High-Pressure Cold Spray Coatings for Aircraft Brakes Application

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials

2.2. Parameters Investigated and Analysis Method

2.2.1. Hardness and Adhesion Tests

2.2.2. Tribological Tests

2.2.3. Thermal Properties

3. Results

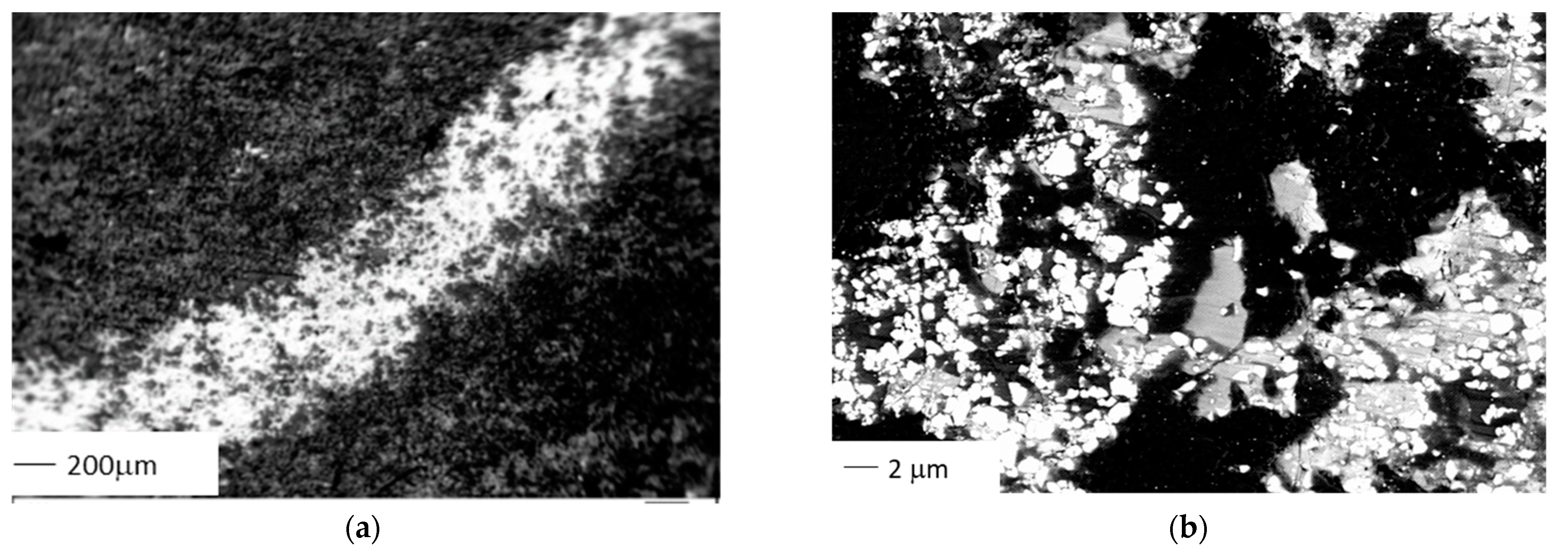

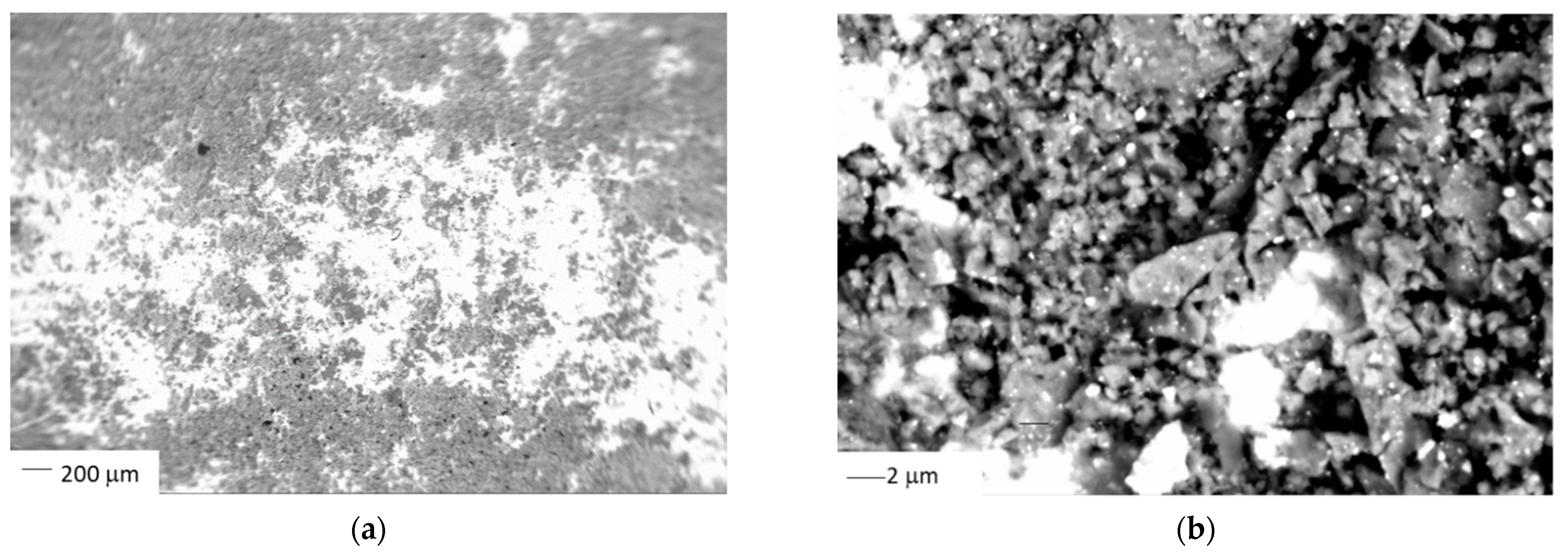

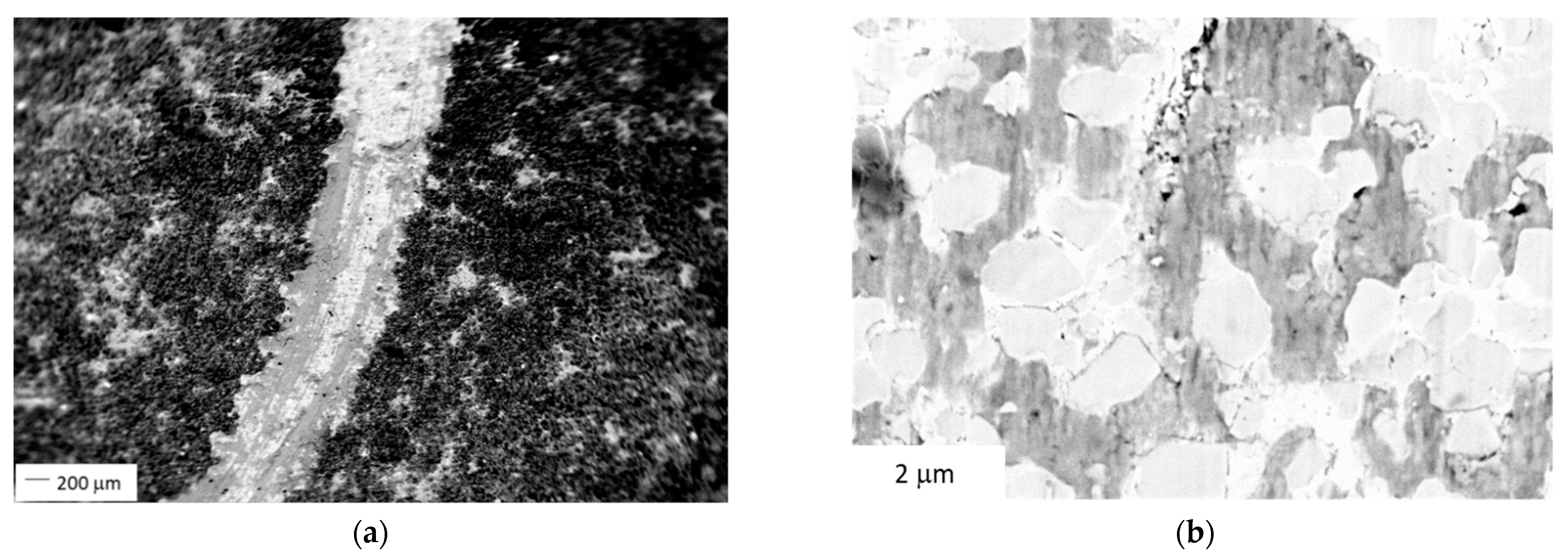

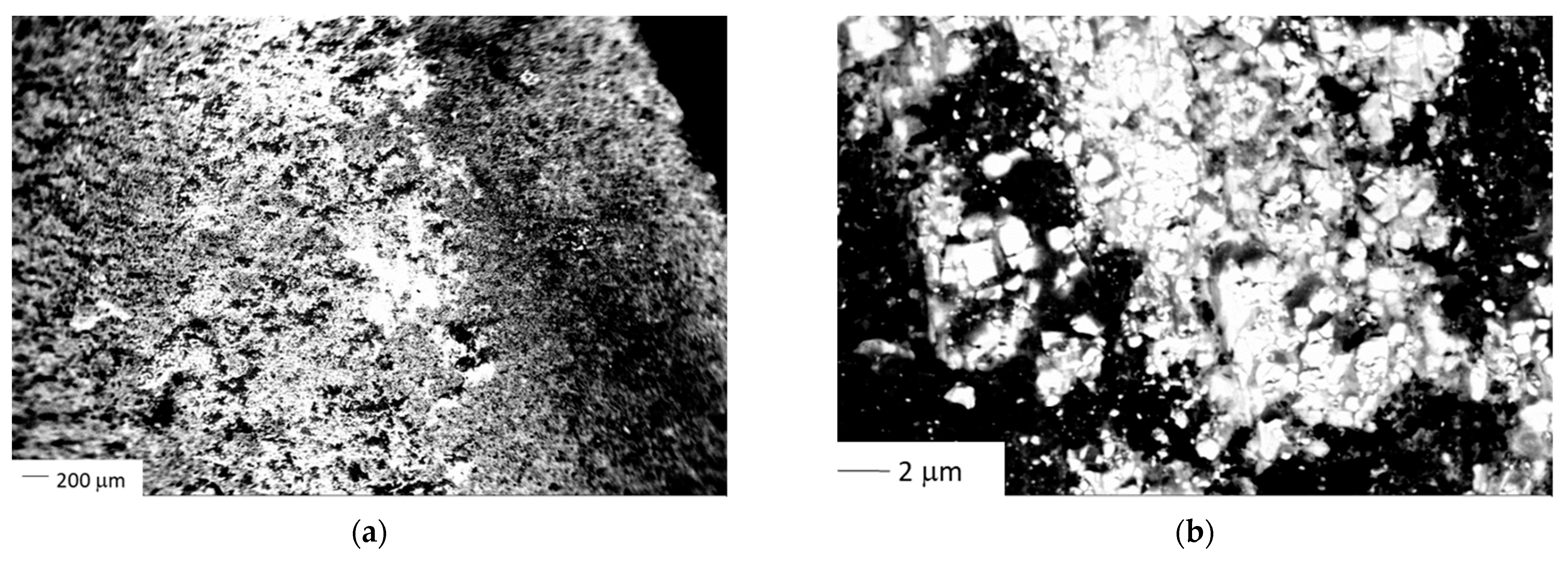

3.1. Hardness and Adhesion of High-Pressure Cold Spray Coatings

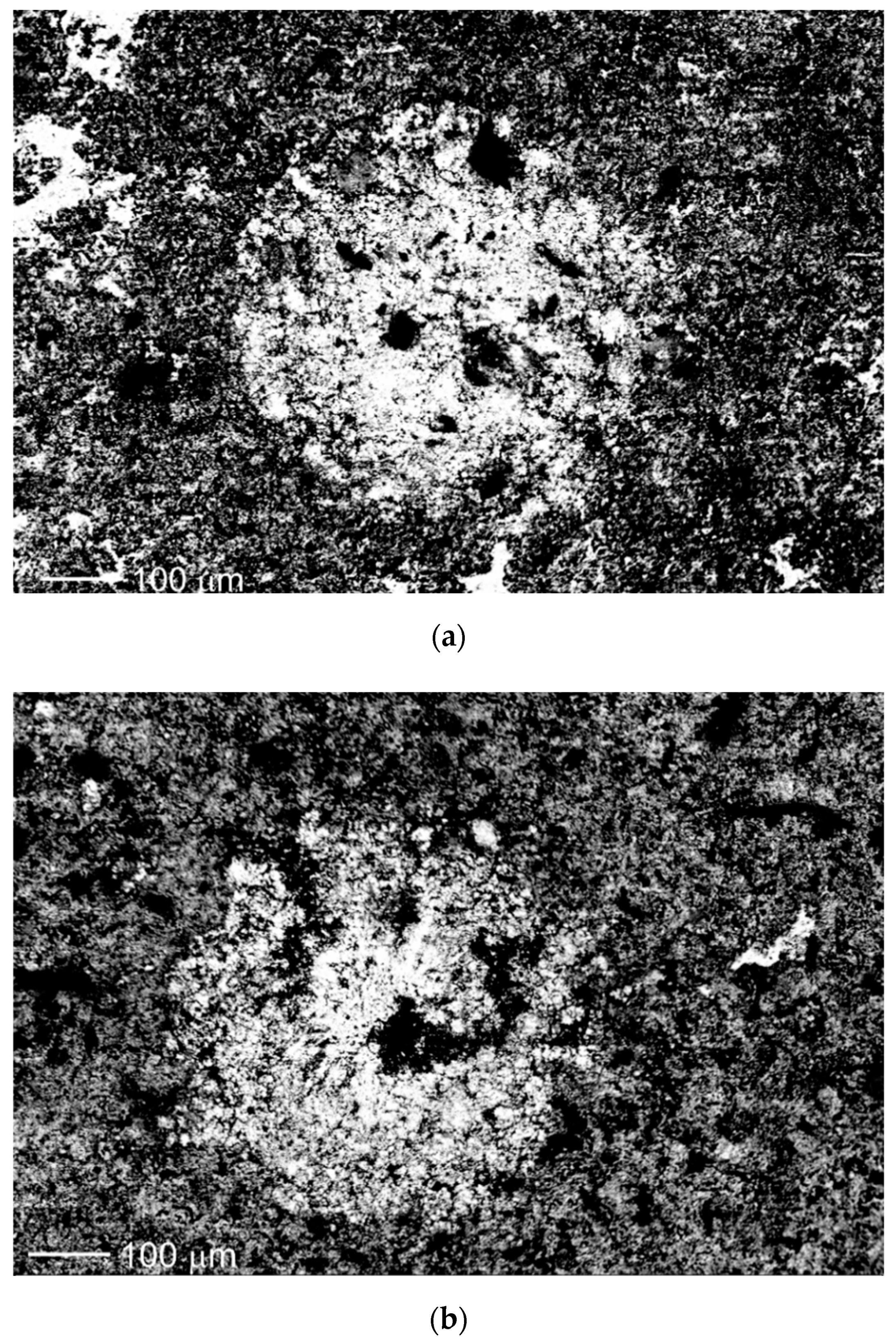

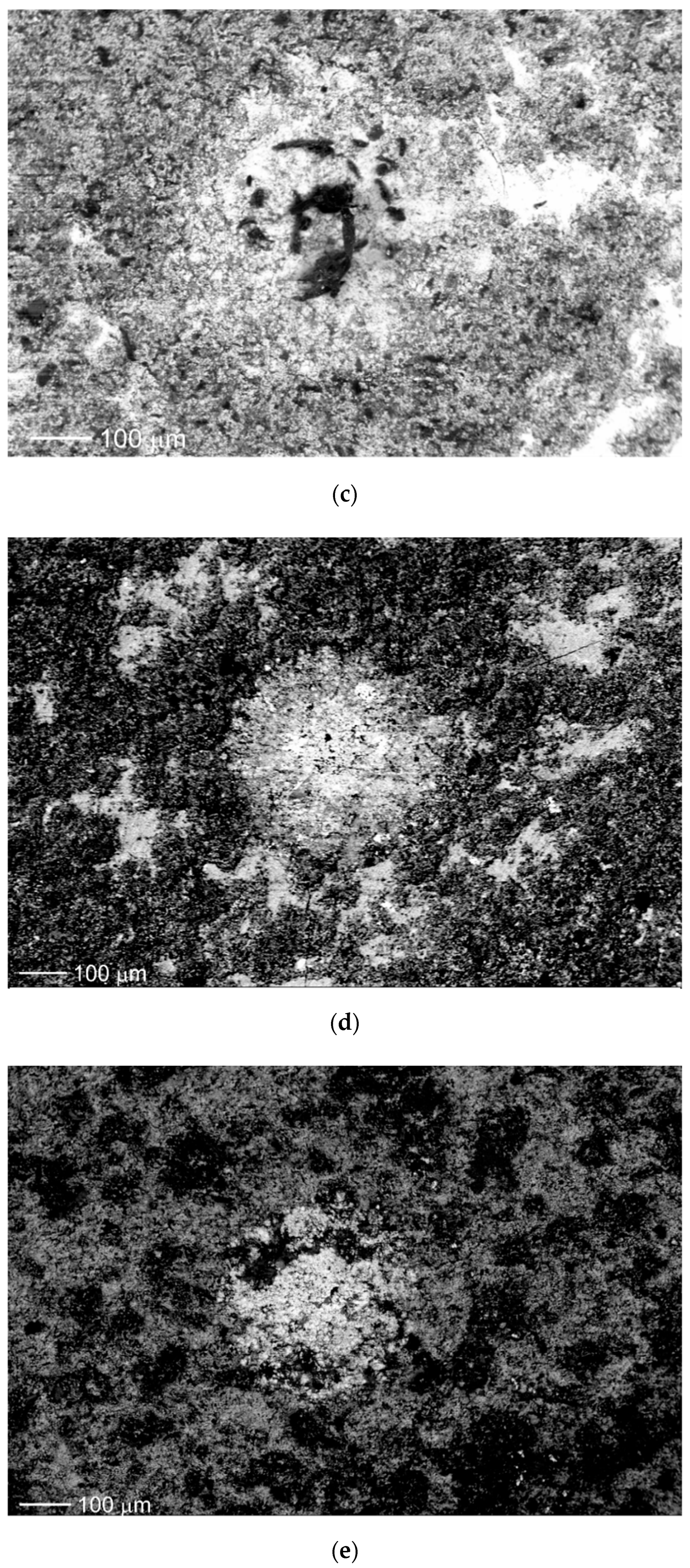

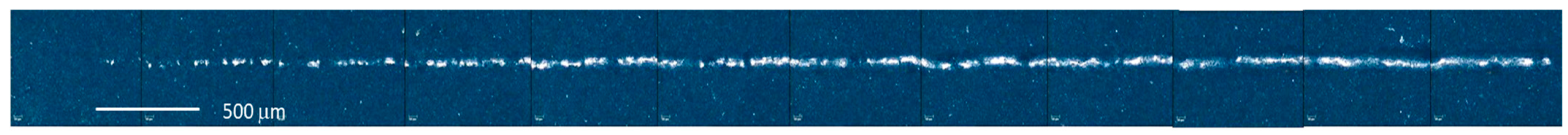

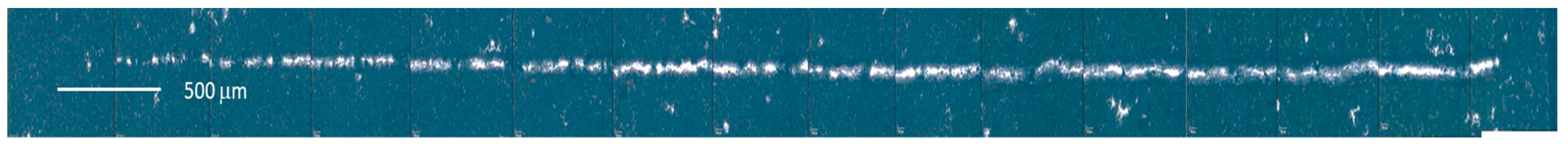

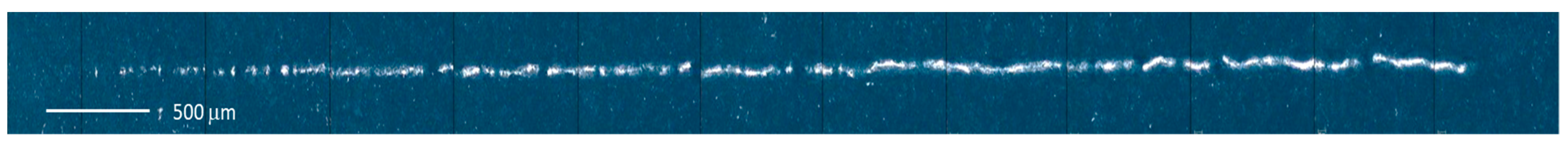

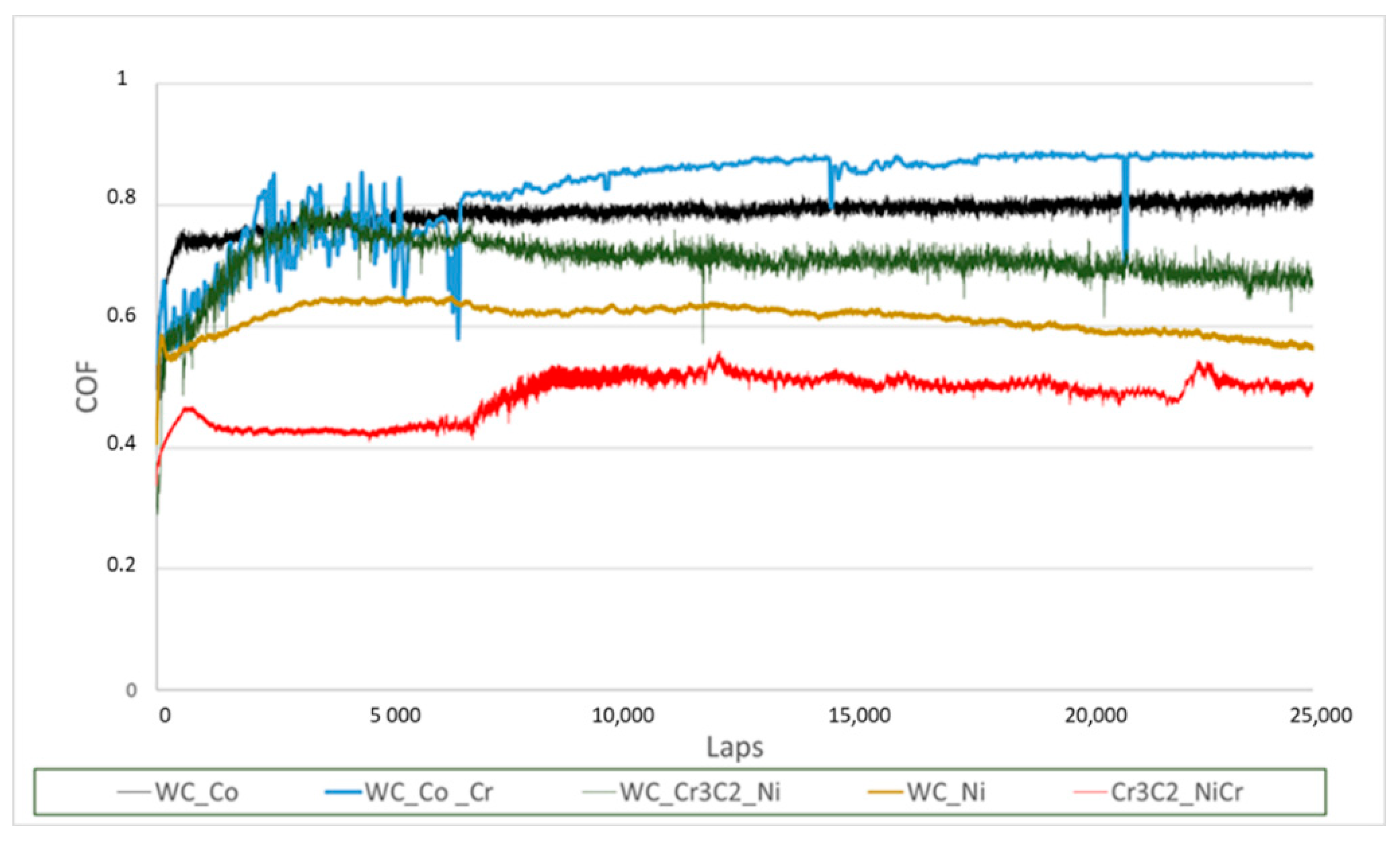

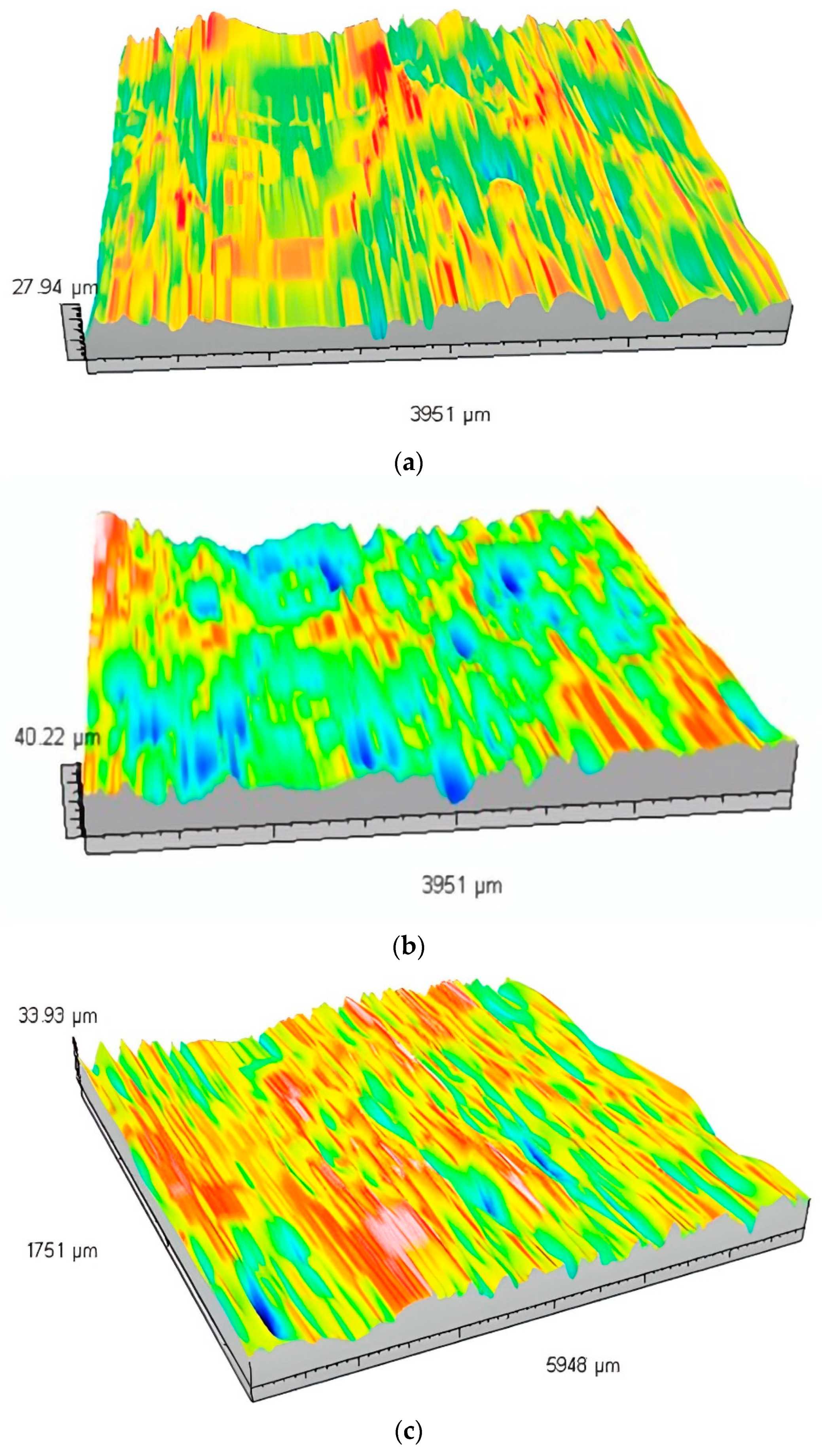

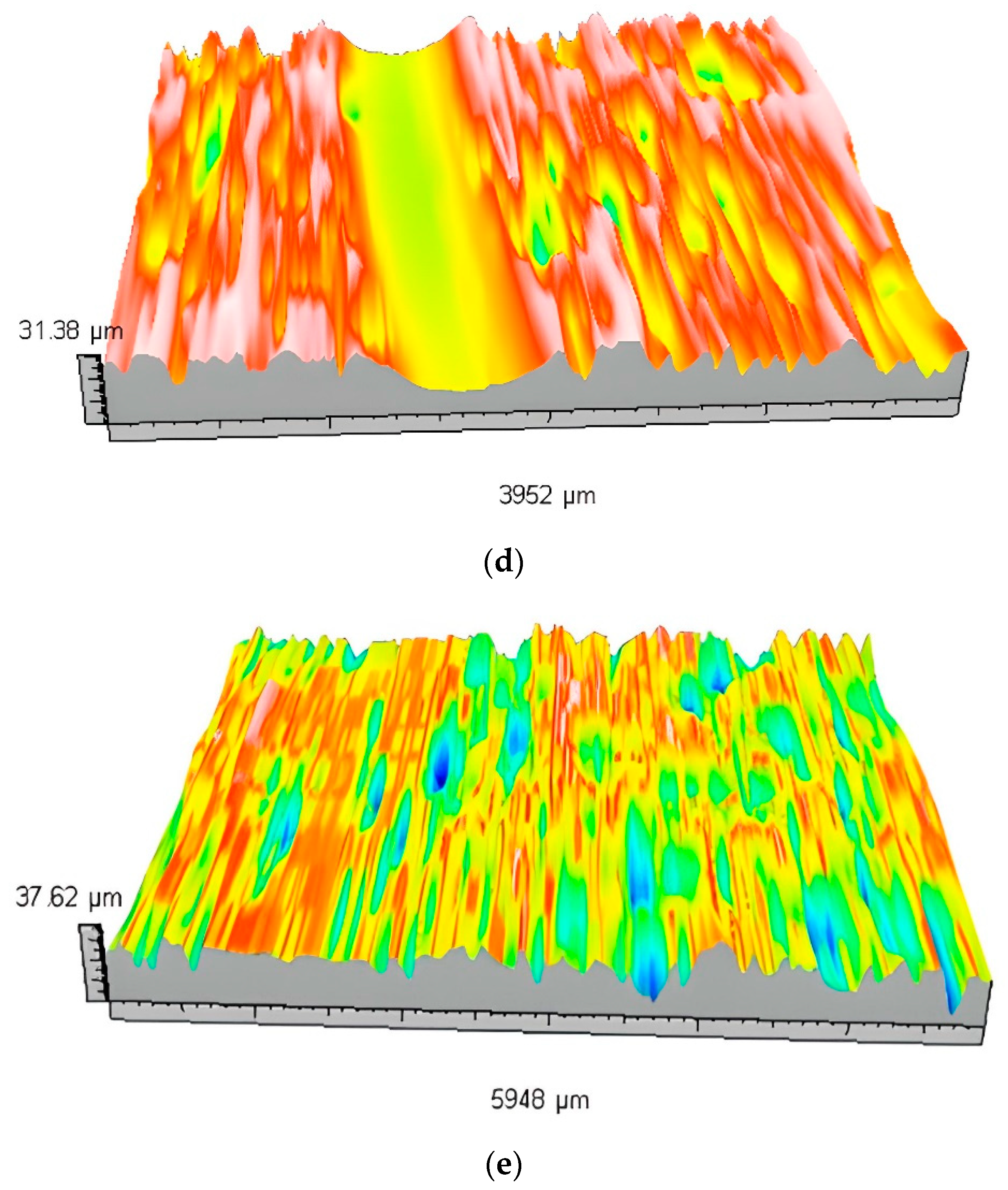

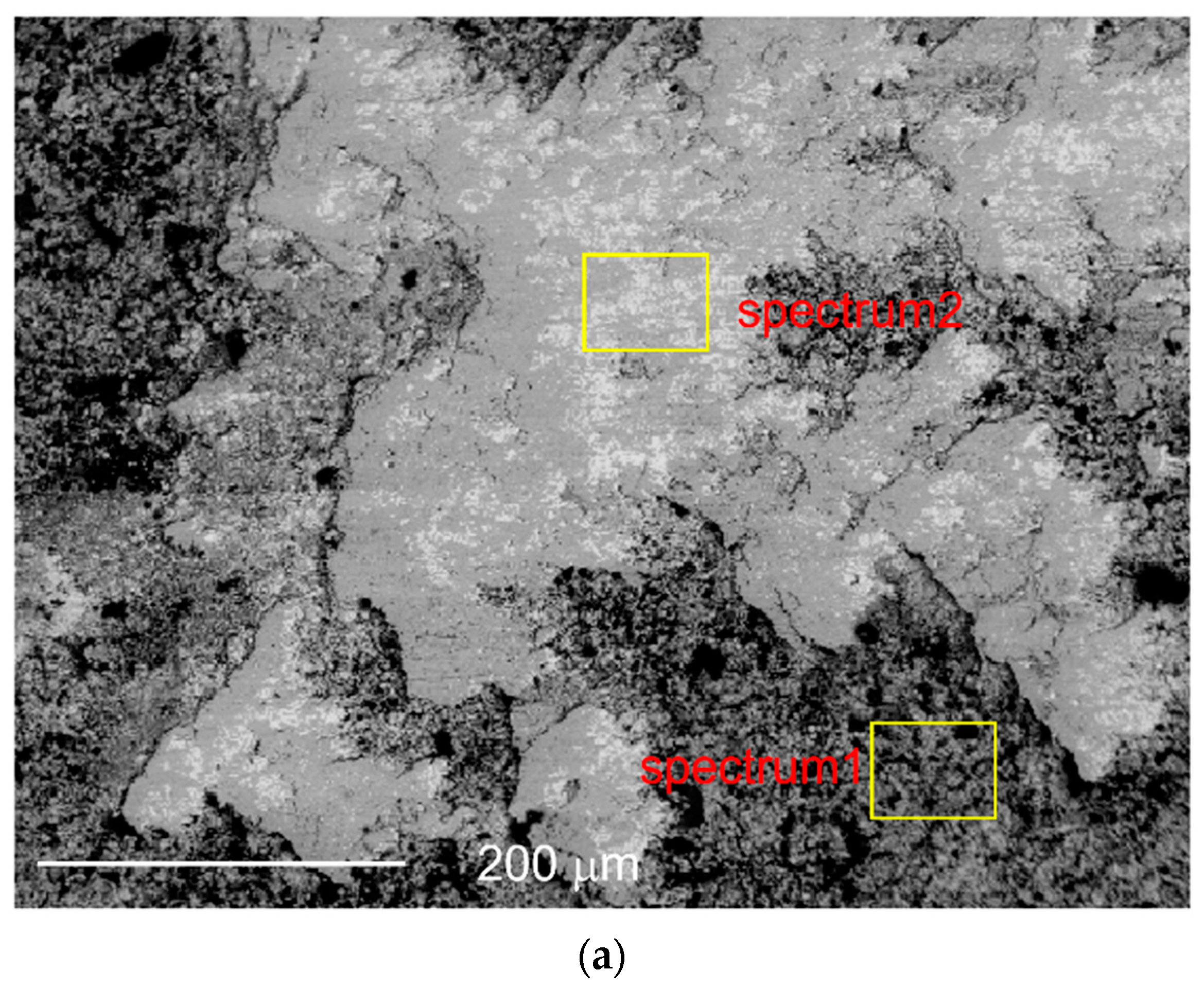

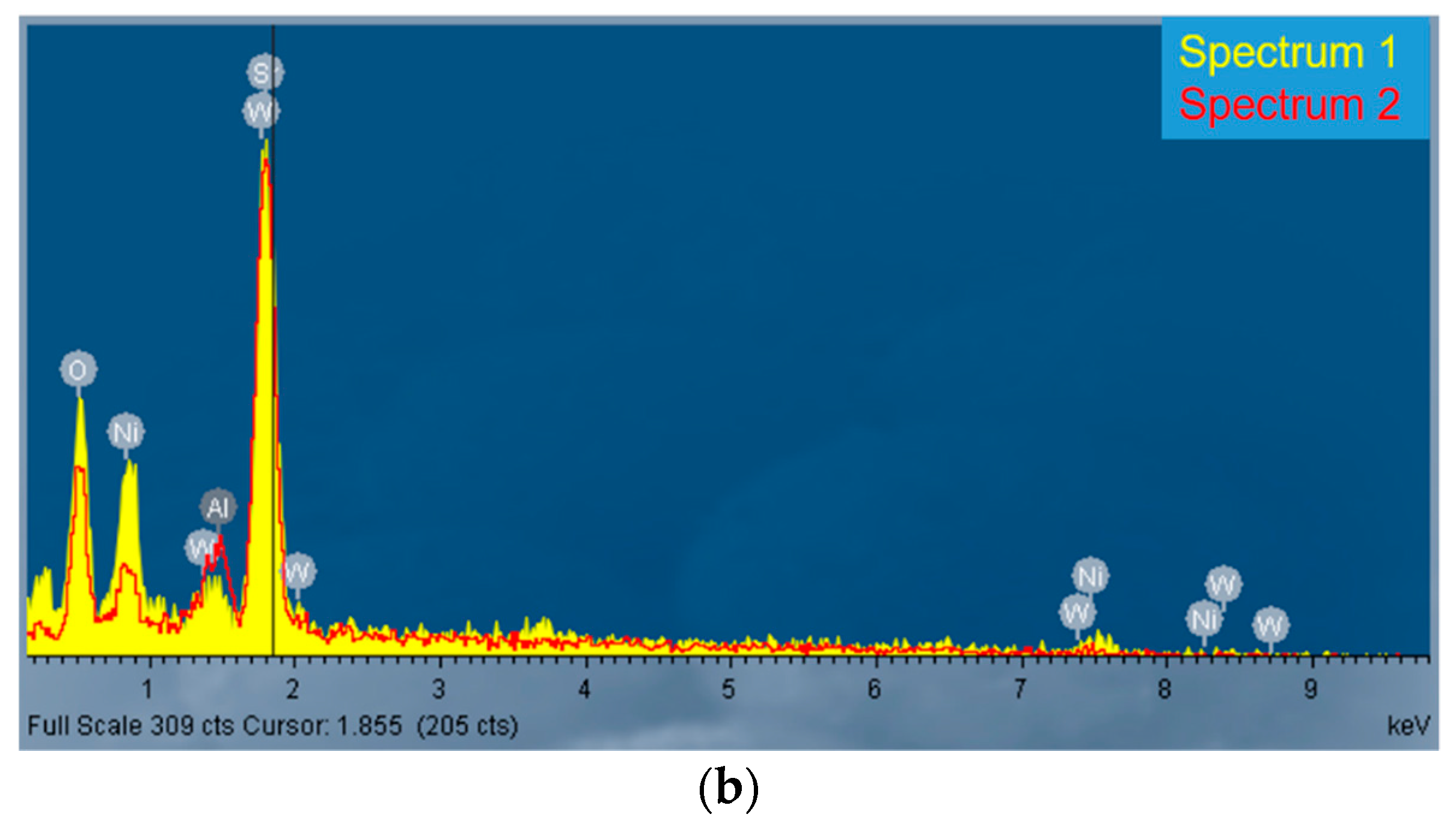

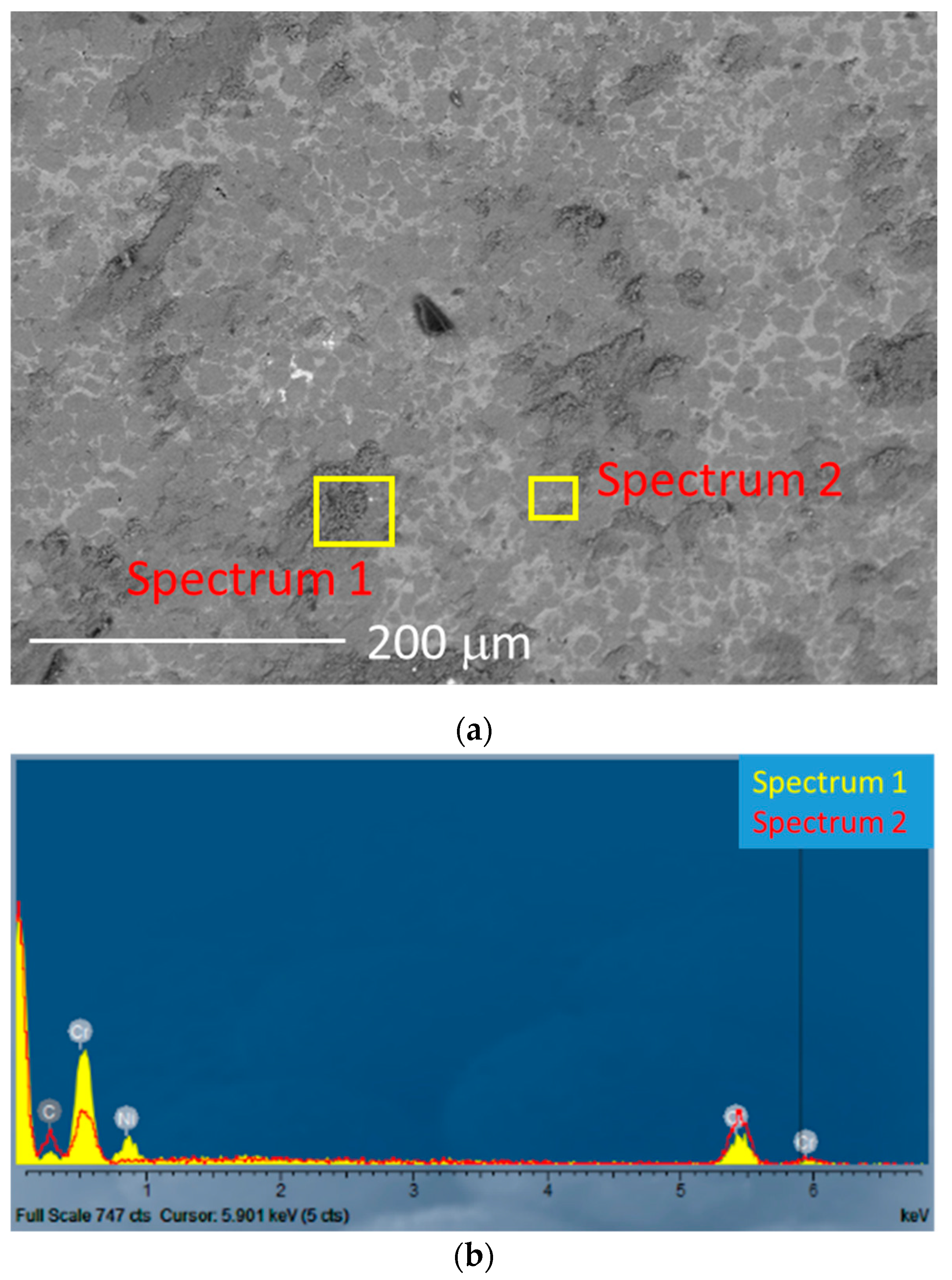

3.2. Tribological Properties

3.3. Thermal Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krenkel, W.; Heidenreich, B.; Renz, R. C/C–SiC composites for advanced friction systems. Adv. Eng. Mater. 2002, 4, 427–436. [Google Scholar] [CrossRef]

- Awasthi, S.; Wood, J.L. Carbon/Carbon Composite Materials for Aircraft Brakes. Ceram. Eng. Sci. Proc. 1988, 9, 553–560. [Google Scholar]

- Guan, Q.F.; Li, G.Y.; Wang, H.Y.; An, J. Friction-wear characteristics of carbon fiber reinforced friction material. J. Mater. Sci. 2004, 39, 641–643. [Google Scholar] [CrossRef]

- Vasiljević, S.; Glišović, J.; Stojanović, B.; Vencl, A. Review of the coatings used for brake discs regarding their wear resistance and environmental effect. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 236, 1932–1949. [Google Scholar] [CrossRef]

- Champagne, V.K. The Cold Spray Materials Deposition Process; Elsevier Science & Technology: Cambridge, UK, 2007. [Google Scholar]

- Karthikeyan, J. The advantages and disadvantages of the cold spray coating process. In The Cold Spray Materials Deposition Process Fundamentals and Applications; Champagne, V.K., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2007; pp. 62–71. [Google Scholar]

- Klinkov, S.V.; Kosarev, V.F.; Rein, M. Cold spray deposition: Significance of particle impact phenomena. Aerosp. Sci. Technol. 2005, 9, 582–591. [Google Scholar] [CrossRef]

- Singh, S.; Raman, R.K.S.; Berndt, C.C.; Singh, H. Influence of Cold Spray Parameters on Bonding Mechanisms: A Review. Metals 2021, 11, 2016. [Google Scholar] [CrossRef]

- Decker, M.K.; Neiser, R.A.; Gilmore, D.; Tran, H.D. Microstructure and Properties of Cold Spray Nickel. In Proceedings of the International Thermal Spray Conference (2001), Singapore, 28–30 May 2001; pp. 433–439. [Google Scholar]

- Van Steenkiste, T.H.; Smith, J.R.; Teets, R.E. Aluminum coatings via kinetic spray with relatively large powder particles. Surf. Coat. Technol. 2002, 154, 237–252. [Google Scholar] [CrossRef]

- Shukla, V.; Elliott, G.S.; Kear, B.H. Nanopowder deposition by supersonic rectangular jet impingement. J. Therm. Spray Technol. 2000, 9, 394–398. [Google Scholar] [CrossRef]

- Rima, R.S.; Karthikeyan, J.; Kay, C.M.; Lindemann, J.; Berndt, C.C. Microstructural characteristics of cold-sprayed nanostructured WC–Co coatings. Thin Solid Films 2002, 416, 129–135. [Google Scholar]

- Vlcek, J.; Gimeno, L.; Huber, H.; Lugscheider, E. A Systematic Approach to Material Eligibility for the Cold Spray Process. J. Therm. Spray Technol. 2005, 14, 125–133. [Google Scholar] [CrossRef]

- Chen, J.; Song, H.; Liu, G.; Ma, B.; An, Y.; Jia, L. Cold Spraying: A New Alternative Preparation Method for Nickel-Based High-Temperature Solid-Lubrication Coating. J. Therm. Spray Technol. 2019, 29, 1892–1901. [Google Scholar] [CrossRef]

- Yandouzi, M.; Sansoucy, E.; Ajdelsztajn, L.; Jodoin, B. WC-based cermet coatings produced by cold gas dynamic and pulsed gas dynamic spraying processes. Surf. Coat. Technol. 2007, 202, 382–390. [Google Scholar] [CrossRef]

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings, 2nd ed.; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- Sapate, S.G.; Roy, M. Thermal Sprayed Coatings and Their Tribological Performances; IGI Global Publications: Hershey, PA, USA, 2015; pp. 193–226. [Google Scholar]

- Bhosale, D.G.; Rathod, W.S.; Nagaraj, M. High-temperature erosion and sliding wear of thermal sprayed WC–Cr3C2–Ni coatings. Mater. High Temp. 2021, 38, 464–474. [Google Scholar] [CrossRef]

- Berger, L.-M.; Saaro, S.; Naumann, T.; Wiener, M.; Weihnacht, V.; Thiele, S.; Suchánek, J. Microstructure and properties of HVOF-sprayed chromium alloyed WC–Co and WC–Ni coatings. Surf. Coat. Technol. 2008, 202, 4417–4421. [Google Scholar] [CrossRef]

- Siwak, P.; Garbiec, D. Microstructure and mechanical properties of WC–Co, WC–Co–Cr3C2 and WC–Co–TaC cermets fabricated by spark plasma sintering. Trans. Nonferr. Met. Soc. China 2016, 26, 2641–2646. [Google Scholar] [CrossRef]

- Bhagat, R.B.; Conway, J.C.; Amateau, M.F.; Brezler, R.A. Tribological performance evaluation of tungsten carbide-based cermets and development of a fracture mechanics wear model. Wear 1996, 201, 233–243. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; Song, X.; Liu, X.; Liu, X. Sliding wear behavior of nanostructured WC–Co–Cr coatings. Appl. Surf. Sci. 2015, 355, 453–460. [Google Scholar] [CrossRef]

- Ji, G.; Li, C.; Wang, Y.; Li, W. Microstructural characterization and abrasive wear performance of HVOF sprayed Cr3C2–NiCr coating. Surf. Coat. Technol. 2006, 200, 6749–6757. [Google Scholar] [CrossRef]

- Guilemany, J.M.; Espallargas, N.; Suegama, P.H.; Benedetti, A.V. Comparative study of Cr3C2–NiCr coatings obtained by HVOF and hard chromium coatings. Corros. Sci. 2006, 48, 2998–3013. [Google Scholar] [CrossRef]

- Kevin, P.S.; Tiwari, A.; Seman, S.; Mohamed, S.A.B.; Jayaganthan, R. Erosion-Corrosion Protection Due to Cr3C2-NiCr Cermet Coating on Stainless Steel. Coatings 2020, 10, 1042. [Google Scholar] [CrossRef]

- He, B.; Zhang, L.; Yun, X.; Wang, J.; Zhou, G.; Chen, Z.; Yuan, X. Comparative Study of HVOF Cr3C2–NiCr Coating with Different Bonding Layer on the Interactive Behavior of Fatigue and Corrosion. Coatings 2022, 12, 307. [Google Scholar] [CrossRef]

- Trabadelo, V.; Giménez, S.; Iturriza, I. Microstructural characterisation of vacuum sintered T42 powder metallurgy high-speed steel after heat treatments. Mater. Sci. Eng. A 2009, 499, 360–367. [Google Scholar] [CrossRef]

- Bull, S.J.; Berasetegui, E.G. An overview of the potential of quantitative coating adhesion measurement by scratch testing. Tribol. Int. 2006, 39, 99–114. [Google Scholar] [CrossRef]

- Sundararajan, G.; Chavan, N.M.; Sivakumar, G.; Phani, P.S. Evaluation of Parameters for Assessment of Inter-Splat Bond Strength in Cold-Sprayed Coatings. J. Therm. Spray Technol. 2010, 19, 1255. [Google Scholar] [CrossRef]

- Dotta, A.L.B.; Costa, C.A.; Farias, M.C.M. Tribological behavior of alumina obtained by low-pressure injection molding using factorial design. Tribol. Int. 2017, 114, 208–220. [Google Scholar] [CrossRef]

- Mishra, T.K.; Kumar, A.; Sinha, S.K. Experimental investigation and study of HVOF sprayed WC-12Co, WC-10Co-4Cr and Cr3C2-25NiCr coating on its sliding wear behaviour. Int. J. Refract. Met. Hard Mater. 2021, 94, 105404. [Google Scholar] [CrossRef]

- Granata, M.; Gautier di Confiengo, G.; Scamardella, D.; Bellucci, F. Potential Coatings for Aircraft Brakes Application. Part I: Thermal Spray Coatings. Int. J. Astronaut. Aeronaut. Eng. 2021, 6, 056. [Google Scholar]

- Mahaidin, A.A.; Jaafar, T.R.; Budin, S.; Selamat, M.A. The effect of cobalt, vanadium carbide and PKS activated carbon addition on WC-Co Composite: A study using taguchi method. J. Mech. Eng. 2017, 5, 42–52. [Google Scholar]

- Chen, K.; Xiao, W.; Li, Z.; Wu, J.; Hong, K.; Ruan, X. Effect of Graphene and Carbon Nanotubes on the Thermal Conductivity of WC–Co Cemented Carbide. Metals 2019, 9, 377. [Google Scholar] [CrossRef]

- Ksiazek, M.; Nejman, I.; Boron, L. Investigation on Microstructure, Mechanical and Wear Properties of HVOF Sprayed Composite Coatings (WC–Co + CR) On Ductile Cast Iron. Materials 2021, 14, 328. [Google Scholar] [CrossRef]

- Umbria Aerospace System, UAS, (via Bufaloro 21, 06089, Torgiano, PG, Italy) Brake Material selection criteria, Doc Number DR-R18001-00-02, 13-Dec-2018, Private Communication.

- Burnett, P.J.; Rickerby, D.S. The relationship between hardness and scratch adhesion. Thin Solid Films 1987, 154, 4. [Google Scholar] [CrossRef]

| Item | Value |

|---|---|

| Gas used | N2 |

| Inlet gas temperature | 1100 °C |

| Inlet gas pressure | 35 bar |

| Spray distance | 30 mm |

| Powder feed rate | 40 g/min |

| Inlet powder temperature | 150 °C |

| Gun travelling speed | 80 mm/s |

| Coating | Thickness (mm) |

|---|---|

| WC-Cr3C2-Ni | 0.55 |

| WC-Ni | 0.54 |

| WC-Co-Cr | 0.52 |

| Cr3C2-NiCr | 0.60 |

| WC-Co | 0.80 |

| Materials | HRC Hardness Value |

|---|---|

| Steel | 21.5 ± 1.00 |

| WC-Cr3C2-Ni | 54.72 ± 0.71 |

| WC-Ni | 58.22 ± 1.93 |

| WC-Co-Cr | 55.16 ± 1.83 |

| Cr3C2-NiCr | 55.22 ± 2.39 |

| WC-Co | 61 ± 2.18 |

| Materials | Average Coefficient |

|---|---|

| Steel | 0.58 ± 0.02 |

| WC-Cr3C2-Ni | 0.71 ± 0.03 |

| WC-Ni | 0.61 ± 0.02 |

| WC-Co-Cr | 0.84 ± 0.02 |

| Cr3C2-NiCr | 0.49 ± 0.03 |

| WC-Co | 0.79 ± 0.01 |

| Materials | Average Coefficient |

|---|---|

| Steel | 0.58 ± 0.02 |

| Inconel 625 [14] | 0.76 ± 0.03 |

| Tungsten Carbide (HVOF process) [32] | 0.87 ± 0.02 |

| WC-Co | 0.79 ± 0.01 |

| Materials | Ball Diameter (mm) |

|---|---|

| WC-Cr3C2-Ni | 2.42 ± 0.03 |

| WC-Ni | 1.02 ± 0.02 |

| WC-Co-Cr | 2.98 ± 0.03 |

| Cr3C2-NiCr | 0.91 ± 0.18 |

| WC-Co | 3.17 ± 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Granata, M.; Gautier di Confiengo, G.; Bellucci, F. High-Pressure Cold Spray Coatings for Aircraft Brakes Application. Metals 2022, 12, 1558. https://doi.org/10.3390/met12101558

Granata M, Gautier di Confiengo G, Bellucci F. High-Pressure Cold Spray Coatings for Aircraft Brakes Application. Metals. 2022; 12(10):1558. https://doi.org/10.3390/met12101558

Chicago/Turabian StyleGranata, Marco, Giovanna Gautier di Confiengo, and Francesco Bellucci. 2022. "High-Pressure Cold Spray Coatings for Aircraft Brakes Application" Metals 12, no. 10: 1558. https://doi.org/10.3390/met12101558

APA StyleGranata, M., Gautier di Confiengo, G., & Bellucci, F. (2022). High-Pressure Cold Spray Coatings for Aircraft Brakes Application. Metals, 12(10), 1558. https://doi.org/10.3390/met12101558