Research on an Ultrasonic Longitudinal Critically Refracted Wave Detection Method for the Depth Distribution of Stress

Abstract

:1. Introduction

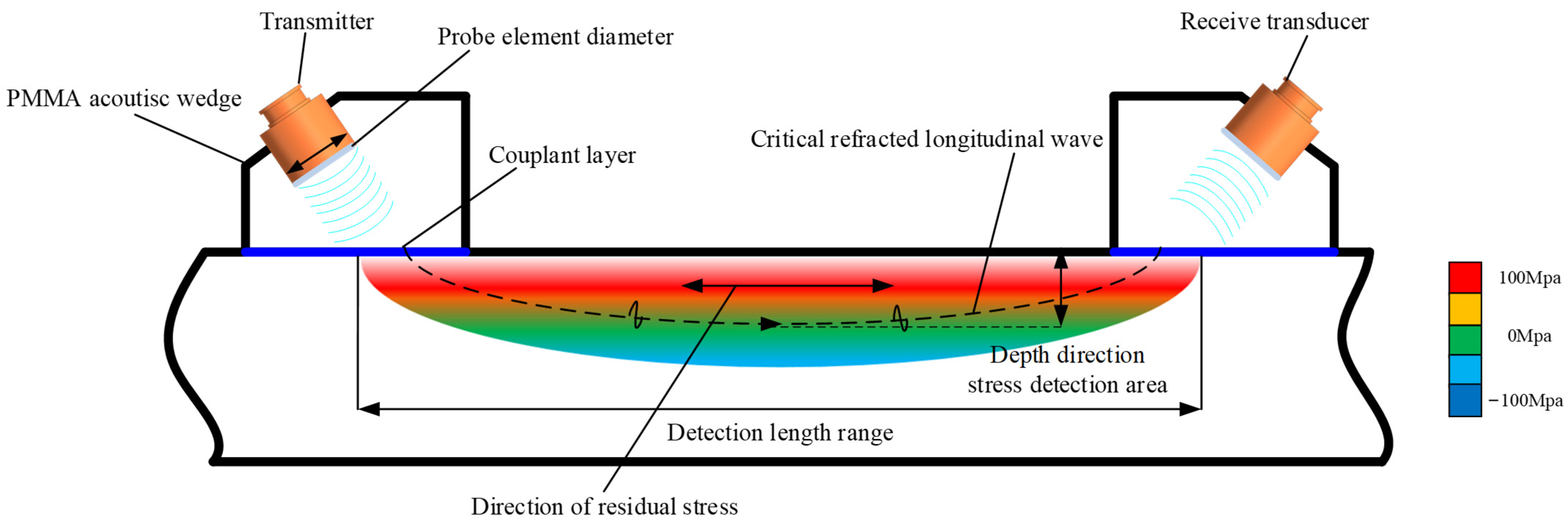

2. Principle of Stress Measurement by LCR Waves

2.1. Testing Method for the Acousto-Elastic Theory

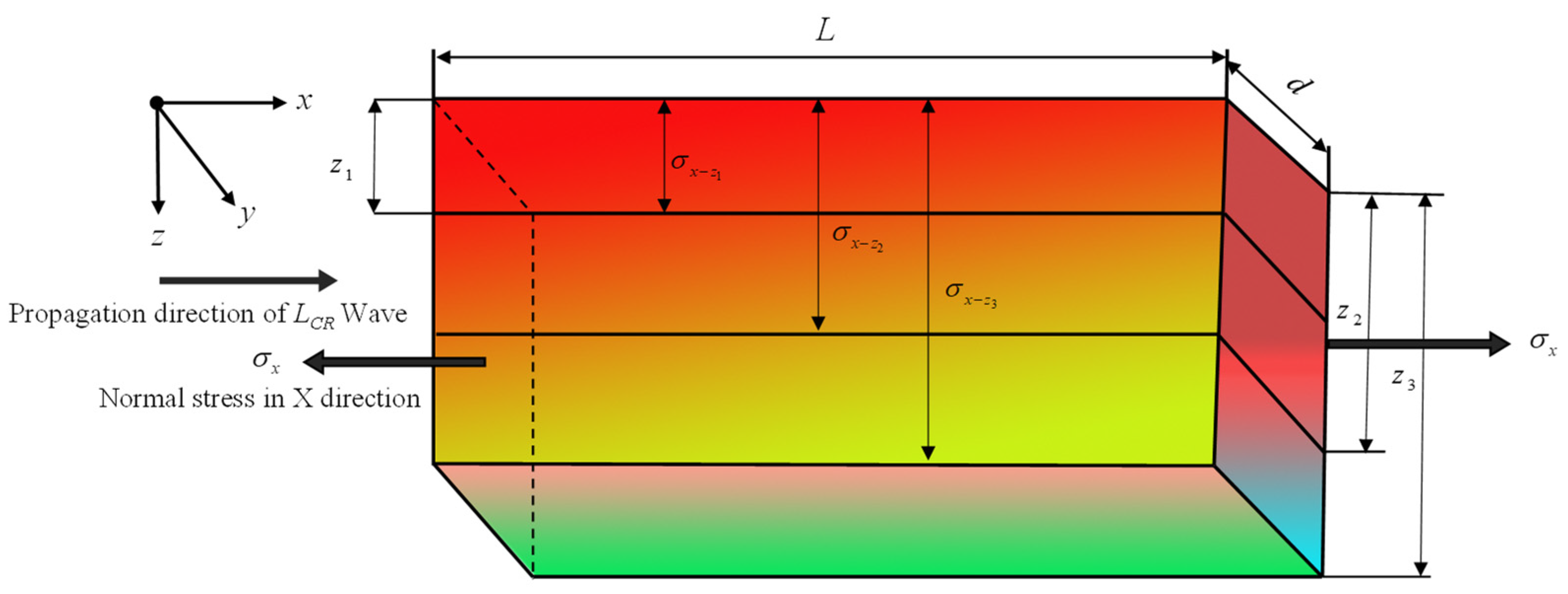

2.2. Detection Principle of Stress Depth Distribution

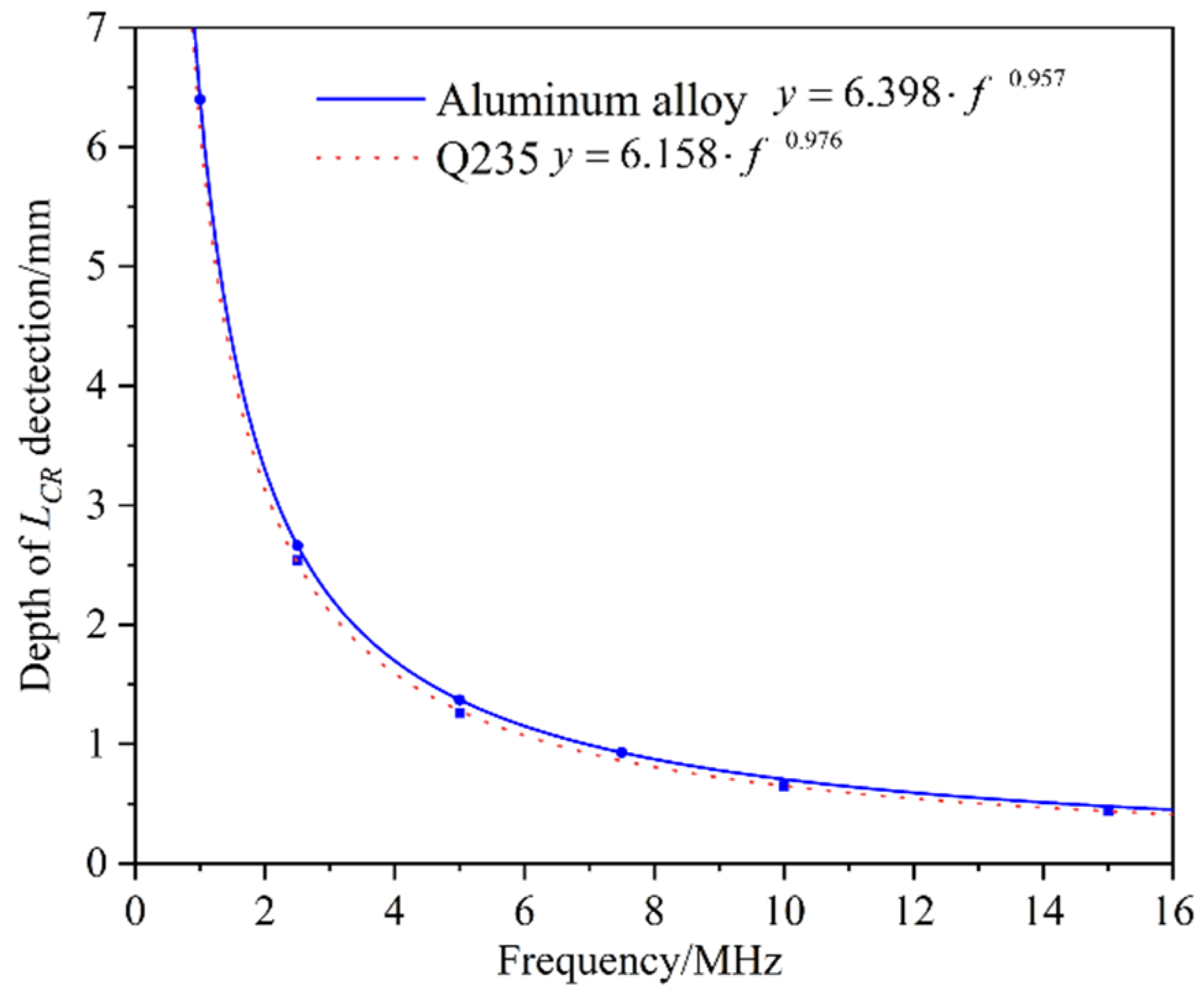

3. The Dependency of LCR Wave Propagation Depth on Its Frequency

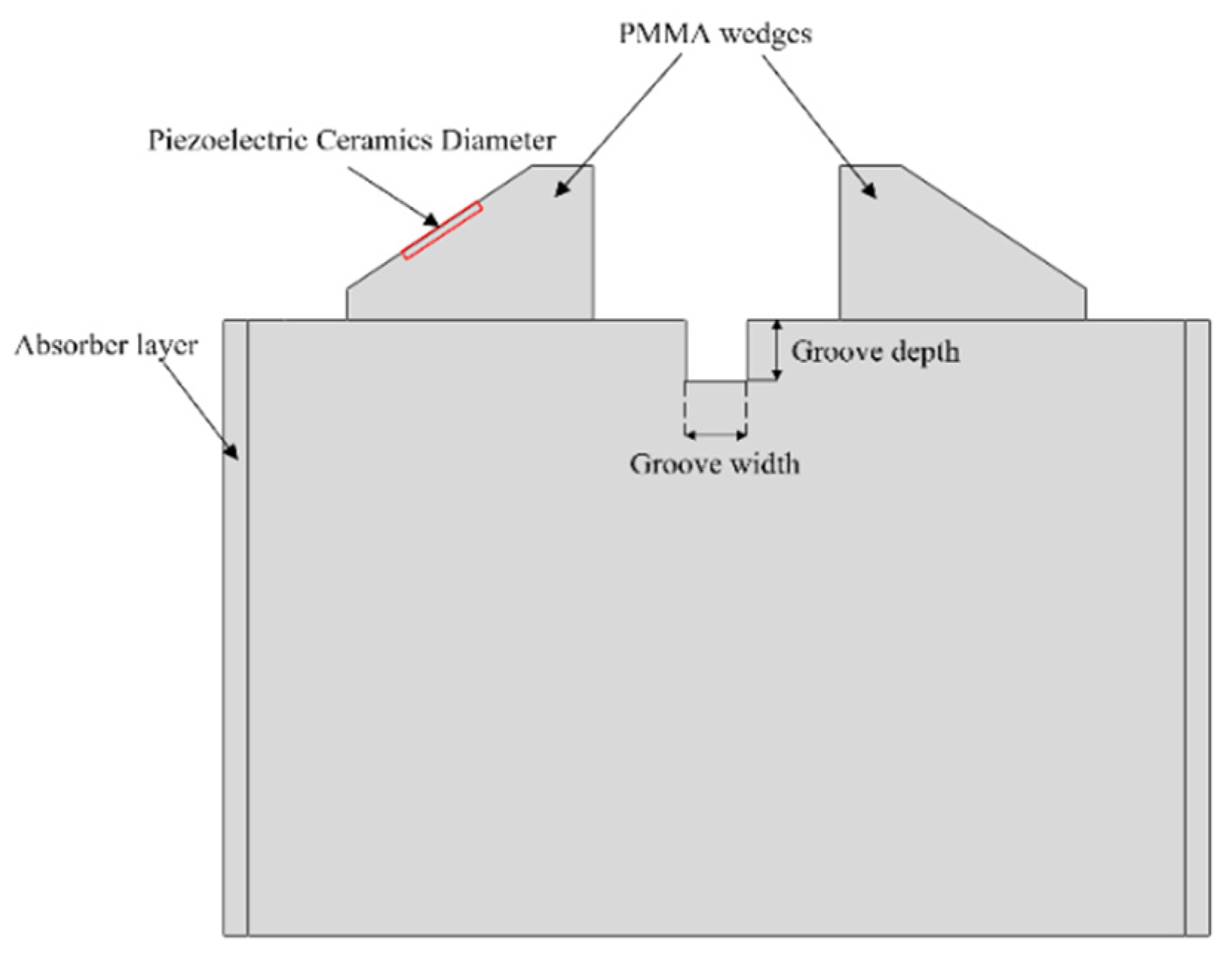

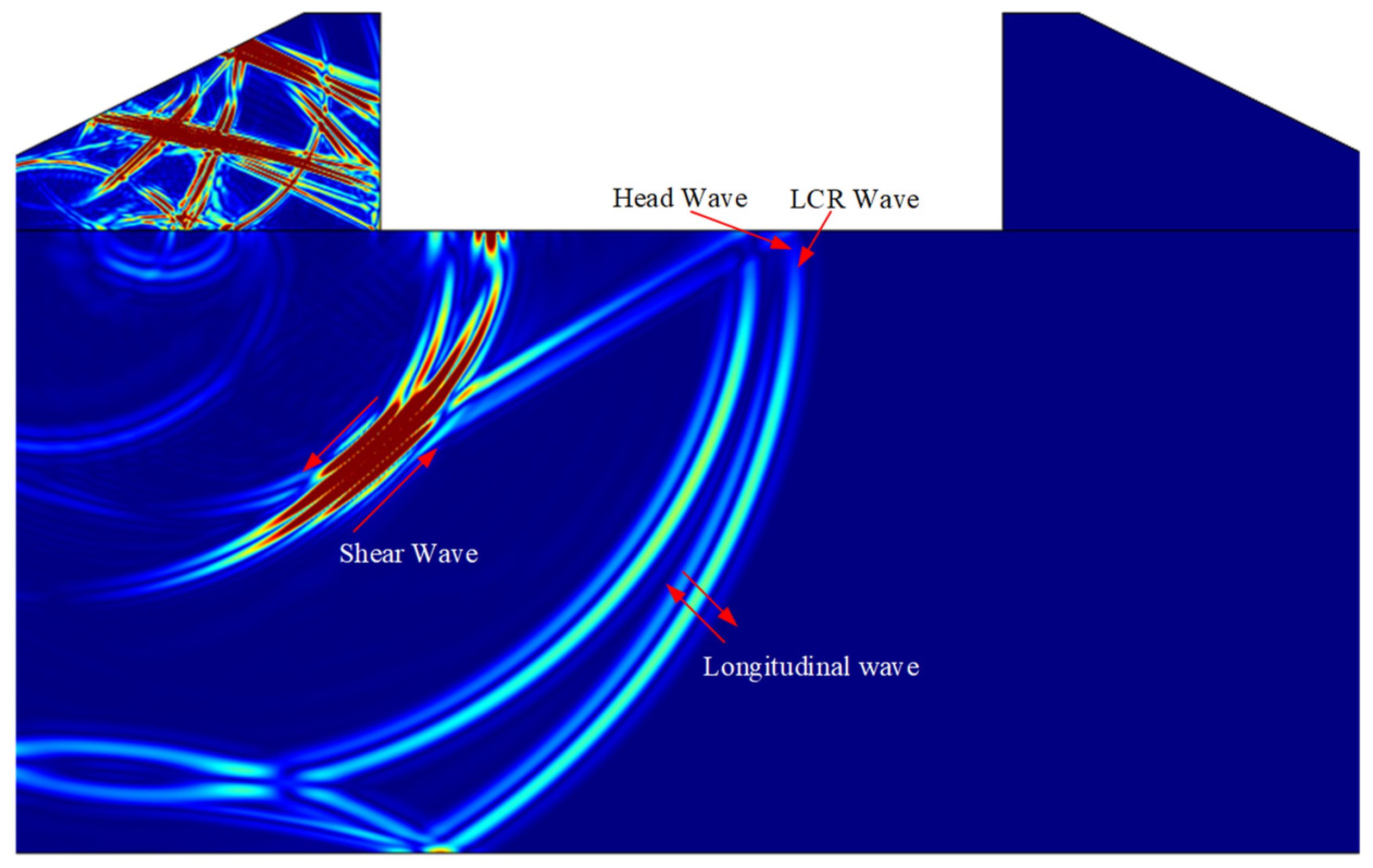

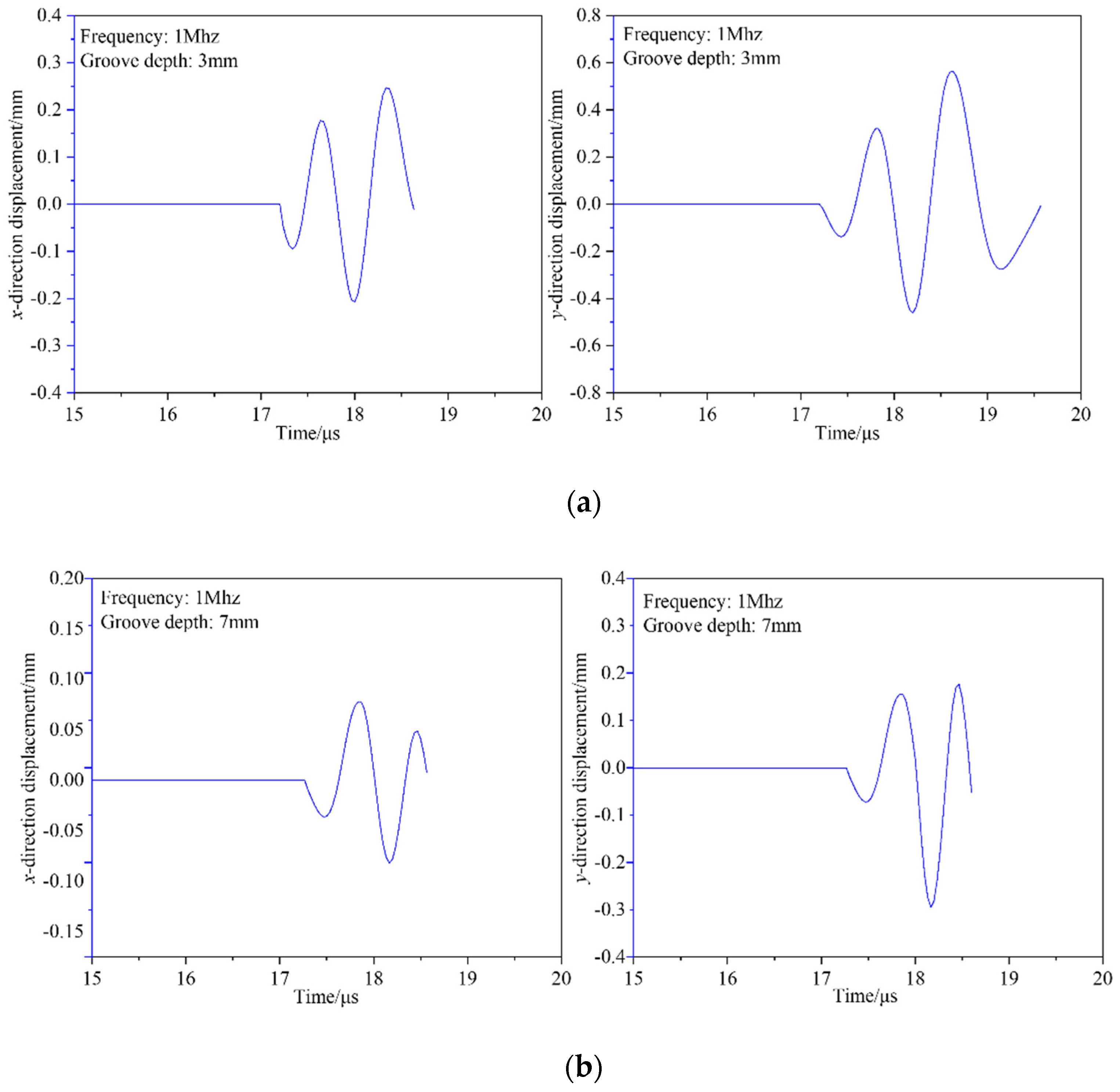

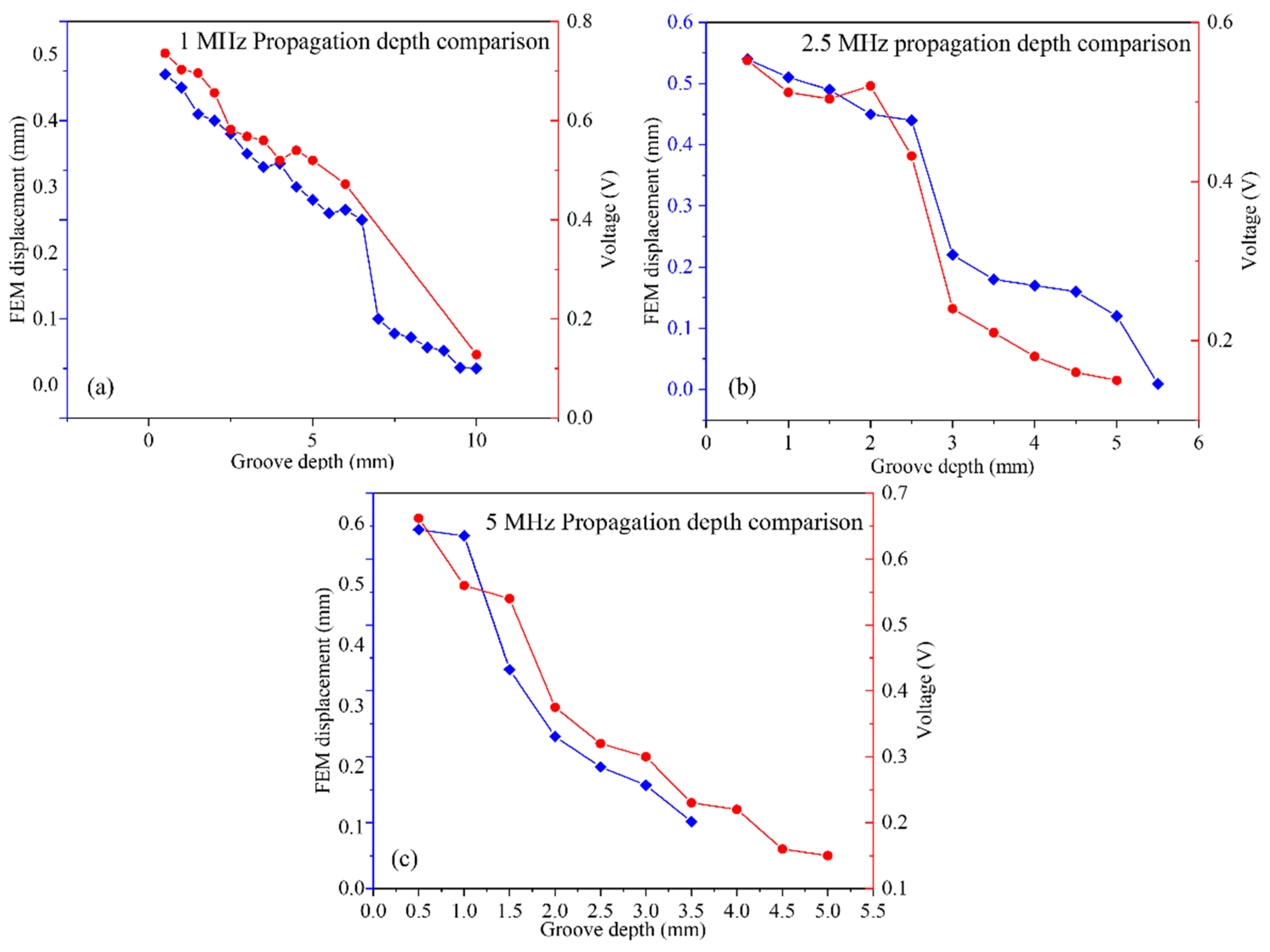

3.1. Finite Element Simulation of LCR Wave Propagation Depth

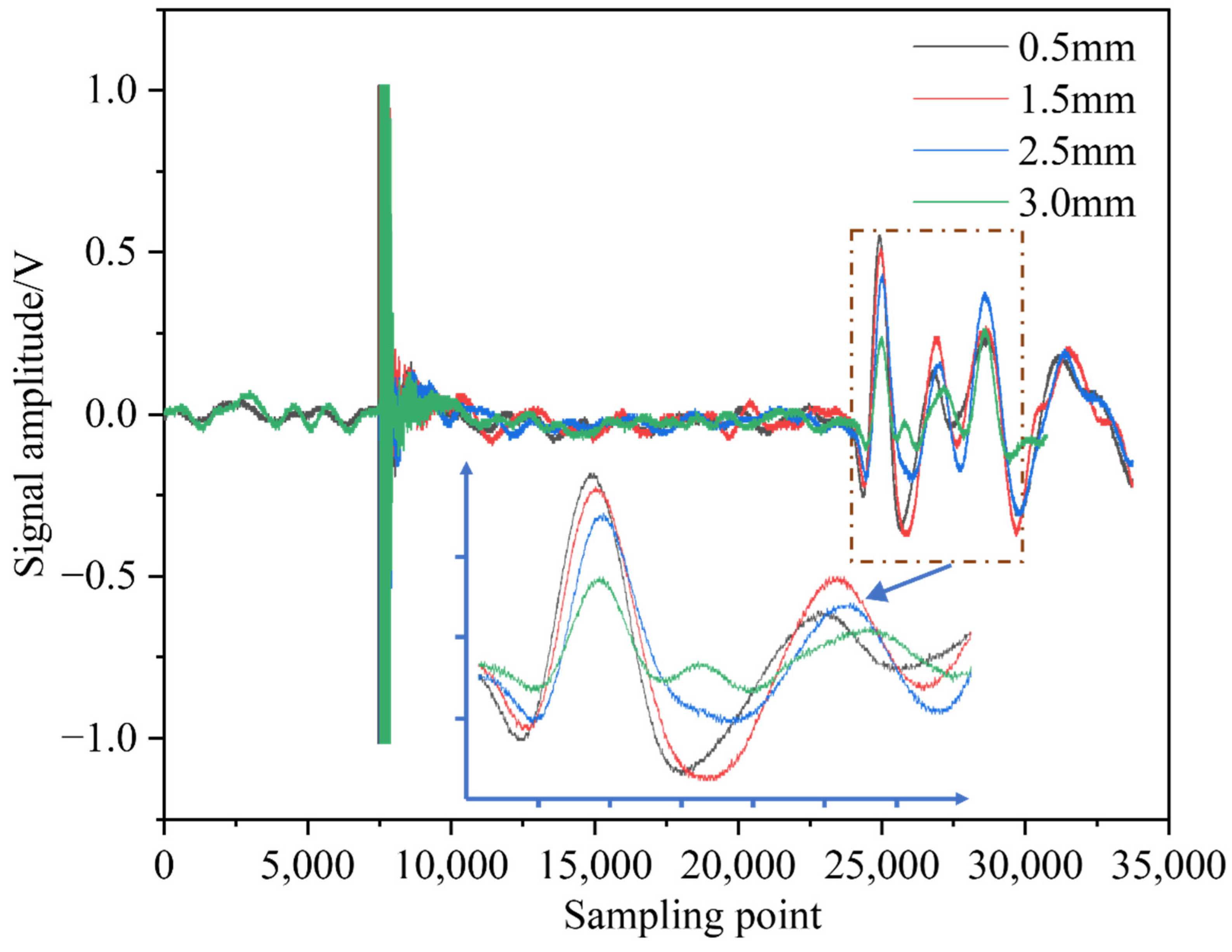

3.2. Propagation Depth Experiment of the LCR Waves

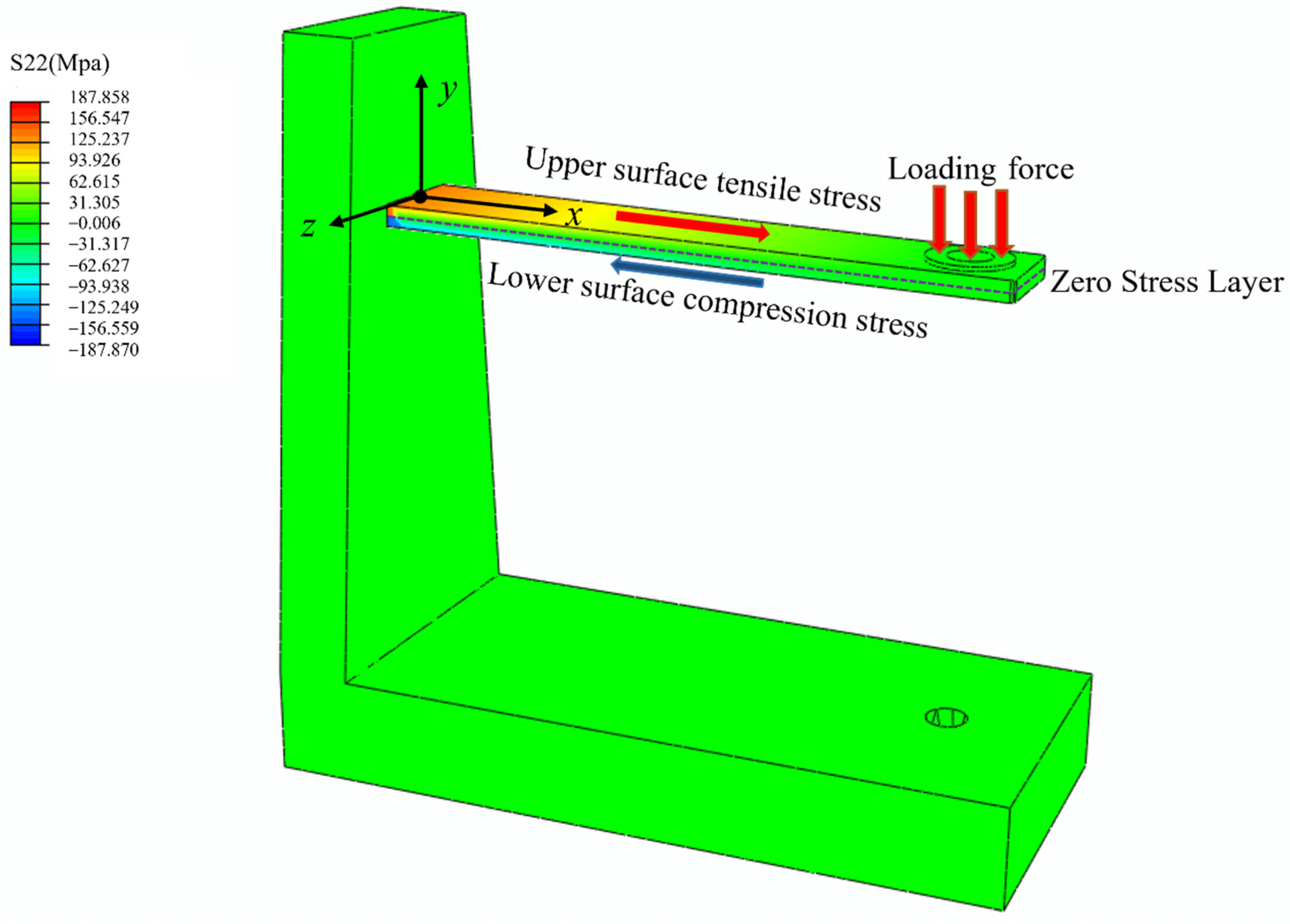

3.3. Verification of Multi-Frequency Ultrasonic Testing of Stress Depth Distribution

4. Results and Discussion

4.1. Simulation Results of the Effective Propagation Depth of the LCR Waves

4.2. Propagation Depth Behaviors of the LCR Waves

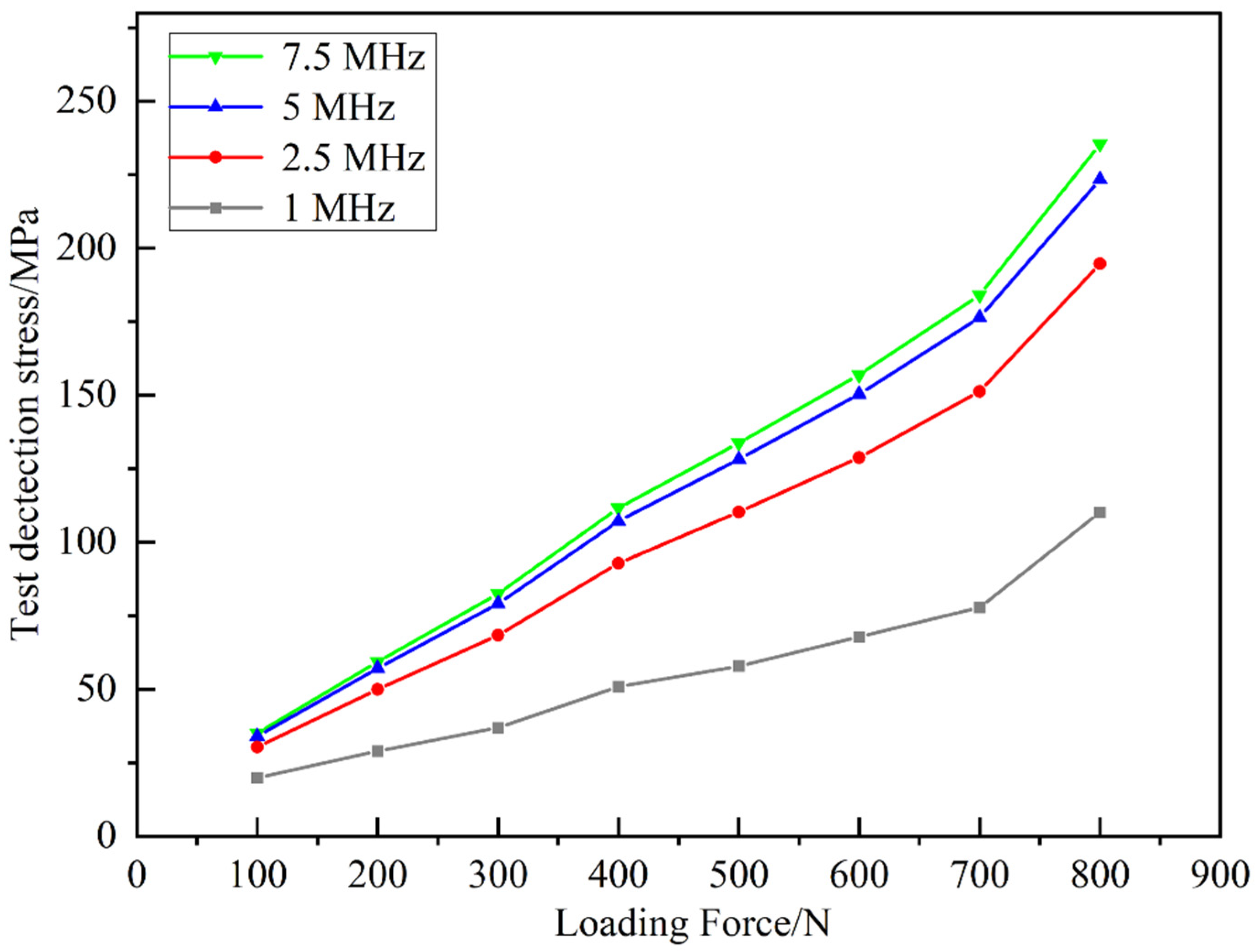

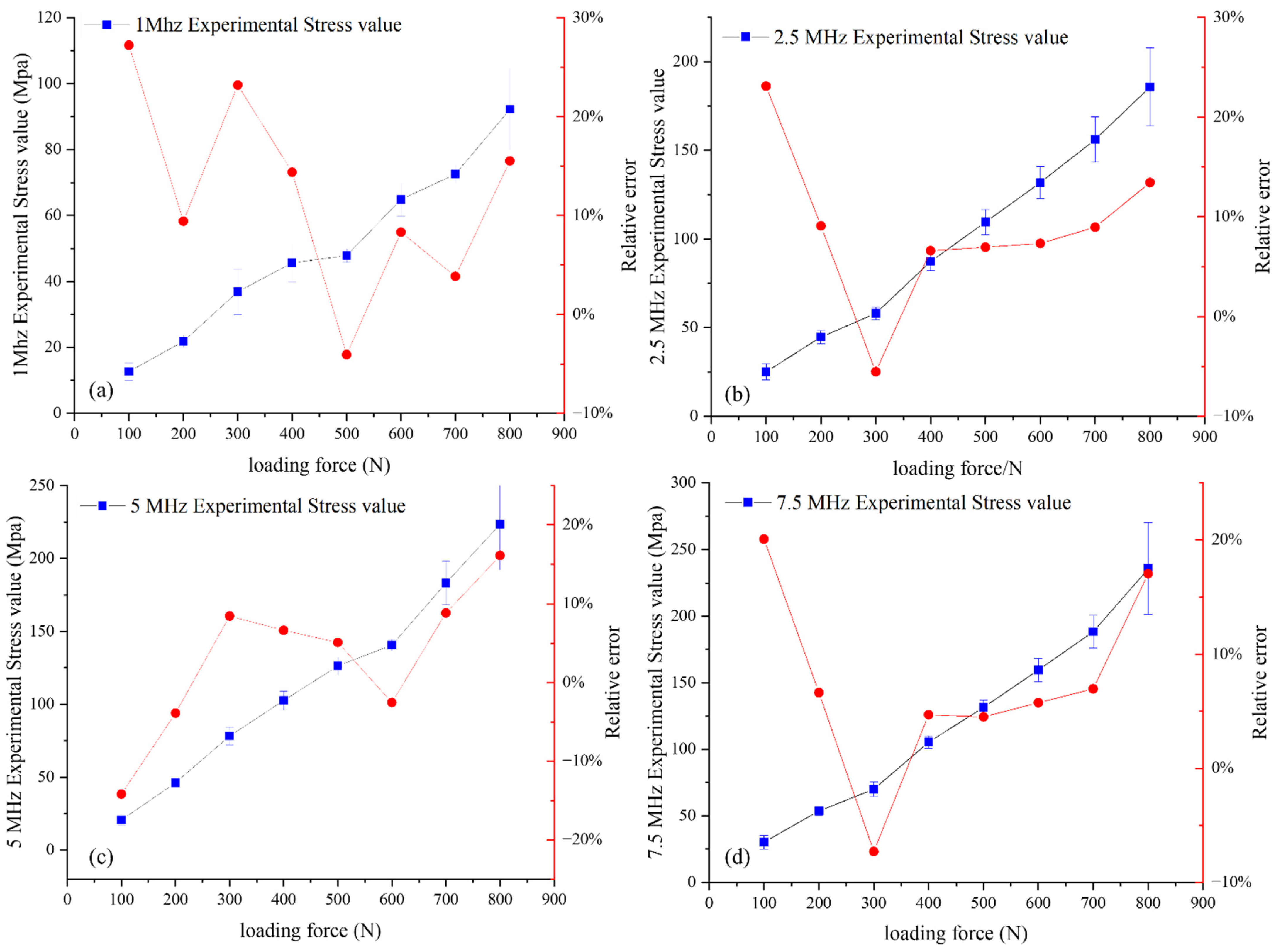

4.3. Multi-Frequency LCR Waves Testing Results of Stress Distribution at Different Depths

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sun, Z.C.; Zheng, L.S.; Yang, H. Softening mechanism and microstructure evolution of as-extruded 7075 aluminum alloy during hot deformation. Mater. Charact. 2014, 90, 71–80. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Cao, L.; Tong, X.; Zou, Y.; Zhu, Q.; Tang, S.; Song, H.; Guo, M. Effect of Ag on aging precipitation behavior and mechanical properties of aluminum alloy 7075. Mater. Sci. Eng. A 2020, 804, 140515. [Google Scholar] [CrossRef]

- Masoudi Nejad, R.; Sina, N.; Ghahremani Moghadam, D.; Branco, R.; Macek, W.; Berto, F. Artificial neural network based fatigue life assessment of friction stir welding AA2024-T351 aluminum alloy and multi-objective optimization of welding parameters. Int. J. Fatigue 2022, 160, 106840. [Google Scholar] [CrossRef]

- Nejad, R.M.; Sina, N.; Ma, W.; Liu, Z.; Berto, F.; Gholami, A. Optimization of fatigue life of pearlitic Grade 900A steel based on the combination of genetic algorithm and artificial neural network. Int. J. Fatigue 2022, 162, 106975. [Google Scholar] [CrossRef]

- Shaikh, M.Q.; Berfield, T.A.; Atre, S.V. Residual stresses in additively manufactured parts: Predictive simulation and experimental verification. Rapid Prototyp. J. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Chernov, A.; Eleonsky, S.; Pisarev, V. Influence of stress ratio on residual stress evolution near cold-expanded hole due to low-cycle fatigue by crack compliance data. Frat. Ed Integrità Strutt. 2020, 15, 174–186. [Google Scholar] [CrossRef]

- Simson, T.; Emmel, A.; Dwars, A.; Böhm, J. Residual stress measurements on AISI 316L samples manufactured by selective laser melting. Addit. Manuf. 2017, 17, 183–189. [Google Scholar] [CrossRef]

- Chighizola, C.R.; D’Elia, C.R.; Weber, D.; Kirsch, B.; Aurich, J.C.; Linke, B.S.; Hill, M.R. Intermethod Comparison and Evaluation of Measured Near Surface Residual Stress in Milled Aluminum. Exp. Mech. 2021, 61, 1309–1322. [Google Scholar] [CrossRef]

- Acevedo, R.; Sedlak, P.; Kolman, R.; Fredel, M. Residual stress analysis of additive manufacturing of metallic parts using ultrasonic waves: State of the art review. J. Mater. Res. Technol. 2020, 9, 9457–9477. [Google Scholar] [CrossRef]

- Guz, A.N.; Makhort, F.G. The physical fundamentals of the ultrasonic nondestructive stress analysis of solids. Int. Appl. Mech. 2000, 36, 1119–1149. [Google Scholar] [CrossRef]

- He, J.; Li, Z.; Teng, J.; Li, M.; Wang, Y. Absolute stress field measurement in structural steel members using the Lcr wave method. Measurement 2018, 122, 679–687. [Google Scholar] [CrossRef]

- Pei, C.; Demachi, K. Numerical simulation of residual stress measurement with acoustic wave. E-J. Adv. Maint. 2011, 2, 160–167. [Google Scholar]

- Ramasamy, R.; Ibrahim, Z.; Chai, H.K. Numerical investigations of internal stresses on carbon steel based on ultrasonic LCR waves. J. Phys. Conf. Ser. 2017, 908, 012044. [Google Scholar] [CrossRef]

- Javadi, Y.; Azari, K.; Ghalehbandi, S.M.; Roy, M.J. Comparison between using longitudinal and shear waves in ultrasonic stress measurement to investigate the effect of post-weld heat-treatment on welding residual stresses. Res. Nondestr. Eval. 2017, 28, 101–122. [Google Scholar] [CrossRef]

- Javadi, Y.; Pirzaman, H.S.; Raeisi, M.H.; Najafabadi, M.A. Ultrasonic inspection of a welded stainless steel pipe to evaluate residual stresses through thickness. Mater. Des. 2013, 49, 591–601. [Google Scholar] [CrossRef]

- Zhan, Y.; Liu, C.; Zhang, J.J.; Mo, G.Z.; Liu, C.S. Measurement of residual stress in laser additive manufacturing TC4 titanium alloy with the laser ultrasonic technique. Mater. Sci. Eng. A 2019, 762, 138093. [Google Scholar] [CrossRef]

- Zhan, Y.; Xu, H.; Du, W.; Liu, C. Research on the influence of heat treatment on residual stress of TC4 alloy produced by laser additive manufacturing based on laser ultrasonic technique. Ultrasonics 2021, 115, 106466. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Hu, Z.; Tang, Y.; Ma, S.; Chu, Y.; Li, X.; Luo, W.; Guo, L.; Zeng, X.; Lu, Y. Laser opto-ultrasonic dual detection for simultaneous compositional, structural, and stress analyses for wire + arc additive manufacturing. Addit. Manuf. 2019, 31, 100956. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhao, H.; Song, C.; Hu, B. The Measurement of Acoustoelastic Constant to evaluate Stress by UsingUltrasonic Waves. J. Phys. Conf. Ser. 2020, 1486, 072057. [Google Scholar] [CrossRef]

- Mohammadi, M.; Fesharaki, J.J. Determination of acoustoelastic/acoustoplastic constants to measure stress in elastic/plastic limits by using LCR wave. NDT E Int. 2019, 104, 69–76. [Google Scholar] [CrossRef]

- Liu, H.; Li, Y.; Li, T.; Zhang, X.; Liu, Y.; Liu, K.; Wang, Y. Influence factors analysis and accuracy improvement for stress measurement using ultrasonic longitudinal critically refracted (LCR) wave. Appl. Acoust. 2018, 141, 178–187. [Google Scholar] [CrossRef]

- Li, Y.; Liu, H.; Liu, Y.; Zhang, X.; Wang, Y. In-plane elastic anisotropic constants (IEACs) measurement of rolling aluminum plate at different depth using ultrasonic LCR wave. Appl. Acoust. 2019, 149, 59–67. [Google Scholar] [CrossRef]

- Liu, B.; Li, J.; Dong, S.; Shu, F. Correction for microstructure effect on residual stress measurement of SR-FSW joint with Lcr wave. Russ. J. Nondestr. Test. 2020, 56, 131–140. [Google Scholar] [CrossRef]

- Javadi, Y.; Hloch, S. Employing the waves to measure longitudinal residual stresses in different depths of a stainless steel welded plate. Adv. Mater. Sci. Eng. 2013, 2013, 746187. [Google Scholar] [CrossRef]

- Javadi, Y.; Najafabadi, M.A. Comparison between contact and immersion ultrasonic method to evaluate welding residual stresses of dissimilar joints. Mater. Des. 2013, 47, 473–482. [Google Scholar] [CrossRef]

- Javadi, Y.; Plevris, V. Evaluation of welding residual stress in stainless steel pipes by using the Lcr ultrasonic waves. In Proceedings of the 3rd South-East European Conference on Computational Mechanics—SEECCM III, Kos Island, Greece, 12–14 June 2013; ECCOMAS. pp. 671–681. [Google Scholar] [CrossRef]

- Song, W.; Xu, C.; Pan, Q.; Song, J. Nondestructive testing and characterization of residual stress field using an ultrasonic method. J. Mech. Eng. Chin. Ed. 2016, 29, 365–371. [Google Scholar] [CrossRef]

- Sadeghi, S.; Najafabadi, M.A.; Javadi, Y.; Mohammadisefat, M. Using ultrasonic waves and finite element method to evaluate through-thickness residual stresses distribution in the friction stir welding of aluminum plates. Mater. Des. 2013, 52, 870–880. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, E.; Chen, Y.; Wang, X.; Sun, C.; Tan, J. Study on propagation depth of ultrasonic longitudinal critically refracted (LCR) wave. Sensors 2020, 20, 5724. [Google Scholar] [CrossRef]

- Pei, N.; Zhao, B.; Zhao, X.; Liu, Z.; Bond, L.J. Analysis of the directivity of Longitudinal Critically Refracted (LCR) waves. Ultrasonics 2021, 113, 106359. [Google Scholar] [CrossRef]

- Rose, J.L. Ultrasonic Waves in Solid Media; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Hughes, D.S.; Kelly, J.L. Second-Order Elastic Deformation of Solids. Phys. Rev. Ser. I 1953, 92, 1145–1149. [Google Scholar] [CrossRef]

- Smith, R.T.; Stern, R.; Stephens, R.W.B. Third-Order Elastic Moduli of Polycrystalline Metals from Ultrasonic Velocity Measurements. J. Acoust. Soc. Am. 1966, 40, 1002–1008. [Google Scholar] [CrossRef]

- Yang, S.; Wang, M.; Yang, L. Investigation of Uncertain Factors on Measuring Residual Stress with Critically Refracted Longitudinal Waves. Appl. Sci. 2019, 9, 485. [Google Scholar] [CrossRef]

- Sotiropoulos, D.; Ogden, R. Generalized Brewster angle for wave reflection from a fluid-transversely isotropic solid interface. Ultrasonics 1996, 34, 487–489. [Google Scholar] [CrossRef]

| Material | (Gpa) | (Gpa) | (Gpa) | (Gpa) | (Gpa) |

|---|---|---|---|---|---|

| Aluminum alloy | 62 | 25 | −69 | −354 | −206 |

| Material | Elastic Modulus (Gpa) | Poisson’s Ratio | Density (kg/m3) |

|---|---|---|---|

| Aluminum alloy (2A14) | 72 | 0.33 | 2750 |

| PMMA | 6.1 | 0.32 | 1160 |

| Frequency | 1 MHz | 2.5 MHz | 5 MHz | 7.5 MHz | ||||

|---|---|---|---|---|---|---|---|---|

| Pressing Force (N) | Simulation Value (Mpa) | Experimental Value (Mpa) | Simulation Value (Mpa) | Experimental Value (Mpa) | Simulation Value (Mpa) | Experimental Value (Mpa) | Simulation Value (Mpa) | Experimental Value (Mpa) |

| 100 | 9.92 | 12.62 | 20.39 | 25.1 | 23.97 | 20.57 | 25.07 | 30.1 |

| 200 | 19.95 | 21.83 | 40.93 | 44.65 | 48.11 | 46.24 | 50.31 | 53.65 |

| 300 | 29.93 | 36.87 | 61.39 | 57.99 | 72.16 | 78.26 | 75.47 | 69.96 |

| 400 | 39.91 | 45.65 | 81.86 | 87.26 | 96.21 | 102.6 | 100.63 | 105.36 |

| 500 | 49.89 | 47.86 | 102.33 | 109.44 | 120.27 | 126.39 | 125.79 | 131.46 |

| 600 | 59.87 | 64.85 | 122.8 | 131.8 | 144.32 | 140.64 | 150.95 | 159.63 |

| 700 | 69.84 | 72.52 | 143.26 | 156.07 | 168.38 | 183.28 | 176.1 | 188.36 |

| 800 | 79.82 | 92.2 | 163.72 | 185.7 | 192.43 | 223.45 | 201.26 | 235.61 |

| Corresponding depth | 6.4 mm | 2.66 mm | 1.37 mm | 0.93 mm | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Xu, C.; Pan, Q.; Li, D. Research on an Ultrasonic Longitudinal Critically Refracted Wave Detection Method for the Depth Distribution of Stress. Metals 2022, 12, 1602. https://doi.org/10.3390/met12101602

Lu Y, Xu C, Pan Q, Li D. Research on an Ultrasonic Longitudinal Critically Refracted Wave Detection Method for the Depth Distribution of Stress. Metals. 2022; 12(10):1602. https://doi.org/10.3390/met12101602

Chicago/Turabian StyleLu, Yuren, Chunguang Xu, Qinxue Pan, and Dezhi Li. 2022. "Research on an Ultrasonic Longitudinal Critically Refracted Wave Detection Method for the Depth Distribution of Stress" Metals 12, no. 10: 1602. https://doi.org/10.3390/met12101602

APA StyleLu, Y., Xu, C., Pan, Q., & Li, D. (2022). Research on an Ultrasonic Longitudinal Critically Refracted Wave Detection Method for the Depth Distribution of Stress. Metals, 12(10), 1602. https://doi.org/10.3390/met12101602