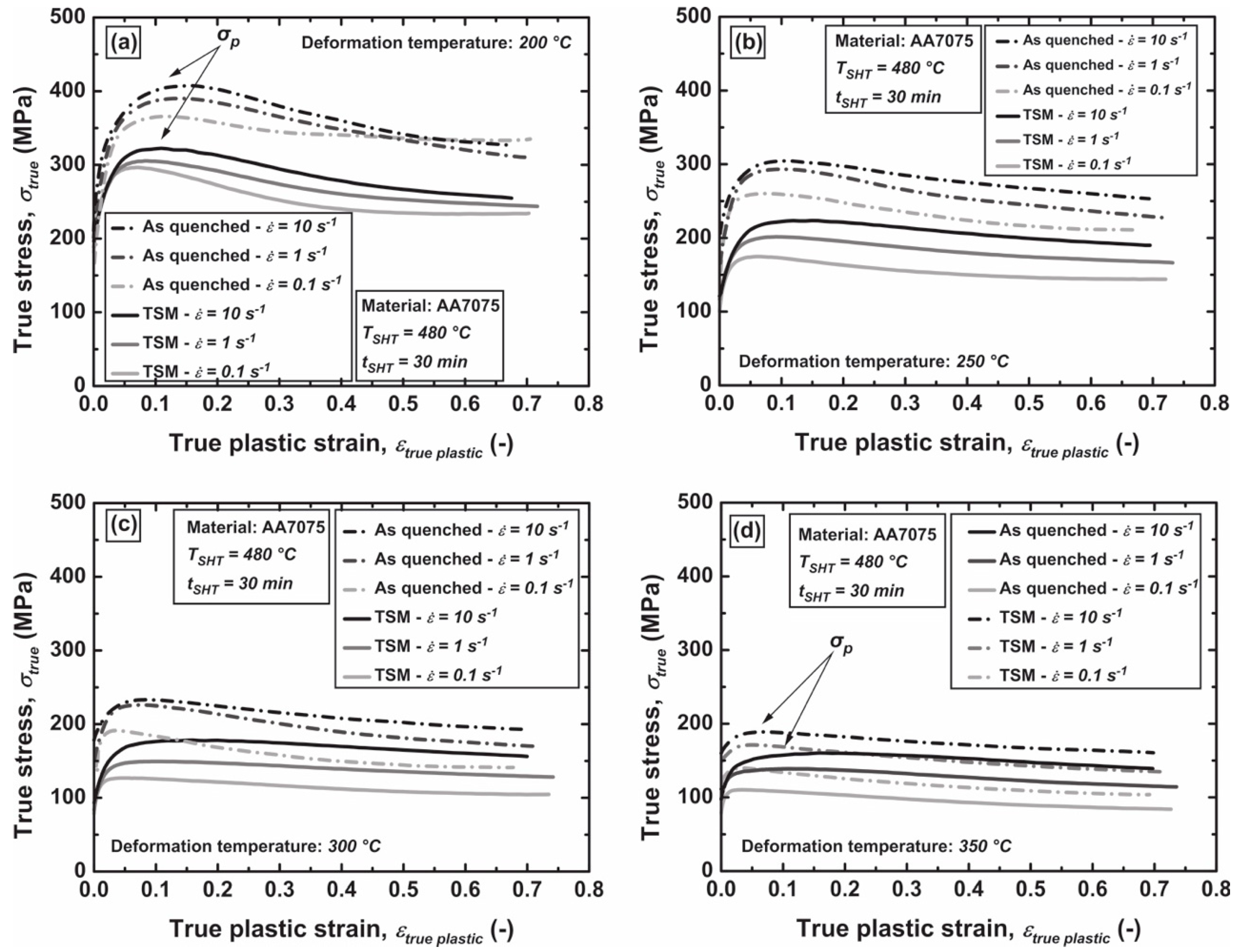

3.1. Flow Stress Behavior at Different Temperatures and Strain Rates

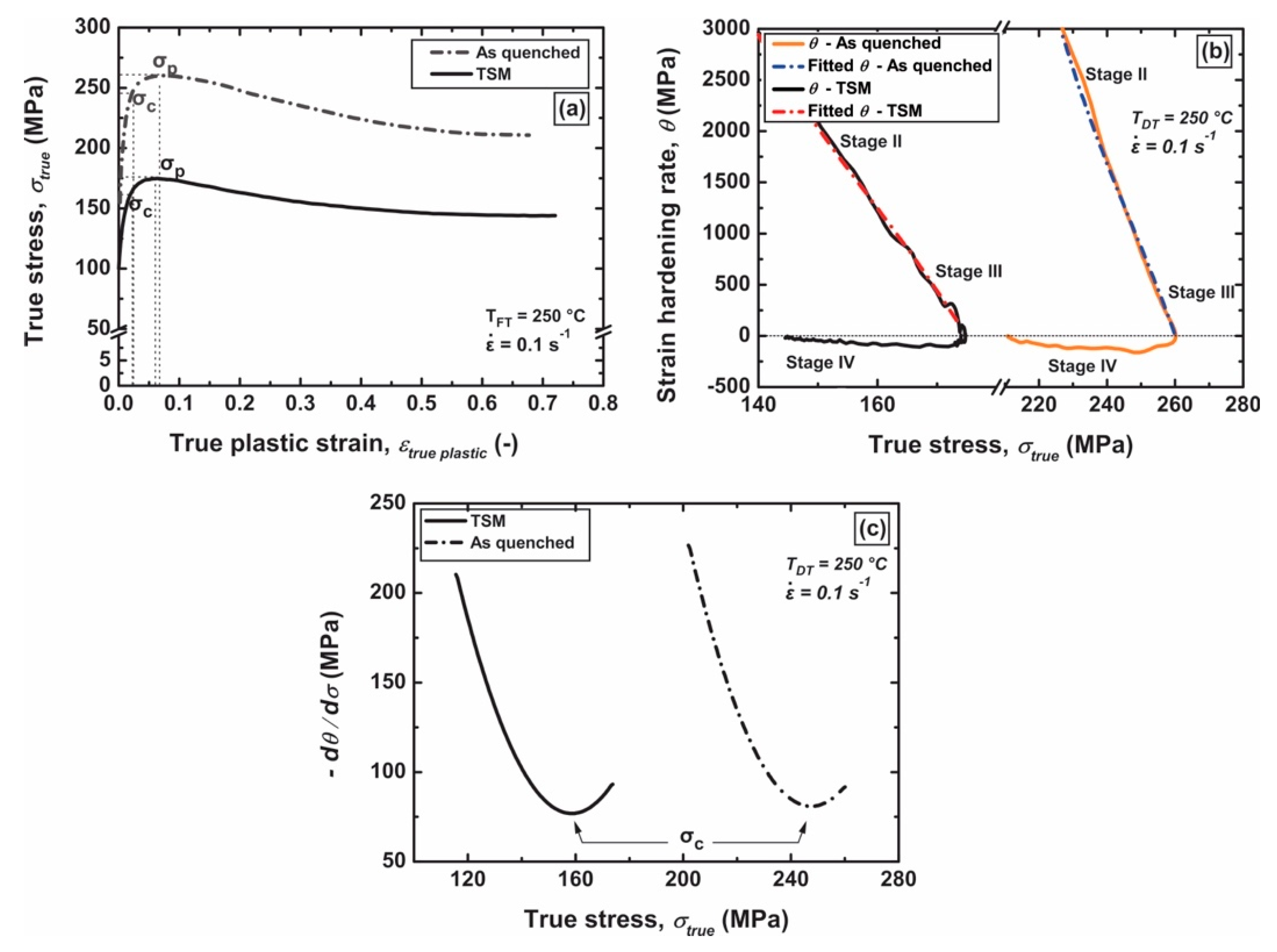

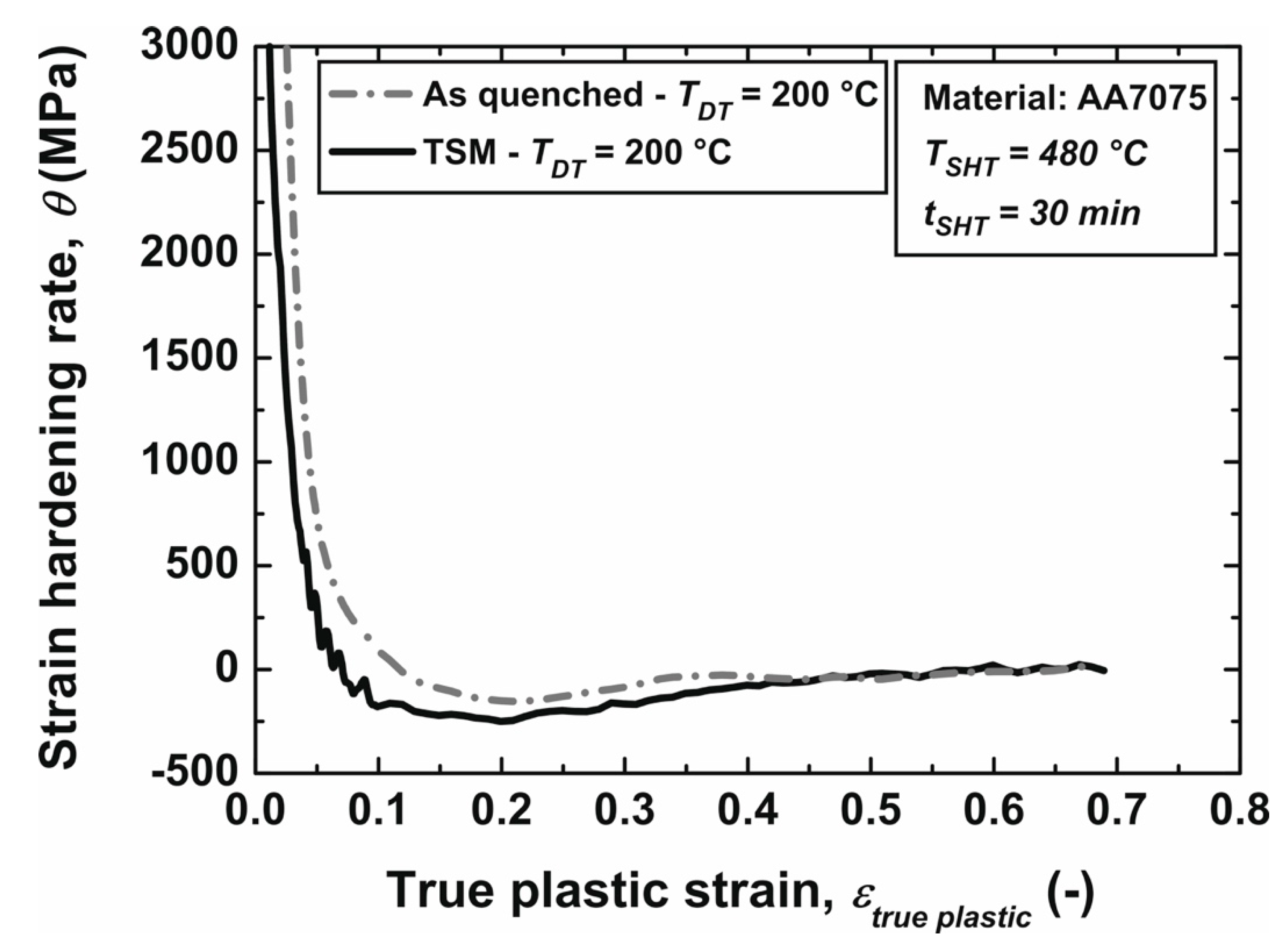

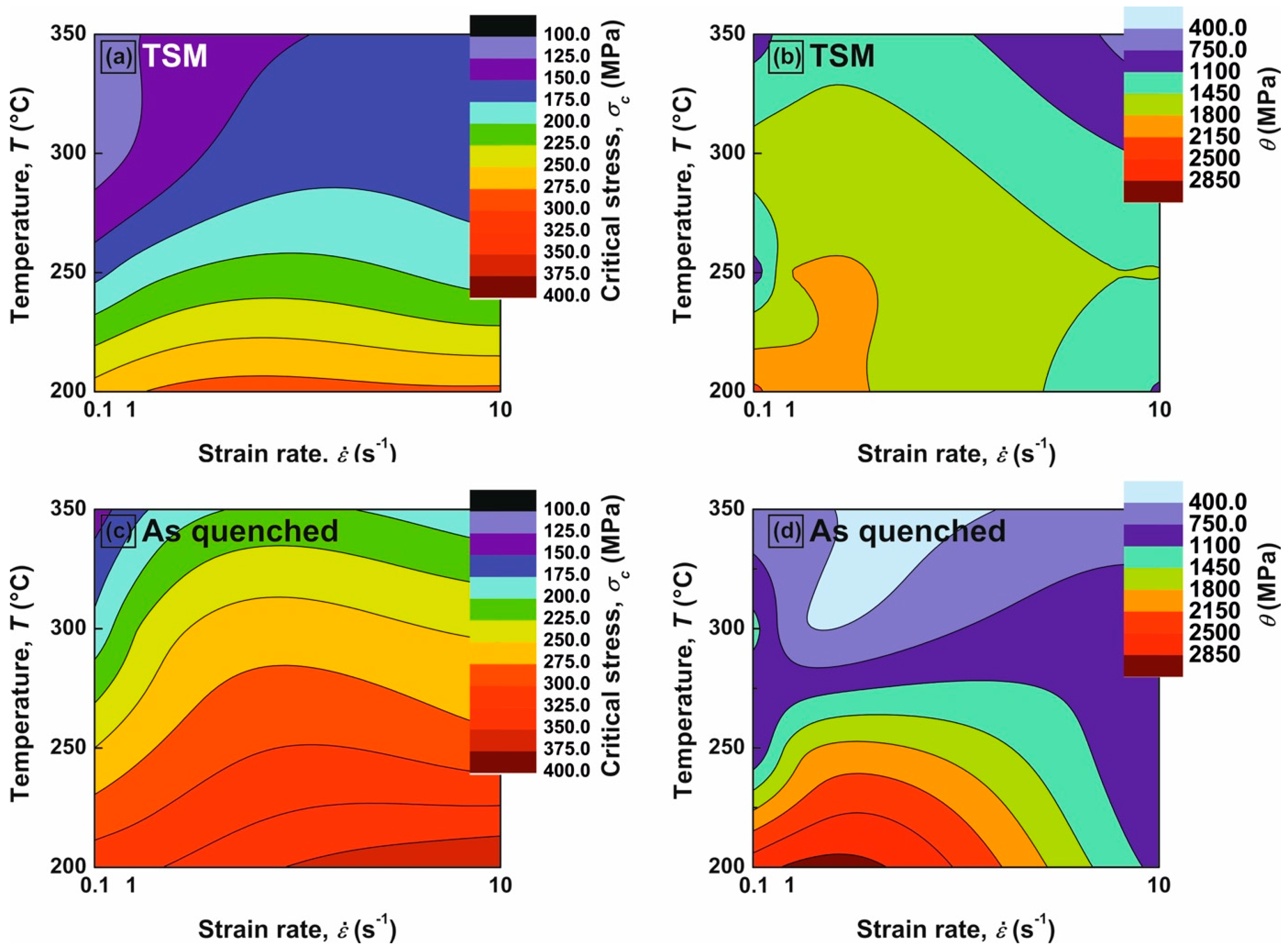

3.2. Strain-Hardening Behavior at Different Temperatures and Strain Rates

3.3. Microstructure Investigation

4. Discussion

5. Conclusions

- Microstructural condition, deformation temperature and strain rate have a significant effect on the prevailing hardening and softening mechanisms of the precipitation-hardenable aluminum alloy AA7075, which determines the resulting hot deformation behavior. In the case of the deformation temperature of 200 °C and strain rate of 10 s−1, a 110 MPa higher peak stress is obtained for the as-quenched microstructure compared to the TSM.

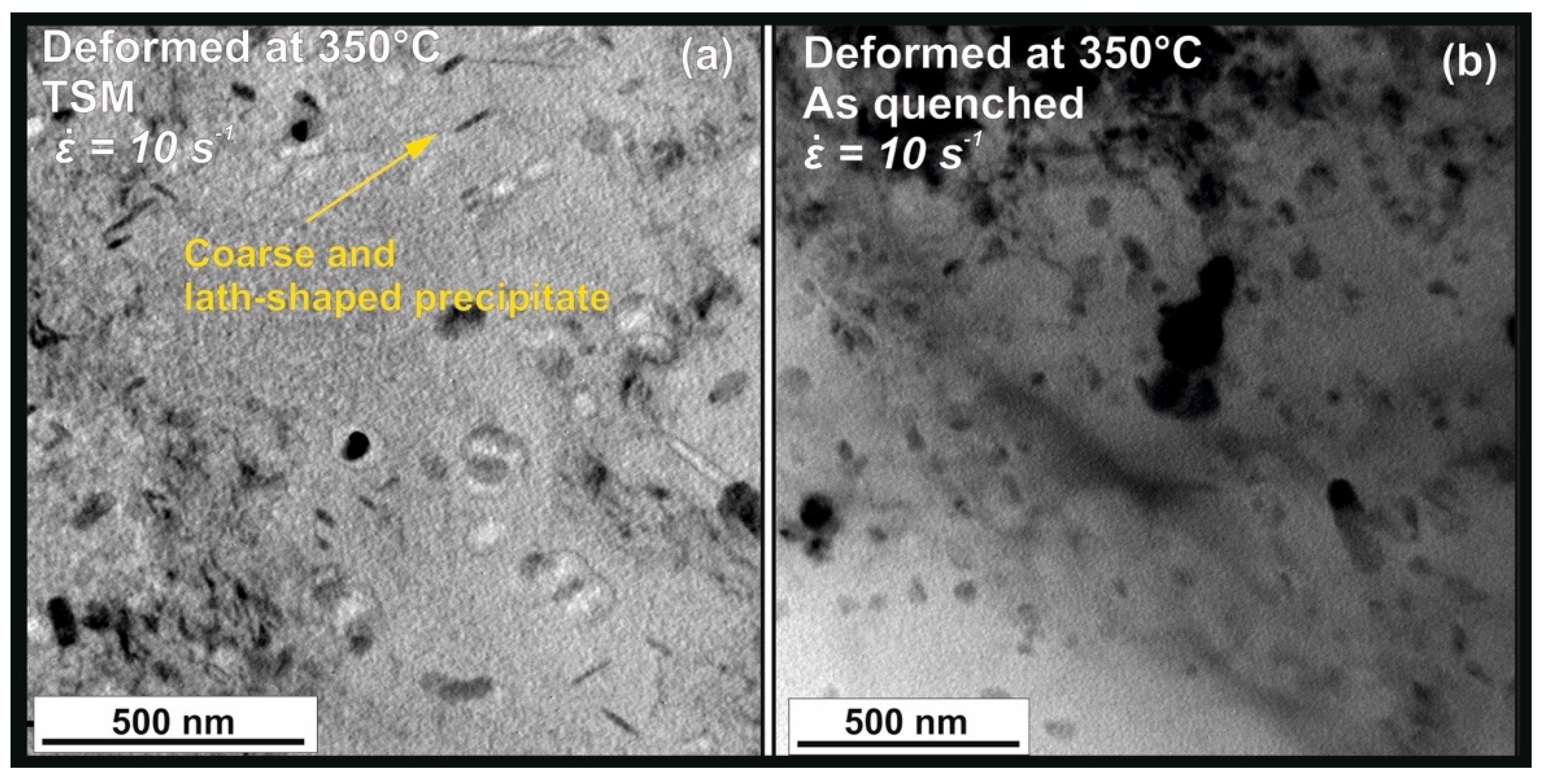

- A higher flow stress level was obtained for the as-quenched condition compared to the TSM in all cases. This behavior can be linked to the dynamic precipitation during hot deformation for the metastable as-quenched condition, leading to higher required stress for moving dislocations to overcome the nucleated fine particles. For the TSM condition, in contrast, coarse and equilibrium precipitates are obtained during the artificial treatment prior to hot deformation, which hardly contributes to the flow stress increase.

- The choice of deformation temperature and strain rate determines the onset of softening mechanisms leading to correspondingly high or low levels of flow stress.

- The microstructural condition prior to the hot deformation influences the hardening mechanisms. The hardening of a stable condition of precipitations is mainly driven by dislocation–dislocation interactions, whilst the metastable supersaturated solid solution of the as-quenched condition experiences a change from strain hardening to dislocation–particle interactions due to the activation of dynamic precipitation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Steinhoff, K.; Weidig, U.; Saba, N. Investigation of plastic forming under the influence of locally and temporally variable temperature and stress states. In Functionally Graded Materials in Industrial Mass Production; Steinhoff, K., Maier, H.J., Biermann, D., Eds.; Verlag Wissenschaftliche Scripten: Auerbach/Vogtland, Germany, 2009; pp. 35–52. [Google Scholar]

- McQueen, H.J.; Imbert, C.A.C. Dynamic recrystallization: Plasticity enhancing structural development. J. Alloys Compod. 2004, 378, 35–43. [Google Scholar] [CrossRef]

- Steinhoff, K.; Maikranz-Valentin, M.; Saba, N.; Weidig, U. Position and time dependent thermo-mechanical treatment of sheet steel for light weight structures. In Proceedings of the Herstellung und Weiterverarbeitung von Flachprodukten, TU Bergakad, Freiberg, Germany, 25–27 March 2009; pp. 130–144. [Google Scholar]

- Raabe, D. Cellular Automata in Materials Science with Particular Reference to Recrystallization Simulation. Annu. Rev. Mater. Res. 2003, 32, 53–76. [Google Scholar] [CrossRef]

- Steinhoff, K.; Weidig, U.; Bergmann, K.; Elsner, A. Verfahren zur Herstellung Eines zum Formhärten Geeigneten Blechhalbzeugs. German Patent DE102006032617B4, 12 July 2006. [Google Scholar]

- Maikranz-Valentin, M.; Weidig, U.; Schoof, U.; Becker, H.; Steinhoff, K. Components with Optimised Properties due to Advanced Thermo-mechanical Process Strategies in Hot Sheet Metal Forming. Steel Res. Int. 2008, 79, 92–97. [Google Scholar] [CrossRef]

- Gottstein, G. Materialwissenschaft und Werkstofftechnik; Springer-Lehrbuch; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-642-36602-4. [Google Scholar]

- Hornbogen, E.; Warlimont, H. Strukturen fester phasen. In Metallkunde; Springer: Berlin/Heidelberg, Germany, 2001; pp. 24–42. [Google Scholar]

- Zhang, J.; Yi, Y.; Huang, S.; Mao, X.; He, H.; Tang, J.; Guo, W.; Dong, F. Dynamic recrystallization mechanisms of 2195 aluminum alloy during medium/high temperature compression deformation. Mater. Sci. Eng. A 2021, 804, 140650. [Google Scholar] [CrossRef]

- McQueen, H.J.; Hockett, J.E. Microstructures of aluminum compressed at various rates and temperatures. Metall. Trans. 1970, 1, 2997–3004. [Google Scholar] [CrossRef]

- Raabe, D. Mesoscale simulation of recrystallization textures and microstructures. Adv. Eng. Mater. 2001, 3, 745–752. [Google Scholar] [CrossRef]

- Li, Y.; He, C.; Wei, J.; Zhang, Z.; Tian, N.; Qin, G.; Zhao, X. Effect of Post-Fabricated Aging on Microstructure and Mechanical Properties in Underwater Friction Stir Additive Manufacturing of Al–Zn–Mg–Cu Alloy. Materials 2022, 15, 3368. [Google Scholar] [CrossRef] [PubMed]

- McQueen, H.J.; Spigarelli, S.; Kassner, M.E.; Evangelista, E. Hot Deformation and Processing of Aluminum Alloys; 1.; CRC Press: Boca Raton, FL, USA, 2011; ISBN 9781420017687. [Google Scholar]

- Sajadifar, S.V.; Scharifi, E.; Wegener, T.; Krochmal, M.; Lotz, S.; Steinhoff, K.; Niendorf, T. On the low-cycle fatigue behavior of thermo-mechanically processed high-strength aluminum alloys. Int. J. Fatigue 2022, 156, 106676. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Scharifi, E.; Weidig, U.; Steinhoff, K.; Niendorf, T. Performance of thermo-mechanically processed AA7075 alloy at elevated temperatures—From microstructure to mechanical properties. Metals 2020, 10, 884. [Google Scholar] [CrossRef]

- Shojaei, K.; Sajadifar, S.V.; Yapici, G.G. On the mechanical behavior of cold deformed aluminum 7075 alloy at elevated temperatures. Mater. Sci. Eng. A 2016, 670, 81–89. [Google Scholar] [CrossRef]

- Mianroodi, J.R.; Rezaei, S.; Siboni, N.H.; Xu, B.X.; Raabe, D. Lossless multi-scale constitutive elastic relations with artificial intelligence. NPJ Comput. Mater. 2022, 8, 67. [Google Scholar] [CrossRef]

- Sakai, T.; Takahashi, C. Flow Softening of 7075 Aluminum Alloy under Hot Compression. Mater. Trans. JIM 1991, 32, 375–382. [Google Scholar] [CrossRef][Green Version]

- Völkers, S.; Scharifi, E.; Sajjadifar, S.V.; Böhm, S.; Weidig, U.; Niendorf, T. On the influence of in situ sound wave superposition on the microstructure of laser welded 7000 aluminum alloys. J. Adv. Join. Process. 2020, 1, 100013. [Google Scholar] [CrossRef]

- Roven, H.J.; Liu, M.; Werenskiold, J.C. Dynamic precipitation during severe plastic deformation of an Al–Mg–Si aluminium alloy. Mater. Sci. Eng. A 2008, 483–484, 54–58. [Google Scholar] [CrossRef]

- Zhang, Y.; Jin, S.; Trimby, P.W.; Liao, X.; Murashkin, M.Y.; Valiev, R.Z.; Liu, J.; Cairney, J.M.; Ringer, S.P.; Sha, G. Dynamic precipitation, segregation and strengthening of an Al-Zn-Mg-Cu alloy (AA7075) processed by high-pressure torsion. Acta Mater. 2019, 162, 19–32. [Google Scholar] [CrossRef]

- Deschamps, A.; Fribourg, G.; Bréchet, Y.; Chemin, J.L.; Hutchinson, C.R. In situ evaluation of dynamic precipitation during plastic straining of an Al-Zn-Mg-Cu alloy. Acta Mater. 2012, 60, 1905–1916. [Google Scholar] [CrossRef]

- Couturier, L.; Deschamps, A.; De Geuser, F.; Fazeli, F.; Poole, W.J. An investigation of the strain dependence of dynamic precipitation in an Al-Zn-Mg-Cu alloy. Scr. Mater. 2017, 136, 120–123. [Google Scholar] [CrossRef]

- Chen, C.; Chen, J.; Yan, H.; Su, B.; Song, M.; Zhu, S. Dynamic precipitation, microstructure and mechanical properties of Mg-5Zn-1Mn alloy sheets prepared by high strain-rate rolling. Mater. Des. 2016, 100, 58–66. [Google Scholar] [CrossRef]

- Cubides, Y.; Zhao, D.; Nash, L.; Yadav, D.; Xie, K.; Karaman, I.; Castaneda, H. Effects of dynamic recrystallization and strain-induced dynamic precipitation on the corrosion behavior of partially recrystallized Mg–9Al–1Zn alloys. J. Magnes. Alloys 2020, 8, 1016–1037. [Google Scholar] [CrossRef]

- Kabir, A.S.H.; Su, J.; Jung, I.H.; Yue, S. Study of Dynamic Precipitation during Hot Deformation of Mg-Al-Sn Alloys. Mater. Sci. Forum 2013, 765, 461–465. [Google Scholar]

- Heider, B.; Scharifi, E.; Engler, T.; Oechsner, M.; Steinhoff, K. Influence of heated forming tools on corrosion behavior of high strength aluminum alloys. Materwiss. Werksttech. 2020, 52, mawe.202000125. [Google Scholar] [CrossRef]

- Scharifi, E.; Sajadifar, S.V.; Moeini, G.; Weidig, U.; Böhm, S.; Niendorf, T.; Steinhoff, K. Dynamic Tensile Deformation of High Strength Aluminum Alloys Processed Following Novel Thermomechanical Treatment Strategies. Adv. Eng. Mater. 2020, 22, 2000193. [Google Scholar] [CrossRef]

- Scharifi, E.; Shoshmina, D.; Biegler, S.; Weidig, U.; Steinhoff, K. Influence of hot deformation on the precipitation hardening of high-strength aluminum aa7075 during thermo-mechanical processing. Metals 2021, 11, 681. [Google Scholar] [CrossRef]

- Scharifi, E.; Knoth, R.; Weidig, U. Thermo-mechanical forming procedure of high strength Aluminum sheet with improved mechanical properties and process efficiency. Procedia Manuf. 2019, 29, 481–489. [Google Scholar] [CrossRef]

- Scharifi, E.; Erbskorn, F.; Ademaj, A.; Kavaklioglu, Z.B.; Weidig, U.; Steinhoff, K. Potentialities of process cycle time reductions at hot stamping of aluminum alloys. In Proceedings of the 7th International Conference Hot Sheet Metal Forming on High Performance Steel, Luleå, Sweden, 2–5 June 2019; Volume 6082, pp. 237–245. [Google Scholar]

- Richtlinie zur Aufnahme von Fließkurven; German Cold Forming Group, German Forging Association: Hagen, Germany, 2008. (In German)

- Kopp, R.; Luce, R.; Leisten, B.; Wolske, M.; Tschirnich, M.; Rehrmann, T.; Volles, R. Flow stress measuring by use of cylindrical compression test and special application to metal forming processes. Steel Res. 2001, 72, 394–401. [Google Scholar] [CrossRef]

- Li, K.; Pan, Q.; Li, R.; Liu, S.; Huang, Z.; He, X. Constitutive Modeling of the Hot Deformation Behavior in 6082 Aluminum Alloy. J. Mater. Eng. Perform. 2019, 28, 981–994. [Google Scholar] [CrossRef]

- Jonas, J.J.; Quelennec, X.; Jiang, L.; Martin, É. The Avrami kinetics of dynamic recrystallization. Acta Mater. 2009, 57, 2748–2756. [Google Scholar] [CrossRef]

- Najafizadeh, A.; Jonas, J.J. Predicting the critical stress for initiation of dynamic recrystallization. ISIJ Int. 2006, 46, 1679–1684. [Google Scholar] [CrossRef]

- Poliak, E.I.; Jonas, J.J. Initiation of Dynamic Recrystallization in Constant Strain Rate Hot Deformation. ISIJ Int. 2003, 43, 684–691. [Google Scholar] [CrossRef]

- Buha, J.; Lumley, R.N.; Crosky, A.G. Secondary ageing in an aluminium alloy 7050. Mater. Sci. Eng. A 2008, 492, 1–10. [Google Scholar] [CrossRef]

- Scharifi, E.; Savaci, U.; Kavaklioglu, Z.B.; Weidig, U.; Turan, S.; Steinhoff, K. Effect of thermo-mechanical processing on quench-induced precipitates morphology and mechanical properties in high strength AA7075 aluminum alloy. Mater. Charact. 2021, 174, 111026. [Google Scholar] [CrossRef]

- Huo, W.; Hou, L.; Zhang, Y.; Zhang, J. Warm formability and post-forming microstructure/property of high-strength AA 7075-T6 Al alloy. Mater. Sci. Eng. A 2016, 675, 44–54. [Google Scholar] [CrossRef]

- Hornbogen, E. Hundred years of precipitation hardening. J. Light Met. 2001, 1, 127–132. [Google Scholar] [CrossRef]

- Hornbogen, E.; Starke, E.A. Overview no. 102 theory assisted design of high strength low alloy aluminum. Acta Metall. Mater. 1993, 41, 1–16. [Google Scholar] [CrossRef]

- Jägle, E.A.; Sheng, Z.; Wu, L.; Lu, L.; Risse, J.; Weisheit, A.; Raabe, D. Precipitation Reactions in Age-Hardenable Alloys During Laser Additive Manufacturing. Jom 2016, 68, 943–949. [Google Scholar] [CrossRef]

- Hull, D.; Bacon, D.J. Introduction to Dislocations; Butterworth-Heinemann: Oxford, UK, 2011; ISBN 9780080966724. [Google Scholar]

- Strohmann, T.; Breitbarth, E.; Besel, M.; Zaunschirm, S.; Witulski, T.; Requena, G. Damage Mechanisms and Anisotropy of an AA7010-T7452 Open-Die Forged Alloy: Fatigue Crack Propagation. Materials 2022, 15, 3771. [Google Scholar] [CrossRef] [PubMed]

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| Mass content in % | 0.10 | 0.11 | 1.49 | 0.03 | 2.38 | 0.20 | 5.57 | 0.03 | 0.04 | Balance |

| Material | TSHT °C | TSHT min | Artificial Aging (°C)/h | Deformation Temperature °C | Strain Rate s−1 |

|---|---|---|---|---|---|

| AA7075— As-quenched | 480 | 30 | - | 200, 250, 300, 350 | 0.1, 1, 10 |

| A7075—TSM | 480 | 30 | (200, 250, 300, 350)/24 | 200, 250, 300, 350 | 0.1, 1, 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scharifi, E.; Nietsch, J.A.; Quadfasel, A.; Weidig, U.; Steinhoff, K. Effect of Thermo-Mechanically Activated Precipitation on the Hot Deformation Behavior of High Strength Aluminum Alloy AA7075. Metals 2022, 12, 1609. https://doi.org/10.3390/met12101609

Scharifi E, Nietsch JA, Quadfasel A, Weidig U, Steinhoff K. Effect of Thermo-Mechanically Activated Precipitation on the Hot Deformation Behavior of High Strength Aluminum Alloy AA7075. Metals. 2022; 12(10):1609. https://doi.org/10.3390/met12101609

Chicago/Turabian StyleScharifi, Emad, Jürgen A. Nietsch, Angela Quadfasel, Ursula Weidig, and Kurt Steinhoff. 2022. "Effect of Thermo-Mechanically Activated Precipitation on the Hot Deformation Behavior of High Strength Aluminum Alloy AA7075" Metals 12, no. 10: 1609. https://doi.org/10.3390/met12101609

APA StyleScharifi, E., Nietsch, J. A., Quadfasel, A., Weidig, U., & Steinhoff, K. (2022). Effect of Thermo-Mechanically Activated Precipitation on the Hot Deformation Behavior of High Strength Aluminum Alloy AA7075. Metals, 12(10), 1609. https://doi.org/10.3390/met12101609